Page 1

Fact Sheet

VLT® AQUA Drive SmartStart

improve efficiency with minimal effort

Perfect

tool for:

- Reduce start-up

complexity

- Easier/faster drive

commissioning

- Improved process

efficiency

Reduce Start-up complexity using the

SmartStart feature found in Danfoss

VLT® AQUA Drives.

As water and wastewater applications

continue to grow in size and complexity,

system commissioning can become a

time consuming and difficult task. Using

the new SmartStart wizard found in

Danfoss VLT® AQUA Drives helps make

it easier and faster to commission your

drive.

The SmartStart feature is found in

software versions 2.04 or newer and

is activated upon initial power-up or

following a factory reset. SmartStart can

also be initiated directly via the Quick

Menu. Settings are selected on the drive’s

28 language graphical control panel.

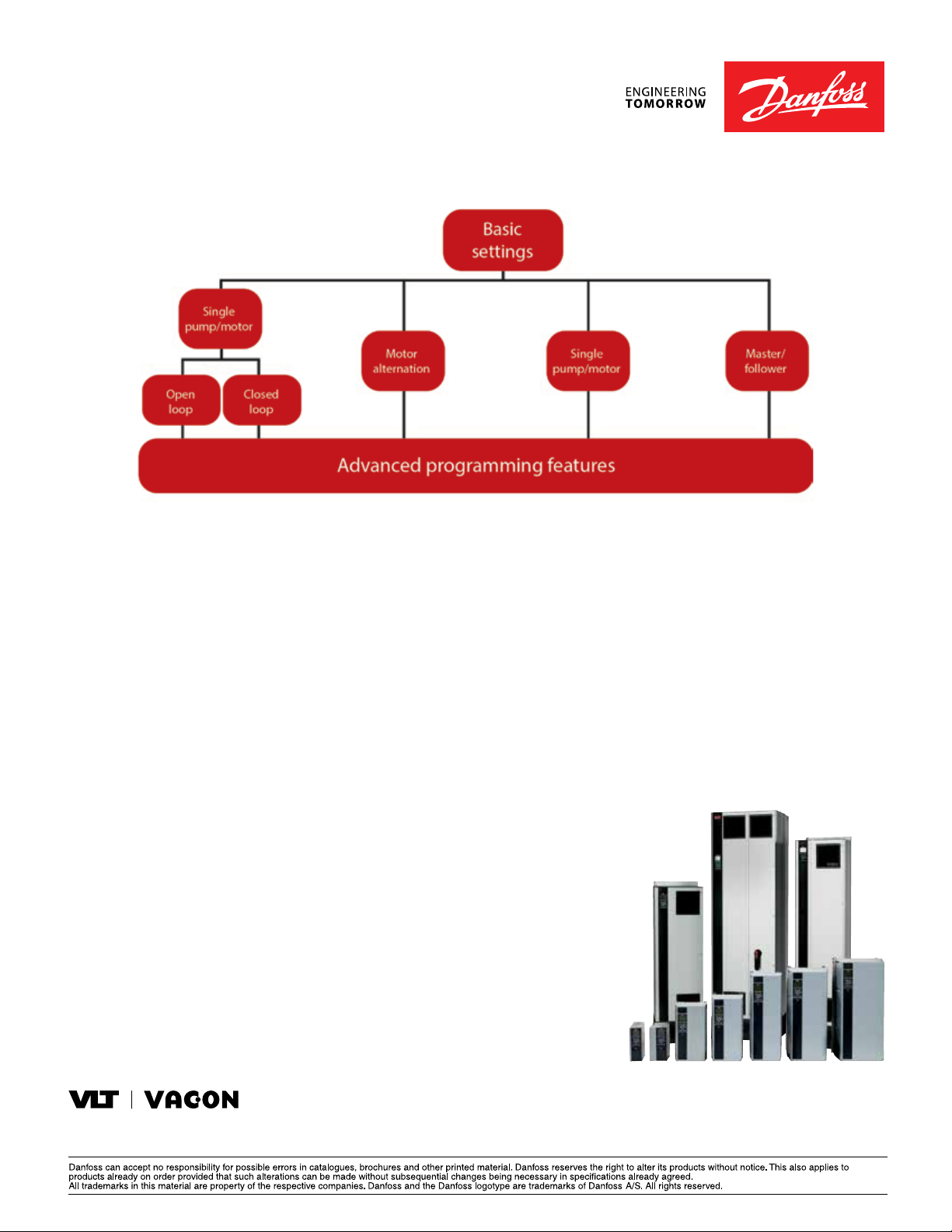

10 Simple Steps to

Optimized Commissioning

The set-up wizard guides users through

a series of 10 simple steps to ensure

accurate and efficient motor control.

Single pump/motor: Select operation

in either an open or closed loop

configuration.

Motor alternation: Used when two

pumps/motors are required to share

one drive.

Feature Benet

Quick set-up – Save time and money

Basic cascade control: Provides

speed control of a single pump/motor

in a multi-pump system. This is an

attractive solution when using booster

sets.

Master-follower: Ability to control

up to eight pumps/motors to ensure

optimal operation of the overall pump

control system.

Flow compensation: The drive will

adapt the pump/motor operation in

relation to a user-selected flow set

point.

Deragging: This proactive feature

helps avoid damage to the pump by

reversing the direction of the flow

in user-selected flow cycles, thereby

helping to remove clogs from the

pump impellers.

Pipe Fill: Ensures that the pipes are

filled gradually to avoid water hammer.

Dry run/end of curve detection: Will

protect the pump from damage by

ensuring that the set point is reached.

If not, the drive will assume that the

pipe is dry or there is excessive leakage

and alert the operator.

Sleep mode: Continuously monitors

the system and shuts down the pump

when there is no demand, helping to

reduce energy consumption.

Special ramps: Used when specific

application parameters require a

dedicated start or stop ramp time.

Step-by-step guideance through settings – Easier/faster drive commissioning

Asks questions relevant to water, wastewater, and

irrigation applications

– Improved process eciency

www.danfossdrives.com

Page 2

Enhanced energy optimization

To help achieve optimum energy

efficiency, SmartStart allows the user to

select the Automatic Motor Adaptation

(AMA) feature within the drive. This

feature streamlines installation by

automatically tuning the drive to the

motor without spinning it or requiring

the load to be decoupled.

The VLT® AQUA Drive is a dedicated drive

for water and wastewater applications.

Available in a power range from 1/3

– 1500 HP in all common voltage

ranges, including 690 V, the drive can

control all relevant motor technologies,

including permanent magnet motors.

For additional flexibility the drive can

be expanded with a wide range of

performance enhancing features that

improve operation and energy efficiency.

Enclosure ratings

Available in Chassis, NEMA 1, NEMA

12, NEMA 3R, and NEMA 4X rated

enclosures designed either for

mounting in existing panels or as

standalone units

Available options

Modular application options:

plug-and-play cards facilitate drive

upgrades, startup and servicing

Advanced Harmonic Filters: reduce

harmonic distortion in sensitive

applications

dV/dt filters: additional protection for

motor insulation.

Sine filters (LC filters): reduce motor

noise

PC software tools

MCT 10: provides powerful

functionality for commissioning and

servicing drives

VLT® Energy Box: comprehensive

energy analysis tool

MCT 31: harmonics calculation tool

Tel. +1 (888) DANFOSS | www.danfossdrives.com | E-mail: salesinformation@danfoss.com

Danfoss Drives: Houston, TX • Loves Park, IL • Milwaukee, WI • Raleigh, NC • Stoney Creek, ON

USDD.PFF.200.A2.22 VLT® is a trademark of Danfoss A/S © Copyright Danfoss Drives | 2019.11

Loading...

Loading...