Page 1

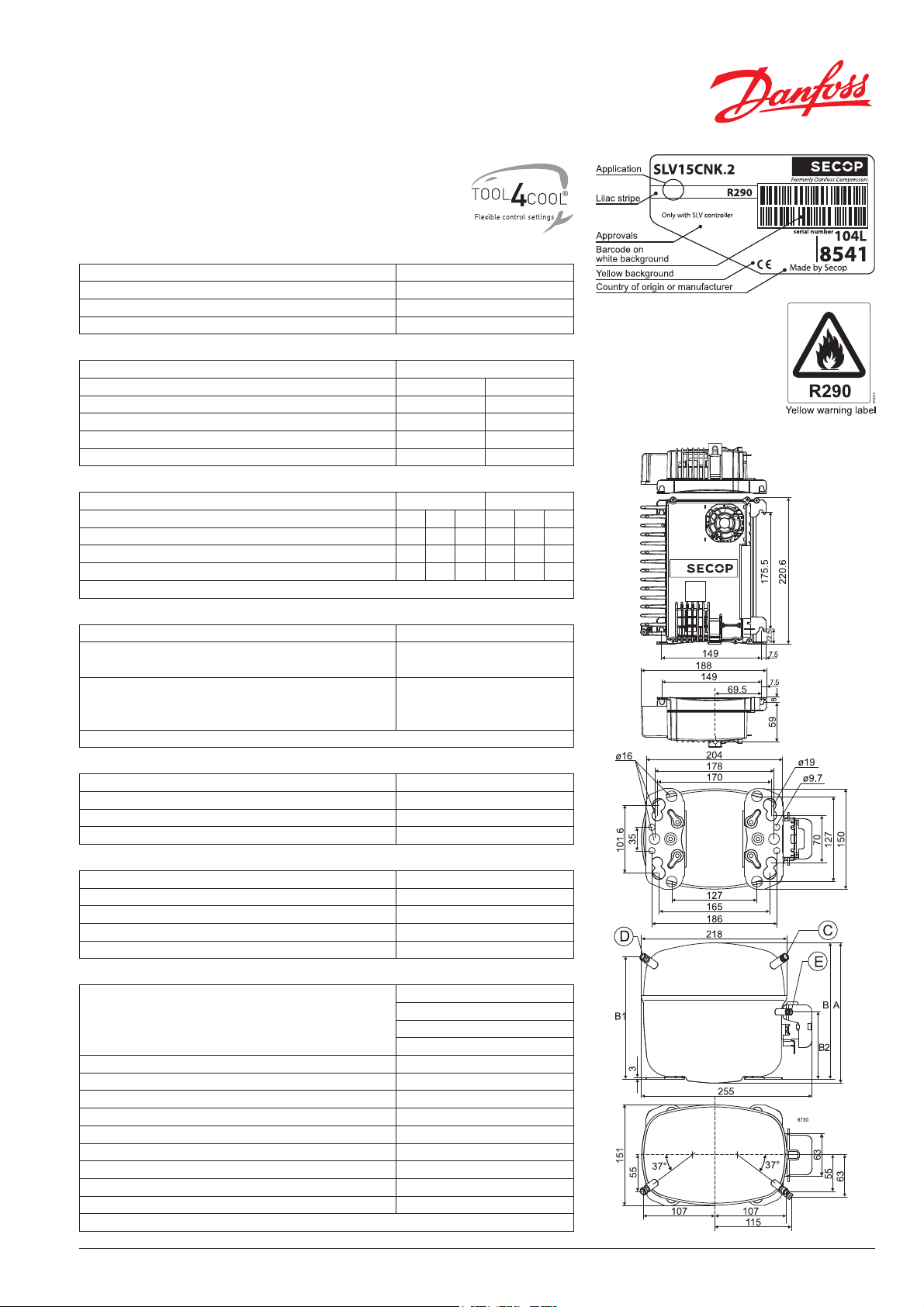

SLV15CNK.2

Variable Speed Drive Compressor

R290

220-240V 50/60Hz

- with 105N46xx Series Controllers

General

Code number (without electronic unit) 104H8541

Electronic unit 105N46xx series controller

Approvals EN 60335-2-34, CCC

Compressors on pallet 80

Application

Application LBP

Frequency Hz 50 60

Evaporating temperature °C -40 to -10 -40 to -10

Voltage range V 180 - 254 180 - 254

Max. condensing temperature continuous (short) °C 55 (65) 55 (65)

Max. winding temperature continuous (short) °C 125 (135) 125 (135)

Cooling requirements

Frequency Hz 50 60

Application

32°C F2– – F2– –

38°C F2– – F2– –

43°C F2– – F2– –

Remarks on application: LST only, airfl ow on compressor and electronic unit: 3m/s

LBP MBP HBP LBP MBP HBP

S = Static cooling normally suffi cient

O = Oil cooling

F

= Fan cooling 1.5 m/s

1

(compressor compartment temp.

equal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

SG = Suction gas cooling normally

suffi cent

– = not applicable in this area

Features

Speed range rpm 2000 - 4000

Thermostat

Protections - current

Remarks:

Motor

Motor type permanent magnet

LRA (rated after 4 sec. UL984), A electronic cut off

Maximum current A 5.6

Resistance, all 3 windings (25°C) Ω 7.7

Design

Displacement cm

Oil quantity (type) cm

Maximum refrigerant charge g 150

Free gas volume in compressor cm

Weight - Compressor/Electronic unit kg 12.0/1.4

Dimensions

Height mm A 199

Suction connector location/I.D. mm | angle C 10.2 | 37°

material | seal Cu-plated steel | Al cap

Process connector location/I.D. mm | angle D 6.2 | 37°

material | seal Cu-plated steel | Al cap

Discharge connector location/I.D. mm | angle E 6.2 | 37°

material | seal Cu-plated steel | Al cap

Oil cooler connector location/I.D. mm | angle F –

material | seal –

Connector tolerance I.D. mm ±0.09

Remarks:

- intregrated

- electronic

- speed

- temperature

3

3

3

600 (polyolester)

B 193

B1 173

B2 90

15.28

1510

July 2011 DEHC.ED.300.G2.02 - 520N1094 1/2

Page 2

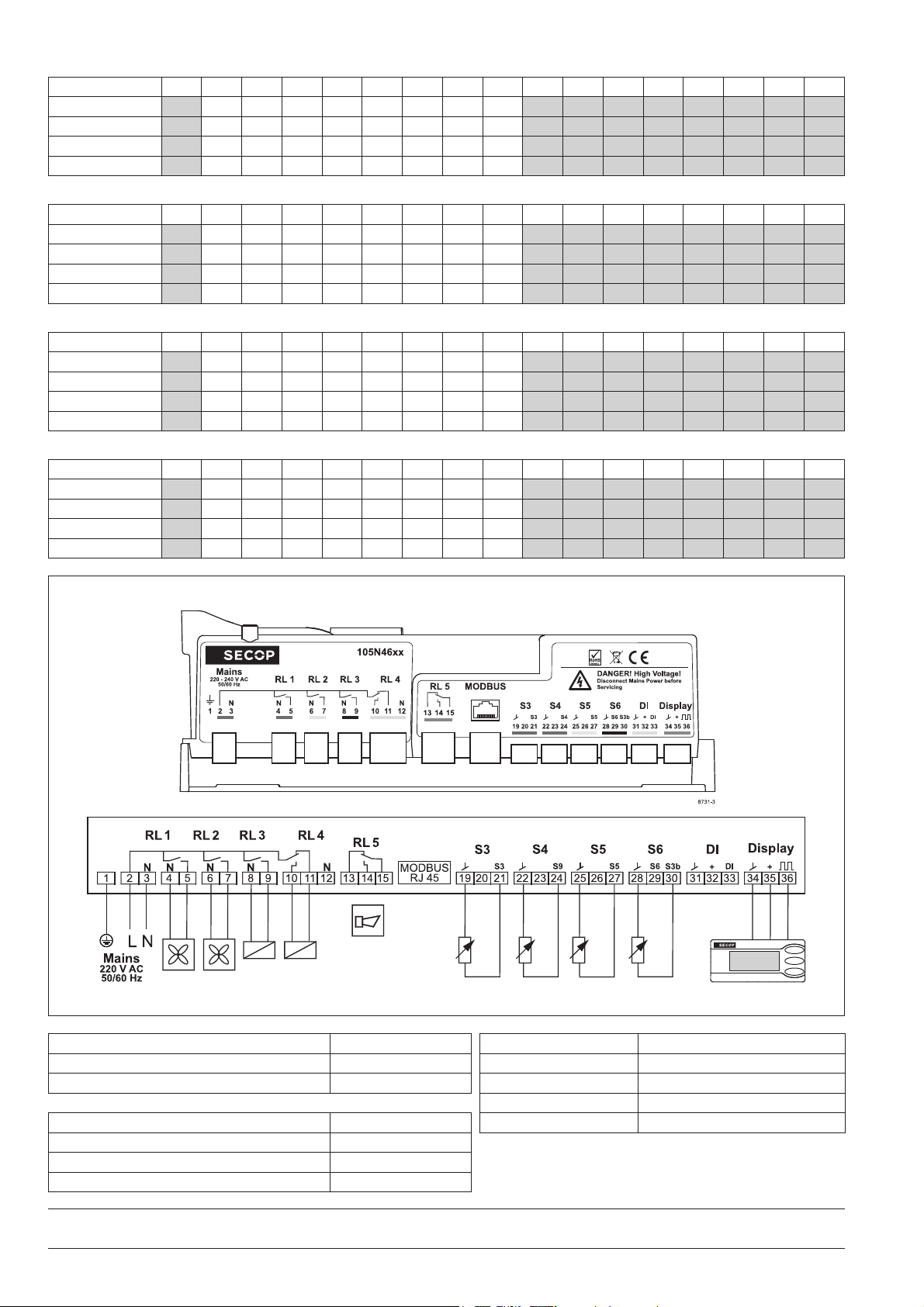

2,000 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 175 236 311 402 437 510 638 786

Power cons. in W 192 229 266 303 315 338 372 402

Current cons. in A 1.01 1.19 1.37 1.54 1.60 1.70 1.86 2.01

COP in W/W 0.91 1.03 1.17 1.33 1.39 1.51 1.72 1.96

2,500 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 218 297 393 509 553 645 805 990

Power cons. in W 242 284 327 371 385 414 455 493

Current cons. in A 1.18 1.39 1.60 1.80 1.87 2.01 2.22 2.42

COP in W/W 0.90 1.05 1.20 1.37 1.43 1.56 1.77 2.01

3,000 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 258 353 467 602 652 759 941 1151

Power cons. in W 271 331 388 441 458 489 533 571

Current cons. in A 1.34 1.57 1.80 2.03 2.11 2.26 2.50 2.73

COP in W/W 0.95 1.07 1.21 1.37 1.43 1.55 1.77 2.02

4,000 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 325 460 615 792 858 996 1228 1494

Power cons. in W 355 436 512 583 607 650 713 771

Current cons. in A 1.68 2.02 2.36 2.68 2.78 2.99 3.28 3.56

COP in W/W 0.92 1.06 1.20 1.36 1.42 1.53 1.72 1.94

Terminal Area 10546xx Series Controller

Mains red

R L 1 blue

R L 2 yellow

R L 3 black

R L 4 grey

R L 5 green

S3 red

S4 blue

S5 yellow

S6 black

DI grey

Display green

Accessories for SLV15CNK.2 Code number Test conditions EN 12900/CECOMAF*

Cover 103N2009 Condensing temperature 45°C

Cord relief 103N1004 Ambient temperature 32°C

Suction gas temperature 32°C

Mounting accessories Code number Liquid temperature no subcooling

Bolt joint for one compressor Ø: 16 m m 118-1917

Bolt joint in quantities Ø: 16 mm 118-1918

Snap-on in quantities Ø: 16 m m 118-1919

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifi cations already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2/2 Manufactured by Secop for Danfoss - DEHC.ED.300.G2.02 - 520N1094 July 2011

Loading...

Loading...