Page 1

Technical Information

Fan Drive Gear Motors

Group 2 and Group 3

www.danfoss.com

Page 2

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Revision history Table of revisions

Date Changed Rev

December 2020 Unavailable options removed from page 20 0102

October 2019 First edition. 0101

2 | © Danfoss | December 2020 BC318050073602en-000102

Page 3

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Contents

General Information

Introduction........................................................................................................................................................................................5

Typical Applications........................................................................................................................................................................ 6

Features and Benefits......................................................................................................................................................................7

Quick reference chart for fan drive motors.............................................................................................................................7

Determination of nominal motor size.......................................................................................................................................8

Fan Drive Motors Circuit Illustrations........................................................................................................................................9

Fan Drive Motor Hydraulic Schematics..................................................................................................................................11

System Requirements

Pressure............................................................................................................................................................................................. 12

Speed..................................................................................................................................................................................................13

Hydraulic Fluids.............................................................................................................................................................................. 13

Temperature and Viscosity.........................................................................................................................................................14

Filtration............................................................................................................................................................................................ 15

Filters.............................................................................................................................................................................................15

Selecting a filter.........................................................................................................................................................................15

Reservoir...................................................................................................................................................................................... 15

Line sizing......................................................................................................................................................................................... 16

Motor Shaft Connection..............................................................................................................................................................16

Motor Life..........................................................................................................................................................................................16

Group 2

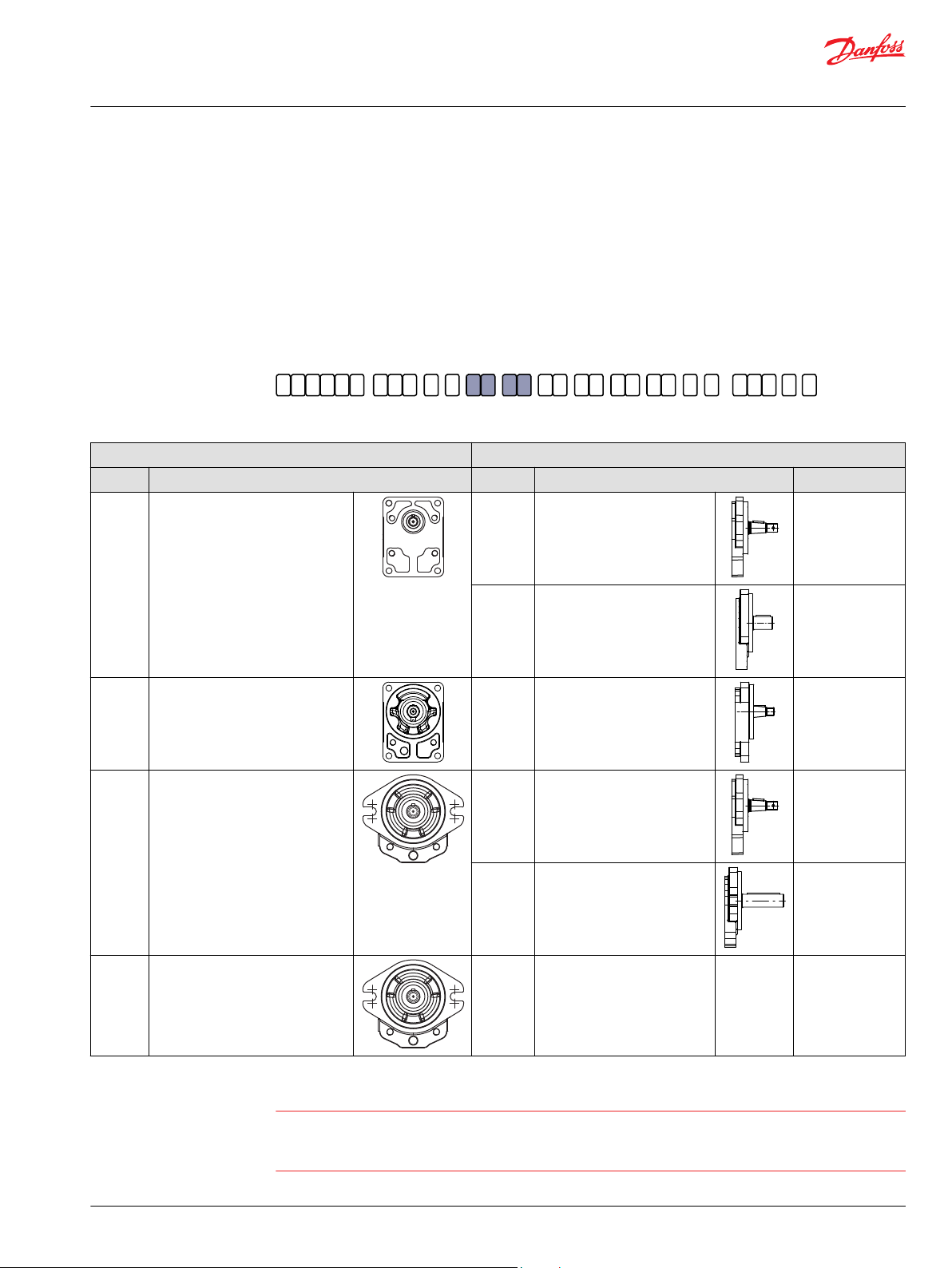

Model Code for Group 2 Fan Drive Motors...........................................................................................................................17

Model Code for Integral Relief Valve Pressure Setting.....................................................................................................20

Model Code for Mounting Flange/Drive Gears (Group 2)...............................................................................................21

SGM2NC Fan Drive Motors (Group 2)

SGM2NC Technical Data..............................................................................................................................................................22

SGM2NC Model Code Examples...............................................................................................................................................22

SGM2NC 02AA Dimensions........................................................................................................................................................23

SGM2NC 06BA Dimensions........................................................................................................................................................ 25

SGM2NC 06GB Dimensions........................................................................................................................................................27

SGM2YN Fan Drive Motors (Group 2)

SGM2YN Technical Data..............................................................................................................................................................29

SGM2YN Model Code Examples...............................................................................................................................................29

SGM2YN Electric Proportional Relief Valve Data................................................................................................................ 30

SGM2YN 02AA Dimensions........................................................................................................................................................31

SGM2YN 06BA Dimensions........................................................................................................................................................ 33

SGM2YN 06GB Dimensions........................................................................................................................................................ 35

SGM2YN Outrigger Bearing Dimensions...............................................................................................................................37

SGM2VC Fan Drive Motors (Group 2)

SGM2VC Technical Data.............................................................................................................................................................. 38

SGM2VC Model Code Examples............................................................................................................................................... 38

SGM2VC Electric Proportional Relief and D03 Directional Valves Data......................................................................39

SGM2VC 02AA Dimensions........................................................................................................................................................ 40

SGM2VC 06BA Dimensions.........................................................................................................................................................42

SGM2VC 06GB Dimensions........................................................................................................................................................ 44

SGM2VC Outrigger Bearing Dimensions...............................................................................................................................46

Group 3

Model Code for Group 3 Fan Drive Motors...........................................................................................................................47

Model Code for Integral Relief Valve Pressure Setting.....................................................................................................50

Model Code for Mounting Flange/Drive Gears (Group 3)...............................................................................................51

SGM3NC Fan Drive Motors (Group 3)

SGM3NC Technical Data..............................................................................................................................................................52

SGM3NC Model Code Examples...............................................................................................................................................52

SGM3NC 07BC Dimensions........................................................................................................................................................ 53

SGM3NC 07GB Dimensions........................................................................................................................................................55

©

Danfoss | December 2020 BC318050073602en-000102 | 3

Page 4

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Contents

SGM3YN Fan Drive Motors (Group 3)

SGM3YN Technical Data..............................................................................................................................................................57

SGM3YN Model Code Examples...............................................................................................................................................57

SGM3YN Electric Proportional Relief Valve Data................................................................................................................ 58

SGM3YN 07BC Dimensions.........................................................................................................................................................59

SGM3YN 07GB Dimensions........................................................................................................................................................ 61

SGM3YN Outrigger Bearing Dimensions...............................................................................................................................63

SGM3VC Fan Drive Motors (Group 3)

SGM3VC Technical Data.............................................................................................................................................................. 64

SGM3VC Model Code Examples............................................................................................................................................... 64

SGM3VC Electric Proportional Relief and D03 Directional Valves Data......................................................................65

SGM3VC 07BC Dimensions.........................................................................................................................................................66

SGM3VC 07GB Dimensions........................................................................................................................................................ 68

SGM3VC Outrigger Bearing Dimensions...............................................................................................................................70

4 | © Danfoss | December 2020 BC318050073602en-000102

Page 5

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

Introduction

Danfoss has for many years built up a wealth of experience with its hydraulic and electro-hydraulic fan

drive systems for vehicles and machines operating both on- and off-highway.

Modern fan drives require proportional electronic control to meet new emissions legislation. SGM2 and

SGM3 fan drive motors are based on the proven high performance Danfossgear motors.

A proportional pressure relief valve with pilot operated spool (normally closed) is integrated in the castiron rear cover of the motor. A gear pump supplies oil to the fan drive motor. The PWM signal to the

solenoid pressure relief valve controls the oil flow through the motor which determines the fan speed.

The fan speed is controlled to maintain optimum engine and hydraulic system temperatures. The

SGM2YN, SGM3YN, SGM2VC and SGM3VC provide this proportional control in an integrated package

within the rear cover.

Bi-directional fan motor capability is necessary when it is desired to switch the rotation of the fan blade

for such reasons as cleaning debris from a radiator. This allows for more efficient cooling of the machine

engine and functions. The SGM2NC and SGM3NC provide the bidirectional capability for use with remote,

inline mounted HIC manifolds that provide the reversing flow. The SGM2VC and the SGM3VC integrate

the reversing valve capability in the rear cover of the motor.

©

Danfoss | December 2020 BC318050073602en-000102 | 5

Page 6

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

Typical Applications

Due to the versatility, flexibility and reliability of Danfoss fan drive systems, they may be applied in

numerous applications, including the following.

Agriculture Machinery

•

On-Off and fully modulating controls

•

Increased engine reliability

•

Automatic or On-demand reversing

Construction Machinery

•

Backhoe loaders

•

Crawler dozer - Crawler loader

•

Wheel loaders

•

Dump trucks - Haulers

•

Excavators

•

Skid steer loaders

Material Handling Vehicles

•

Fork lift trucks

•

Rough terrain trucks

•

Telehandlers

Road Building Vehicles

•

Pavers

•

Graders

•

Road rollers

•

Crawlers

Forestry Machinery

•

Feller bunchers

•

Forwarders

•

Harvesters

•

Log skidders

On Highway Vehicles

•

Buses

•

RV motorhomes

•

Garbage trucks

•

Sweepers

High Power Specialty Vehicles

•

Marine

•

Oil and Gas drilling/Fracking

•

Mining

6 | © Danfoss | December 2020 BC318050073602en-000102

Page 7

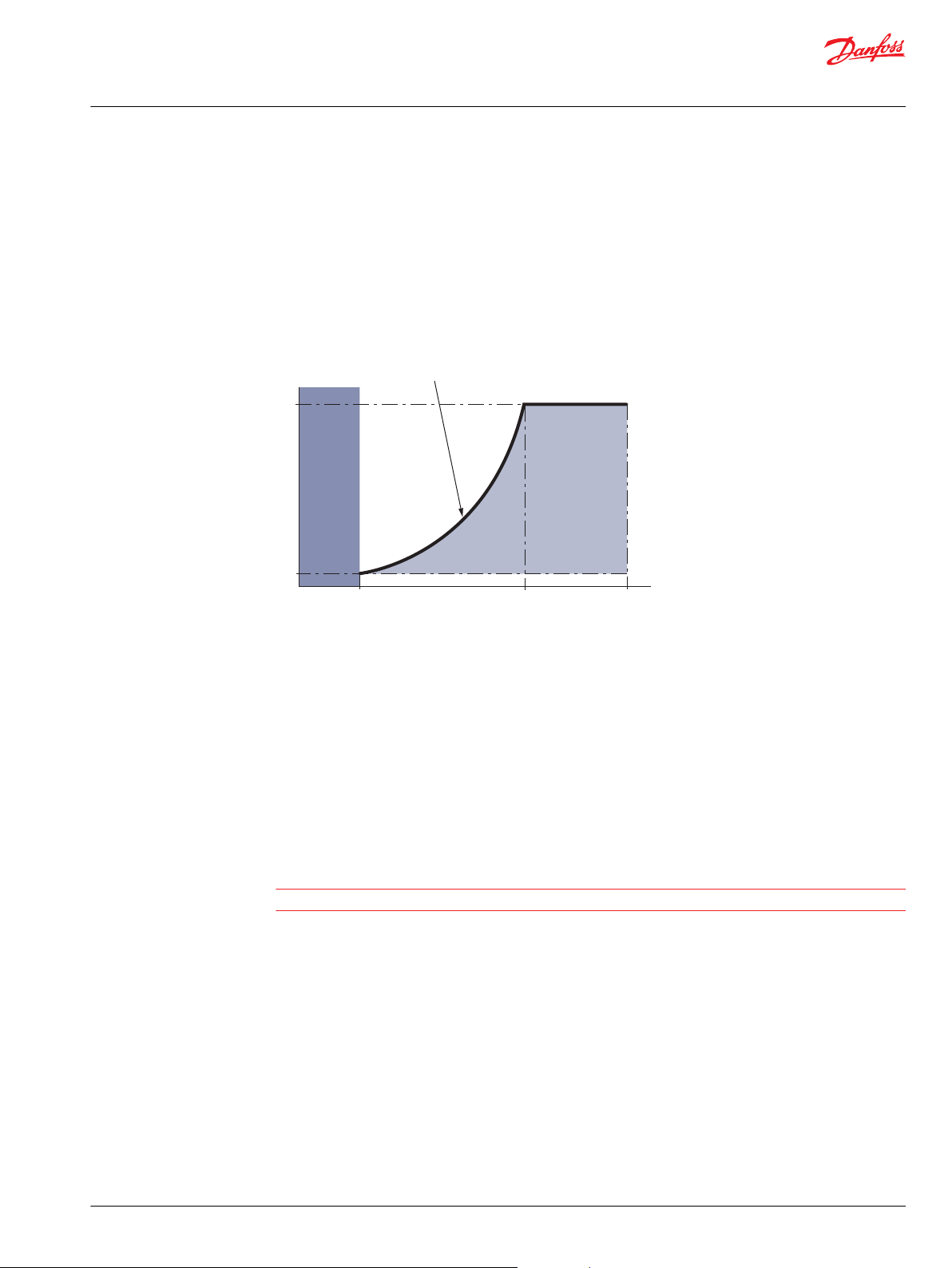

300

250

200

150

100

50

0

0 5 10 15 20 25 30 35 40 45 50

Displacement

cm3/rev

P

ressure

psi

SGM2**

SGM3**

bar

in3/rev

4000

3000

2000

1000

0

0.5

0

1.0

1.5

2.0 2.5

3.0

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

Features and Benefits

•

Two groups of frame size (Group 2 and 3)

•

Steel and cast iron rear covers for 250 bar [3626 psi] continuous performance and 270 bar [3916 psi]

peak pressure for all port configurations

•

Displacement from 8 to 44 cm3/rev [from 0.51 to 2.69 in3/rev]

•

Maximum speed 3500 min-1 (rpm) for Group 2 and 2500 min-1 (rpm) for Group 3

•

Extreme temperature seals for continuous operation from –20°C [–4°F] up to 95°C [203°F], for today's

more demanding applications.

•

Two electro-hydraulic proportional valve options: PRV for standard fan speed modulation and

optional flat curve valves for such applications as fan motors in series.

•

DEUTSCH electrical connectors as standard to withstand dust and debris in the environment.

•

12 VDC and 24 VDC coils.

•

Fail safe function - full fan speed if electrical signal fails.

•

Pressure settings factory pre-set for individual system performance.

•

High efficiency gear motors to reduce system losses and retain useful hydraulic power work functions

•

Outrigger bearings available for all 3 models to provide increased bearing capacity and therefore

more durability or extended life in applications such as slewing, tracked machines, vibe and shock

load applications that possess gyroscopic and impact loads or heavy steal fan blades

•

Shaft seal dust protector standard on all models for extended seal life in fan drive applications

•

2 Anti-Cavitation High Pressure Shock Valves, to clip pressure spikes in both directions of motor

rotation, while reversing, where the competition uses only 1

•

Integrated Reversing Directional Control Valves with open spool transitions to reduce system

pressure spikes

•

High performance valves and the use of steel / cast iron allows for full system pressure capability

without de-rating the SGM product during reversing or proportional control

•

Integrated valves packages and factory sealed outrigger bearings with high speed capability to

preserve engine space

•

PLUS+1® Compliant electronic interface allows for integration with PLUS+1® micro-controllers and

other compliant products including sensors and graphical displays

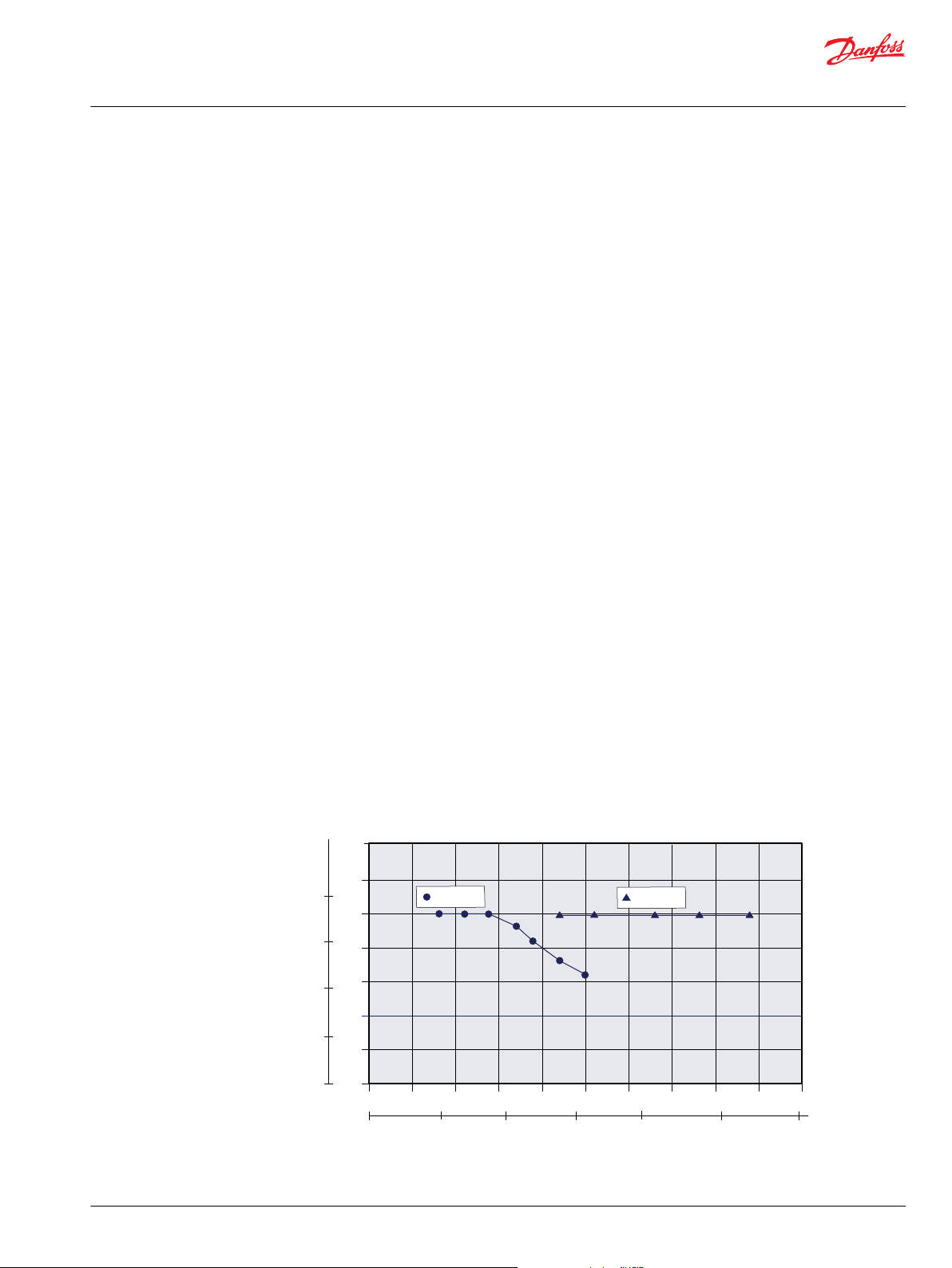

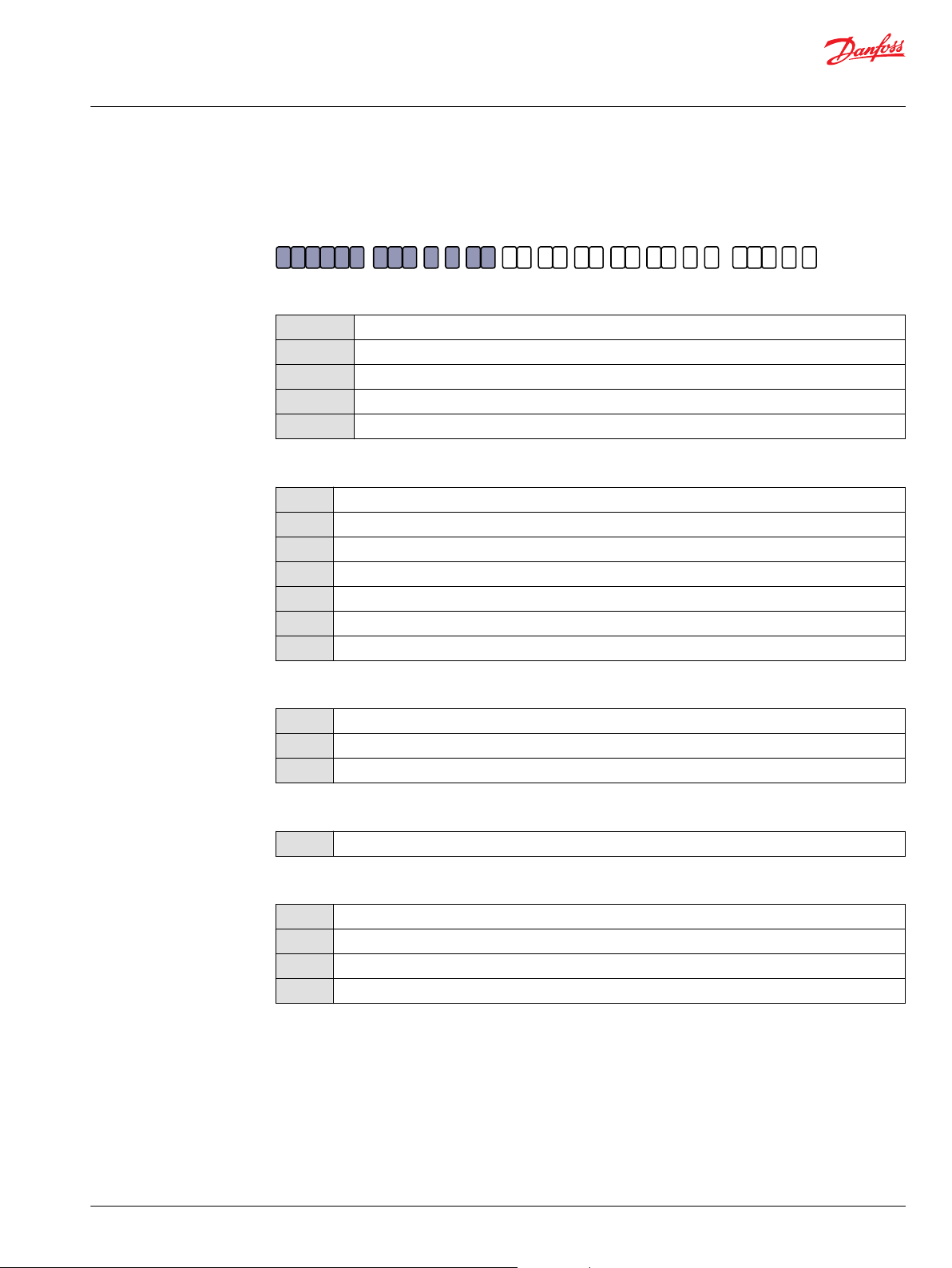

Quick reference chart for fan drive motors

©

Danfoss | December 2020 BC318050073602en-000102 | 7

Page 8

Vg • n

1000 •

v

Qe =

Vg • p •

mh

20 •

Me =

Qe • p •

t

600

=

Me • n

9550

Pe=

n =

Qe • 1000 •

v

V

g

Vg • n

231 •

v

Qe =

Vg • p •

mh

2 •

Me =

Vg • n • p •

t

396 000

Pe=

n =

Qe • 231 •

v

V

g

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

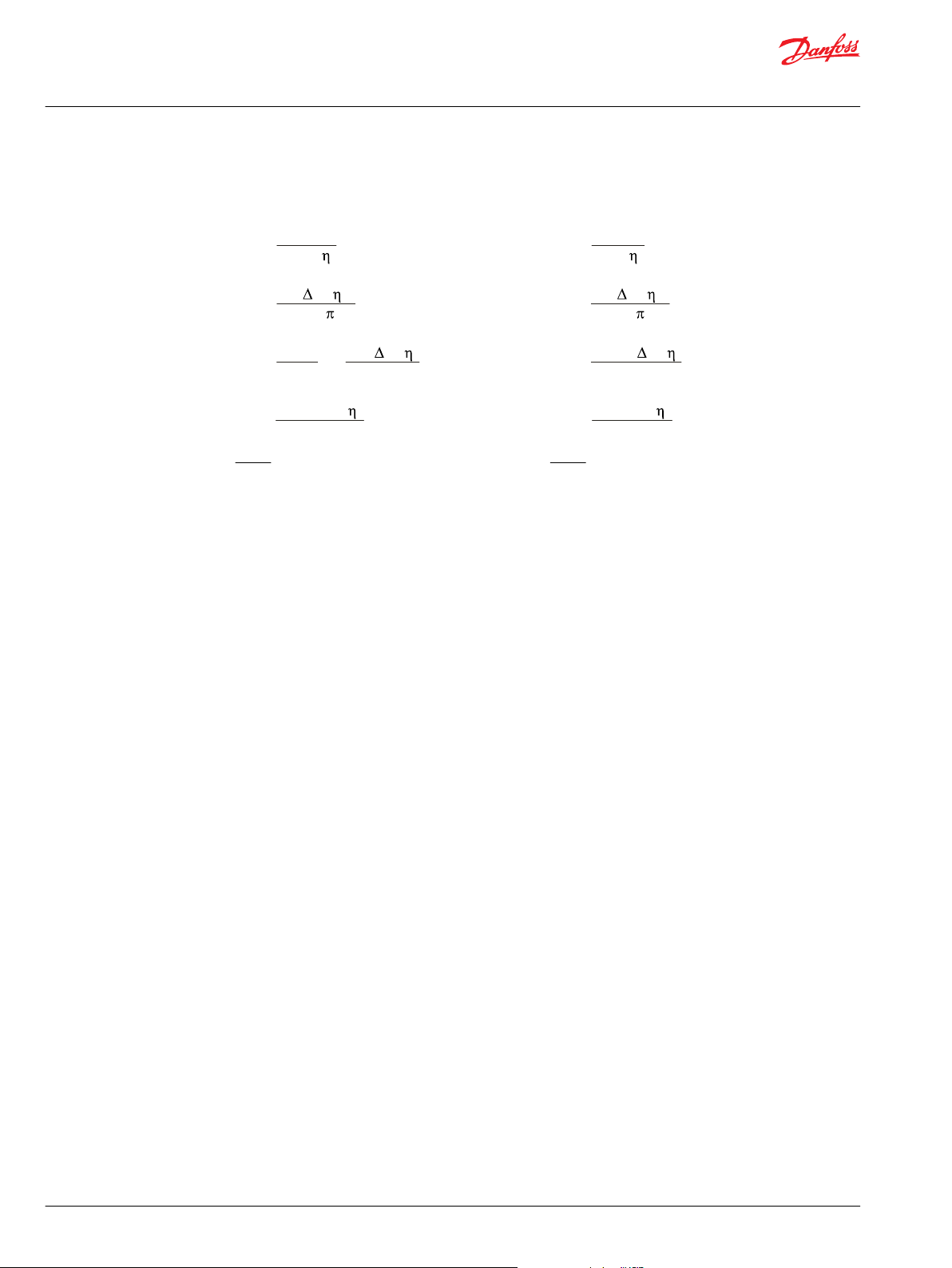

Determination of nominal motor size

Based on SI units Based on US units

Where:

Q

Input flow (l/min)

e

M

Output torque (N•m)

e

P

Output power (kW)

e

n Speed (min-1)

V

Motor displacement per rev. (cm3/rev)

g

p

High pressure (bar)

high

p

Low pressure (bar)

low

∆p High pressure minus Low pressure (bar)

η

Motor volumetric efficiency

v

η

Mechanical-hydraulic efficiency

mh

η

Motor total efficiency (ηv • ηmh)

t

Where:

Q

Input flow [US gal/min]

e

M

Output torque [lb•in]

e

P

Output power [hp]

e

n Speed [rpm]

V

Motor displacement per rev. [in3/rev]

g

p

High pressure [psi]

high

p

Low pressure [psi]

low

∆p High pressure minus Low pressure [psi]

η

Motor volumetric efficiency

v

η

Mechanical-hydraulic efficiency

mh

η

Motor total efficiency (ηv • ηmh)

t

8 | © Danfoss | December 2020 BC318050073602en-000102

Page 9

Diesel engine

Gear pump

(SNP)

Microcontroller

(PLUS+1TM)

Filter

T3

T2

T1

Temperature

sensors

Fan drive

gear motor

(SGM)

Reservoir

CAN Bus

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

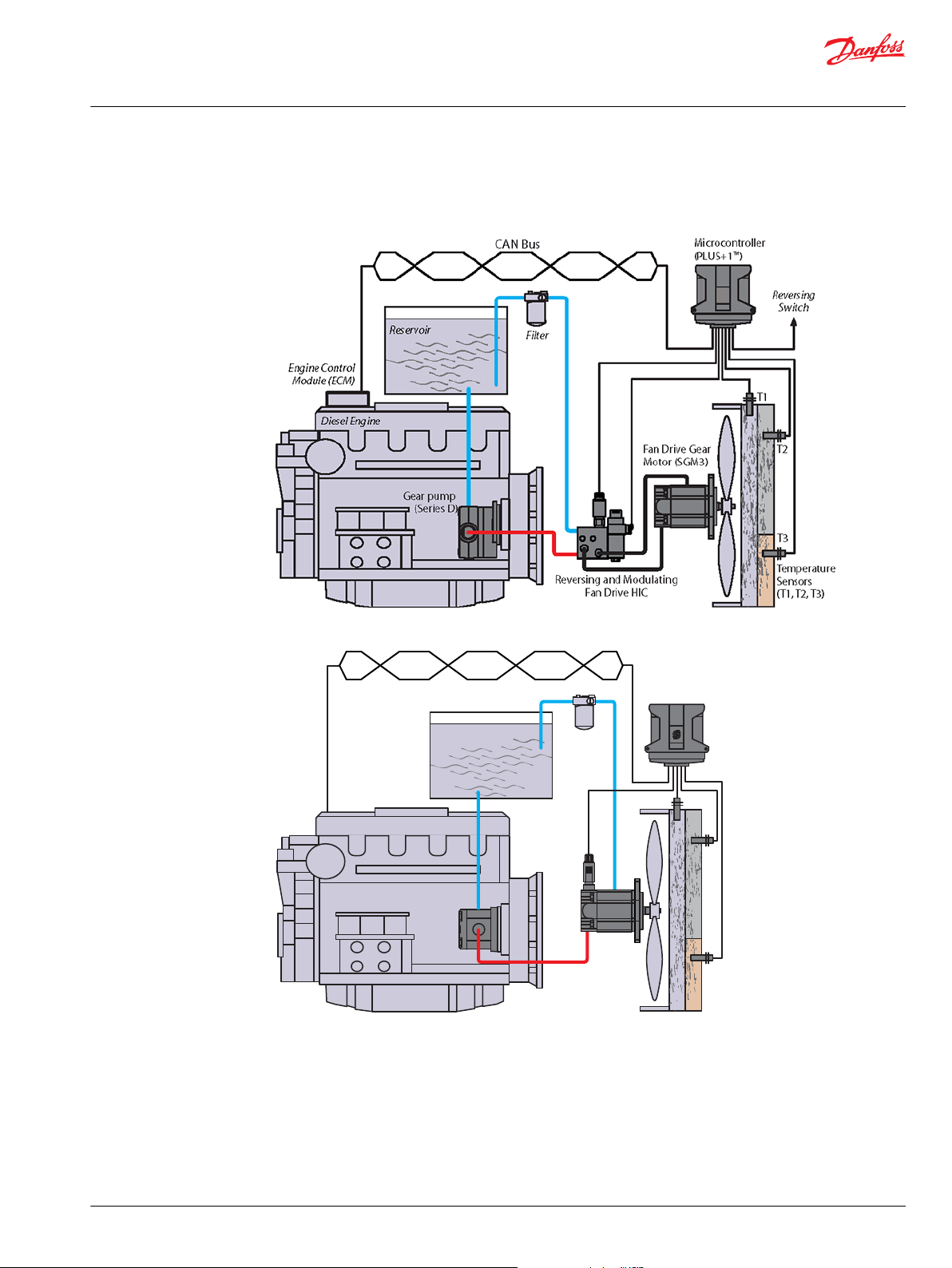

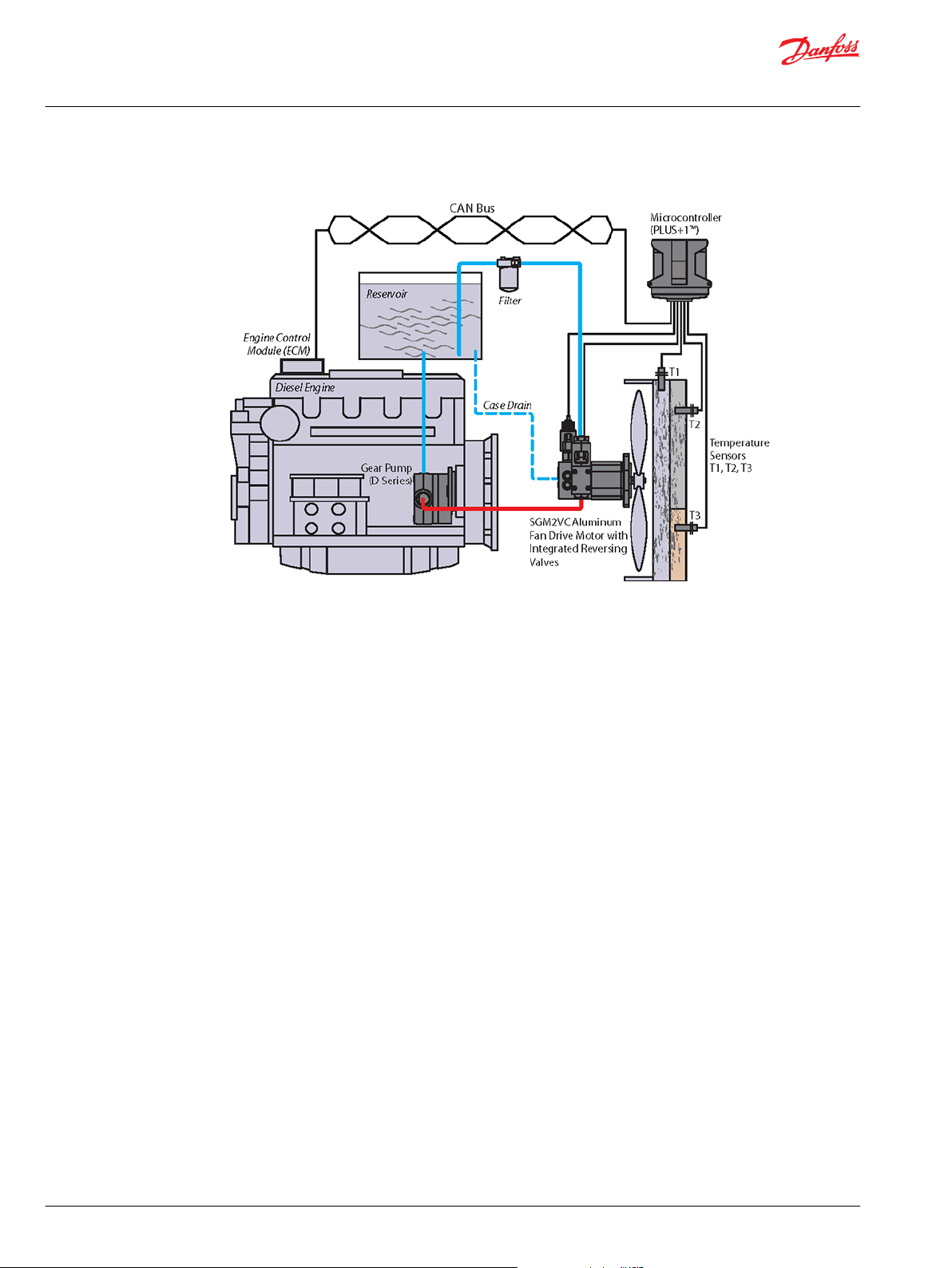

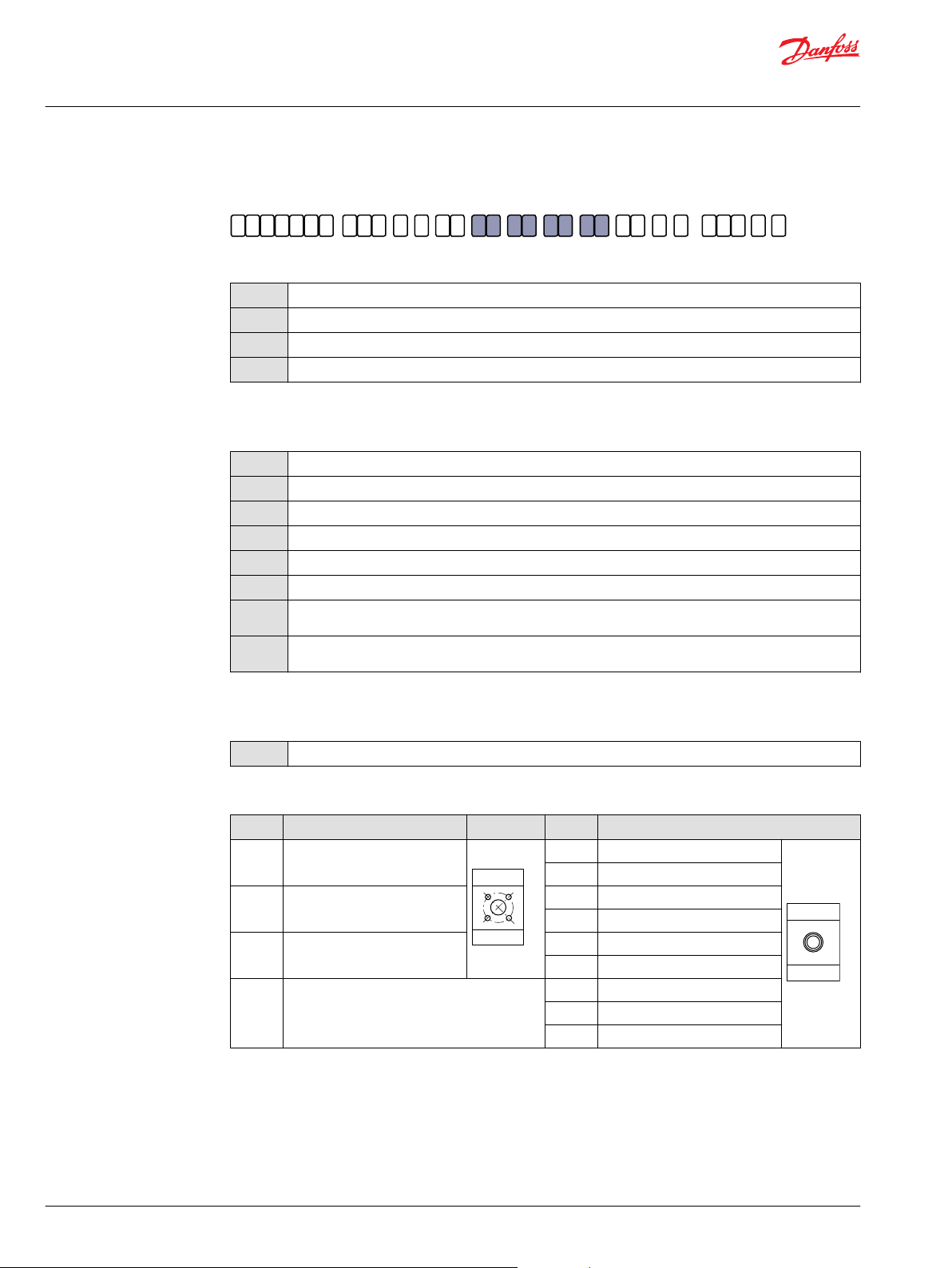

Fan Drive Motors Circuit Illustrations

Gear pump/gear motor with HIC electrical control

Gear pump/gear motor with electro-proportional relief valve

©

Danfoss | December 2020 BC318050073602en-000102 | 9

Page 10

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

Gear pump/gear motor with integrated reversing control valve

10 | © Danfoss | December 2020 BC318050073602en-000102

Page 11

Dr

P

T

Dr

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

General Information

Fan Drive Motor Hydraulic Schematics

SGM*NC Schematic

SGM*Y Schematic

SGM*VC Schematic

©

Danfoss | December 2020 BC318050073602en-000102 | 11

Page 12

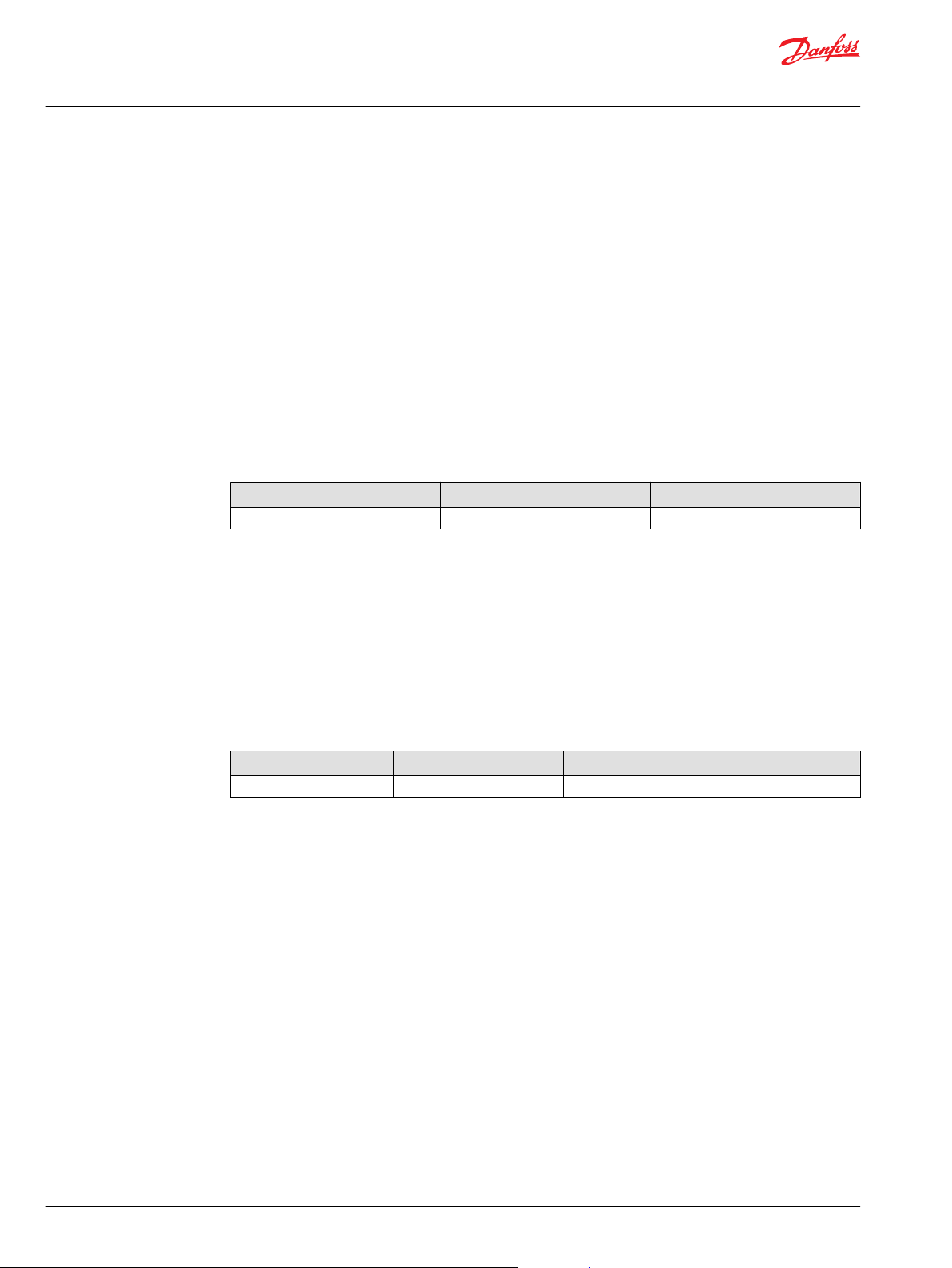

Peak pressure

Rated pressure

Reaction time (100 ms max)

Time

Pressure

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

System Requirements

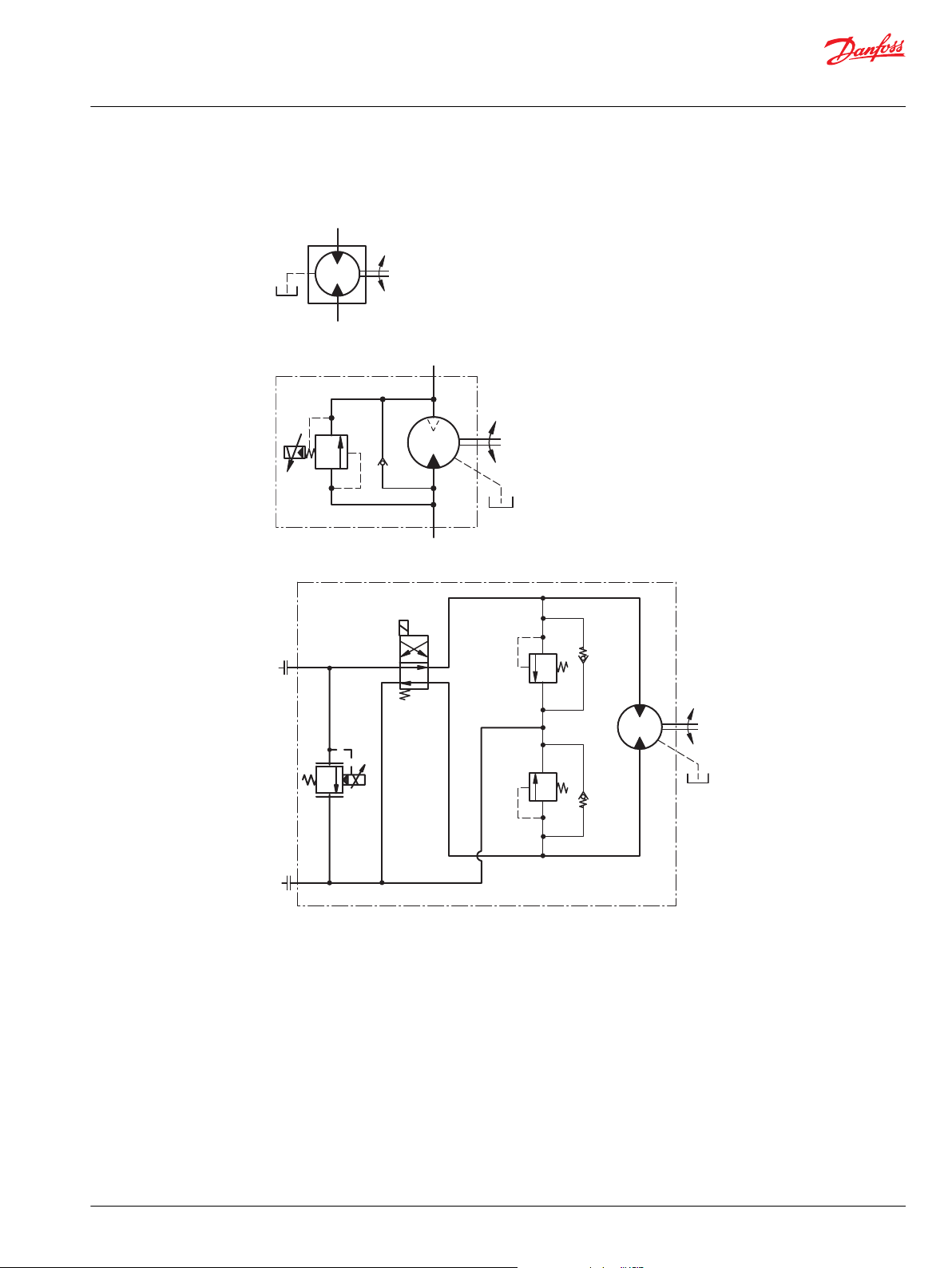

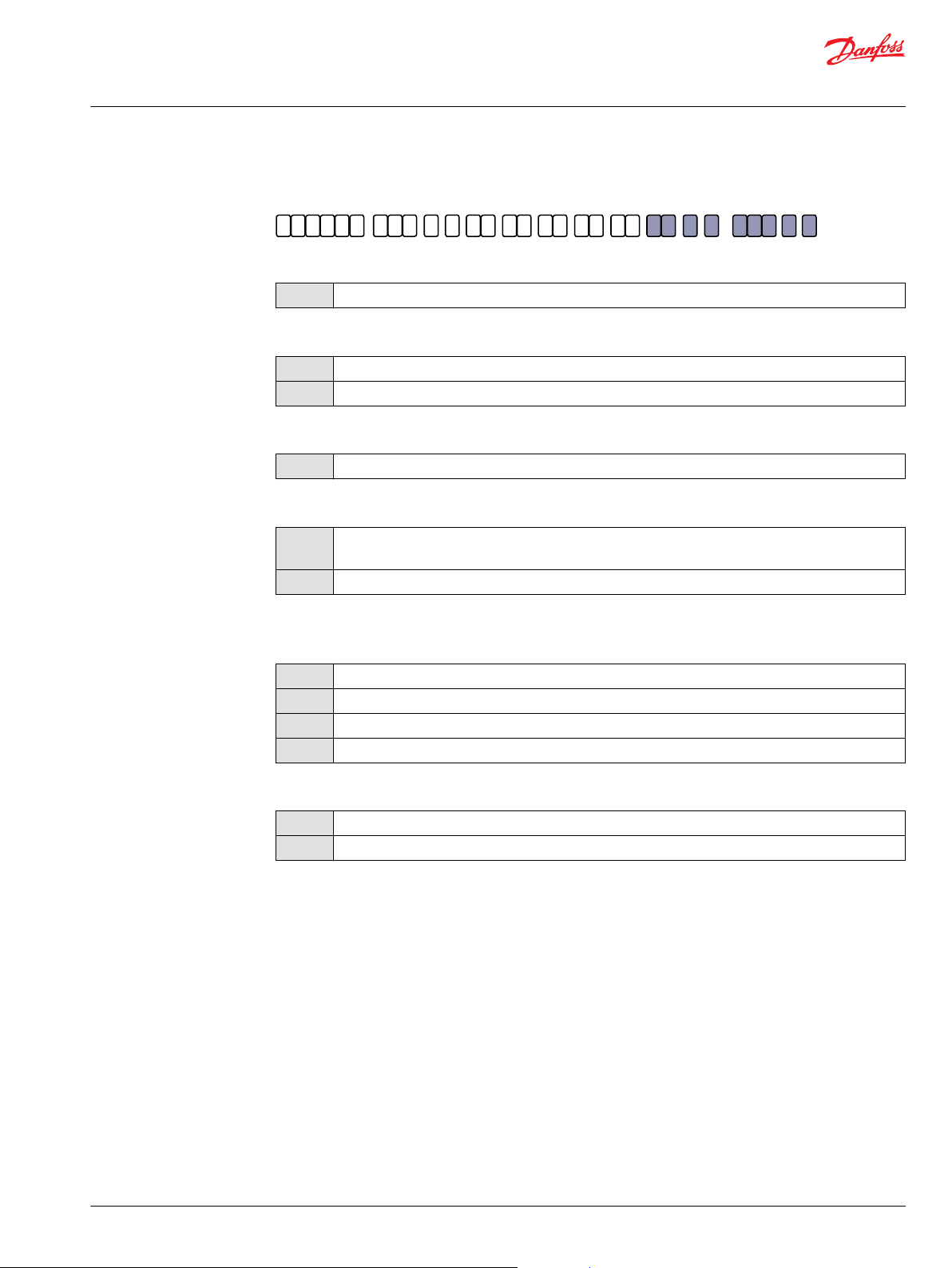

Pressure

Peak pressure is the highest intermittent pressure allowed at the pump's outlet. The relief valve

overshoot (reaction time) determines peak pressure. It is assumed to occur for less than 100 ms.

Rated pressure is the average, regularly occurring operating inlet pressure that should yield satisfactory

product life. The maximum machine load at the motor shaft determines rated pressure.

The illustration below shows peak pressure in relation to rated pressure and reaction time (100 ms

maximum).

System pressure is the differential between the inlet and outlet ports. It is a dominant operating variable

affecting hydraulic unit life. High system pressure, resulting from high load at the motor shaft, reduces

expected life. System pressure must remain at, or below, rated pressure during normal operation to

achieve expected life.

Back pressure is the average, regularly occurring operating outlet pressure that should yield satisfactory

motor life. The hydraulic load demand downstream of the motor determines the back pressure. The fan

drive gear motor can work with back pressure and the maximum back pressure allowed is 60% of the

maximum rated pressure.

Case drain pressure is the regularly occurring case drain line pressure that should yield satisfactory

motor life. It is recommended to design the case drain piping connecting the case drain direct to the tank

in order to keep the case drain pressure as low as possible. Max. continuous case drain pressure allowed

is 5 bar [72.5 psi] with a peak of 7 bar [101.5 psi].

12 | © Danfoss | December 2020 BC318050073602en-000102

Page 13

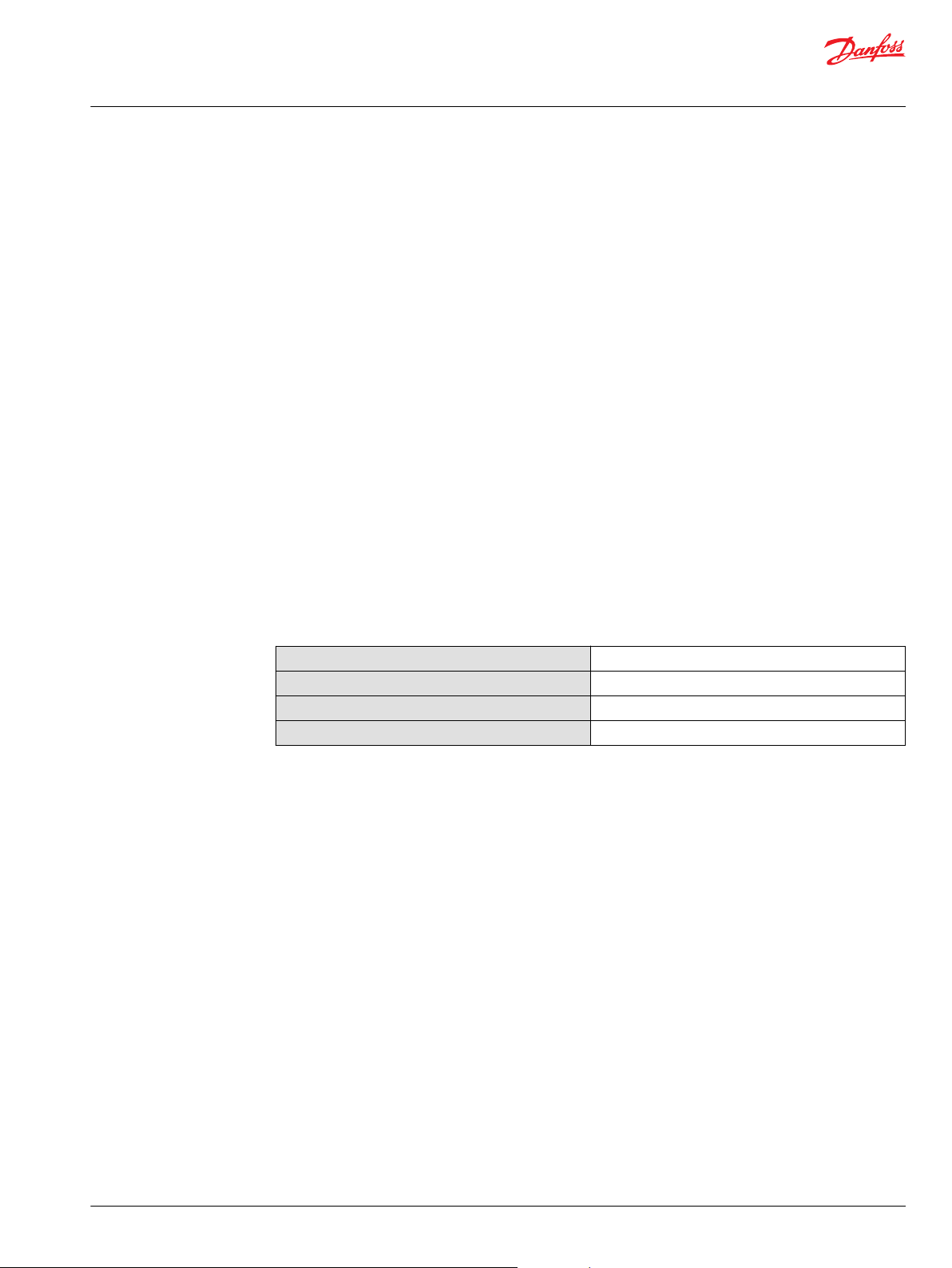

Rated

Example of typical fan loading curve

Start-up

area

P

2

P

1

Pressure

0

N

Speed

N

N

2

max

Operating

envelope

1

C

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

System Requirements

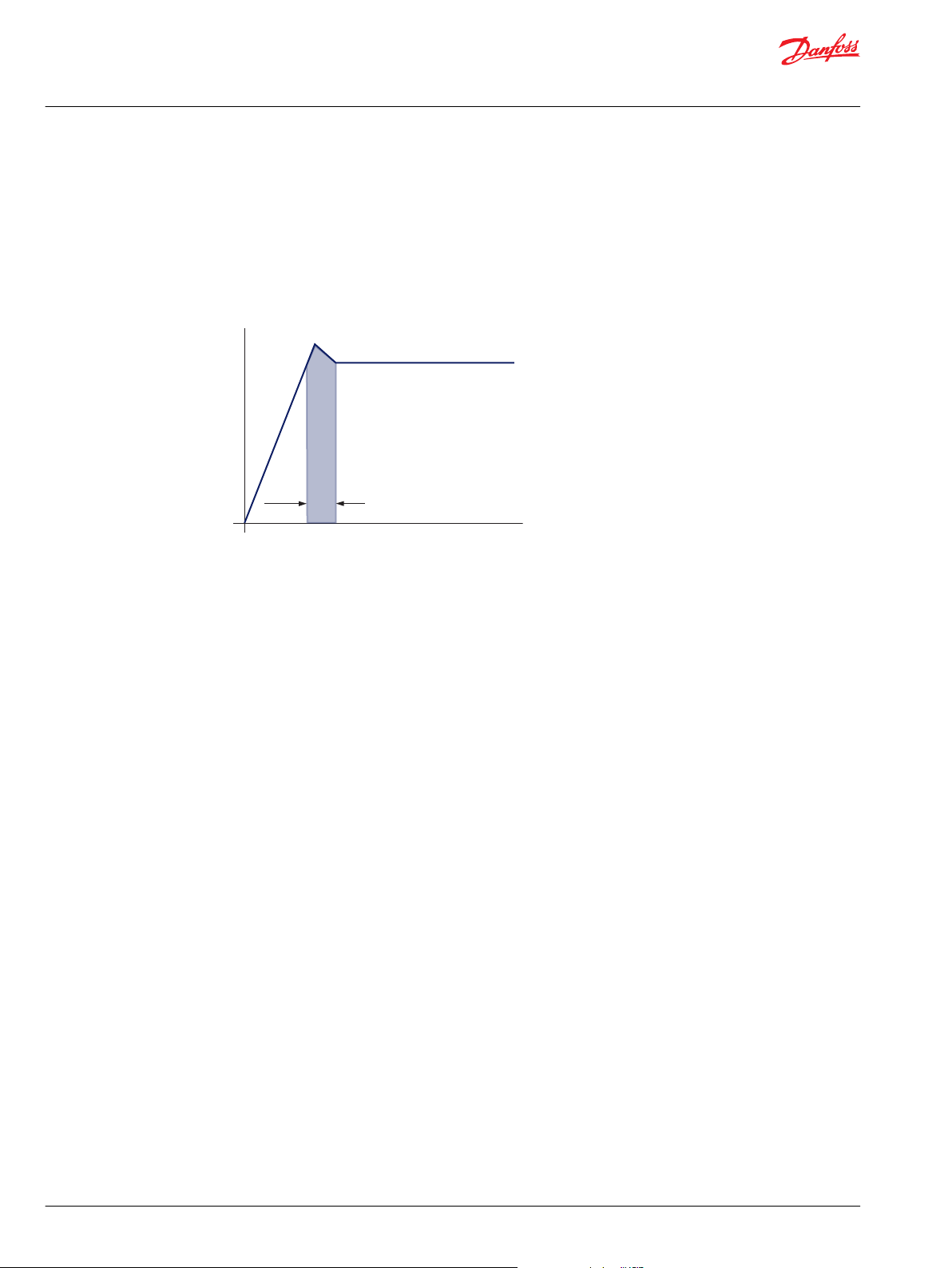

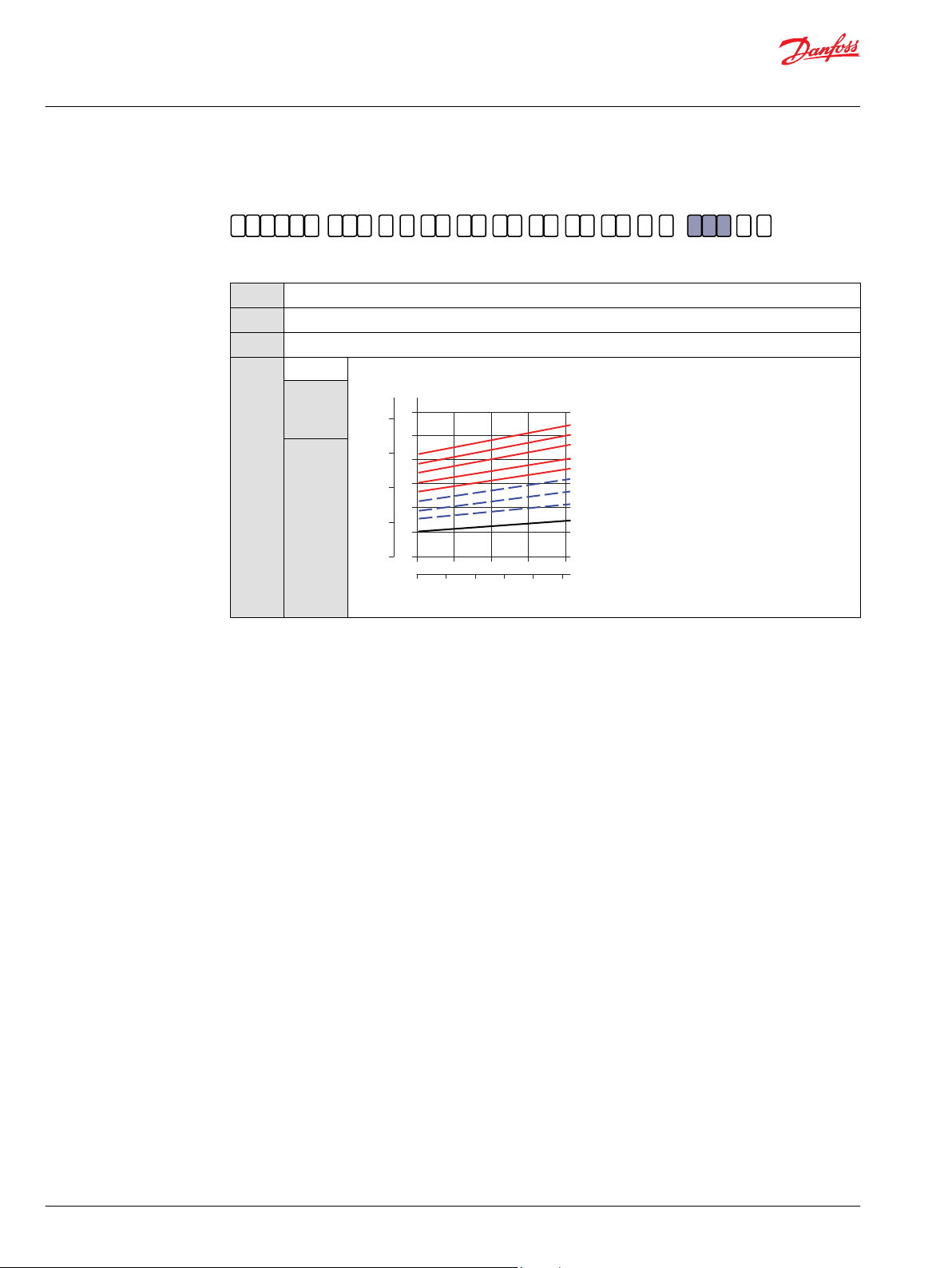

Speed

Maximum speed is the limit recommended by Danfoss for a particular gear motor when operating at

rated pressure. It is the highest speed at which normal life can be expected.

N2 is max. speed related to the RV valve setting ( p2) and type of fan.

Minimum speed is the lowest operating speed limit at which normal life can be expected. The minimum

speed increases according to operating pressure increase.

When operating at higher pressures, a higher minimum speed must be maintained, see below:

Speed versus pressure

Hydraulic Fluids

Ratings and data for SGM2, SGM3 gear motors are guaranteed when the hydraulic system operates with

premium hydraulic fluids without containing oxidation, rust, or foam inhibitors.

These fluids have to work with good thermal and hydrolytic stability to prevent wear, erosion, or

corrosion of internal components. They include:

•

Hydraulic fluids following DIN 51524, part 2 (HLP) and part 3 (HVLP) specifications

•

API CD engine oils conforming to SAE J183

•

M2C33F or G automatic transmission fluids

•

Certain agricultural tractor fluids

Caution

Use only clean fluid in the gear motors and hydraulic circuit. Never mix hydraulic fluids.

©

Danfoss | December 2020 BC318050073602en-000102 | 13

Page 14

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

System Requirements

Temperature and Viscosity

Temperature and viscosity requirements must be concurrently met. Use of petroleum/mineral-based

fluids is highly recommended.

High temperature limits apply at the inlet port of the motors. The motors should run at or below the

maximum continuous temperature.

Minimum (cold start) temperature relates to the physical properties of component materials.

Maximum continuous temperature allowed at which normal life can be expected.

Peak (intermittent) temperature is the overheating temperature that is tolerable by the machine for a

transient/limited time.

Cold oil, generally, doesn’t affect the durability of motors components. It may affect the ability of oil to

flow and transmit power. For this reason, keep the temperature at 16°C [60 °F] above the pour point of

the hydraulic fluid.

Temperature limits

Minimum (cold start) Maximum continuous Peak (intermittent)

-20°C [-4°F] 95°C [203°F] 110°C [230°F]

Minimum viscosity occurs only during brief occasions of maximum ambient temperature and severe

duty cycle operation. It’s the minimum acceptable viscosity to allow normal motor life.

Maximum viscosity occurs only during cold start at very low ambient temperatures. It’s the upper limit

of viscosity that allows the motor to start.

•

Size heat exchangers to keep the fluid within these limits

•

Test regularly to verify that these temperatures and viscosity limits aren’t exceeded

•

Keep the fluid viscosity in the recommended viscosity range for maximum unit efficiency and bearing

life

Fluid viscosity limits, in mm2/s [SUS]

Maximum (cold start) Recommended range Range for high efficiency Minimum

1600 [7273] 12-100 [66-456] 20-50 [97-231] 10 [60]

14 | © Danfoss | December 2020 BC318050073602en-000102

Page 15

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

System Requirements

Filtration

Filters

Use a filter that conforms to Class 22/18/13 of ISO 4406 (or better). It may be on the motor outlet

(discharge filtration) or inlet (pressure filtration).

Selecting a filter

When selecting a filter, please consider:

•

Contaminant ingression rate (determined by factors such as the number of actuators used in the

system)

•

Generation of contaminants in the system

•

Required fluid cleanliness

•

Desired maintenance interval

•

Filtration requirements of other system components

Measure filter efficiency with a Beta ratio (βX). βx ratio is a measure of filter efficiency defined by ISO 4572.

It is the ratio of the number of particles greater than a given diameter (in microns) upstream of the filter

to the number of these particles downstream of the filter.

•

For discharge filtration with controlled reservoir ingression, use a β

•

For pressure filtration, use a filtration with an efficiency of β10 = 75

35-45

= 75 filter

The filtration requirements for each system are unique. Evaluate filtration system capacity by monitoring

and testing prototypes.

Fluid cleanliness level and βX ratio

Fluid cleanliness level (per ISO 4406)

βX ratio (discharge filtration)

βX ratio (pressure or return filtration)

Recommended inlet screen size

Reservoir

The reservoir provides clean fluid, dissipates heat, removes entrained air, and allows fluid volume

changes associated with fluid expansion and cylinder differential volumes. A correctly sized reservoir

accommodates maximum volume changes during all system operating modes. It promotes de-aeration

of the fluid as it passes through, and accommodates a fluid dwell-time between 60 and 180 seconds,

allowing entrained air to escape.

Minimum reservoir capacity depends on the volume required to cool and hold the oil from all retracted

cylinders, allowing for expansion due to temperature changes. A fluid volume of 1 to 3 times the pump

output flow (per minute) is satisfactory. The minimum reservoir capacity is 125% of the fluid volume.

Install the suction line above the bottom of the reservoir to take advantage of gravity separation and

prevent large foreign particles from entering the line. Cover the line with a 100-125 micron screen. The

pump should be below the lowest expected fluid level.

Put the return-line below the lowest expected fluid level to allow discharge into the reservoir for

maximum dwell and efficient deaeration. A baffle (or baffles) between the return and suction lines

promotes deaeration and reduces fluid surges.

Class 22/18/13 or better

β

= 75 and β10 = 2

35-45

β10 = 75

100 – 125 μm [0.004 – 0.005 in]

©

Danfoss | December 2020 BC318050073602en-000102 | 15

Page 16

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

System Requirements

Line sizing

Choose pipe sizes that accommodate minimum fluid velocity to reduce system noise, pressure drops and

overheating in order to maximize system life and performance. Line velocity should not exceed 5.0 m/s

[16.4 ft/s].

Most systems use hydraulic oil containing 10% dissolved air by volume. Over-aeration, or entrained air, is

the result of flow line restrictions, where the dissolved air comes out of solution, or when air is allowed to

leak into the hydraulic circuit. These include inadequate pipe sizes, sharp bends, or elbow fittings,

causing a reduction of flow-line cross-sectional area. This problem will not occur if these circuit

recommendations are followed, rated speed requirements are maintained, and reservoir size and

location are adequate.

Motor Shaft Connection

Allowable radial shaft loads are a function of the load position, load orientation, and operating pressure

of the hydraulic motor. All external shaft loads have an effect on bearing life, and may affect motor

performance.

Shaft options for fan drive gear motors include tapered (1:5 and 1:8) and parallel.

In applications where the external shaft loads cannot be avoided, minimize the impact on the motor by

optimizing the orientation and the magnitude of the load. Danfoss fan drive gear motors are capable of

carryng most manufaturer's plastic fans up to 7.27 kg (16 lb) fan blades for the Group 2 and 11.75 kg (26

lb) fan blades for the Group 3.

For fan drives exceeding these loads, with presence of shock loads, or for slewing (swing) and oscilating

applications such as excavators, wheel loaders, harvesters, and windrowers, please consult your Danfoss

technical representative for the potential usage of an outrigger bearing.

Motor Life

Motor life is a function of speed, system pressure, and other system parameters (such as fluid quality and

cleanliness).

All Danfoss gear motors use hydrodynamic journal bearings that have an oil film maintained between the

gear/shaft and bearing surfaces at all times. If the oil film is sufficiently sustained through proper system

maintenance and operating within recommended limits, long life can be expected.

High pressure impacts motor life. When submitting an application for review, provide machine duty cycle

data that includes percentages of time at various loads and speeds.

B10 life expectancy number is generally associated with rolling element bearings. It does not exist for

hydrodynamic bearings.

Danfoss strongly recommends a prototype testing program to verify operating parameters and their

impact on life expectancy before finalizing any system design.

16 | © Danfoss | December 2020 BC318050073602en-000102

Page 17

G H

J

M N O

/

DC E FA B I K L

/

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 2

Model Code for Group 2 Fan Drive Motors

A – Family

SGM2NC

SGM2GC

SGM2YN

SGM2YL

SGM2VC

B – Frame size and displacement

8,0

011

014

017

019

022

025

Fan Drive Bi-directional Motor; External Axial Drain

Fan Drive Uni-directional Motor; Anti-cavitation Check valve

Fan Drive Motor with Proportional Pressure Valve, Axial Drain

Fan Drive Motor with Proportional Pressure Valve, Radial Drain

Reversible Fan Drive Motor with Proportional Pressure Valve

3

8.4 cm

3

10.8 cm

3

14.4 cm

3

16.8 cm

3

19.2 cm

3

22.8 cm

3

25.2 cm

C – Direction of rotation

B

L

R

Bi-directional (SGM2NC) or Uni-directional (SGM2GC)

Left hand (Counter-clockwise)

Right hand (Clockwise)

D – Project version

A

High temperature sealing, dust protector, rust protected screws

E – Mounting flange

01

02

06

9Y

European 01: Pilot Ø36.5 mm; 4 holes, special for fan drive (without dust protector)

European 02: Pilot Ø80 mm; 4 holes

SAE A pilot Ø82.55 mm; 2 holes

SAE A pilot Ø82.55 mm; 2 holes; outrigger bearing with dust cover

©

Danfoss | December 2020 BC318050073602en-000102 | 17

Page 18

/

/

G H

J

M N ODC E FA B I K L

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 2

Model Code for Group 2 Fan Drive Motors

F – Drive gear

AA

BA

FA

GB

For more details about configuration, see Model Code for Mounting Flange/Drive Gears (Group 2) on page 21.

G – Rear cover

C5

CX

CZ

Y6

Y4

YX

RA

RB

Taper 1:5; M12x1.25 with Key 3

Taper 1:8; M12x1.25 with Key 4

Parallel Ø15 x 36,5 mm; with Key 4x25

Parallel SAE Ø15.875 x 50.8 mm; with Key 4x40

Cast Iron cover: 7/8–14 UNF–2B; In/Out Ports: 9/16–18 UNF–2B Axial Drain (idler gear side)

Cast Iron cover: 7/8–14 UNF–2B; In/Out Ports: 9/16–18 UNF–2B Radial Drain (idler gear side)

Cast Iron cover: 7/8–14 UNF–2B; In/Out Ports: 9/16–18 UNF–2B Radial Drain (shaft side)

Cast Iron cover: 7/8–14 UNF–2B; In Port: 9/16–18 UNF–2B Axial Drain (idler gear side)

Cast Iron cover: 7/8–14 UNF–2B; In Port: 9/16–18 UNF–2B Radial Drain (idler gear side)

Cast Iron cover: 7/8–14 UNF–2B; In Port: 9/16–18 UNF–2B Radial Drain (shaft side)

Proportional PRV Reversing Valve Cover, 12 VDC V03 DEUTSCH connector, Anti-Shock-MakeUp Valve, 7/8–

14 UNF Work Ports, 9/16–18 UNF Radial Drain Port

Proportional PRV Reversing Valve Cover, 24 VDC V03 DEUTSCH connector, Anti-Shock-MakeUp Valve, 7/8–

14 UNF Work Ports, 9/16–18 UNF Radial Drain Port

H – Inlet ports

NN

Without inlet on body

I – Outlet ports

Code Dimensions Ports Code Thread Dimensions

B5 15x35xM6

B6 15x40xM6

B7 20x40xM6

NN Without outlet on body

D7

D9

E5

E6

F4

F5

H5

H7

H8

M22x1.5

M26x1.5

7/8-14UNF

11/16-12UN

1/2 Gas

3/4 Gas

M18 x 1.5 per ISO6149

M22 x 1.5 per ISO6149

M27 x 2 per ISO6149

18 | © Danfoss | December 2020 BC318050073602en-000102

Page 19

G H

J

M N O

/

DC E FA B I K L

/

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 2

Model Code for Group 2 Fan Drive Motors

J – Ports positions and special body

NN

K – Seals

N

W

L – Screws

N

M – Valve setting

NNN

XNN

***

*

For more details see Model Code for Integral Relief Valve Pressure Setting on page 20.

Standard from catalogue

Standard seals for high temperature (11172969)

Standard seals for high temperature without dust cover

Rust protected screws

No valve

Integral relief valve pressure setting

*

N – Type marking

N

A

Z

*

Standard Danfoss marking

Standard Danfoss marking + Customer code

No marking

Special customer marking

O – Marking position

N

A

Standard marking on the top

Special marking position at the bottom

©

Danfoss | December 2020 BC318050073602en-000102 | 19

Page 20

G H J M N O

/

DC E FA B I K L

/

D

Pressure

50

I

Y

W

U

S

Q

O

M

0

l/min80604020

0

0

20

0 8 16124

US gal/min

F

Bypass flow

300

barpsi

200

150

250

100

0

1000

2000

3000

4000

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 2

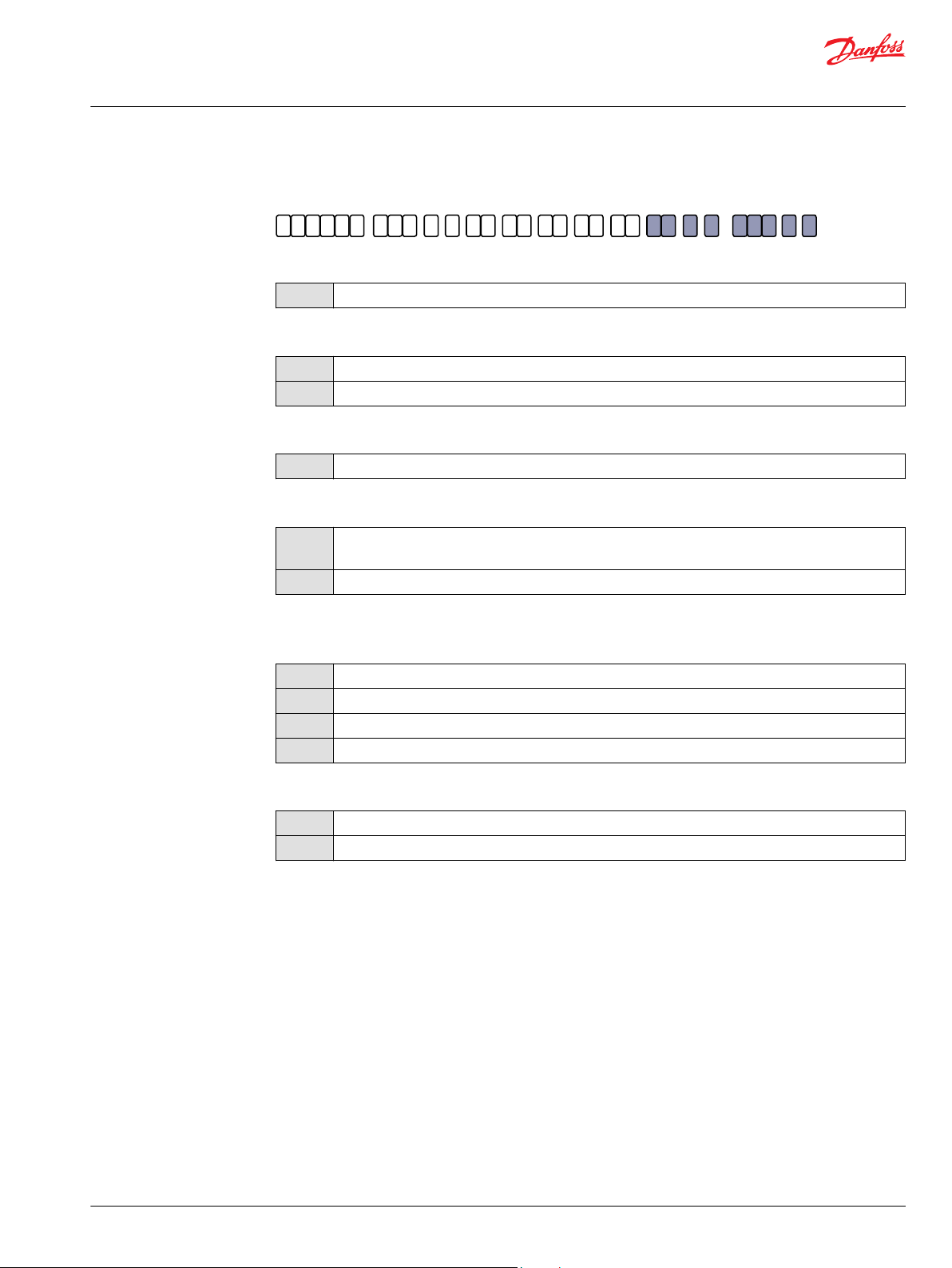

Model Code for Integral Relief Valve Pressure Setting

M – Valve setting

XNN

XA*

XB*

X**

No valve

Standard relief valve with coil voltage 12 VDC, DT connector

Standard relief valve with coil voltage 24 VDC, DT connector

X*F Three color curves represent three types of valves. Each valve is characterized by different

X*I

nominal spring ranges. Select requirements using the graph Pressure vs. Bypass flow below:

X*M

X*O

X*Q

X*S

X*U

X*W

X*Y

20 | © Danfoss | December 2020 BC318050073602en-000102

Page 21

G H J M N O

/

DC E FA B I K L

/

C

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 2

Model Code for Mounting Flange/Drive Gears (Group 2)

Danfoss offers two types of industry standard mounting flange:

•

02 European, Pilot Ø80 mm; 4 holes

•

06 SAE A pilot Ø82.55 mm; 2 holes

Spline configuration is not available for fan drive motors. Other shaft options may exist. Contact your

Danfoss representative for availability. The table below shows order codes for each available mounting

flange and shaft:

Model code sections: E and F

Mounting flange/Drive gear availability with max. torque

Mounting Flange Drive Gear

Code E Description Code F Description Maximum torque

01

European,

Pilot Ø 36.5 mm; 4 holes

Special for fan drive

BA Taper 1:8; M12x1.25 with Key 4 150 N•m

[1328 lbf•in]

FA Parallel Ø15 mm; 36.5 mm long 90 N•m

02

06 SAE A pilot Ø82.55 mm; 2 holes BA Taper 1:8; M12x1.25 with Key 4 150 N•m [1328

9Y Outrigger Bearing with dust cover

SAE A pilot Ø82.55 mm; 2 holes

European

Pilot Ø80 mm; 4 holes

AA Taper 1:5; M12x1.25 with Key 3 140 N•m

GB Parallel Ø15.875 mm; 50.8 mm

long

DB Taper 1:8; M12x1.25 with Key 4 130 N•m

[797 lbf•in]

[1239 lbf•in]

lbf•in]

80 N•m

[708 lbf•in]

[1151 lbf•in]

Caution

Shaft torque capability may limit allowable pressure. Torque ratings assume no external radial loading.

Applied torque must not exceed these limits, regardless of stated pressure parameters. Maximum torque

ratings are based on shaft torsional fatigue strength.

©

Danfoss | December 2020 BC318050073602en-000102 | 21

Page 22

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

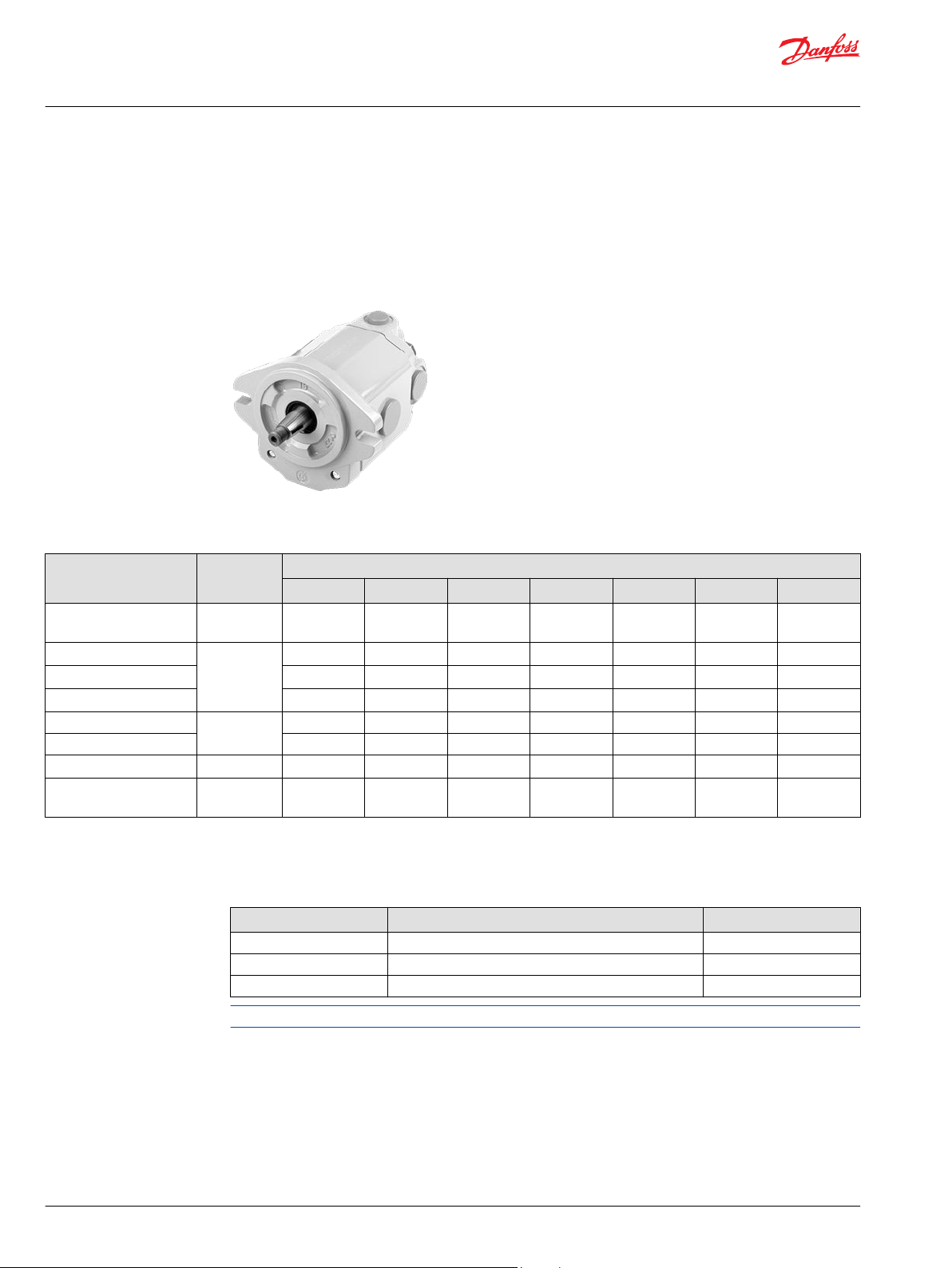

SGM2NC Fan Drive Motors (Group 2)

SGM2NC is Group 2 bidirectional fan drive motor with inlet/outlet on cast iron rear cover and axial drain

line, PLUS+1 compliant.

Group 2 fan drive motors are available in displacements from 8.4 cm3/rev [0.51 in3/rev]to 25 cm3/rev [1.54

in3/rev].

Configurations include European and SAE flanges; taper 1:8, 1:5, and straight shafts Ø15.875 mm [0.62 in].

Outrigger bearing available as SAE A flange with taper shaft 1:8 and European flange with taper shaft 1:5.

SGM2NC Technical Data

Units Frame size

8.0 011 014 017 019 022 025

Displacement

Peak pressure bar [psi] 270 [3916] 270 [3916] 270 [3916] 250 [3626] 230 [3336] 200 [2900] 180 [2610]

Rated pressure 250 [3626] 250 [3626] 250 [3626] 230 [3336] 210 [3046] 180 [2610] 160 [2320]

Back pressure 250 [3626] 250 [3626] 250 [3626] 230 [3336] 210 [3046] 180 [2610] 160 [2320]

Maximum speed

Minimum speed 700 700 700 500 500 500 500

Weight

Moment of inertia of

rotating components

cm3/rev

[in3/rev]

min-1 [rpm]

kg [lb]

x 10-6 kg•m

[x 10-6 lbf•ft2]

8.4 [0.51] 10.8 [0.66] 14.4 [0.88] 16.8 [1.03] 19.2 [1.17] 22.8 [1.39] 25.2 [1.54]

3500 3500 3500 3500 3200 3200 3200

3.2 [7.05] 3.75 [8.26] 3.9 [8.60] 4.05 [8.93] 4.15 [9.15] 4.3 [9.48] 4.4 [9.70]

2

32.4 [796] 38.4 [911] 47.3 [1122] 53.3 [1265] 59.2 [1405] 68.1 [1616] 74.1 [1758]

SGM2NC Model Code Examples

Model code examples with maximum shaft torque

Flange/shaft Model code example Maximum shaft torque

02AA SGM2NC/011BA02AAC5NNNNNNNN/NNNNN 140 N•m [1239 lb•in]

06BA SGM2NC/011BA06BAC5NNNNNNNN/NNNNN 150 N•m [1328 lb•in]

06GB SGM2NC/011BA06GBC5NNNNNNNN/NNNNN 80 N•m [708 lb•in]

For further details on ordering, see Model Code for Group 2 Fan Drive Motors on page 17.

22 | © Danfoss | December 2020 BC318050073602en-000102

Page 23

26

Inlet/Outlet

[1.02 ±0.04 ]

[0.62 ±0.02 ]

89 max

[3.504 max.]

92 [3.622] max.

12.5

[ 0.49 ]

A

15.7

Ø 80

[Ø3.15 ]

-0.002

-0.004

-0.06

-0.106

7.2

±1

±1

±0.039

±0.25

±0.5

±1.0 [±0.04]

A

±1[±0.04]

B

+1.5 [+0.059] max

[0.28 ±0.01]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

120 [4.72] max.

103 [4.055] max.

(100 [3.94])

65.5

[2.59]

72

[2.83]

34.5

[1.36]

9

+0.5

0

[0.35 ]

+0.02

0

36.2 max.

[1.425 max.]

67.6 max.

[2.66 max.]

Inlet/Outlet

Drain

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2NC Fan Drive Motors (Group 2)

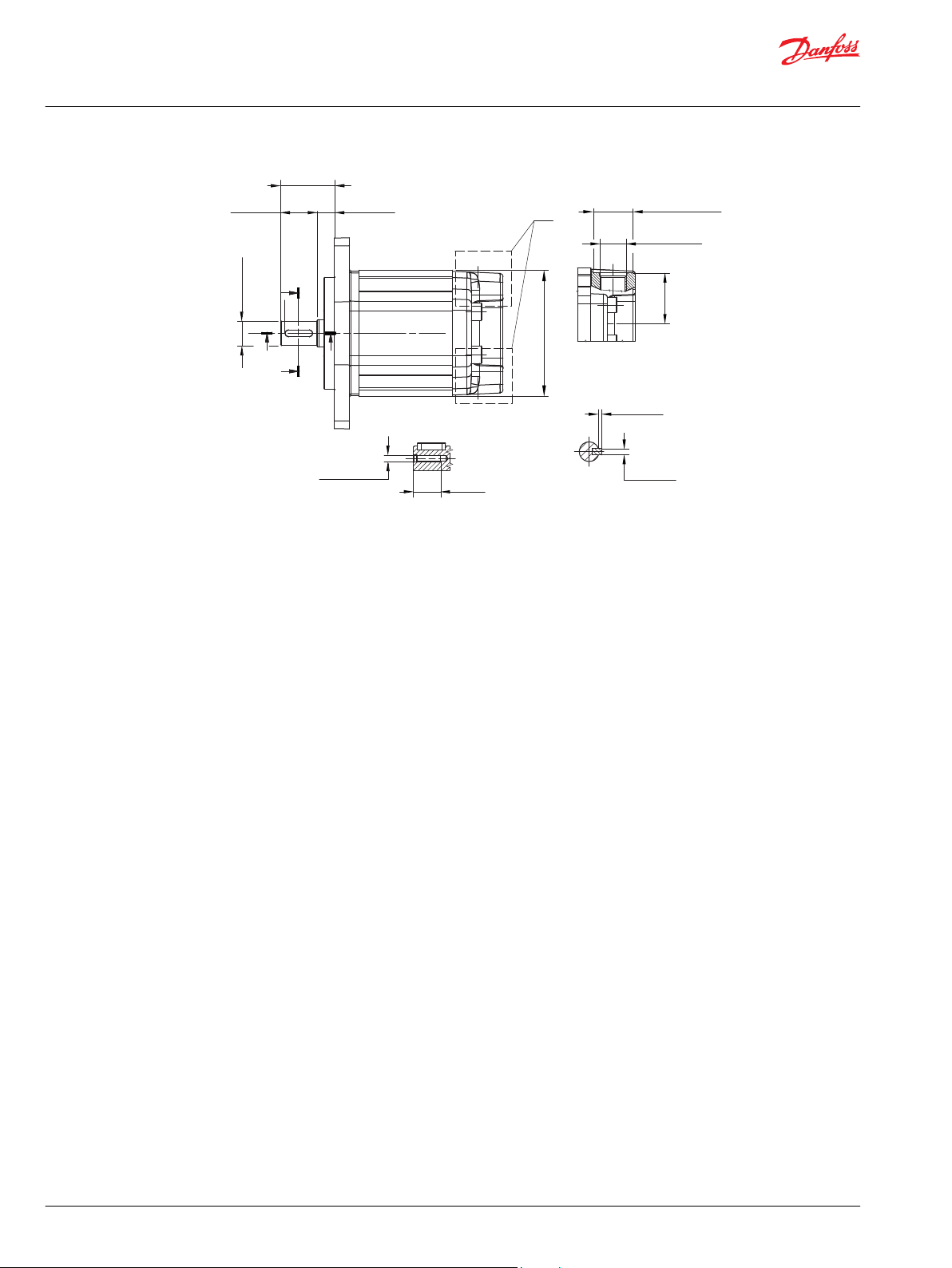

SGM2NC 02AA Dimensions

SGM2NC – 02AA dimensions

Dimension Frame size

A

©

Danfoss | December 2020 BC318050073602en-000102 | 23

B

Inlet/Outlet

Drain port

[3.86]

118.5

[4.66]

8,0 011 014 017 019 022 025

98

102

[4.01]

122.5

[4.83]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

108

[4.25]

128.5

[5.05]

112

[4.41]

132.5

[5.22]

116

[4.57]

136.5

[5.37]

122

[4.80]

142.5

[5.61]

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

126

[4.96]

146.5

[5.77]

Page 24

M12x1.25-6g

11.5 [0.453] min.

full thread

13 ±0.5

[0.51 ±0.02]

3.7 max

[0.14 max]

5.7 ±0.75

[0.22 ±0.029]

16.5 ±0.75

[0.65 ±0.029]

A-A

Detail ‘P’

P

Ø 0.35

X

90 ±0.25

[3.54 ±0.01]

[0.118 ]

3

0

-0.025

0

-0.001

[0.354 ]

9

+0.3

-0.1

+0.012

-0.004

[Dia 0.687]

Ø 17.46

1: 5

A

D

A

38 ±1

[1.5 ±0.04]

(19.3)

([0.76])

Inlet/Outlet

Detail ‘D’

39.5 ±0.25

[1.555 ±0.01]

Ø 34 [Dia 1.34]

Depth 2.4 [0.09] max

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2NC Fan Drive Motors (Group 2)

24 | © Danfoss | December 2020 BC318050073602en-000102

Page 25

26

Drain: 9/16–18UNF–2B

(SAE J1926/1 O-Ring boss)

12.7 [0.5] min. full thread

[1.02 ±0.04 ]

[0.62 ±0.02 ]

89 max

[3.504 max.]

12

[ 0.47 ]

A

A

15.7

6.35

±1

±1

±0.04

-0.5

0

-0.02

0

±0.5

±1.0 [±0.04]

±1 [±0.04]

B

+1.5 [+0.06] max.

[0.25 ]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

36.2 max.

[1.43] max.

19.5 max.

[0.77] max.

R 12.7 max.

[0.5] max.

R 48 max.

[1.89] max.

115.5 max.

[4.55] max.

67.6 max.

[2.66] max.

103 max.

[4.055] max.

11–11.6

[0.43–0.46]

Ø 82.55

[Ø3.25 ]

0

+0.05

0

+0.002

132 max

[5.2 max.]

106.38

[4.19]

Inlet/Outlet: 7/8–14UNF–2B

(SAE J1926/1 O-Ring boss)

16.7 [0.66] min. full thread

Inlet/Outlet: 7/8–14UNF–2B

(SAE J1926/1 O-Ring boss)

16.7 [0.66] min. full thread

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2NC Fan Drive Motors (Group 2)

SGM2NC 06BA Dimensions

©

Danfoss | December 2020 BC318050073602en-000102 | 25

SGM2NC – 06BA dimensions

Dimension Frame size

A

B

Inlet/Outlet

Drain port

8,0 011 014 017 019 022 025

95.5

[3.76]

116

[4.57]

99.5

[3.92]

120

[4.72]

105.5

[4.15]

126

[4.96]

109.5

[4.31]

130

[5.11]

113.5

[4.47]

134

[5.28]

119.5

[4.70]

140

[5.51]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

123.5

[4.86]

144

[5.67]

Page 26

Inlet/Outlet

M12x1.25-6g

11 [0.433] min.

full thread

12.5 ±0.5

[0.49 ±0.02]

6.3 ±0.75

[0.25 ±0.029]

17 ±0.75

[0.67 ±0.029]

A-A

P

Ø 0.35

X

90 ±0.25

[3.54 ±0.01]

[0.16 ]

Ø 34 [Dia 1.34]

Depth 2.4 [0.39] max

4

5.7 max.

[0.22 max.]

0

-0.03

0

-0.0012

[0.37 ]

9.5

+0.15

-0.25

+0.006

-0.0098

[Dia 0.687 ]

Ø 17.46

39.5 ±0.25

[1.56 ±0.01]

1: 8

A

D

A

40.5 ±1

[1.59 ±0.04]

Detail ‘P’

Detail ‘D’

(21.7)

([0.85])

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2NC Fan Drive Motors (Group 2)

26 | © Danfoss | December 2020 BC318050073602en-000102

Page 27

26

Drain

[1.02 ±0.04 ]

[0.62 ±0.02 ]

89 max

[3.504 max.]

12

[ 0.47 ]

A

A

15.7

6.35

±1

±1

±0.04

-0.5

0

-0.02

0

±0.5

±1.0 [±0.04]

±1 [±0.04]

B

+1.5 [+0.06] max.

[0.25 ]

R 0.8 [0.03] max.

[0.62 ±0.02 ]

15.7 ±0.5

36.2 max.

[1.43] max.

19.5 max.

[0.77]

R 12.7 max.

[0.5]

R 48 max.

[1.89]

115.5 max.

[4.55]

67.6 max.

[2.66] max.

103 max.

[4.055] max.

11–11.6

[0.43–0.46]

Ø 82.55

[Ø3.25 ]

0

+0.05

0

+0.002

132 max

[5.2 max.]

106.38

[4.19]

Inlet/Outlet

Inlet/Outlet

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2NC Fan Drive Motors (Group 2)

SGM2NC 06GB Dimensions

SGM2NC – 06BA dimensions

Dimension Frame size

A

B

Inlet/Outlet

Drain port

8,0 011 014 017 019 022 025

95.5

[3.76]

116

[4.57]

99.5

[3.92]

120

[4.72]

105.5

[4.15]

126

[4.96]

109.5

[4.31]

130

[5.11]

113.5

[4.47]

134

[5.28]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

119.5

[4.70]

140

[5.51]

123.5

[4.86]

144

[5.67]

©

Danfoss | December 2020 BC318050073602en-000102 | 27

Page 28

Inlet/Outlet

D

Detail ‘D’

0

-0.25

[0.62 ]

39.5

±0.25

±0.01

Ø 15.875

0

-0.01

[Dia 0.625 ]

7.9 ±0.75

[0.51 ±0.029]

50.8 ±0.25

[2.0 ±0.01]

58.0 ±1

[2.31 ±0.04]

[0.16 ]

-0.001

4

-0.03

17.475–17.729

[0.688–0.698]

Ø 34 [Dia 1.34]

Depth 2.4 [0.39] max.

M6 - 6H

16 min.

[0.63 min.]

90

[3.54 ±0.01 ]

B

B

A

A

A-A

B-B

±0.25

Ø 0.35

X

Ø 0.1 / 25.4

K

0

0

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2NC Fan Drive Motors (Group 2)

28 | © Danfoss | December 2020 BC318050073602en-000102

Page 29

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN is Group 2 fan drive motor with inlet on rear cover and outlet on body. Integrated proportional

relief valve, anti-cavitation check valve and axial drain line.

Group 2 fan drive motors are available in displacements from 8.4 cm3/rev [0.51 in3/rev]to 25 cm3/rev [1.54

in3/rev].

Configurations include European and SAE flanges; taper 1:8, 1:5, and straight shafts Ø15.875 mm [0.62 in].

Outrigger bearing available as SAE A flange with taper shaft 1:8 and European flange with taper shaft 1:5.

SGM2YN Technical Data

Units Frame size

8.0 011 014 017 019 022 025

Displacement

Peak pressure

Rated pressure 250 [3626] 250 [3626] 250 [3626] 230 [3336] 210 [3046] 180 [2610] 160 [2320]

Back pressure

Maximum speed

Minimum speed 700 700 700 500 500 500 500

Weight

Moment of inertia of

rotating components

cm3/rev

[in3/rev]

bar [psi]

min-1 [rpm]

kg [lb]

x 10-6 kg•m

[x 10-6 lbf•ft2]

8.4 [0.51] 10.8 [0.66] 14.4 [0.88] 16.8 [1.03] 19.2 [1.17] 22.8 [1.39] 25.2 [1.54]

270 [3916] 270 [3916] 270 [3916] 250 [3626] 230 [3336] 200 [2900] 180 [2610]

150 [2176] 150 [2176] 150 [2176] 150 [2176]

3500 3500 3500 3500 3200 3200 3200

4.73 [10.43] 4.83 [10.65] 5.03 [11.1] 5.18 [11.42] 5.23 [11.53] 5.33 [11.75] 5.53 [12.2]

2

32.4 [796] 38.4 [911] 47.3 [1122] 53.3 [1265] 59.2 [1405] 68.1 [1616] 74.1 [1758]

130 [1885] 100 [1450] 100 [1450]

SGM2YN Model Code Examples

Model code examples with maximum shaft torque

Flange/shaft Model code example Maximum shaft torque

02AA SGM2YN/014LA02AAY6NNE5NNNN/XNNNN 140 N•m [1239 lb•in]

06BA SGM2YN/025RA06BAY6NNE6NNNN/XNNNN 150 N•m [1328 lb•in]

06GB SGM2YN/022L406GBY6NNE6NNNN/XNNNN 80 N•m [708 lb•in]

For further details on ordering, see Model Code for Group 2 Fan Drive Motors on page 17.

©

Danfoss | December 2020 BC318050073602en-000102 | 29

Page 30

156 [6.14] max

168 [6.61] max

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN Electric Proportional Relief Valve Data

Electric Proportional Relief Valve use DEUTSCH DT 04-2P connector with protection rate IP 69K per DIN

40050.

Relief valve – Standard

Relief valve with flat curve

Description Standard Flat Curve

PWM frequency range 100 to 200 Hz 100 to 250 Hz

Supply 0 to 1.1 A @ 12 V

Supply 0 to 0.55 A @ 24 V

Coil resistance of 7.2 Ω @ 20 °C [68 °F] Coil resistance of 6.4 Ω @ 20 °C [68 °F]

DC

Coil resistance of 28.8 Ω @ 20 °C [68 °F] Coil resistance of 26.2 Ω @ 20 °C [68 °F]

DC

30 | © Danfoss | December 2020 BC318050073602en-000102

Page 31

Inlet

Outlet

26

F

Drain: 9/16–18UNF–2B

(SAE J1926/1 O-Ring boss)

12.7 [0.5] min. full thread

G M6-6H

12 [0.47] min.

full thread

Connector: Deutsch DT 04-2P

Voltage: 12V DC (Current 1.1 A)

24V DC (Current 0.55 A)

PWM 100-200 Hz

[1.02 ±0.04 ]

[0.62 ±0.02 ]

89 max

[3.504 max.]

92 max

[3.622 max.]

156 max

[6.142 max.]

12.5

[ 0.49 ]

B

A

D

15.7

Ø 80

[Ø3.15 ]

-0.002

-0.004

-0.06

-0.106

7.2

±1

±1

±0.039

±0.25

±0.5

±0.5 [±0.02]

E

+0.5

0

±1[±0.04]

B

±1[±0.04]

C

+1.5 [+0.059] max

[0.28 ±0.01]

±0.2 [±0.008]

R 0.8 max.

[0.03 max.]

45

o

[0.62 ±0.02 ]

15.7

±0.5

120 [4.72] max.

103 [4.055] max.

(100 [3.94])

65.5

[2.59]

72

[2.83]

34.5

[1.36]

9

+0.5

0

[0.35 ]

+0.02

0

36.2 max.

[1.425 max.]

67.6 max.

[2.66 max.]

+0.02

0

][

Valve type: PRV10–IS2

M12x1.25-6g

11.5 [0.453] min.

full thread

13 ±0.5

[0.51 ±0.02]

3.7 max

[0.14 max]

5.7 ±0.75

[0.22 ±0.029]

16.5 ±0.75

[0.65 ±0.029]

A-A

Detail ‘P’

P

90 ±0.25

[3.54 ±0.01]

[0.118 ]

3

0

-0.025

0

-0.001

[0.354 ]

9

+0.3

-0.1

+0.012

-0.004

[Dia 0.687]

Ø 17.46

A

H

A

38 ±1

[1.5 ±0.04]

(19.3)

([0.76])

Inlet D

(SAE J1926/1 O-Ring boss)

16.7 [0.66] min. full thread

Detail ‘H’

39.5 ±0.25

[1.555 ±0.01]

Ø 34 [Dia 1.34]

Depth 5 [0.2] max

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN 02AA Dimensions

©

Danfoss | December 2020 BC318050073602en-000102 | 31

Page 32

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN – 02AA dimensions

Dimension Frame size

8,0 011 014 017 019 022 025

A

B

C

D

E

F

G

Drain port

43.1 [1.70] 47.5 [1.87] 47.5 [1.87] 47.5 [1.87] 47.5 [1.87] 55.0 [2.17] 64.5 [2.54]

98 [3.86] 102 [4.01] 108 [4.25] 112 [4.41] 116 [4.57] 122 [4.80] 126 [4.96]

118.5

[4.66]

122.5

[4.83]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

15 [0.59] 20 [0.79]

35 [0.38] 40 [0.57]

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

128.5

[5.05]

M6–6H; 12 [0.47] min. full thread

132.5

[5.22]

136.5

[5.37]

142.5

[5.61]

146.5

[5.77]

32 | © Danfoss | December 2020 BC318050073602en-000102

Page 33

Inlet D

26

Outlet E/F

Drain port

Valve Type: PRV10-IS2

[1.02 ±0.04 ]

[0.62 ±0.02 ]

89 max

[3.504 max.]

12

[ 0.47 ]

B

A

15.7

6.35

±1

±1

±0.04

-0.5

0

-0.02

0

±0.5

±0.5 [±0.02]

±1 [±0.04]

C

+1.5 [+0.06] max.

[0.25 ]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

36.2 max.

[1.43] max.

19.5 max.

[0.77] max.

R 12.7 max.

[0.5] max.

R 48 max.

[1.89] max.

115.5 max.

[4.55] max.

67.6 max.

[2.66] max.

103 max.

[4.055] max.

11–11.6

[0.43–0.46]

Ø 82.55

[Ø3.25 ]

0

+0.05

0

+0.002

132 max

[5.2 max.]

156 max

[6.142 max.]

106.38

[4.19]

Connector: Deutsch DT 04-2P

Voltage: 12V DC (Current: 1.1 A)

24V DC (Current: 0.55 A)

PWM: 100–200 Hz

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN 06BA Dimensions

A

B

C

D

8,0 011 014 017 019 022 025

47

[1.85]

95.5

[3.76]

116

[4.57]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66]

49

[1.93]

99.5

[3.92]

120

[4.72]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

SGM2YN – 06GB dimensions

Dimension Frame size

E/F

Drain

52

[2.05]

105.5

[4.15]

126

[4.96]

54

[2.13]

109.5

[4.31]

130

[5.11]

56

[2.21]

113.5

[4.47]

134

[5.28]

59

[2.32]

119.5

[4.70]

140

[5.51]

61

[2.40]

123.5

[4.86]

144

[5.67]

1–1/16–12UN–2B (SAE J1926/1, O-Ring

boss); 19 [0.75] min. full thread

©

Danfoss | December 2020 BC318050073602en-000102 | 33

Page 34

Inlet D

(SAE J1926/1 O-Ring boss)

16.7 [0.66] min. full thread

M12x1.25-6g

11 [0.433] min.

full thread

12.5 ±0.5

[0.49 ±0.02]

6.3 ±0.75

[0.25 ±0.029]

17 ±0.75

[0.67 ±0.029]

A-A

P

Ø 0.35

X

90 ±0.25

[3.54 ±0.01]

[0.16 ]

Ø 34 [Dia 1.34]

Depth 5 [0.2] max

4

5.7 max.

[0.22 max.]

0

-0.03

0

-0.0012

[0.37 ]

9.5

+0.15

-0.25

+0.006

-0.0098

[Dia 0.687 ]

Ø 17.46

39.5 ±0.25

[1.56 ±0.01]

1: 8

A

H

A

40.5 ±1

[1.59 ±0.04]

Detail ‘P’

Detail ‘H’

(19.3)

([0.76])

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

34 | © Danfoss | December 2020 BC318050073602en-000102

Page 35

Inlet D

26

Outlet E/F

Drain port

Valve Type: PRV10-IS2

[1.02 ±0.04 ]

[0.62 ±0.02 ]

89 max

[3.504 max.]

12

[ 0.47 ]

B

A

15.7

6.35

±1

±1

±0.04

-0.5

0

-0.02

0

±0.5

±0.5 [±0.02]

±1 [±0.04]

C

+1.5 [+0.06] max.

[0.25 ]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

36.2 max.

[1.43] max.

19.5 max.

[0.77] max.

R 12.7 max.

[0.5] max.

R 48 max.

[1.89] max.

115.5 max.

[4.55] max.

67.6 max.

[2.66] max.

103 max.

[4.055] max.

11–11.6

[0.43–0.46]

Ø 82.55

[Ø3.25 ]

0

+0.05

0

+0.002

132 max

[5.2 max.]

156 max

[6.142 max.]

106.38

[4.19]

Connector: Deutsch DT 04-2P

Voltage: 12V DC (Current: 1.1 A)

24V DC (Current: 0.55 A)

PWM: 100–200 Hz

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN 06GB Dimensions

SGM2YN – 06GB dimensions

Dimension Frame size

A

B

C

D

E/F

Drain

8,0 011 014 017 019 022 025

47

[1.85]

95.5

[3.76]

116

[4.57]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66]

49

[1.93]

99.5

[3.92]

120

[4.72]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

52

[2.05]

105.5

[4.15]

126

[4.96]

54

[2.13]

109.5

[4.31]

130

[5.11]

56

[2.21]

113.5

[4.47]

134

[5.28]

59

[2.32]

119.5

[4.70]

140

[5.51]

61

[2.40]

123.5

[4.86]

144

[5.67]

1–1/16–12UN–2B (SAE J1926/1, O-Ring

boss); 19 [0.75] min. full thread

©

Danfoss | December 2020 BC318050073602en-000102 | 35

Page 36

0

-0.25

Ø 15.875

0

-0.01

[Dia 0.625 ]

7.9 ±0.75

[0.51 ±0.029]

50.8 ±0.25

[2.0 ±0.01]

58.0 ±1

[2.31 ±0.04]

[0.16 ]

-0.001

4

-0.03

17.475–17.729

[0.688–0.698]

M6 - 6H

16 min.

[0.63 min.]

B

B

A

P

A

A-A

B-B

0

0

5.7 max.

[0.224 max.]

Detail ‘P’

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

36 | © Danfoss | December 2020 BC318050073602en-000102

Page 37

B

A

Taper 1:8

+0.15

-0.25

0

-0.03

35 ±0.1

[1.378±0.004]

6

[0.236]

44 ±0.75

[1.732 ±0.03]

4

9.5

[0.16 ]

-0.001

0

[0.374 ]

+0.006

-0.010

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2YN Fan Drive Motors (Group 2)

SGM2YN Outrigger Bearing Dimensions

Dimension Frame size

8,0 011 014 017 019 022 025

A 95.5 [3.76] 99.5 [3.92] 105.5 [4.15] 109.5 [4.31] 113.5 [4.47] 119.5 [4.70] 123.5 [4.86]

B 116 [4.66] 120 [4.83] 126 [5.05] 130 [5.22] 134 [5.37] 140 [5.61] 144 [5.77]

©

Danfoss | December 2020 BC318050073602en-000102 | 37

Page 38

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

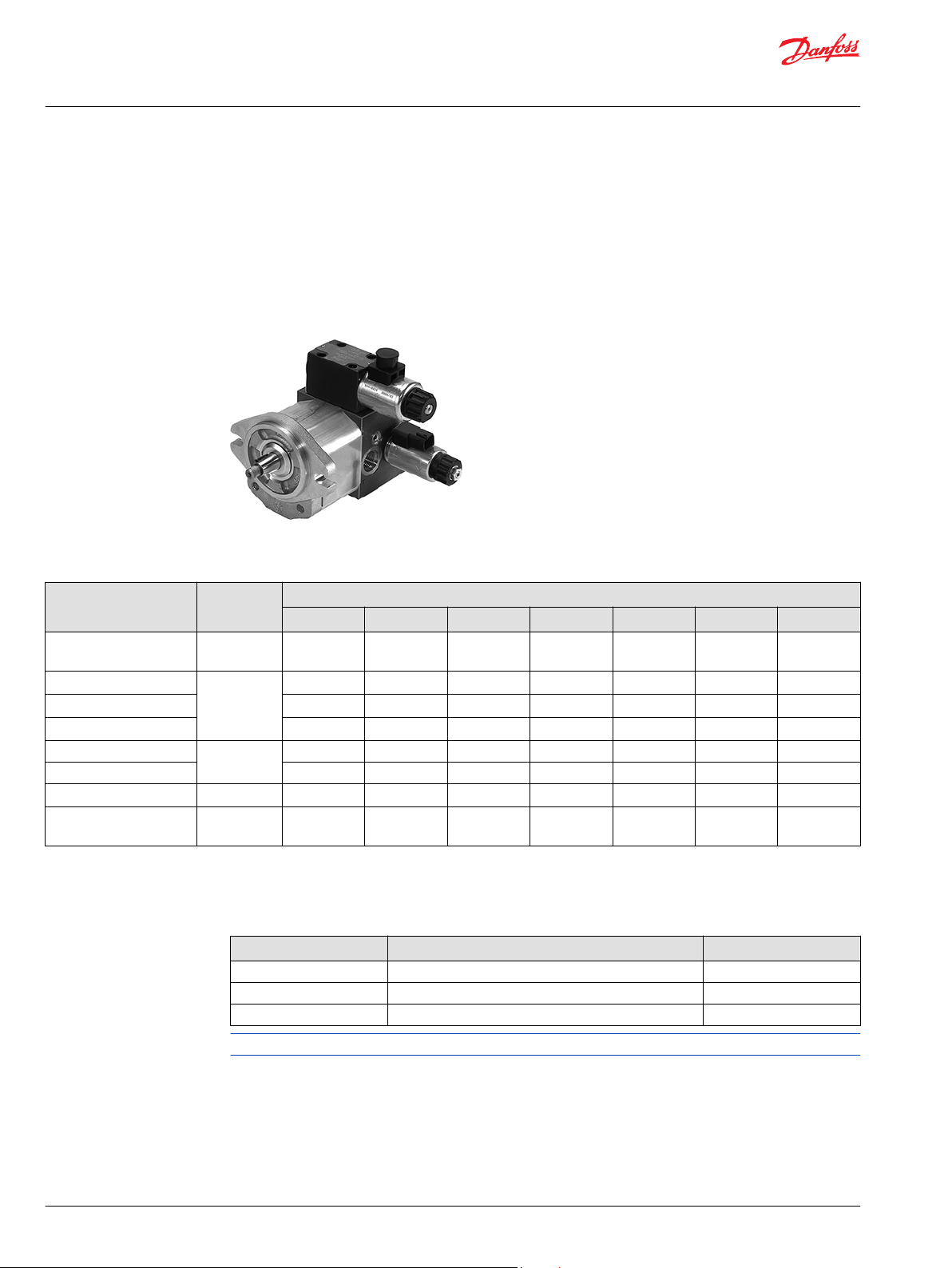

SGM2VC Fan Drive Motors (Group 2)

SGM2VC is Group 2 fan drive motor with integrated DCV valve for “reverse function”, anti-shock and

proportional relief valve. Inlet/outlet and radial drain line are on cast iron rear cover.

Displacement range from 8.4 up to 25.2 cm3/rev [from 0.51 up to 1.54 in3/rev].

Configurations include European and SAE flanges; taper 1:8, taper 1:5 and parallel Ø15.875 mm [Dia 0.62

in] shafts.

Outrigger bearing available as SAE A flange with taper shaft 1:8 and European flange with taper shaft 1:5.

SGM2VC 9YBA Outrigger bearing with dust cover

SGM2VC Technical Data

Units Frame size

8.0 011 014 017 019 022 025

Displacement

Peak pressure

Rated pressure 250 [3626] 250 [3626] 250 [3626] 230 [3336] 210 [3046] 180 [2610] 160 [2320]

Back pressure

Maximum speed

Minimum speed 700 700 700 500 500 500 500

Weight

Moment of inertia of

rotating components

cm3/rev

[in3/rev]

bar [psi]

min-1 [rpm]

kg [lb]

x 10-6 kg•m

[x 10-6 lbf•ft2]

8.4 [0.51] 10.8 [0.66] 14.4 [0.88] 16.8 [1.03] 19.2 [1.17] 22.8 [1.39] 25.2 [1.54]

270 [3916] 270 [3916] 270 [3916] 250 [3626] 230 [3336] 200 [2900] 180 [2610]

150 [2176] 150 [2176] 150 [2176] 150 [2176]

3500 3500 3500 3500 3200 3200 3200

8.41 [18.54] 8.96 [19.75] 9.11 [20.08] 9.26 [20.41] 9.36 [20.63] 9.51 [20.96] 9.61 [21.19]

2

32.4 [796] 38.4 [911] 47.3 [1122] 53.3 [1265] 59.2 [1405] 68.1 [1616] 74.1 [1758]

130 [1885] 100 [1450] 100 [1450]

SGM2VC Model Code Examples

Model code examples with maximum shaft torque

Flange/shaft Model code example Maximum shaft torque

02AA SGM2VC/014LA02AARANNNNNNNN/XASNN 140 N•m [1239 lb•in]

06BA SGM2VC/014LA06BARANNNNNNNN/XASNN 150 N•m [1328 lb•in]

06GB SGM2VC/014RA06GBRANNNNNNNN/SASNN 80 N•m [708 lb•in]

For further details on ordering, see Model Code for Group 2 Fan Drive Motors on page 17.

38 | © Danfoss | December 2020 BC318050073602en-000102

Page 39

159 max

170 max

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

SGM2VC Electric Proportional Relief and D03 Directional Valves Data

Electric Proportional Relief Valve and Directional Valve (D03) use DEUTSCH DT 04-2P connector with

protection rate IP 69K per DIN 40050.

Relief and directional valve – Standard

Relief valve and D03 directional valve with flat curve

Description Standard Flat Curve

PWM frequency range 100 to 200 Hz 100 to 250 Hz

Supply 0 to 1.1 A @ 12 V

Supply 0 to 0.55 A @ 24 V

Coil resistance of 7.2 Ω @ 20 °C [68 °F] Coil resistance of 6.4 Ω @ 20 °C [68 °F]

DC

Coil resistance of 28.8 Ω @ 20 °C [68 °F] Coil resistance of 26.2 Ω @ 20 °C [68 °F]

DC

©

Danfoss | December 2020 BC318050073602en-000102 | 39

Page 40

Outlet

Inlet

88.5 max

[3.48 max.]

92 max

[3.622 max.]

159 max

[6.26 max.]

109 max

[4.29 max.]

12.5

[ 0.49 ]

Ø 80

[Ø3.15 ]

-0.002

-0.004

-0.06

-0.106

7.2

±1

±0.25

B

±1 [±0.04]

[0.28 ±0.01]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

25.6 ±0.5

[1 ±0.02]

120 [4.72] max.

100.5 [3.96] max.

76 max

[2.99] max.

36 max

[1.42] max.

67 max

[2.64] max.

(100 [3.94])

65.5

[2.59]

72

[2.83]

34.5

[1.36]

9

0.5

0

[0.35 ]

0.02

0

±0.039

A

±1 [±0.04]

C

±1.5 [±0.06] max

[0.949 ±0.02 ]

24.1

±0.5

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

SGM2VC 02AA Dimensions

SGM2VC – 02AA dimensions

Dimension Frame size

A

B

C

D

Inlet/Outlet

Drain port

8,0 011 014 017 019 022 025

97.5 [3.84] 101.5 [4.0] 107.5 [4.23] 111.5 [4.39] 115.5 [4.55] 121.5 [4.78] 125.5 [4.94]

114 [4.49] 118 [4.65] 124 [4.88] 128 [5.04] 132 [5.20] 138 [5.43] 142 [5.59]

160 [6.30] 164 [6.46] 170 [6.69] 174 [6.85] 178 [7.0] 184 [7.24] 188 [7.40]

98.5 [3.88] 102.5 [4.04] 108.5 [4.27] 112.5 [4.43] 116.5 [4.59] 122.5 [4.82] 126.5 [4.98]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

40 | © Danfoss | December 2020 BC318050073602en-000102

Page 41

M12x1.25-6g

11.5 [0.453] min.

full thread

13 ±0.5

[0.51 ±0.02]

3.7 max

[0.14 max]

5.7 ±0.75

[0.22 ±0.029]

16.5 ±0.75

[0.65 ±0.029]

A-A

Detail ‘P’

P

90 ±0.25

[3.54 ±0.01]

[0.118 ]

3

0

-0.025

0

-0.001

[0.354 ]

9

+0.3

-0.1

+0.012

-0.004

[Dia 0.687]

Ø 17.46

38 ±1

[1.5 ±0.04]

(19.3)

([0.76])

A

A

Drain

D

±1 [±0.04]

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

©

Danfoss | December 2020 BC318050073602en-000102 | 41

Page 42

24.1±0.5

[0.949 ±0.02]

B

±1 [±0.04]

132 max

[5.2 max.]

106.38

[4.19]

R 48 max.

[1.89] max.

Outlet

Inlet

88.5 max

[3.48 max.]

159 max

[6.26 max.]

109 max

[4.29 max.]

12 ±1

[ 0.47 ]

Ø 82.55

[Dia 3.25 ]

-0.002

0

0

-0.05

6.35

-0.5

-0.02

0

0

[0.25 ]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

25.6 ±0.5

[1 ±0.02]

100.5 [3.96] max.

76 max

[2.99] max.

36 max

[1.42] max.

67 max

[2.64] max.

±0.039

A

±1 [±0.04]

C

±1.5 [±0.06] max

(R 12.7 max.)

[0.5] max.

19.5 max.

[0.77] max.

115.5 max.

[4.55] max.

11–11.6

[0.43–0.46]

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

SGM2VC 06BA Dimensions

SGM2VC – 06BA dimensions

Dimension Frame size

A

B

C

D

Inlet/Outlet

Drain port

8,0 011 014 017 019 022 025

95 [3.74] 99 [3.9] 105 [4.13] 109 [4.29] 113 [4.45] 119 [4.69] 123 [4.84]

114.4 [4.45] 115.4 [4.54] 121.4 [4.78] 125.4 [4.94] 129.4 [5.09] 135.4 [5.33] 139.4 [5.49]

157.4 [6.20] 161.4 [6.35] 167.4 [6.59] 171.4 [6.75] 175.4 [6.90] 181.4 [7.14] 185.4 [7.30]

96 [3.78] 100 [3.94] 106 [4.17] 110 [4.33] 114 [4.49] 120 [4.72] 124 [4.88]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

42 | © Danfoss | December 2020 BC318050073602en-000102

Page 43

Ø 17.46

[Dia 0.687]

6.3±0.75

[0.248±0.029]

(21.7)

[0.85]

12.5 ±0.5

[0.49 ±0.02]

17±0.75

[0.669±0.029]

90 ±0.25

[3.54 ±0.01]

40.5 ±1

[1.594 ±0.04]

[0.16 ]

-0.001

4

-0.03

A

P

A

A-A

D

0

0

[0.374 ]

+0.006

-0.010

9.5

+0.15

-0.25

±1 [±0.04]

5.5 max.

[0.217 max.]

Detail ‘P’

Drain

M12x1.25-6g

11.5 [0.45]

min. full thread

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

©

Danfoss | December 2020 BC318050073602en-000102 | 43

Page 44

24.1±0.5

[0.949 ±0.02]

B

±1 [±0.04]

19.5 max.

[0.77] max.

(R 12.7 max.)

[0.5] max.

115.5 max.

[4.55] max.

11–11.6

[0.43–0.46]

132 max

[5.2 max.]

106.38

[4.19]

R 48 max.

[1.89] max.

Outlet

Inlet

88.5 max

[3.48 max.]

159 max

[6.26 max.]

109 max

[4.29 max.]

12 ±1

[ 0.47 ]

Ø 82.55

[Dia 3.25 ]

-0.002

0

0

-0.05

6.35

-0.5

-0.02

0

0

[0.25 ]

R 0.8 max.

[0.03 max.]

[0.62 ±0.02 ]

15.7

±0.5

25.6 ±0.5

[1 ±0.02]

100.5 [3.96] max.

76 max

[2.99] max.

36 max

[1.42] max.

67 max

[2.64] max.

±0.039

A

±1 [±0.04]

C

±1.5 [±0.06] max

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

SGM2VC 06GB Dimensions

SGM2VC – 06GB dimensions

Dimension Frame size

A

B

C

D

Inlet/Outlet

Drain port

8,0 011 014 017 019 022 025

95 [3.74] 99 [3.9] 105 [4.13] 109 [4.29] 113 [4.45] 119 [4.69] 123 [4.84]

114.4 [4.45] 115.4 [4.54] 121.4 [4.78] 125.4 [4.94] 129.4 [5.09] 135.4 [5.33] 139.4 [5.49]

157.4 [6.20] 161.4 [6.35] 167.4 [6.59] 171.4 [6.75] 175.4 [6.90] 181.4 [7.14] 185.4 [7.30]

96 [3.78] 100 [3.94] 106 [4.17] 110 [4.33] 114 [4.49] 120 [4.72] 124 [4.88]

7/8–14UNF–2B (SAE J1926/1, O-Ring boss); 16.7 [0.66] min. full thread

9/16–18UNF–2B (SAE J1926/1 O-Ring boss); 12.7 [0.5] min. full thread

44 | © Danfoss | December 2020 BC318050073602en-000102

Page 45

0

-0.25

Ø 15.875

0

-0.01

[Dia 0.625 ]

7.9 ±0.75

[0.51 ±0.029 ]

50.8

±0.25

[2.0 ±0.01]

58.0 ±1

[2.31 ±0.04]

[0.16 ]

-0.001

4

-0.03

17.475–17.729

[0.688–0.698]

M6 - 6H

16 min.

[0.63 min.]

B

B

A

P

A

A–A

B–B

0

0

5.7 max.

[0.224 max.]

Detail ‘P’

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

©

Danfoss | December 2020 BC318050073602en-000102 | 45

Page 46

B

A

C

Taper 1:8

+0.15

-0.25

0

-0.03

4

9.5

35 ±0.1

[1.378±0.004]

6

[0.236]

44 ±0.75

[1.732 ±0.03]

[0.16 ]

-0.001

0

[0.374 ]

+0.006

-0.010

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

SGM2VC Fan Drive Motors (Group 2)

SGM2VC Outrigger Bearing Dimensions

Dimension Frame size

8,0 011 014 017 019 022 025

A 95 [3.74] 99 [3.90] 105 [4.13] 109 [4.29] 113 [4.45] 119 [4.69] 123 [4.84]

B 111.4 [4.39] 115.4 [4.54] 121.4 [4.78] 125.4 [4.94] 129.4 [5.09] 135.4 [5.33] 139.4 [5.49]

C 157.4 [6.20] 161.4 [6.35] 167.4 [6.59] 171.4 [6.75] 175.4 [6.90] 181.4 [7.14] 185.4 [7.30]

46 | © Danfoss | December 2020 BC318050073602en-000102

Page 47

G H

J

M N O

/

DC E FA B I K L

/

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 3

Model Code for Group 3 Fan Drive Motors

A – Family

SGM3NC

SGM3GC

SGM3YN

SGM3YL

SGM3VC

B – Frame size and displacement

022

026

033

038

044

Fan Drive Bi-directional Motor; External Axial Drain

Fan Drive Uni-directional Motor; Anti-cavitation Check valve

Fan Drive Motor with Proportional Pressure Valve, Axial Drain

Fan Drive Motor with Proportional Pressure Valve, Radial Drain

Reversible Fan Drive Motor with Proportional Pressure Valve

3

22.1 cm

3

26.2 cm

3

33.1 cm

3

37.9 cm

3

44.1 cm

C – Direction of rotation

B

L

R

Bi-directional (SGM3NC) or Uni-directional (SGM3GC)

Left hand (Counter-clockwise)

Right hand (Clockwise)

D – Project version

A

High temperature sealing, dust protector, rust protected screws

E – Mounting flange

01

07

91

9Y

European 01: Pilot Ø50.8 mm; 4 holes (98.4 x 128.1)

SAE B: Pilot Ø101.6 mm; 2 holes,

Outrigger bearing flange 01; M14x1.5 Key 4x7.5

SAE B: Pilot Ø101.6 mm; 2 holes; outrigger bearing with dust cover

©

Danfoss | December 2020 BC318050073602en-000102 | 47

Page 48

/

/

G H

J

M N ODC E FA B I K L

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 3

Model Code for Group 3 Fan Drive Motors

F – Drive gear

BA

BC

BP

GB

For more details about configuration, see Model Code for Mounting Flange/Drive Gears (Group 3) on page 51.

G – Rear cover

C6

CX

CZ

Y6

Y4

YX

RA

RB

Taper 1:8; M14x1.5; Key 4 (Special for flange 01 and Outrigger Bearing 91)

Taper 1:8; 5/8–18UNF–2A; Key 6.375

Taper 1:8; 5/8–18UNF–2A; Key 6.375 with Nut and Washer (Special for SAE B flange)

Parallel Ø22.225 x 25.4; Key 6.375 x 6.375 x 25.4 + thread hole: 1/4–20UNC–2B

Cast iron cover: 1-1/16–12 UN; In/Out ports: 9/16–18 UNF–2B Axial Drain (idler gear side)

Cast iron cover: 1-1/16–12 UN; In/Out ports: 9/16–18 UNF–2B Radial Drain (idler gear side)

Cast iron cover: 1-1/16–12 UN; In/Out ports: 9/16–18 UNF–2B Radial Drain (shaft side)

Cast iron cover: 1-1/16–12 UN; In port: 9/16–18 UNF–2B Axial Drain (idler gear side)

Cast iron cover: 1-1/16–12 UN; In port: 9/16–18 UNF–2B Radial Drain (idler gear side)

Cast iron cover: 1-1/16–12 UN; In port: 9/16–18 UNF–2B Radial Drain (shaft side)

Proportional PRV Reversing Valve Cover, 12 VDC V03 DEUTSCH connector, Anti-Shock-MakeUp Valve,

1-1/16–12 UN Work Ports, 9/16–18 UNF Radial Drain Port

Proportional PRV Reversing Valve Cover, 24 VDC V03 DEUTSCH connector, Anti-Shock-MakeUp Valve,

1-1/16–12 UN Work Ports, 9/16–18 UNF Radial Drain Port

H – Inlet ports

NN

Without inlet on body

I – Outlet ports

Code Dimensions Ports Code Thread Dimensions

A3

M5

M6

M7

C7

CA

BB

NN Without outlet on body H8 M27x2 per ISO6149

25x26,19x52,37x3/8-16UNC

25x52.37x26.19xM10

31x30.18x58.72xM10

37.5x35.71x69.85xM12

20x40xM8

27x51xM10

27x55xM8

E6 11/16–12UN

E8 15/16–12UN

E9 15/8–12UN

EI 17/8–12UN

F5

F6

F7

BSP 3/4 Gas

BSP 1 Gas

BSP 1-1/4 Gas

48 | © Danfoss | December 2020 BC318050073602en-000102

Page 49

G H

J

M N O

/

DC E FA B I K L

/

Technical Information

SGM2 and SGM3 Fan Drive Gear Motors (Group 2 and 3)

Group 3

Model Code for Group 3 Fan Drive Motors