Page 1

Data sheet

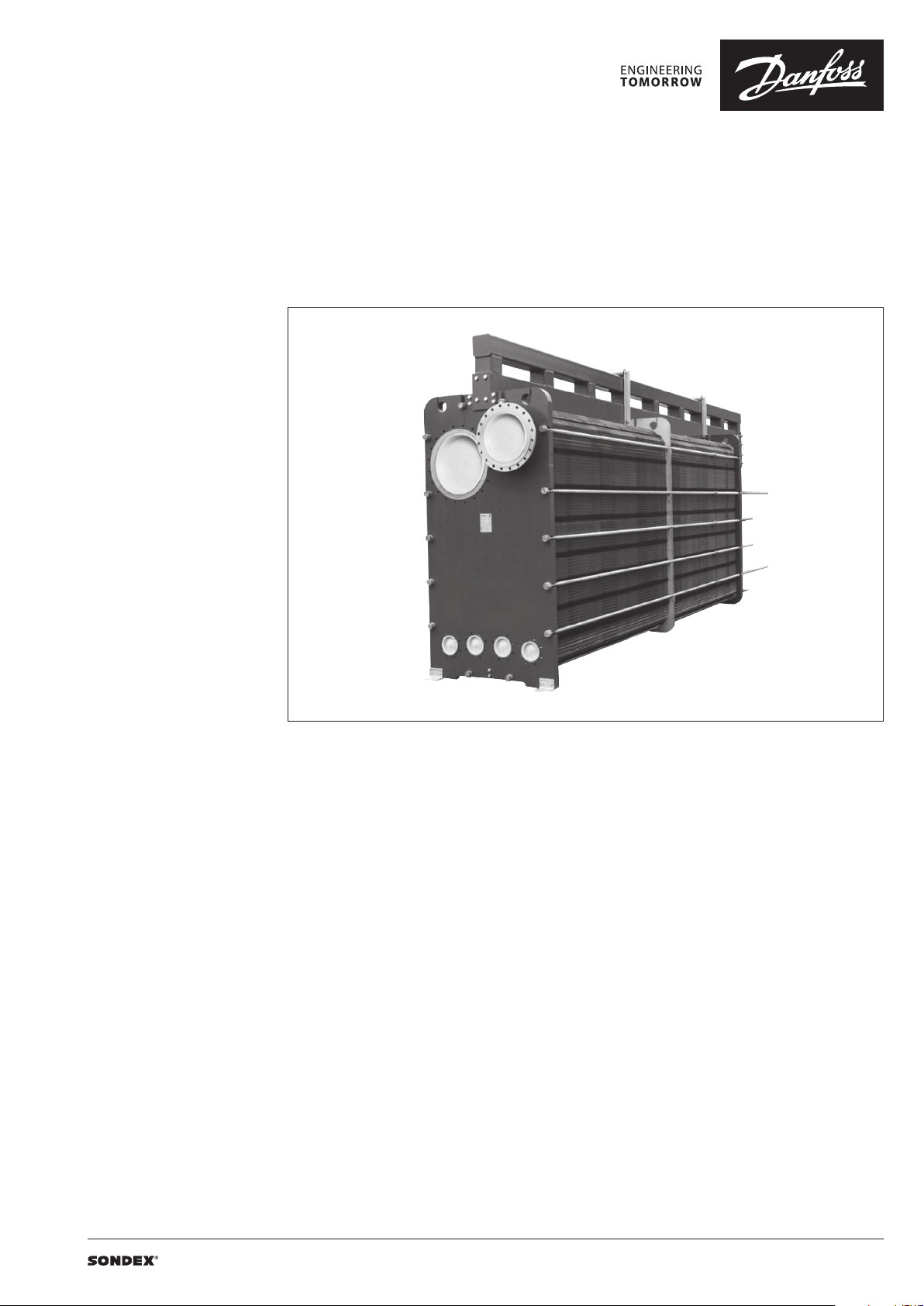

SEC174

Rising Film Evaporator

Description

Recommended Applications

The SEC174 Sondex plate evaporator is a specially

developed heat exchanger for evaporation

duties.

Design Principle

The plate is designed as a semi-welded cassette,

with a welded channel for the medium side, and

on the evaporation side there is a traditional

plate heat exchanger gasket.

The unique plate design ensures an even

distribution of the product over the whole plate

making optimal rising film evaporation. The

special designed plate pattern ensures a high

turbulence of the fluids on both sides, resulting

in a high heat transmission co-efficient. This

results in a very compact heat exchanger with a

small hold-up volume.

Installation:

The large DN600/24” connection on the

evaporator makes it possible to cover many

duties in a single connection solution. This

means that the connections will be on the head

of the heat exchanger, which is of big advantage

during service work and if the capacity is to be

increased.

The plate pattern and inlet area are also

designed for CIP cleaning, which makes the

service of the plate heat exchanger easy.

Data Required for Correct Quotation:

• Duty

• Flow rate

• Temperature

• Type of media

• Working pressure

• Working Temperature

• Pressure loss

• Boiling point

• Thermodynamic properties

• Preferred number of effects

• Product concentration by inlet and outlet

Above data determines the choice of heat

exchanger.

| 2020.02 AI334344867691en-000101 | 1

Page 2

Data sheet SEC174 - Rising Film Evaporator

Tehnical data

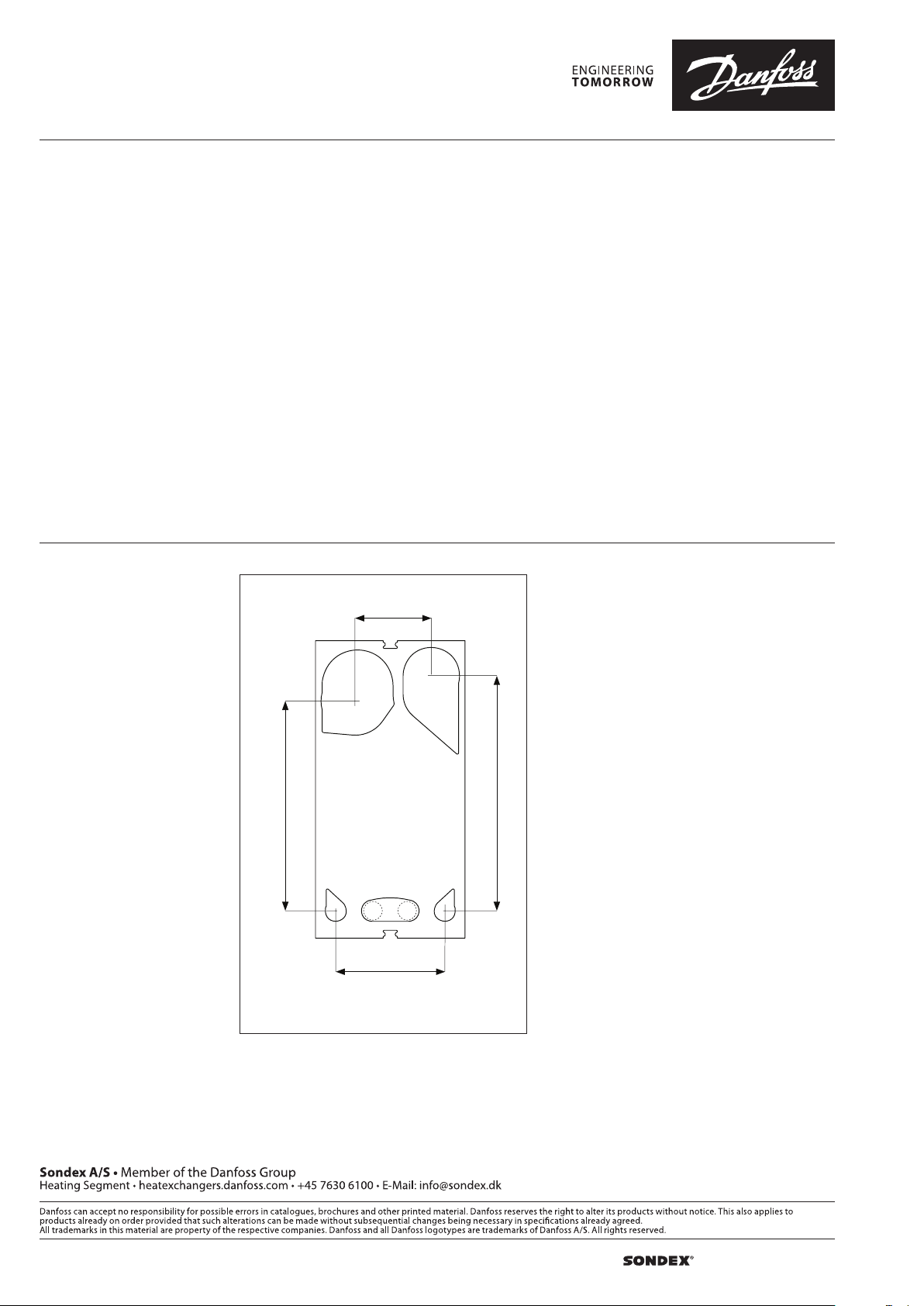

Dimensions

Frame

Painted frame, colour RAL 5010

(available in other colours)

The frame comes with clamping bolts placed

around the frame edge.

Design Pressure

Painted frames: 0.6/1.0 MPa. (87/145 PSI)

Construction Standard

• EN13445 (PED 2014/68/EU)

• ASME sec VIII, Div. 1

Connections:

Inlet product side (F4 & F5): DN150/6” flange.

• Outlet (F1): DN600/28” flange.

• Inlet medium side (F2): DN450/18” flange.

• Outlet (F3 & F6): DN150/6” flange.

Flanges in carbon steel, rubberlined or

stainless steel. According to all known

standards.

Plate Material

AISI 304 and AISI 316

Other materials available on request.

628 mm (24,7”)

Gaskets

The gasket is placed in the closed gasket

groove, that is formed by the plates. This

design makes the plate suitable for high

working pressures. The plates are strongly

guided by the gasket during the assembly of

the plate heat exchanger.

Materials: NBR and EPDM

Other materials available on request.

Extra Equipment:

• Safety cover in stainless steel

• Insulating jacket

• Assembling spanner

• Foundation feet

• Instrument flange

• Thermometer and manometer

1725 mm (68”)

SEC174

F1

F6

F5 F4

898 mm (35,3”)

F2

1935 mm (76,2”)

F3

| DHS-SRMT/SI | 2020.022 | AI334344867691en-000101

Loading...

Loading...