Page 1

■ Contents

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

Functionality

How Does It Work? ................................................................................................ 3

Limitations .............................................................................................................. 5

Parameter Setting - Head ....................................................................................... 6

Par. 705 Quadratic Head ........................................................................................ 6

Par. 707 Head Qmin .............................................................................................. 6

Par. 716 Head Working Point ................................................................................. 6

Par. 717 Flow Working Point .................................................................................. 7

..................................................................................................... 2

Control Principle ............................................................................................. 8

Parameter Setting - Control .................................................................................... 10

Par. 701 Power Error .............................................................................................. 10

Par. 702 Delta Frequency ....................................................................................... 10

Par. 703 Integral Power .......................................................................................... 10

Par. 704 Integral Frequency .............. ..................................................................... 10

Programming other Functionalities ...................................................... 11

Par. 708 Power Compensation .............................................................................. 11

Analog Output ........................................................................................................ 12

Par. 720 AO Max Value .......................................................................................... 12

Analog Input ........................................................................................................... 13

Read-outs in LCP ................................................................................................... 14

Power/Frequency Read-out ................................................................................... 15

VLT 6000 ................................................................................................................ 16

Measuring Values ........................................................................................... 17

Introduction ............................................................................................................ 17

Installation and Setup of the Software .................................................................... 17

Installation .............................................................................................................. 17

Entering Pump Data ............................................................................................... 18

Number of Measurements ...................................................................................... 20

Other Functionalities of the Program ....................................................................... 20

Data and Read-outs ............................................................................................... 21

MG.10.T1.02 - VLT is a registered Danfoss trademark

1

Page 2

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Functionality

Sensorless Pump Control (Sensorless) has been

developed to enable the drive to control the pressure

(Head) in a circuit with non-compressible liquid,

e.g. water, WITHOUT using a pressure transducer.

This has several advantages such as:

• Cost savings as there is no need for a

pressure transducer.

• Increased reliability, as there are no additional

components (transducer, cable, connections)

that can cause malfunction.

• No maintenance and exchange of pressure

transmitters.

• Very dynamic with a response time of

only 1-2 seconds.

• Increased energy savings.

Sensorless contains three different ways of

controlling the pressure where the choice depends

onthetypeofapplication.

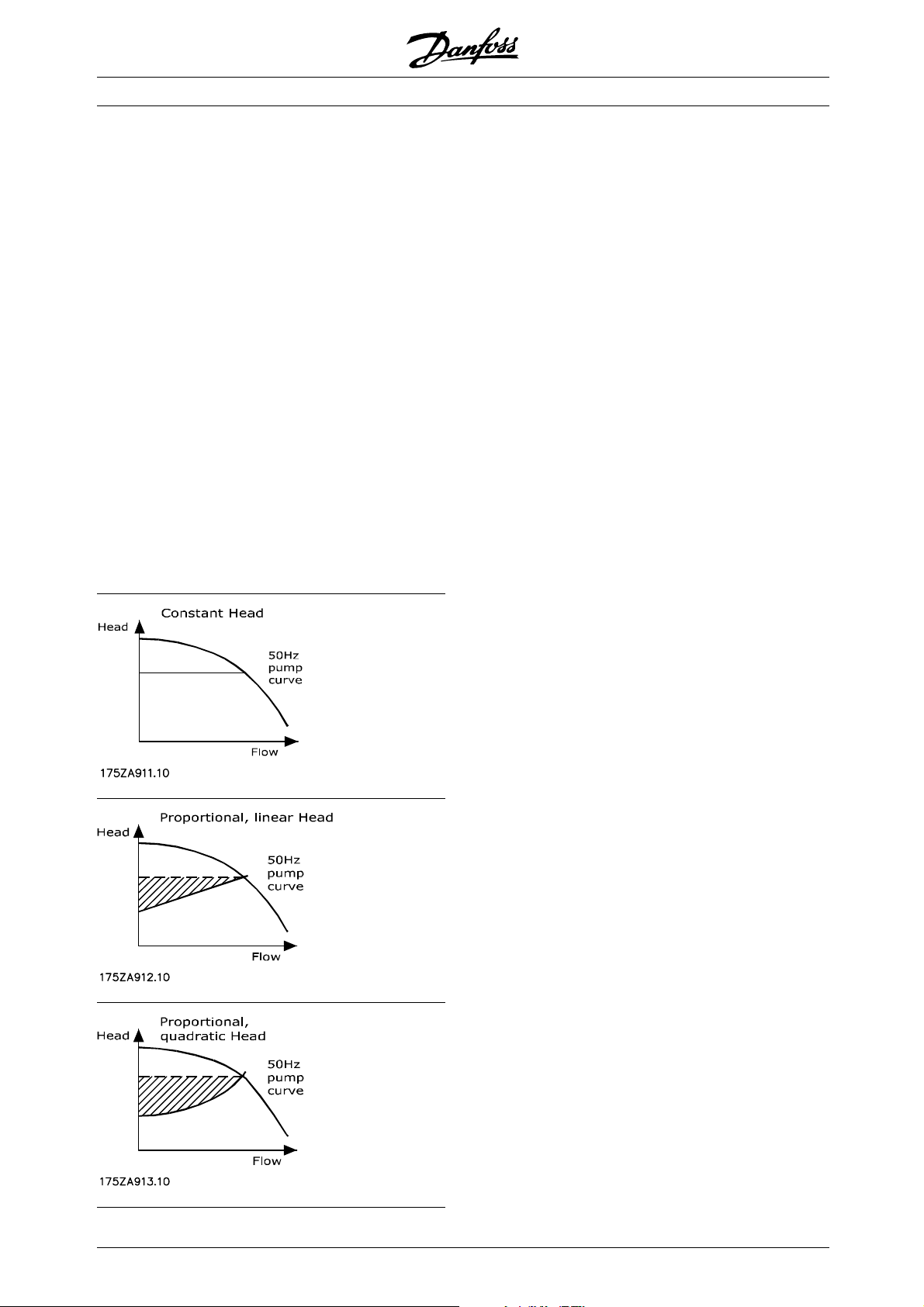

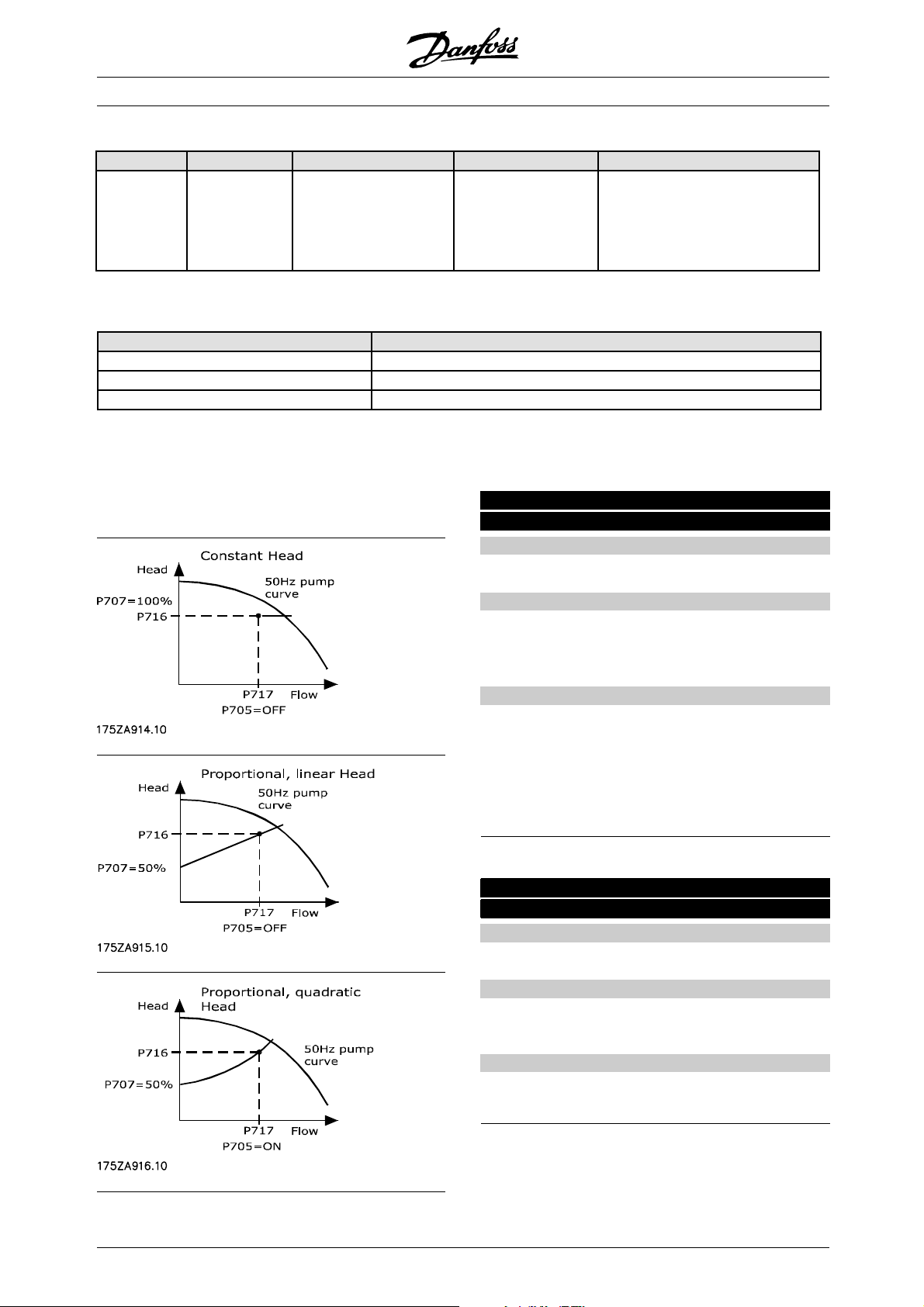

Constant Head: The controller keeps a constant head

across the pump regardless of the flow through the

pump. Does not take pipe friction loss into account.

Proportional linear head: The controller increases the

head across the pump when the flow through the

pump increases, and it decreases the head when the

flow decreases. Takes pipe friction loss into account,

with a linear approximation to the real system curve.

Proportional, quadratic Head: Same as Proportional

Head, but with a quadratic Head curve instead of

linear. Takes pipe friction loss into account, with a

quadratic approximation to the real system curve.

In the manual, these three types of pressure control

are referred to as the user-defined head.

Marked area: Energy savings compared to

constant head control.

(P = K x Flow x Head)

2

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 3

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■How Does It Work?

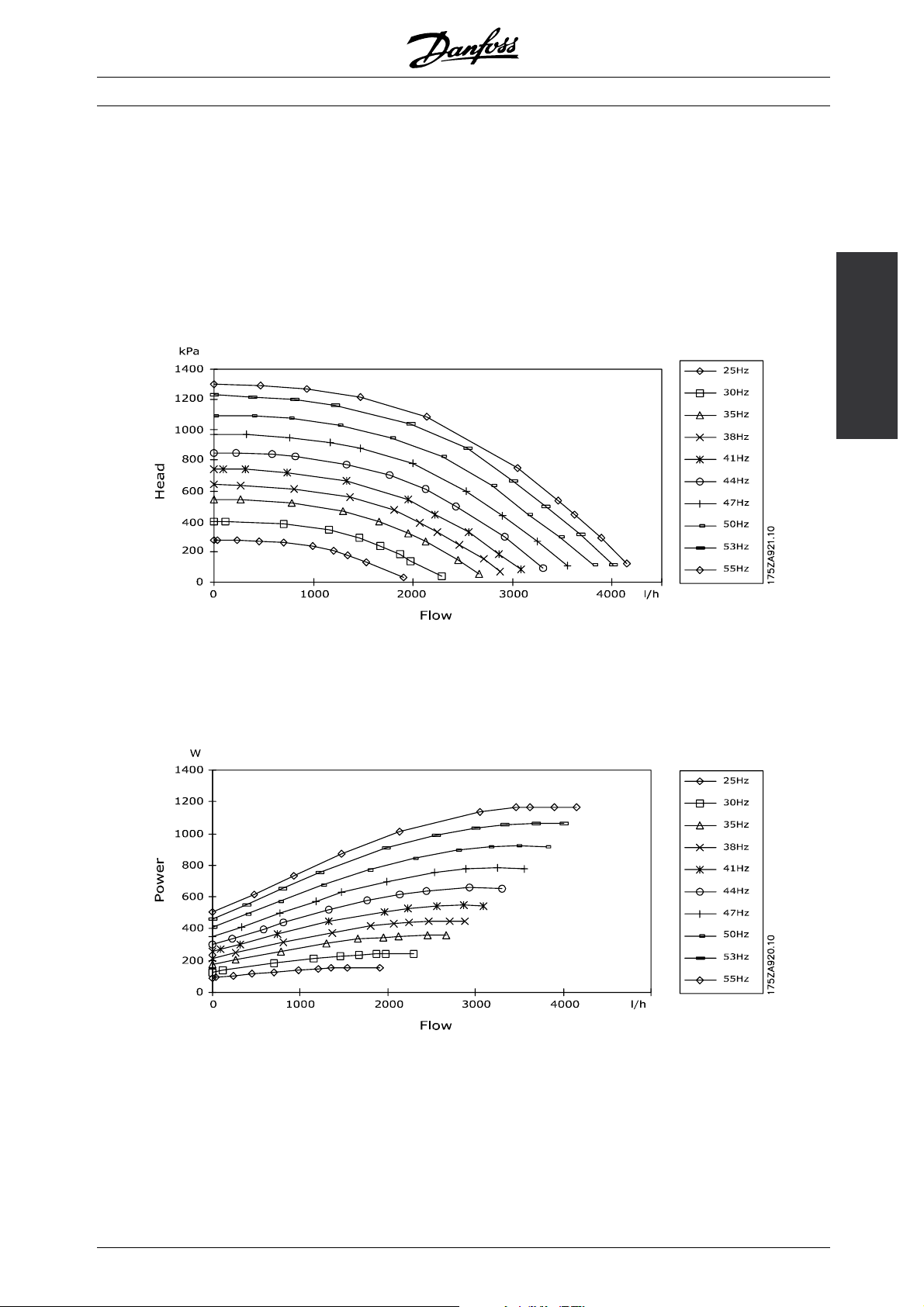

Sensorless is based on the relations between frequency, flow, head and power. So consequently the drive

needs the data shown in the graphs below as input for the calculations. The data are pump specific and need

to be found by measurement. Alternatively, the data can be found by data sheet from the pump supplier if

accurate enough.

The graph below shows a n example of some measured values for flow/head on a typical centrifugal pump.

Head/flow (H/Q) Curves on a 1.5 kW pump

Functionality

The graph below shows the measured values for flow/power.

Power/flow (P/Q) Curves on a 1.5 kW pump

MG.10.T1.02 - VLT is a registered Danfoss trademark

3

Page 4

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

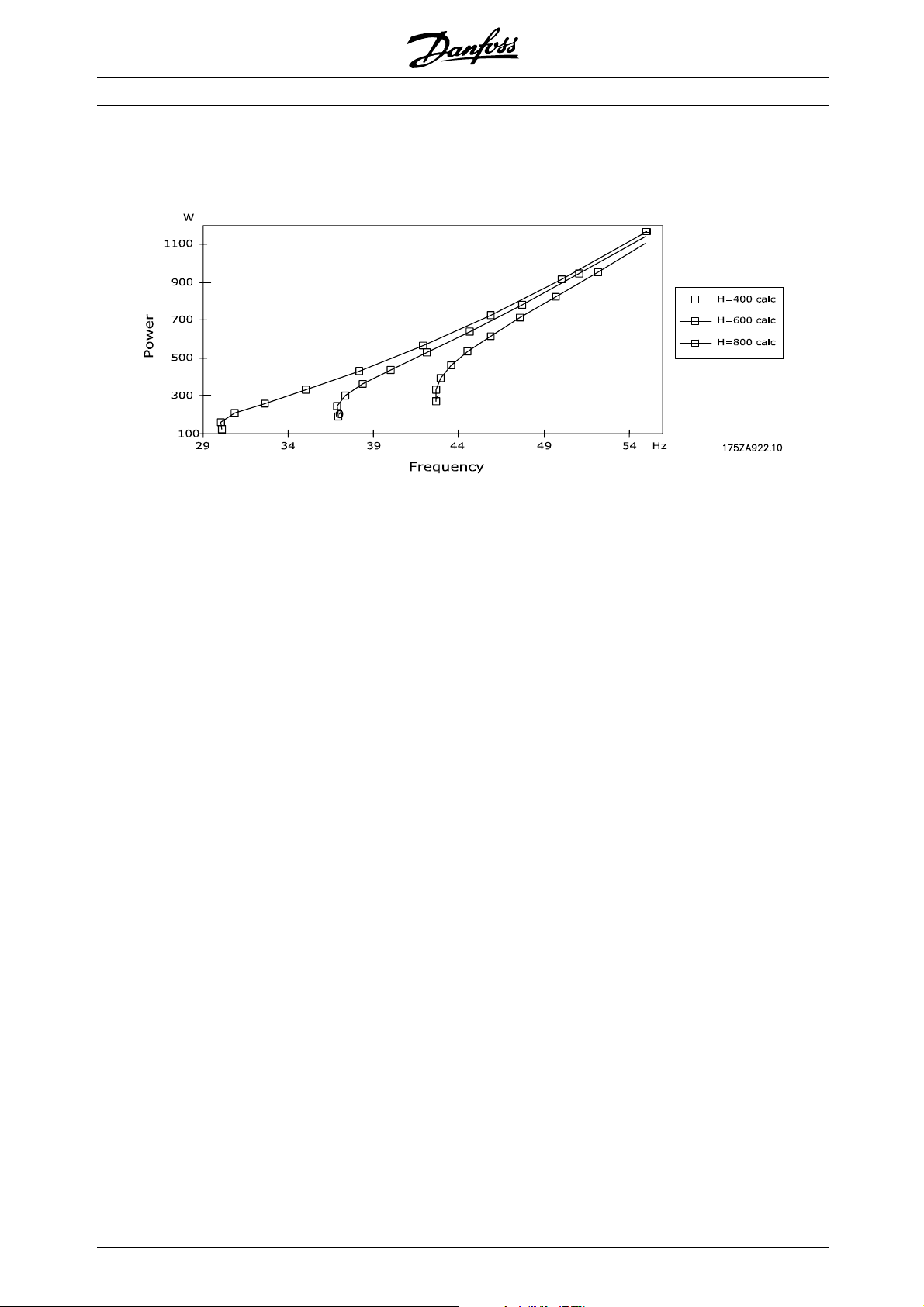

With these values it is possible to create the relation between Power and frequency (P/f curve).

Power/frequency (P/f) Curves on a 1.5 kW pump

With these relations it is now possible to control the pressure (e.g. keeping it constant if that is desired) by

controlling the frequency according to the p ower measurement.

4

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 5

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Limitations

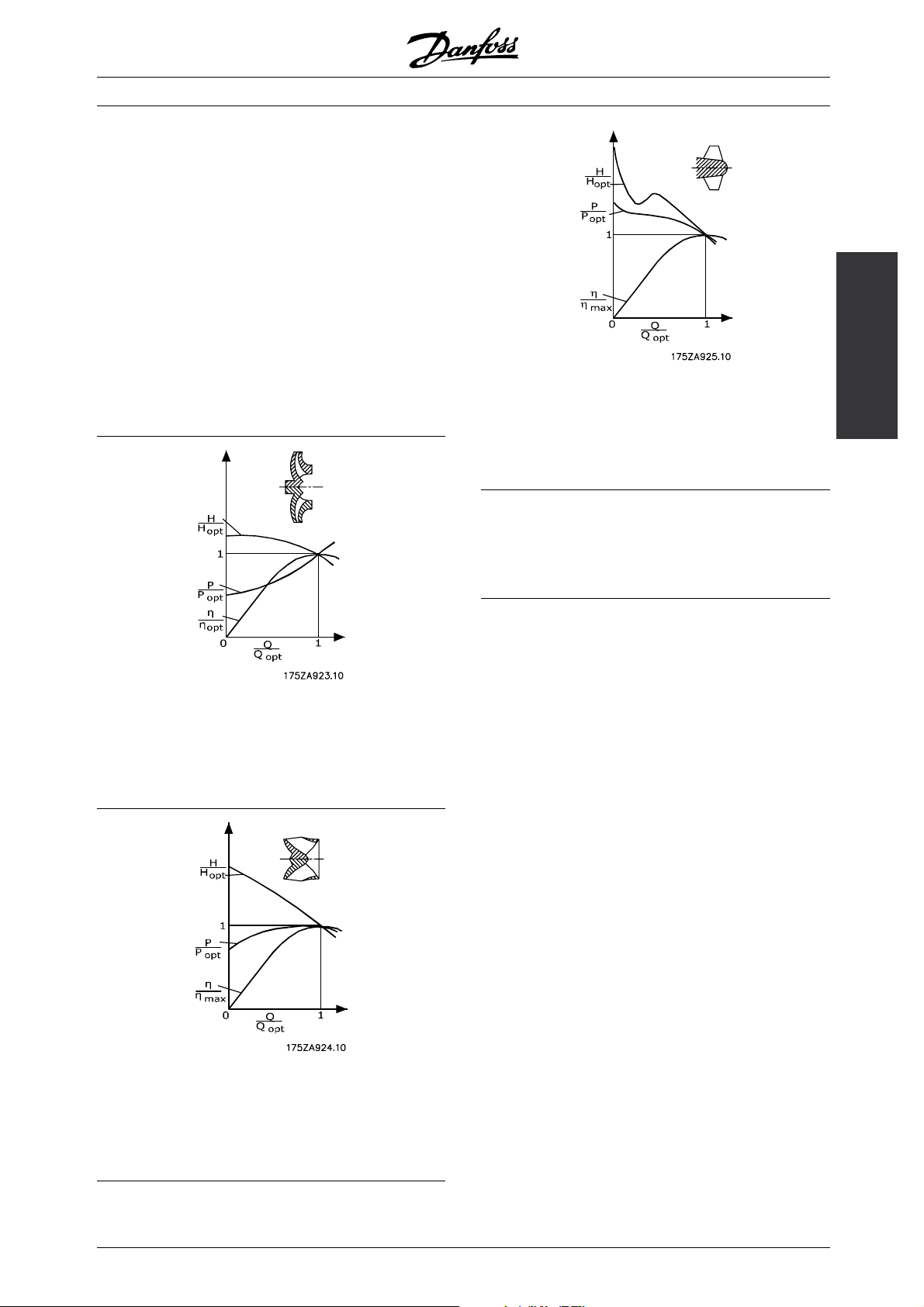

A criteria for Sensorless to work is that there must be a

clear one-to-one relation between head and flow, and

power and flow, (i.e. only one H-value to one Q-value

and opposite) as this forms the basis for the P/f-curve.

Sensorless can be used with ce ntrifugal pumps

that have radial impeller. On pumps with mixed

flow impellers t here is only limited use as the power

curve is typically flat at high flow rates. A centrifugal

pump with axial impeller cannot be controlled with

sensorless control due to the particular shape of

the head curve. The graphics below show typical

characteristics for the different pump types.

Axial impeller

=200 min

n

q

-1

Not possible

Other limitations: Sensorless control is limited to

non-compressible liquids such as water. Furthermore

the solution is recommended only in closed systems.

Functionality

Radial impeller

=20 min

n

q

-1

Possible

Mixed flow impeller

=80 min

n

q

-1

Limited

MG.10.T1.02 - VLT is a registered Danfoss trademark

5

Page 6

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

This parameter activates the Sensorless control:

Par. No. Par. Name Selection Default Description

Par. 700 (SENSOR-

LESS CONTROL)

The following parameters must be set to make Sensorless work:

VLT 6000 FCM

Par. 100 must be OPEN LOOP Par. 003 must be LOCAL

Par. 101 must be MULTIPLE M OTORS Par. 100 mus t be O PEN LOOP

- Par. 101mustbeVTHIGH

FCM: OFF/ON

VLT 6000:

ENABLE/DISABLE

OFF/DISABLE Set parameter to enable/ON

to activate Sensorless control.

Please observe that this parameter

must be set to disable when doing

measurements.

The following parameters determine the user-defined

head for the system.

■Par. 705 Quadratic Head

Par. 705 Quadratic head

(QUADRATIC HEAD)

Value:

ON/OFF

Function:

Used when selecting the desired type of

Sensorless control: Quadra

tic head or linear

(proportional or constant) head.

Description of choice:

OFF: Generates a linear head/flow reference between

Head Q

(Par. 707) and Head working point (Par. 716).

min

ON: Generates a quadratic head/flow reference

between Head Q

(Par. 707) and Head

min

working point (Par. 716)

■Par. 707 Head Qmin

Par. 707 Head Q

min

(HEAD QMIN)

Value:

0-100%

✭ OFF

✭ 100%

Function:

Sets the head reference at zero flow as a percentage

of the value specified in Par. 716.

Description of choice:

Set a value between

6

MG.10.T1.02 - VLT is a registered Danfoss trademark

0 and 100%.

Page 7

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Par. 716 Head Working Point

Par. 716 Head Working Point

(HEAD WORK. POINT)

Value:

FCM

0-2000 kPa

VLT 6000

0-20000 kPa

Function:

Defines the head at the working point.

✭ 10 kPa

✭ 10 kPa

Description of choice:

Set the value in kPa according to the desired head

working point parameter 717. Note the difference

in range for FCM and VLT 6000.

■Par. 717 Flow Working Point

Par. 717 Flow Working Point

(FLOW WORK. POINT)

Value:

0-999 l/s

Function:

Defines the flow at the working point.

Description of choice:

Set the value in l/s according to the desired flow

working point parameter 716.

Functionality

✭ 1l/s

MG.10.T1.02 - VLT is a registered Danfoss trademark

7

Page 8

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Control Principle

The control principle builds on converting an internal feedback of inverter pa rameters into a power reference

that the controller uses to adjust the output frequency. The control scheme is illustrated below.

The control part is divided into two parts:

•The Integration control part sums up the actual power error

as the value

decreased w ith the value x

Power error (par. 701)

Integral Power (par. 703)

Delta freq. (par. 702)

is exceeded, the actual speed is increased resp.

and whenever the threshold defined

Integral freq. (par. 704)

•The Three point contro l part uses par. 701 to define the threshold. If the deviation to the actual

power setpoint exceeds the value in par. 701, the

speed increases respectively decreases with

the value in par. 702.

For VLT 6000 the updating takes place every 160ms and for FCM every 20ms.

8

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 9

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

Control

Principle

MG.10.T1.02 - VLT is a registered Danfoss trademark

9

Page 10

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Parameter Setting - Control

The following parameters are use d for setting

up the control:

■Par. 701 Power Error

Par. 701 Power Error

(POWER ERROR)

Value:

FCM: 1-50W

VLT 6000: 1-250W

Function:

See description under "Control Principle".

Description of choice:

A sm all value leads to a lower threshold for the

integration part o f the controller, and thereby faster

reaction. Larger pumps will require a larger value.

■Par. 702 Delta Frequency

Par. 702 Delta Frequency

(DELTA FREQUENCY)

Value:

0,1-1 Hz

✭ 20W

✭ 20W

✭ 0,4 Hz

■Par. 704 Integral Frequency

Par. 704 Integral Frequency

(INTEGRAL FREQUENCY)

Value:

1-100

Function:

See description under "Control Principle".

Description of choice:

A small value leads to a larger frequency step

in the three-point control part. This means

faster but rougher control.

✭ 20

Function:

See description under "Control Principle".

Description of choice:

A small value leads to a smaller frequency step

in the integration control part. This means slower

but more precise control.

■Par. 703 Integral Power

Par. 703 Integral Power

(INTEGRAL POWER)

Value:

1-100

Function:

See description under "Control Principle".

Description of choice:

A small value leads to a higher threshold

for the in tegration part of the controller, and

thereby faster reaction.

✭ 20

10

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 11

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Power Compensation

Par. 708 Power Compensation

(POWER C OMP)

Value:

VLT 6000: -1000W-1000W

FCM: -100W-100W

Function:

To obtain a more precise control and read-out, it can be

an advantage to correct the total power in the P/f table

by an offset, positive or n egative. Example on effect:

On a 1½ kW pump, about -30W can change the flow

read-out from 2.2 l/s to 1.8l/s. at m ax flow of 10 l/s.

Description of choice:

When preparing the system for sensorless control,

compare the calculated flow values with real measured

values. If there is a deviation in figures, this can

be caused by an offset in values. Enter the value

necessary to obtain as small a deviation as possible.

✭ 0

✭ 0

Functionalities

Programming other

MG.10.T1.02 - VLT is a registered Danfoss trademark

11

Page 12

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Analog Output

Terminal 45 on the VLT 6000 and terminal 9 on the

FCM can be used to read out either flow or head.

VLT 6000:

Par. 321 Terminal 45, output

FCM:

Par. 304 Terminal 9, output

Value

The following choices ha ve been added :

Choice Choice no. FCM Choice no. VLT 6000

SENS. FLOW = 0-20 mA [22] [44]

SENS. FLOW = 4-20 mA [23] [45]

SENS. HEAD = 0-20 mA [24] [46]

SENS. HEAD = 4-20 mA [25] [47]

■Par. 720 AO Max Value

Par. 720 AO Max Value

(AO MAX VALUE)

Value:

1-9999

✭ 1

Function:

This parameter is used to convert the current

signal to a head or flow value.

Description of choice:

Enterthemaximumvalueforheadorflow,atwhich

the analog output must give 20 mA.

Example:

Par. 321 is SENS. HEAD = 4-20 mA

Par. 720 is 200 (kPa)

The actual head is 100kPa. That brings

terminal 45 up to 12mA.

12

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 13

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Analog Input

It is possible to reduce the user-defined head

with the following parameters.

Drive Input Parameter Choice Value

FCM DI 9 332 [38] SENSORLESS

VLT 6000 AI 53 308 [10] SENSORLESS HEAD

Function: The ana

the user-defined head Q with a desired percentage.

Using a 0-10 V potentiometer means that 0 V equals

0% and 1 0 V e

is desired, set the potentiometer to 2.5 V.

log input can be used to reduce

quals 100%. So if a 25% reduction

Functionalities

Programming other

MG.10.T1.02 - VLT is a registered Danfoss trademark

13

Page 14

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Read-outs in LCP

In display line 1.1, 1.2 and 1.3 it is possible

to read out the following:

Sensorless Head (very useful, if the user-defined

Head is proportional)

Sensorless Flow

Sensorless Power, which is the actual power

consumption of the system. It is recommended to use

this read-out when measuring the pump characteristics.

The value is filtered to make it more stable (Filter time

constant FCM: 500 ms and V LT 6000: 4000 ms).

These choices can be programmed into the following parameters:

Functionality Par. no. FCM Par. no. VLT 6000

Large d isplay read-out/Display line 2 009 007

Display line 1.1 010 008

Display line 1.2 011 009

Display line 1.3 012 010

The read-outs have the following numbers:

Choice Choice no. FCM Choice no. VLT 6000

Sensorless Power [33] [33]

Sensorless Flow [34] [34]

Sensorless Head [35] [35]

14

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 15

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Power/Frequency Read-out

To enable the user to check if the calculated points

used for control look right, Parameter 799 (PF

READOUT) has been created. The parameter is

indexed as read-only and contains 20 values: 10

points holding P ower/frequency values. The values

should develop like shown in the g rap h below:

All odd numbers show the power, and the even numbers

show the frequencies. It is important for the control that:

[1] < [3] < [5] < [7] < [9] < [11] < [13] <

[15] < [17] < [19] and

[2] < [4] < [6] < [8] < [10] < [12] < [14] < [16] < [18] < [20].

Functionalities

Programming other

MG.10.T1.02 - VLT is a registered Danfoss trademark

15

Page 16

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■VLT 6000

Please note that the choice in pa rameter 300 "selection

of MSB" has been removed, and consequently

only 2 setups are available.

16

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 17

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Measuring Values

■Introduction

This instruction concerns the use of SControl for Sensorless Pump Control for VLT 60 00 and FCM 30 0. Please

contact Danfoss to acquire th e SControl Software.

■Installation and Setup of the Software

SControl operates in two modes:

•Productionmode

This mode is used in production in cases where pump data are not supposed to be changed. A pump can

be chosen and data can be downloaded to the drive.

•Editmode

This mode is used when entering different pump data, adding and removing pumps. Also in this mode,

data can be downloaded to the drive.

Please note that only the command buttons show which mode is active.

■Installation

Run the "Setup.exe" file and the program will be installed. Only the Production Mode is installed in the first

step. In order to install the Edit mode, create a short-cut of the program and type " edit" at the end of the

path: "C:\Program F iles\Dan fo ss Drives\SControl\Scontrol.exe" edit Remember to include a space before

edit; otherwise it will not work.

Values

Measuring

MG.10.T1.02 - VLT is a registered Danfoss trademark

17

Page 18

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Entering Pump Data

To add a pump: Push the command button +

To remove a pump: Push the command button -

If the pump is connected to a VLT 6000, write VLT6*** in the p um p type followed by the pump type.

For entering data, choose Database Editor.

Enter frequencies (one or more) in the left column. Start with the highest value. More frequencies can be

added later.

18

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 19

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

Select one frequency and add flow/power/head values for that s

important to have the same order as this:

pecific frequency. Start with no flow. It is

Values

Measuring

MG.10.T1.02 - VLT is a registered Danfoss trademark

19

Page 20

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Number of Measurements

The specified accuracy of Sensorless Pump Control (maximum 5% deviation) is based on having 100

measurements (10 frequencies and 10 flow/power and head measurements for each frequency). The minimum

number is 16 measurements (flow/power/head values) for at least 4 frequencies.

The program also has a func tion ality called "Auto Insert Data". It is only necessary to use t his functionality with

10 measurements for 1 frequency, and the program will calculate the remaining points.

Please note that using less tha n 100 measurements will decrease the accurac y. Therefore check the accuracy

after programming and make sure tha t it is within an acceptable level.

Step by step

1. Put the drive at fixed speed.

2. Find max flow (do not write it into SControl)

3. Measure Power/Head at 0 flow, write data in SControl.

4. Spread the flow measurements evenly in 10 steps, from 0 to max flow, and enter Power/Head/Flow

values in to SControl (see example above) .

5. Do the measurements for 10 frequency steps evenly spread between Fmax and Fmin (unles s using

less than 100 measurements as described above).

■Other Functionalities of the Program

Pressing the "VLT paramete

rs" command button, you can enter desired values for parameters. When

downloading data to the drive, the listed parameters will be changed according to the entered values. The

default setting of these parameters can be changed in "Setup" and "Default VLT Parameter Setting".

NOTE:TheparametersinFCMandVLT6000HVACaredifferent,soitisnotpossibletomakeagenerallist.

Pressing the "Download Da ta" and "Start" button will start downlo ad ing of pump data and parameter settings

into the drive.

20

MG.10.T1.02 - VLT is a registered Danfoss trademark

Page 21

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

■Data and Read-outs

The information on the left (P_A, P_B…) is in fact the coefficients to HEAD/FLOW and POWER/FLOW curves:

3

H=f(Q)=aQ

P=f(Q)=aQ

+bQ2+cQ+d

2

+bQ+c

The feature "DB plotter" in "Actions" can give a graphical overview of data measured at one frequency at a time:

This graph displays th ese data:

MG.10.T1.02 - VLT is a registered Danfoss trademark

21

Values

Measuring

Page 22

Sensorless Pump Control for VLT®6000 HVAC / FCM 300

If more data have bee n entered for other frequencies, simp ly sele

the plotter window.

Use "Export to Excel" to copy all data to the Excel sheet that comes with the installa tion of Scontrol: Open the

Excel sheet "Sensorless Plot" and place the marker at cell A1, a nd choose "Edit" and "Paste".

ct the other frequency witho ut closing

22

MG.10.T1.02 - VLT is a registered Danfoss trademark

Loading...

Loading...