Page 1

Piston Ring

Service Kit Instructions

Series 42

Servo piston replacemnet

PURPOSE: Special precautions must be followed when installing a servo piston into a Series 42 pump.

Sharp edges on the interior servo bore will damage the piston sealing rings. This bulletin is

intended to give instructions for installation of the servo piston on a Series 42.

PROCEDURE:

Note: Once a servo adjustment seal lock

nut has been removed, it should be discarded and replaced because it will lose its

sealing properties. The nut is included in

the overhaul seal kit.

1. Lubricate the piston rings with a

piston ring has already been placed on

the neutral adjust screw end of the servo

piston.

2. Slide the servo piston through the

housing bore, inserting the non neutral

that the cavity for the servo piston/

swashplate bearing assembly faces the

center of the housing. Push the piston

through the housing just far enough so

the other piston ring may be installed,

but do not let the neutral adjust screw

end piston ring pass into the interior

servo bore.

Note: It is important to not twist or stretch

the piston rings too much, as looseness

may cause piston ring damage when

installing the servo piston. Do not distort

the piston rings any more than is necessary. After installing a piston ring, allow

it to contract for a few minutes prior to

inserting the piston into the housing bore.

5. Replace servo covers and gaskets as outlined

in the Series 42 Repair Manual (11007277).

Note: Neutral setting adjustments must be made

to any pump that is disassembled. The seal nut

must be torqued as outlined in the Series 42 Service

Manual (520L0638), once the neutral adjustments

have been made.

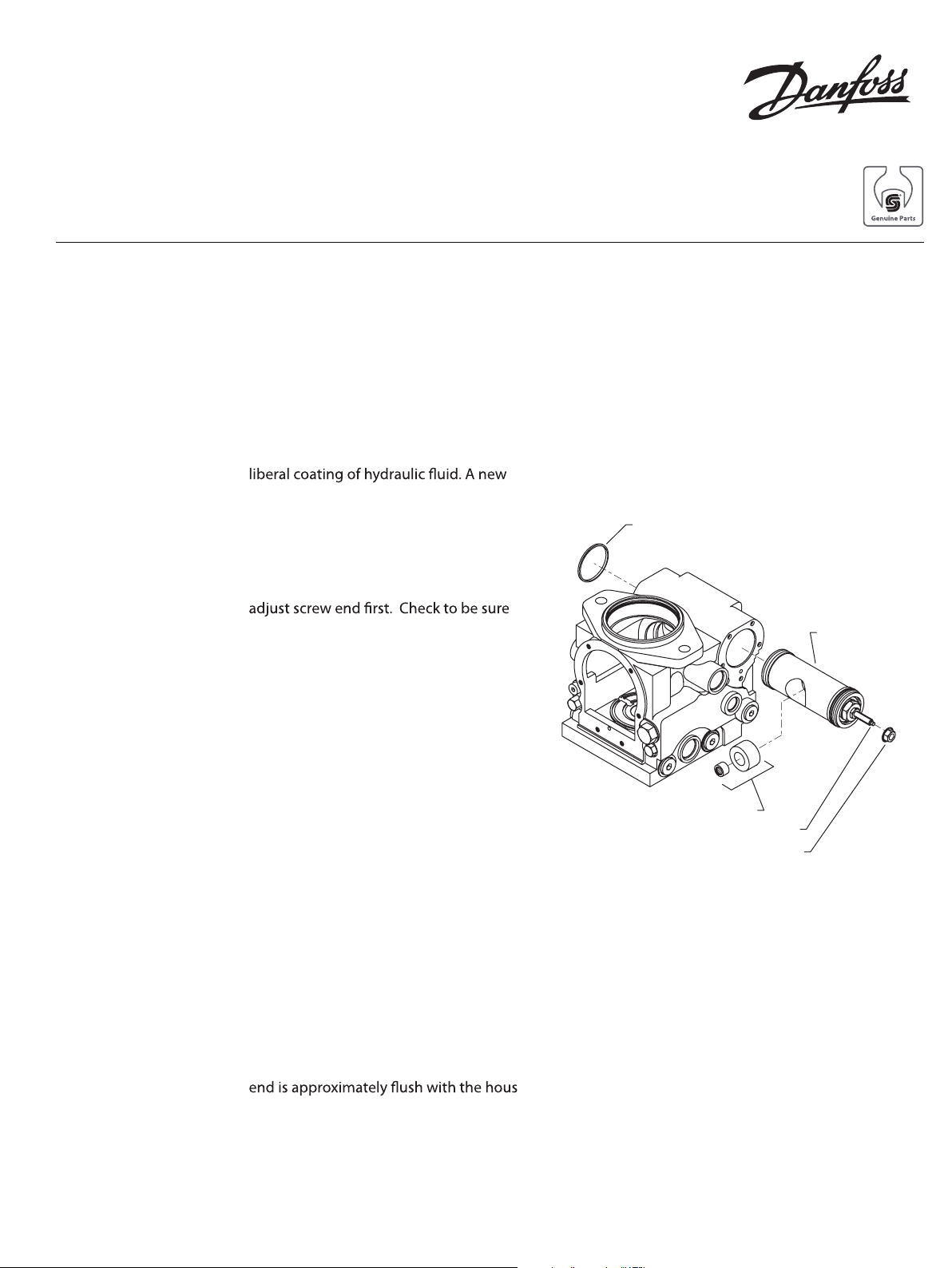

Servo Piston

Swashplate Bearing Assembly

Neutral Adjust Screw

Seal Nut

3. Place the second new piston ring on

the servo piston. Allow the piston ring a

few minutes to ‘relax’.

4. Push the servo piston back through

the bore so that the neutral adjust screw

ing. Do not allow the piston ring to show

again.

© Danfoss, 2013 BLN-10117 • Rev BB • September 2013 1

Loading...

Loading...