Page 1

Technical Information

Bent Axis Variable Displ. Motors

Series 51 and 51-1

powersolutions.danfoss.com

Page 2

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Revision history Table of revisions

Date Changed Rev

October 2017 Modified theor. corner power ratings and updated to Engineering Tomorrow 0401

March 2015 Major update. Corrected DITA CMS structure, layout, colors and all tables. CA

Jan 2014 Converted to Danfoss layout - DITA CMS BA

Jun 2005 First version AA

2 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 3

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Contents

Series 51 general information

Sectional view of Series 51, proportional control.................................................................................................................7

Sectional view of Series 51-1, two-position control.............................................................................................................8

Pictorial diagram...............................................................................................................................................................................9

System circuit diagram...................................................................................................................................................................9

Series 51/51-1 name plates........................................................................................................................................................ 10

Technical specifications

General specifications.................................................................................................................................................................. 11

Specific data.....................................................................................................................................................................................11

Fluid specifications........................................................................................................................................................................12

Determination of nominal motor size....................................................................................................................................13

General technical specifications

Case pressure...................................................................................................................................................................................14

Speed range.....................................................................................................................................................................................14

Pressure limits................................................................................................................................................................................. 15

Loop flushing...................................................................................................................................................................................16

Minimum displacement limiter................................................................................................................................................ 17

Hydraulic fluids............................................................................................................................................................................... 17

Temperature and viscosity......................................................................................................................................................... 18

Filtration system ............................................................................................................................................................................18

Fluid selection................................................................................................................................................................................. 19

Reservoir............................................................................................................................................................................................19

Independent braking system.................................................................................................................................................... 19

Motor bearing life.......................................................................................................................................................................... 20

External shaft loads....................................................................................................................................................................... 21

External shaft load orientation..................................................................................................................................................21

Radial and thrust loads to the output shaft.................................................................................................................... 22

Allowable external shaft load, when shaft load distance is different from standard.................................22

Efficiency graphs and maps....................................................................................................................................................... 23

Speed sensor................................................................................................................................................................................... 25

Typical control and regulator applications...........................................................................................................................26

Controls circuit diagram – nomenclature – description

Option N1NN – hydraulic two-position control for 51-1 (frame size: 060, 080, 110).............................................27

Option HZB1 – hydraulic two-position control for 51 (frame size: 160, 250)........................................................... 28

Options TA** – pressure compensator control for 51-1 (frame size: 060, 080, 110)..............................................30

Option TACA: pressure compensator configuration with hydraulic Brake Pressure Defeat.........................31

Options TAD1, TAD2, TAD7: pressure compensator configuration with electric BPD.................................... 31

TAD* solenoid connectors............................................................................................................................................... 31

Option TAC2: pressure compensator configuration without Brake Pressure Defeat......................................31

Options TA** – pressure compensator controls for 51 (frame size 160, 250).......................................................... 33

Option TAC0: pressure compensator configuration with hydraulic Brake Pressure Defeat......................... 34

Option TAC2: pressure compensator configuration without Brake Pressure Defeat......................................34

Options TH** – hydraulic two-position control for 51-1 (frame size: 060, 080, 110)............................................. 35

Pressure Compensator OverRide (PCOR).........................................................................................................................35

Option THCA: pressure compensator configuration with hydraulic Brake Pressure Defeat.........................36

Options THD1, THD2, THD7: pressure compensator configuration with electric BPD....................................36

THD* solenoid connectors...............................................................................................................................................37

Option THC2: pressure compensator configuration without Brake Pressure Defeat......................................37

Options TH** – hydraulic two-position control for 51 (frame size 160, 250)............................................................38

Pressure Compensator OverRide (PCOR).........................................................................................................................38

Option THC0: pressure compensator configuration with hydraulic BPD............................................................ 39

Option THC2: pressure compensator configuration without Brake Pressure Defeat......................................39

Options E1B1, E2B1, E7B1 – electrohydraulic two-position control for 51-1 (frame size 060, 080, 110)........40

E1B1, E2B1, E7B1 solenoid connectors............................................................................................................................. 41

Options E1A5, E2A5 – electrohydraulic two-position control for 51 (frame size 160, 250).................................42

E1A5, E2A5 solenoid connectors.........................................................................................................................................43

Options F1B1, F2B1 – electrohydraulic two-position control for 51-1 (frame size 060, 080, 110)....................44

F1B1, F2B1 solenoid connectors......................................................................................................................................... 45

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 3

Page 4

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Contents

Options F1A5, F2A5 – electrohydraulic two-position control for 51 (frame size 160, 250).................................46

F1A5, F2A5 solenoid connectors.........................................................................................................................................47

Options T1**, T2**, T7** – electrohydraulic two-position control for 51-1 (frame size 060, 080, 110)...........48

Option T*CA: pressure compensator configuration with hydraulic Brake Pressure Defeat..........................49

Options T*D1, T*D2, T* D7: pressure compensator configuration with electric BPD......................................49

T1D1, T2D2, T7D7 solenoid connectors......................................................................................................................50

Option T*C2: pressure compensator configuration without Brake Pressure Defeat.......................................50

Options T1**, T2** – electrohydraulic two-position control for 51 (frame size 160, 250)................................... 51

Option T*C0: pressure compensator configuration with hydraulic Brake Pressure Defeat.......................... 52

Option T*C2: pressure compensator configuration without Brake Pressure Defeat.......................................52

T1C2, T2C2 solenoid connectors................................................................................................................................... 52

Options EP**, EQ** – electrohydraulic proportional control for 51 (all frame sizes)............................................. 53

Pressure Compensator Override (PCOR)..........................................................................................................................54

Options EPA1, EQA1: pressure compensator configuration with Brake Pressure Defeat.............................. 55

Options EPA2, EQA2: pressure compensator configuration without Brake Pressure Defeat....................... 55

Options L1B1, L2B1, L7B1 – electrohydraulic proportional control for 51 (all frame sizes)................................ 56

L1B1, L2B1, L7B1 solenoid connectors..............................................................................................................................57

Options D7M1, D8M1 – electrohydraulic proportional control with PCOR and hydraulic BPD for 51

(all frame sizes)........................................................................................................................................................................58

Options D7M1, D8M1: pressure compensator configuration with hydraulic Brake Pressure Defeat........59

D7M1, D8M1 solenoid connector..................................................................................................................................59

Options HS** – hydraulic proportional control for 51 (all frame sizes)...................................................................... 60

Pressure Compensator OverRide (PCOR).........................................................................................................................60

Option HSA1: pressure compensator configuration with Brake Pressure Defeat.............................................61

Option HSA2: pressure compensator configuration without Brake Pressure Defeat......................................61

Option HZB1 – hydraulic proportional control for 51 (all frame sizes).......................................................................62

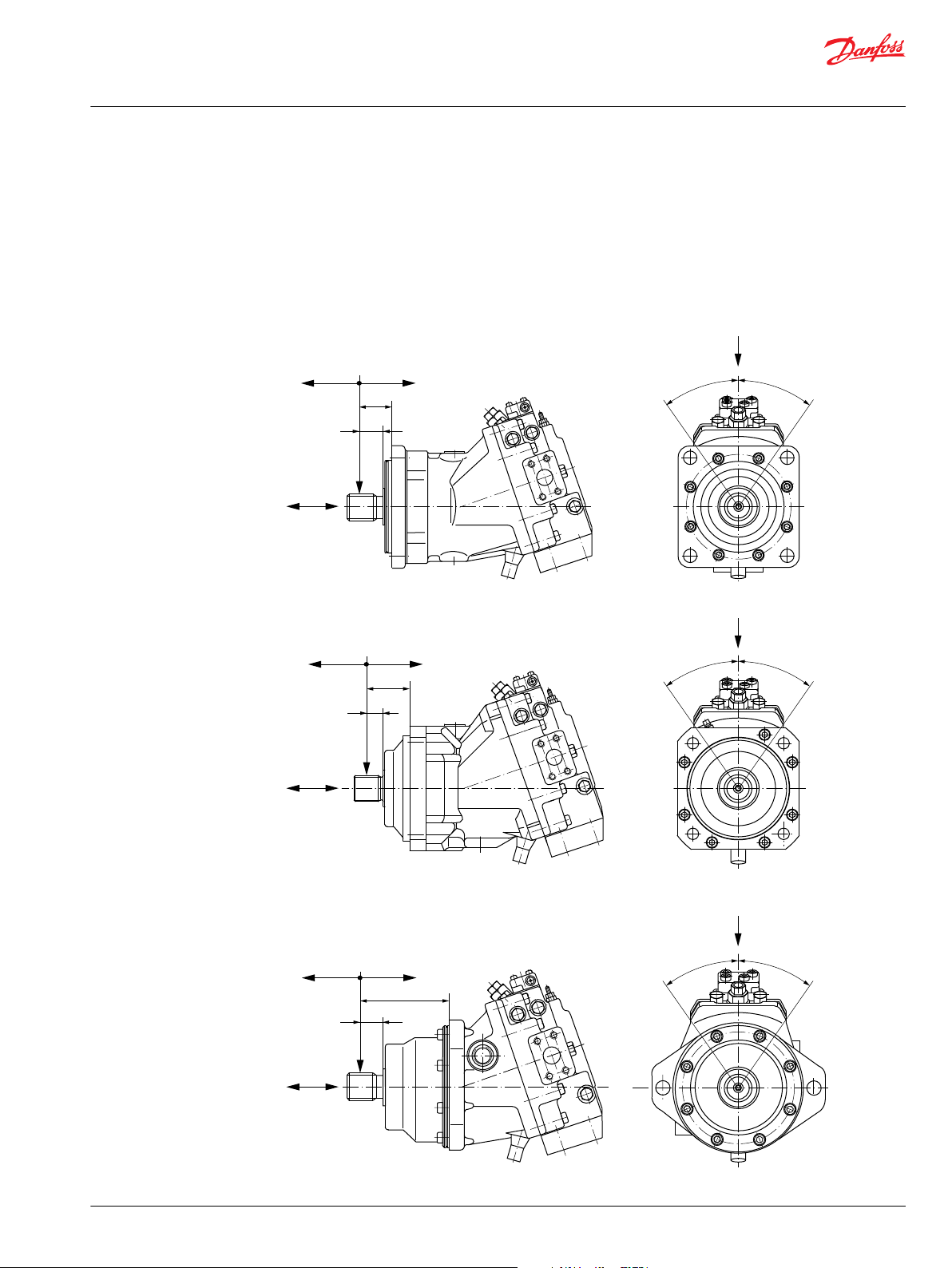

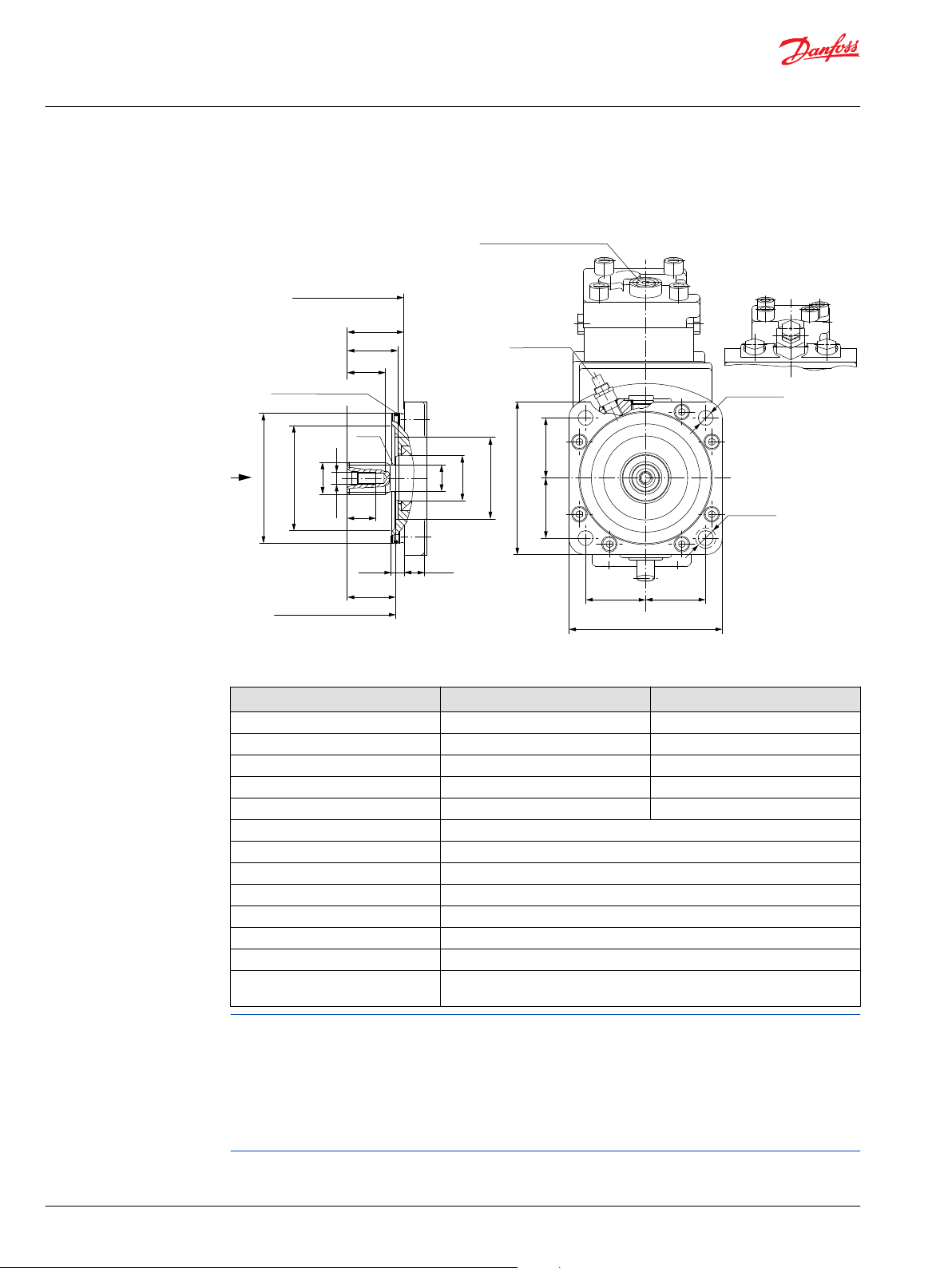

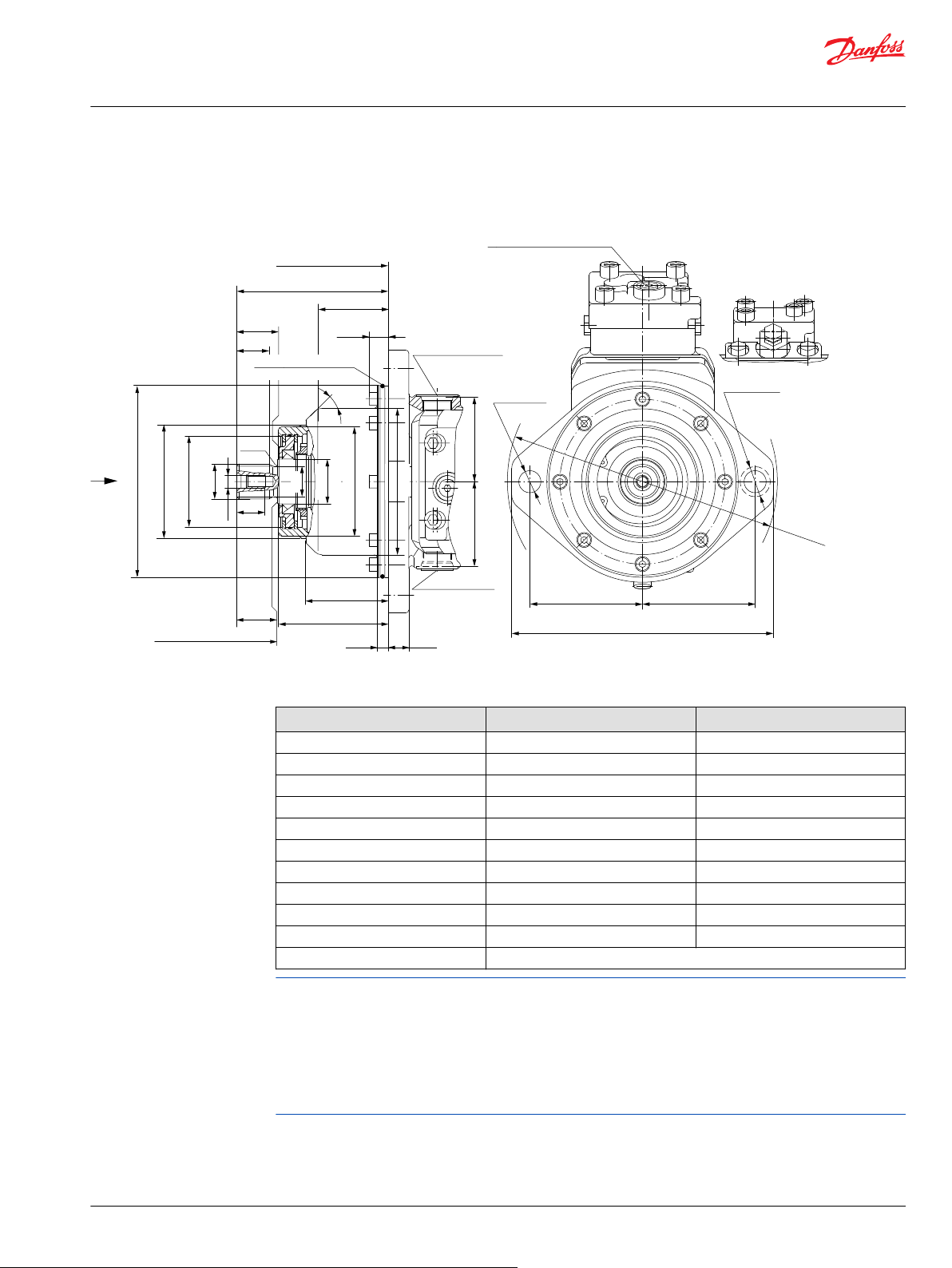

General dimensions – frame size 060

SAE flange design per ISO 3019/1............................................................................................................................................64

DIN flange design per ISO 3019/2............................................................................................................................................67

Cartridge flange..............................................................................................................................................................................70

General dimensions – frame size 080

SAE flange design per ISO 3019/1............................................................................................................................................73

DIN flange design per ISO 3019/2............................................................................................................................................76

Cartridge flange..............................................................................................................................................................................79

General dimensions – frame size 110

SAE flange design per ISO 3019/1............................................................................................................................................82

DIN flange design per ISO 3019/2............................................................................................................................................85

Cartridge flange..............................................................................................................................................................................88

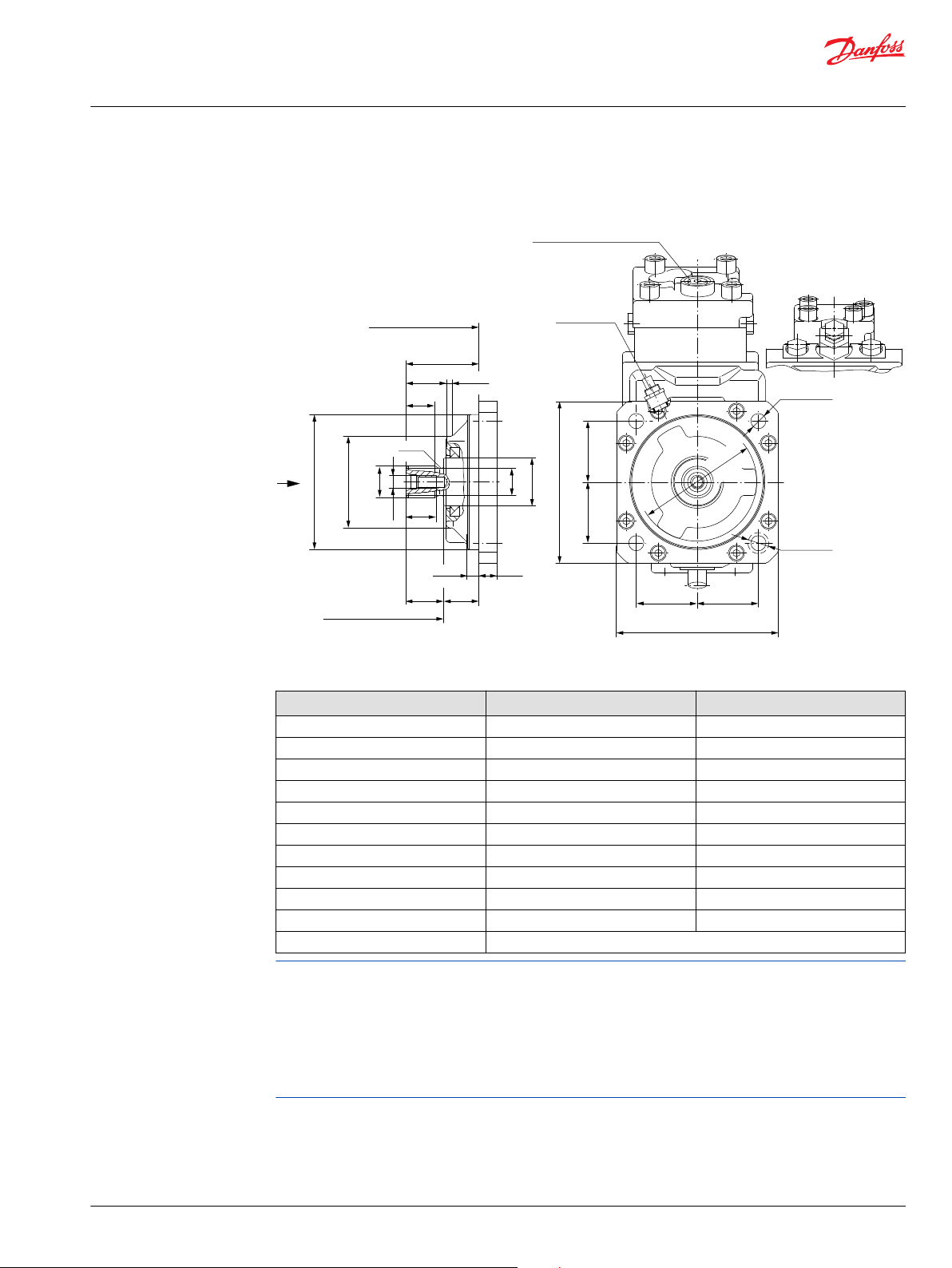

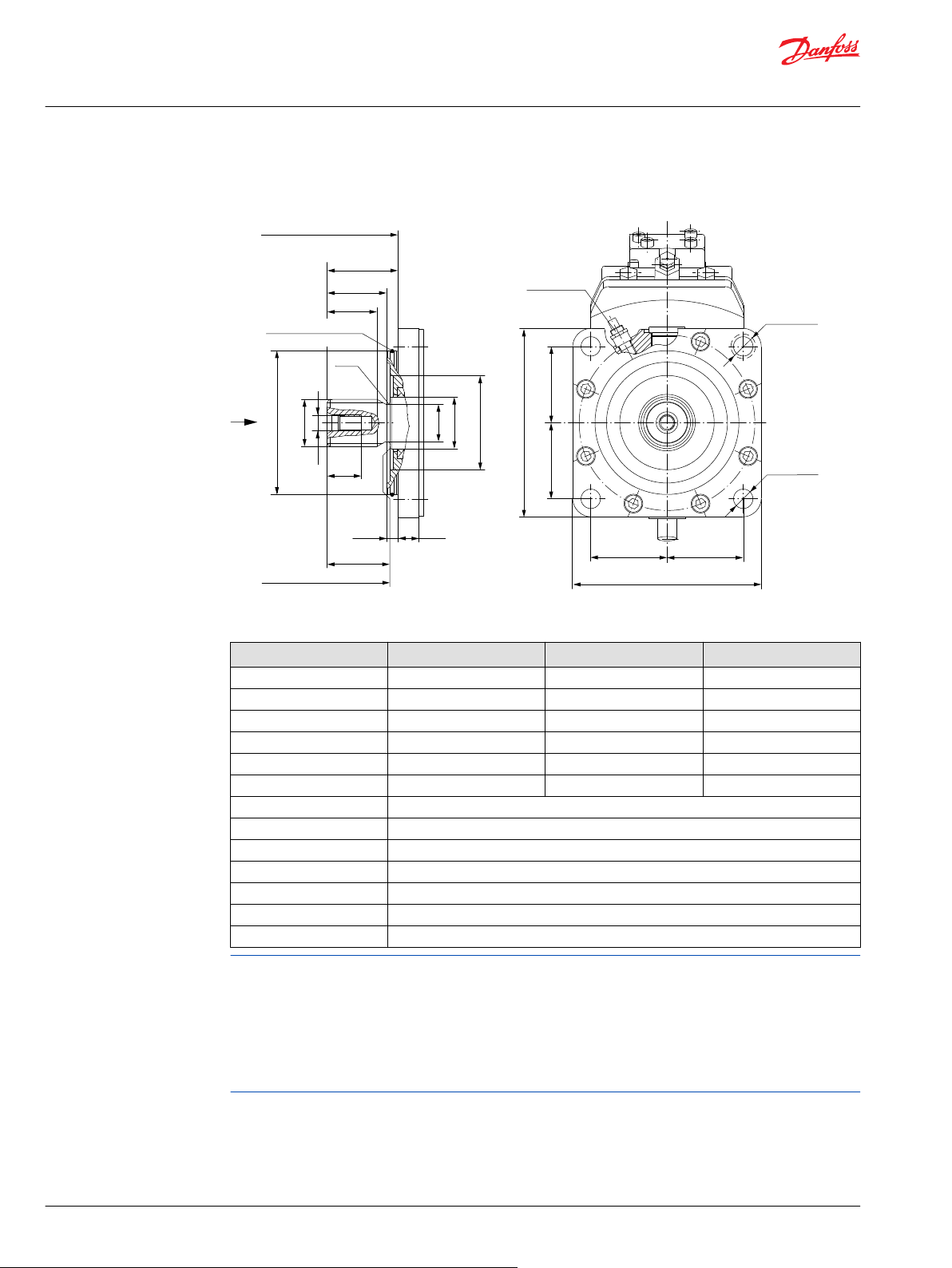

General dimensions – frame size 160

SAE flange design per ISO 3019/1............................................................................................................................................91

DIN flange design per ISO 3019/2............................................................................................................................................93

Cartridge flange..............................................................................................................................................................................95

General dimensions – frame size 250

SAE flange design per ISO 3019/1............................................................................................................................................97

Dimension – Controls

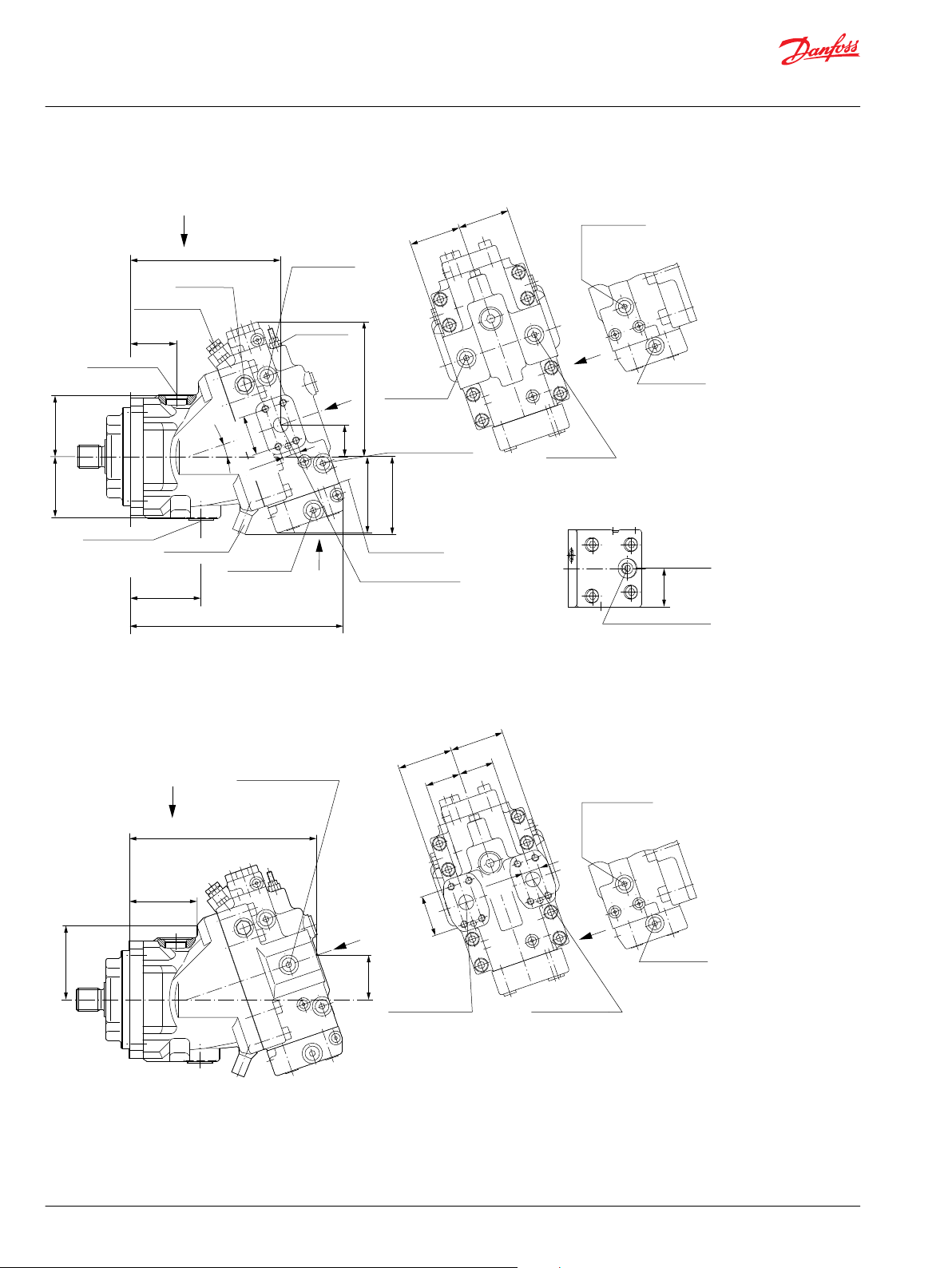

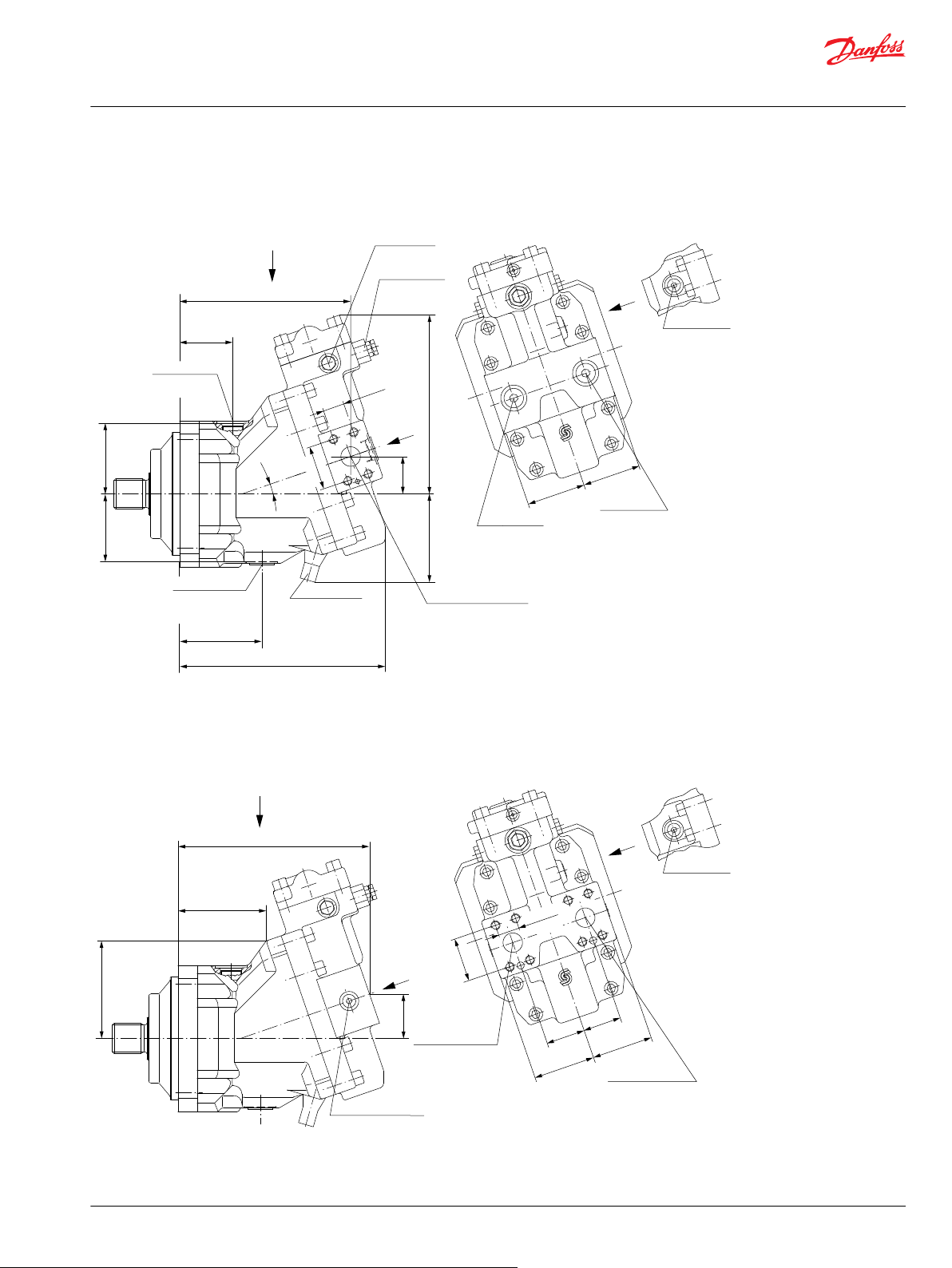

Options TA** for 51-1 – Pressure Compensator Control (Frame Size: 060, 080, 110)........................................... 99

Options TA** for 51 – Pressure Compensator Control (Frame Size: 160, 250)...................................................... 100

Options TH** for 51-1 – Hydraulic Two-Position Control (Frame Size: 060, 080, 110)........................................101

Options TH** for 51 – Hydraulic Two-Position Control (Frame Size: 160, 250).....................................................102

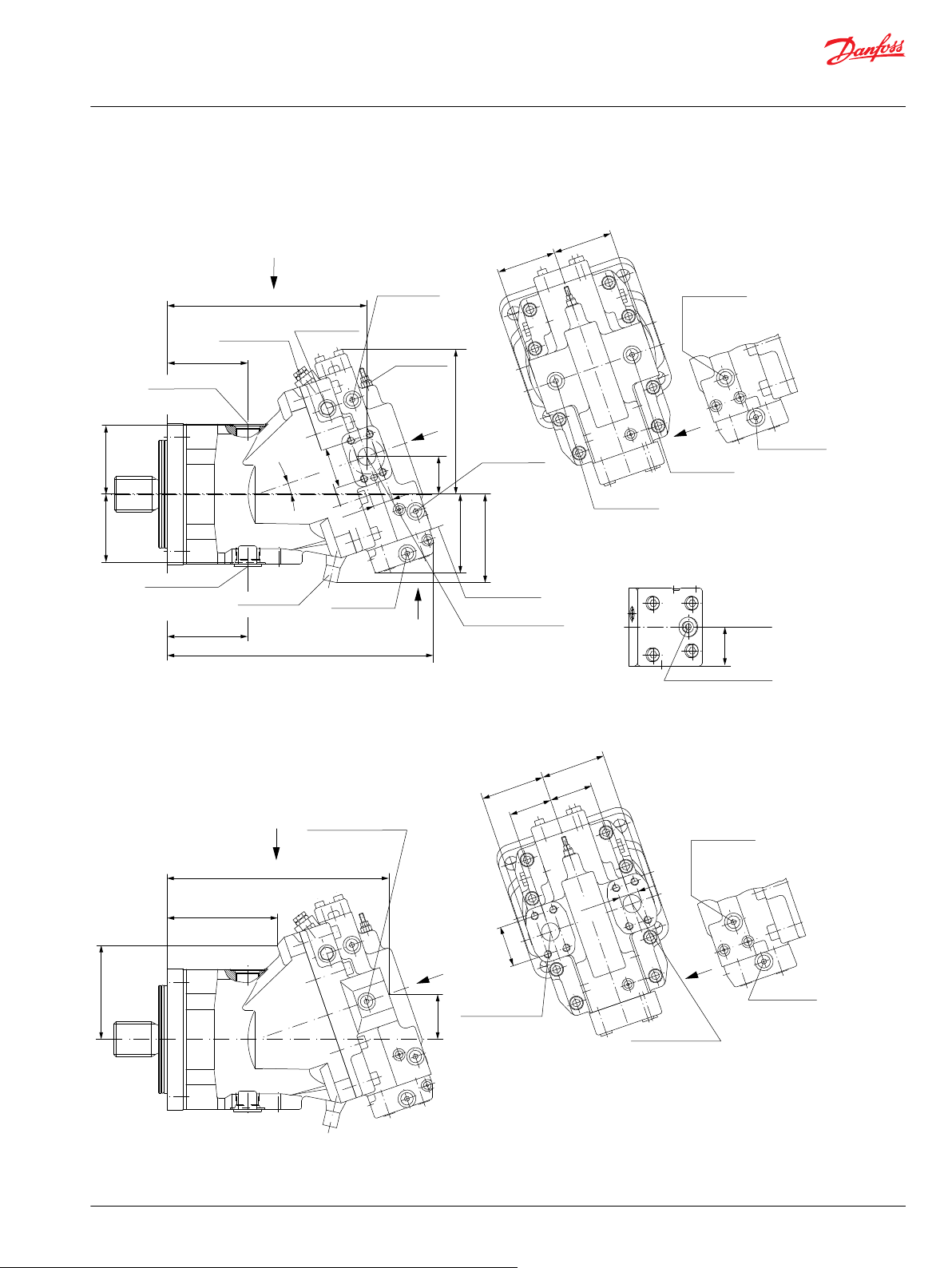

Options E*B1, F*B1 for 51-1 – Electrohydraulic Two-Position Control (Frame Size: 060, 080, 110)...............103

Options E*A5, F*A5 for 51 – Electrohydraulic Two-Position Control (Frame Size: 160, 250)........................... 104

Options T1**, T2**, T7** for 51-1 – Electrohydraulic Two-Position Control (Frame Size: 060, 080, 110).....105

Options T1C2, T2C2 for 51 – Electrohydraulic Two-Position Control (Frame Size: 060, 080, 110)................. 106

Options EPA1, EQA1 for 51 – Electrohydraulic Two-Position Control (All Frame Sizes).................................... 107

Options L1B1, L2B1, L7B1 for 51 – Electrohydraulic Two-Position Control (All Frame Sizes).......................... 108

Options D7M1, D8M1 for 51 – Electrohydraulic Two-Position Control (Frame Size: 060, 080, 110)............. 109

4 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 5

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Contents

Options D7M1, D8M1 for 51 – Electrohydraulic Two-Position Control (Frame Size: 160, 250).......................110

Option HSA* for 51 – Hydraulic Proportional Control (All Frame Sizes)..................................................................111

Option HZB1 for 51 – Hydraulic Proportional Control (All Frame Sizes)................................................................. 112

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 5

Page 6

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Series 51 general information

Series 51 and 51-1 variable displacement motors are bent axis design units, incorporating spherical

pistons.

These motors are designed primarily to be combined with other products in closed circuit systems to

transfer and control hydraulic power. Series 51 and 51-1 motors have a large maximum / minimum

displacement ratio (5:1) and high output speed capabilities. SAE, cartridge, and DIN flange configurations

are available.

A complete family of controls and regulators is available to fulfill the requirements of a wide range of

applications.

Motors normally start at maximum displacement. This provides maximum starting torque for high

acceleration.

The controls may utilize internally supplied servo pressure. They may be overridden by a pressure

compensator which functions when the motor is operating in motor and pump modes. A defeat option is

available to disable the pressure compensator override when the motor is running in pump mode.

The pressure compensator option features a low pressure rise (short ramp) to ensure optimal power

utilization throughout the entire displacement range of the motor. The pressure compensator is also

available as a stand-alone regulator.

The series 51 and 51-1 motors – Advanced technology

•

The most technically advanced hydraulic units in the industry

•

SAE, cartridge, and DIN flange motors

•

Cartridge motors designed for direct installation in compact planetary drives

•

Large displacement ratio (5:1)

•

Complete family of control systems

•

Proven reliability and performance

•

Optimum product configurations

•

Compact, lightweight

•

6 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 7

3

7

1

5

121094 8

P001196

11

2

6

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Series 51 general information

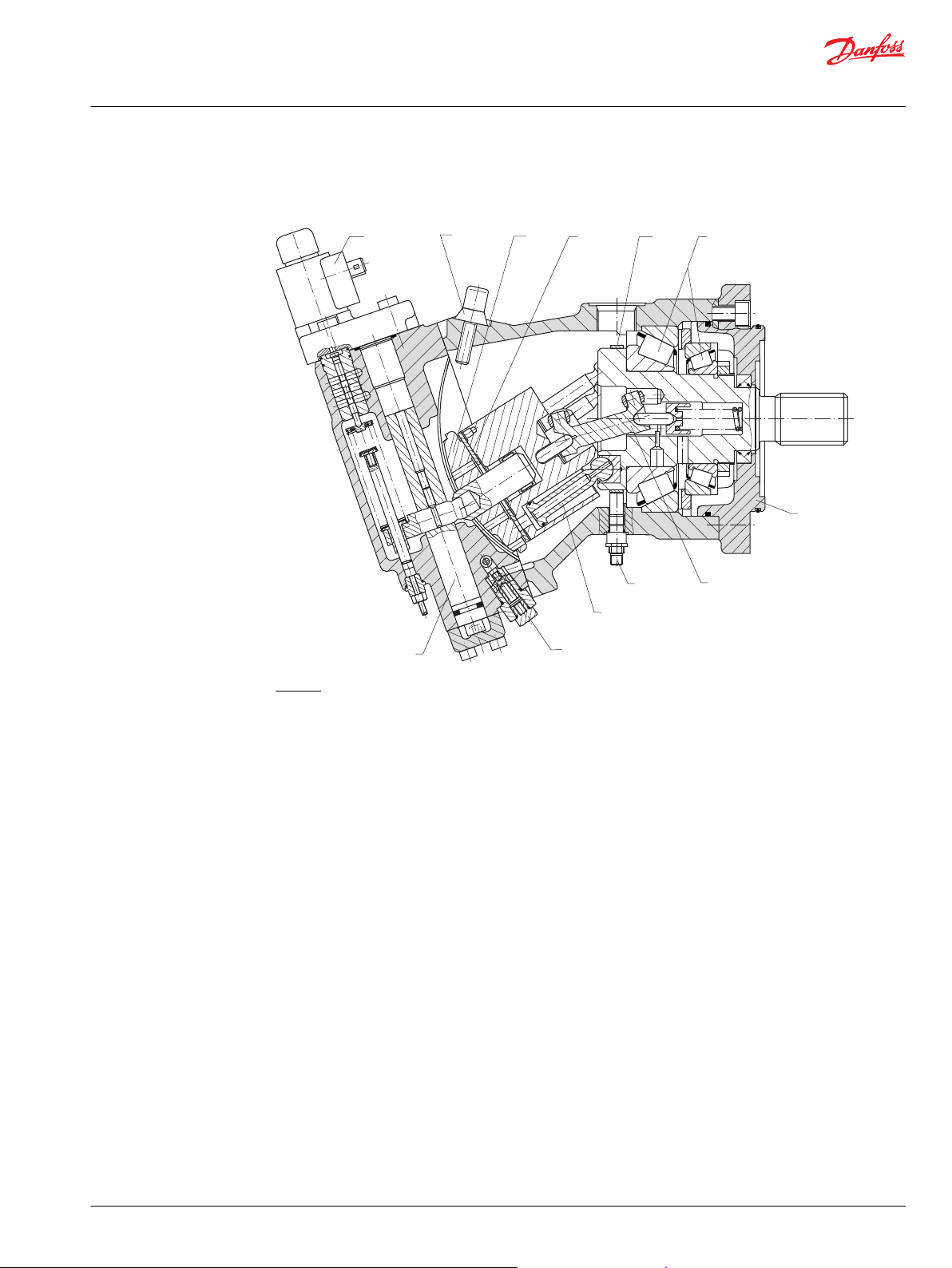

Sectional view of Series 51, proportional control

Series 51 with electric proportional control

Legend:

1 – Piston

2 – Flange

3 – Servo piston

4 – Electric proportional control

5 – Synchronizing shaft

6 – Speed sensor

7 – Charge pressure relief valve

8 – Minimum displacement limiter

9 – Valve segment

10 – Bearing plate

11 – Speed pickup ring

12 – Tapered roller bearings

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 7

Page 8

P001831

3

7

1

5

12109

4

8

11

2

6

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Series 51 general information

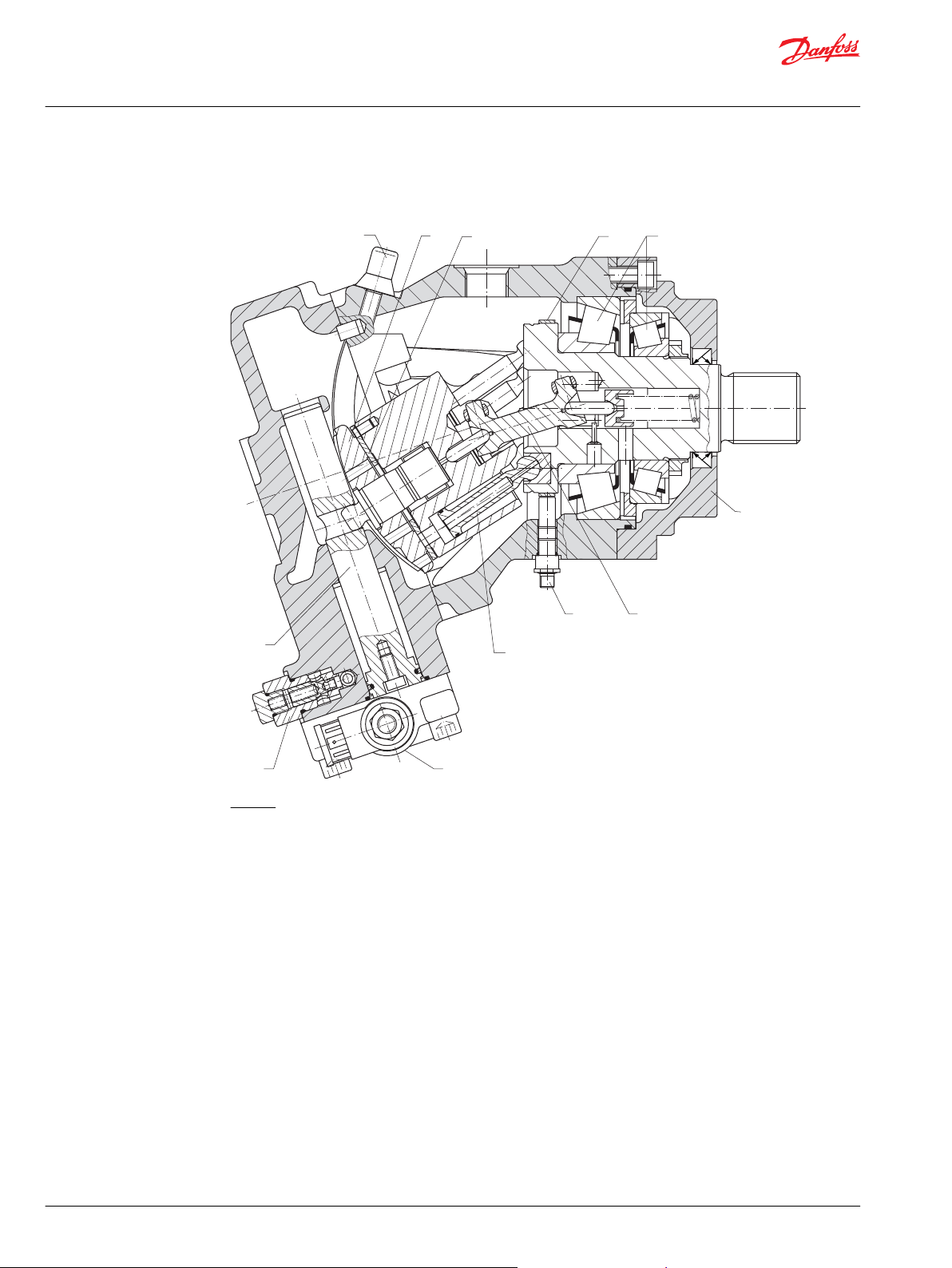

Sectional view of Series 51-1, two-position control

Series 51 with electrohydraulic two-position control

Legend:

1 – Piston

2 – Flange

3 – Servo piston

4 – Electrohydraulic two-position control

5 – Synchronizing shaft

6 – Speed sensor

7 – Charge pressure relief valve

8 – Minimum displacement limiter

9 – Valve segment

10 – Bearing plate

11 – Speed pickup ring

12 – Tapered roller bearings

8 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 9

Multi-function

valve

Synchronizing shaft

Pump swashplate

Servo control

cylinder

Servo control

cylinder

Reversible variable

displacement pump

Input shaft

Heat exchanger

Loop

flushing

valve

Charge pump

Orificed check

valve

Multi-function

valve

Charge pressure

relief valve

Servo

pressure

relief

valves

to pump

case

P001 175E

Control handle

Displacement

control valve

Heat exchanger

Bypass valve

Reservoir

Vacuum gauge

Hydraulic two-position

control

Bent axis variable

displacement motor

Output shaft

Case drain fluid

Working loop

(High pressure)

Working loop

(Low pressure)

Loop flushing relief valve

Servo pressure

Suction

to motor

case

max.

disp.

T1

T7 T8

T2

T3

M

M7

Signal pressure supply

X1

L1

BB

L2

M2

M1

M4

M5

M3

L2

M4

M3

N

M1

M5

M2

A A

S

n

P001833E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Series 51 general information

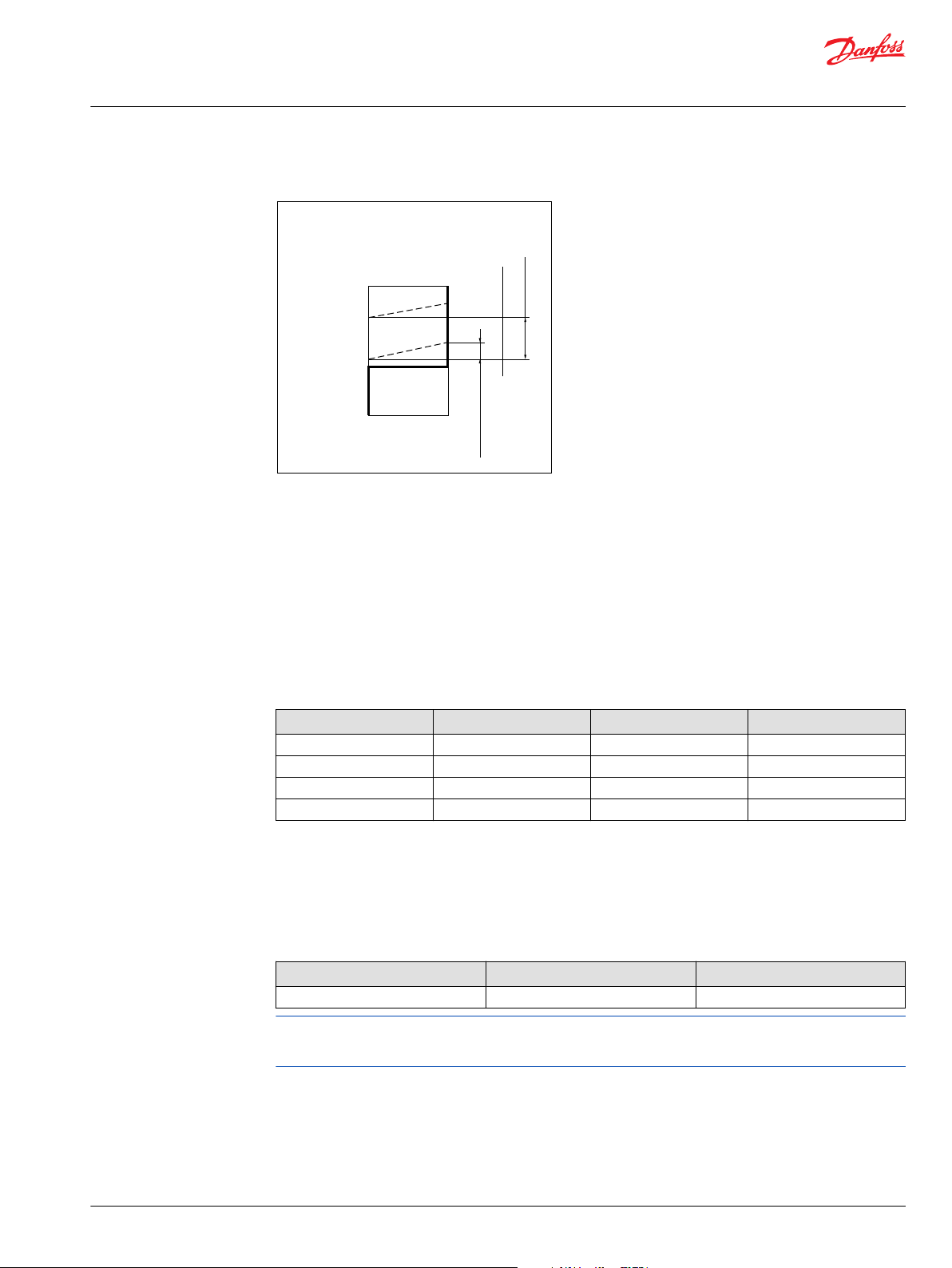

Pictorial diagram

System circuit diagram

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 9

Above schematic shows the function of a hydrostatic transmission using a Series 90 Axial Piston Variable

Displacement Pump with manual displacement control (MA) and a Series 51 Bent Axis Variable

Displacement Motor with hydraulic two-position control (HZ).

Page 10

Made in Germany

Serial No.

Model Code

Model No./Ident. No.

Neumünster/Germany

Place of manufacture

Ident

number

Serial

number

Model

code

Barcode

serial number

P001 832E

5084092

51V080 RS1N

L1B1 WB31 ADA

051AAF0 D400

N982211215

508 4092

Made in Germany

Serial No.

Model Code

Model No./Ident. No.

Neumünster/Germany

Place of manufacture

Ident

number

Serial

number

Model

code

Barcode

serial number

P001 832E

511685

51D110-1-RD4N

E1B1 NNU2 ADD

030AAA3 0000

N973212355

511 685

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Series 51 general information

Series 51/51-1 name plates

Series 51 name plate

Series 51-1 name plate

10 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 11

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Technical specifications

General specifications

Most specifications for bent axis variable displacement motors are listed on these pages. For definitions

of the various specifications, see the related pages in this publication. Not all hardware options are

available for all configurations; consult the series 51 and 51-1 model code supplement or price book for

more information.

General specifications

Design

Direction of rotation

Recommended installation

Other system requirements

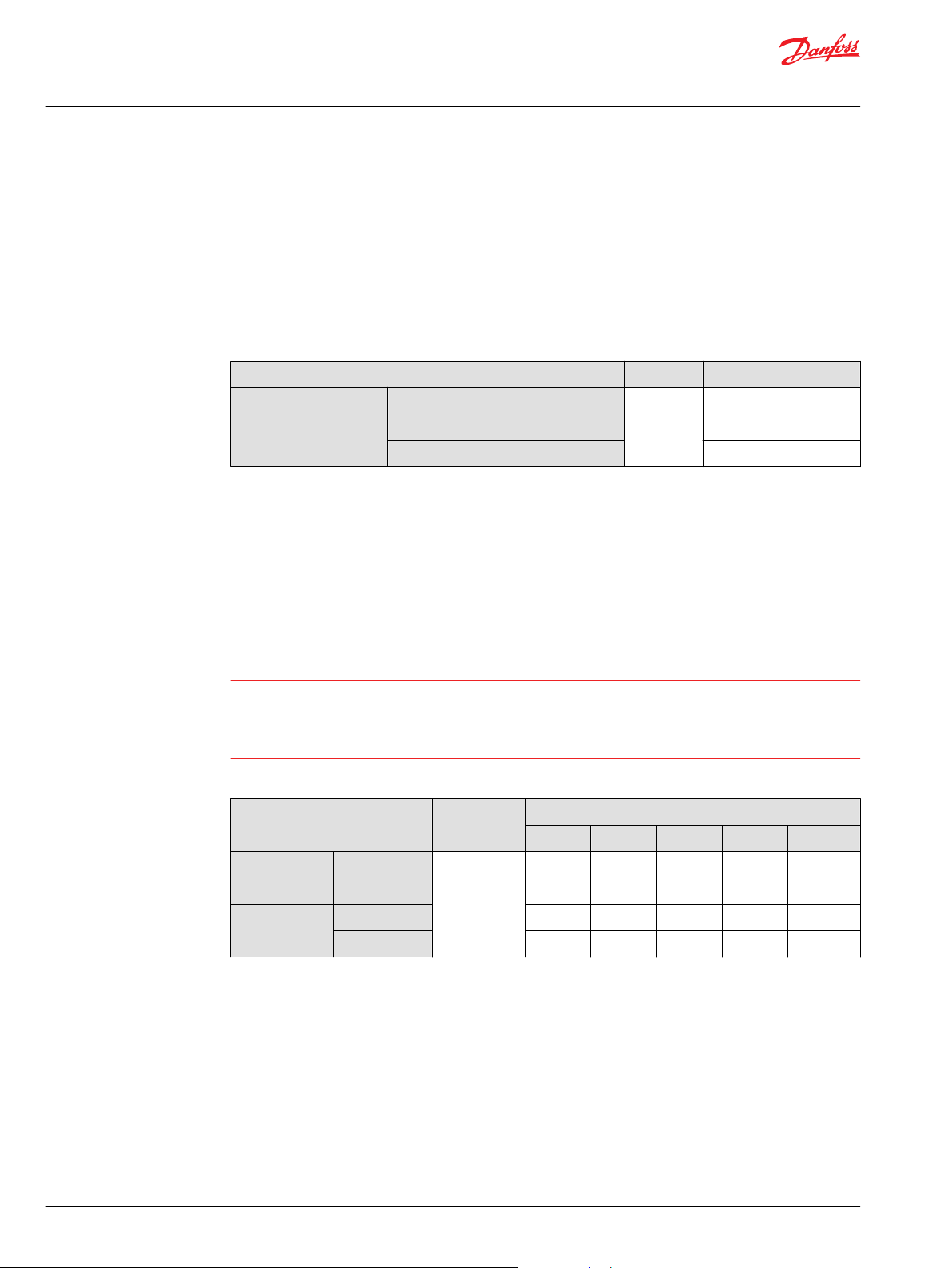

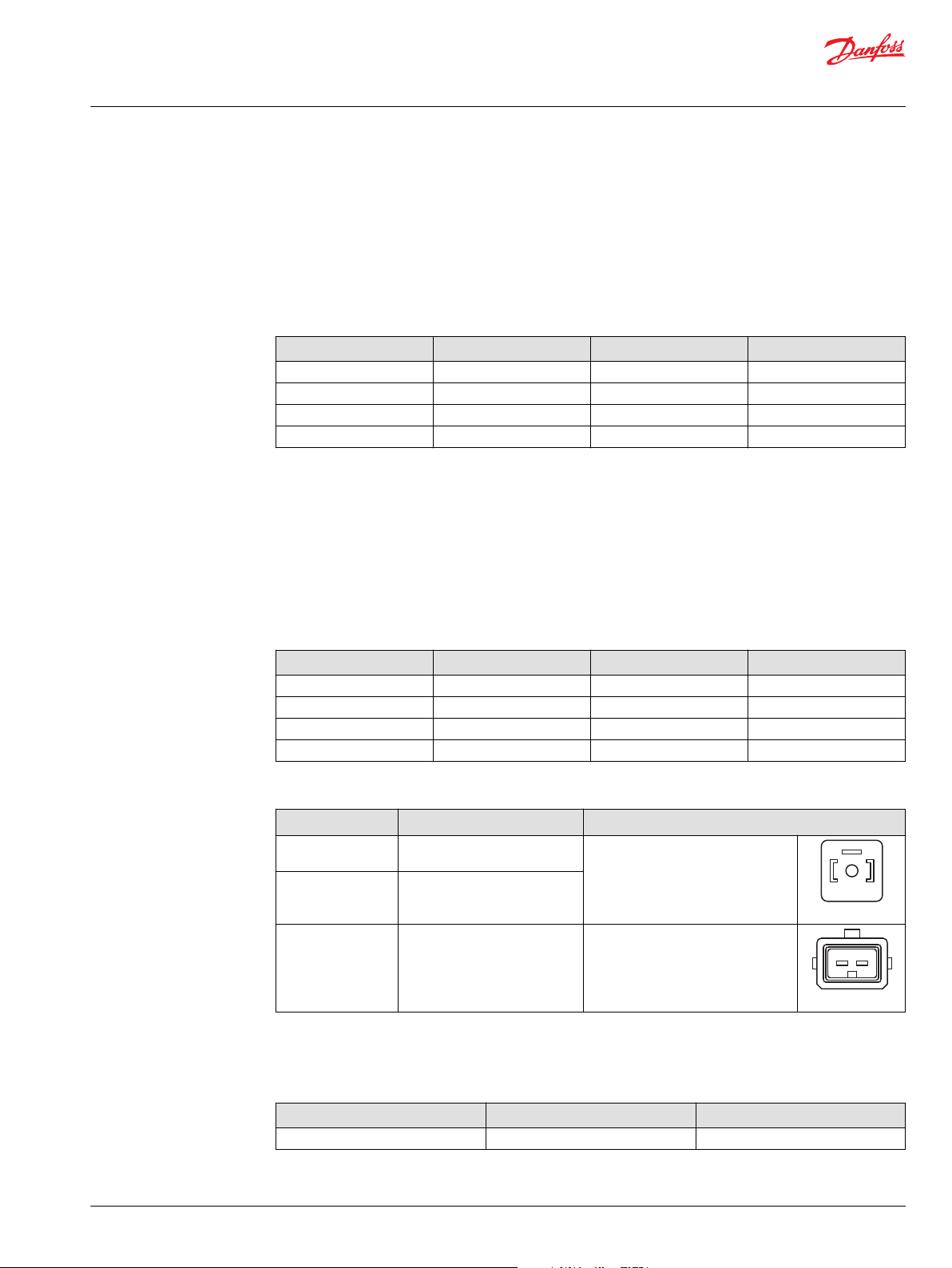

Specific data

Physical properties

Features Unit

Maximum

Displacement

Minimum

Theor. flow at

max. displ.

Theor. corner power at rated

speed and max. working pressure

(Δp = 450 bar [6527 psi])

Theoretical

torque

Mass moment of inertia of

rotating components

Rated speed

Maximum

*

speed

*

Contact Danfoss representative for max. speed at displacements between max. and min. displacement.

at rated speed

at max. speed

at max. displ.

at min. displ.

at max. displ.

at min. displ.

at max. displ.

at min. displ.

Axial piston motor with variable displacement, bent axis design

Clockwise and counter-clockwise (bi-directional)

Discretionary, the housing must always be filled with hydraulic fluid

Independet braking system, circuit overpressure protection, suitable reservoir

Size

060 080 110 160 250

cm3 [in3]

l/min

[US gal/min]

kW

[hp]

N•m/bar

[lbf•in/1000 psi]

2

kg•m

[slug•ft2]

min-1(rpm)

60.0 [3.66] 80.7 [4.92] 109.9

[6.71]

12 [0.73] 16.1 [0.98] 22 [1.34] 32.2 [1.96] 50.0 [3.05]

216 [57] 250 [66] 308 [81] 402 [106] 550 [145]

264 [71] 323 [85] 396 [105] 515 [136] 675 [178]

252

[338]

0.95

[583]

0.19

[117]

0.0046

[0.1092]

3600 3100 2800 2500 2200

5600 5000 4500 4000 3400

4400 4000 3600 3200 2700

7000 6250 5600 5000 4250

300

[402]

1.28

[784]

0.26

[156]

0.0071

[0.1685]

371

[498]

1.75

[1067]

0.35

[214]

0.0128

[0.3037]

160.9

[9.82]

480

[644]

2.56

[1563]

0.51

[313]

0.0234

[0.5553]

250 [15.26]

638

[856]

3.98

[2428]

0.80

[486]

0.0480

[1.1580]

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 11

Page 12

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Technical specifications

System and case pressure

Parameter

Maximum delta

Fluid specifications

System pressure

Case pressure

Fluid specifications

Features Unit

Viscosity

Temperature range

Cleanliness and Filtration

1)

At the hottest point, normally case drain port.

2)

Minimum: cold start, short term t<3 min, p<50 bar, n<1000 rpm.

Maximum

Minimum low

Rated

Maximum (cold start)

Minimum (at rated speed)

Minimum intermittent

Recommended range

Maximum intermittent

Minimum

1)2)

Rated

Maximum intermittent

Required cleanliness per ISO 4406

Efficiency (charge pressure filtration)

Efficiency (suction / return line filtration)

Recommended inlet screen mesh size

Unit

bar [psi]

mm2/s

[SUS]

°C

[°F]

-

β-ratio

µm 100 – 125

All sizes

480 [7000]

510 [7400]

10 [145]

3 [44]

5 [73]

0.3 [4.35]

All sizes

7 [49]

12-80 [66-366]

1600 [7416]

-40 [-40]

104 [220]

115 [240]

22/18/13

β

= 75 (β10 ≥ 10)

15-20

β

= 75 (β10 ≥ 2)

35-45

12 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 13

Vg • n

1000 •

v

Qe =

Vg • p •

mh

20 •

Me =

Qe • p •

t

600

=

Me • n

9550

Pe=

n =

Qe • 1000 •

v

V

g

Vg • n

231 •

v

Qe =

Vg • p •

mh

2 •

Me =

Vg • n • p •

t

396 000

Pe=

n =

Qe • 231 •

v

V

g

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Technical specifications

Determination of nominal motor size

Based on SI units Based on US units

Where:

Q

Input flow (l/min)

e

M

Output torque (N•m)

e

P

Output power (kW)

e

n Speed (min-1)

V

Motor displacement per rev. (cm3/rev)

g

p

High pressure (bar)

high

p

Low pressure (bar)

low

∆p High pressure minus Low pressure (bar)

η

Motor volumetric efficiency

v

η

Mechanical-hydraulic efficiency

mh

η

Motor total efficiency (ηv • ηmh)

t

Where:

Q

Input flow [US gal/min]

e

M

Output torque [lb•in]

e

P

Output power [hp]

e

n Speed [rpm]

V

Motor displacement per rev. [in3/rev]

g

p

High pressure [psi]

high

p

Low pressure [psi]

low

∆p High pressure minus Low pressure [psi]

η

Motor volumetric efficiency

v

η

Mechanical-hydraulic efficiency

mh

η

Motor total efficiency (ηv • ηmh)

t

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 13

Page 14

W

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Case pressure

Under normal operating conditions, case pressure must not exceed the rated pressure. Momentary case

pressure exceeding this rating is acceptable under cold start conditions, but still must stay below the

maximum pressure rating.

The minimum pressure provides proper lubrication at high speeds.

Operation with case pressure in excess of these limits may result in external leakage due to damage to

seals, gaskets, and/or housings.

Case pressure

Parameter

Rated

Case pressure

Speed range

Rated speed is the speed limit recommended at full power condition and is the highest value at which

normal life can be expected.

Maximum speed is the highest operating speed permitted and cannot be exceeded without reduction

in the life of the product or risking immediate failure and loss of driveline power (which may create a

safety hazard). In the range between rated and maximum speed please contact your Danfoss Power

Solutions representative.

Maximum (cold start)

Minimum (at rated speed)

Unit

bar [psi]

All sizes

3 [44]

5 [73]

0.3 [4.35]

Warning

The loss of hydrostatic drive line power in any mode of operation (e.g., forward, reverse, or “neutral”) may

cause the loss of hydrostatic braking capacity. A braking system, redundant to the hydrostatic

transmission must, therefore, be provided which is adequate to stop and hold the system should the

condition develop.

Speed limits

Features Unit

at max. displ.

Rated speed

at min. displ.

min-1(rpm)

at max. displ.

Maximum speed

at min. displ.

060 080 110 160 250

3600 3100 2800 2500 2200

5600 5000 4500 4000 3400

4400 4000 3600 3200 2700

7000 6250 5600 5000 4250

Size

14 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 15

Rated speed

at min. displacement

Rated speed

at max. displacement

Acceptable operating range

Maximim speed

at min. displacement

Maximum speed

at max. displacement

Curve determined by rated flow

Min. displacement Max. displacement

P001 781E

Speed min

-1

(rpm)

Motor angle (degrees)

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Speed limits

For operation within the range above the acceptable range contact Danfoss Power Solutions

representative.

Pressure limits

System pressure is the dominant operating variable affecting hydraulic unit life. High pressure, which

results from high load, reduces expected life in a manner similar to the affects of high load on other

mechanical assemblies such as engines and gear boxes. There are load-to-life relationships for the

rotating group and for the shaft anti-friction bearings.

Continuous pressure is the pressure at which the hydrostatic system could operate continuously and still

achieve acceptable hydrostatic life. This pressure level varies depending on operating speed, and on the

life requirements for a particular application. While most mobile applications require system pressure to

vary widely during operation, a “weighted average” pressure can be derived from a machine duty cycle.

(A duty cycle is a means of quantifying the pressure and speed demands of a particular system on a

percent time basis). Once a duty cycle has been determined or estimated for a specific application,

contact your Danfoss representative for system life ratings for the application.

Maximum delta pressure is the highest intermittent pressure allowed, and is the relief valve setting. It is

determined by the maximum machine load demand. For most systems, the load should move at this

pressure.

Maximum pressure is assumed to occur a small percentage of operating time, usually less than 2 % of

the total. Both the continuous and maximum pressure limits must be satisfied to achieve the expected

life.

Minimum low pressure must maintained under all operating conditions to avoid cavitation.

System pressure range, input

Maximum delta pressure Minimum low pressure Maximum pressure

480 [7000 psi] 10 [145 psi] 510 [7400 psi]

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 15

Page 16

W

Loop flushing relief valve

Loop flushing shuttle spool

P001 782E

A B

P001 830

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

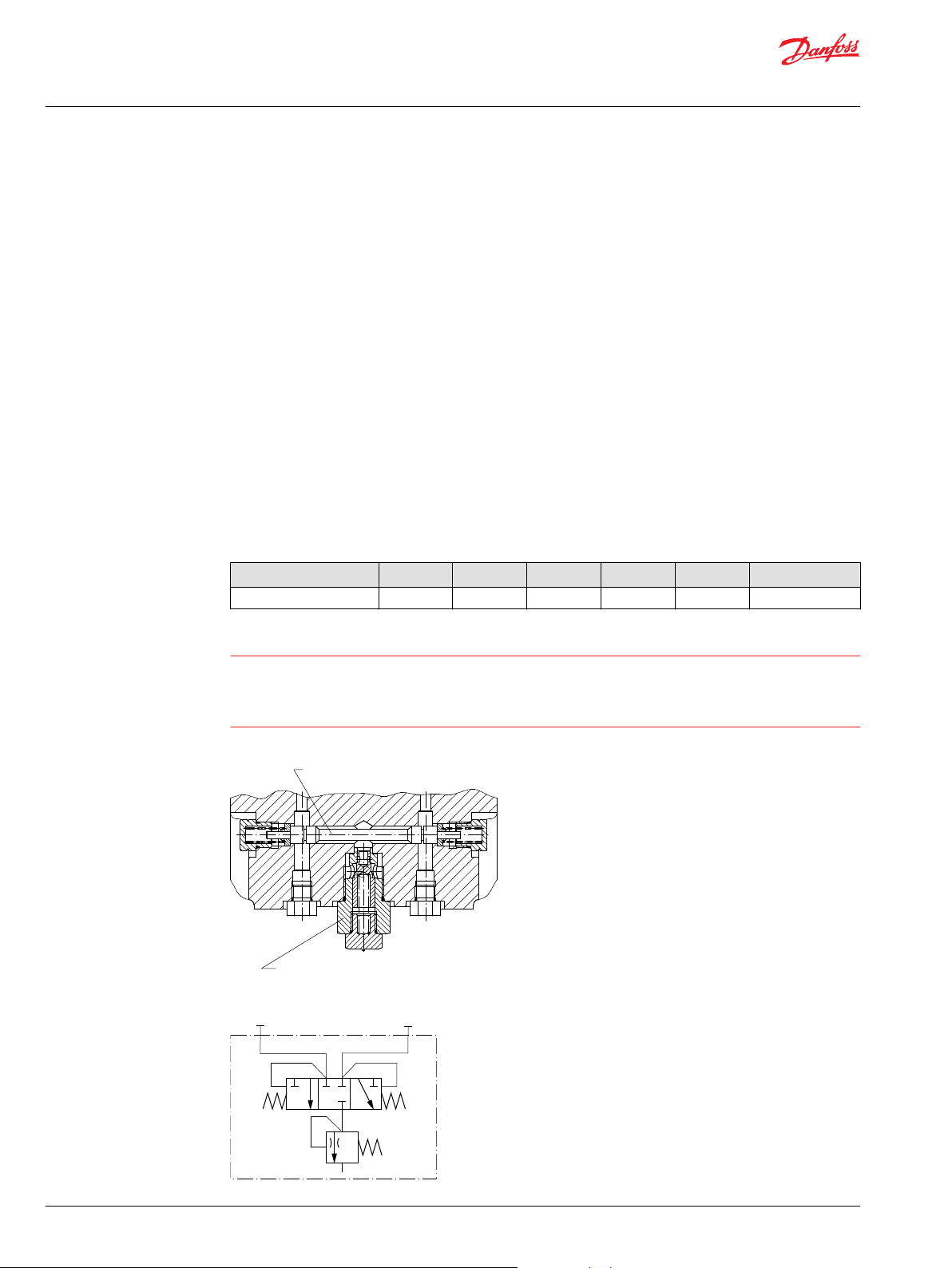

Loop flushing

An integral non-adjustable loop flushing valve is incorporated into all these motors. Installations that

require fluid to be removed from the low pressure side of the system circuit because of cooling

requirements or contamination removal will benefit from loop flushing.

The integral loop flushing valve is equipped with an orificed charge pressure relief valve designed with a

cracking pressure of 16 bar [232 psi].

Valves are available with several orifice sizes to meet the flushing flow requirements of all system

operating conditions.

The total system charge pump flow should be of sufficient volume to accommodate:

The number of motors in the system

•

System efficiency under worst case conditions

•

Pump control requirements

•

External needs

•

Although charge pump sizing requires the consideration of many system variables, the following table

gives a recommendation of what charge pump displacement may be required to accommodate the

flushing flow of each available charge relief valve orifice.

Recommended charge pump displacement

Loop flushing valve E4, E6 F0 F3 G0 G3 H0

Charge pump size (cm3) 8 11 14 17 or 20 26 34, 47 or 65

Warning

The loss of hydrostatic drive line power in any mode of operation (e.g., forward, reverse, or “neutral”

mode) may cause the loss of hydrostatic braking capacity. A braking system, redundant to the hydrostatic

transmission must, therefore, be provided which is adequate to stop and hold the system should the

condition develop.

Loop flushing valve

Hydraulic schematic

16 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 17

0 5

[1.3]10[2.6]15[4.0]20[5.3]

Case flow l/min [US gal/min]

Low system pressure minus case pressure

bar [psi]

25

[6.6]30[8.0]35[9.2]40[10.6]

[508]

35

[363]

25

[218]

15

[73]

5

P001 860E

E4 E6 F0 F3 G0 G3 H0

C

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

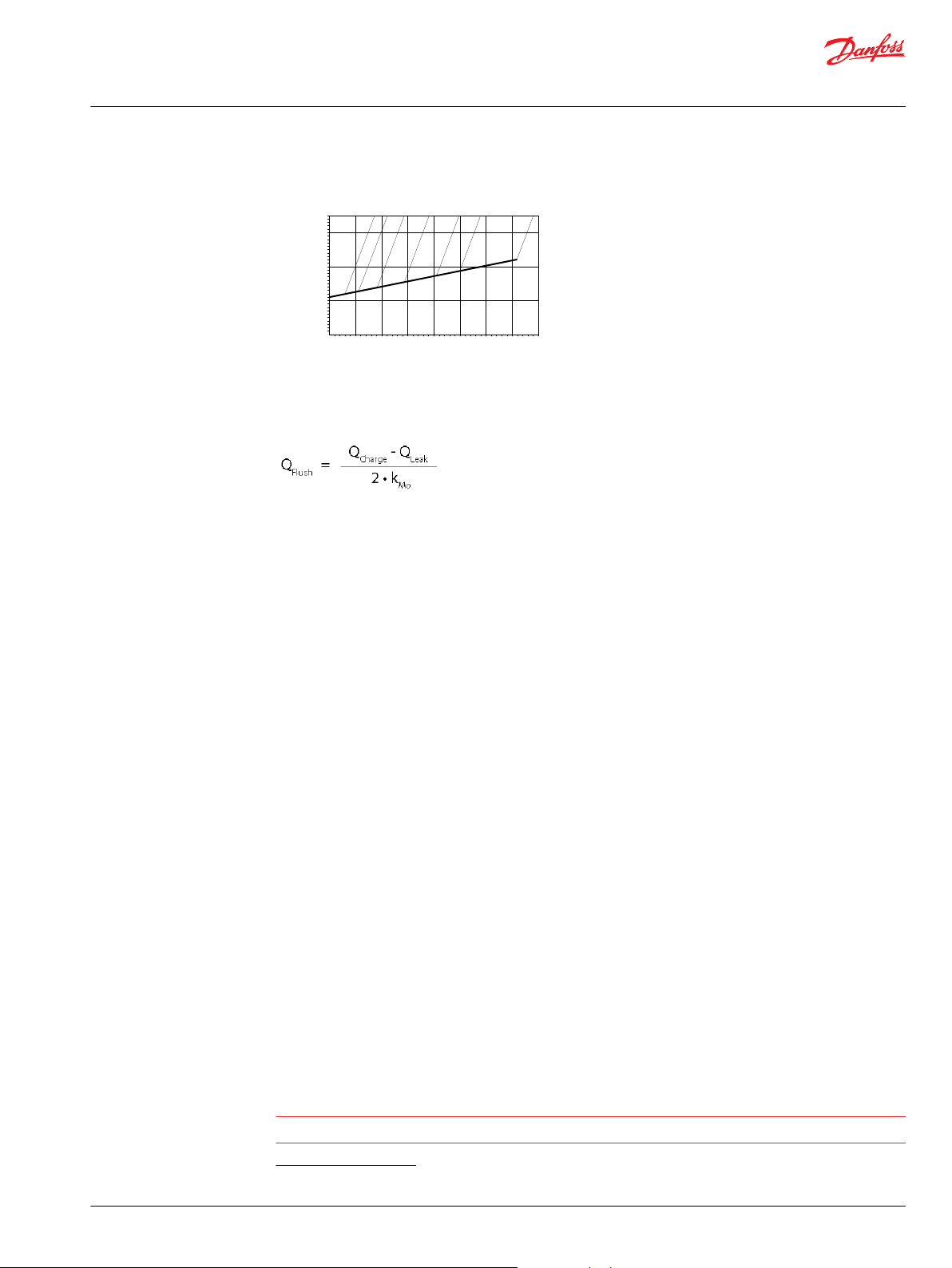

Case flow characteristic

Equation:

Where:

Q

– flushing flow per motor

Flush

Q

– charge flow at operating speed

Charge

kMo – number of motors feeded by one pump

Q

– sum of external leakages

Leak

Minimum displacement limiter

Hydraulic fluids

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 17

Q

includes:

Leak

motor leakage

•

pump leakage + internal consumers:

•

8 l/min [2.11 US gal/min] for displacement control pumps or

‒

for non-feedback controlled pumps at 200 bar [2900 psi]

‒

external consumers:

•

e.g. brakes, cylinders, and other pumps

‒

All Series 51 and 51-1 motors incorporate mechanical displacement limiters.

The minimum displacement of the motor is preset at the factory with a set screw in the motor housing. A

tamper-proof cap is provided.

Ratings and data are based on operating with hydraulic fluids containing oxidation, rust and foam

inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear, erosion and

corrosion of the internal components.

Fire resistant fluids are also suitable at modified operating conditions. Please see Danfoss literature

Technical Information Hydraulic Fluids and Lubricants for more information.

For more information contact your Danfoss representative.

Caution

It is not permissible to mix hydraulic fluids.

Suitable hydraulic fluids:

Page 18

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Hydraulic fluids per DIN 51 524, part 2 (HLP)

•

Hydraulic fluids per DIN 51 524, part 3 (HVLP)

•

API CD, CE and CF engine fluids per SAE J183

•

M2C33F or G automatic transmission fluids (ATF)

•

Agricultural multi purpose oil (STOU)

•

Premium turbine oils (for Premium turbine oils contact your Danfoss representative).

•

Temperature and viscosity

Temperature and viscosity requirements must be concurrently satisfied. The data shown in the tables

assume petroleum-based fluids, are used.

The high temperature limits apply at the hottest point in the transmission, which is normally the motor

case drain. The system should generally be run at or below the rated temperature. The maximum

temperature is based on material properties and should never be exceeded.

Cold oil will generally not affect the durability of the transmission components, but it may affect the

ability to flow oil and transmit power; therefore temperatures should remain 16 °C [30 °F] above the pour

point of the hydraulic fluid. The minimum temperature relates to the physical properties of component

materials.

For maximum unit efficiency and bearing life the fluid viscosity should remain in the recommended

operating range. The minimum viscosity should be encountered only during brief occasions of

maximum ambient temperature and severe duty cycle operation. The maximum viscosity should be

encountered only at cold start.

Heat exchangers should be sized to keep the fluid within these limits. Testing to verify that these

temperature limits are not exceeded is recommended.

Filtration system

Viscosity and temperature range

Features Unit

Minimum intermittent

Viscosity

Temperature range

1)

At the hottest point, normally case drain port.

2)

Minimum: cold start, short term t<3 min, p<50 bar, n<1000 rpm.

Recommended range

Maximum intermittent

Minimum

1)2)

Rated

Maximum intermittent

mm2/s

[SUS]

°C

[°F]

All sizes

7 [49]

12-80 [66-366]

1600 [7416]

-40 [-40]

104 [220]

115 [240]

To prevent premature wear, ensure that only clean fluid enters the hydrostatic transmission circuit. A

filter capable of controlling the fluid cleanliness to ISO 4406, class 22/18/13 (SAE J1165) or better, under

normal operating conditions, is recommended.These cleanliness levels cannot be applied for hydraulic

fluid residing in the component housing/case or any other cavity upon delivery from the factory.

The filter may be located on the pump (integral) or in another location (remote or suction). The integral

filter has a filter bypass sensor to signal the machine operator when the filter requires changing. Filtration

strategies include suction or pressure filtration. The selection of the filter strategy depends on a number

of factors including the contaminant ingression rate, the generation of contaminants in the system, the

required fluid cleanliness, and the desired maintenance interval. Filters are selected to meet the above

requirements using rating parameters of efficiency and capacity.

Filter efficiency can be measured with a Beta ratio (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter with a β-ratio within the

18 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 19

C

W

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Fluid selection

range of β

= 75 (β10 ≥ 2) or better has been found to be satisfactory. For some open circuit systems,

35-45

and closed circuits with cylinders being supplied from the same reservoir, a higher filter efficiency is

recommended. This also applies to systems with gears or clutches using a common reservoir. For these

systems, a charge pressure or return filtration system with a filter β-ratio in the range of β

= 75 (β10 ≥

15-20

10) or better is typically required.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. For more information, see Design Guidelines for Hydraulic Fluid Cleanliness, Technical

Information BC00000095.

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the number

of particles greater than a given diameter (“x” in microns) upstream of the filter to the number of these

particles downstream of the filter.

Filtration, cleanliness level and βx-ratio (recommended minimum)

Cleanliness per ISO 4406

Efficiency βx (charge pressure filtration)

Efficiency βx (suction and return line filtration)

Recommended inlet screen mesh size

22/18/13

β

= 75 (β10 ≥ 10)

15-20

β

= 75 (β10 ≥ 2)

35-45

100 – 125 µm

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion, and corrosion of motor components.

Reservoir

Independent braking system

Caution

Never mix hydraulic fluids of different types.

Fire resistant fluids are also suitable at modified operating conditions. For more information, see

Hydraulic Fluids and Lubricants, Technical Information BC00000093.

The function of the reservoir is to remove air and to provide make up fluid for volume changes associated

with fluid expansion or contraction, possible cylinder flow, and minor leakage.

The reservoir should be designed to accommodate maximum volume changes during all system

operating modes and to promote deaeration of the fluid as it passes through the tank.

A minimum reservoir volume equal to 1/2 to 1 1/2 times charge pump flow/min is suggested. This allows

30 seconds fluid dwell for removing entrained air at the maximum return flow. This is usually adequate to

allow for a closed reservoir (no breather) in most applications. The reservoir outlet to the charge pump

inlet should be above the bottom of the reservoir to take advantage of gravity separation and prevent

large foreign particles from entering the charge inlet line.

The reservoir inlet (fluid return) should be positioned so that the flow to the reservoir is discharged below

the normal fluid level, and also directed into the interior of the reservoir for maximum dwell and efficient

deaeration.

Warning

The loss of hydrostatic drive line power in any mode of operation (e.g., forward, reverse, or “neutral”

mode) may cause the loss of hydrostatic braking capacity. A braking system, redundant to the hydrostatic

transmission must, therefore, be provided which is adequate to stop and hold the system should the

condition develop.

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 19

Page 20

L1 • 1500

n

2

L2 =

hours

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Motor bearing life

The rated motor bearing life L

bearings, when operating at a speed of n = 1500 min-1 (rpm) with a charge pressure of 20 bar [290 psi]

and without external shaft load.

h10

shown in the table below is based on a 90 % survival rate of shaft

The rated motor bearing life L

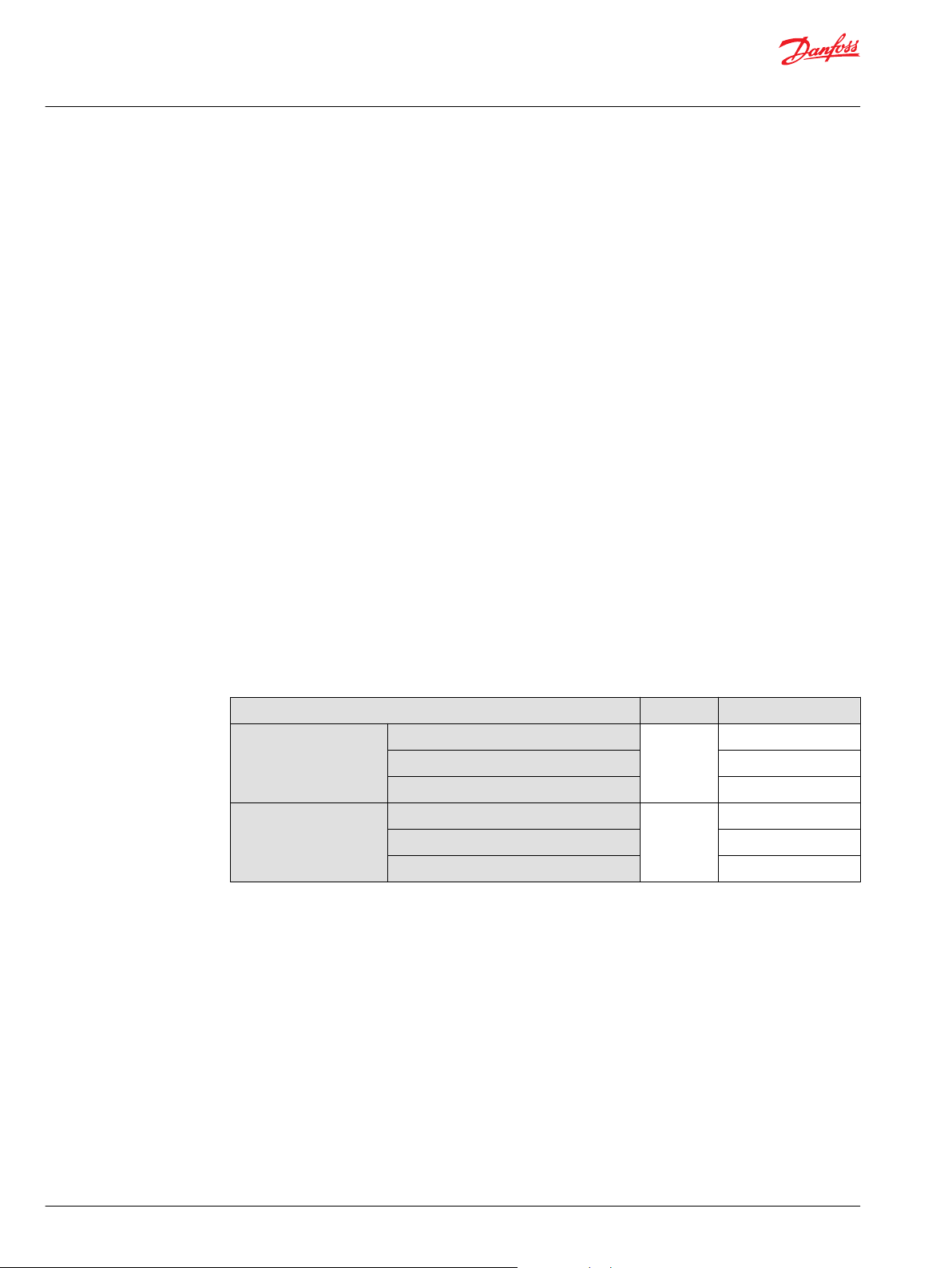

Frame Size Effective ∆ pressure

bar [psi]

140 [2030] 19 800 18 530 16 370

060

080

110

160

250

210 [3050] 6320 5960 5340

280 [4060] 2740 2600 2350

140 [2030] 14 420 13 580 12 120

210 [3050] 4610 4370 3960

280 [4060] 2000 1910 1750

140 [2030] 15 800 14 890 13 330

210 [3050] 5040 4790 4350

280 [4060] 2180 2090 1920

140 [2030] 15 670 14 770 13 200

210 [3050] 5005 4750 4300

280 [4060] 2170 2070 1900

140 [2030] 11 760 11 130 10 020

210 [3050] 3750 3580 3260

280 [4060] 1630 1560 1440

h10

(hours)

Motor angle

6° 15° 32°

Lifetimes for speeds other than 1500 min-1 (rpm) can be calculated from:

Where: Units:

L

==Rated L10 life at 1500 min-1 (rpm)

1

n

2

Operating speed

hours

min-1 (rpm)

Contact your Danfoss Power Solutions representative for bearing life values at other pressure and angle.

20 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 21

Fr

35°

35°

Fr

A

X

1

A

A

SAE-Flange design per ISO 3019/1

DIN-Flange design per ISO 3019/2

Cartridge Flange design

35°

35°

Fa

Fa

Fa

X

1

Fr

X

1

X2 < X

1

X2 > X

1

X2 < X

1

X2 > X

1

X2 < X

1

X2 > X

1

P001 166E

35°

Fr

Fr

Fr

35°

OPTIMUM LOAD

ORIENTATION

OPTIMUM LOAD

ORIENTATION

OPTIMUM LOAD

ORIENTATION

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

External shaft loads

Series 51 and 51-1 motors are designed with bearings that can accept external radial and thrust loads.

The external radial shaft load limits are a function of the load position, the load orientation, and operating

conditions of the unit.

External shaft load orientation

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 21

Page 22

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

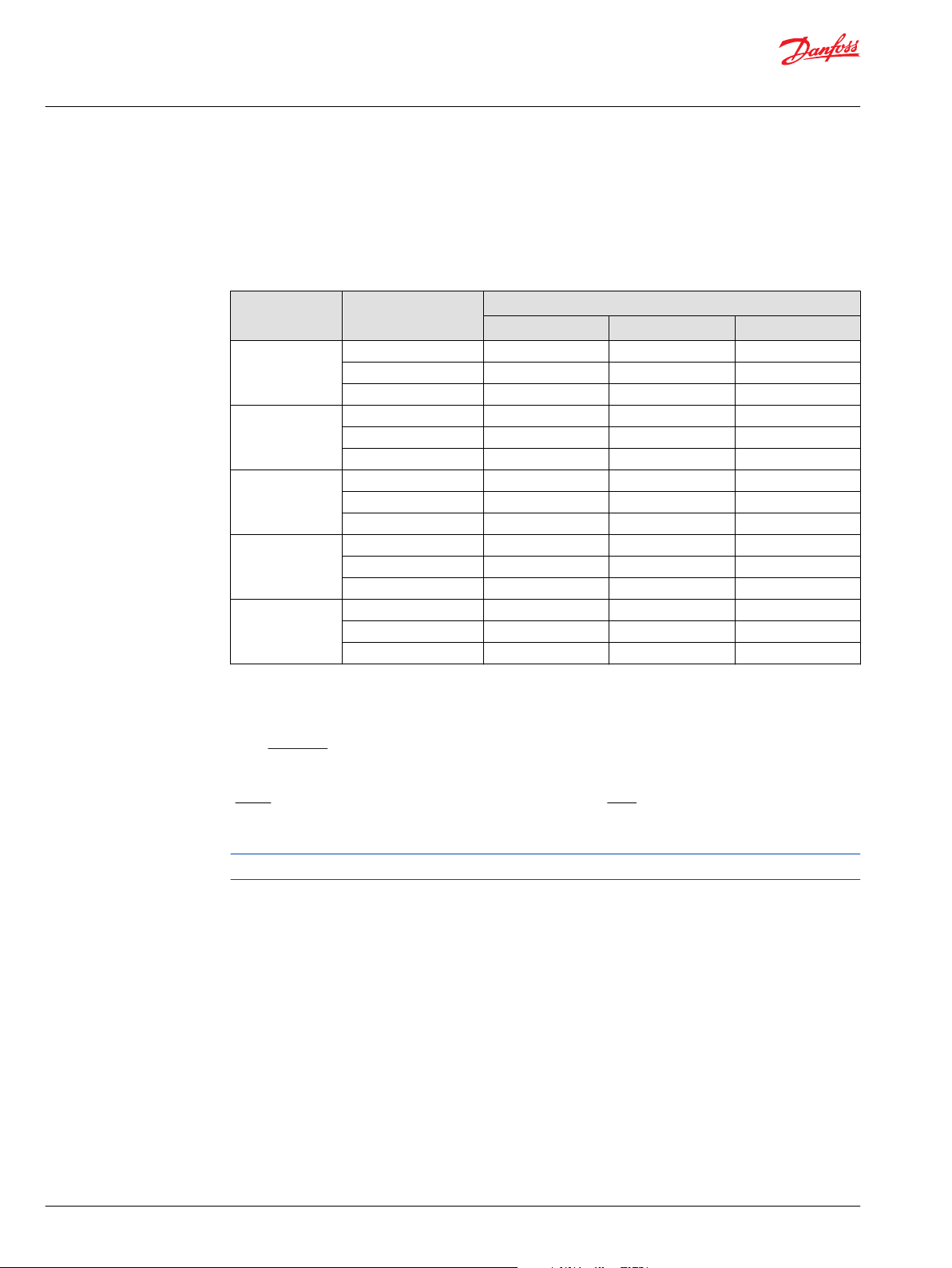

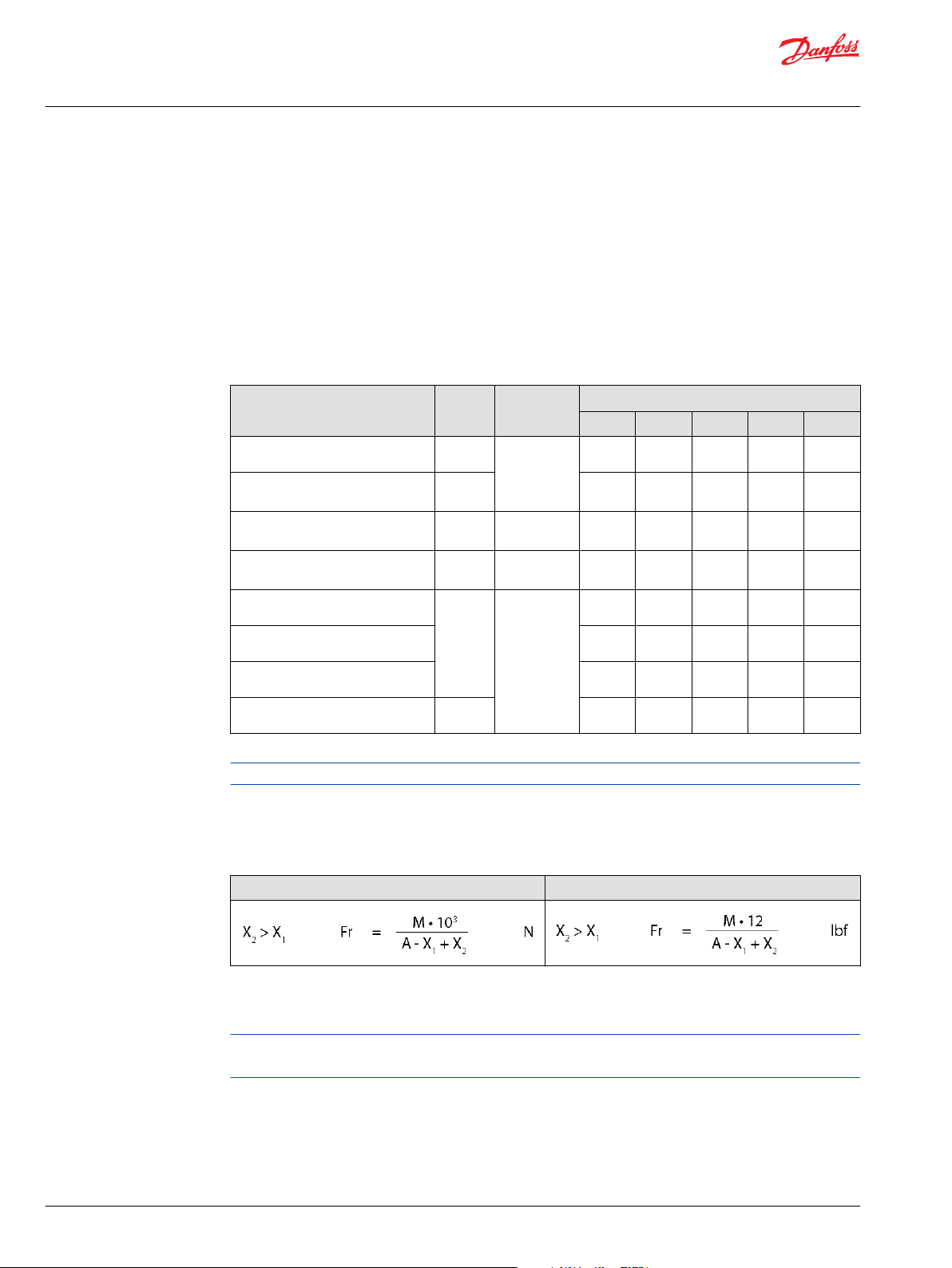

Radial and thrust loads to the output shaft

The table below provides the following information:

•

The maximum allowable radial load (Fr) based on the distance (X1) from the mounting flange to the

load.

•

The maximum allowable axial load (Fa).

•

The actual distance of Fr for a given application from the mounting flange to the load (X2).

•

The basic distance (A).

•

Fa/∆p ratio of allowable axial load, dependent upon the system pressure.

Radial and thrust loads to the output shaft

Feature Symbol Unit

Maximum allowable radial load

Max. allow. axial load at zero rpm, or

running in the idle pressure

Max. allowable bending moment

Max. allowable axial load at pressure

Distance SAE mounting flange

Distance DIN mounting flange 57.2

Distance Cartridge mount. flange 117.6

Basic distance A 25.2

– = not available

060 080 110 160 250

Fr

Fa 1100

M

Fa/∆p

X

1

N [lb]

N•m

[lb•in]

N/bar

[lb/1000 psi]

mm [in]

10 000

[2248]

[247]

252

[2230]

10.4

[161]

33.6

[1.32]

[2.25]

[4.63]

[0.99]

12 000

[2698]

1400

[315]

307

[2717]

12.6

[195]

33.6

[1.32]

57.6

[2.27]

136.1

[5.36]

25.6

[1.01]

Frame Size

14 000

[3147]

1800

[405]

766

[6780]

15.2

[236]

62.7

[2.47]

94.7

[3.73]

177.5

[7.0]

54.7

[2.15]

18 000

[4047]

2500

[562]

805

[7125]

19.2

[298]

52.7

[2.07]

84.7

[3.33]

– –

44.7

[1.76]

26 000

[5845]

4500

[1012]

970

[8585]

26.4

[409]

45.3

[1.78]

–

37.3

[1.47]

The values in the table are maximum values and are not allowed under continuous load conditions.

Allowable external shaft load, when shaft load distance is different from standard

Use this formula to calculate maximum allowable radial load when max. shaft load distance X2 is different

from X1:

Metric system: Inch system:

Metric or Inch system:

X2 > X1 Fr = Fr

max

N [lbf]

X2 is the actual distance of Fr from the mounting flange to the load for a given application. If X2< X1, Fr

could also be calculated by the first equation, but in addition the bearing life has to be checked.

Contact your Danfoss representative for load ratings of specific shafts or when the load orientation

deviates more than 35° in either direction from the optimum.

22 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 23

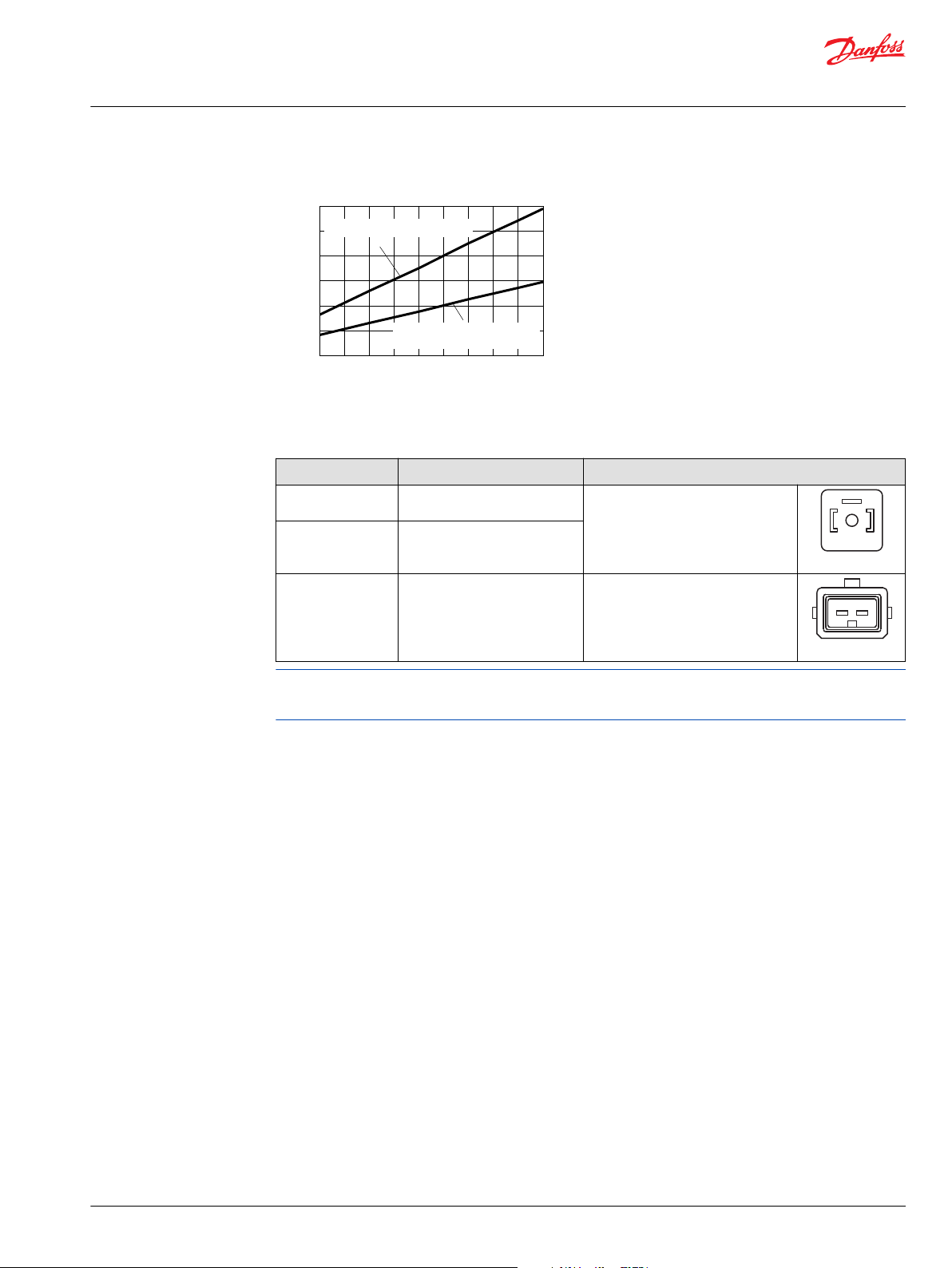

Efficiency

%

v

o

l

u

m

e

t

r

i

c

e

f

f

i

c

i

e

n

c

y

η

v

=

2

1

0

b

a

r

[

3

0

5

0

p

s

i

]

100

95

90

85

80

0

25

50

75

100

Speed % of rated speed

P001 155E

η

t

=

4

2

0

b

a

r

[

6

0

9

0

p

s

i

]

t

o

t

a

l

e

f

f

i

c

i

e

n

c

y

η

t

=

2

1

0

b

a

r

[

3

0

5

0

p

s

i

]

η

v

=

4

2

0

b

a

r

[

6

0

9

0

p

s

i

]

Speed% of rated speed

0

System pressure bar [psi]

420

[6090]

280

[4060]

140

[2030]

0

25

50

75

100

74.5%

84.5%

90.5%

93.5%

94.5%

P001 137E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Efficiency graphs and maps

This graph provides the volumetric and overall efficiencies for a typical Series 51 and 51-1 motor

operating at maximum displacement, system pressures of 210 and 420 bar [3050 and 6090 psi], and a

fluid viscosity of 8.2 mm²/s [53 SUS]. These efficiencies can be used for all frame sizes.

Overall and volumetric efficiency at maximum displacement

This graph shows typical overall efficiencies for Series 51 and 51-1 motors operating at maximum

displacement and system pressures up to 420 bar [6090 psi], and a fluid viscosity of 8.2 mm²/s [53 SUS].

These efficiencies can be used for all frame sizes.

Overall efficiency at maximum displacement

This graph shows typical overall efficiencies for Series 51 and 51-1 motors operating at 30% of maximum

displacement and system pressures up to 420 bar [6090 psi], and a fluid viscosity of 8.2 mm²/s (53 SUS).

These efficiencies can be used for all frame sizes.

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 23

Page 24

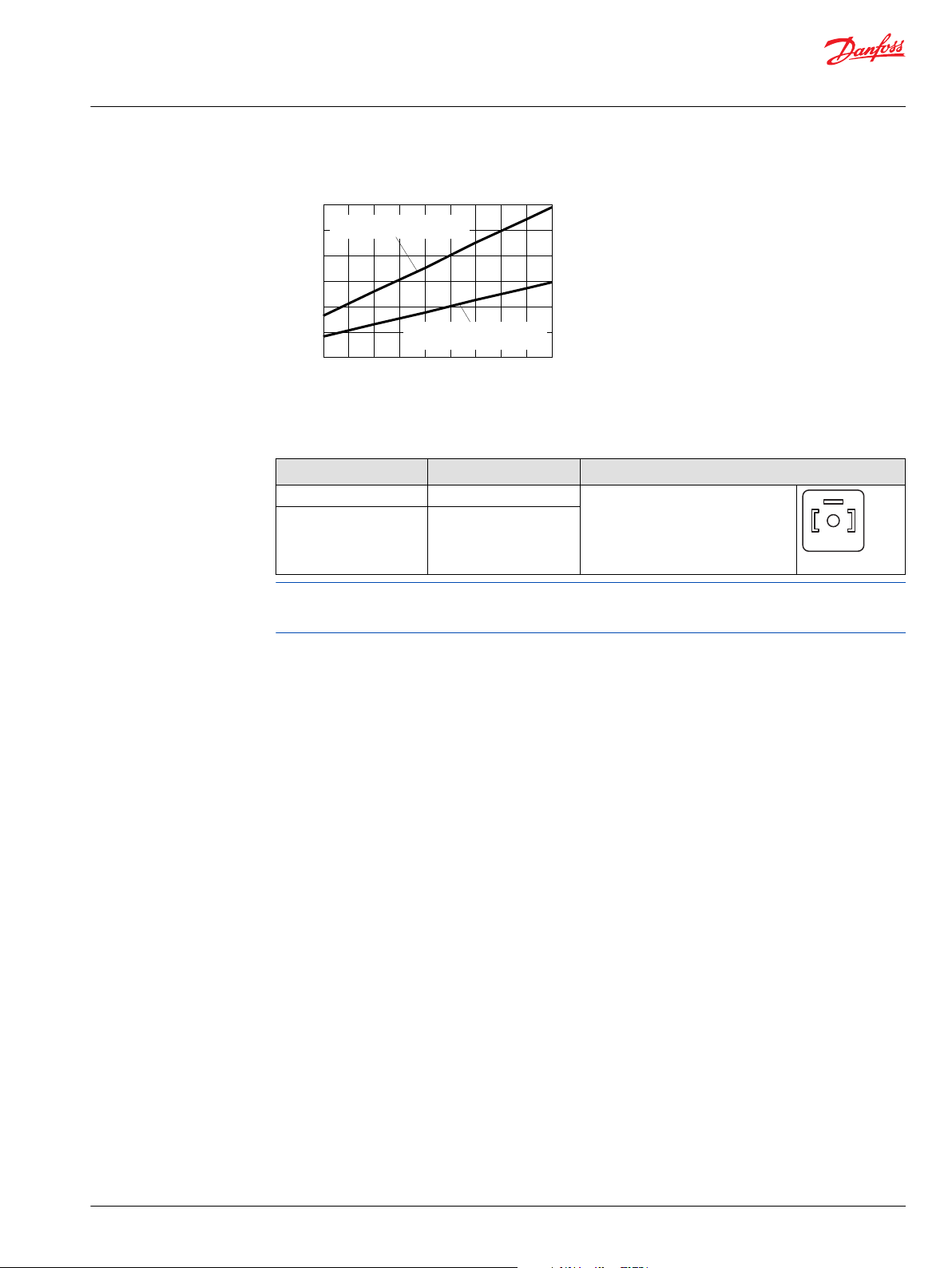

80

η

v

=

4

2

0

b

a

r

[

6

0

9

0

p

s

i

]

v

o

l

u

m

e

t

r

i

c

e

f

fi

c

i

e

n

c

y

η

v

=

2

1

0

b

a

r

[

3

0

5

0

p

s

i

]

η

t

=

4

2

0

b

a

r

[

6

0

9

0

p

s

i

]

25 50

75

1000

60

65

70

75

85

90

95

100

Efficiency %

Speed % of rated speed

o

v

e

r

a

l

l

e

f

fi

c

i

e

n

c

y

η

t

=

2

1

0

b

a

r

[

3

0

5

0

p

s

i

]

P001 156E

Speed % of rated speed

0

System pressure bar [psi]

420

[6090]

280

[4060]

140

[2030]

0

25

50

75

100

P001 138E

61%

71%

77%

80%

81%

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Overall and volumetric efficiency at 30% of maximum displacement

This graph shows typical overall efficiencies for Series 51 and 51-1 motors operating at 30% of maximum

displacement and system pressures up to 420 bar [6090 psi], and a fluid viscosity of 8.2 mm²/s (53 SUS).

These efficiencies can be used for all frame sizes.

Overall efficiency at 30% of maximum displacement

24 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 25

P001 492

Turck Eurofast Connector

4 pin

(Supplied connector)

IP Rating (DIN 40 050) IP 67

Mating connector

straight right angle

No.: K14956 No.: K14957

Id.-No.: 500724 Id.-No.: 500725

P001 755E

1

2

3

4

Keyway (Ref)

Red

White

Black

Green

P002 108E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

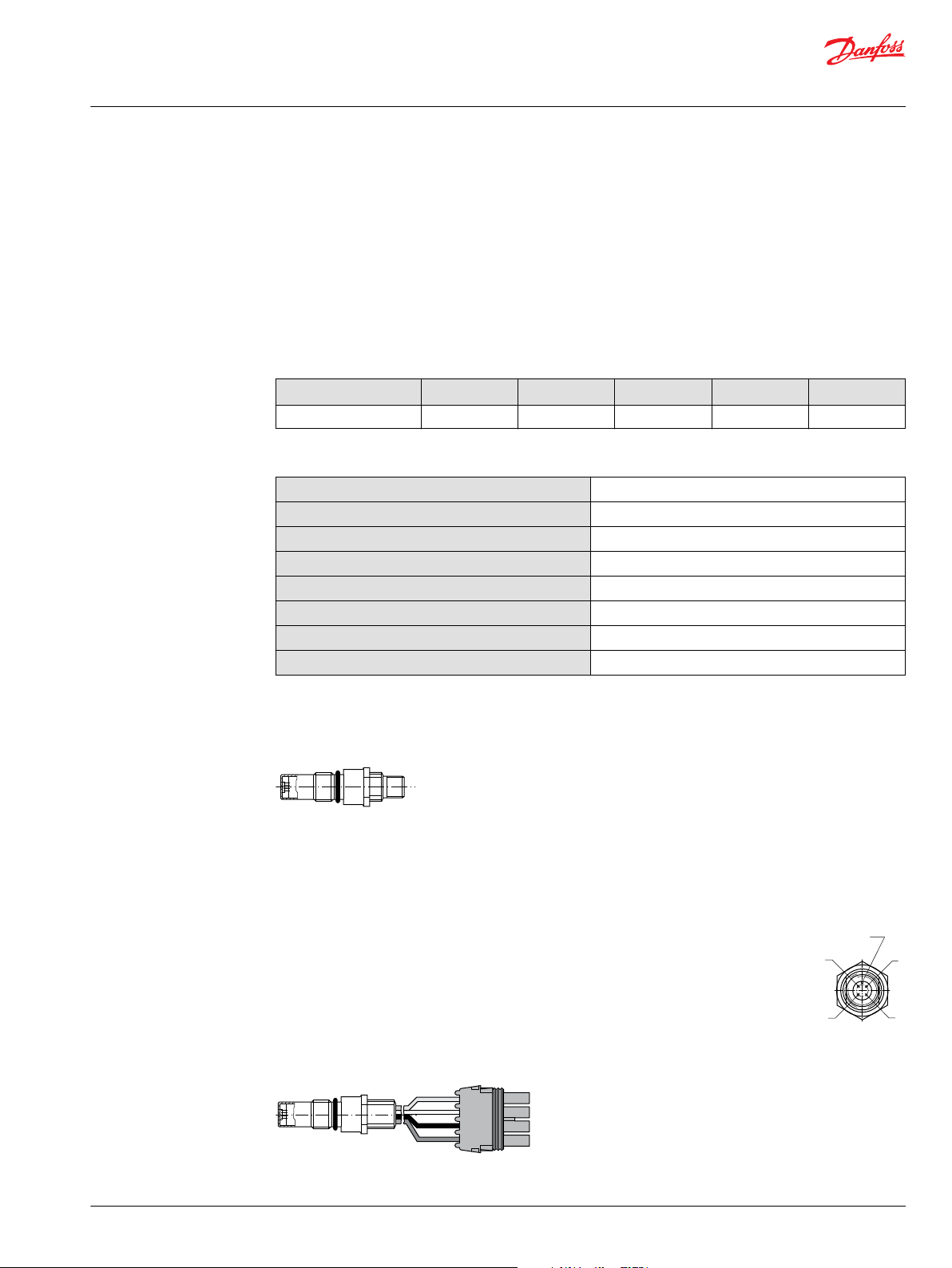

Speed sensor

An optional speed sensor for direct measurement of speed is available. This sensor may also be used to

sense the direction of rotation. A special magnetic speed pick-up ring is pressed onto the outside

diameter of the shaft and a Hall effect sensor is located in the motor housing. The sensor accepts supply

voltage and outputs a digital pulse signal in response to the speed of the ring. The output changes its

high/low state as the north and south poles of the permanently magnetized speed ring pass by the face

of the sensor. The digital signal is generated at frequencies suitable for microprocessor based controls.

The sensor is available with different connectors (see below). The SAE and DIN flange motors use a flat

end speed sensor. The cartridge flange motors use a conical end speed sensor.

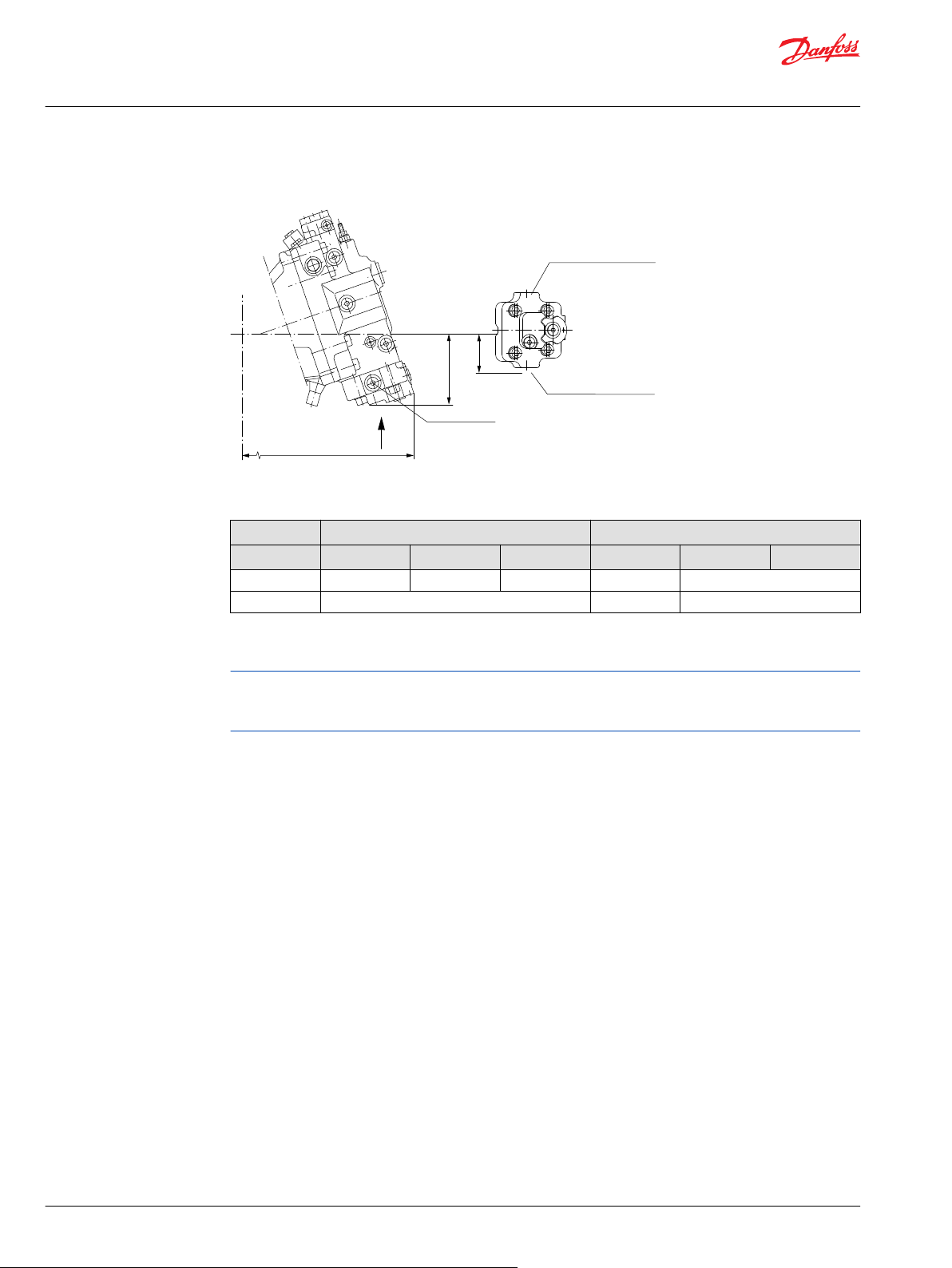

Data magnetic speed pick-up ring

Frame size

Pulze/Rev 45 49 54 61 71

Speed sensor technical data

Supply voltage

Supply voltage regulated

Required current

Maximum current

Maximum frequency

Voltage "high"

Voltage "low"

Temperature range

1)

It is not acceptable to energize the 4.5-8.5 VDC speed sensor with 12 VDC battery voltage; it must be energized by a

regulated power supply. If it is desirable to energize the sensor with battery voltage, contact your Danfoss

representative for an optional speed sensor.

1)

060 080 110 160 250

4.5 – 8.5 V

15 VDC max.

12 mA at 5 VDC (no load)

20 mA at 5 VDC and 1 Hz

15 kHz

Supply voltage -0.5 VDC min.

0.5 VDC max.

-40 to 110 °C [-40 to 230 °F]

DC

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 25

Speed sensor with Turck Eurofast 4-pin connector

Pin 1 or A: Supply voltage

Pin 2 or B: Direction of rotation

Pin 3 or C: Speed signal, digital

Pin 4 or D: Ground common

Speed sensor with Packard Weather-Pack 4-pin connector

Page 26

A

B

C

D

Packard Weather-Pack

4 pin

(Supplied Connector)

Mating Connector

No.: K03379

Id.-No.: 505341

P001 758E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

General technical specifications

Contact your Danfoss representative for more information.

Typical control and regulator applications

Application Control / Regulators

without PCOR with PCOR with PCOR and BPD

N1 HZ E1, E2, E7 EP, EQ F1, F2 L1, L2, L7 TA T1, T2 TH HS TA T1, T2 EP, EQ D7, D8 HS

Wheel loader

Roller compactor

Paver wheeled

Paver tracked

Sweeper

Trencher

Excavator wheeled

Fork lift truck

Agricultural

Forestry

Telehandler

Railroad

Snow groomer

Snow blower

Crane

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

2)

3)

Suitable configuration

1)

Propel function

2)

Blow drive function

3)

Winch function

The table above is provided to assist in selecting controls and regulators for various applications. These

recommendations are based on experience with a wide range of applications.

Contact your Danfoss Power Solutions representative for more information on control selection.

26 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 27

X1

(M3)

M5

B

M4

L1

N

L2

A

P001 779E

n

min.

disp.

T3

T2

System pressure bar [psi]

Servo pressure bar [psi]

0

0

200

[2900]

100

[1450]

10

[145]

20

[290]

30

[435]

300

[4350]

400

[5800]

minimum servo pressure

under all conditions

P001 877E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

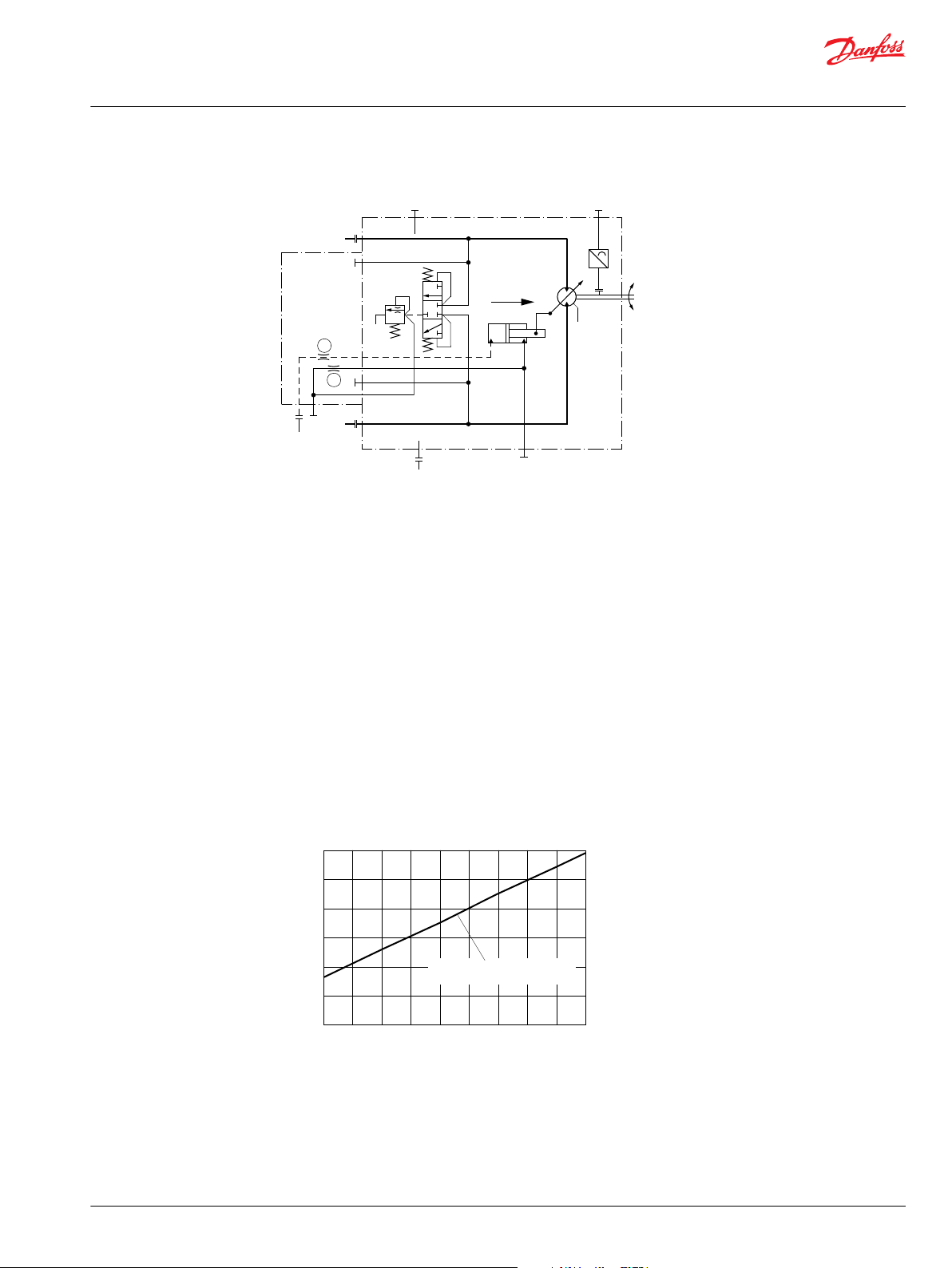

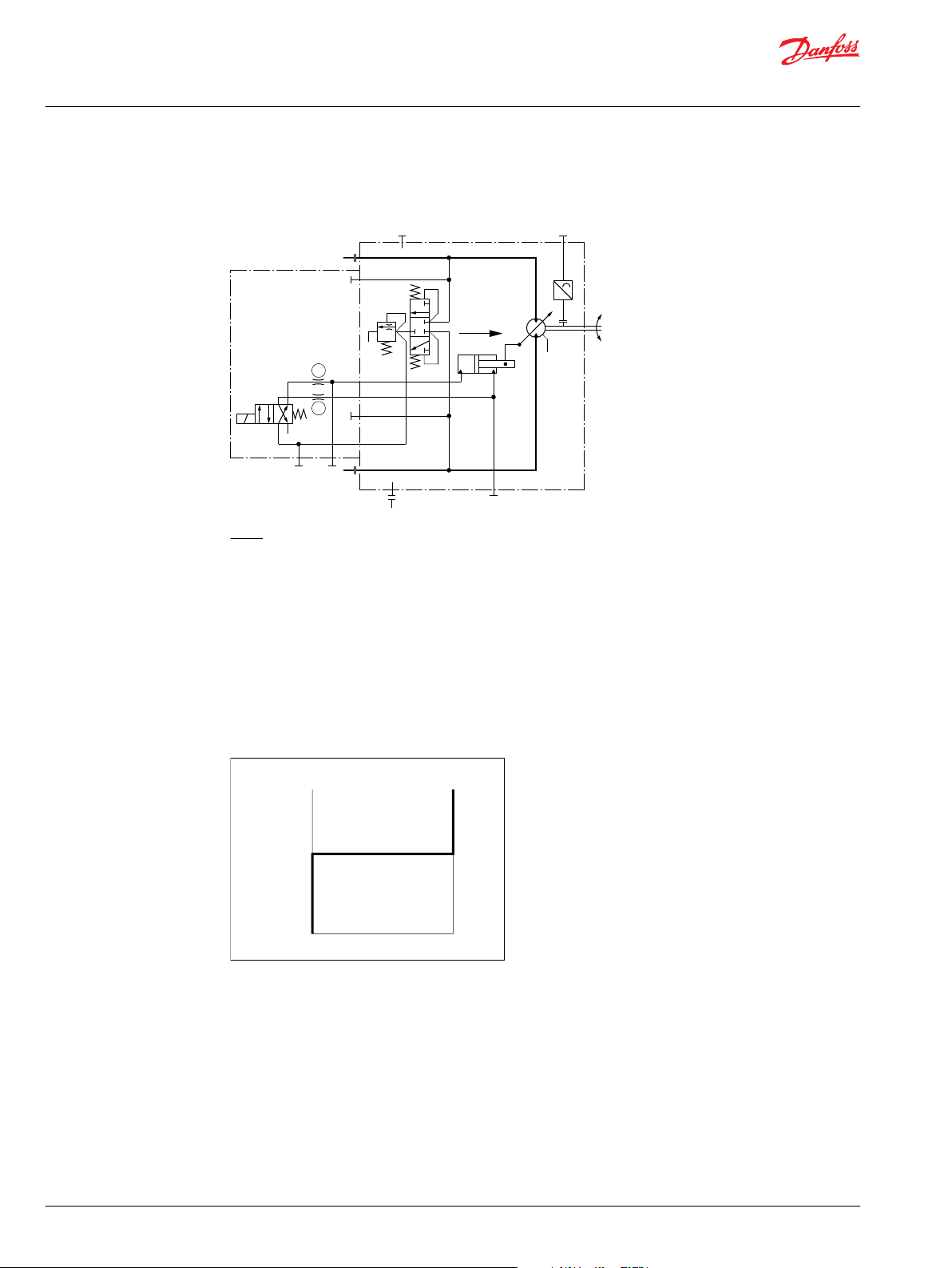

Option N1NN – hydraulic two-position control for 51-1 (frame size: 060, 080, 110)

A, B = Main pressure lines

L1, L2 = Drain lines

M4 = Gauge port servo pressure

M5 = Gauge port servo supply pressure

X1 (M3) = Control pressure

T1, T2, T3 = Optional orifices

N = Speed sensor

Displacement changes from maximum displacement to minimum displacement position, under load, as

control pressure at port X1 (M3) is equal to low pressure or higher.

Control pressure on port X1 (M3)

No pressure on port = maximum displacement

Control pressure on port = minimum displacement

Maximum control pressure = 50 bar [725 psi]

The graph shows the necessary external and internal (= low system pressure) control pressure X1, which

is needed to stroke the motor depending on high system pressure.

Control N1NN necessary control pressure

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 27

Page 28

P001 875E

min

max

Control pressure

Displacement

T8T3T7

T1

T2

max.

disp.

M2

X1

M7

B

M5

L1

M1

M4L2

A

M3 N

P100 177E

n

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

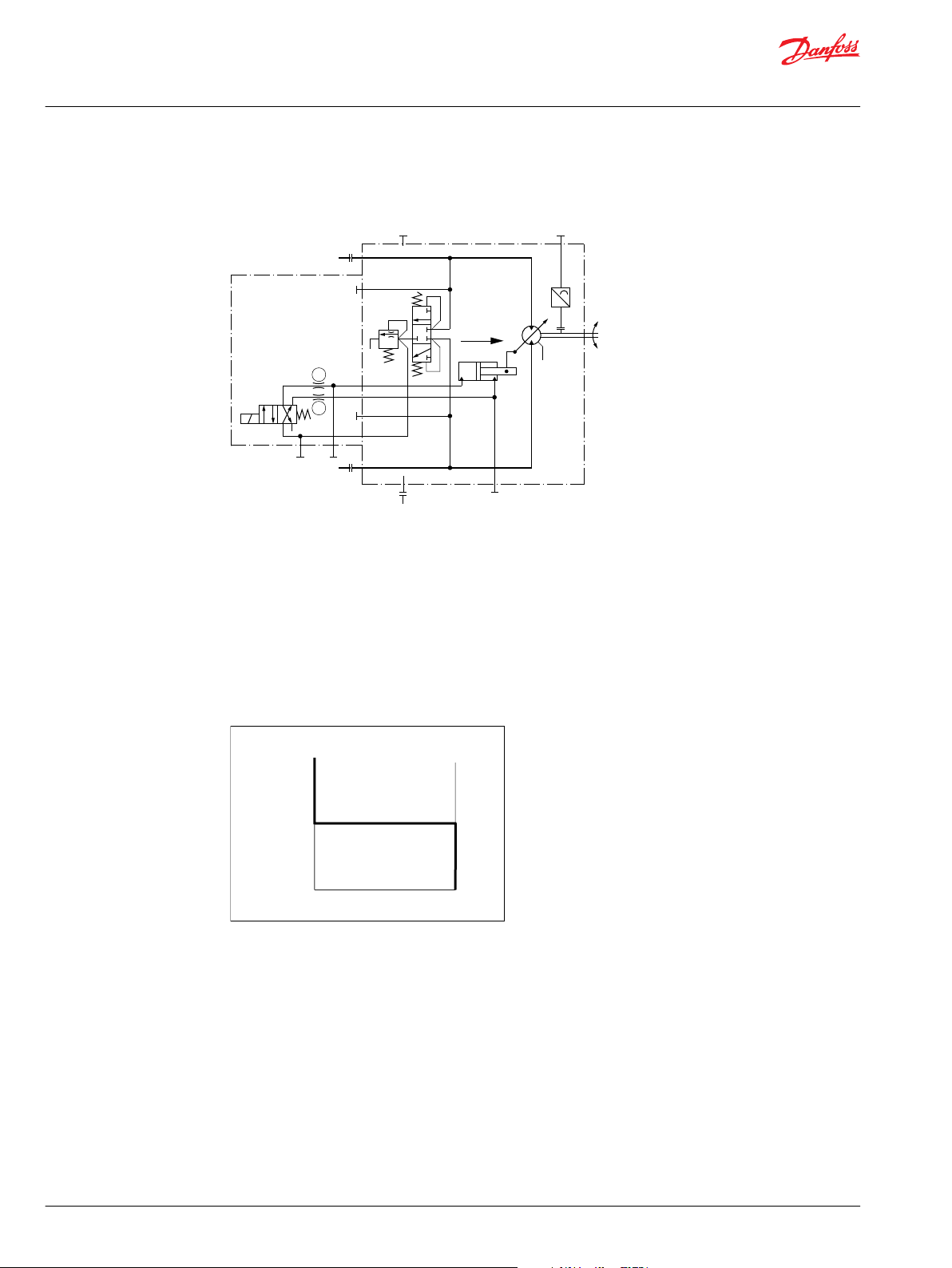

Control operation N1NN

Not all control options are shown in this Technical Information.

Contact your Danfoss representative for special control functions.

Option HZB1 – hydraulic two-position control for 51 (frame size: 160, 250)

A, B = Main pressure lines

L1, L2 = Drain lines

M1, M2 = Gauge port for A and B

M3, M4 = Servo pressure

M5 = Gauge port servo supply pressure internal

M7 = Gauge port control pressure

X1 = Control pressure

T1, T2, T3, T7, T8 = Optional orifices

N = Speed sensor

Displacement can be changed hydraulically under load from minimum displacement to maximum

displacement and vice versa by control pressure to port X1. For proportional control see Option HZB1 –

hydraulic proportional control for 51 (all frame sizes) on page 62

Control pressure on port X1

28 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 29

P100 179E

Control pressure Δ bar [psi]

0

3

[44]

min

max

Displacement

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

No pressure on port = maximum displacement

Control pressure on port = minimum displacement

Maximum control pressure = 50 bar [725 psi]

The standard control start point setting = 3 bar [44 psi]

Control operation HZB1

Not all control options are shown in this Technical Information.

Contact your Danfoss representative for special control functions.

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 29

Page 30

M3

T3

M3

with Electric

brake pressure

defeat

with Hydraulic

brake pressure

defeat

without

Brake pressure

defeat

XB

XA

T3

M3

T3

min.

disp.

n

B

A

L1

M4

L2

N

P001 834E

min max

Displacement

Ramp < 10 bar

[145 psi]

Regulator start

Setting range

130

[1890]

370

[5370]

System pressure Δ p bar [psi]

P001 173E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

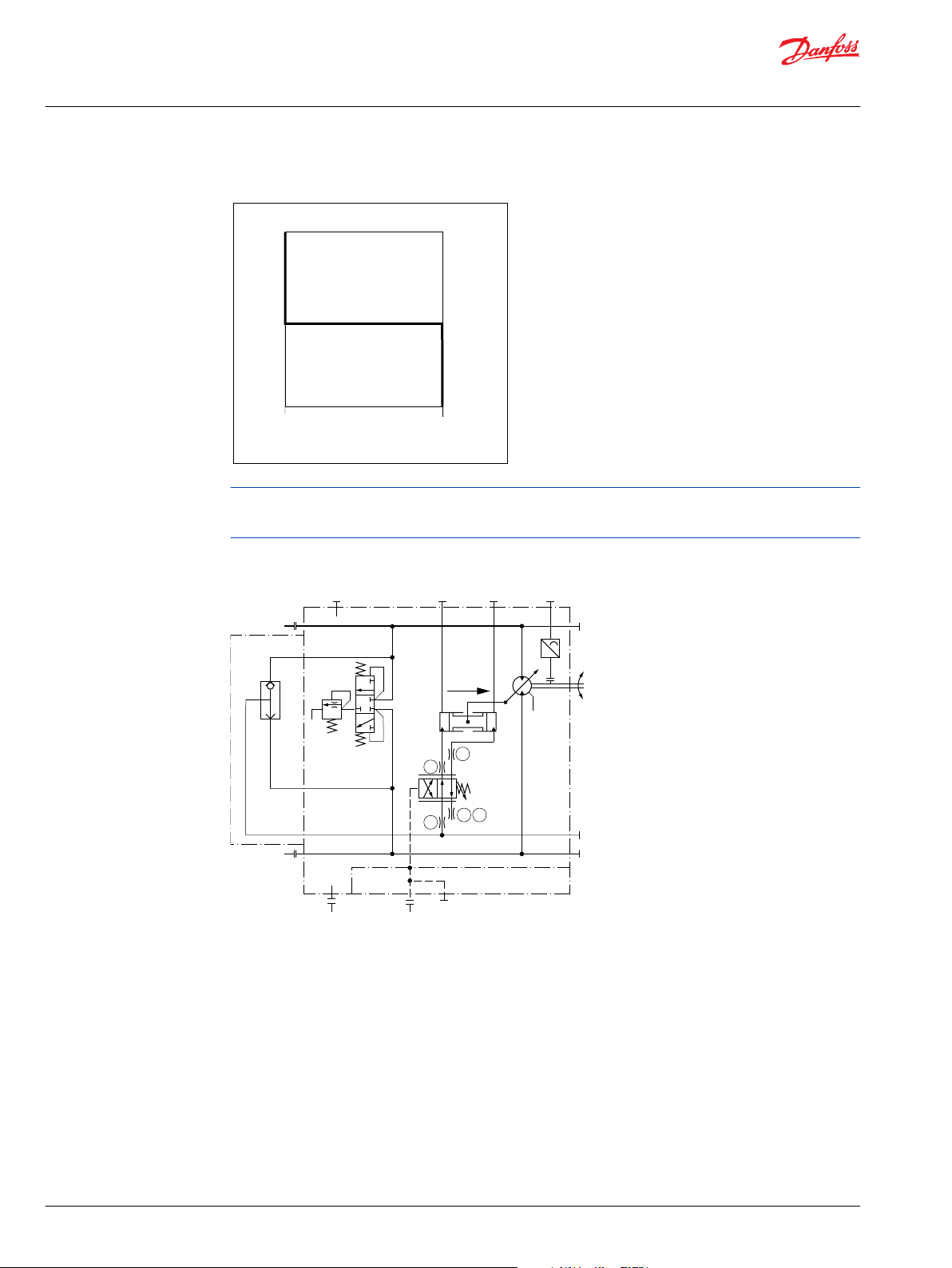

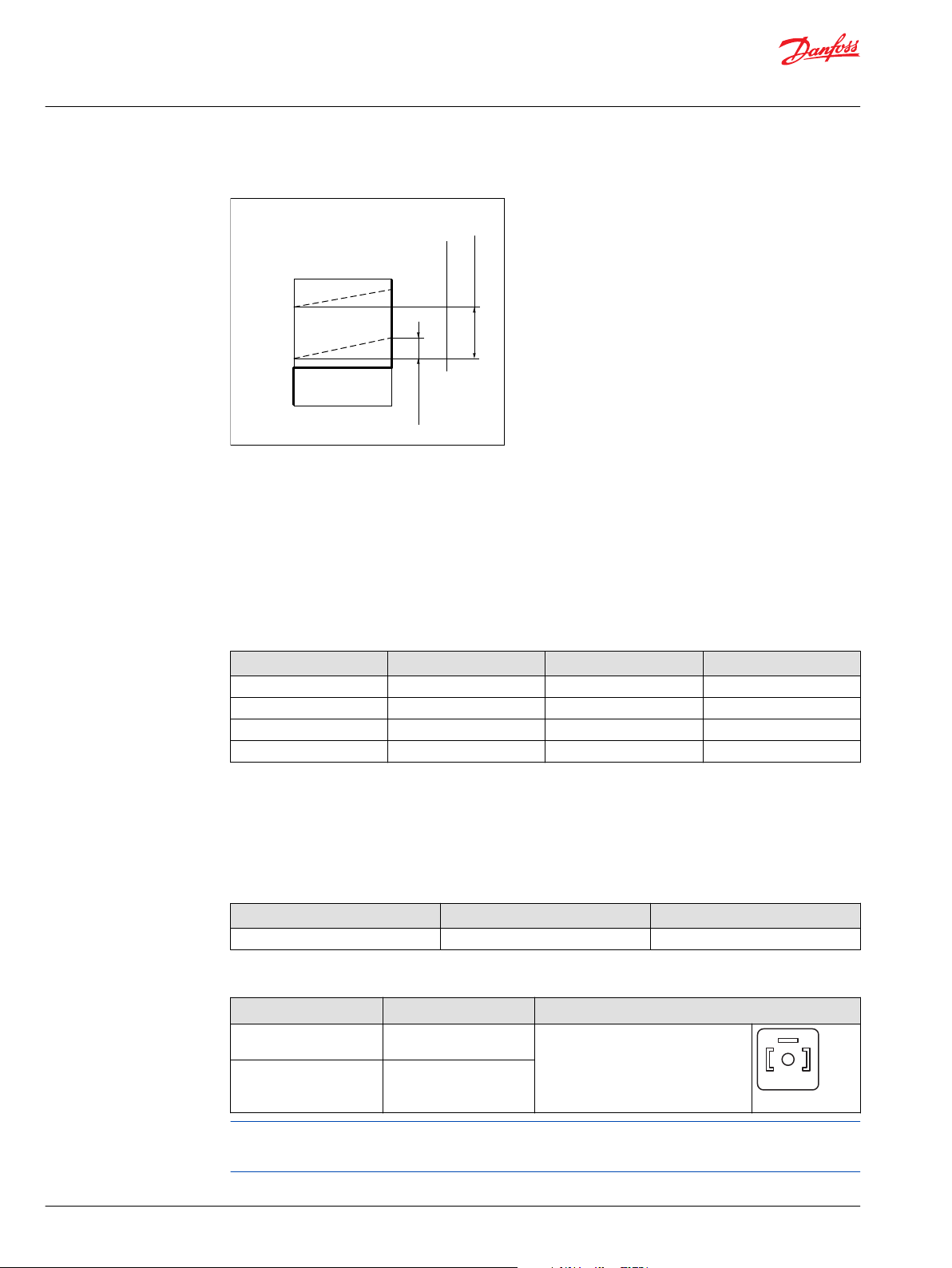

Options TA** – pressure compensator control for 51-1 (frame size: 060, 080, 110)

Circuit diagram–motor with pressure compensator control TA**

Ports:

A, B = Main pressure lines

L1, L2 = Drain lines

M3, M4 = Servo pressure

XA, XB = Control pressure port brake pressure defeat (BPD)

T3 = Orifice

N = Speed sensor

Displacement is regulated automatically between minimum and maximum displacement in response to

system pressure.

Regulator start = minimum displacement

Regulator end = maximum displacement

Regulator start pressure is adjustable from 130 to 370 bar [1890 to 5370 psi].

Pressure ramp from regulator start pressure (with motor at minimum displacement) until maximum

displacement is reached is less than 10 bar [145 psi]. This ensures optimal power utilization throughout

the entire displacement range of the motor.

Control operation TA**

30 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 31

A B

P001752

2 1

P001751

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

Option TACA: pressure compensator configuration with hydraulic Brake Pressure Defeat

A shuttle valve ahead of the pressure compensator prevents operation in the deceleration direction

(when motor is running in pump mode). This is designed to prevent rapid or uncontrolled deceleration

while the vehicle/machine is slowing down. Pressure compensator override with brake pressure defeat is

mainly used in systems with pumps having electric or hydraulic proportional controls or automotive

controls.

The shuttle valve must be controlled by a 2-line external signal, based on direction of motor rotation,

based on the following table:

Motor rotation High pressure port Control pressure on port*PCOR function

CW A XA yes

CW A XB no

CCW B XA no

CCW B XB yes

*

Differencial control pressure between port XA/XB:

∆p

= 0.5 bar [7 psi]

min

∆p

= 50 bar [725 psi]

max

Options TAD1, TAD2, TAD7: pressure compensator configuration with electric BPD

A solenoid-switched valve ahead of the pressure compensator prevents operation in the deceleration

direction (when motor is running in pump mode). This is designed to prevent rapid or uncontrolled

deceleration while the vehicle/machine is slowing down.

The solenoid valve must be controlled by an external electric signal, based on direction of motor rotation,

see the following table:

Motor rotation High pressure port Solenoid PCOR function

CW A energized yes

CW A non energized no

CCW B energized no

CCW B non energized yes

TAD* solenoid connectors

Configuration Voltage / Electric power

TAD1 12 VDC / 34 W

TAD2 24 VDC / 34 W

TAD7 12 VDC / 34 W

Solenoid plug face for DIN 46350

Mating connector No.: K09129

Id. No.: 514117

AMP Junior Timer two-pin

Mating connector No.: K19815

Id. No.: 508388

Connector (supplied)

Option TAC2: pressure compensator configuration without Brake Pressure Defeat

Pressure compensator functions when the motor is running in motor mode as well as in pump

(deceleration) mode.

Configuration option High pressure port PCOR function

TAC2 A and B yes

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 31

Page 32

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

Not all control options are shown in this Technical Information.

Contact your Danfoss representative for special control functions.

32 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 33

n

max.

disp.

T7 T8

T2

T1

T3

B

M2

(X3)

M5

L1

with

Brake pressure

defeat

without

Brake pressure

defeat

M1

N

M3M4

L2

A

P001 836E

XB

XA

X4 X4

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

Options TA** – pressure compensator controls for 51 (frame size 160, 250)

Circuit Diagram–Motor with Pressure Compensator Control TA**

Ports:

A, B = Main pressure lines

L1, L2 = Drain lines

M1, M2 = Gauge port for A and B

M3, M4 = Gauge port servo pressure

M5 (X3) = Gauge port servo supply

XA, XB = Control pressure ports, brake pressure defeat

X4 = Gauge port pressure compensator

T1, T2, T3, T7, T8 = Optional orifices

N = Speed sensor

Displacement is regulated automatically between minimum and maximum displacement in response to

system pressure.

Regulator start = minimum displacement

Regulator end = maximum displacement

Regulator start pressure is adjustable from 130 to 370 bar [1890 to 5370 psi].

Pressure ramp from regulator start pressure (with motor at minimum displacement) until maximum

displacement is reached is less than 10 bar [145 psi]. This ensures optimal power utilization throughout

the entire displacement range of the motor.

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 33

Page 34

min max

Displacement

Ramp < 10 bar

[145 psi]

Regulator start

Setting range

130

[1890]

370

[5370]

System pressure Δ p bar [psi]

P001 173E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

Control operation TA**

Option TAC0: pressure compensator configuration with hydraulic Brake Pressure Defeat

A shuttle valve ahead of the pressure compensator prevents operation in the deceleration direction

(when motor is running in pump mode). This is designed to prevent rapid or uncontrolled deceleration

while the vehicle/machine is slowing down.

Pressure compensator override with brake pressure defeat is mainly used in systems with pumps having

electric or hydraulic proportional controls or automotive controls.

The shuttle valve must be controlled by a 2-line external signal, based on direction of motor rotation, see

the following table.

Motor rotation High pressure port Control pressure on port*PCOR function

CW A XA no

CW A XB yes

CCW B XA yes

CCW B XB no

*

Differencial control pressure between port XA/XB:

∆p

= 0.5 bar [7 psi]

min

∆p

= 50 bar [725 psi]

max

Option TAC2: pressure compensator configuration without Brake Pressure Defeat

Pressure compensator functions when the motor is running in motor mode as well as in pump

(deceleration) mode.

Configuration option High pressure port PCOR function

TAC2 A and B yes

Not all control options are shown in this Technical Information.

Contact your Danfoss representative for special control functions.

34 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 35

n

min.

disp.

B

M4

L1

N

L2

A

P001 835E

T3

M3

X1

T3

M3

XB

XA

X1

T3

M3

X1

with Electric

brake pressure

defeat

with Hydraulic

brake pressure

defeat

without

Brake pressure

defeat

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

Options TH** – hydraulic two-position control for 51-1 (frame size: 060, 080, 110)

Circuit diagram – motor with two-position control TH**

Ports:

A, B = Main pressure lines

L1, L2 = Drain lines

M1, M2 = Gauge port for A and B

M3, M4 = Gauge port servo pressure

M5 (X3) = Gauge port servo supply

XA, XB = Control pressure ports, brake pressure defeat

X1 = Hydraulic two-position signal

X4 = Gauge port pressure compensator

T1, T2, T3, T7, T8 = Optional orifices

N = Speed sensor

Displacement can be changed hydraulically under load from minimum displacement to maximum

displacement and vice versa.

Pressure on port X1 must be equal to the pressure of the motor case ± 0.2 bar [3.0 psi] this keeps the

motor at minimum displacement.

Pressure from 10 bar [145 psi] to 35 bar [510 psi] above case pressure on port X1 strokes the motor to

maximum displacement.

Pressure Compensator OverRide (PCOR)

The control can be overridden by PCOR using high loop pressure.

When the PCOR activates, the motor displacement increases toward maximum. Pressure ramp from

PCOR start pressure (with motor at minimum displacement) until maximum displacement is reached is

less than 10 bar [145 psi]. This ensures optimal power utilization throughout the entire displacement

range of the motor.

PCOR start pressure is adjustable from 130 to 370 bar [1890 to 5370 psi].

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 35

Page 36

min.

[145 psi]

min. 10 bar

[510 psi]

max. 35 bar

max.

Displacement

Hydraulic

two-positioncontrol

PCOR start

setting range

Ramp < 10

[145]

130

[1890]

370 [5370]

Pressure compensator

override bar, [psi]

P001 776E

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

Control operation TH**

Option THCA: pressure compensator configuration with hydraulic Brake Pressure Defeat

A shuttle valve ahead of the pressure compensator prevents operation in the deceleration direction

(when motor is running in pump mode). This is designed to prevent rapid or uncontrolled deceleration

while the vehicle/machine is slowing down. Pressure compensator override with brake pressure defeat is

mainly used in systems with pumps having electric or hydraulic proportional controls or automotive

controls. The shuttle valve must be controlled by a 2-line external signal, based on direction of motor

rotation, based on the following table:

Pressure compensator operation

Motor rotation High pressure port Control pressure on port*PCOR function

CW A XA yes

CW A XB no

CCW B XA no

CCW B XB yes

*

Differencial control pressure between port XA / XB:

∆p

∆p

Options THD1, THD2, THD7: pressure compensator configuration with electric BPD

A solenoid-switched valve ahead of the pressure compensator prevents operation in the deceleration

direction (when motor is running in pump mode). This is designed to prevent rapid or uncontrolled

deceleration while the vehicle/machine is slowing down. The solenoid valve must be controlled by an

external electric signal, based on direction of motor rotation, see the following table:

Motor rotation High pressure port Solenoid PCOR function

CW A energized yes

CW A non energized no

CCW B energized no

CCW B non energized yes

= 0.5 bar [7 psi];

min

= 50 bar [725 psi]

max

36 | © Danfoss | October 2017 520L0440 | BC00000018en-US0401

Page 37

A B

P001752

2 1

P001751

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description

THD* solenoid connectors

Configuration Voltage / Electric power

THD1

THD2 24 VDC / 34 W

THD7 12 VDC / 34 W

12 VDC / 34 W

Solenoid plug face for DIN 46350

Mating connector No.: K09129

Id. No.: 514117

AMP Junior Timer two-pin

Mating connector No.: K19815

Id. No.: 508388

Connector (supplied)

Option THC2: pressure compensator configuration without Brake Pressure Defeat

Pressure compensator functions when the motor is running in motor mode as well as in pump

(deceleration) mode.

Configuration option High pressure port PCOR function

THC2 A and B yes

Not all control options are shown in this Technical Information.

Contact your Danfoss representative for special control functions.

©

Danfoss | October 2017 520L0440 | BC00000018en-US0401 | 37

Page 38

max.

disp.

A

L2

M4

M3

N

M1

L1

X1X1

M2

B

(X3)

M5

P001 837E

n

T8

T1

T2 T3

T7

XB

XA

X4

X4

with

Brake pressure

defeat

without

Brake pressure

defeat

Technical Information

Series 51 and 51-1 Bent Axis Variable Displ. Motors

Controls circuit diagram – nomenclature – description