Page 1

Instructions

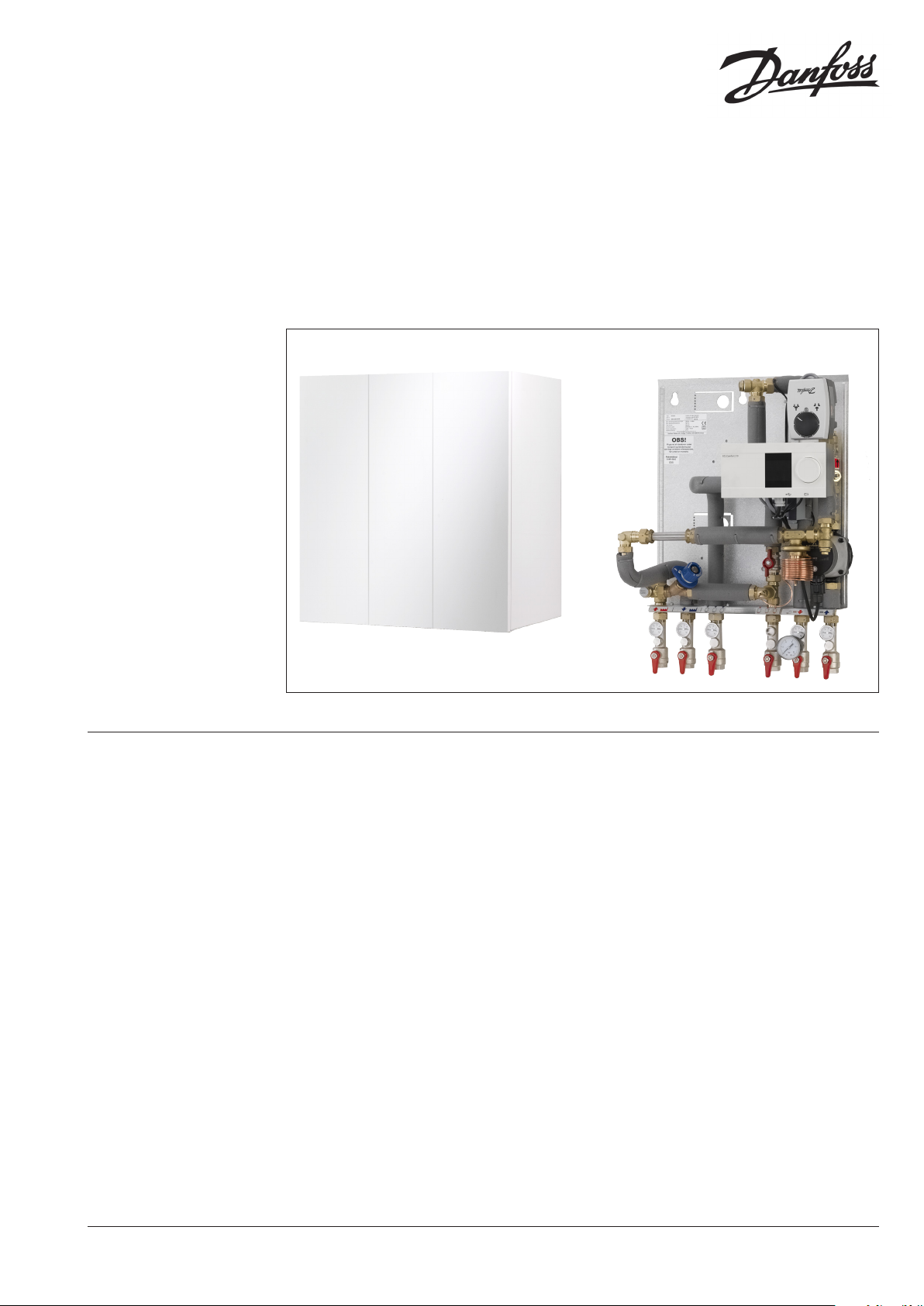

S-Solo HWP

District heating substation for direct heating and

connection pipes for domestic hot water cylinder

Table of contents Safety notes / Mounting & Start-up .................................2

Types / Main components / Dimensioned sketch ......4

Description ...............................................................................5

Heating circuit .........................................................................5

Domestic hot water ...............................................................7

Troubleshooting HE ...............................................................8

Maintenance ............................................................................10

EU Declaration of conformity.............................................11

Page 2

Instructions S-Solo HWP

Safety notes

The following instructions refer to the standard

design of the S-Solo HWP substation. Special

versions are available on request.

To avoid injury of persons and damages to the

device, it is absolutely necessary to read and

observe these instructions carefully.

Necessary assembly, start-up and maintenance

work must be performed by qualified and

authorized personnel only.

Please comply with the instructions of the system

manufacturer or system operator.

Unused connections and shut-o valves must be

sealed with a plug. The plugs must be removed by

an authorized service technician only.

Choice of materials

Choice of materials always in compliance with

local legislation

Warning of high pressure and temperature

The maximum temperature of the ow medium

in the S-Solo HWP substations is 90 °C.

The maximum operating pressure of the substation

is 10 bar.

Be aware of the installation’s permissible system

pressure and temperature.

The substation installation must be equipped with

safety valves, however, always in accordance with

local regulations.

Warning of hot surface

The substation has got hot surfaces, which can

cause skin burns. Please be extremely cautious in

close proximity to the substation.

Warning of electric shock risk

Before cleaning or servicing disconnect power

supplies.

Warning of transport damage

Before substation installation, please make sure

that the substation has not been damaged during

transport.

Sound level

≤ 55 dB

Corrosion protection

All pipes and components are made of stainless

steel and brass.

The maximum chloride compounds of the ow

medium should not be higher than 300 mg/l.

The risk of equipment corrosion increases considerably if the recommended permissible chloride

compounds are exceeded

Disposal

Storage

The risk of persons being injured and equipment

damaged increases considerably if the

recommended permissible operating parameters

are exceeded.

This product consists of materials which must not

be disposed of together with domestic waste.

Dismantle the product and sort the components

in various groups before disposal. Observe the

disposal rules of the local legislation.

If the substation is stored before installation, make

sure that the place is dry and heated.

2

Produced by Danfoss Redan A/S · 03.2012

Page 3

Instructions S-Solo HWP

Mounting

The substation must be installed and connected by

authorized service personnel only.

Installation must be in compliance with the local

standards and regulations.

Allow for adequate space around the substation for

mounting and maintenance purposes.

Prior to the substation installation all substation

pipes and connections should be cleaned and

rinsed.

The substation should be wall-mounted. The

mounting sheet on the back of the substation has

got holes for screw installation.

A symbol for each of the dierent connections is

placed on the substation.

Tightening of connections

Due to vibrations during transport all connections

must be checked and tightened before the

substation is installed.

After observing that the substations operates

in accordance with the dimensioning basis, the

connections must be tightened again and the

substation can be taken into continuous use.

Heat meter assembly, tting piece

The at station is equipped with a tting piece for

insertion of a heat meter.

Assembly of heat meter

Loosen nuts from tting piece, remove tting

piece and replace with heat meter.

Mount the heat meter according to the medium

ow direction.

After mounting of heat meter remember to

check all threaded connections

DCW meter (option)

The substation can be equipped with a tting

piece for insertion of DCW meter.

Assembly of DCW meter

Please refer to above assembly instructions for

heat meter.

Electrical connection Electrical connections must be made by an au-

thorised electrician only.

Electrical connections must be made in accordance with current regulations and local standards.

Start-up

Prior to the S-Solo HWP installation all its pipes and

connections should be cleaned and rinsed. After

that the strainers should be cleaned.

Before starting-up, check if:

- pipes are connected according to the circuit

diagram,

- release valves are shut o,

- threaded and anged connections are

tightened.

Before making electrical connections, please note

the following:

- Please read the relevant parts of safety notes.

- The substation must be connected to 230 VAC

and earth.

- The substation must be connected via an exter nal main switch, which can be disconnected

by repairs.

All Danfoss substations have been pressure tested

prior to delivery.

Produced by Danfoss Redan A/S · 03.2013

3

Page 4

Instructions S-Solo HWP

Components

1 Danfoss controller

2 Actuator HE

3 2-way valve *

4 Dierential pressure controller

5 Danfoss sensor *

6 Manometer

7 Balancing valve

8 Air valve *

9 Circulation pump

10 Thermometer, DH supply

11 Thermometer, DH return

12 Thermometer, cylinder return

13 Thermometer, HE supply

14 Thermometer, HE return

15 Sensor pocket for heat meter *

16 Fitting piece for heat meter

17 Strainer

18 Throttle valve

* not visible on photo

Please note:

Your substation may look dierent

than the substation shown, as variants with other components may

be supplied. The control function,

however, is basically as stated in this

instruction manual.

17

15

10

16

11

7

12

17

1

5

4

13

6

3

2

8

18

9

14

Instructions for the tted components will be supplied together

with the substation.

District heating (DH) - In the following

DH is specied as the heat source

for the substations. However, also

other heat sources such as an oil or

gas boiler or solar heating etc. could

be used as the primary supply for

the tted substations, enabling the

Danfoss Redan substations to be used

in numerous schemes with dierent

energy sources, depending on the

local operating conditions. In order

to simplify we have decided to use

DH as designation for the primary

supply.

Cylinder

DH

Supply

1 DH supply 5 HE supply

2 DH return 6 HE return

3 Cylinder return

4 Cylinder supply

DH

Return

Primäry Secundary

Return

Cylinder connection

Top view

Cylinder

Supply

HE

Supply

wall

HE

Return

4

Produced by Danfoss Redan A/S · 03.2012

Page 5

7369267-9 SIBC R&D

EI.97.Q2.00 © Danfoss 12/01 1

INSTRUCTIONS

VS2 2-way

065R9075

065R9075

DN L (mm)

15 65

20 70

25 75

DN L

1

(mm)

15 131

20 142

25 159

DN L

2

(mm)

15 139

20 154

25 159

DN L

3

(mm)

15 69

20 74

25 79

Instructions

AMV 150

73691180 DH-SMT/SI

VI.KU.N2.1J

© Danfoss 01/2008

1

ENGLISH

Actuators for three point control AMV 150 www.danfoss.com Page 2

DANSK

Motorer til 3-punkts styring AMV 150 www.danfoss.dk Side 3

DEUTSCH

Stellantriebe für 3-Pkt.- Eingangssignal AMV 150 www.danfoss.de Seite 3

SVENSKA

Motor för 3-punktsreglering AMV 150 varme.danfoss.se Sida 4

NEDERLANDS

Servomotor met 3-puntssturing AMV 150 www.danfoss.nl Pagina 4

LIETUVIŲ K.

Pavaros trijų padėčių valdymui AMV 150 www.danfoss.lt 5 puslapis

LATVISKI

Motori trīs punktu kontrolei AMV 150 www.danfoss.com Lpp. 5

MAGYAR

Szelepmozgatók hárompontos szabályozáshoz AMV 150 www.danfoss.com 6. oldal

ČESKY

Servopohony s tříbodovým regulačním signálem AMV 150 www.danfoss.cz Strana 6

POLSKI

Siłowniki sterowane sygnałem 3-punktowym AMV 150 www.danfoss.pl Strona 7

РУССКИЙ

Электроприводы для трехпозиционного регулирования AMV 150

www.danfoss.ru Страница 7

AMV 150 + AMV 150 + AMV 150 +

VS2 (DN 15) VMV AVQM (DN 15)

Instructions S-Solo HWP

General PLEASE NOTE, that other variants may be supplied.

The control function, however, is basically as described below, and the control of the substation

should be done in accordance with the enclosed producer instructions for the mounted controller.

Description

Heating circuit

Temperature control

District heating substation for direct heating with

mixing loop for single-family, semi-detached and

terraced houses as well as ats. With one heating

circuit and with connection pipes for cylinder on

primary side. Designed for wall-mounting.

The heating temperature is controlled by an electronic temperature controller Danfoss ECL with

an outdoor temperature sensor.

The substation is supplied with mixing ciruit and

is thereby especially suitable for systems with

oor heating. The task of the mixing circuit is to

ensure a correct supply temperature for the heating circuit (to protect the heating circuit against

too high temperatures) and to ensure, that the

return water is cooled down to the required

temperature, before it ows back to the district

heating plant. The mixing circuit temperature is

controlled by an electronic temperature controller Danfoss ECL.

The temperature for the heating circuit is controlled

electronically by the Danfoss ECL controller. The supply

temperature ist calculated by the controller on basis of

the outdoor temperature.

The ECL Comfort 210 controller is loaded with a selected

application by means of an ECL Application Key (Plug&-Play). The Application Key contains information about

application, languages and factory settings.

From factory the VX Solo II H2WP is loaded with Application 1d. Other applications can, however, be loaded by

means of the ECL Application Key, and it is possible to

update the controller with new application software.

The controller is factory preset to turn o the heating

automatically in the summer period.

The controller settings can be changed in accordance with the enclosed producer instructions for the

mounted controller.

See ECL Application Key Box with ECL Comfort

210/310 user guide and mounting guide, for further

information.

Please see enclosed user guide,

2-way valve + electrical actuator.

The S-Solo HWP is supplied with a 2-way valve VS

2, which in combination with an electrical actuator Danfoss AMV 150 controls the heating circuit.

The electrical actuator is preset from factory. In

case of operating disturbances the actuator can

be closed manually.

Please see enclosed instructions,

Electrical actuator AMV 150

2-way valve VS 2

Close actuator by turning the manual override

knob on top of actuator counterclockwise.

Produced by Danfoss Redan A/S · 03.2013

Manual override

Note: Press and hold the button on the bottom side of

the actuator during manual override.

5

Page 6

Instructions S-Solo HWP

Balancing valve For regulation of the ow through the system the

S-Solo HWP can be supplied with a balancing valve.

For information about pre-regulation etc. please

refer to the enclosed instructions for use:

Kombi-3-Plus

Instruction for use

Dierential pressure controller

AVPL

AVPL is a self-acting dierential pressure controller

for PN 16 with adjustable dierential pressure setting.

Der AVPL keeps a constant dierential pressure even

with a variable system resistance.

The AVPL can be set at any dierential pressure between 0,05 bar and 0,25 bar. The preset factory setting

of the controller is 0,1 bar.

To alter the dierential pressure, use an Allen Key NV 3.

1 full turn is equivalent to approx. 0.01 bar. The arrow

on the controller top shows that the setting of the differential pressure is increased when it is turned clockwise and reduced when turned counter-clockwise.

The controller settings can be changed in accordance

with the enclosed producer instructions.

Circulation pump Grundfos Pumpe ALPHA2 L

Substation start-up /pump

Do not start up the pump untill the system has

been lled with the ow media and vented. See

Grundfos instructions for the pump.

The pump is self-venting. It need not be vented

before start-up.

Air in the pump may cause noise, This noise ceases

after a few minu-tes running.

Please note, that the system cannot be vented

through the pump

Please note, that the pump must not run dry.

Pumpeneinstellung

GRUNDFOS ALPHA2 L has seven optional settings

which can be

selected with the push-button.

Enclosed photo shows the recommended and alternative pump settings for system types.

The pump is set at the factory to the “Higest proportional-pressure curve” (PP2). In this control

mode, the pump performance and consequently

the power consumption are adjusted according to

the heat demand in the system.

If the recommended pump setting does not give

the desired distribution of heat in the rooms of the

house, change the pump setting to the shown alternative.

For further infomation about pump settings please

Recommended and alternative pump settings according to system type.

refer to the enclosed Grundfos instructions.

ALPHA2 L,

Installation and operating instructions

6

Produced by Danfoss Redan A/S · 03.2012

Page 7

Instructions S-Solo HWP

GRUNDFOS ANLEITUNG

GRUNDFOS ALPHA2 L

Montage- und Betriebsanleitung

ALPHA2 L

GRUNDFOSINSTRUCTIONS

www.grundfos.com/ALPHA2L

Summer operation

Stationen with Danfoss T°C Thermostat

In the summer, you can stop the pump by switching it o at the mains. However, remember to start

the pump (briey) at least once a month during the

summer.

Systems with Danfoss ECL:

Outside the heating period, the pump will be disconnected automatically from the heating system.

During the summer period, the controller will start

the pump for a minute at least once very three days

to prevent the pump from blocking.

Start-up after summer operation - venting

Please note that it may be necessary to vent the

system again. To vent the system, use the air vent,

if any, in the substation, or the radiators or, if appropriate, the air valve at the highest point of the

system.

Push-button for selection of pump setting

Domestic hot water

The S-Solo HWP is supplied with connection

pipes for cylinder on the primary side.

Produced by Danfoss Redan A/S · 03.2013

7

Page 8

Instructions S-Solo HWP

Troubleshooting

Heating

If operating disturbances occur, the following

basic features should be checked before carrying

out actual troubleshooting:

- the substation is connected to electricity

- the strainer on the district heating supply is

- the dierential pressure is higher than or equal

to the normal (local) dierential pressure in the

district heating network. - if in doubt, ask the

district heating plant,

- there is pressure on the system.

clean,

- the district heating ow temperature is at the

normal level (summer, at least 60 °C, winter at

least 70 °C),

Problem Possible cause Solution

Strainer clogges on DH or HE

side (radiator circuit)

Filter in district heating meter

clogged

Defective dierential pressure

controller

Defective actuator

2-vay valve defective - or possibly dirt in the valve housing

Clean strainer.

Clean the lter (after consulting the district heating plant).

Check the functioning of the

dierential pressure controller

- clean valve seat if required.

Check the functioning of the

actuator.

Check the functioning of valve

- clean valve seat if required.

No heat

Uneven heat distribution Air pockets in the system Vent the installation thorough-

Supply temperature too high

Automatic controls wrongly set

or defective - possibly power

failure

Pump out of operation

The pump is set at too low

speed of rotation

Air pockets in the system

Wrong setting of automatic

controls

Defective controller. The

controller does not react as it

should in accordance with the

instructions

Check if the setting of the controller is correct - see separate

instructions. Check the power

supply.

Check if the pump is receiving

power and that it runs. Check

if there is air trapped in the

pump housing - see pump

manual.

Set the pump at higher speed

of rotation.

Vent the installation thoroughly.

ly

Adjust automatic controls,

see instructions for automatic

controls.

Call in automatic controls

manufacturer or replace

controller.

8

Produced by Danfoss Redan A/S · 03.2012

Page 9

Instructions S-Solo HWP

Troubleshooting

Heating

Problem Possible cause Solution

Adjust automatic controls - see

instructions for automatic

controls

Call in automatic controls

manufacturer or replace

controller.

Place / t outdoor temperature

sensor correctly.

Clean strainer.

Increase total heating surface

Make sure that the heat is

distributed evenly across the

full heating surface - open all

radiators and keep the radiator

in the system from heating up

at the bottom.

Supply temperature too low

Poor cooling

Wrong setting of automatic

controls

Defective controller. The

controller does not react as it

should in accordance with the

instructions

Wrong placement / tting of

outdoor temperature sensor

Strainer clogges.

Too small heating surface/ too

small radiators compared to the

total heating requirement of

the building.

Poor utilization of existing heating surface.

The system is single-pipe

It is extremely important to

keep the supply temperature

to the radiators as low as ever

possible, while maintaining a

reasonable level of comfort.

Produced by Danfoss Redan A/S · 03.2013

9

Page 10

Instructions S-Solo HWP

Maintenance

Meter reading

Cooling

Cleaning

Tightening

The substation requires little monitoring, apart

from routine checks and cleaning of strainers. To

ensure the best operating conditions regular inspection of the substation and a check of all relevant operating parameters are recommended,

for example in connection with meter reading.

Meter reading

We recommend that you read your meter regularly and that you write down the meter read.

Cooling / Return temperature reading

The cooling, i.e. the temperature dierence between district heating supply and district heating

return is of great importance for the total heat

economy. It is therefore very important to observe the supply and return temperatures.

Cleaning

All strainers should be checked and cleaned at

least once every year, typically in connection with

start-up of the heating system.

Tightening of connections

All threaded and anged connections should be

checked and tightened in connection with meter

reading. All threaded and anged connections

should be tightened regularly and especially in

connection with start-up after the summer period.

Venting

Strainer

Venting of system

Always vent the radiators and the substation before the heating season.

Strainer

Strainers should frequently be cleaned from

sediments by authorized personnel, according

to producer’s instructions and dependent on the

substation’s operating conditions.

10

Produced by Danfoss Redan A/S · 03.2012

Page 11

Danfoss Redan A/S

District Energy

Omega 7, Søften

DK-8382 Hinnerup

Telephone +45 87 43 89 43

EC-DECLARATION OF CONFORMITY

For CE marking in EU (European Union)

Danfoss Redan A/S District Energy

DK-8382 Hinnerup

Declares under our sole responsibility that below products including all available power and control options:

S-Solo HWP

Main components: See Instruction Manual

Covered by this declaration is in conformity with the following directive(s), standard(s) or other normative document(s), provided that the products are used in accordance with our instructions.

EU Directives:

EMC Directive 2004/108/EEC

EN 61000-6-1 2007

industry.

EN 61000-6-2 2005 Electromagnetic compatibility- Generic standard: Immunity industry.

EN 61000-6-3 2007 Electromagnetic compatibility- Generic standard: Emission for residential, commercial and light

industry.

EN 61000-6-4 2007 Electromagnetic compatibility- Generic standard: Emission industry.

Machinery Directive 2006/42/EEC

EN ISO 14121-

EN 60204-1-Safety of machinery - Electrical equipment of machines — Part 1: General requirements

PED Directive 97/23/EEC

Conformity assessment procedure followed: Module A - Internal control of production

All substations that falls under Article 3 §3 and category 1 shall not be CE-marked according to this directive

CE marked affixed year 2010

Approved by:

Place and date of issue: Hinnerup, Aug. 24th, 2010

Name: Thavarupan Perinpam

Title: Quality and Lean Manager

Electromagnetic compatibility- Generic standard: Immunity for residential, commercial and light

1 Safety of machinery -- Risk assessment

Produced by Danfoss Redan A/S · 03.2013

11

Page 12

Instruktion S-Solo HWP

Danfoss Redan A/S

Omega 7, Søften

DK-8382 Hinnerup

Telefon: +45 87438943

Telefax: +45 87438944

redan@danfoss.com

www.redan.danfoss.dk

VI.GE.E2.02 · Produced by Danfoss Redan A/S · 03.2013

Loading...

Loading...