Page 1

Data sheet

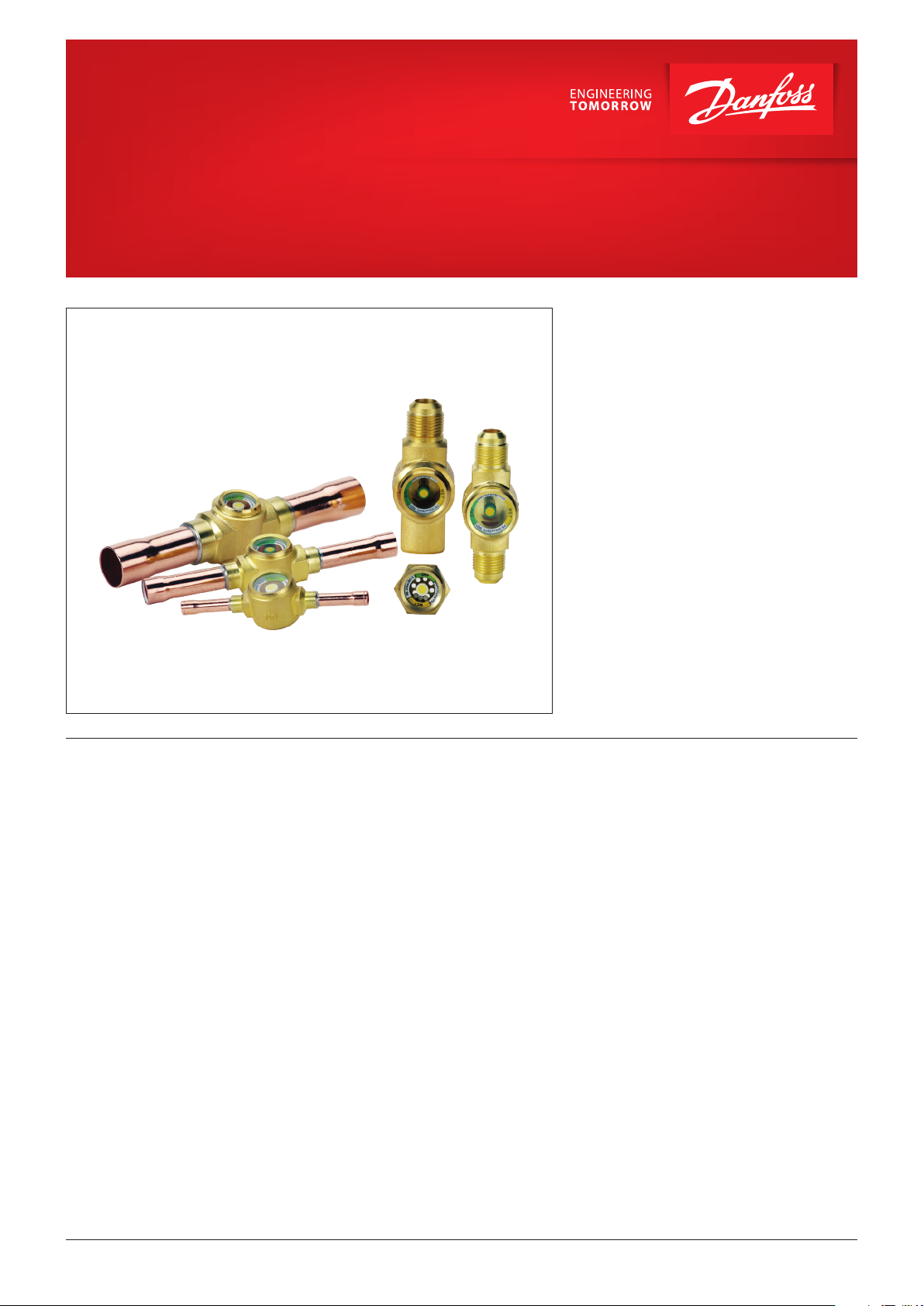

Sight glass (Low pressure)

Types SG, SGI, SGN, SGR, SGRI and SGRN

SG is sight glasses for low pressure application

(Max Working Pressure 500 psig).

SG is available with flare, solder and socket

connections, and with and without moisture

indicators.

SG and SGR, without moisture indicator, are

mainly used to indicate the condition of the

refrigerant in the liquid line or the flow in the oil

return line from the oil separator.

SGI / SGN and SGRI / SGRN are equipped

with sensitive indicators that reflects a color,

which depends on the moisture content in the

refrigerant.

Features • Provides fast and easy indication of:

– High system moisture content

– Lack of subcooling or low system charge

– Liquid level in receiver

(vessel mount versions only)

• Oil level in compressor

(vessel mount versions only)

• Two Indicator types:

– Type “I” – provides optimal moisture

indication for refrigerants with mineral oil,

e.g. R22

– Type “N” – provides optimal moisture

indication for refrigerants: R22, R134a,

R404A, R407C, R507, R407A, R407F, R448A,

R449A, R450A, R452A, R513A

• All indicators are dirt resistant

• Available in both inline and vessel mount

versions

• Hermetically sealed, tempered glass for easy

viewing

• Available in flare / flare, solder / solder

connection or socket type

© Danfoss | DCS (jmn) | 2018.06

DKRCC.PD.EK0.B4.22 | 1

Page 2

Data sheet | Sight Glass, Types SG, SGI, SGN, SGR, SGRI and SGRN

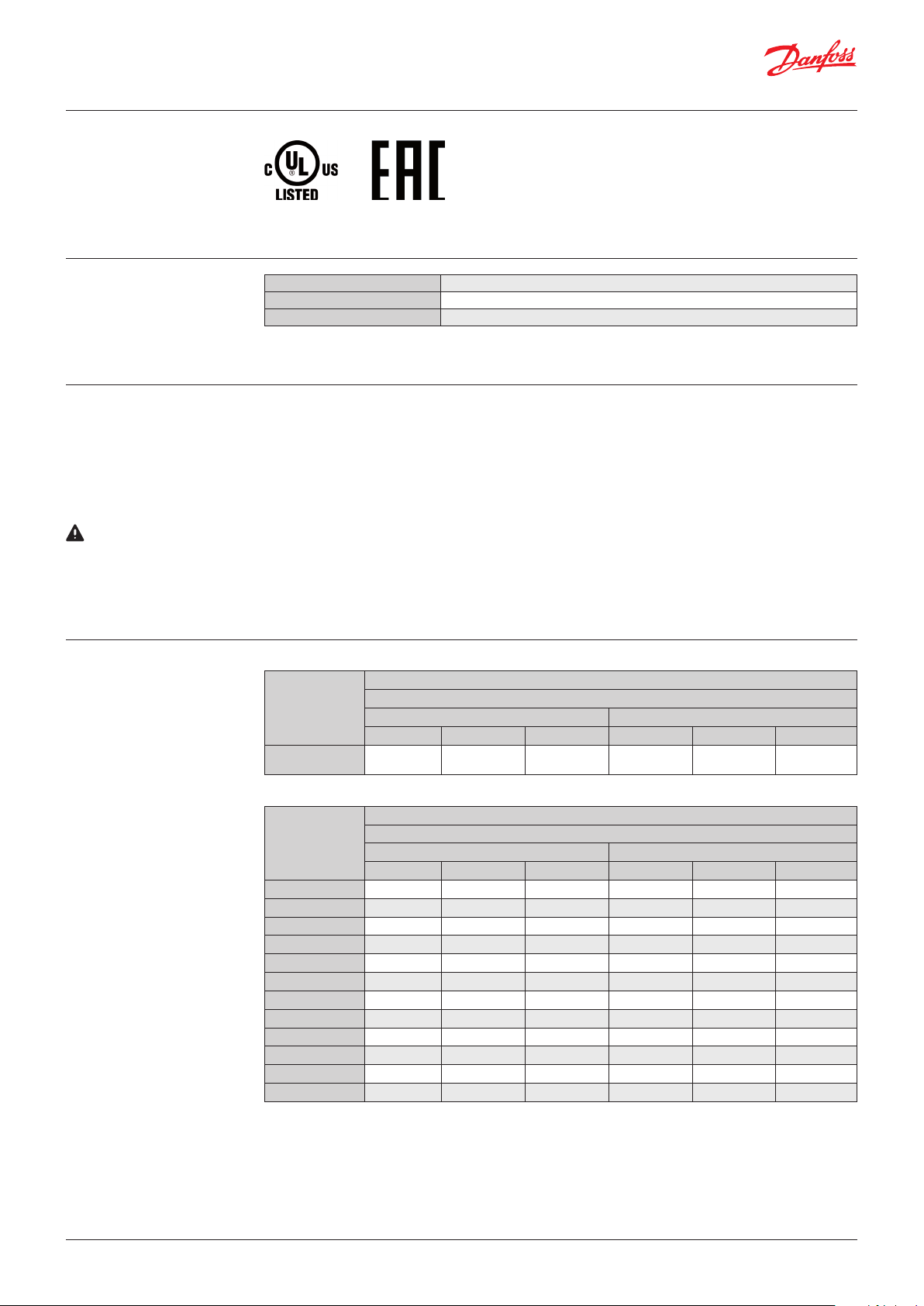

Approvals

Technical data

Media temperature -58 – 175 °F

Maximum working pressure PS / MWP = 500 psig

Refrigerant oil All mineral oils and ester oils

Selection Prior to selecting a sightglass with moisture

indicator, the following should be considered:

• Type of refrigerant

• Water solubility of refrigerant

• The level at which a danger signal is required

to prevent the formation of harmful acids

Note: when storing, transporting

or installing the Sight Glass, avoid

the chemical indicator to get in

contact with non-refrigerant

medium or fluid (like water, oil, ect.)

SGI / SGRI for refrigerants with mineral oil

Media temperature 77 °F Media temperature 110 °F

Green / dry Intermed. color Yellow / wet Green / dry Intermed. color Yellow / wet

Refrigerants with

mineral oil, e.g. R22

< 150 150 – 300 > 300 < 250 250 – 500 > 500

The following tables indicate moisture content

levels at which the sightglass indicator will

register a dry or wet system for various

refrigerants.

The values under “green / dry” are to be taken as

the maximum permissible moisture content for

the system. When the green color begins to fade

indicating an increase in moisture levels, the

sightglass should be checked more frequently.

If the moisture levels increase enough to change

the indicator to “yellow” indicating a wet system,

the filter drier must be changed immediately.

Moisture content ppm = parts per million

SGI / SGRI

SGN / SGRN for R22, R134a, R404A, R407C, R507, R407A, R407F, R448A, R449A, R450A, R452A, R513A

Moisture content ppm = parts per million

SGN / SGRN

Media temperature 77 °F Media temperature 110 °F

Green / dry Intermed. color Yellow / wet Green / dry Intermed. color Yellow / wet

R22 < 30 30 – 120 > 120 < 50 50 – 200 > 200

R134a < 30 30 – 100 > 100 < 45 45 – 170 > 170

R404A < 20 20 – 70 > 70 < 25 25 – 100 > 100

R407C < 30 30 – 140 > 140 < 60 60 – 225 > 225

R507 < 15 15 – 60 > 60 < 30 30 – 110 > 110

R407A < 29 29 – 115 > 115 < 48 48 – 192 > 192

R407F < 30 30 – 168 >168 < 60 60 – 240 > 240

R448A < 28 28 – 110 > 110 < 70 70 – 227 > 227

R449A < 29 29 – 105 > 105 < 53 53 – 200 > 200

R450A < 23 23 – 148 > 148 < 46 46 – 245 > 245

R452A < 20 20 – 79 > 79 < 30 30 – 143 > 143

R513A < 22 22 – 75 > 75 < 22 22 – 123 > 123

Notes:

– For colours reflecting moisture values of other refrigerants, please contact Danfoss

– For a fully updated list of approved refrigerants, visit www.products.danfoss.com and search for

individual code numbers, where refrigerants are listed as part of product specifications.

© Danfoss | DCS (jmn) | 2018.06

DKRCC.PD.EK0.B4.22 | 2

Page 3

Data sheet | Sight Glass, Types SG, SGI, SGN, SGR, SGRI and SGRN

Ordering

SG without indicator

Valve type Connection type

SG 22s Solder ODF x ODF

SGR NPT

SGI with I type indicator

Valve type Connection type

SGI 6

SGI 10

SGI 6s Solder ODF x ODF

SGI 10s Solder ODF x ODF

SGI 12s Solder ODF x ODF

SGI 16s Solder ODF x ODF

SGI 22s

SGRI NPT

1

) Can be screwed directly onto the Danfoss filter drier

Flare int. x ext. 1)

Solder ODF x ODF

Connection

[in.]

7

⁄8 014-1207

1

⁄2 014-0002

Connection

[in.]

1

⁄4 014-0063

3

⁄8 014-0064

1

⁄4 014-0066

3

⁄8 014-0067

1

⁄2 014-0068

5

⁄8 014-0069

7

⁄8 014-0070

1

⁄2 014-0131

Code no.

Code no.

Note: for other connection SG

codes, please contact

Danfoss manufacture factory

Metric conversions

1 in. = 25.4 mm

SGN with N type indicator

Valve type Connection type

SGN 6

SGN 10

SGN 6

SGN 10

SGN 12

SGN 6s

SGN 10s

SGN 12s

SGN 16s

SGN 22s

SGN 6s

SGN 12s

SGRN NPT

1

) Can be screwed directly onto the Danfoss filter drier

Flare int. x ext.

Flare int. x ext. 1)

Solder ODF x ODF

Solder ODF x ODM

Connection

[in.]

1

⁄4 014-0132

3

⁄8 014-0133

1

⁄4 014-0137

3

⁄8 014-0138

1

⁄2 014-0139

1

⁄4 014-0142

3

⁄8 014-0143

1

⁄2 014-0144

5

⁄8 014-0145

7

⁄8 014-0147

1

⁄4 014-0151

5

⁄16 014-0155

1

⁄2 014-0006

Code no.

© Danfoss | DCS (jmn) | 2018.06

DKRCC.PD.EK0.B4.22 | 3

Page 4

Data sheet | Sight Glass, Types SG, SGI, SGN, SGR, SGRI and SGRN

Dimensions and weights

SGI, SGN flare, int. × ext. SGI, SGN flare, ext. × ext.

D

1

H

D

H

L

1

B

L

SGI, SGN solder ODF × ODF SGI, SGN solder ODF × ODM

D D

1

H

H

1

H

H

1

B

1

H

H

Metric conversions

1 in. = 25.4 mm

1 lb = 0.454 kg

L

1

L

Type

SGI / SGN 6

SGI / SGN 10 3.228 — 1.102 0.630 0.748 1.260 0.44

SGI / SGN 6

SGI / SGN 10 2.244 — 1.181 0.669 0.866 1.260 1.260

SGI / SGN 12 2.323 — 1.181 1.181 0.945 1.260 0.66

Connection

type

Flare

ext. × ext.

Flare

int. × ext

SGI / SGN 6s

SGI / SGN 10s 4.685 0.354 0.945 0.551 0.551 1.063 0.22

SGI / SGN 12s 5.748 0.394 1.102 0.630 0.748 1.063 0.44

SGI / SGN 16s 5.748 0.472 1.181 0.709 0.866 1.063 0.44

ODF × ODF

solder

L L

[in.] [in.] [in.] [in.] [in.] [in.] [lbs]

2.638 — 0.945 0.551 0.551 1.063 0.22

1.811 — 0.945 0.551 0.630 1.063 0.22

3.976 0.276 0.945 0.551 0.551 1.063 0.22

L

1

1

B

L

1

1

B

L

1

H H

1

B

1

øD

Net

weight

SGI / SGN 22s 6.811 0.699 1.457 0.827 1.063 1.260 0.66

SGI / SGN 6s

SGI / SGN 12s 5.748 0.394 1.102 0.630 0.748 1.063 0.44

ODF × ODM

solder

3.976 0.276 0.945 0.551 0.551 1.063 0.22

© Danfoss | DCS (jmn) | 2018.06

DKRCC.PD.EK0.B4.22 | 4

Page 5

Danf

already on order pro

All trademarks in this material are property of the respec

Dimensions and weights

(continued)

SG socket

H

1

H

1

B

Metric conversions

1 in. = 25.4 mm

1 lb = 0.454 kg

Type

Connection

type

L L

1

H H

1

B

1

øD

[in.] [in.] [in.] [in.] [in.] [in.] [lbs]

Net

weight

SGR 1⁄2 NPT – – 1.181 0.709 1.063 – 0.22

SGRI / SGRN 1⁄2 NPT – – 1.181 0.709 1.063 – 0.22

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (jmn) | 2018.06

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCC.PD.EK0.B4.22 | 5

Loading...

Loading...