Page 1

MAKING MODERN LIVING POSSIBLE

Technical Information

Series T90

Transit Mixer Drive System

powersolutions.danfoss.com

Page 2

Technical Information Series T90 Transit Mixer Drive System

Contents

Series T90

Transit Mixer Drive

Transit Mixer Pump

Series T90

Transit Mixer Motor

Series 90

General Description .......................................................................................................................................3

General Description .......................................................................................................................................4

Technical Specications ............................................................................................................................... 6

Operating Parameters ..................................................................................................................................8

System Design Parameters .......................................................................................................................10

Features ...........................................................................................................................................................11

Control ..............................................................................................................................................................13

Inatallation Drawings ..................................................................................................................................14

General Description .....................................................................................................................................17

Inatallation Drawings ..................................................................................................................................18

L1207419 • Rev BA • October 20142

Page 3

Technical Information Series T90 Transit Mixer Drive System

General Description

General

Product Features

System Features

The new Transit Mixer Drive System from Danfoss is based on more than 30 years‘

experience in the worldwide use of drum drive systems in transit mixers. Innovative

electronics suitable for mobile use, combined with reliable technology, are the result of this

development.

Danfoss oers, as a single supplier, complete systems for drum sizes from 6-18m³

[8-24 yd

3

] from one source.

The smart system resets the standard relating to the market requirements for reliability and

simple handling.

• Hydrostatic transmission

- overall size 055, 075 and 100 cm³ [3.35, 4.49 and 6.10 in3]

- rotational group proven over millions in units

- noise reduction by 12 dB (A)

- exemplary reductions in overall volume and weight

• Operating units

- external and cab-mounted station

- simple installation and wiring

- electric plug connections suitable for mobile use

- no adjustments,“Plug and Perform“

• direction of rotation and speed via latched rotary switch on the cab-mounted or

external station

• identical operating elements on the cab-mounted and external stations

• external station pushbutton: STOP/START the drum

• external station pushbutton: STOP/START the drum with the cab-mounted station

active

• cab-mounted station pushbutton: change over to external station and vice versa

• status reporting from the cab-mounted and external stations via LEDs

• active cab-mounted station during transit means the external station is switched o

• constant drum speed with variable pump-drive speed

• constant drum speed, irrespective of the loading of the drum

• exact repeatability of the drum speed by means of a latched rotary switch

• automatic maximum drum-speed limitation

A convincing, reliable and smart system solution from Danfoss which

(at present) is still missing from your transit mixer?

Contact us! Our worldwide sales organization is ready to serve you.

L1207419 • Rev BA • October 2014 3

Page 4

Technical Information Series T90 Transit Mixer Drive System

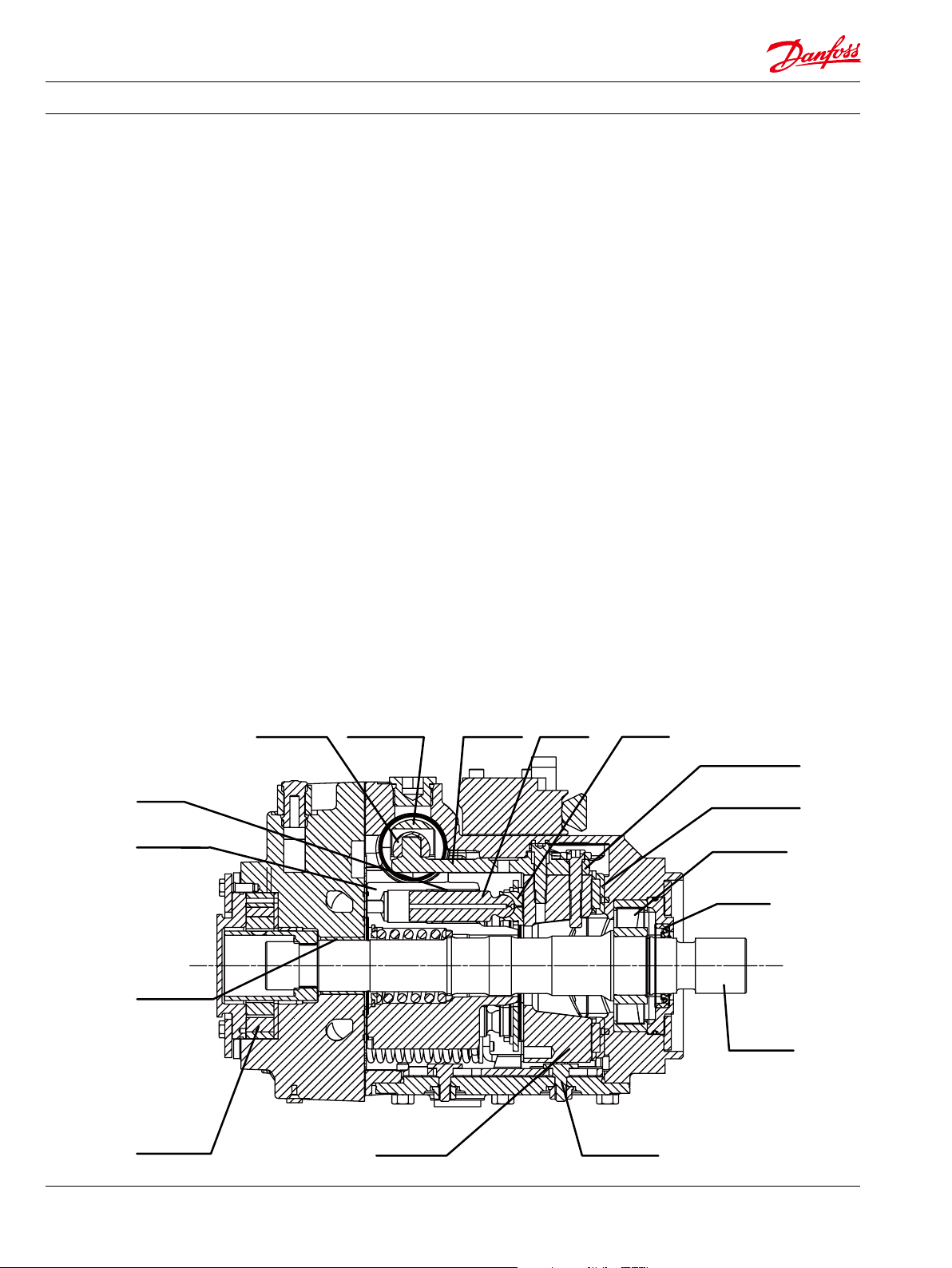

Servo piston Servo armPiston Slipper

General Description

Series T90 Family of

Pumps

Danfoss provides Series T90 as an advanced type of axial piston variable displacement

pumps for concret mixers, the development of which is based on more than 30 years

of our experience in applying our products in the global market. The new T90 axial piston variable displacement pumps are derived from the sophisticated earlier type of S90

pumps, and are suitable for extended concrete mixer applications.

Series T90 variable displacement pumps are compact, high power density units. All

models utilize the parallel axial piston/slipper concept in conjunction with a tiltable

swashplate to vary the pump’s displacement. Reversing the angle of the swashplate reverses the ow of oil from the pump and thus reverses the direction of rotation of the

motor output.

Series T90 pumps include an integral charge pump which is manually controlled to provide system replenishing and cooling oil ow, as well as control uid ow.

• Series T90 axial piston pumps are designed with the most advanced technology

• With optional sizes 055, 075, 100

• Installation: SAE standard ange

• Axial piston design of high eeciency

• Proved reliability and excellent performance

• Compact, light weight

• Worldwide sales and services

• Metric standard threads for main ports (A and B)

Design Series T90 pump cross-section

Slider block

Bushing

Cylinder block

Rear bushing

Charge pump

Feedback linkage

Cradle bearing

Roller bearing

Shaft seal

Input shaft

Cradle guideSwash plate

L1207419 • Rev BA • October 20144

Page 5

Technical Information Series T90 Transit Mixer Drive System

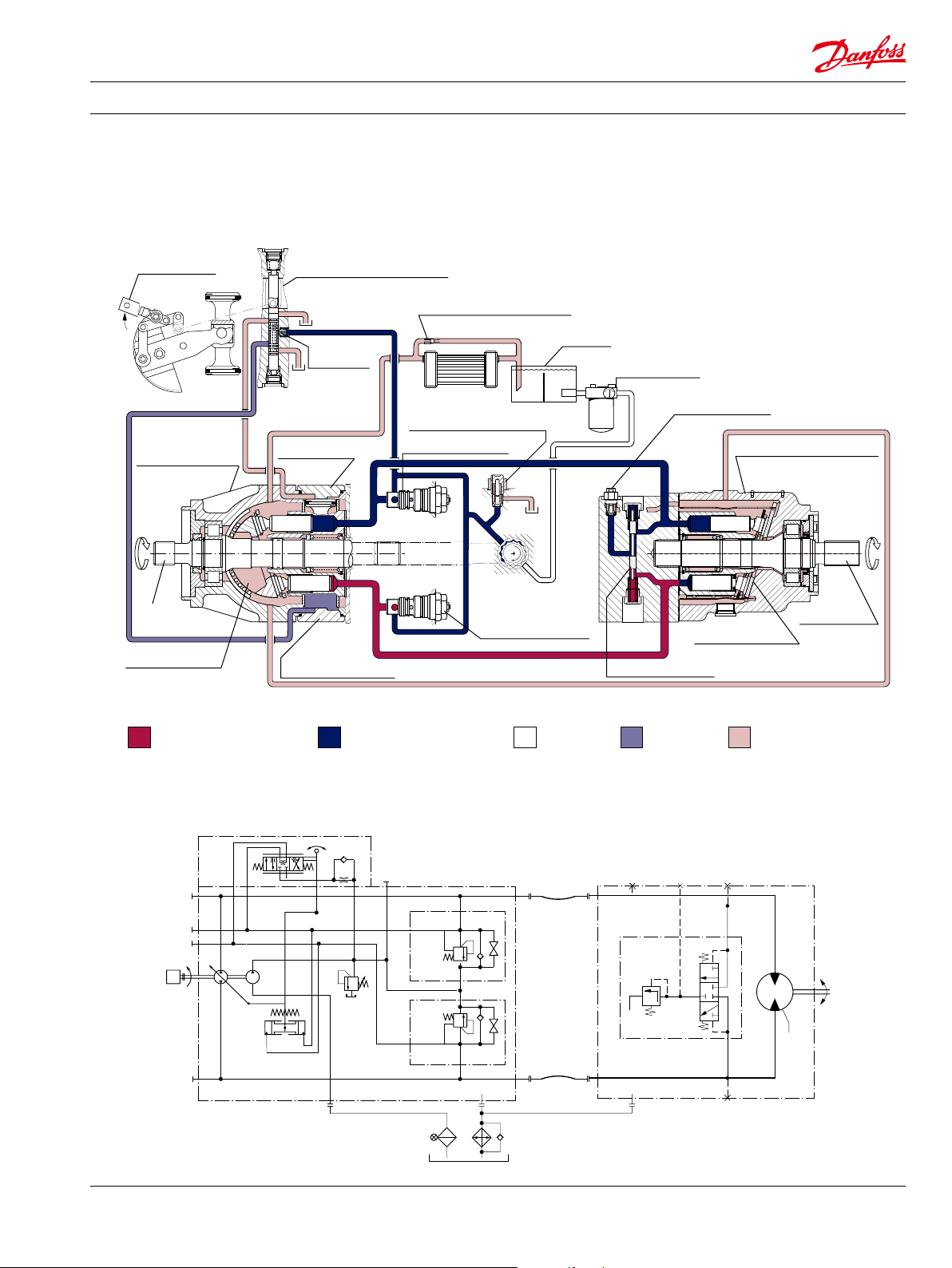

General Description

Pictorial Circuit Diagram

Control handle

Reversible variable

displacement pump

Input shaft

Pump swashplate

This conguration shows a hydrostatic transmission using a Series T90 axial piston

variable displacement pump and a Series 90 xed displacement motor.

Displacement control valve

Heat exchanger bypass valve

Orice check

valve

Servo control cylinder

Servo control cylinder

Heat Exchanger

Charge pressure relief valve

Multi-function valve

To

pump

case

Charge pump

Multi-function valve

Reservoir

Vacuum gauge

Purge relief valve

Fixed displacement motor

Motor swashplate

Loop ushing valve

P400053

Output shaft

working loop (high pressure)

System Schematic

M1

M4

M5

M

M2

Pump Motor

working loop (low pressure)

M3

S

Suction line

AA

BB

L2

Control uid

L2 M1

M3

L1

M2

Case drain uid

P400054

L1207419 • Rev BA • October 2014 5

Page 6

Technical Information Series T90 Transit Mixer Drive System

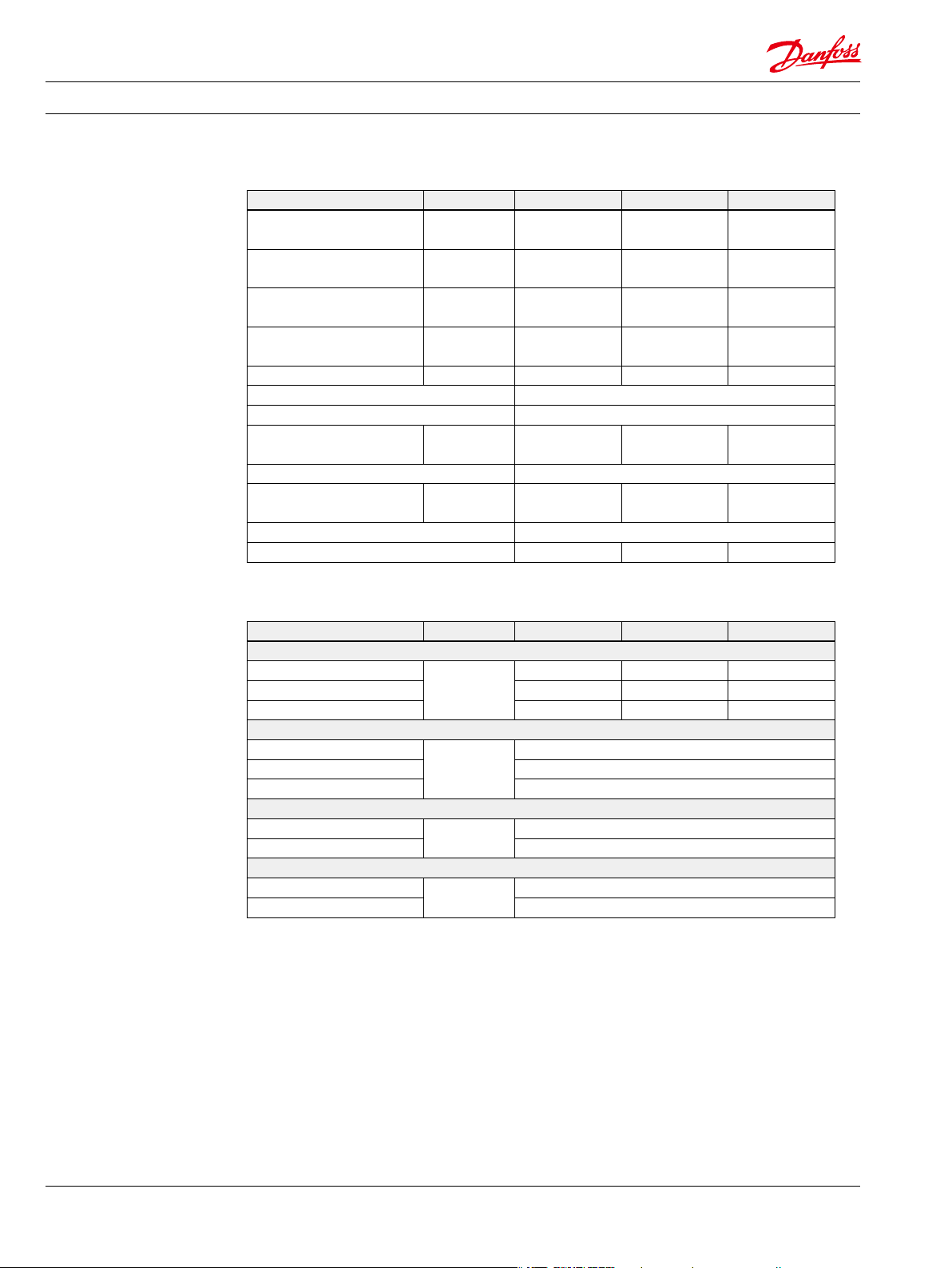

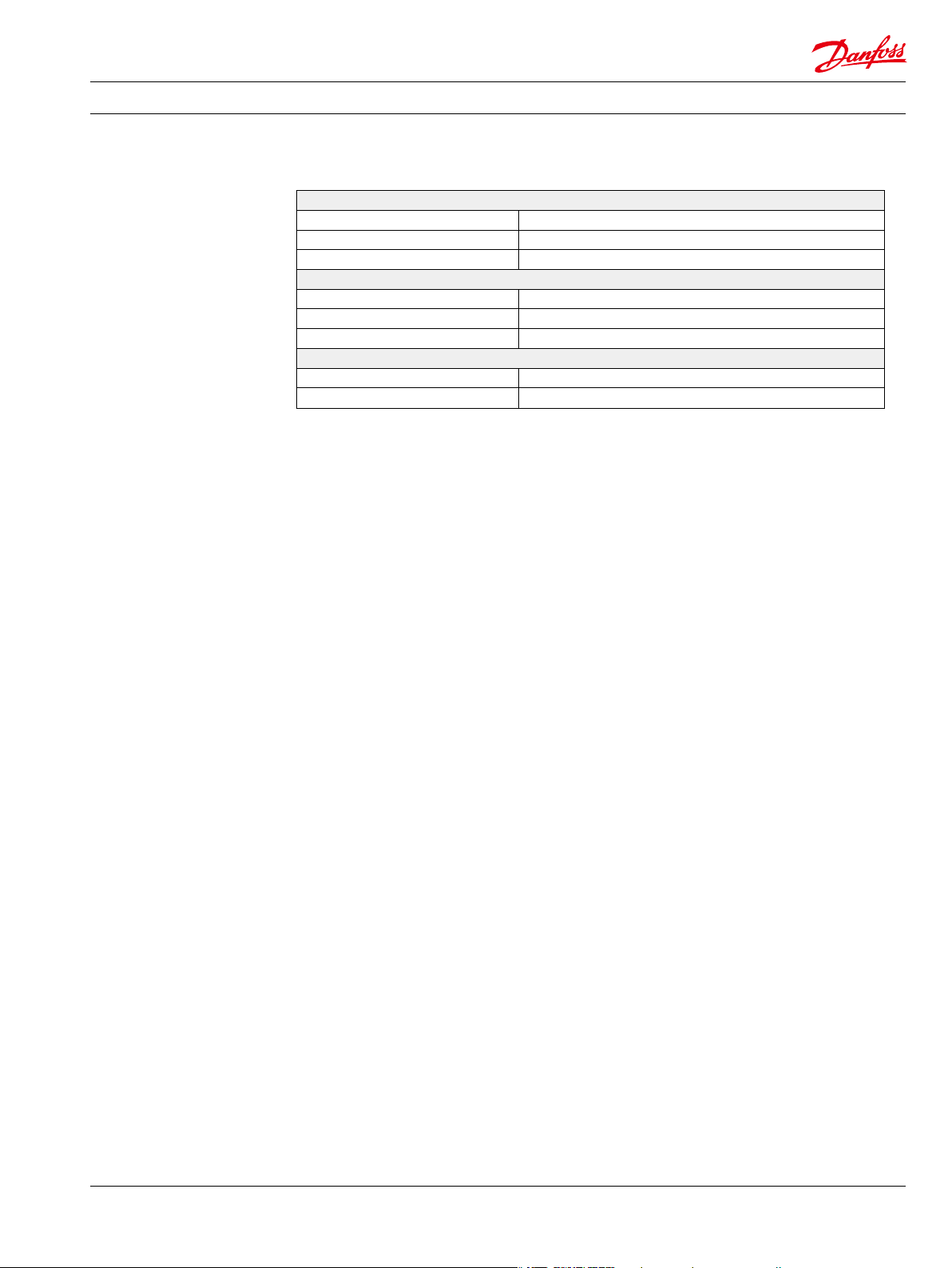

Technical Specications

Features

Operating Parameters

Feature Unit 055 075 100

Displacement

Flow at rated speed

(theoretical)

Torque at maximum

displacement (theoretical)

Mass moment of inertia of

rotating components

cm³

[in³]

l/min

[US gal/min]

N•m/bar

[lbf•in/1000 psi]

kg•m²

[slug•ft²]

55

[3.35]

215

[57]

0.88

[530]

0.0060

[0.0044]

75

[4.59]

236

[62]

1.19

[730]

0.0100

[0.0074]

100

[6.10]

300

[79]

1.59

[970]

0.0171

[0.0126]

Weight (with control opt. MA) kg [lb] 40 [88] 49 [108] 68 [150]

Mounting (per SAE J744) Flange SAE C

Rotation Right hand or Left hand rotation

Main ports: 4-bolts split-ange

(per ISO 6162)

mm

[in]

25.4

[1.0]

25.4

[1.0]

25.4

[1.0]

Main port conguration Twin Ports

Case drain ports

UNF thread (in.)

1.0625–12 1.0625–12 1.0625–12

(SAE O-ring boss)

Other ports SAE O-ring boss

Input Shafts Splined, 21 teeth Splined, 23 teeth Splined, 23 teeth

Parameters Unit 055 075 100

Input speed

Minimum

-1

Rated 3900 3150 3000

min

(rpm)

400 400 400

Maximum 4250 3350 3200

System pressure

Continuous

Maximum 420 [6090]

bar [psi]

400 [5800]

Minimum low loop pressure 10 [650]

Suction port pressure (charge pump inlet)

Minimum

Minimum(cold start) 0.2 [24]

(abs)

bar

[in. Hg vac.]

0.7 [9]

Case pressure

Continuous

Maximum(cold start) 5.0 [73]

bar [psi]

3.0 [44]

L1207419 • Rev BA • October 20146

Page 7

Technical Information Series T90 Transit Mixer Drive System

Technical Specications

Fluid Specications

Viscosity mm²/sec (cSt) [SUS]

Minimum 7 [49]

Recommended range 12-80 [70-370]

Maximum 1600 [7500]

Temperature range °C [°F]

Minimum -40 [-40]

Rated 104 [220]

Maximum intermittent 115 [240]

Filtration

Cleanliness 22/18/13 or higher standard ISO 4406

Eciency (suction line ltration)

=75 (β10≥2)

β

35-45

L1207419 • Rev BA • October 2014 7

Page 8

Technical Information Series T90 Transit Mixer Drive System

Operating Parameters

Input Speed

System Pressure

Minimum speed is the lowest input speed recommended during engine idle condition.

Operating below minimum speed limits the pump’s ability to maintain adequate flow

for lubrication and power transmission.

Rated speed is the highest input speed recommended at full power condition.

Operating at or below this speed should yield satisfactory product life.

System pressure is the dierential pressure between high pressure system ports. It is

the dominant operating variable aecting hydraulic unit life. High system pressure,which

results from high load, reduces expected life. Hydraulic unit life depends on the speed and

normal operating, or weighted average, pressure that can only be determined from a duty

cycle analysis.

Application pressure is the high pressure relief or pressure limiter setting normally

dened within the order code of the pump. This is the applied system pressure at which

the drive-line generates the maximum calculated pull or torque in the application.

Maximum working pressure is the highest recommended Application pressure.

Maximum working pressure is not intended to be a continuous pressure. Propel systems

with application pressures at, or below, this pressure should yield satisfactory unit life

given proper component sizing.

All pressure limits are differential pressures referenced to low loop (charge) pressure.

Subtract low loop pressure from gauge readings to compute the differential.

Case Pressure

Fluid Selection

Under normal operating conditions, the rated case pressure must not be exceeded

3 bar (44 psi). During cold start case pressure must be kept below maximum intermittent

case pressure 5 bar (73 psi). Size drain plumbing accordingly.

CCaution

Possible component damage or leakage

Operation with case pressure in excess of stated limits may damage seals, gaskets,

and/or housings, causing external leakage. Performance may also be affected since

charge and system pressure are additive to case pressure.

Ratings and performance data are based on operating with hydraulic fluids containing

oxidation, rust and foam inhibitors. These fluids must possess good thermal and

hydrolytic stability to prevent wear, erosion, and corrosion of motor components.

Never mix hydraulic fluids of different types.

Fire resistant fluids are also suitable at modified operating conditions. Please see

Hydraulic Fluids and Lubricants Technical Information, 520L0465, for more information.

The following hydraulic fluids are suitable:

• Hydraulic Oil DIN 51 524-2 - HLP

• Hydraulic Oil DIN 51 524-3 - HVLP

• SAE J183 API CD, CE and CF

L1207419 • Rev BA • October 20148

Page 9

Technical Information Series T90 Transit Mixer Drive System

Operating Parameters

Temperature and

Viscosity

Filtration System

The high temperature limits apply at the hottest point in the transmission, which is

normally the motor case drain. The system should generally be run at or below the

quoted rated temperature.The maximum intermittent temperature is based on

material properties and should never be exceeded.

Cold oil will generally not affect the durability of the transmission components, but

it may affect the ability of oil to flow and transmit power; therefore temperatures

should remain 16 °C [30 °F] above the pour point of the hydraulic fluid.The minimum

temperature relates to the physical properties of component materials. Size heat

exchangers to keep the fluid within these limits. Danfoss recommends testing to verify

that these temperature limits are not exceeded.

For maximum efficiency and bearing life, ensure the fluid viscosity remains in the

recommended range. The minimum viscosity should be encountered only during

brief occasions of maximum ambient temperature and severe duty cycle operation.

The maximum viscosity should be encountered only at cold start.

To prevent premature wear, ensure only clean fluid enters the hydrostatic transmission

circuit. A filter capable of controlling the fluid cleanliness to ISO 4406 class 22/18/13

(SAE J1165) or better, under normal operating conditions, is recommended.

These cleanliness levels can not be applied for hydraulic fluid residing in the component

housing/case or any other cavity after transport.

The selection of a filter depends on a number of factors including the contaminant

ingression rate, the generation of contaminants in the system, the required fluid

cleanliness, and the desired maintenance interval. Filters are selected to meet the

above requirements using rating parameters of efficiency and capacity.

Reservoir

Case Drain

Filter efficiency can be measured with a Beta ratio¹ (βX). For simple suction-filtered

closed circuit transmissions and open circuit transmissions with return line filtration,

a filter with a β-ratio within the range of β

= 75 (β10 ≥ 2) or better has been found to

35-45

be satisfactory.

The hydrostatic system reservoir should accommodate maximum volume changes

during all system operating modes and promote de-aeration of the fluid as it

passes through the tank. A suggested minimum total reservoir volume is 5⁄8 of the

maximum charge pump flow per minute with a minimum fluid volume equal to ½ of

the maximum charge pump flow per minute. This allows 30 seconds fluid dwell for

removing entrained air at the maximum return flow. This is usually adequate to allow

for a closed reservoir (no breather) in most applications.

Locate the reservoir outlet (charge pump inlet) above the bottom of the reservoir to

take advantage of gravity separation and prevent large foreign particles from entering

the charge inlet line. Position the reservoir inlet (fluid return) to discharge below the

normal fluid level, toward the interior of the tank. A baffle (or baffles) will further

promote de-aeration and reduce surging of the fluid.

A case drain line must be connected to one of the case outlets (L1 or L2) to return

internal leakage to the system reservoir.

L1207419 • Rev BA • October 2014 9

Page 10

Technical Information Series T90 Transit Mixer Drive System

System Design Parameters

Shaft Loads

The table below indicates the bearing life in B

hours.These data are based on the condition

10

where the pump is operated with system pressure at 240bar[3500 psi], input speed at

1800RPM, with max. displacement and no external thrust/radial shaft loads. Nearly

equal amounts of foward vs. reverse swashplate operation is experienced. The charge

pump is of standard displacement and is a standard charge pressure pump.

T90 piston pumps are designed with

bearings that can accept some external

radial and thrust loads. The external shaft

radial load limits are a function of the load

position and orientation, and operating

conditions of the motor.

Shaft life

Parameter Bearing life – B10 hours

55 22 090

75 22 970

100 22 670

The maximum allowable radial load (Re) is

based on the maximum external moment

(Me) and the distance (L) from the

mounting ange to the load. It may be

determined using the following table and

formula.

Radial/thrust load position

0°Re

90°

Re

270°

Re

Re

inTout

T

L

Formula :

Re = Me / L

180°Re

Pump swashplate

P400055

All external shaft loads aect bearing life. In applications where external shaft loads

cannot be avoided, minimize the impact by positioning the load at 90° or 270° as shown

in the gure.

Contact your Danfoss representative for an evaluation of unit bearing life, if

• you have continuously applied external loads exceeding 25 % of the maximum allowable

radial load (Re)

• or the pump swashplate is positioned on one side of center all or most of the time.

• bearing life B10 is critical.

Use of tapered output shafts or clamp-type couplings is recommended where radial

shaft loads are present.

Allowable external shaft load

Parameters 055 075 100

External moment (Me)

N•m [lbf•in]

Maximum shaft thrust in (T

Maximum shaft thrust in (T

)

in

N [lbf]

out

N [lbf]

101

[893]

3340

[750]

)

910

[204]

118

[1043]

4300

[996]

930

[209]

126

[1115]

5160

[1160]

1000

[224]

L1207419 • Rev BA • October 201410

Page 11

Technical Information Series T90 Transit Mixer Drive System

System Design Parameters

Shaft Availability and

Torque Ratings

Shaft availability and torque ratings

Shaft description 055 075 100

21 teeth

16/32 pitch spline

23 teeth

16/32 pitch spline

Filtration Suction ltration

The suction ltration is placed in the

circuit between the reservoir and inlet to

the charge pump, as shown below.

Filter with block alarm is recommended

Multi-Function Valves

1130

[10 000]

—

— —

1580

[14 000]

1580

[14 000]

Suction ltration

Hydraulic uid reservoir

To low

loop and

control

Charge pump

Ajustable

charge pressure relief valve

To pump case

Manometer

Filter

P102 003E

M1

M4

M5

M3

To control

A

A

Port

Multifunction valve

A

Bypass hex

ajustment

M

Port

B

M2

B

S

L2

Multifunction valve

Charge

pressure

relief valve

P400056

L1207419 • Rev BA • October 2014 11

Page 12

Technical Information Series T90 Transit Mixer Drive System

Features

Charge Pump

Manual Displacement

Control (MDC)

Charge ow is required on all Series T90 pumps applied in closed circuit installations. The

charge pump provides ow to make up internal leakage, maintain a positive pressure in

the main circuit, provide ow for cooling and ltration, replace any leakage losses from

external valving or auxiliary systems, and to provide ow and pressure for the control

system.

Many factors inuence the charge ow requirements and the resulting charge pump size

selection. These factors include system pressure, pump speed, pump swashplate angle,

type of uid, temperature, size of heat exchanger, length and size of hydraulic lines,control

response characteristics, auxiliary ow requirements, hydrostatic motor type, etc.When

initially sizing and selecting hydrostatic units for an application, it is frequently not

possible to have all the information necessary to accurately evaluate all aspects of charge

pump size selection.

Recommend charge pump sizes and speed limits

Charge pump size

cm³ [in³]

20 [1.20] 3600

Rated speed

min-1 (rpm)

Operation

The manual displacement control converts a mechanical input signal to a hydraulic

signal that tilts the cradle swashplate through an angular rotation varying the pump’s

displacement from full displacement in one direction to full displacement in the

opposite direction.

The manual displacement control has a mechanical feedback mechanism which moves

a servo valve in the proper relationship to the input signal and the angular position of

the swashplate. The control is designed so that the angular rotation of the swashplate

is proportional to the mechanical input signal. The control is designed with an internal

override mechanism which allows the mechanical input to be moved at a faster rate

than the movement of the swashplate without damage to the control.

Features and benets of the manual displacement control:

• Precision parts provide repeatable, accurate displacement settings with a given input

signal.

• The manual displacement control is a high gain control: With only small movement of

the control handle (input signal), the servo valve moves to full open position porting

maximum ow to the servo cylinder. This is a high response system with low input

force.

• The integral override mechanism allows rapid changes in input signal without

damaging the control mechanism.

• The double-acting servo piston is coupled to a spring centering mechanism. The

servo control valve is spring centered such that with no input signal the servo valve

is open centered and thus no uid is ported to the servo cylinder.

• Benets:

- Pump returns to neutral after prime mover shuts down.

- Pump returns to neutral if external control linkage fails at the control handle or

if there is a loss of charge pressure.

L1207419 • Rev BA • October 201412

Page 13

Technical Information Series T90 Transit Mixer Drive System

Features

Manual Displacement

Control (MDC)

Manual displacement control schematic

A – 0 – B

T P

M5

Feedback

from

swashplate

M4

P400057

External control handle requirements

• Torque required to move handle

to maximum displacement is

0.68 to 0.9 N•m [6 to 8 lbf•in].

• Torque required to hold handle

at given displacement is

0.34 to 0.57 N•m [3 to 5 lbf•in].

• Torque required to overcome the

override mechanism is 1.1 to 2.3 N•m

[10 to 20 lbf•in] with the maximum

torque required for full forward to

full reverse movement.

Cross-section

Control handle input signal

P400058

M5

M4 P

T

T

Pump displacement vs. control lever rotation

100 %

-24° to 30°

"A"

-35

Max

Displacement

-2

"0"

100 %

Handle degree

2

35

24° to 30°

P400059

Max

"B"

• Maximum allowable input torque is

17 N•m [150 lbf•in].

Control lever rotation range

a 0.5° - 4.5°

b 24° - 30°

Volumetric eciencies of the system will have impacts on the start- and end

inputcommands.

Pump output ow direction and control lever rotation

Input shaft rotation CW CCW

Handle rotation A CCW B CW A CCW B CW

Port A ow (M1) Out In In Out

Port B ow (M2) In Out Out In

Servo cylinder M5 M4 M5 M4

Refer to Installation drawings for handle connection requirements

L1207419 • Rev BA • October 2014 13

Page 14

Technical Information Series T90 Transit Mixer Drive System

Control

High Current Electric

Displacement Control

(HCEDC)

Option PH and PJ

Operation

The HCEDC uses two solenoid operated, proportional-pressure reducing valves to

control the pilot pressure to a 4-way servo valve, which ports hydraulic pressure to

either side of a double acting servo piston. The servo piston tilts the cradle swashplate,

thus varying the pump’s displacement from full displacement in one direction to full

displacement in the opposite direction. Each solenoid valve acts independently for

forward or reverse operation; therefore, the electronic controller must be able to

accommodate two independent pilot valve signal outputs.

The control has a mechanical feedback mechanism which moves the servo valve in

relation to the input signal and the angular position of the swashplate. The electrical

displacement control is designed so the angular rotation of the swashplate (pump

displacement) is proportional to the electrical input signal. Swashplate position

changes due to load variation are sensed by feedback linkage system connected to

the swashplate and control valve. This will activate the valve and supply pressure

to the servo piston, maintaining the swashplate in its commanded position. The

solenoids are equipped with manual override capability thereby allowing the pump

to be commanded to maximum angle in either direction. This is done by depressing

the plunger on the top of the solenoid. Manual operation of the control override is

intended for system troubleshooting only.

High current electric displacement control schematic

Electric Characteristics

(CCW) AS SEEN FROM SHAFT (CW) AS SEEN FROM SHAFT

Active Solenoid A B A B

Pressurized port X1 X2 X1 X2

System port A ow In Out (M1) Out (M1) In

System port B ow Out (M2) In In Out (M2)

Servo port active 2 (M5) 1 (M4) 2 (M5) 1 (M4)

Options PH PJ

Starting current “a” 350mA 178mA

Maximum current “b” 850mA 440mA

L1207419 • Rev BA • October 201414

Page 15

Technical Information Series T90 Transit Mixer Drive System

Control

High Current Electric

Displacement Control

(HCEDC)

Option PH and PJ

-Continued

PH PJ

Maximum current 850mA 440mA

PWM frequency 100 - 200 Hz

Coil resistance @ 20 ºC

9.0 W 35.6 W

The Option PJ coils have an IP 69 K environmental protection rating. The coils include a

uni-directional, polarity diode which protects downstream electronic components from

power surges originating from the coil. Therefore, care must be taken to not reverse the “+”

and “–“ terminals. Failure to do so will damage the diode and render the coil unusable. The

coils have a “1” and “2” molded in the connector for proper identication of the poles.

The Option PH (12V) and Option PJ (24V) controls can be distinguished by the color of the

shroud. The 24V Option PJ has a yellow shroud while the 12V Option PH has a blue shroud.

L1207419 • Rev BA • October 2014 15

Page 16

Technical Information Series T90 Transit Mixer Drive System

Installation Drawings

Manual Displacement Control(MDC), endcap twin portsSize 055

M2

138.8

[5.46]

134.2

[5.28]

Port S :

Charge pump inlet

1-5/16-12UN-2B

27.8

Split ange boss

Ports A and B

1.00 - 6000 psi

Per ISO 6162

M12 x 1.75

Minimum full thread 24mm

"X"

Gauge port

syetem pressure B

9/16-18UNF-2B

117.6

[4.63]

[1.09]

57.2

[2.25]

Approximate

center of

gravity

287.8

[11.33]

"Y"

246.8

[9.72]

Case drain L1

1-1/16-12UN-2B

(0.92)

Case drain L2

1-1/16-12UN-2B

156.8

[6.17]

231.8

[9.13]

7.9

47.6

[1.87]

12.7

[0.50]

33.8

[1.33]

31.3

Max.

22.86 Min.

[0.900]

Spline data:

Pitch diameter = 33.338 [1.3125]

Pressure Angle = 30°

Number of teeth= 21

120.5

Pitch = 16/32

[4.74]

ANSI B92.1-1970, class 5,

llet root, side t

Coupling must not protrude

beyond this point

M10

[10.000]

Ø28.7

[1.36]

[1.13]

Ø34.42

0

-0.05

Ø 127

"Z"

[+0.00]

[-0.02]

[Ø 5]

4x

Approximate

center of

gravity

Ø83 Min.

[Ø3.27]

95.2

57.3

[3.75]

86.24

[3.395]

Ø 14.27

[Ø 0.56]

[2.25]

+0.25

-0.13

[+0.01]

[-0.005]

89.9

[3.54]

CCW CW

57.25

[2.254]

View "Z"

43.7

[1.72]

108.7

[4.28]

Case drain L2

1-1/16-12UN-2B

mm [in]

85.2

[3.355]

Neutral

position

Gauge port M5

servo pressure

9/16-18UNF-2B

Ø 50.8±0.3

[Ø 2.0±0.01]

Maximum

displacement

B

30°

A

Maximum

displacement

View "Y"

Manual displacement control handle

dimensions

A-A

minimum

30°

minimum

Gauge port M4

servo pressure

9/16-18UNF-2B

169

[6.65]

Ø 6.73±0.13

[Ø 0.265±0.005]

Ø 25.4±0.3

[Ø 1.0±0.01]

Ø 41.3±0.3

[Ø 1.6±0.01]

73

[2.87]

View "X"

Gauge port M2

Charge pressure B

9/16-18UNF-2B

Multifunction

valve

Charge pressure

relief valve

M2

M1

B

S

A

P400060

41.7

[1.64]

3x

Gauge port M3

Charge pressure

9/16-18UNF-2B

Multifunction

valve

M3

M10

Gauge port M1

Charge pressure A

9/16-18UNF-2B

L1207419 • Rev BA • October 201416

Page 17

Technical Information Series T90 Transit Mixer Drive System

Installation Drawings

Manual Displacement Control(MDC), endcap twin portsSize 075

mm [in]

1.00 - 6000 psi

Per ISO 6162

bolt M21 x 1.75

Minimum full thread 24mm

139.6

[5.50]

129.5

[5.10]

124.2

[4.89]

27.8

[1.09]

Spline ange port

"X"

Case drain L1

1-1/16-12UN-2B

57.2

[2.25]

Approximate

center of

gravity

247.7

[247.74]

"Y"

AA

14.15

[0.557]

2

Case drain L2

242.2

[9.54]

View "Y"

1-1/16-12UN-2B

155.7

[6.13]

305.14

[12.013]

Gauge port M4

servo pressure

9/16-18UNF-2B

141.7

[5.58]

Coupling must not protrude beyond

7.9

this point

[0.31]

12.45

[12.45]

38.9

M10

[1.53]

28.5

[10.000]

Max.

Ø34.16

Min.

20

[0.787]

Spline data:

Pitch diameter =

Pressure Angle = 30°

Number of teeth= 23

Pitch = 16/32

ANSI B92.1-1970, class 5,

llet root, side t

Ø 0.8

Max.

[0.03]

[1.345]

36.513 [1.4375]

"Z"

41.7

[1.64]

[1.48]

Ø37.59

0

-0.05

[+0.00]

[-0.02]

[Ø 5]

Ø 127

4x

[Ø 0.565±0.007]

Charge pressure

relief valve

Gauge port M3

Charge pressure

9/16-18UNF-2B

155.7

[6.13]

Appr.

center of

gravity

95.5

[3.76]

Ø 14.34±0.18

57.25

[2.254]

View "Z"

94.2

[3.71]

CCW CW

4x 57.25

[2.254]

94

[3.70]

Charge pressure

relief valve

M4

M3

40.6

[1.60]

View "X"

110.7

[4.36]

Case drain L2

1-1/16-12UN-2B

Gauge port M2

Charge pressure B

9/16-18UNF-2B

Ø 94

M5

M2

B

[3.7]

Min.

91.7

[3.61]

Maximum

displacement

Neutral

position

Maximum

displacement

Gauge port M5

servo pressure

9/16-18UNF-2B

Manual displacement control handle

Ø 50.8±0.3

[Ø 2.0±0.01]

B

30°

minimum

A

30°

minimum

A

M1

Gauge port M1

Charge pressure A

9/16-18UNF-2B

dimensions

172.2

[6.78]

81.2

[3.20]

Charge pressure

relief valve

A-A

Ø 6.73±0.13

[Ø 0.265±0.005]

Ø 25.4±0.3

[Ø 1.0±0.01]

Ø 41.3±0.3

[Ø 1.6±0.01]

3x

P400061

L1207419 • Rev BA • October 2014 17

Page 18

Technical Information Series T90 Transit Mixer Drive System

Gauge port M2

Installation Drawings

Manual displacement control (MDC) endcap twin portsSize 100

mm [in]

164.7

[6.48]

153.7

[6.05]

Port S :

Charge pump inlet

1-5/8-12UN-2B

27.8

Split ange boss

Ports A and B

1.00 - 6000 psi

Per ISO 6162

M12 x 1.75

Minimum full thread 24mm

"X"

syetem pressure B

9/16-18UNF-2B

[5.45]

138.32

[1.09]

57.15

[2.25]

Approximate

center of

gravity

338.3

[13.33]

"Y"

280.4

[11.04]

Case drain L1

1-1/16-12UN-2B

(0.8)

Case drain L2

1-1/16-12UN-2B

180.3

[7.1]

277.8

[10.93]

7.9

[1.87]

12.4

[0.49]

28.5

Spline data:

Pitch diameter =

Pressure Angle = 30°

Number of teeth= 23

Pitch = 16/32

160.9

ANSI B92.1-1970, class 5,

[6.34]

llet root, side t

Coupling must not protrude

47.6

beyond this point

M10

38.9

[10.000]

[1.53]

Max.

Ø34.16

[1.345]

20 Min.

[0.787]

36.513 [1.4375]

"Z"

[1.48]

Ø37.59

0

-0.05

Ø 127

Approximate

center of

gravity

Ø101.3 Min.

[+0.00]

[-0.02]

[Ø 5]

108.8

4x

[Ø3.99]

[4.28]

101.4

Ø 14.27

[Ø 0.56]

57.25

[3.99]

+0.25

-0.13

[+0.01]

[-0.005]

[2.25]

View "Y" View "X"

Gauge port M4

servo pressure

9/16-18UNF-2B

View "Z"

107.95

[4.25]

CCW CW

57.25

[2.25]42[1.65]

Charge pressure

relief valve

119.6

[4.71]

Case drain L2

1-1/16-12UN-2B

Gauge port M2

Charge pressure B

9/16-18UNF-2B

[3.95]

100.36

Neutral

position

Gauge port M5

servo pressure

9/16-18UNF-2B

Ø 50.8±0.3

[Ø 2.0±0.01]

Maximum

displacement

B

A

Maximum

displacement

Manual displacement control handle

30°

minimum

30°

minimum

dimensions

A-A

204.6

[8.06]

Ø 6.73±0.13

[Ø 0.265±0.005]

Ø 25.4±0.3

[Ø 1.0±0.01]

Ø 41.3±0.3

[Ø 1.6±0.01]

87.66

[3.45]

Charge pressure

relief valve

M2

[1.3]

33.02

Gauge port M3

servo pressure

9/16-18UNF-2B

Charge pressure

relief valve

3x

M3

M10

B

S

A

M1

Gauge port M1

Charge pressure A

9/16-18UNF-2B

P400062

L1207419 • Rev BA • October 201418

Page 19

Technical Information Series T90 Transit Mixer Drive System

General Description

Series 90 Family of

Motors

Features

Specications

Series 90 motors also use the parallel axial piston/slipper design in conjunction with a

xed or tiltable swashplate. They can intake/discharge uid through either port; they are

bidirectional. They also include an optional loop ushing feature that provides additional

cooling and cleaning of uid in the working loop.

Parameter 055 MF 075 MF 100 MF

Types of mounting (SAE ange

size per SAE J744)

Port connections Twin, axial Twin, axial Twin

Output shaft options Spline, tapered, straight Spline, tapered, straight Spline, tapered, straight

Loop ushing

Speed sensor

Standard Optional

Parameter 055 MF 075 MF 100 MF

Swashplate Fixed Fixed Fixed

Max. displacement

cm³/rev [in³/rev]

Maximum corner power

kW [hp]

Theoretical torque

N•m/bar [lbf•in/1000 psi]

Weight

kg [lb]

Mass moment of inertia

kg•m² [slug•ft²]

SAE C SAE C SAE C

55 [3.35] 75 [4.57] 100 [6.10]

164 [220] 176[236] 224 [300]

0.88 [530] 1.19 [730] 1.59 [970]

22 [49] 26 [57] 34 [74]

0.0060

[0.0044]

0.0100

[0.0074]

0.0171

[0.0126]

Operating Parameters

Parameter Unit 055 MF 075 MF 100 MF

Speed limits

Continuous (max. disp.)

Maximum (max. disp.) 4250 3350 3200

System pressure

Continuous

Maximum 420 [6090]

Flow ratings

Rated

(max. disp., rated speed)

Maximum

(max. disp., max. speed)

Case pressure

Continuous

Maximum (cold start) 5.0 [73]

L1207419 • Rev BA • October 2014 19

-1

(rpm)

min

bar [psi]

l/min [US gal/min]

bar [psi]

3900 3150 3000

400 [5800]

215 [57] 236 [62] 300 [79]

234 [62] 251 [66] 320 [85]

3.0 [44]

Page 20

Technical Information Series T90 Transit Mixer Drive System

Installation Drawings

S90M55

189.5

[7.46]

Port “B”

73.9 [2.91]

case outlet

76.2 [3.00]

case outlet

alternate position

1

End cap ports

1.00 in dia. 6000 psi

(4) bolt split flange

type per SAE J518

(code 62) except

20.8 [0.82] minimum

full thread depth

S90M75

41.78

[1.645]

41.78

[1.645]

Port “A”

103.6

[4.08]

0.875 – 14 straight

thread O-ring boss

per SAE J514 case

outlet port L2

57.25

[2.254]

(2) places

CCW

Port“B”

73.2

[2.88]

(2) places

CW

Port“A”

mm [in]

84.8

[3.34]

minimum

73.2

[2.88]

(2) places

57.25

[2.254]

(2) places

R. 7.4 ± 0.8

[0.29 ± 0.03]

(4) places

Approximate

center of

gravity

End cap ports:

options: 1 & 8

twin ported

1.00 dia. – 6000 psi

(4) bolt split

flange type per SAE

J518 (code 62) except

20.8 [0.82] minimum

full thread depth

option: D

1.00 – 6000 psi (4) bolt

split flange type per SAE

J518 (Code 62) except

M12 x 1.75 thread 0.87

[22] minimum full thread

41.78

[1.645]

41.78

[1.645]

S90M100

End cap ports

1.00 – 6000 psi (4) bolt

split flange type per SAE

J518 (Code 62) except

20.8 [0.82] minimum

full thread depth

Port "B"

Port "A"

41.78

[1.645]

41.78

[1.645]

Port "B"

Port "A"

1.0625 – 12 straight

thread O-ring boss

per SAE J514 case

outlet port L2

1

208.8

[8.22]

113.8

[4.48]

230.9

[9.09]

0.5625 – 18 straight thread

O-ring boss per SAE J514

shaft speed sensor port

1.0625 – 12 straight thread

O-ring boss per SAE J514.

case outlet (alternate

position) port L2

128

[5.04]

1

case outlet

(alternate

position)

1

95

[3.74]

case

outlet

92.2

[3.63]

case outlet

(alternative position)

3.25

[82.6]

case

outlet

82.6

[3.25]

57.25

[2.254]

(2) places

Port "B"

57.25

[2.254]

(2) places

CCW

CCW

Port "B"

CW

CW

Port "A"

Port "A"

(2) places

94

[3.70]

minimum

73.2

[2.88]

(2) places

57.25

[2.254]

(2) places

Approximate

center of

gravity

7.4 ± 0.8

[0.29 ± 0.031]

(4) places

73.2

[2.88]

Ø100.6

[Ø3.96]

minimum

73.2

[2.88]

(2) places

57.25

[2.254]

(2) places

R. 7.37 ± 0.76

[0.29 ± 0.03]

(4) places

Approximate

center of

gravity

73.2

[2.88]

(2) places

L1207419 • Rev BA • October 201420

Page 21

Technical Information Series T90 Transit Mixer Drive System

L1207419 • Rev BA • October 2014 21

Page 22

Products we o er:

Bent Axis Motors

Closed Circuit Axial Piston

Pumps and Motors

Displays

Electrohydraulic Power

Steering

Electrohydraulics

Hydraulic Power Steering

Integrated Systems

Joysticks and Control

Handles

Microcontrollers and

Software

Open Circuit Axial Piston

Pumps

Orbital Motors

PLUS +1® GUIDE

Proportional Valves

Sensors

Steering

Transit Mixer Drives

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile o -highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of o -highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever o -highway vehicles are at work, so is Danfoss.

We o er expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-

Local address:

inverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Danfoss

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

L1207419 • Rev BA • October 2014 www.danfoss.com © Danfoss A/S, 2014

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Power Solutions

(Shanghai) Co. Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Loading...

Loading...