Danfoss Series 51 - HZ, Series 51 - HA, Series 51 - HB, Series 51 - HE, Series 51 - HS Service guide

...Page 1

MAKING MODERN LIVING POSSIBLE

Service Manual

Series 51 - HZ, HA, HB, HE, HS, H1,

H2, K1, K2, HP, HC, J1, J2, J3, J4, JA

Hydraulic Proportional Controls

powersolutions.danfoss.com

Page 2

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

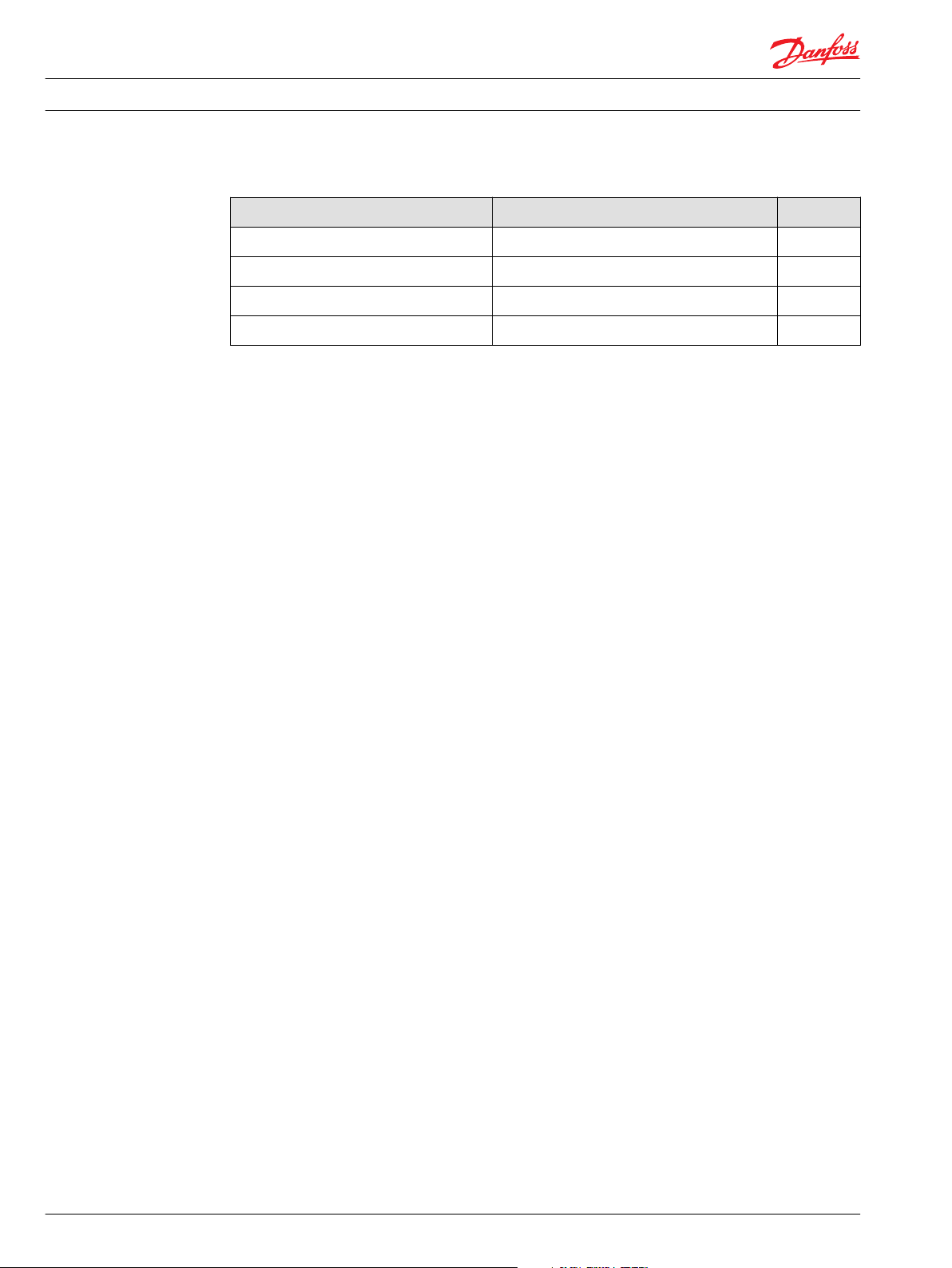

Revision history Table of revisions

Date Changed Rev

July 2014 Danfoss layout BA

November 2010 new last page AC

February 2010 Fix Osaka address AB

July 2009 First edition AA

2 11009446 • Rev BA • July 2014

Page 3

Service Manual

Contents

Introduction

Pressure measurements

Adjustments

PCOR

Multifunction block

HZ, HA, HB, HE Controls

HS Control

Series 51 Hydraulic Proportional Controls Service Manual

Safety Precautions............................................................................................................................................................................5

Unintended Machine Movement..........................................................................................................................................5

Flammable Cleaning Solvents................................................................................................................................................5

Fluid Under Pressure..................................................................................................................................................................5

Personal Safety.............................................................................................................................................................................5

Hazardous Material.....................................................................................................................................................................5

Symbols used in Danfoss literature............................................................................................................................................6

Overview..............................................................................................................................................................................................6

General Instructions........................................................................................................................................................................ 7

Keep it Clean.................................................................................................................................................................................7

Inspect for System Contamination....................................................................................................................................... 7

Replace the O-rings and Gaskets...........................................................................................................................................7

Lubricate all Moving Parts........................................................................................................................................................7

Torque Procedure....................................................................................................................................................................... 7

General Description.........................................................................................................................................................................7

Overview........................................................................................................................................................................................ 7

Threshold and Ramp Springs..................................................................................................................................................7

Multiblock......................................................................................................................................................................................8

Pressure Compensator OverRide (PCOR) Function........................................................................................................ 8

Brake Pressure Defeat (BPD) Option.................................................................................................................................... 9

Port locations and Gauge Installation.................................................................................................................................... 10

Threshold Setting...........................................................................................................................................................................11

Checking Threshold Setting................................................................................................................................................. 11

Adjusting Threshold Setting.................................................................................................................................................11

Pressure Compensator OverRide (PCOR) Setting...............................................................................................................12

PCOR Adjustment.....................................................................................................................................................................12

Checking PCOR Setting on a Test Stand.......................................................................................................................... 13

Adjusting the PCOR Setting..................................................................................................................................................13

Optional PCOR Housing...............................................................................................................................................................14

Disassembly................................................................................................................................................................................14

Inspection....................................................................................................................................................................................14

Assembly......................................................................................................................................................................................14

Optional Multifunction block ................................................................................................................................................... 16

Disassembly................................................................................................................................................................................16

Inspection....................................................................................................................................................................................17

Assembly......................................................................................................................................................................................17

Operation..........................................................................................................................................................................................18

Functional Description........................................................................................................................................................... 18

HZ Control...................................................................................................................................................................................18

HA and HB Controls................................................................................................................................................................. 18

HE Control................................................................................................................................................................................... 18

Repair..................................................................................................................................................................................................19

Disassembly................................................................................................................................................................................19

Inspection....................................................................................................................................................................................20

Assembly......................................................................................................................................................................................20

Operation..........................................................................................................................................................................................21

Functional Description........................................................................................................................................................... 21

Repair..................................................................................................................................................................................................21

Disassembly................................................................................................................................................................................21

11009446 • Rev BA • July 2014 3

Page 4

Service Manual

Contents

H1, H2, K1, K2 Controls

HP Controls

HC Controls

J1, J2, J3, J4 Controls

JA Control

Series 51 Hydraulic Proportional Controls Service Manual

Inspection....................................................................................................................................................................................22

Assembly......................................................................................................................................................................................22

Operation..........................................................................................................................................................................................23

Functional Description........................................................................................................................................................... 23

Solenoid Valve........................................................................................................................................................................... 23

Repair..................................................................................................................................................................................................23

Removing Solenoid Valve......................................................................................................................................................24

Disassembly................................................................................................................................................................................24

Inspection....................................................................................................................................................................................24

Assembly......................................................................................................................................................................................24

Installing Solenoid....................................................................................................................................................................24

Operation..........................................................................................................................................................................................25

Functional Description........................................................................................................................................................... 25

HP Control...................................................................................................................................................................................25

Shuttle Valve...............................................................................................................................................................................25

Connecting Pin..........................................................................................................................................................................25

Repair..................................................................................................................................................................................................26

Disassembly................................................................................................................................................................................26

Inspection....................................................................................................................................................................................27

Assembly......................................................................................................................................................................................27

Operation..........................................................................................................................................................................................28

Functional Description........................................................................................................................................................... 28

Check Valve.................................................................................................................................................................................28

Shuttle Valve...............................................................................................................................................................................28

Connecting Pin..........................................................................................................................................................................28

Repair..................................................................................................................................................................................................28

Diassembly..................................................................................................................................................................................28

Inspection....................................................................................................................................................................................29

Assembly......................................................................................................................................................................................31

Operation..........................................................................................................................................................................................32

Functional Description........................................................................................................................................................... 32

Solenoid Valve........................................................................................................................................................................... 32

Repair..................................................................................................................................................................................................33

Removing the Solenoid Valve..............................................................................................................................................33

Disassembly................................................................................................................................................................................34

Inspection....................................................................................................................................................................................34

Assembly......................................................................................................................................................................................35

Installing the Solenoid Valve................................................................................................................................................35

Operation..........................................................................................................................................................................................36

Functional Description........................................................................................................................................................... 36

Signal Pressure...........................................................................................................................................................................36

Repair..................................................................................................................................................................................................36

Disassembly................................................................................................................................................................................36

Inspection....................................................................................................................................................................................38

Assembly......................................................................................................................................................................................38

4 11009446 • Rev BA • July 2014

Page 5

W

W

W

W

W

Service Manual

Introduction

Safety Precautions

Series 51 Hydraulic Proportional Controls Service Manual

Always consider safety precautions before beginning a service procedure. Protect yourself and others

from injury. Take the following general precautions whenever servicing a hydraulic system.

Unintended Machine Movement

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

To protect against unintended movement, secure the machine or disable/disconnect the mechanism

while servicing.

Flammable Cleaning Solvents

Warning

Some cleaning solvents are flammable. To avoid possible fire, do not use cleaning solvents in an area

where a source of ignition may be present.

Fluid Under Pressure

Warning

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. This fluid may also be hot enough to cause burns. Use caution when dealing with

hydraulic fluid under pressure. Relieve pressure in the system before removing hoses, fittings, gauges, or

components. Never use your hand or any other body part to check for leaks in a pressurized line. Seek

medical attention immediately if you are cut by hydraulic fluid.

Personal Safety

Warning

Protect yourself from injury. Use proper safety equipment, including safety glasses, at all times.

Hazardous Material

Warning

Hydraulic fluid contains hazardous material. Avoid prolonged contact with hydraulic fluid. Always

dispose of used hydraulic fluid according to state, and federal environmental regulations.

11009446 • Rev BA • July 2014 5

Page 6

Service Manual

Series 51 Hydraulic Proportional Controls Service Manual

Introduction

Symbols used in Danfoss literature

WARNING may result in injury Tip, helpful suggestion

CAUTION may result in damage to product or

property

Reusable part Apply grease / petroleum jelly

Non-reusable part, use a new part Apply locking compound

Non-removable item Inspect for wear or damage

Option - either part may exist Clean area or part

Superseded - parts are not interchangeable Be careful not to scratch or damage

Measurement required Note correct orientation

Flatness specification Mark orientation for reinstallation

Parallelism specification Torque specification

External hex head Press in - press fit

Internal hex head Pull out with tool – press fit

Lubricate with hydraulic fluid

Overview

Torx head Cover splines with installation sleeve

O-ring boss port Pressure measurement/gauge location or

specification

The symbols above appear in the illustrations and text of this manual. They are intended to communicate

helpful information at the point where it is most useful to the reader. In most instances, the appearance

of the symbol itself denotes its meaning. The legend above defines each symbol and explains its purpose.

This manual includes information for the installation, maintenance, and minor repair of Series 51

hydraulic proportional controls. It includes a description of the unit and its individual components, and

minor repair procedures.

Performing minor repairs may require removal of the unit from the vehicle/machine. Thoroughly clean

the unit before beginning maintenance, or repair activities. Since dirt and contamination are the greatest

enemies of any type of hydraulic equipment, follow cleanliness requirements strictly. This is especially

important when changing the system filter and when removing hoses or plumbing.

A worldwide network of Danfoss Global Service Partners is available for major repairs. Danfoss Global

Service Partners are trained by the factory and certified on a regular basis. You can locate your nearest

Global Service Partner using the distributor locator at www.powersolutions.danfoss.com. Click on the

Sales and Service link.

6 11009446 • Rev BA • July 2014

Page 7

Service Manual

Introduction

General Instructions

Series 51 Hydraulic Proportional Controls Service Manual

Keep it Clean

You can complete many repairs or adjustments without removing the unit from the machine, if the unit is

accessible and you can thoroughly clean it before beginning any procedures.

Cleanliness is a primary means of assuring satisfactory motor life on either new or repaired units. Clean

the outside of the motor thoroughly before disassembly. Take care to avoid contamination of the system

ports. Cleaning parts with a clean solvent wash and air drying is usually adequate.

As with any precision equipment, keep all parts free of foreign materials and chemicals. Protect all

exposed sealing surfaces and open cavities from damage and foreign material. Cap all hoses after

removal, and plug all open ports. Cover any unattended parts with a protective layer of plastic.

Inspect for System Contamination

Inspect the motor for signs of system contamination. If you find contamination, fully disassemble, clean

and inspect all components of the motor.

Replace the O-rings and Gaskets

Replace all O-rings and gaskets. Discard them only after you make certain that you have the correct

replacement parts. Lightly lubricate all O-rings with clean petroleum jelly before assembly.

General Description

Lubricate all Moving Parts

During reassembly, coat all moving parts with a film of clean hydraulic oil. This helps lubricate the

surfaces during start-up.

For fluid quality requirements, refer to 520L0463 Hydraulic Fluids and Lubricants, Technical Information.

Torque Procedure

During reassembly, cross torque all retaining screws to the given value. Do not overtorque.

Overview

Hydraulic proportional controls infinitely vary the motor displacement between maximum and minimum

by feeding a variable hydraulic signal pressure to the end of the 4-way valve directly, or to a piston that

moves the 4-way valve As signal-pressure shifts the 4-way valve, it ports pressure to the ends of the servo

piston, changing motor displacement. A threshold spring and a ramp spring act on the opposite end of

the 4-way valve.

Threshold and Ramp Springs

The threshold adjustment screw varies the threshold spring force required to move the 4-way valve and

start the change in displacement. The ramp spring(s)—2 used in 160cc and 250cc motors, and one used

in the 80 cc and 110cc motors—increase the force on the 4-way valve as the servo piston moves toward

minimum displacement. This provides a motor displacement proportional to the input signal pressure.

The control operating threshold (the signal pressure when the motor starts to shift) is adjustable. Adjust it

using the adjusting screw in the end cap.

Changing ramp spring force requires replacing the springs. There are several spring rates available.

Optional orifices may be installed at several locations to regulate shift speed. Refer to the Model Code for

your motor for details.

11009446 • Rev BA • July 2014 7

Page 8

Spring seat

Threshold spring

Threshold adjustment screw

locknut

J50

Spring seat

S10*

S20

S10*

S10

J30

Ramp spring(s)

P106 438E

n

T6

T2

T1

T7 T8

T3

T4

U6

U7

T5

max.

disp.

A

L2 M4 M3 N

M1

L1

M2

M7

X1

M5

XA XB

B

P106 417E

Control

Multiblock

PCOR Valve

BPD Spool

Shuttle

Loop Flush

4-Way Valve

Service Manual

Introduction

Series 51 Hydraulic Proportional Controls Service Manual

Threshold and Ramp Springs

Multiblock

Some hydraulic proportional controls are used in conjunction with the multiblock. The multiblock is a

manifold with a shuttle-valve that routes high loop (system pressure) from port A or port B to the 4-way

valve to serve as servo supply and to the PCOR function. The shuttle valve also routes the low pressure

side of the loop to the PCOR function.

Multifunction Schematic

Pressure Compensator OverRide (PCOR) Function

The Pressure Compensator OverRide (PCOR) function allows the motor to match its displacement to the

8 11009446 • Rev BA • July 2014

system load. The PCOR overrides the control command allowing the motor to increase displacement

when system pressure reaches a set level due to load. This permits the motor to regulate system pressure

by modulating the displacement of the rotating group. As displacement increases, available torque

increases. Output speed decreases and system pressure remains nearly constant at the PCOR setting.

The PCOR setting is adjustable from 110 to 370 bar [1595 to 5365 psi]. Optional orifices at locations T4, T5,

T6, U6, and U7 regulate the PCOR operation speed.

Page 9

T4

T6

T5

U7

U6

P106 415E

Shuttle valve

Brake defeat spool

PCOR spool

P106 431E

PCOR adjuster

Service Manual

Introduction

Series 51 Hydraulic Proportional Controls Service Manual

Optional Orifices: T4, T5, T6, U6, U7

Brake Pressure Defeat (BPD) Option

The PCOR function can be equipped with an optional brake pressure defeat (BPD) option that defeats the

PCOR operation during dynamic braking. A shuttle spool ahead of the PCOR valve directs only

acceleration system pressure to the PCOR. During deceleration the dynamic braking pressure is blocked

from the PCOR limiting rapid deceleration, uncontrolled pressures or engine over-speeding while the

vehicle/machine is slowing down. An external hydraulic signal pressure fed to ports XA or XB are required

to operate the BPD spool. PCOR operation on one system pressure side is also an option.

BPD Option

11009446 • Rev BA • July 2014 9

Page 10

M2

M1

Threshold

adjustment

M3

M5

M1

M5

M3

A

L2

L1

M7

P106 434E

M4

M4

X1

M7

X1

Radial ported motor

M3

M5

B

A

M4

System port A

M1+M2

System port B

Axial ported motor

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

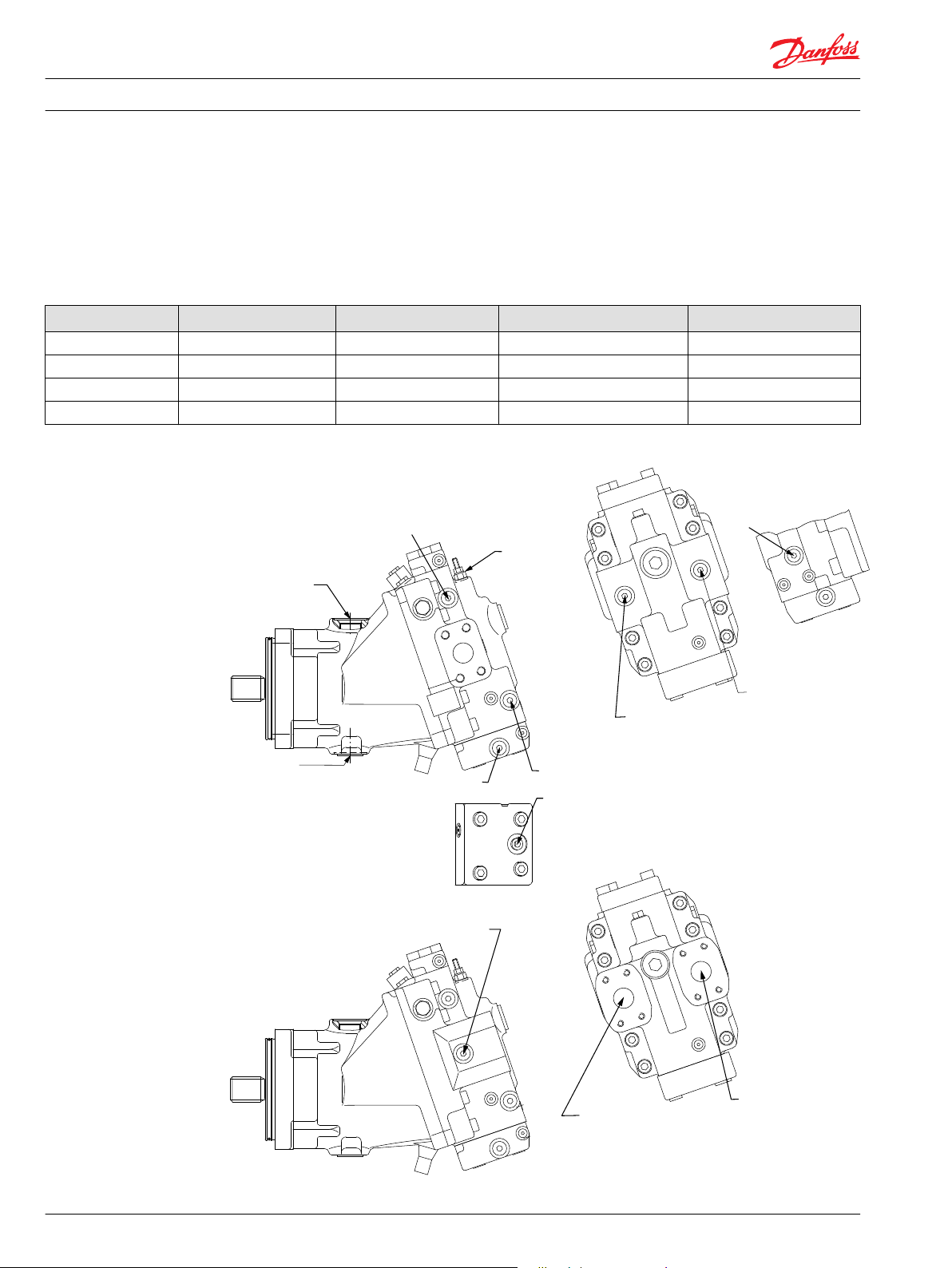

Pressure measurements

Port locations and Gauge Installation

The following table and drawings show the port locations and gauge sizes needed. When testing system

pressures, calibrate pressure gauges frequently to ensure accuracy. Use snubbers to protect gauges.

Port Information

Port identifier Port size Wrench size Reading Gauge size, bar [psi]

L1, L2 1 1/16-12 UNF 9/16 internal hex Case drain 10 bar [100 psi]

M1, M2 9/16-18 UNF 1/4 internal hex System pressure 600 bar [10,000 psi]

M3, M4, M5 9/16-18 UNF 1/4 internal hex Servo pressure 50 bar [1000 psi]

X1, M7 9/16-18 UNF 1/4 internal hex Control pressure 50 bar [1000 psi]

Port Locations

10 11009446 • Rev BA • July 2014

Page 11

Service Manual

Adjustments

Threshold Setting

Series 51 Hydraulic Proportional Controls Service Manual

Checking Threshold Setting

1. Install a 50 bar [600 psi] gauge at port M3 to read minimum servo pressure.

2. Install a 50 bar [600 psi] gauge at port M4 to read maximum servo pressure.

3. Install meter to read signal current.

4. Increase the signal current to the proper setting.

The pressure at port M3 should rise to about 100 psi [6.89 bar] higher than the pressure at port M4.

This causes the servo piston to move toward minimum position. Signal current at this point is the

threshold setting.

On a test stand, increase signal current until the flow from the motor begins to decrease. The signal

current at this point is the threshold setting.

Adjusting Threshold Setting

1. Using a 10 mm wrench, loosen the locknut on the adjustment screw.

2. Using a 3 mm internal hex wrench turn the adjusting screw:

Clockwise (cw) to increase the setting

•

Counterclockwise (ccw) to decrease the setting.

•

3. While holding the position of the adjustment screw:

tighten the locknut

•

using a 10 mm wrench torque the locknut to 9 N•m [6.6 lbf•ft].

•

11009446 • Rev BA • July 2014 11

Page 12

Adjusting screw

Spring seat

P101 911

Locknut

10 mm

9 Nm [6.6 lbf•ft]

Service Manual

Adjustments

Series 51 Hydraulic Proportional Controls Service Manual

Locknut and Threshold

Pressure Compensator OverRide (PCOR) Setting

PCOR Adjustment

In order to measure and adjust the start pressure setting for the PCOR function:

1. Install a 600 bar [10000 psi] gauge at port M1 or M2 or M5 to read high system pressure.

2. Install a 600 bar [10000 psi] gauge at port M3 to read minimum servo pressure.

3. Lock the motor shaft from moving by:

4. Start the prime mover. Operate at medium RPM.

Applying the park brake, apply an extreme load, or

•

Position the machine against an immovable object, or

•

Other means to hold the machine.

•

12 11009446 • Rev BA • July 2014

Page 13

W

Service Manual

Adjustments

Series 51 Hydraulic Proportional Controls Service Manual

5. Stroke the pump very slowly to gradually increase the system pressure.

An alternate method to slowly increase the system pressure is to use the pump’s pressure limiter (PL)

valve. Lower the PL setting below the PCOR setting. Stroke the pump to about one-fourth

displacement. Raise the PL setting slowly to increase system pressure until pressure at the M3 port

drops down. System pressure at this point is the PCOR setting. Adjust the PL back to its proper setting

after checking the PCOR setting.

6. Increase system pressure until pressure at port M3 drops down, system pressure at this point is the

PCOR setting.

Checking PCOR Setting on a Test Stand

Increase system pressure until the system flow begins to increase. System pressure at this point is the

PCOR setting.

Warning

System pressure may increase rapidly when flow increases.

Adjusting the PCOR Setting

For PCOR valves mounted on a Multiblock; use a 1-1/16 inch wrench to loosen the lock nut on the

•

adjusting screw. Using a large screw driver or a 13 mm wrench, turn the adjusting screw clockwise to

increase pressure setting or counter clockwise to lower pressure setting. One turn of the adjusting

screw changes the setting approximately 69 bar [1000 psi].

For controls using the threshold adjusting screw for PCOR adjustment; use a 10 mm wrench to loosen

•

the locknut. Using a 3 mm wrench, turn the adjusting screw clockwise to increase pressure or counter

clockwise to lower pressure setting. One turn of the adjusting screw changes the setting

approximately 55 bar [800 psi].

11009446 • Rev BA • July 2014 13

Page 14

N82

N29

N20

N14

N18

N16J

Z00

N87

U6

U7

N24P

P106 384E

N23

N27

N27

Service Manual

PCOR

Optional PCOR Housing

Series 51 Hydraulic Proportional Controls Service Manual

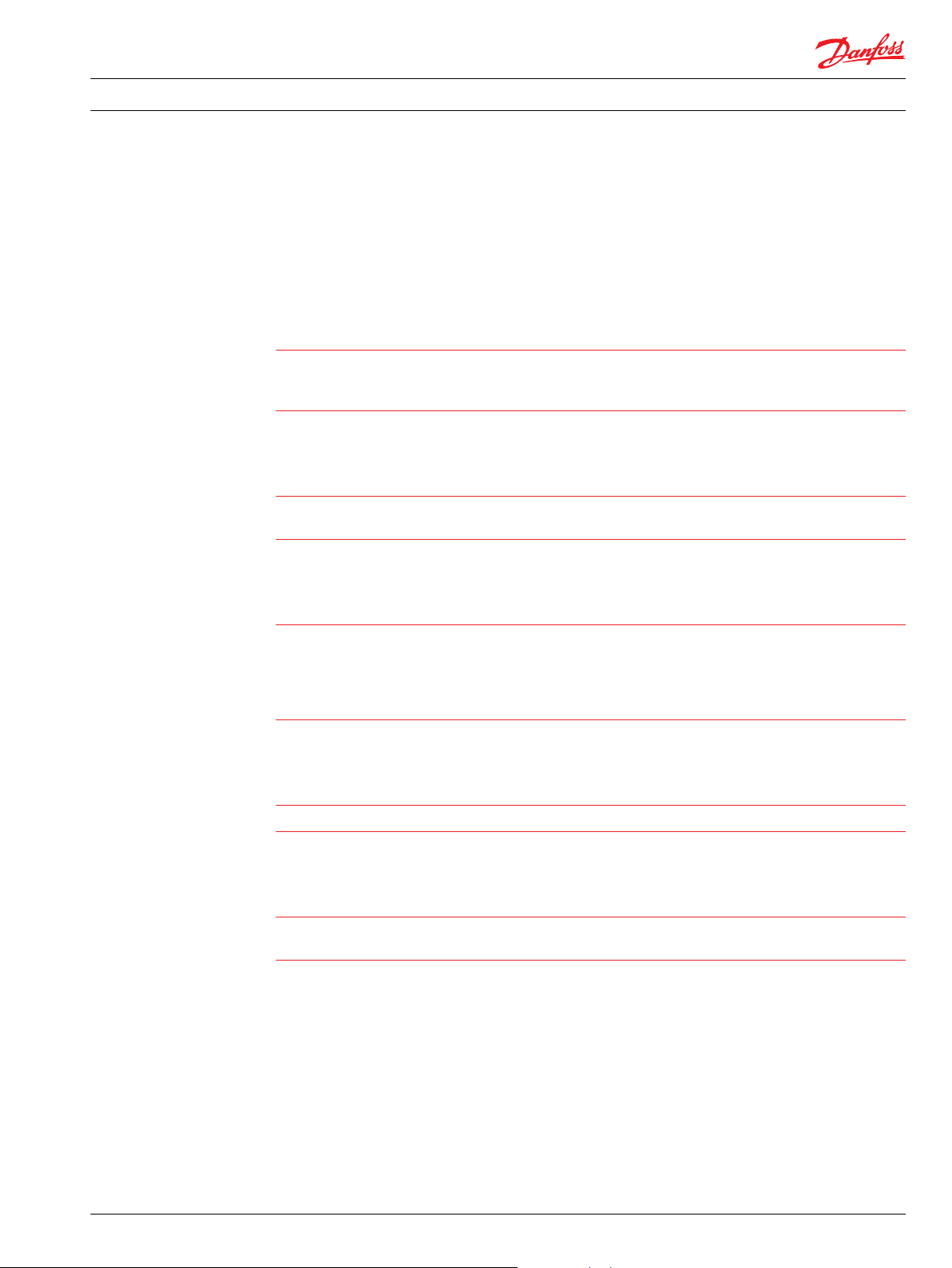

Disassembly

1. Remove plugs (N27). Remove and discard O-rings (N27A).

2. Using a 1 inch wrench, remove plug (N23). Remove and discard O-ring (N23A).

3. Remove locknut (N14).

4. Remove adjustment plug (Z00). Remove and discard O-ring (N16J).

5. Remove spring (N18).

6. Remove spool and spring guide assembly (N20).

7. Remove screws (N29).

8. Remove and discard O-rings (N24P, N82).

9. If present, remove orifices (U6, U7).

PCOR

Legend

Item Wrench size Torque

N27 1/8 inch internal hex 7 Nm [4 lbf•ft]

N23 1 inch 40 Nm [30 lbf•ft]

U6, U7 3 mm internal hex 6 Nm [4 lbf•ft]

N29 5 mm internal hex 16 Nm [12 lbf•ft]

N14 1-5/16 inch N/A

Inspection

Clean and inspect components for damage or foreign material. Replace damaged parts.

Assembly

1. If previously removed, use a 3mm internal hex wrench to install orifices (U6, U7). Torque to 6 N•m [4

lbf•ft].

2. Using petroleum jelly to retain them, install new interface O-rings (N24P, N82).

3. Position PCOR on multiblock. Install screws (N29). Torque using a 5 mm internal hex wrench to 16

14 11009446 • Rev BA • July 2014

N•m [12 lbf•ft].

Page 15

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

PCOR

4. Lubricate and install spool and spring guide assembly (N20).

5. Install spring (N18) to cavity.

6. Lubricate and install new O-ring (N16J). Install adjustment plug (Z00).

7. Using a 1-1/16 inch hex wrench, install locknut (N14). Do not torque until after PCOR adjustment.

Refer to page 13 for instructions.

8. Lubricate and install a new O-ring (N23A). Using a 1 inch hex wrench, install plug (N23). Torque to 40

N•m [30 lbf•ft].

9. Lubricate and install new O-rings (N27A). Using a 1/8 inch internal hex wrench, install and torque

plugs (N27) to 7 N•m [4 lbf•ft].

11009446 • Rev BA • July 2014 15

Page 16

G42

G42

G38

G38

G38

G36

N52

N30

N1A1

N58

P101210

N27

N27

N27

N27

N26

N26

N240

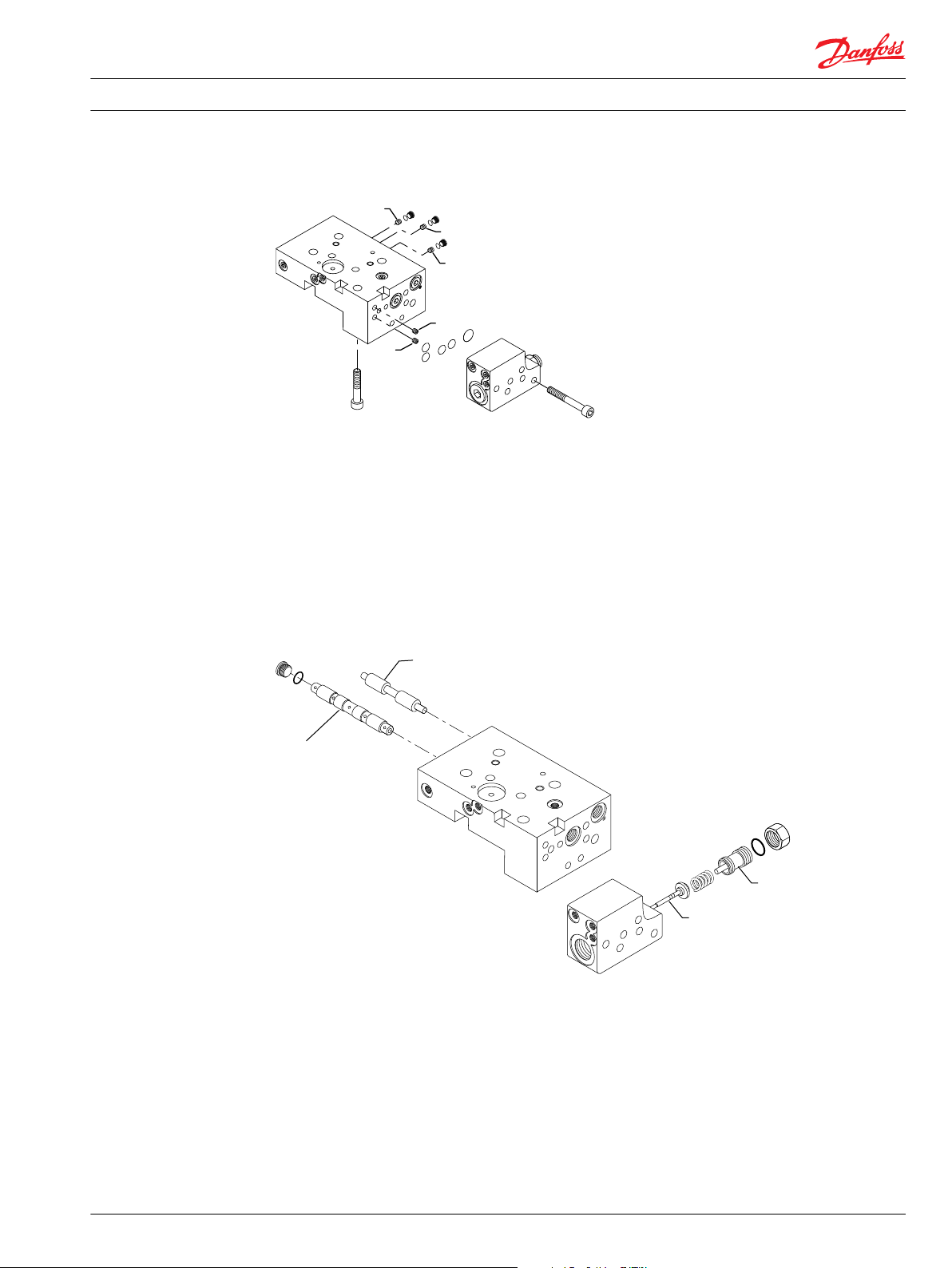

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

Multifunction block

Optional Multifunction block

Disassembly

1. Using a ¼ inch internal hex wrench, remove plugs (N26). Remove and discard O-rings (N26A).

2. Remove the spool (N30).

3. Using a 1/8 inch internal hex wrench, remove plugs (N27). Remove and discard O-rings (N27A).

4. Remove screws (N58).

5. Remove the multifunction block (N1A1).

6. Remove and discard O-rings (G36, G38, and G42) or gasket (N240).

7. If present, remove and discard screens (N52). They are no longer used.

E*, F* Control

16 11009446 • Rev BA • July 2014

Page 17

Service Manual

Multifunction block

Series 51 Hydraulic Proportional Controls Service Manual

Legend

Item Wrench size Torque

N27 1/8 inch internal hex 7 Nm [4 lbf•ft]

N26 1/4 inch internal hex 37 Nm [28 lbf•ft]

N58

80cc, 110cc

N58

160cc, 250cc

Inspection

Clean and inspect components for damage or foreign material. Replace damaged parts.

Assembly

1. Lubricate and install new O-rings (N27A). Install plugs (N27) using a 1/8 inch internal hex wrench.

Torque to 7 N•m [4 lbf•ft].

2. Using petroleum jelly to retain them, install new interface O-rings (G36, G38, G42) or gasket (N240).

3. Position the multifunction block on the endcap. Install screws (N58). Torque screws as shown in the

table.

4. Lubricate and install the double-resolver spool (N30). The spool is symetrical, either end in first.

5. Lubricate and install new O-rings (N26A). Using a 1/4 inch internal hex wrench, install plugs (N26).

Torque to 37 N•m [28 lbf•ft].

8 mm internal hex 78 Nm [58 lbf•ft]

10 mm internal hex 110 Nm [81 lbf•ft]

11009446 • Rev BA • July 2014 17

Page 18

T2

T1

B

A

T7

max.

disp.

L2

M4 M3

M2

M5

T8

T3

L1

M1

M7

X1

P107 823

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

HZ, HA, HB, HE Controls

Operation

Functional Description

The HZ, HA, HB, and HE controls consist of a ported housing mounted directly to the end cap. Variable

signal pressure fed to port X1 is routed to the end of the 4-way valve. A threshold spring and ramp

spring(s) act on the opposite end of the 4-way valve.

HZ Control

The HZ control has a check valve to resolve which port (system A or B) is higher pressure. It routes this

high pressure to the 4-way valve to power the servo piston.

HA and HB Controls

The HA and HB controls have internal porting to feed system A or B pressures, respectively, to the 4-way

valve to power the servo piston.

HE Control

The HE control has no internal porting for servo supply pressure. An external servo supply pressure fed to

port M5 is required.

HZ Schematic Diagram

18 11009446 • Rev BA • July 2014

Page 19

M1HZ

M18

M14

M12

M10

P106 423E

N240

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

HZ, HA, HB, HE Controls

Repair

Disassembly

1. Remove screws (M22) using a:

8 mm internal hex wrench for 80 cc and 110cc motors

•

10 mm internal hex wrench for 160 cc and 250 cc motors.

•

2. Remove control block ( M1HZ).

3. Remove and discard O-rings (G38, G42, and G36) or gasket (G420).

4. If present, remove plugs (M16) using a ¼ inch internal hex wrench (HZ controls only).

5. Remove and discard O-rings ( M16A).

6. If present, remove orifice (M12) using a 5mm internal hex wrench (HZ controls only).

7. If present, remove shuttle valve (M10) (HZ controls only).

If necessary, tap the housing on a solid surface to remove the shuttle valve.

8. Remove plugs (M18) using a 1/8 inch internal hex wrench.

9. Remove and discard O-rings (M18A).

Disassembly

11009446 • Rev BA • July 2014 19

Page 20

C

Service Manual

HZ, HA, HB, HE Controls

Series 51 Hydraulic Proportional Controls Service Manual

Legend

Item Wrench size Torque

M18 1/8 internal hex 6 Nm [4 lbf•ft]

M12 5 mm internal hex 12 Nm [6 lbf•ft]

M16 1/4 internal hex 31 Nm [27 lbf•ft]

M22 (80, 110) 8 mm internal hex 78 Nm [58 lbf•ft]

M22 (160, 1250) 10 mm internal hex 110 Nm [81 lbf•ft]

Inspection

1. Inspect the housing and shuttle valve for damage or foreign material.

2. Check internal passages for contamination and clean them if necessary. If present, discard the 2

screens ( M14) (they are no longer necessary).

Assembly

1. If used, install the shuttle valve assembly (M10) (HZ controls only).

2. If used, install orifice (M12) using a 5 mm internal hex wrench (HZ controls only). Torque to 8 N•m [6

lbf•ft].

Caution

Overtorquing orifice (M12) may crush shuttle valve (M10).

3. Lubricate and Install new O-rings to all plugs.

4. Using a 1/4 inch internal hex wrench, install plugs (M16). Torque to 37 N•m [27 lbf•ft].

5. Using a 1/8 inch internal hex wrench, install plugs (M18). Torque to 6 N•m [4 lbf•ft].

6. Using petroleum jelly to retain them, install new O-rings (G36, G38, G42) or install gasket (G420).

7. Install the control housing onto the end cap.

8. Install screws (M22). Torque screws to:

78 N•m [58 lbf•ft] for 80 cc, and 110cc motors using an 8mm internal hex wrench.

•

110 N•m [81 lbf•ft] for 160cc and 250cc motors using a 10 mm internal hex wrench.

•

20 11009446 • Rev BA • July 2014

Page 21

n

T6

T2

T1

T7 T8

T3

T4

U6

U7

T5

max.

disp.

A

L2 M4 M3 N

M1

L1

M2

M7

X1

M5

XA XB

B

P106 417E

Control

Multiblock

PCOR Valve

BPD Spool

Shuttle

Loop Flush

4-Way Valve

Service Manual

HS Control

Operation

Series 51 Hydraulic Proportional Controls Service Manual

Functional Description

The HS control consists of a ported housing mounted on a multiblock. External variable signal pressure

fed to port X1 is routed to the 4-way valve. As signal pressure shifts the 4-way valve it ports pressure to

the ends of the servo piston changing motor displacement. A threshold spring and ramp spring(s) act on

the opposite end of the 4-way valve.

HS Schematic

Repair

Disassembly

1. Using a 4 mm internal hex wrench, remove screws (M10).

2. Remove the HS valve housing from the multifunction block.

3. Remove and discard O-ring (M12).

11009446 • Rev BA • July 2014 21

Page 22

E101 489E

M10

M17

M17A

M12

Service Manual

HS Control

Series 51 Hydraulic Proportional Controls Service Manual

Disassembly

4. Remove plug (M17) using a 1/4 internal hex wrench.

5. Remove and discard O-ring (M17A).

Inspection

1. Inspect the housings for damage or foreign material.

2. Check internal passages for contamination. Clean passages if necessary.

Assembly

1. Using petroleum jelly to retain it, install a new O-ring (M12).

2. Install the HS valve housing on to the multifunction block.

3. Using a 4 mm internal hex, install screws (M10). Torque to 6.4 Nm [4.7 lbf•ft].

4. Lubricate and install a new O-ring (M17A).

5. Using a 1/4 internal hex wrench install plug (M17). Torque to 37 N•m [28 lbf•ft].

Refer to Optional Multifunction block on page 16 for multiblock repair.

22 11009446 • Rev BA • July 2014

Page 23

P107 825

T2

T1

B

A

T7

max.

disp.

L2

M4 M3

M2

M3 (M5)

T8

T3

L1

M1

X1

M7

T6

T4

U6

U7

T5

XA XB

Multiblock

PCOR Valve

BPD Spool

Shuttle

Loop Flush

4-Way Valve

Service Manual

H1, H2, K1, K2 Controls

Operation

Series 51 Hydraulic Proportional Controls Service Manual

Functional Description

The H1, H2, K1, and K2 controls consist of a ported housing mounted on the multiblock. It contains a

solenoid valve and internal porting to direct the external variable signal pressure through the solenoid

valve to the end of the 4-way valve. A threshold spring and ramp spring(s) act on the opposite end of the

4-way valve.

Solenoid Valve

The solenoid valve (M1) is a 2-position 3-way valve that passes the external signal pressure to the end of

the 4-way valve, or blocks the external signal and drains the end of the 4-way valve to the motor case.

The H1 and K1 solenoid valves have a 12-volt coil with DIN connector. The H2 and K2 solenoid valves

have a 24-volt coil with DIN connector. The 4-way valve and the solenoid valve are the same for H1, H2,

K1, and K2 controls. The control housings are different between the H1, H2, and the K1, K2 controls. The

logic for the control is:

If H1 or H2 are energized operation is proportional; if de-energized output is maximum displacement.

•

If K1 or K2 are energized, output is maximum displacement; if de-energized, operation is

•

proportional.

Refer to Multiblock on page 8 Pressure Compensator OverRide (PCOR) Function on page 8 and Brake

Pressure Defeat (BPD) Option on page 9 for multiblock, PCOR and brake pressure defeat information.

H1, H2 Schematic

Repair

The solenoid valve (M1) is available as a complete assembly only. Do not remove unless it is being

replaced.

11009446 • Rev BA • July 2014 23

Page 24

P106 428E

Service Manual

H1, H2, K1, K2 Controls

Series 51 Hydraulic Proportional Controls Service Manual

Removing Solenoid Valve

1. Using a 3/4 wrench, remove the coil nut from the solenoid cartridge valve (M1).

2. Remove the coil from the solenoid cartridge valve (M1). Using a 7/8 wrench, remove the solenoid

cartridge valve (M1) from the control housing.

Disassembly

1. Using a 1/4 internal hex wrench, remove plugs (M22, M18) (and M24 if present).

2. Remove and discard O-rings (M22A, M18A, and M24A).

3. Using a 4 mm internal hex wrench, remove screws (M14). Remove control (M10).

4. Remove and discard O-rings (M16 and M20).

Inspection

Inspect all components for damage or foreign material. Clean all parts and replace damaged

components as necessary.

Control Block

Legend

Item Wrench size Torque

M1 coil nut 3/4 inch 6 Nm [4 lbf•ft]

M1 solenoid valve 7/8 inch 12 Nm [6 lbf•ft]

M22, M18, M24 1/4 internal hex 31 Nm [27 lbf•ft]

M14 4 mm internal hex 6.4 Nm [4.7 lbf•ft]

Assembly

1. Using petroleum jelly to retain them, install O-rings (M16, M20).

2. Install the control housing to the multifunction block.

3. Install mounting screws (M14) to the multifunction block. Using a 4 mm internal hex wrench. Torque

to 6.4 N•m [4.7 lbf•in].

4. Lubricate and install new O-rings (M18A, M22A, and M24A).

5. Install plugs (M18A, M22A, and M24A). Using a 1/4 internal hex wrench, torque to 37 N•m [28 lbf•ft].

Installing Solenoid

1. Lubricate O-rings and install solenoid valve. Using a 7/8 wrench, torque to 78 Nm [58 lbf•ft].

2. Install coil and nut. Using a 3/4 wrench, torque to 1.2 Nm [0.9 lbf•ft].

24 11009446 • Rev BA • July 2014

Page 25

M4

M3

M1

L1

L2

M5

M2

B

XB XA

A

Max.

displ.

X2

X1

P101 871

Service Manual

HP Controls

Operation

Series 51 Hydraulic Proportional Controls Service Manual

Functional Description

The HP and HC two-line hydraulic proportional controls vary the motor displacement between maximum

and minimum by feeding hydraulic signal pressure to both ends of a piston. A pin connects the piston to

the 4-way valve. A threshold spring and ramp spring(s) act on the opposite end of the 4-way valve.

As deferential pressure moves the piston, it shifts the 4-way valve that ports servo supply pressure to the

ends of the servo piston. A threshold spring and ramp spring(s) act on the opposite end of the 4-way

valve. The threshold adjustment screw varies the threshold spring force and the signal pressure required

to move the 4-way valve and start the change in displacement. The ramp spring(s)—two used in 160 cc

and 250 cc motors, one in 80 cc and 110 cc motors—increases the force on the 4-way valve as the servo

piston moves toward minimum displacement. This provides a motor displacement proportional to the

input signal delta pressure. Optional orifices at locations T1, T2, T3, T7, and T8 regulate shift speed.

HP Schematic Diagram

HP Control

The HP control consists of a ported housing that mounts onto the multifunction block. The ported

housing contains a shuttle valve, a piston, a connecting pin, and a bias spring.

Shuttle Valve

The shuttle valve ports higher signal pressure to the top of the piston. It ports lower signal pressure to the

bottom of the piston.

Connecting Pin

The connecting pin links the piston to the 4-way valve. The bias spring holds the piston and pin against

the 4-way valve.

11009446 • Rev BA • July 2014 25

Page 26

P101 873

M26

M10

M30

M30

M18

M14

M24

M16

M12

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

HP Controls

Repair

Disassembly

1. Using a 4 mm internal hex wrench remove screws (M36).

2. Remove the housing cover (M10). Remove gasket (M12).

3. Remove spring (M16).

4. Remove housing (M1HP) with the shuttle valve assembly.

5. Remove the pilot piston (M14). Remove and discard O-ring (M24).

6. Remove pin (M18) from the multifunction block.

7. Use screw (M36) as a threaded puller to remove plug (M28). Remove O-ring (M30).

8. Remove shuttle spool (M26).

9. Remove plug (M32). Remove O-ring (M30).

HP Control

26 11009446 • Rev BA • July 2014

Page 27

Service Manual

HP Controls

Series 51 Hydraulic Proportional Controls Service Manual

Legend

Item Wrench size Torque

M36 4 mm internal hex 6.4 Nm [4.7 lbf•ft]

Inspection

1. Clean and inspect all parts.

2. Discard any parts that are worn or damaged.

Assembly

1. Install new O-rings (M30).

2. Install new O-ring (M24).

3. Install plug (M32) with the large chamfer toward the inside of the block.

4. Install shuttle spool (M26).

5. Install plug (M28) with the large chamfer toward the inside of the block.

6. Install pin (M18) in the multiblock.

7. Position the control valve housing on the multifunction block.

8. Install the pilot piston (M14) into the control valve housing over pin (M18).

9. Install spring (M16).

10. Install new gasket (M12).

11. Install control cover (M10).

12. Position control assembly (M1HP) on multifunction block to align the screw holes.

13. Using a 4 mm internal hex wrench, install screws (M36). Torque to 6.4 Nm [4.7 lbf•ft].

11009446 • Rev BA • July 2014 27

Page 28

M4

M3

M1

L1

L2

M5

M2

B

Max.

displ.

X2

X1

A

P101 875

Service Manual

HC Controls

Operation

Series 51 Hydraulic Proportional Controls Service Manual

Functional Description

The HC control consists of a ported housing, mounted directly on the end cap. It contains a check valve, a

shuttle valve, a piston, a connecting pin, and a bias spring. The HC control does not have pressure

compensating override (PCOR) function.

Check Valve

The check valve resolves which port (system A or B) is at higher pressure. It routes that higher pressure to

the 4-way valve to power the servo piston.

Shuttle Valve

The shuttle valve ports higher signal pressure to the top of the servo piston. It ports lower signal pressure

to the bottom of the servo piston.

Connecting Pin

The connecting pin links the piston to the 4-way valve. The bias spring holds the piston and pin against

the 4-way valve. A threshold spring and ramp spring(s) act on the opposite end of the 4-way valve.

HC Schematic Diagram

Repair

Diassembly

28 11009446 • Rev BA • July 2014

1. Using a 10 mm wrench, loosen locknut (M40).

2. Using a 4 mm internal hex, remove bleed valve (M38).

3. Using a 1/4-inch internal hex, remove plug (M48)

Page 29

Service Manual

HC Controls

Series 51 Hydraulic Proportional Controls Service Manual

4. Remove and discard O-ring (M48A).

5. Remove check ball seat (M46) using a 5 mm internal hex.

6. Remove check ball (M47) using a pencil magnet.

7. Using a 1/4-inch internal hex, remove plugs (M34).

8. Remove and discard O-rings (M34A).

9. Slide shuttle spool (M44) out of block.

10. Using a 10 mm wrench, loosen locknut (M16). Using a 4 mm internal hex, remove adjustment screw

(M18).

11. Remove screws (M28).

12. Remove cover (M12). Remove gasket (M14).

13. Remove spring seat (M20). Remove spring (M22).

14. Remove the pilot piston (M24).

15. Remove spring seat (M25). Remove pin (M26).

16. Remove spring (J10).

17. Remove screws (M10) and washers (M11).

18. Remove block (M1HC).

19. Remove and discard O-rings (G38), (G36) and (G42) or gasket (N240).

20. Remove 4-way valve (F32).

21. Remove and discard O-rings (F324).

Inspection

1. Inspect the control block for signs of corrosion or damage.

2. Discard any damaged or worn parts.

11009446 • Rev BA • July 2014 29

Page 30

J10

M26

M11

M47

M46

M34

M38

M40

M50A

M50

F32

F324

G38

G42

G38

G42

M48A

M48

M34A

M34

M34

M10

M25

M22

M20

M14

M12

M16

P101 882

G36

M1HC

M28

N240

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

HC Controls

HC Control Disassembly

Legend

Item Wrench size Torque

M48 1/4 internal hex 37 Nm [27 lbf•ft]

M40 10 mm 18 N•m [13.3 lbf•ft]

M34 1/4 internal hex 37 Nm [27 lbf•ft]

M28 4 mm internal hex 6.4 Nm [4.7 lbf•ft]

M16 10 mm 9 Nm [6.6 lbf•ft]

30 11009446 • Rev BA • July 2014

Page 31

Service Manual

HC Controls

Series 51 Hydraulic Proportional Controls Service Manual

Legend (continued)

Item Wrench size Torque

M18 4 mm internal hex N/A

M10 (060, 080, 110) 8 mm internal hex 78 Nm [58 lbf•ft]

M10 (160, 250) 10 mm internal hex 110 Nm [81 lbf•ft]

Assembly

1. Lubricate and install O-rings (F324).

2. Install 4-way valve (F32).

3. Using petroleum jelly, lubricate and install O-rings (G38), (G36) and (G42) or install gasket (N240).

4. Install block (M1HC).

5. Install screws (M10) and washers (M11), if present.

6. Install spring (J10).

7. Install pin (M26). Install spring seat (M25).

8. Install the pilot piston (M24).

9. Install spring (M22). Install spring seat (M20)

10. Install gasket (M14). Install cover (M12).

11. Using a 4 mm internal hex wrench, install screws (M28). Torque to 6.4 Nm [4.7 lbf•ft].

12. Install adjustment screw (M18). Install locknut (M16).

13. Hold adjustment screw in place and torque locknut (M16) to 9 Nm [6.6 lbf•ft].

14. Slide shuttle spool (M44) into block.

15. Lubricate and install O-rings (M34A).

16. Using a 1/4-inch internal hex, install plugs (M34).

17. Install check ball (M47)

18. Install check ball seat (M46)

19. Lubricate and install O-ring (M48A).

20. Using a 1/4-inch internal hex, install plug (M48)

21. Using a 4 mm internal hex, install bleed valve (M38).

22. Using a 10 mm wrench, install locknut (M40).

23. Hold bleed valve in place and torque lock nut per table.

11009446 • Rev BA • July 2014 31

Page 32

T2

T1

B

A

T7

max.

disp.

L2

M4 M3

M2

M5

T8

T3

L1

M1

P107 826

X1

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

J1, J2, J3, J4 Controls

Operation

Functional Description

J1, J2, J3, and J4 controls are one-line hydraulic proportional with a solenoid valve that overrides the

hydraulic signal to hold the motor at maximum displacement. The control housing contains a solenoid

valve, a pressure compensating override (PCOR) valve, optional brake pressure defeat (BPD) valve, and

passages to route oil to the 4-way valve and to the servo piston ends. As signal pressure shifts the 4-way

valve, it ports pressures to the ends of the servo piston changing motor displacement. A threshold spring

and ramp spring(s) act on the opposite end of the 4-way. Variable signal pressure is fed to port X1.

Solenoid Valve

The solenoid valve (item M1) is a 2-position 3-way valve that passes the external signal pressure to the

end of the 4-way valve, or blocks the external signal and drains the end of the 4-way valve to the motor

case. The J1 and J3 solenoid coils are 12 volt. The J2 and J4 are 24 volt. The J1 and J2 solenoids have DIN

connectors. The J3 and J4 solenoids have Jet Jr. Timer connectors. The logic for the control is

If J3 or J4 are energized operation is proportional; if de-energized output is maximum displacement.

•

If J1 or J2 are energized output is maximum displacement; if de-energized operation is proportional.

•

J1, J2 Schematic Diagram

32 11009446 • Rev BA • July 2014

Page 33

F32

F324

M24

T6

T4

M23

M23A

M24

U7

N84

M21

M18

M16

M14

M20

N34

N33

N33

N34

M22

M24

M24A

M22A

M24

M24

U6

M151

M150

M1

Z*

G38

G42

G38

G42

G36

N32

M22

M22A

M15

M1

Note: Orifices (T4 and T6) and

PCOR adjuster (Z*) are

not included in control

J1, J2

J3, J4

The difference

between J3, J4 and

J1, J2 is the way the solenoid

valve is attached to the housing

P106 406E

N240

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

J1, J2, J3, J4 Controls

Repair

Removing the Solenoid Valve

It is not necessary to remove the valve unless it is being replaced.

Individual parts are not available. Replace entire valve.

Solenoid for J1, J2

If replacing the valve, use a 7/8 wrench to remove the valve from the housing.

Solenoid for J3, J4

If replacing the valve, use a 3 mm internal hex wrench to remove screws (M15). Remove the valve.

Control Disassembly

Legend

Item Wrench size Torque

M15 3 mm internal hex 2.8 Nm [1 lbf•ft]

M1 (J1, J2) 7/8 20 Nm [15 lbf•ft]

M150, M151

(80, 110)

11009446 • Rev BA • July 2014 33

8 mm internal hex 78 Nm [58 lbf•ft]

Page 34

C

C

Service Manual

J1, J2, J3, J4 Controls

Series 51 Hydraulic Proportional Controls Service Manual

Legend (continued)

Item Wrench size Torque

M150, M151

(160, 1250)

Item Wrench size Torque

M14 1 1/16 54 Nm [40 lbf•ft]

T4, T5, U6, U7 3 mm internal hex 3.7 Nm [2.7 lbf•ft]

N34, M22 1/4 internal hex 37 Nm [27 lbf•ft]

M23 3/8 internal hex 95 Nm [70 lbf•ft]

M24 1/8 internal hex 6 Nm [4.5 lbf•ft]

N84, N33 7/16 internal hex 12 Nm [9 lbf•ft]

Disassembly

1. Remove PCOR lock nut (M14).

2. Remove and discard O-ring (M16).

3. Remove the adjuster (Z*).

4. Remove the spring (M18).

5. Remove the PCOR spool assembly (M20).

10 mm internal hex 110 Nm [81 lbf•ft]

Caution

Do not remove the PCOR valve bushing (M21).

6. Using a 7/16 wrench, remove the pin/plugs (N84) or (N33).

7. Remove and discard the O-rings (N84A) or (N33A).

8. Using a 1/8 internal hex wrench, remove 15 plugs (M24).

9. Remove and discard O-rings (M24A).

10. Using a 1/4 internal hex wrench, remove plugs (M22, N34).

11. Remove and discard O-rings (M22A, N34A).

12. Remove spool (N32).

13. Using a 3/8 internal hex, remove plug (M23). Discard O-rings (M23A).

14. Remove screws (M150 and M151) using a:

8mm internal hex wrench for 80 cc and 110cc motors

•

10 mm internal hex wrench for 160cc and 250cc motors

•

15. Remove the control assembly from the end cap.

16. Remove the 4-way valve assembly (F32).

Caution

Read Series 51 and 51-1 Bent Axis Motors Service Manual 11008567 for minor repair instructions for the

4-way valve, threshold spring, and ramp spring components, if repair is necessary.

17. Remove and discard O-rings (F324).

18. Remove and discard O-rings (G38), (G36) and (G42) or the gasket (N240).

19. Using a 3 mm internal hex, remove orifices (T4, T6, U6, U7).

Inspection

1. Inspect the housing for signs of corrosion or damage.

2. Discard any damaged parts.

34 11009446 • Rev BA • July 2014

Page 35

C

Service Manual

J1, J2, J3, J4 Controls

Series 51 Hydraulic Proportional Controls Service Manual

Assembly

1. Using a 3mm internal hex, install orifices (T4, T5, U6, U7). Torque to 3.7 Nm [2.7 lbf•ft].

2. Lubricate and install O-rings (F324).

3. Install the 4-way valve assembly (F32).

4. Using petroleum jelly, lubricate and install a new O-rings (G38, G36 and G42) or install gasket (N240).

5. Install the control assembly to the end cap.

6. Install screws (M150 and M151).

7. Torque screws (M150 and M151) to:

78 N•m [58 lbf•ft]. Use an 8mm internal hex wrench for 80 cc and 110cc motors.

•

110 N•m [81 lbf•ft]. Use a 10 mm internal hex for 160cc and 250ccmotors.

•

8. Install spool (N32).

9. Lubricate and install O-rings (N34A and M22). Using a 1/4 internal hex wrench, install plugs (M22 and

N34). Torque to 25 Nm [18 lbf•in].

10. Lubricate O-ring (M23A). Using a 3/8 internal hex wrench, install plug (M23). Torque to 95 Nm [70

lbf•in].

11. Lubricate and install 15 O-rings (M24A). Using an 1/8 internal hex wrench, install 15 plugs M24).

Torque to 6 Nm [4 lbf•in].

12. Lubricate and install O-rings (N84A) or (N33A). Using a 7/16 wrench, install plugs (N84) or (N33).

Torque to 12 Nm [9 lbf•in].

13. Install the PCOR spool assembly (M20).

14. Install spring (M18). Install adjuster (Z*).

15. Lubricate and install O-ring (M16).

16. Install lock nut (M14). Torque to 54 Nm [40 lbf•in].

Caution

Readjust the PCOR to its proper setting

Installing the Solenoid Valve

Solenoid for J1, J2

Lubricate O-rings. Use a 7/8 wrench to install the valve. Torque to 20 Nm [15 lbf•ft].

Solenoid for J3, J4

Use a 3 mm internal hex wrench to install screws (M15). Torque to 2.8 Nm [2.1 lbf•ft].

11009446 • Rev BA • July 2014 35

Page 36

n

T2

T3

T7 T8

T1

T6

T4

max.

disp.

B

XB XA

A

L2 M4 M3 N

M1

L1

M2

(M5)

X3

P106 420E

U7

Loop flush

PCOR

BPD

C

Service Manual

JA Control

Operation

Series 51 Hydraulic Proportional Controls Service Manual

Functional Description

JA control is a stand-alone, dual signal hydraulic proportional control. The control housing contains a

pressure compensating override (PCOR) valve, a brake pressure defeat (BPD) valve, and passages to route

oil to the 4-way valve and to the servo piston ends. An external servo supply pressure fed to port M5 is

required. A threshold spring and ramp spring(s) act on the opposite end of the 4-way valve.

Signal Pressure

Separate external variable signal pressures are fed into ports XA or XB. The BPD spool resolves which

signal pressure is higher and routes this signal pressure to the end of the 4-way valve. The signal pressure

shifts the 4-way valve and it ports servo supply pressure to the ends of the servo piston, changing motor

displacement in proportion to the signal pressure.

JA Control Schematic Diagram

Repair

Disassembly

1. Remove PCOR lock nut (M14).

2. Remove and discard O-ring (M16).

3. Remove adjuster ( Z*).

4. Remove spring (M18).

5. Remove spool assembly (M20).

Caution

Do not remove PCOR valve bushing (M21).

36 11009446 • Rev BA • July 2014

Page 37

E101 480E

JA

M24

T6

T4

M23

M23A

M24

U7

M84

M21

M18

M16

M14

M20

M24

M24A

M24

M24

Z*

G38

G42

G38

G42

M32

M84A

N240

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

JA Control

Control Disassembly

Legend

Item Wrench size Torque

M150, M151

(80, 110)

M150, M151

(160, 1250)

M14 1 1/16 54 Nm [40 lbf•ft]

Item Wrench size Torque

T4, T6, U7 3 mm internal hex 3.7 Nm [2.7 lbf•ft]

M23 3/8 internal hex 25 Nm [18 lbf•ft]

M24 1/8 internal hex 6 Nm [4.5 lbf•ft]

M84 7/16 internal hex 12 Nm [9 lbf•ft]

8 mm internal hex 78 Nm [58 lbf•ft]

10 mm internal hex 110 Nm [81 lbf•ft]

11009446 • Rev BA • July 2014 37

Page 38

C

Service Manual

JA Control

Series 51 Hydraulic Proportional Controls Service Manual

6. Using a 7/16 wrench remove pin/plugs (M84).

7. Remove and discard O-rings (M84A).

8. Remove spool (M32).

9. Using a 1/8 internal hex wrench remove 13 plugs (M24).

10. Remove and discard O-rings (M24A).

11. Using a 3/8 internal hex wrench remove plug (M23).

12. Remove and discard O-ring (M23A).

13. Remove screws (M150 and M151) using a:

8mm internal hex wrench for the 80 cc and 110cc motors

•

10 mm internal hex wrench for the 160cc and 250cc motors.

•

14. Remove the control from the endcap.

15. Remove 4-way valve assembly (F32).

Caution

If repair is necessary to the 4-way valve, threshold spring, and ramp spring components, refer to Series

51 and Series 51-1 Motors Service Manual 11008567.

16. Remove and discard O-rings (F324).

17. Remove O-rings (G38), (G36) and (G42) or gasket (N240).

18. Using a 3 mm internal hex, remove orifices (T4, T6, U7).

Inspection

1. Inspect the housing (M1) for signs of corrosion or damage.

2. Replace any damaged parts.

Assembly

1. Using a 3 mm internal hex, install orifices (T4, T6, U7). Torque to 3.7 Nm [2.7 lbf•ft].

2. Lubricate and install O-rings (F324).

3. Install the 4-way valve assembly (F32).

4. Using petroleum jelly, lubricate and install a new O-rings (G38, G36 and G42) or install gasket (N240).

5. Install the control assembly to the end cap.

6. Install screws (M150 and M151).

7. Torque screws (M150 and M151) to:

78 N•m [58 lbf•ft]. Use an 8mm internal hex wrench for 80 cc and 110cc motors.

•

110 N•m [81 lbf•ft]. Use a 10 mm internal hex for 160cc and 250ccmotors.

•

8. Install spool (M32).

9. Lubricate O-ring (M23A). Using a 3/8 internal hex wrench, install plug (M23). Torque to 25 Nm [18

lbf•in].

10. Lubricate and install 13 O-rings (M24A). Using an 1/8 internal hex wrench, install 13 plugs M24).

Torque to 6 Nm [4 lbf•in].

11. Lubricate and install O-rings (M84A). Using a 7/16 wrench, install plugs (M84). Torque to 12 Nm [9

lbf•in].

12. Install the PCOR spool assembly (M20).

13. Install spring (M18). Install adjuster (Z*).

14. Lubricate and install O-ring (M16).

15. Install lock nut (M14). Torque to 54 Nm [40 lbf•in].

38 11009446 • Rev BA • July 2014

Page 39

C

Service Manual Series 51 Hydraulic Proportional Controls Service Manual

JA Control

Caution

Readjust the PCOR to its proper setting

11009446 • Rev BA • July 2014 39

Page 40

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions US Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed..

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11009446 • Rev BA • July 2014 www.danfoss.com

Local address:

©

Danfoss A/S, 2014

Loading...

Loading...