SLV12CLK.2

Variable Speed Drive Compressor

R404A/R507

220-240V 50/60Hz

- with 105N46xx Series Controllers

General

Code number (without electronic unit) 104L2603

Electronic unit 105N46xx series controller

Approvals EN 60335-2-34, CCC

Compressors on pallet 80

Application

Application LBP

Frequency Hz 50 60

Evaporating temperature °C -40 to -10 -40 to -10

Voltage range V 180 - 254 180 - 254

Max. condensing temperature continuous (short) °C 50 (60) 50 (60)

Max. winding temperature continuous (short) °C 125 (135) 125 (135)

Cooling requirements

Frequency Hz 50 60

Application

32°C F2– – F2– –

38°C F2– – F2– –

43°C F2– – F2– –

Remarks on application: LST only, airfl ow on compressor and electronic unit: 3m/s

LBP MBP HBP LBP MBP HBP

S = Static cooling normally suffi cient

O = Oil cooling

F1 = Fan cooling 1.5 m/s

(compressor compartment temperature

equal to ambient temperature)

F2 = Fan cooling 3.0 m/s necessary

SG = Suction gas cooling normally suffi cent

– = not applicable in this area

Features

Speed range rpm 2000 - 4000

Thermostat

Protections - current

Remarks:

Motor

Motor type permanent magnet

LRA (rated after 4 sec. UL984), A electronic cut off

Maximum current A 5.6

Resistance, all 3 windings (25°C) Ω 7.7

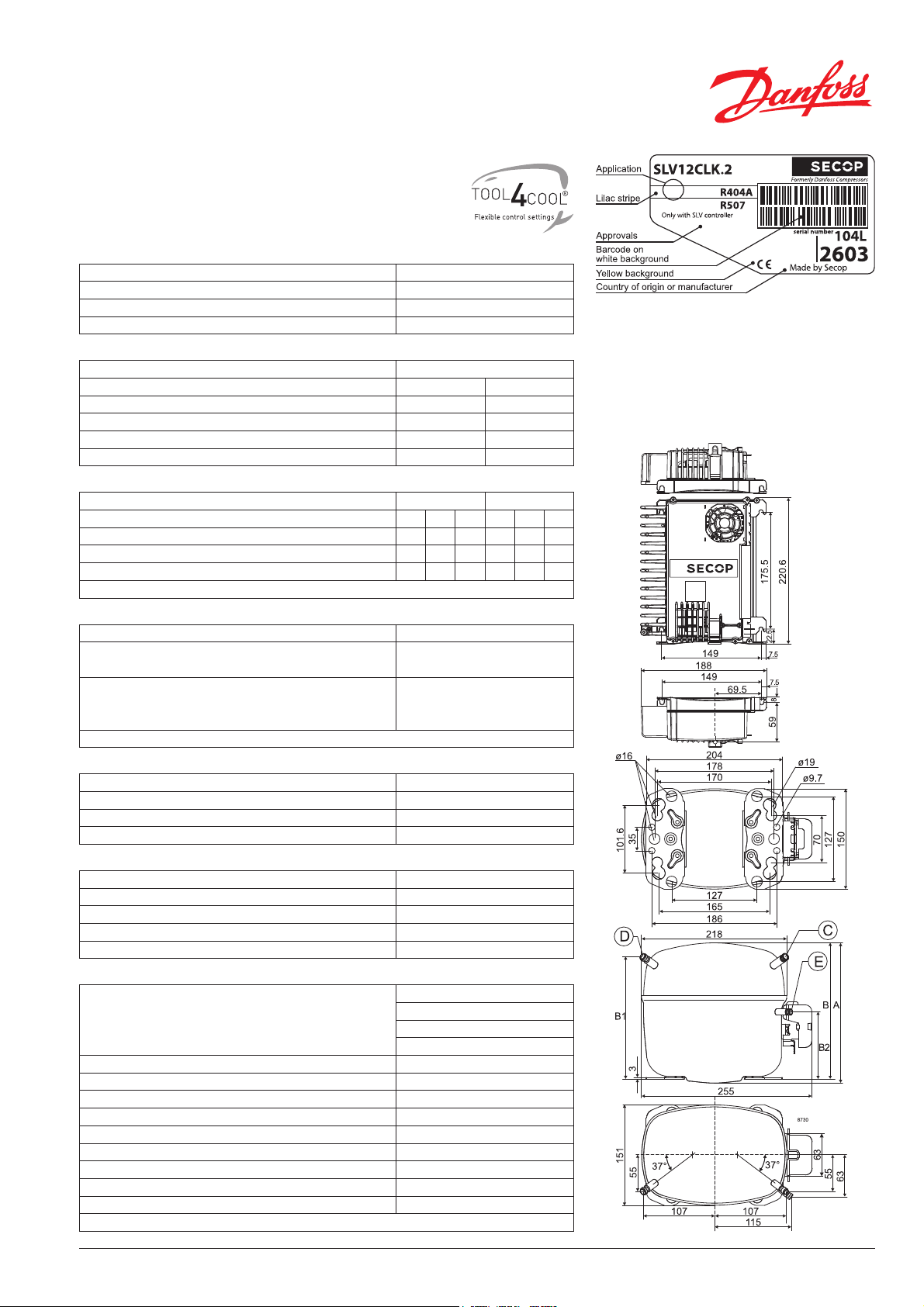

Design

Displacement cm

Oil quantity (type) cm

Maximum refrigerant charge g 1300

Free gas volume in compressor cm

Weight - Compressor/Electronic unit kg 12.0/1.4

Dimensions

Height mm A 199

Suction connector location/I.D. mm | angle C 10.2 | 37°

material | comment Cu-plated steel | Al cap

Process connector location/I.D. mm | angle D 6.2 | 37°

material | comment Cu-plated steel | Al cap

Discharge connector location/I.D. mm | angle E 6.2 | 37°

material | comment Cu-plated steel | Al cap

Oil cooler connector location/I.D. mm | angle F –

material | comment –

Connector tolerance I.D. mm ±0.09

Remarks:

- intregrated

- electronic

- speed

- temperature

3

3

3

600 (polyolester)

B 193

B1 173

B2 90

12.87

1510

July 2011 DEHC.ED.300.H2.02 / 520N1095 1/2

2,000 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 134 196 269 355 387 455 572 705

Power cons. in W 182 227 268 308 321 345 379 410

Current cons. in A 0.97 1.16 1.36 1.55 1.62 1.74 1.94 2.13

COP in W/W 0.74 0.86 1.00 1.15 1.21 1.32 1.51 1.72

2,500 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 160 243 342 459 502 592 742 910

Power cons. in W 212 270 325 377 394 426 472 515

Current cons. in A 1.06 1.32 1.58 1.82 1.91 2.07 2.30 2.53

COP in W/W 0.75 0.90 1.05 1.22 1.27 1.39 1.57 1.77

3,000 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 181 283 406 550 604 714 895 1093

Power cons. in W 237 308 375 439 460 499 557 612

Current cons. in A 1.13 1.45 1.76 2.06 2.16 2.35 2.62 2.88

COP in W/W 0.76 0.92 1.08 1.25 1.31 1.43 1.61 1.79

4,000 rpm EN 12900 Household (CECOMAF)* 220V, 50Hz, fan cooling F

2

Evap. temp. in °C -45 -40 -35 -30 -25 -23.3 -20 -15 -10 -6.7 -5 0 5 7.2 10 15 20

Capacity in W 200 370 542 720 782 909 1114 1339

Power cons. in W 270 404 508 588 611 649 695 731

Current cons. in A 0.91 1.68 2.30 2.77 2.90 3.10 3.28 3.31

COP in W/W 0.74 0.92 1.07 1.22 1.28 1.40 1.60 1.83

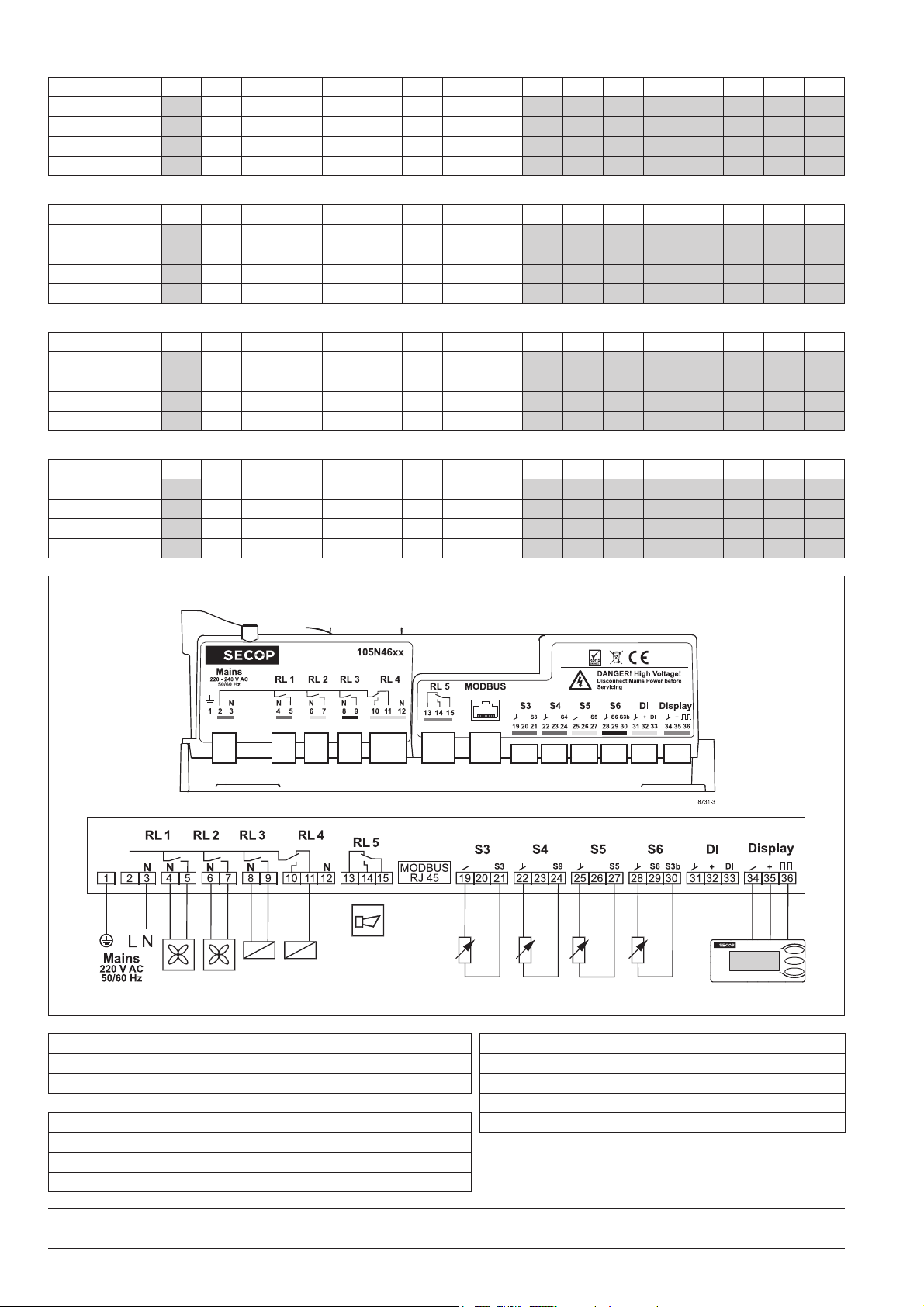

Terminal Area 10546xx Series Controller

Mains red

R L 1 blue

R L 2 yellow

R L 3 black

R L 4 grey

R L 5 green

S3 red

S4 blue

S5 yellow

S6 black

DI grey

Display green

Accessories for SLV12CLK.2 Code number Test conditions EN 12900/CECOMAF*

Cover 103N2009 Condensing temperature 45°C

Cord relief 103N1004 Ambient temperature 32°C

Suction gas temperature 32°C

Mounting accessories Code number Liquid temperature no subcooling

Bolt joint for one compressor Ø: 16 mm 118-1917

Bolt joint in quantities Ø: 16 m m 118-1918

Snap-on in quantities Ø: 1 6 mm 118-1919

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifi cations already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2/2 Manufactured by Secop for Danfoss - DEHC.ED.300.H2.02 / 520N1095 July 2011

Loading...

Loading...