Page 1

Datasheet

TP5000M Si

Programmable Room Thermostat

Features

The TP5000M Si is a microprocessor based

programmable room thermostat with many

advanced features. All models in the range

utilise an advanced PI algorithm to provide close

and accurate temperature control to reduce

energy waste and ensure comfort under all load

conditions.

The TP5000M Si incorporates a factory set real time

clock, both date and time are set in the factory to

the appropriate time zone, eliminating the need

to set the time at installation or to change the

time in spring or autumn. This function is powered

from a separate lithium battery which lasts for the

lifetime of the product.

The calendar clock is also used to provide a service

due timer function which can be enabled by the

installer if required. If enabled, several operating

options are available ranging from audible & visual

service due warning to proportional reduction of

heating until the boiler is serviced and the service

due feature is reset by the installer.

The TP5000M Si is a 5-day / 2-day programmable

thermostat which also includes a feature which

allows two blocks of programmes to be set up

(A/B Programming), either programme can then

be assigned to any day of the week allowing the

programming to closer match the lifestyle of the

consumer, all without the need to go for a far

more complex 7-day unit.

this allows the thermostat to be matched with

consumers lifestyle.

Versions with programmable remote inputs are

also available. Remote inputs can be either remote

temperature sensing, (control or limit), or digital

inputs from window contacts, telephone operated

switches, card readers or building automation

systems.

For standard applications the product can be

installed and will work straight out of the box,

however there is a wide range of user and installer

options which allow the product operation to

be tuned to the speci cation requirements of

the system. Some of these options are hardware

settings made by DIL switches, but the majority

are software settings made in one of two advanced

programming modes.

Settings made by the installer or the end user are

stored for the life of the product in a non-volatile

memory chip which does not require power. This

same storage technique allows customer speci c

programmes to be established as factory defaults,

but is only available for larger projects.

Signi cant e ort has been made to make the

product as energy e cient as possible, this

includes improving both on/o performance and

chrono-proportional performance, charts on page

4 detail the relative performance of each mode.

Unlike earlier models, the TP5000M Si can be

con gured by the installer to provide 2, 4 or 6

events per day, it can also be set up to provide

constant temperature control if required, again

Part No. 698v01 08/07

Programming of the TP5000M Si is as simple

as it has always been, just ve buttons and an

intuitive MMI ensure that the product is no more

complicated to the user than previous models.

1

Page 2

Datasheet TP5000M Si Programmable Room Thermostat

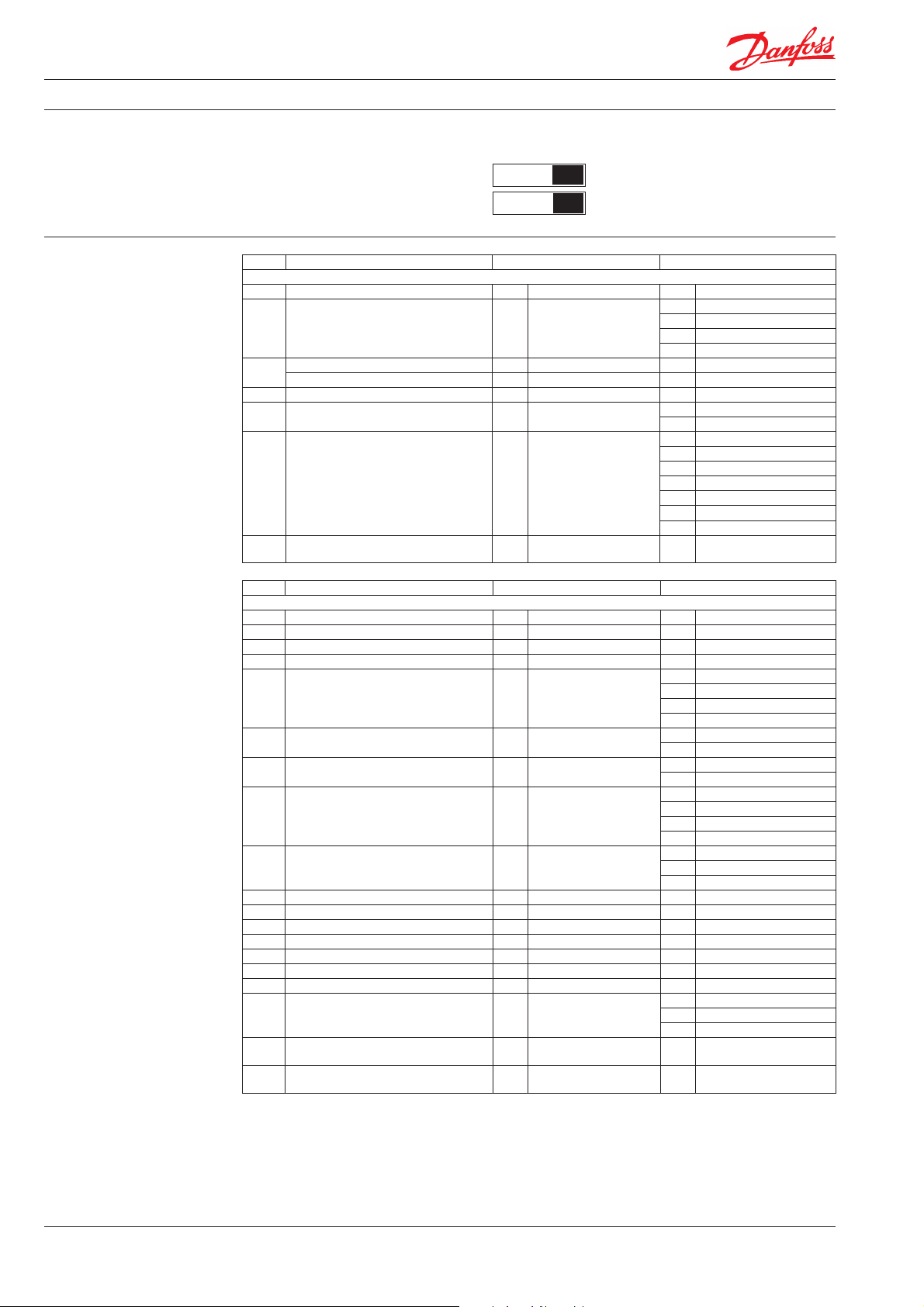

Installer Hardware Settings

(Switches show factory setting)

Installer Advanced

Programming Settings

Sw. No.

Keyboard disabled

1

Reset disabled Reset enabled

2

Option Description Factory Setting Other Setting

User Advanced Programming Options Use + or - key to scroll between options, use Λ or V keys to select option setting

1 Enable/disable A/B block programming 0 Disabled 1 Enabled

3 Automatic summer/winter time change 2 European rules

Time zone o set - UST models 00:00 Use UST clock setting ± 12 Hours o set from UST

4

Time zone o set - CET models 00:00 Use CET clock setting ± 12 Hours o set from CET

10 Set frost protection default temperature 5°C 5-30°C

11 Start-up method 0 Fixed time start-up

Optimum start control setting, maximum

pre-heat period based upon 2°C deviation

12

from next event temperature.

(Only accessible if option 11 is set to 2)

OSC or delay start function active

13

(Only accessible if option 11 is set to 1 or 2)

Option Description Factory Setting Other Setting

Installer Advanced Programming Options Use + or - key to scroll between options, use Λ or V keys to select option setting

30 Set range upper limit 30°C 40-50°C

31 Set range lower limit 5°C 5-40°C

32 Enable/disable O function at lower limit 1 Enabled 0 Disabled

33 Enable/disable On function at upper limit 0 Disabled 1 Enabled

34 Set chrono-proportional cycle rate 3 3 cycles per hour

35 Set integration time 2.5 2.50%

36 Set temperature override limit 0 No limit

37 Set time duration of override 0 Next event

40 Number of Events 6 6 switching events per day

41 Operating Mode 5-2 5/2 day programming 24 24 hour programming

70 Keyboard lock type 0 Normal Lock 1 Full lock

71 Random time on start-up 0 Disabled 1 Enabled

72 Site ID number (user de ned) 00 01 to 99

73 Thermostat ID number (user de ned) 00 001 to 999

74 Date format for calendar clock 0 European (dd/mm/yy) 1 North American (mm/dd/yy)

81 Thermostat calibration bias 0 ±1.5K

Remote sensor con guration

90

(A models only)

Limit sensor set point adjustment

93

(Only accessible if Option 90 is set to 2)

Start-up (digital input) NO or NC

94

(Only accessible if Option 90 is set to 3)

OFF

ON

Keyboard enabled

0:15 15 minutes

0 First event of day only 1 All events

0 0, Disabled

27°C 20-50°C

NC, open circuit to change

0

to thermostat mode

0 Disabled

1 Manual time change

3 USA rules, post 2006

4 USA rules. pre-2007

1 Optimum start control

2 Delayed start-up

0:30 30 minutes

0:45 45 minutes

1:00 60 minutes

1:15 75 minutes

1:30 90 minutes

1:45 105 minutes

2:00 120 minutes

0 On/O

6 6 cycles per hour

9 9 cycles per hour

12 12 cycles per hour

55%

10 10%

1 Limited to ±2°C

2 Disabled, no override

1 1 hour

2 2 hours

3 3 hours

4 4 hours

1 Thermostat mode

2 2 switching events per day

4 4 switching events per day

1 Room/duct

2 Limit, ( oor)

3 Start-up (digital input)

NO, close circuit to change to

1

thermostat mode

2

Part No. 698v01 08/07

Page 3

Datasheet

TP5000M Si Programmable Room Thermostat

Service Interval Timer Service due date is reached or passed

The service interval timer allows the installer to

select a service due date for the boiler, this can

be set at between 28 days and 366 days from the

current date.

When the service due date is reached the visual

and audible warning are repeated each hour of

the day commencing at midday, but the duration

of the alarm is increased to 60 seconds, this can

Service due date is within 28 days

From 28 days prior to the service due date, a visual

warning will appear in the display and a buzzer will

sound for ten seconds each hour commencing at

midday, this can be cancelled for the current day

be cancelled for the current day by pressing any

button. All override and programming buttons

are disabled and depending upon service interval

timer setting, heating can be restricted to 15, 30 or

45 minutes in each programmed hour.

by pressing any button.

Option Service Interval Timer Function

Setting 0 Disabled, (factory default)

Setting 1 Active, visual and audible warning, no heat reduction

Setting 2 Active, visual and audible warning, heat reduced to 45 minutes per hour

Setting 3 Active, visual and audible warning, heat reduced to 30 minutes per hour

Setting 4 Active, visual and audible warning, heat reduced to 15 minutes per hour

Speci cation and Ordering

Thermostat Features

Hard-wired, built-in sensor

Hard-wired, remote sensor inputs

5/2 day or 24 hour programmable room thermostat Yes, selectable by installer

2, 4 or 6 events per day with optional A/B programming Yes, selectable by installer

Factory pre-set programmes Yes, one for weekdays, another for weekends

Factory set calendar clock Automatic summer/wintertime change

Time accuracy ± 1 minute per year

Memory back-up, time and all user and installer settings Retained for life of product

Temperature range 5-30°C

Programmable frost thermostat function Yes

Control output, derived from PI algorithm On/O or Chrono-proportional, 3, 6, 9 or 12 cycles per hour

Switching di erential in On/O mode ±1°C

Installer selectable advanced programming options Yes, refer to installation instructions for list

Installer selectable service interval timer Yes, 28 to 366 days from current date

Programmable range limitation Yes, max and min

Electronic keyboard lock Yes, full or part

Power supply 230V, 50Hz

Switching action of output relay SPDT (voltage free)

Switch rating of output relay 3 (1) A, 10-230V

Dimensions, mm 110 wide x 88 high x 28 deep

Design standard EN60730-2-9

(1)

Can be con gured by installer for remote temperature sensor, limit sensor, window contact or telephone activated switch contact.

(2)

Remote sensor is supplied as an accessory, if remote room sensor is required order TS2 sensor, code 087N681100.

(1) (2)

Type

Sales Code

Type

Sales Code

230V models

Hard-wired

TP5000M Si

087N791700

TP5000MA Si

087N791800

Part No. 698v01 08/07

3

Page 4

Datasheet

2

)

2

TP5000M Si Programmable Room Thermostat

Wiring

TP5000M Si

Electronics

C

N

L

123

NC

OFF

COM

NO

B

N

ON

Heating

Load

Please note:

On 230V version the power supply is connected to L and N.

On the 24V version the power supply is connected to A and B.

Remote Input Options

S1

S2

S1

S2

Window or

teleswitch

contact

(NO or NC)

S1

S2

Window

contact (NC)

Teleswitch

contact (NC)

S1

S2

S1LS2

Remote Input

(TP5000MA Si only)

Remote Input

(TP5000MA Si only)

Con gured for

remote room

sensor or limit

sensor

Thermal Performance

Danfoss can accept no responsibility for possible errors in catalogues, brochures, and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already

on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

22

21

20

19

18

17

16

15

Room Temperature (C)

14

13

12

11

10

012345678910111

Con gured for

window contact or

other contact such

as teleswitch

Time (Hours

Con gured for

window contact

and other contact

such as teleswitch

On/O Con trol

22

21

20

19

18

17

16

15

Room Temperature (C)

14

13

12

11

10

012345678910111

Chrono-Proportional Control

Time (Hours)

(Chrono 6)

Danfoss Randall Ltd.

Ampthill Road

Bedford MK42 9ER

Tel: 0845 1217 400

Fax: 0845 1217 515

Email: danfossrandall@danfoss.com

Website: www.danfoss-randall.co.uk

4

Part No. 698v01 08/07

Loading...

Loading...