Page 1

Technical Information

Series T90 Axial Piston Pumps

Size 055/075/100

www.danfoss.com

Page 2

Technical Information

Series T90 Axial Piston Pumps

Revision history Table of revisions

Date Changed Rev

March 2022 Updated Mating pump requirements 0306

August 2021 Updated Operating Parameters 0304

February 2021 Corrected Size 100 HCEDC on Installation Drawings. 0203

September 2020 Updated an introduction. 0202

August 2020 Updated HCEDC in Control Options. 0201

July 2020 Added drawings of HCEDC Size 075 and 100. 0109

July 2020 Updated Model Code M, T and W. 0108

April 2020 Changed document number from 'BC00000063' to 'BC152886484177', updated Installation

drawings

March 2020 5th edition - fixed value of input speed 0106

February 2020 4th edition - added HCEDC 0105

January 2019 3rd edition 0104

September 2014 2nd edition BA

February 2012 1st edition AA

0107

2 | © Danfoss | March 2022 BC152886484177en-000306

Page 3

Technical Information

Series T90 Axial Piston Pumps

Contents

General Description

T90 Family of Pumps....................................................................................................................................................................... 5

PLUS+1 Compliant Controls and Sensors................................................................................................................................5

Design...................................................................................................................................................................................................6

Pictorial Circuit Diagram................................................................................................................................................................7

System Schematic (with PL function)........................................................................................................................................7

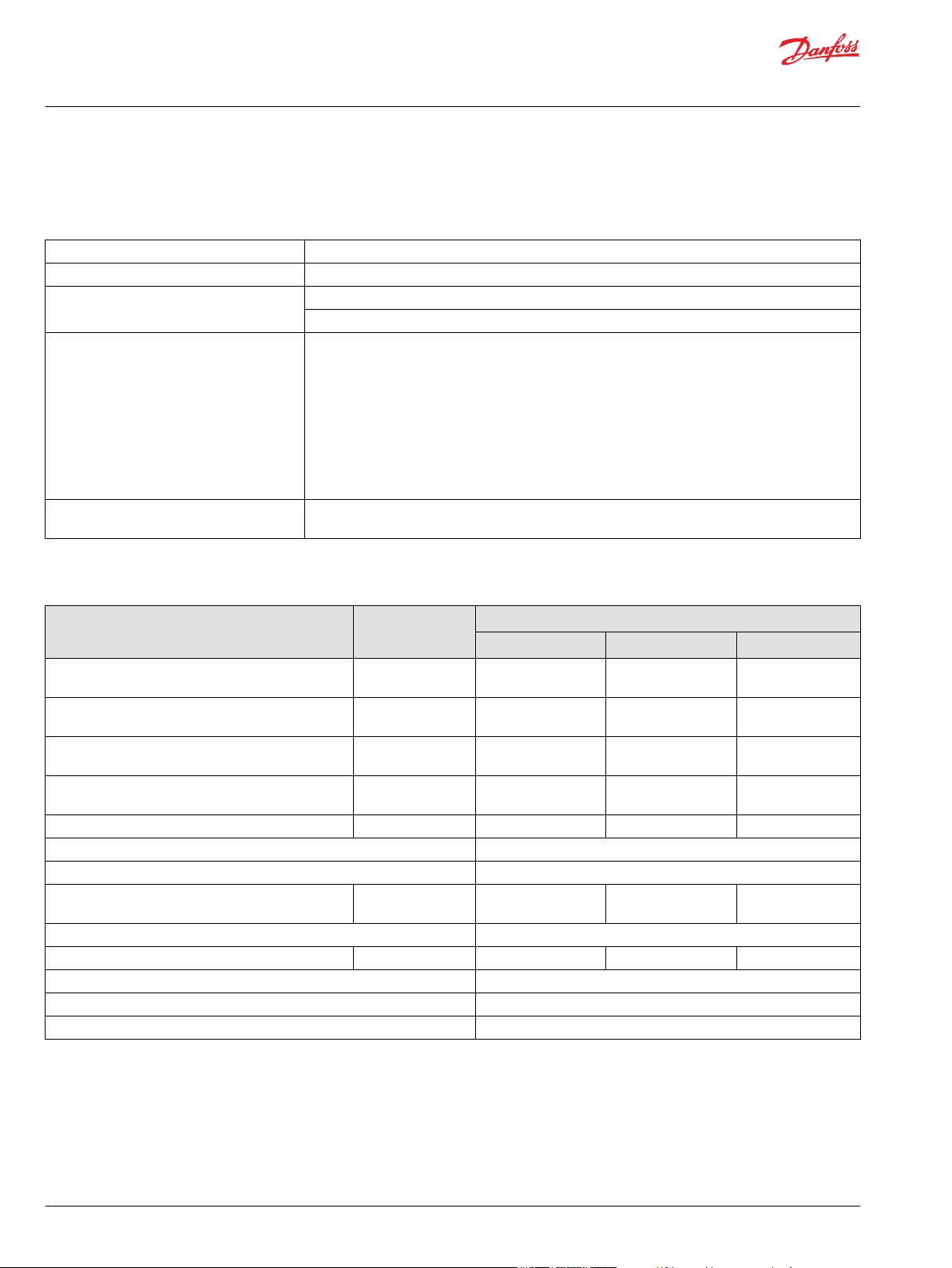

Technical Specifications

General Specifications.................................................................................................................................................................... 8

Features and Options......................................................................................................................................................................8

Operating Parameters.....................................................................................................................................................................9

Fluid Specifications..........................................................................................................................................................................9

Operating Parameters

Overview........................................................................................................................................................................................... 10

Input Speed......................................................................................................................................................................................10

Independent Braking System....................................................................................................................................................10

System Pressure..............................................................................................................................................................................10

Servo Pressure.................................................................................................................................................................................11

Charge Pressure..............................................................................................................................................................................11

Case Pressure...................................................................................................................................................................................11

External Shaft Seal Pressure....................................................................................................................................................... 12

Temperature and Viscosity.........................................................................................................................................................12

System Design Parameters

Filtration System.............................................................................................................................................................................13

Filtration Options...........................................................................................................................................................................13

Suction filtration - Option S.................................................................................................................................................. 13

Charge pressure filtration (partial charge pump flow)............................................................................................... 14

Remote charge pressure filtration......................................................................................................................................14

Fluid selection................................................................................................................................................................................. 15

Reservoir............................................................................................................................................................................................15

Case Drain.........................................................................................................................................................................................15

Pump Life..........................................................................................................................................................................................15

Charge Pump...................................................................................................................................................................................15

Charge pump sizing/selection.............................................................................................................................................16

Bearing Loads and Life.................................................................................................................................................................16

Applications with external shaft loads..............................................................................................................................16

Understanding and Minimizing System Noise....................................................................................................................17

Sizing Equations............................................................................................................................................................................. 18

Mounting Flange Loads...............................................................................................................................................................19

Master Model Code

Model Code (R-Size-M-P-J)......................................................................................................................................................... 21

Model Code (G-N-F-L-H)..............................................................................................................................................................23

Model Code (T-W-Y/Z-K)..............................................................................................................................................................24

Control Options

3-Position Electric Control(FNR), Options: DD.....................................................................................................................25

Response time........................................................................................................................................................................... 26

Manual Displacement Control (MDC), Options: MA, MS, LU, LW..................................................................................27

Features and Benefits..............................................................................................................................................................27

External Control Handle Requirements............................................................................................................................27

MDC with Neutral Start Switch (NSS)................................................................................................................................ 28

High Current Electric Displacement Control (HCEDC); Options A4, A5......................................................................29

EDC Control Signal Requirements......................................................................................................................................29

Connectors..................................................................................................................................................................................30

EDC solenoid data.................................................................................................................................................................... 30

Features and Options

Multi-Function Valves...................................................................................................................................................................31

Overpressure protection........................................................................................................................................................31

©

Danfoss | March 2022 BC152886484177en-000306 | 3

Page 4

Technical Information

Series T90 Axial Piston Pumps

Contents

Pressure limiting function..................................................................................................................................................... 31

Bypass Function........................................................................................................................................................................ 32

Auxiliary Mounting Pads............................................................................................................................................................. 32

Mating pump requirements................................................................................................................................................. 32

Displacement Limiter................................................................................................................................................................... 33

Shaft Torque.....................................................................................................................................................................................34

Shaft torque and spline lubrication................................................................................................................................... 34

Shaft torque for tapered shafts............................................................................................................................................34

Shaft Availability and Torque Ratings.....................................................................................................................................35

Tapered Shaft Customer Acknowledgement.................................................................................................................35

Charge Pump...................................................................................................................................................................................36

Charge pump sizing/selection.............................................................................................................................................36

Charge pump flow and power curves...............................................................................................................................36

Speed Sensor...................................................................................................................................................................................38

Connector Pin Assignments.......................................................................................................................................................39

Installation Drawings

Frame Size 055 : MDC................................................................................................................................................................... 40

Frame Size 075 : MDC................................................................................................................................................................... 41

Frame Size 100 : MDC................................................................................................................................................................... 42

Frame Size 075 : HCEDC...............................................................................................................................................................43

Frame Size 100 : HCEDC...............................................................................................................................................................44

4 | © Danfoss | March 2022 BC152886484177en-000306

Page 5

Technical Information

Series T90 Axial Piston Pumps

General Description

T90 Family of Pumps

Danfoss T90 variable pump is on the base of S90 variable pump, combined with Danfoss’s the global

application of experience and the latest technology to develop a new axial piston variable pump, it can

cooperate T90 motor or other hydraulic products of hydraulic drive system to achieve the fluid

transmission and control, mainly used in closed system.

Currently, Danfoss T90 products not only for truck mixer drum drive, but also walk close system of

agricultural machinery and road roller. For the three applications, T90 has released different

configuration options for the user to select. Please refer pump type code.

Series T90 axial piston pumps are designed with the most advanced technology.

•

With optional sizes 055, 075, 100.

•

Axial piston design of high effeciency.

•

Proved reliability and excellent performance.

•

Compact, light weight.

•

PLUS+1TM compliant controls and sensors.

•

Series T90 variable displacement pumps are compact, high power density units. All models utilize the

parallel axial piston/slipper concept in conjunction with a tiltable swashplate to vary the pump’s

displacement. Reversing the angle of the swashplate re-verses the flow of oil from the pump and thus

reverses the direction of rotation of the motor output.

Series T90 pumps include an integral charge pump which is manually controlled to pro-vide system

replenishing and cooling oil flow, as well as control fluid flow.

PLUS+1 Compliant Controls and Sensors

A wide range of Series T90 controls and sensors are PLUS+1™ compliant. PLUS+1 compliance means our

controls and sensors are directly compatible with the PLUS+1 machine control architecture. Adding

Series T90 pumps to your application using PLUS+1 GUIDE software is as easy as drag-and-drop. Software

development that used to take months can now be done in just a few hours. For more information on

PLUS+1 GUIDE, visit www.sauer-danfoss.com/plus1.

Series T90 pumps can be used together in combination with other Danfoss pumps and motors in the

overall hydraulic system. Danfoss hydrostatic products are designed with many different displacement,

pressure and load-life capabilities.

Go to the Danfoss website or applicable product catalog to choose the components that are right for

your complete closed circuit hydraulic system.

©

Danfoss | March 2022 BC152886484177en-000306 | 5

Page 6

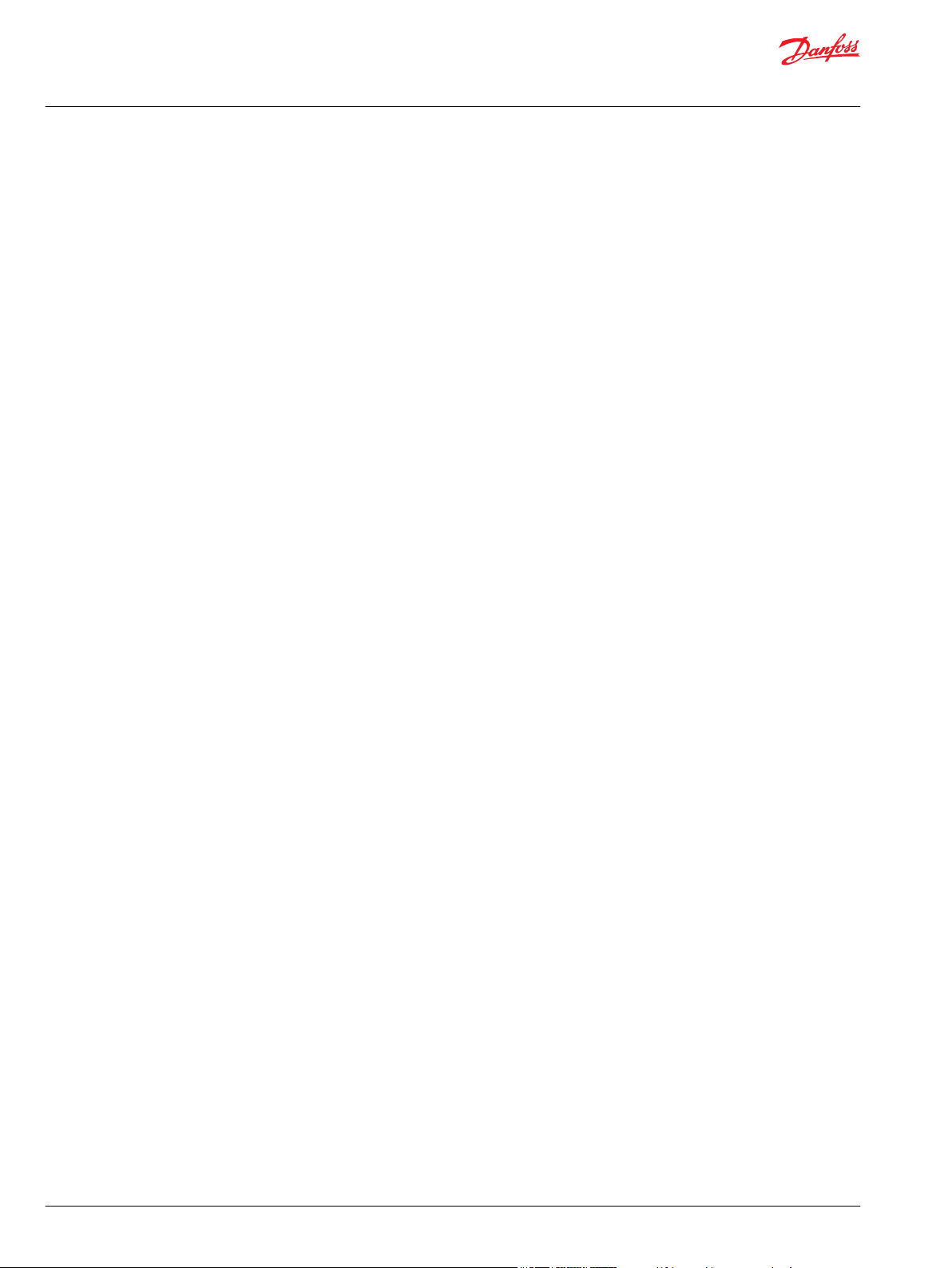

Slider block

Servo piston Servo arm Piston Slipper

Feedback linkage

Roller bearing

Cradle bearing

Shaft seal

Input shaft

P400621

Cradle guideSwash plate

Charge pump

Rear bushing

Cylinder block

Bushing

Model-No./Ident-No.

Model Code

Serial-No.

Made in China

Place of Manufacture

Model

Number

Serial

Number

Model

Code

A - 88 - 126 - 67890

501829

P400622

T90L055 MA 1 AB

60 P 3 C6 C 03

MKX 35 35 24

Technical Information

Series T90 Axial Piston Pumps

General Description

Design

Series T90 pump cross-section

Typical name plate

Series T90 pumps are manufactured in China. Place of manufacture shown on nameplate will correspond

with the actual place of manufacture.

6 | © Danfoss | March 2022 BC152886484177en-000306

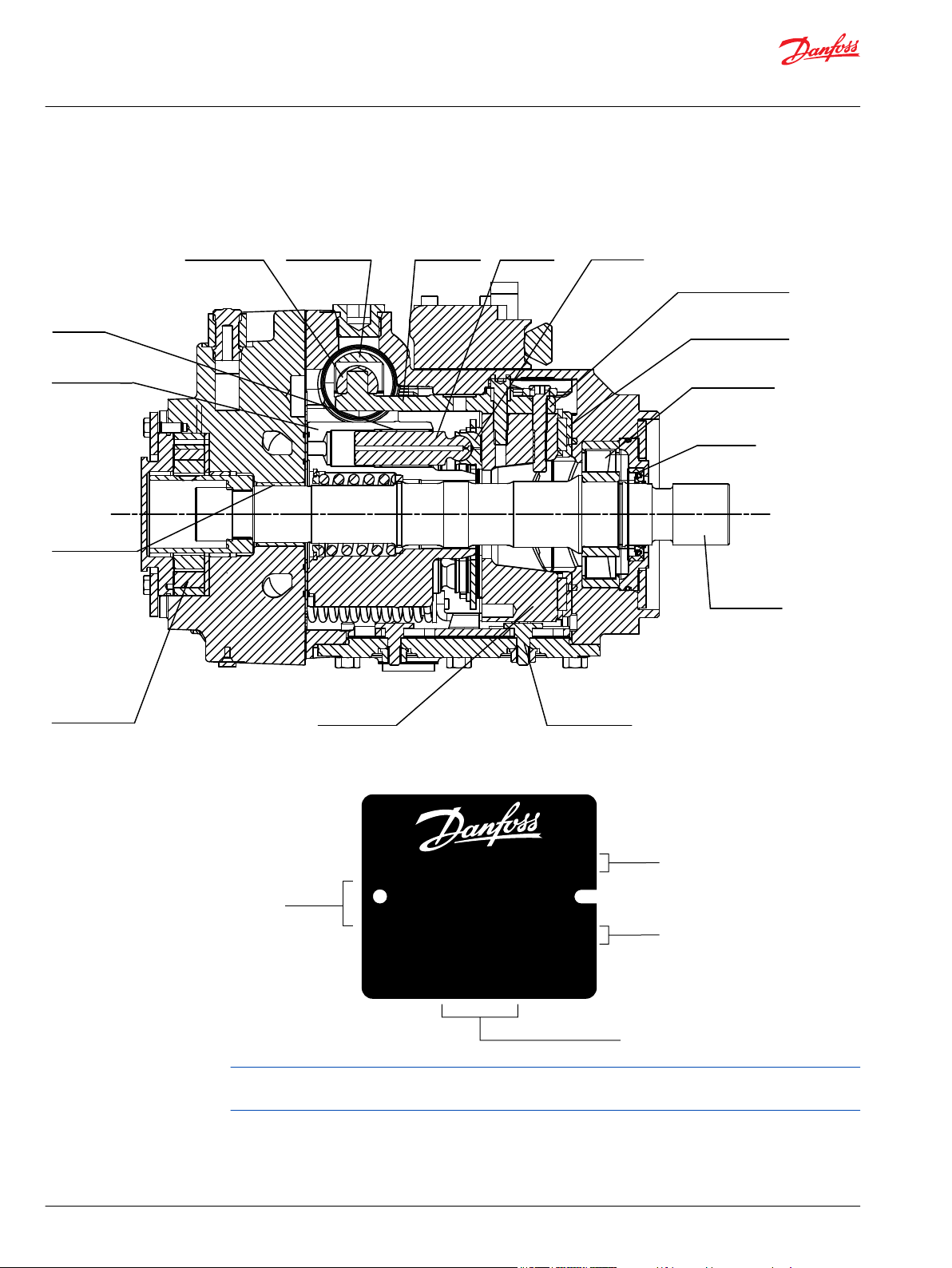

Page 7

Pump Motor

working loop (low pressure)

Control fluid

Suction line

Case drain fluid

P400053

working loop (high pressure)

Motor swashplate

Loop flushing valve

Displacement control valve

Heat exchanger bypass valve

Reservoir

Vacuum gauge

Purge relief valve

P400053

Fixed displacement motor

Output shaft

Multi-function valve

Charge pump

To

pump

case

Servo control cylinder

Pump swashplate

Input shaft

Reversible variable

displacement pump

Servo control cylinder

Heat Exchanger

Multi-function valve

Charge pressure relief valve

Orifice check

valve

Control handle

M

BB

L2

M2

M1

M4

M5

M3

A A

S

L2 M1

M2

L1

M3

P104 286E

Technical Information

Series T90 Axial Piston Pumps

General Description

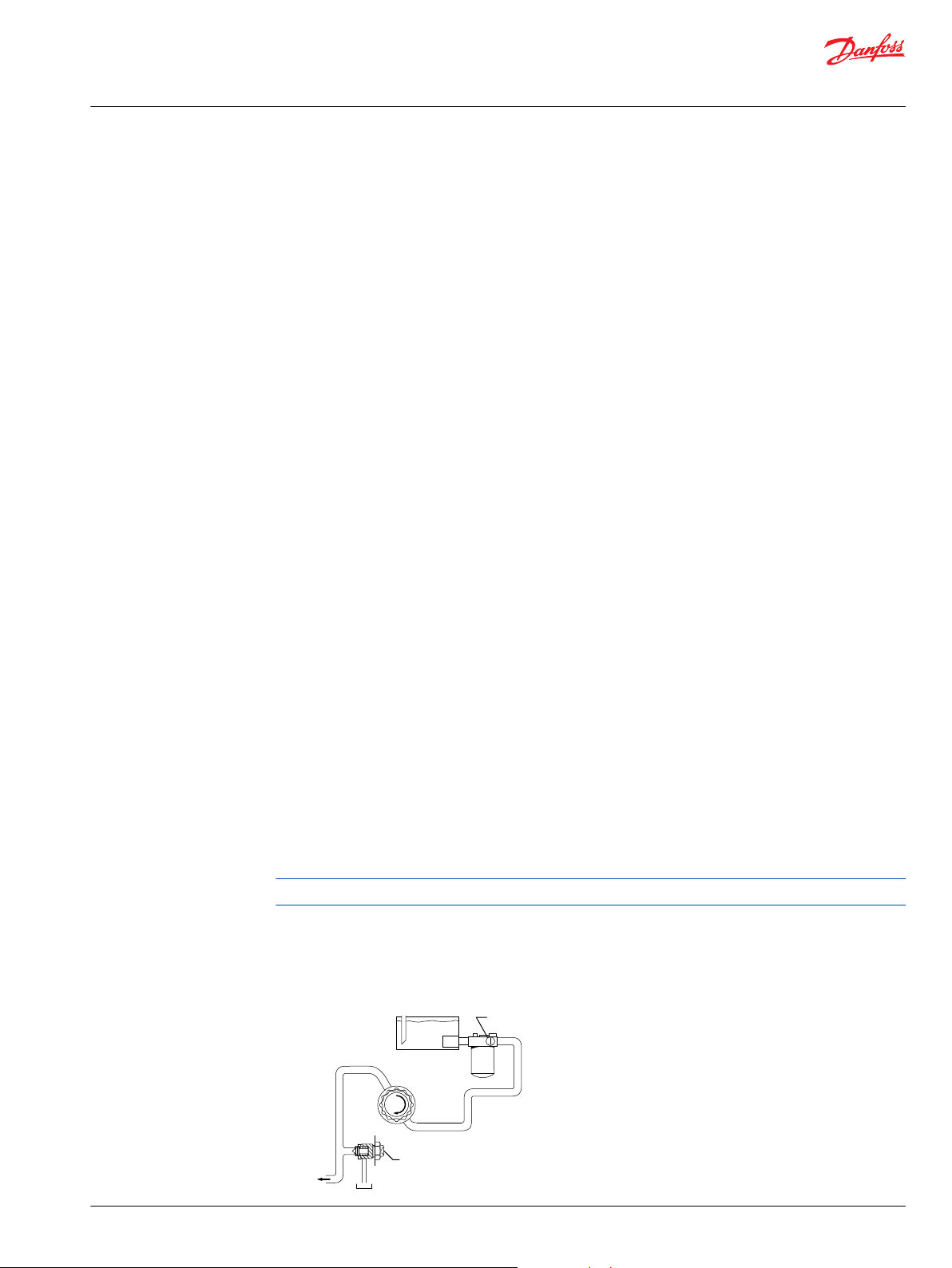

Pictorial Circuit Diagram

System Schematic (with PL function)

©

Danfoss | March 2022 BC152886484177en-000306 | 7

Page 8

Technical Information

Series T90 Axial Piston Pumps

Technical Specifications

General Specifications

Design Axial piston pump of cradle swashplate design with variable displacement

Direction of rotation Clockwise, counterclockwise

Pipe connections Main pressure ports: ISO split flange boss

Remaining ports: SAE straight thread O-ring boss

Recommended installation position Pump installation position is discretionary, however the recommended control position is on the top

or at the side, with the top position preferred.

Vertical input shaft installation is acceptable.

If input shaft is at the top 1 bar case pressure must be maintained during operation.

The pump housing must be filled with hydraulic fluid under all conditions; including after a long

period of shutdown. Before operating the machine, ensure the pump housing and case drain lines are

free of air.

Recommended mounting for a multiple pump stack is to arrange the highest power flow towards the

input source.

Consult Danfoss for nonconformance to these guidelines.

Auxiliary cavity pressure Will be inlet pressure with internal charge pump. For reference see Operating Parameters. Will be case

pressure with external charge supply.

Features and Options

Feature Unit Frame

055 075 100

Displacement cm³/rev.

[in³]/rev.

Flow at rated speed (theoretical) l/min.

[US gal/min.]

Torque at maximum displacement (theoretical) N•m/bar

[lbf•in/1000 psi]

Mass moment of inertia of rotating components kg•m²

[slug•ft²]

Weight (with control opt. MA) kg [lb] 40 [88] 49 [108] 68 [150]

Mounting (per ISO 3019-1)

Rotation Right hand or Left hand rotation

Main ports: 4-bolt split-flange

(per SAE J518 code 62)

Main port configuration Twin or side port

Case drain ports (SAE O-ring boss) UNF thread (in.) 1.0625–12 1.0625–12 1.0625–12

Other ports SAE O-ring boss

Shafts Splined

Auxiliary mounting SAE-A, B, C

mm

[in]

55

[3.35]

193

[51]

0.88

[530]

0.0065

[0.0048]

25.4

[1.0]

75

[4.59]

270

[62]

1.19

[730]

0.0100

[0.0074]

SAE C

25.4

[1.0]

100

[6.10]

300

[79]

1.59

[970]

0.0171

[0.0126]

25.4

[1.0]

8 | © Danfoss | March 2022 BC152886484177en-000306

Page 9

Technical Information

Series T90 Axial Piston Pumps

Technical Specifications

Operating Parameters

Parameter Unit Frame

055 075 100

Input speed

Minimum min-1(rpm) 500 500 500

Rated Speed 3500 3150 3000

Maximum 3700 3350 3200

System pressure

Maximum working pressure

bar[psi]

Maximum pressure 420 [6092]

Minimum low loop pressure 10 [650]

Charge pump inlet pressure

Rated

Minimum (cold start) 0.2 [24]

bar(absolute)

[in. Hg vac.]

Case pressure

Rated

bar[psi]

Maximum 5.0 [75]

350 [5076]

0.7 [9]

3.0 [40]

Fluid Specifications

Features Units 28/32/38/45

Intermittent

Viscosity

Minimum 7 [49]

Recommended range 12 - 80 [66 - 370]

Maximum (cold start)

Minimum (cold start)

Temperature range

3

Recommended range 60 - 85 [140 - 185]

Maximum continuous 104 [220]

Maximum intermittent

Cleanliness per ISO 4406 22/18/13

Efficiency (charge pressure

Filtration (recommended

minimum)

filtration)

Efficiency (suction filtration) β35-45=75(β10≥2)

Recommended inlet screen

mesh size

1

Intermittent=Short term t <1 min per incident and not exceeding 2 % of duty cycle based load-life.

2

Cold start = Short term t < 3 min, p < 50 bar [725 psi], n < 1000 min-1 (rpm)

3

At the hottest point, normally case drain port.

1

5 [42]

mm2/sec. [ SUS]

2

1600 [7500]

-40 [-40]

°C [°F]

115 [240]

β-ratio

β15-20=75(β10≥10)

µm 100 - 125

©

Danfoss | March 2022 BC152886484177en-000306 | 9

Page 10

W

Technical Information

Series T90 Axial Piston Pumps

Operating Parameters

Overview

This section defines the operating parameters and limitations for Series T90 pumps with regard to input

speeds and pressures. For actual parameters, refer to the Operating parameters for each displacement.

Input Speed

Minimum speed is the lowest input speed recommended during engine idle condition. Operating below

minimum speed limits the pump’s ability to maintain adequate flow for lubrication and power

transmission.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed should yield satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Operating conditions between Rated and Maximum speed should be restricted to less than full power

and to limited periods of time. For most drive systems, maximum unit speed occurs during downhill

braking or negative power conditions.

For more information consult Pressure and speed limits, BC152886484313, when determining speed limits

for a particular application.

Independent Braking System

System Pressure

During hydraulic braking and downhill conditions, the prime mover must be capable of providing

sufficient braking torque in order to avoid pump over speed. This is especially important to consider for

turbocharged and Tier 4 engines.

Warning

Unintended vehicle or machine movement hazard.

Exceeding maximum speed may cause a loss of hydrostatic drive line power and braking capacity.

You must provide a braking system, redundant to the hydrostatic transmission, sufficient to stop and

hold the vehicle or machine in the event of hydrostatic drive power loss. The braking system must also be

sufficient to hold the machine in place when full power is applied.

System pressure is the differential pressure between high pressure system ports. It is the dominant

operating variable affecting hydraulic unit life. High system pressure, which results from high load,

reduces expected life. Hydraulic unit life depends on the speed and normal operating, or weighted

average, pressure that can only be determined from a duty cycle analysis.

Application pressure is the high pressure relief or pressure limiter setting normally defined within the

order code of the pump. This is the applied system pressure at which the driveline generates the

maximum calculated pull or torque in the application.

Maximum Working pressure is the highest recommended application pressure. Maximum working

pressure is not intended to be a continuous pressure. Propel systems with application pressures at, or

below, this pressure should yield satisfactory unit life given proper component sizing.

Maximum pressure is the highest allowable application pressure under any circumstance. Application

pressures above maximum working pressure will only be considered with duty cycle analysis and factory

approval.

10 | © Danfoss | March 2022 BC152886484177en-000306

Page 11

C

Technical Information

Series T90 Axial Piston Pumps

Operating Parameters

Minimum low loop pressure must be maintained under all operating conditions to avoid cavitation.

Servo Pressure

Servo pressure is the pressure in the servo system needed to position and hold the pump on stroke. It

depends on system pressure and speed. At minimum servo pressure the pump will run at reduced stroke

depending on speed and pressure.

Minimum servo pressure at corner power holds the pump on full stroke at max speed and max

Maximum servo pressure is the highest pressure typically given by the charge pressure setting.

Charge Pressure

An internal charge relief valve regulates charge pressure. Charge pressure supplies the control with

pressure to operate the swashplate and to maintain a minimum pressure in the low side of the

transmission loop.

The charge pressure setting listed in the order code is the set pressure of the charge relief valve with the

pump in neutral, operating at 1800 min-1 [rpm], and with a fluid viscosity of 32 mm²/s [150 SUS].

Pumps configured with no charge pump (external charge supply) are set with a charge flow of 30 l/min

[7.93 US gal/min] and a fluid viscosity of 32 mm²/s [150 SUS].

The charge pressure setting is referenced to case pressure. Charge pressure is the differential pressure

above case pressure.

Minimum charge pressure is the lowest pressure allowed to maintain a safe working condition in the

low side of the loop. Minimum control pressure requirements are a function of speed, pressure, and

swashplate angle, and may be higher than the minimum charge pressure shown in the Operating

parameters tables.

Maximum charge pressure is the highest charge pressure allowed by the charge relief adjustment, and

which provides normal component life. Elevated charge pressure can be used as a secondary means to

reduce the swashplate response time.

At normal operating temperature charge inlet pressure must not fall below rated charge inlet pressure

(vacuum).

Minimum charge pump inlet pressure is only allowed at cold start conditions. In some applications it is

recommended to warm up the fluid (e.g. in the tank) before starting the engine and then run the engine

at limited speed.

Maximum charge pump inlet pressure may be applied continuously.

pressure.

Case Pressure

Under normal operating conditions, the rated case pressure must not be exceeded. During cold start

case pressure must be kept below maximum intermittent case pressure. Size drain plumbing accordingly.

Auxiliary Pad Mounted Pumps. The auxiliary pad cavity of S90 pumps configured without integral

charge pumps is referenced to case pressure. Units with integral charge pumps have auxiliary mounting

pad cavities referenced to charge inlet (vacuum).

Caution

Possible component damage or leakage

Operation with case pressure in excess of stated limits may damage seals, gaskets, and/or

housings,causing external leakage. Performance may also be affected since charge and system pressure

are additive to case pressure.

©

Danfoss | March 2022 BC152886484177en-000306 | 11

Page 12

C

Technical Information

Series T90 Axial Piston Pumps

Operating Parameters

External Shaft Seal Pressure

In certain applications the input shaft seal may be exposed to external pressure. In order to prevent

damage to the shaft seal the maximum differential pressure from external sources must not exceed 0.4

bar (5.8 psi) over pump case pressure. The case pressure limits of the pump must also be followed to

ensure the shaft seal is not damaged.

Regardless of the differential pressure across the shaft seal, the shaft seal has been known to pump oil

from the external source (e. g. gear box) into the pump case.

Temperature and Viscosity

Temperature

The high temperature limits apply at the hottest point in the transmission, which is normally the motor

case drain. The system should generally be run at or below the quoted rated temperature.

The maximum intermittent temperature is based on material properties and should never be

exceeded.

Cold oil will generally not affect the durability of the transmission components, but it may affect the

ability of oil to flow and transmit power; therefore temperatures should remain 16 °C [30 °F] above the

pour point of the hydraulic fluid.

The minimum temperature relates to the physical properties of component materials.

Size heat exchangers to keep the fluid within these limits. Danfoss recommends testing to verify that

these temperature limits are not exceeded.

Caution

Viscosity

For maximum efficiency and bearing life, ensure the fluid viscosity remains in the recommended range.

The minimum viscosity should be encountered only during brief occasions of maximum ambient

temperature and severe duty cycle operation.

The maximum viscosity should be encountered only at cold start.

12 | © Danfoss | March 2022 BC152886484177en-000306

Page 13

Charge pump

Filter

Hydraulic fluid reservoir

Adjustable

charge pressu re relief valve

To pump case

To low

loop and

control

Manomete r

P102 003E

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Filtration System

To prevent premature wear, ensure only clean fluid enters the hydrostatic transmission circuit. A filter

capable of controlling the fluid cleanliness to ISO 4406 class 22/18/13

(SAE J1165) or better, under normal operating conditions, is recommended.

These cleanliness levels can not be applied for hydraulic fluid residing in the component housing/case or

any other cavity after transport.

The filter may be located on the pump (integral) or in another location (remote).

The integral filter has a filter bypass sensor to signal the machine operator when the filter requires

changing. Filtration strategies include suction or pressure filtration. The selection of a filter depends on a

number of factors including the contaminant ingression rate, the generation of contaminants in the

system, the required fluid cleanliness, and the desired maintenance interval. Filters are selected to meet

the above requirements using rating parameters of efficiency and capacity.

Filter efficiency can be measured with a Beta ratio¹ (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter

with a β-ratio within the range of β

some open circuit systems, and closed circuits with cylinders being supplied from the same reservoir, a

considerably higher filter efficiency is recommended. This also applies to systems with gears or clutches

using a common reservoir.

For these systems, a charge pressure or return filtration system with a filter β-ratio in the range of β

75 (β10 ≥ 10) or better is typically required.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness Technical Information,

BC152886482150 for more information.

1

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the number

of particles greater than a given diameter (“x” in microns) upstream of the filter to the number of these

particles downstream of the filter.

= 75 (β10 ≥ 2) or better has been found to be satisfactory. For

35-45

15-20

=

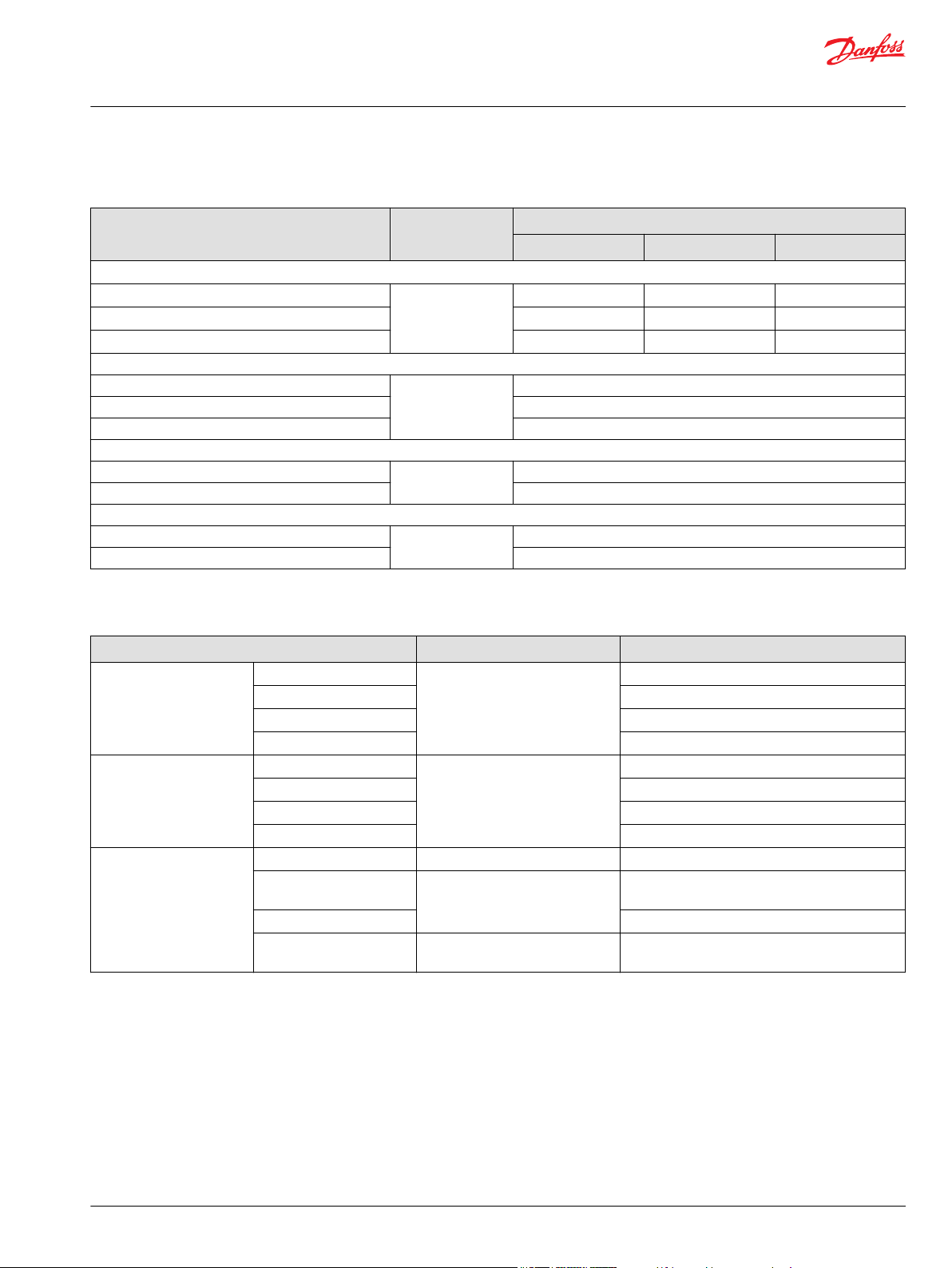

Filtration Options

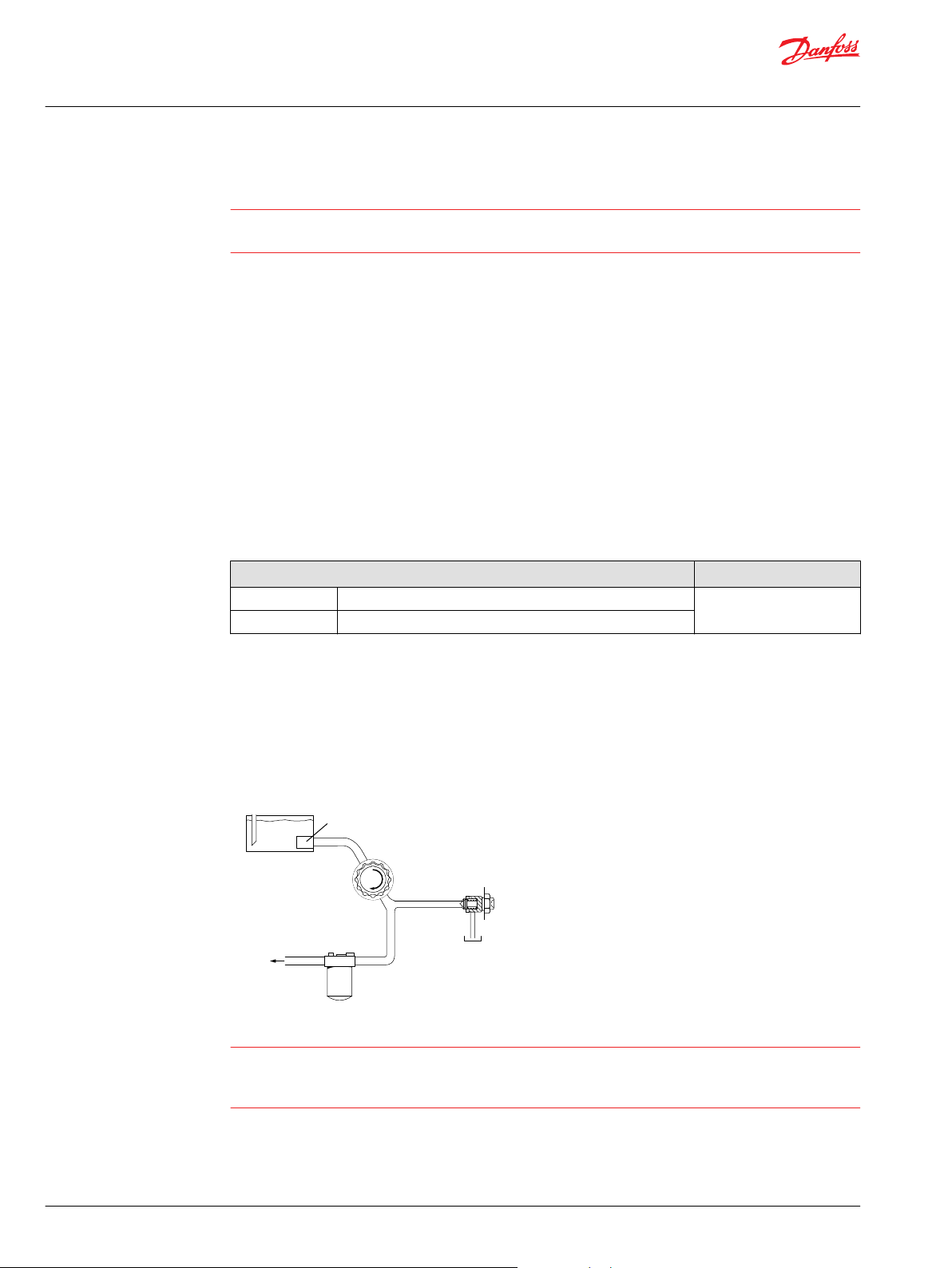

Suction filtration - Option S

Suction filtration is the only option available for concrete pumps.

The suction filter is placed in the circuit between the reservoir and the inlet to the charge pump, as

shown below.

The use of a filter contamination monitor is recommended.

Suction filtration

©

Danfoss | March 2022 BC152886484177en-000306 | 13

Page 14

C

To pump case

Charge pump

Hydraulic fluid reservoir

Filter

To low

pressure

side and

control

Screen

Adjustable

charge pressure

relief valve

P102 004E

W

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Clogged filters can cause cavitation, which damages the charge pump. We recommend a filter bypass

with a filter bypass sensor to prevent damage due to blocked suction filters.

Charge pressure filtration (partial charge pump flow)

Two types of pressure filtration exist for most Series 90 pumps. The two types are: remote pressure

filtration (filter remotely mounted on vehicle) and integral pressure filtration (filter mounted to the

endcap). Verify option availability in the size specific technical information.

In either case the filtration circuit is the same with the filter element situated in the circuit downstream

the charge pump and upstream of the charge relief valve such that full charge flow is continuously

filtered, as shown in the accompanying illustrations. Charge pressure filtration can mitigate high inlet

vacuum in cold start-ups and provides fluid filtration immediately prior to entrance to the loop and the

control system. Pressure filtration provides a higher level of filtering efficiency than suction filtration.

Filters used in charge pressure filtration circuits must be rated to at least 35 bar [508 psi] pressure. A 100 –

125 μm screen located in the reservoir or in the charge inlet line is recommended when using charge

pressure filtration.

Caution

Technical data according to ISO 16889

Nominal flow at 30mm2/s and ∆P 0.5 bar[7.3 psi] (clean filter element only) Minimum β-ratio

Short 60 l/min β7.5(C)=75 (β5(C) ≥10)

Long 105 l/min

Remote charge pressure filtration

A special adapter head is available to allow for the charge filter to be located conveniently for easy

service and replacement. Care should be taken to minimize the hydraulic pressure drops associated with

long connecting lines, small diameter hoses, or restrictive port adaptors at the filter head or endcap.

Ensure the normal operating pressure drop across the remote filtration in and out ports is sufficiently

below the crack pressure setting of the recommended filter bypass valve.

Charge pressure filtration

Warning

Remote filter heads without bypass and poor plumbing design can encounter excessive pressure drops

14 | © Danfoss | March 2022 BC152886484177en-000306

that can lead to charge pump damage in addition to contaminants being forced through the filter media

and into the transmission loop.

Page 15

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Fluid selection

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion, and corrosion of pump components.

Never mix hydraulic fluids of different types.

Reservoir

The hydrostatic system reservoir should accommodate maximum volume changes during all system

operating modes and promote de-aeration of the fluid as it passes through the tank. A suggested

minimum total reservoir volume is 5⁄8 of the maximum charge pump flow per minute with a minimum

fluid volume equal to ½ of the maximum charge pump flow per minute. This allows 30 seconds fluid

dwell for removing entrained air at the maximum return flow. This is usually adequate to allow for a

closed reservoir (no breather) in most applications.

Locate the reservoir outlet (charge pump inlet) above the bottom of the reservoir to take advantage of

gravity separation and prevent large foreign particles from entering the charge inlet line. A 100-125 μm

screen over the outlet port is recommended. Position the reservoir inlet (fluid return) to discharge below

the normal fluid level, toward the interior of the tank. A baffle (or baffles) will further promote de-aeration

and reduce surging of the fluid.

Case Drain

Pump Life

Charge Pump

All single S90 pumps are equipped with multiple drain ports. Port selection and case drain routing must

enable the pump housing to maintain a volume of oil not less than half full and normal operating case

pressure limits of the unit are maintained. Case drain routing and design must consider unit case pressure

ratings.

A case drain line must be connected to one of the case outlets to return internal leakage to the system

reservoir.

Do not over torque the fitting on case drain port L2 (located on the side cover). The proper torque is 100

N•m [74 lbf•ft] maximum. Over torquing the fitting may change the neutral position of the swashplate.

Pump life depends on several factors, such as speed, pressure, and swashplate angle. For detailed

product life calculation, please contact your Danfoss representative.

Charge flow is required on all Series 90 pumps applied in closed circuit installations. The charge pump

provides flow to make up internal leakage, maintain a positive pressure in the main circuit, provide flow

for cooling and filtration, replace any leakage losses from external valving or auxiliary systems, and to

provide flow and pressure for the control system.

Many factors influence the charge flow requirements and the resulting charge pump size selection. These

factors include system pressure, pump speed, pump swashplate angle, type of fluid, temperature, size of

heat exchanger, length and size of hydraulic lines, control response characteristics, auxiliary flow

requirements, hydrostatic motor type, etc. When initially sizing and selecting hydrostatic units for an

application, it is frequently not possible to have all the information necessary to accurately evaluate all

aspects of charge pump size selection.

Unusual application conditions may require a more detailed review of charge pump sizing. Charge

pressure must be maintained at a specified level under all operating conditions to prevent damage to the

transmission. Danfoss recommends testing under actual operating conditions to verify this.

©

Danfoss | March 2022 BC152886484177en-000306 | 15

Page 16

B

A

P108 549E

0°Re

90°

Re

270°

Re

180°Re

L

Re

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Charge pump sizing/selection

In most applications a general guideline is that the charge pump displacement should be at least 10 % of

the total displacement of all components in the system. Unusual application conditions may require a

more detailed review of charge flow requirements. Refer to Selection of Drive line Components,

BC157786484430, for a detailed procedure.

System features and conditions which may invalidate the 10 % guideline include (but are not limited to):

Continuous operation at low input speeds (< 1500 min-1 (rpm))

•

High shock loading and/or long loop lines

•

High flushing flow requirements

•

Multiple Low Speed High Torque motors

•

•

Bearing Loads and Life

In vehicle propel drives with no external shaft loads , and where the system pressure and swashplate

angle are changing direction and magnitude regularly, the normal L20 bearing life (80% survival) will

exceed the hydraulic life of the unit.

In non-propel drives, such as vibratory drives, conveyor drives and fan drives, the operating speed and

pressure are often nearly constant and the swashplate angle is predominantly at maximum. These drives

have a distinct duty cycle compared to a propulsion drive. In these types of applications, a bearing life

review is recommended.

For bearing life, speed, pressure, swashplate angle, plus external loads will be considered. Other factors

that affect bearing life include fluid type, viscosity, and cleanliness.

Applications with external shaft loads

External loads are found in applications where the pump is driven with a side/thrust load (belt drive or

gear drive) as well as in installations with misalignment and improper concentricity between the pump

and drive coupling. All external loads act to reduce bearing life.

In applications where you cannot avoid external radial shaft loads, orient the load to 0° or 180° position.

Use tapered output shafts or clamp-type couplings where radial shaft loads are present.

In addition, external thrust loads can reduce bearing life in systems with low delta pressure or in

combination with external radial loads/bending moments.

Re = Me / L

Me = Shaft moment

L = Flange distance

Re = External force

Radial load position

16 | © Danfoss | March 2022 BC152886484177en-000306

Page 17

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Maximum allowable external shaft load

Parameter 055 075 100

External moment (Me)

N•m [lbf•in]

* no tapered shaft available

If continuous applied external radial loads are 25% of the maximum allowable or more or thrust loads/

bending moments known to occur, contact your Danfoss representative for an evolution of bearing life.

Avoid external thrust loads in either direction.

Understanding and Minimizing System Noise

Noise is transmitted in fluid power systems in two ways: as fluid borne noise, and structure borne noise.

Fluid-borne noise (pressure ripple or pulsation) is created as pumping elements discharge oil into the

pump outlet. It is affected by the compressibility of the oil, and the pump's ability to transition pumping

elements from high to low pressure. Pulsations travel through the hydraulic lines at the speed of sound

(about 1400 m/s [4600 ft/sec] in oil) until there is a change (such as an elbow) in the line. Thus, amplitude

varies with overall line length and position.

Structure born noise is transmitted wherever the pump casing connects to the rest of the system. The

way system components respond to excitation depends on their size, form, material, and mounting.

System lines and pump mounting can amplify pump noise.

Follow these suggestions to help minimize noise in your application:

Use flexible hoses.

•

Limit system line length.

•

If possible, optimize system line position to minimize noise.

•

If you must use steel plumbing, clamp the lines.

•

If you add additional support, use rubber mounts.

•

Test for resonants in the operating range; if possible avoid them.

•

101

[893]

118

[1043]

126

[1114]

©

Danfoss | March 2022 BC152886484177en-000306 | 17

Page 18

Outp ut f ow Q = (l/min..)

Input torque M = (N•m)

Input power P = = (kW)

SI units Vg= Displacement per revolution

(cm3/rev)

∆p = pO- pi(system pressure)

(bar)

n = Speed (min-1(rpm))

ηv= Volumetric eff ciency

ηm= Mechanical eff ciency

ηt= Overall eff ciency (ηv• ηm)

Vg• n • η

v

1000

Vg• ∆p

20 • π • η

m

Q •∆p

600 • η

t

M • n • π

30 000

g

= Displacement per revolution

(in3/rev)

∆p = pO- pi(system pressure)

(psi)

n = Speed (min-1(rpm))

ηv= Volumetric eff ciency

ηm= Mechanical eff ciency

ηt= Overall eff ciency (ηv• ηm)

Outp ut f ow Q = (US gal/min..)

Input torque M = (lbf•in)

Input power P = = (hp)

Vg• n • η

v

231

Vg• ∆p

2 •π • η

m

Q •∆p

1714 • η

t

M • n • π

198 000

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Sizing Equations

The following equations are helpful when sizing hydraulic pumps. Generally, the sizing process is

initiated by an evaluation of the machine system to determine the required motor speed and torque to

perform the necessary work function. Refer to Selection of drive line components, BC157786484430, for a

more complete description of hydrostatic drive line sizing. First, the motor is sized to transmit the

maximum required torque. The pump is then selected as a flow source to achieve the maximum motor

speed.

18 | © Danfoss | March 2022 BC152886484177en-000306

Page 19

First stageSecond stage

Third

stage

P108 511E

L1

L2

L3

F2 F1

F3

R

= g • GR(W1L1+ W2L2+ ... + WnLn)

S

= g • GS(W1L1+ W2L2+ ... + WnLn)

R

= Rated load moment N•m

S

= Shock load moment N•m

2

R

= Calculation factor for rated (vibratory) acceleration (G’s)*

S

= Calculation factor for maximum shock acceleration (G’s)*

MR= GR(W1L1+ W2L2+ ... + WnLn)

MS= GS(W1L1+ W2L2+ ... + WnLn)

Based on US units

W = We ight of pump [lb]

L = Distan ce from mounting f ange [in]

to pump center of gravity

Where:

MR= Rated load moment N•m

MS= Shock load moment N•m

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Mounting Flange Loads

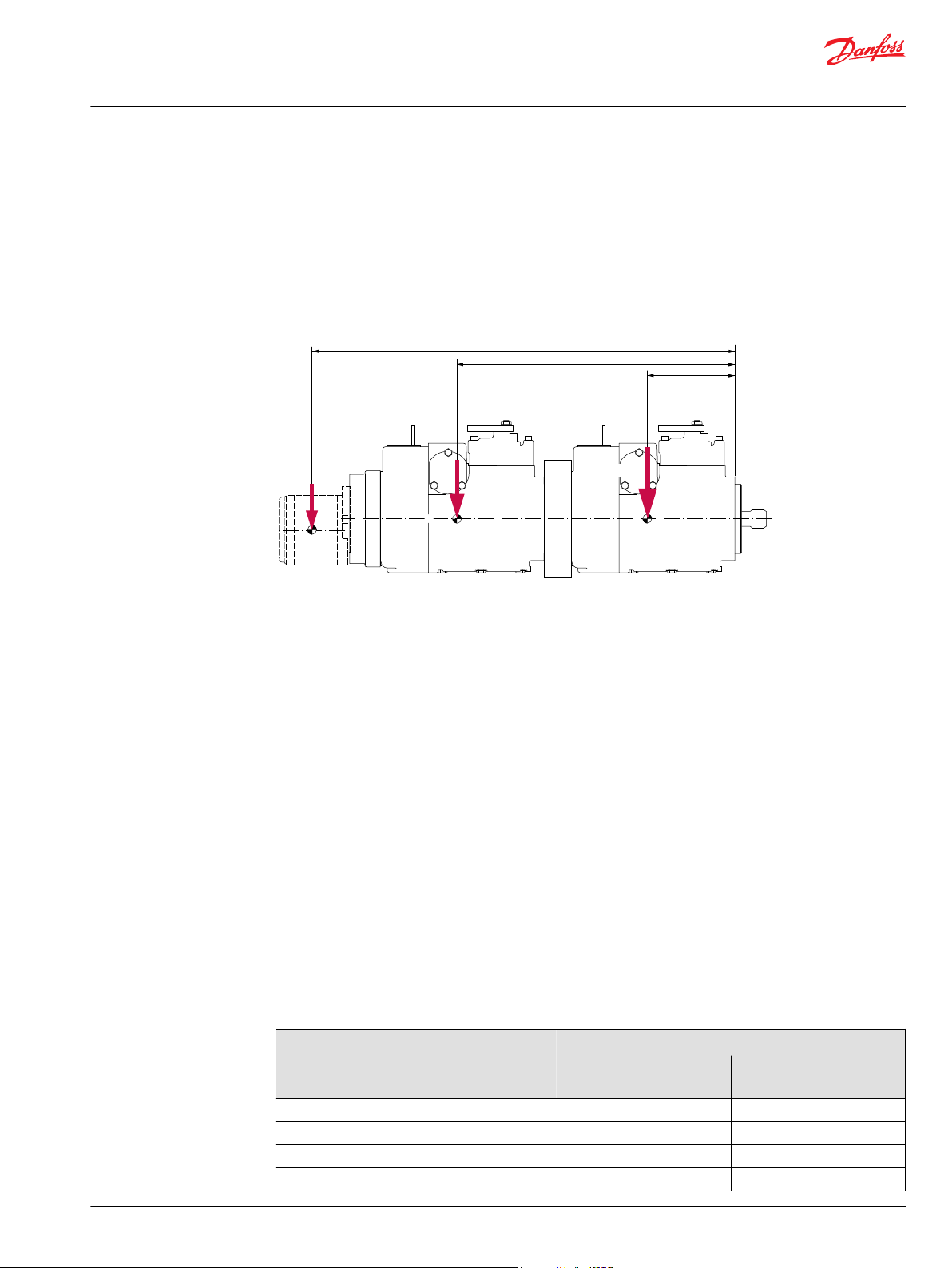

Adding tandem mounted auxiliary pumps and/or subjecting pumps to high shock loads may result in

excessive loading of the mounting flange.

Applications which experience extreme resonant vibrations or shock may require additional pump

support. The overhung load moment for multiple pump mounting may be estimated using the formula

below.

Overhung load example

Estimated maximum and rated acceleration factors for some typical applications are shown in the table

below.

Use these values for a rough load estimation in the absence of specific data.

Typical G loads for various applications

Application Calculation factor

©

Danfoss | March 2022 BC152886484177en-000306 | 19

Skid Steer Loader 8 15-20

Trencher (rubber tires) 3 8

Asphalt Paver 2 6

Windrower 2 5

Rated (vibratory)

acceleration G

R

Maximum (shock)

acceleration G

S

Page 20

Technical Information

Series T90 Axial Piston Pumps

System Design Parameters

Typical G loads for various applications (continued)

Application Calculation factor

Aerial Lift 1.5 4

Turf Care Vehicle 1.5 4

Vibratory Roller 6 10

T000 165E

Allowable overhung load moment values are shown in the following table.

Allowable overhung load moments

Frame size Rated moment (MR) Shock load moment (MS)

055 1580 14 000 5650 50 000

075 1580 14 000 5650 50 000

100 1580 14 000 5650 50 000

Rated (vibratory)

acceleration G

N•m lbf•in N•m lbf•in

R

Maximum (shock)

acceleration G

S

20 | © Danfoss | March 2022 BC152886484177en-000306

Page 21

WP N F HJ G L

T90

SizeR M T Y Z K

Technical Information

Series T90 Axial Piston Pumps

Master Model Code

Model Code (R-Size-M-P-J)

R - Type and Rotation

Code Description 055 075 100

R

L Left Hand [CCW]

Size

Code Description 055 075 100

055 55 cc [3.36 in3] max. displacement per revolution

075 75 cc [4.58 in3] max. displacement per revolution

075 100 cc [6.10 in3] max. displacement per revolution

Right Hand [CW]

M - Controls

Code Description 055 075 100

DD 3 positon F-N-R solenoid control ( 24 V , DC ), DIN connector

MA

MS MDC With Neutral Start Switch

LU MDC With Offset Handle, Dust Seal Feature

LW MDC For Rough/Open Enviroments

LY

L1

A4

A5

MDC

2 Positon Solenoid Valve (24 V,DC), Brake Pressure Port,

Dust Seal Feature

2 Positon Solenoid Valve (24V,DC), Brake Pressure Port,

Offset Handle,

Dust Seal Feature

12V, HCEDC,Dual 2-Pin Deutsch Connector,

(710-1640mA), IP69 rated coils

24V, HCEDC,Dual 2-Pin Deutsch Connector,

(352-820mA), IP69 rated coils

P - High Pressure Regulation

Code Description 055 075 100

D High pressure relief only, For Mixer Truck

1

Pressure limiter for port A and B (140-450 bar)

J - Auxiliary Mounting Pad

Code Description 055 075 100

NN No auxiliary mounting pad

AB SAE-A with sealed cover, 9 teeth coupling

©

Danfoss | March 2022 BC152886484177en-000306 | 21

Page 22

Technical Information

Series T90 Axial Piston Pumps

Master Model Code

J - Auxiliary Mounting Pad (continued)

Code Description 055 075 100

BC SAE-B with sealed cover, 13 teeth coupling

CD

SAE-C with sealed cover, 4 bolt adapter, 14 teeth coupling,

(2) ½-13 UNC

22 | © Danfoss | March 2022 BC152886484177en-000306

Page 23

WP N F HJ G L

T90

SizeR M T Y Z K

Technical Information

Series T90 Axial Piston Pumps

Master Model Code

Model Code (G-N-F-L-H)

G - Endcap Ports

Code Description 055 075 100

60 Side Ports

80 Twin Ports

8A

N - Filtration

Code Description 055 075 100

F Suction (For Use With Internal Charge Pump)

P

R Rremote Pressure Filtration

S Suction (For Use With Internal Charge Pump)

Twin Ports With Metric Threads At The HD Ports, For Mixer

Truck

Pressure Integral (Short Filter)

F - Displacement Limitation

Code Description 055 075 100

3 no limiters

4 limitation both sides

L - Shaft Options

Code Description 055 075 100

C6 splined shaft, 21 teeth, pitch = 16 / 32

C7 splined shaft, 23 teeth, pitch = 16 / 32

D7 splined shaft, 23 teeth, pitch = 16 / 32, with thread M10

D9 splined shaft, 21 teeth, pitch = 16 / 32, with thread M10

DC

DD

S1 splined shaft, 14 teeth, pitch = 12/24

splined shaft, 23 teeth, pitch = 16 / 32, with thread

M10,With Flange, For Mixer Truck

splined shaft, 21 teeth, pitch = 16 / 32, with thread

M10,With Flange,For Mixer Truck

H - Charging System

Code Description 055 075 100

C 14 cc / rev

D 17 cc / rev

E 20 cc / rev

F 26 cc / rev

©

Danfoss | March 2022 BC152886484177en-000306 | 23

Page 24

WP N F HJ G L

T90

SizeR M T Y Z K

Technical Information

Series T90 Axial Piston Pumps

Master Model Code

Model Code (T-W-Y/Z-K)

T - Control Orifice Options

Code Description 055 075 100

FNR inlet P drain TA drain TB servo A servo B

G8 0.66 1.20 1.20 n/o n/o

GB 0.81 1.20 1.20 n/o n/o

MDC inlet P drain TA drain TB servo A servo B 055 075 100

00 n/o n/o n/o n/o n/o

03 0.81 n/o n/o n/o n/o

C5 0.81 1.40 1.40 n/o n/o

HCEDC inlet P drain TA drain TB servo A servo B 055 075 100

F4 0.81 n/o n/o 2.50 2.50

F5 1.57 n/o n/o 2.50 2.50

F6 2.34 n/o n/o 2.50 2.50

W - Special Hardware Features

Code Description 055 075 100

FBK

FBL

MIL

MIX CP15+0,5° valve plate, For Mixer Truck

MJX CP15+0,5° valve plate, Not For Transit Mixer Application

MKX CP15+0,5° valve plate, nested t- bar springs

CP15+0,5° valve plate, nested t- bar springs,

Only For HCEDC Control

CP15+0,5° valve plate,

Only For HCEDC Control

CP15+0,5° valve plate, For Mixer Truck,

Only For HCEDC Control

Y/Z - High Pressure Setting

Code Description 055 075 100

26 260 bar

29 290 bar

32 320 bar

35 350 bar

K - Charge Pressure Setting

Code Description 055 075 100

20 20 bar

24 24 bar

24 | © Danfoss | March 2022 BC152886484177en-000306

Page 25

W

1 2

Not connected

Voltage between terminals 1 and 2

DANFOSS

mating parts kit

Part No. K09129

Solenoid plug face for DIN 43650 connector

"0"

Voltage VDC

Displacement

100 %

b

100 %

-b

P102 023

M5

a

b

M4

T

P

P102021

Technical Information

Series T90 Axial Piston Pumps

Control Options

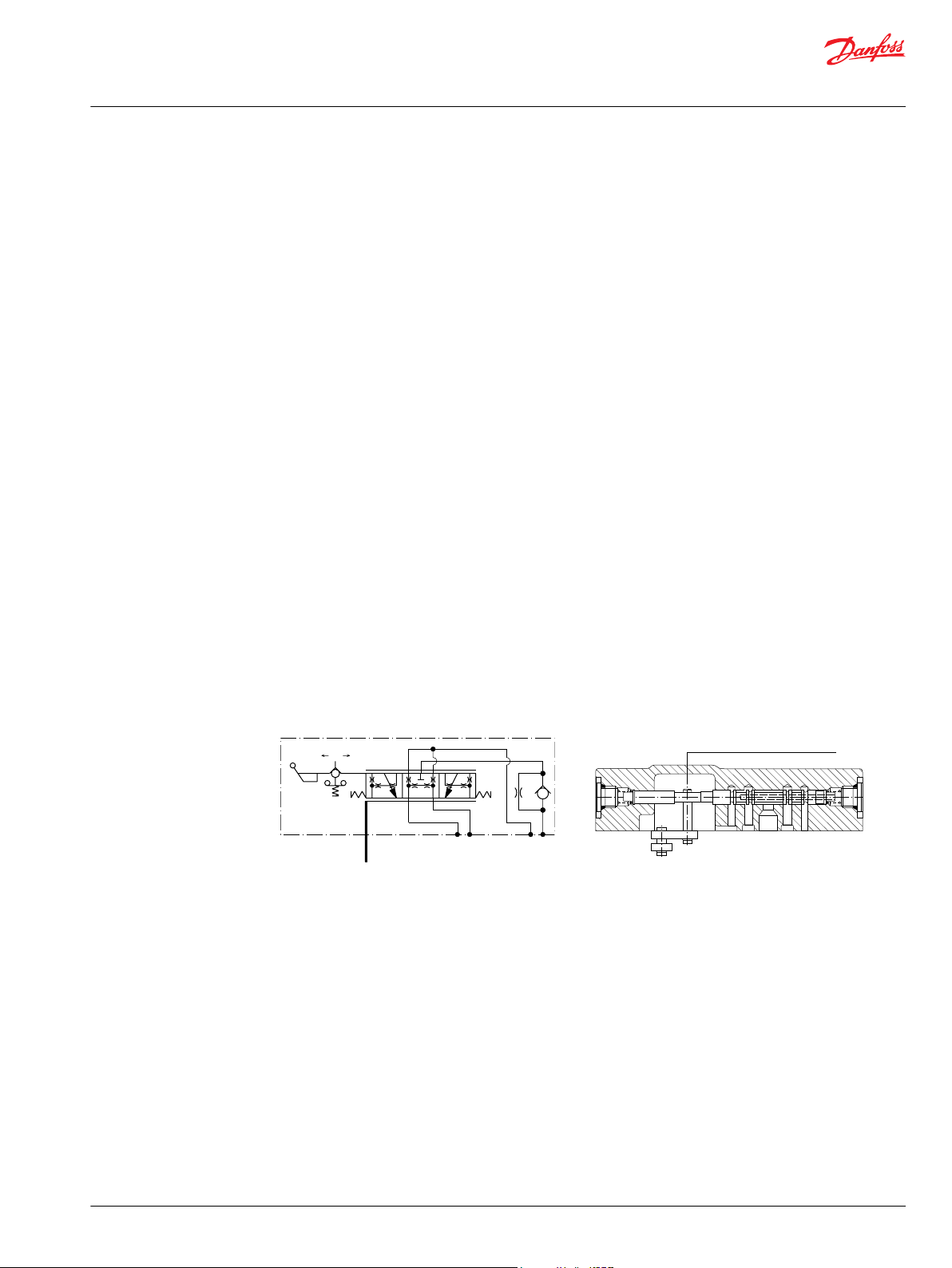

3-Position Electric Control(FNR), Options: DD

The 3-Position (FNR) control uses an electric input signal to switch the pump to a full stroke position. To

use the FNR control in a PLUS+1 Guide application, download HWD file 10106826 from

www.Danfoss.com/PLUS+1.

Warning

Avoid designing a system which places the swashplate into full stroke when control operation is blocked

by contamination.

Solenoid connector

Pump displacement vs. electrical signal

3-position electric control hydraulic schematic

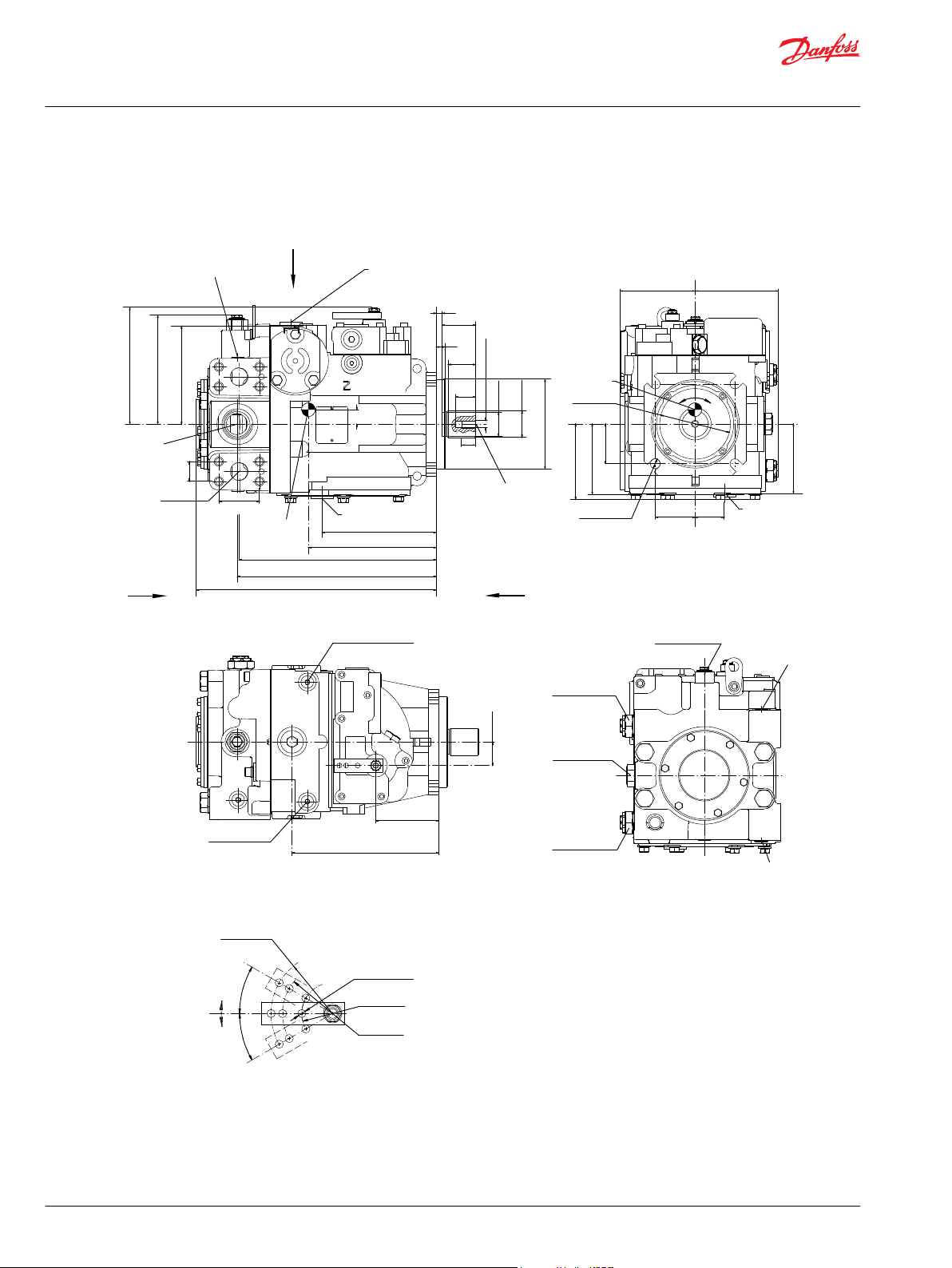

©

Danfoss | March 2022 BC152886484177en-000306 | 25

Page 26

A

P108 495E

B

W

Technical Information

Series T90 Axial Piston Pumps

Control Options

Solenoid Data

Code Voltage Current Connector

DC 12 Vdc 340 mA DIN 46350

DD 24 Vdc 170 mA DIN 46350

Response time

The time required for the pump to change from zero to full flow (acceleration), or full flow to zero

(deceleration), is a function of the size of the orifice, the charge pressure, valve plates and other vehicle

dynamics.

A range of orifice sizes are available for the Series 90 FNR Control to assist in matching the rate of

swashplate response to the acceleration and deceleration requirements of the application. Testing

should be carried out to determine the proper orifice selection for the desired response. For more

information regarding response time for individual orifices, please contact your Danfoss representative.

Pump output flow direction vs. control signal

Input shaft rotation CW CCW

Signal at solenoid A B A B

Port A flow (M1) Out In In Out

Port B flow (M2) In Out Out In

Servo cylinder (side) M5 (2) M4 (1) M5 (2) M4 (1)

Warning

Avoid designing a system which puts the swashplate into full stroke when control operation is blocked

by contamination.

26 | © Danfoss | March 2022 BC152886484177en-000306

Page 27

M4

M5

T P

Feedback

from

swashplate

A – 0 – B

Switch

Neutral

Start

P102 035E

T

M5 P

M4

T

Control handle input signal

P102 033E

Technical Information

Series T90 Axial Piston Pumps

Control Options

Manual Displacement Control (MDC), Options: MA, MS, LU, LW

The manual displacement control converts a mechanical input signal to a hydraulic signal that tilts the

cradle swashplate through an angular rotation varying the pump's displacement from full displacement

in one direction to full displacement in the opposite direction.

The manual displacement control has a mechanical feedback mechanism which moves a servo valve in

the proper relationship to the input signal and the angular position of the swashplate. The control is

designed so that the angular rotation of the swashplate is proportional to the mechanical input signal.

The control is designed with an internal override mechanism which allows the mechanical input to be

moved at a faster rate than the movement of the swashplate without damage to the control.

Features and Benefits

Precision parts provide repeatable, accurate displacement settings with a given input signal.

•

The manual displacement control is a high gain control: With only small movement of the control

•

handle (input signal), the servo valve moves to full open position porting maximum flow to the servo

cylinder. This is a high response system with low input force.

The integral override mechanism allows rapid changes in input signal without damaging the control

•

mechanism.

Precision parts provide repeatable, accurate displacement settings with a given input signal.

•

The double-acting servo piston is coupled to a spring centering mechanism. The servo control valve is

•

spring centered such that with no input signal the servo valve is open centered and thus no fluid is

ported to the servo cylinder.

Benefits:

- Pump returns to neutral after prime mover shuts down.

•

- Pump returns to neutral if external control linkage fails at the control handle or if there is a loss of

•

charge pressure.

Manual displacement control schematic

External Control Handle Requirements

Torque required to move handle to maximum displacement is 0.68 to 0.9 N•m [6 to 8 lbf•in].

•

Torque required to hold handle at given displacement is 0.34 to 0.57 N•m [3 to 5 lbf•in].

•

Torque required to overcome the override mechanism is 1.1 to 2.3 N•m [10 to 20 lbf•in] with the

•

maximum torque required for full forward to full reverse movement.

Maximum allowable input torque is 17 N•m [150 lbf•in].

•

Pump displacement vs. control lever rotation

Cross-section

©

Danfoss | March 2022 BC152886484177en-000306 | 27

Page 28

0

Lever rotation

A

Displacement

100 %

a

-a

100 %

B

-b

b

P102 034E

-35 max.

35 max.

Neutral Start Switch

Eccentric Plug

Switch Pin

Special Lock Nut

for Eccentric Plug

Switch Lock Nut

Control Shaft

Switch Cam

P108 499E

Technical Information

Series T90 Axial Piston Pumps

Control Options

Control lever rotation range

a 0,5° - 4.5°

b 24° - 30°

Pump output flow direction vs. Control handle rotation

Input shaft rotation CW CCW

Handle rotation A B A B

Port A flow (M1) Out In In Out

Port B flow (M2) In Out Out In

Servo cylinder (side) M5 (2) M4 (1) M5 (2) M4 (1)

Refer toInstallation Drawings on page 40 for handle connection requirements

MDC with Neutral Start Switch (NSS)

The neutral start switch (NSS) stops the prime mover from starting unless the pump is in neutral. When

the control is not in neutral position, the switch is disengaged, and the prime mover will not start. When

the control is in neutral position, the switch is engaged, allowing the prime mover to start.

MDC with neutral start switch

28 | © Danfoss | March 2022 BC152886484177en-000306

Page 29

Feedback from

Swash plate

PTF00B

M14

1C2C

F00A

P003 478E

"0"

-b -a

ba

100 %

100 %

Displacement

Current mA

Technical Information

Series T90 Axial Piston Pumps

Control Options

High Current Electric Displacement Control (HCEDC); Options A4, A5

The Electrical Displacement Control (EDC) consists of a pair of proportional solenoids on each side of a

three-position, four-way porting spool. The proportional solenoid applies a force input to the spool,which

ports hydraulic pressure to either side of a double acting servo piston.

Differential pressure across the servo piston rotates the swash-plate, changing the pump‘s displacement

from full displacement in one direction to full displacement in the opposite direction. A serviceable

125μm screen is located in the supply line immediately before the control porting spool.

Under some circumstances, such as contamination, the control spool could stick and cause the pump to

stay at some displacement.

EDC schematic, feedback from swash-plate

EDC Control Signal Requirements

Pump displacement vs. control current

EDC control current

Voltage a

12 V 710 mA 1640 mA any order

24 V 352 mA 820 mA

*

Factory test current, for vehicle movement or application actuation expect higher or lower value.

*

b Pin connections

©

Danfoss | March 2022 BC152886484177en-000306 | 29

Page 30

1 2

P003 480

Technical Information

Series T90 Axial Piston Pumps

Control Options

Connectors

Description Quantity Ordering Number

Mating Connector 1 DEUTSCH DT06-2S

Wedge Lock 1 DEUTSCH W25

Socket Contact (16 and 18 AWG) 2 DEUTSCH 0462-201-16141

Danfoss mating connector kit 1 K29657

EDC solenoid data

Description 12 V 24 V

Maximum current 1800 mA 920 mA

Nominal coil resistance @ 20 °C [68 °F] 3.66 Ω 14.20 Ω

Inductance 33 mH 140 mH

PWM signal frequency Range 70 – 200 Hz

IP Rating IEC 60 529 IP 67

Connector color Black

*

PWM signal required for optimum control performance.

@ 80 °C [176 °F] 4.52 Ω 17.52 Ω

Recommended

*

100 Hz

DIN 40 050, part 9 IP 69K with mating connector

Pump output flow direction vs. control signal

Shaft rotation CW CCW

Coil energized

Port A out in in out

Port B in out out in

Servo port pressurized M4 M5 M4 M5

*

For coil location see Installation drawings.

30 | © Danfoss | March 2022 BC152886484177en-000306

*

C1 C2 C1 C2

Page 31

M

B

L2

M2

M1

M4

M5

M3

A

S

Charge

pressure

relief valve

Multifunction valve

Multifunction valve

To control

Servo piston

Servo piston

Port A

Port B

C

Bypass hex

adjustment

P102 007E

Servo pressure

relief valves

A

B

Technical Information

Series T90 Axial Piston Pumps

Features and Options

Multi-Function Valves

Overpressure protection

The Series 90 pumps are designed with a sequenced pressure limiting system and high pressure relief

valves. When the preset pressure is reached, the pressure limiter system acts to rapidly de-stroke the

pump to limit the system pressure. For unusually rapid load application, the high pressure relief valve is

also available to limit the pressure level. The pressure limiter sensing valve acts as the pilot for the relief

valve spool, such that the relief valve is sequenced to operate above the pressure limiter level.

Both the pressure limiter sensing valves and relief valves are built into the multi-function valves located

in the pump endcap. The sequenced pressure limiter/high pressure relief valve system in the Series 90

provides an advanced design of overpressure protection.

The pressure limiter avoids system overheating associated with relief valves and the sequenced relief

valves are available to limit pressure spikes which exist in severe operating conditions.

Pressure limiting function

When set pressure is exceeded, the pressure sensing valve (A) flows oil through passage (B) and across an

orifice in the control spool raising pressure on the servo which was at low pressure. Servo pressure relief

valves (C) limit servo pressure to appropriate levels. The pressure limiter action cancels the input

command of the displacement control and tends to equalize servo pressure. Swashplate moments assist

to change the displacement as required to maintain system pressure at the set point. The HPRV is always

set 30 bar above the pressure limiter setting.

HPRVs are factory set at a low flow condition. Any application or operating condition which leads to

elevated HPRV flow will cause a pressure rise with flow above a valve setting. Consult factory for

application review. Excessive operation of the HPRV will generate heat in the closed loop and may cause

damage to the internal components of the pump.

Multifunction valve, pressure limiter, pressure regulation, option 1

©

Danfoss | March 2022 BC152886484177en-000306 | 31

Page 32

W

W

Technical Information

Series T90 Axial Piston Pumps

Features and Options

Bypass Function

In some applications it is desirable to bypass fluid around the variable displacement pump when pump

shaft rotation is either not possible or not desired. For example, an inoperable vehicle may be moved to a

service or repair location or winched onto a trailer without operating the prime mover. To provide for

this, Series 90 pumps are designed with a bypass function.

The bypass is operated by mechanically rotating the bypass hex on both multifunction valves three (3)

turns counterclockwise (CCW). This connects working loop A and B and allows fluid to circulate without

rotating the pump and prime mover.

Excessive speeds and extended load/vehicle movement must be avoided while moving in bypass

function. The load or vehicle should be moved not more than 20 % of maximum speed and for a duration

not exceeding 3 minutes. Damage to drive motor(s) is possible. When the bypass function is no longer

needed care should be taken to re-seat the HPRV hex plugs to the normal operating position.

Possible pump and/or motor damage.

Bypass valves are intended for moving a machine or vehicle for very short distances at very slow speeds.

They are NOT intended as tow valves.

Warning

Warning

Auxiliary Mounting Pads

Auxiliary mounting pad specifications

Mounting pad Option code Spline coupling Frame size/Maximum torque N•m [lbf•ft]

055 075 100

SAE A AB 9T 16/32 93 [69] 97 [72] 97 [72]

SAE B BC 13T 16/32 204 [150] 211 [156] 211 [156]

SAE B-B BB 15T 16/32 342 [252] 281 [207] 281 [207]

SAE C CD 14T 12/24 408 [301] 447 [330] 447 [330]

Mating pump requirements

The accompanying drawing provides the dimensions for the auxiliary pump mounting flange and shaft.

Pump mounting flanges and shafts with the dimensions noted below are compatible with the auxiliary

mounting pads on the Series 90 pumps. An O-ring is required when a pump is bolted to an aux pad. Refer

to outline drawings for more details and O-ring dimensions.

The auxiliary flange cover seal is only used for product transportation. If there is no tandem pumps

requirement, it is recommended to use pump without auxiliary flange option. If you need to use pump

with auxiliary flange but not rear pump for a long time, Please contact Danfoss technical personnel.

32 | © Danfoss | March 2022 BC152886484177en-000306

Page 33

Ø P

0

-0.05

[+0.000]

[-0.002]

F

min.

Minimum spline

engagement

D

B

max.

E

Mounting flange

(Ref)

Coupling

0.8 [0.03] R

preferred

P102 015E

W

Technical Information

Series T90 Axial Piston Pumps

Features and Options

Auxiliary pump mounting flange and shaft

Auxiliary pump dimensions

Flange size Units P diameter B maximum D F minimum

SAE A mm [in] 82.55

SAE B 101.6

SAE B-B 101.6

SAE C 127.0

[3.25]

[4.00]

[4.00]

[5.00]

7.4

[0.29]

10.7

[0.42]

10.7

[0.42]

14.3

[0.56]

32

[1.26]

41

[1.61]

46

[1.81]

56

[2.20]

13.5

[0.53]

14.2

[0.56]

16.1

[0.63]

18.3

[0.72]

Displacement Limiter

All Series 90 pumps are designed with optional mechanical displacement (stroke) limiters.

The maximum displacement of the pump can be set independently for forward and reverse using the

two adjustment screws.

Warning

Adjusting the displacement limiter with the machine running may result in leakage. If backed out too far,

the adjustment screw will come completely out of its threaded bore.

Displacement limiter location

Pump rotation Displacement limiter mounted on

servo side

Right [CW] 1 A

©

Danfoss | March 2022 BC152886484177en-000306 | 33

Left [CCW] 1 B

2 B

2 A

Displacement limitation at high

pressure side

Page 34

P108 705E

Side 2

Technical Information

Series T90 Axial Piston Pumps

Features and Options

Displacement limiter

Shaft Torque

Frame size Lock nut wrench size and torque Adjusting screw

wrench size

internal hex

055 13 mm 24 N•m [18 lbf•ft] 4 mm 4.2 cm³/rev [0.26 in³/rev]

075 13 mm 24 N•m [18 lbf•ft] 4 mm 5.1 cm³/rev [0.31 in³/rev]

100 13 mm 24 N•m [18 lbf•ft] 4 mm 6.2 cm³/rev [0.38 in³/rev]

Approximate displacement change

per revolution of adjusting screw

Shaft torque and spline lubrication

The rated torque is a measure of tooth wear and is the torque level at which a normal spline life of 2x109

shaft revolutions can be expected. The rated torque presumes a regularly maintained minimum level of

lubrication via a moly-disulfide grease in order to reduce the coefficient of friction and to restrict the

presence of oxygen at the spline interface. It is also assumed that the mating spline has a minimum

hardness of Rc 55 and full spline depth. The rated torque is proportional to the minimum active spline

length.

Maximum torque ratings are based on torsional fatigue strength considering 100.000 full load reversing

cycles. However, a spline running in oil-flooded environment provides superior oxygen restriction in

addition to contaminant flushing. The rated torque of a flooded spline can increase to that of the

maximum published rating. A flooded spline would be indicative of a pump driven by a pump drive or

plugged into an auxiliary pad of a pump.

Maintaining a spline engagement at least equal to the Pitch Diameter will also maximize spline life. Spline

engagements of less than ¾ Pitch Diameter are subject to high contact stress and spline fretting.

Shaft torque for tapered shafts

The rated torque is based on the contact pressure between the shaft and hub surfaces with poor surface

contact areas. With an increased quality of the contact areas, the contact pressure between the shaft and

hub is increased and allows higher torque to be transmitted.

When a key is used for orientation of the hub on the shaft in conjunction with poor quality contact

surfaces, the transmitted torque will drop significantly. This is due to the key carrying the torque, which

limits the shaft torque carrying capability.

Maximum torque rating is based on an ideal contact area of 100 % and the retaining nut properly

torqued. This allows for the highest contact pressure between the shaft and the hub.

34 | © Danfoss | March 2022 BC152886484177en-000306

Page 35

First stageSecond stageThird

stage

for the first pumpM

e

1

second pump

for the M

e

2

next pumpfor the M

e

3

Input torqueM

e

P102 014E

W

Technical Information

Series T90 Axial Piston Pumps

Features and Options

Shaft Availability and Torque Ratings

Alignment between the mating spline's pitch diameters is another critical feature in determining the

operating life of a splined drive connection. Plug-in, or rigid spline drive installations can impose severe

radial loads on the shafts. The radial load is a function of the transmitted torque and shaft eccentricity.

Increased spline clearance will not totally alleviate this condition; but, increased spline clearance will

prevent mechanical interference due to misalignment or radial eccentricity between the pitch diameters

of the mating splines. Spline life can be maximized if an intermediate coupling is introduced between the

bearing supported splined shafts.

For multiple pump installations, consider load of the entire pump stack. All torques are additive. Include

charge pumps loads when calculating torques.

Through torque diagram

Refer to the outline drawings for shaft dimensions.

Torque required by auxiliary pumps is additive. Ensure requirements don't exceed shaft torque ratings.

Shaft availability and maximum input torque - splined shafts

Option code Customer end Frame size/Maximum torque N•m [lbf•ft]

055 075 100

C6 21T 16/32 1287 [949] 1214 [895] 1214 [895]

C7 23T 16/32 n/a 1625 [1218] 1822 [1344]

S1 14T 12/24 832 [613] 853 [629] 974 [718]

Tapered Shaft Customer Acknowledgement

Warning

The customer is responsible for proper analysis, design, and quality of the mating female coupling, key,

and applied torque on the nut. Torque must be transmitted by the taper fit between the shaft and

mating coupling, not the key. Failure to properly analyze the nut torque required to create a robust joint

could result in transmitting torque through the key which may lead to premature shaft failure.

The specified torque rating of the tapered shaft is based on the cross-sectional diameter of the shaft

through the keyway and assumes proper clamp and fit between shaft and coupling. Danfoss guarantees

the design and manufactured quality of the tapered shaft.

Danfoss has made provisions for the key in accordance to the ISO specification with the understanding

that the key is solely to assist in the installation of the mating coupling.

©

Danfoss | March 2022 BC152886484177en-000306 | 35

Page 36

Technical Information

Series T90 Axial Piston Pumps

Features and Options

Charge Pump

Charge flow is required on all Series 90 pumps applied in closed circuit installations. The charge pump

provides flow to make up internal leakage, maintain a positive pressure in the main circuit, provide flow

for cooling and filtration, replace any leakage losses from external valving or auxiliary systems, and to

provide flow and pressure for the control system.

Many factors influence the charge flow requirements. These factors include system pressure, pump

speed, pump swashplate angle, type of fluid, temperature, size of heat exchanger, length and size of

hydraulic lines, control response characteristics, auxiliary flow requirements, hydrostatic motor type, etc.

Unusual application conditions may require a more detailed review of charge pump sizing. Charge

pressure must be maintained at a specified level under all operating conditions to prevent damage to the

transmission. Danfoss recommends testing under actual operating conditions to verify this.

Charge pump sizing/selection

In most applications a general guideline is that the charge pump displacement should be at least 10% of