MAKING MODERN LIVING POSSIBLE

Electrical Installation

Series 90 Pump

Non Feedback Proportional

Electric (NFPE)

powersolutions.danfoss.com

Electrical Installation S90 NFPE

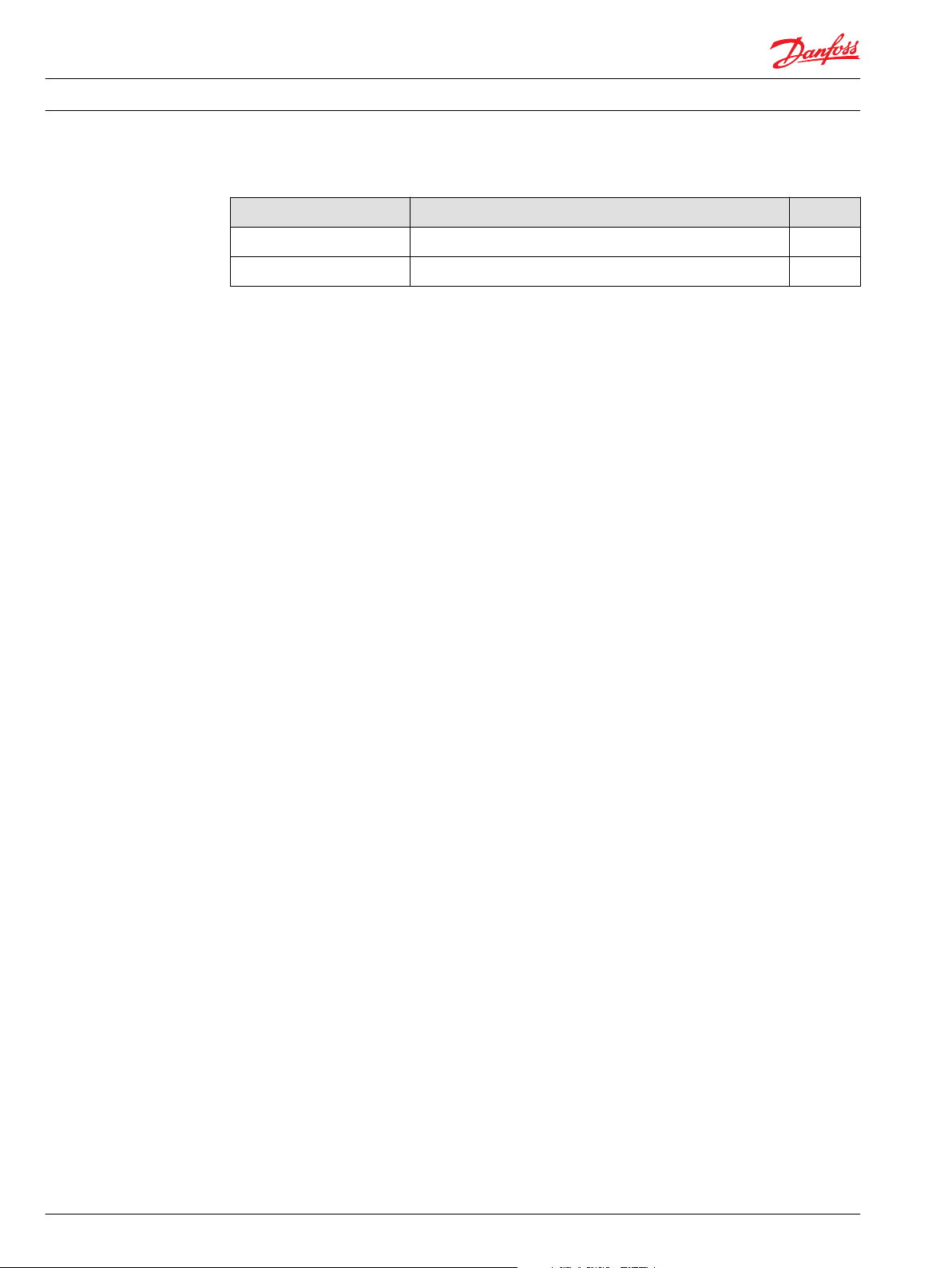

Revision history Table of revisions

Date Changed Rev

August 2015 Converted to Danfoss layout BA

Apr 2007 AA

2 11023289 • Rev BA • August 2015

Electrical Installation S90 NFPE

Contents

Literature references

S90 Pump NFPE literature references....................................................................................................................................... 4

Latest version of technical literature.........................................................................................................................................4

Product overview

Product image................................................................................................................................................................................... 5

Nomenclature....................................................................................................................................................................................5

Theory of operation.........................................................................................................................................................................6

Signal current versus displacement..................................................................................................................................... 6

Hydrostatic drive line power...................................................................................................................................................6

Hydraulic schematics...................................................................................................................................................................... 7

Electrical specifications.................................................................................................................................................................. 7

Electrical installation

Pinout....................................................................................................................................................................................................8

AMP Junior Power Timer connector.....................................................................................................................................8

Pin compatibility...............................................................................................................................................................................8

S90 NFPE input/output matrix.....................................................................................................................................................8

Mating connector.............................................................................................................................................................................9

AMP connector parts list.......................................................................................................................................................... 9

11023289 • Rev BA • August 2015 3

Electrical Installation S90 NFPE

Literature references

S90 Pump NFPE literature references

Literature title Description Literature number

S90 Axial Pumps Technical Information Complete product electrical

PLUS+1® Compliant S90 NFPE Control Function Block User

Manual

Latest version of technical literature

Danfoss product literature is online at: http://powersolutions.danfoss.com/literature/

and mechanical

specifications

Compliant function block

set-up information

520L0603

11022913

4 11023289 • Rev BA • August 2015

9 0

A R C M P J G N F L H T W Y Z K

Electrical Installation

Product overview

Product image

Nomenclature

S90 NFPE

S90 Pump NFPE

M module - NFPE control options

Option Description

FA Non Feedback Proportional Electric Control, 12 Vdc, 25 bar

FB Non Feedback Proportional Electric Control, 24 Vdc, 25 bar

FC Non Feedback Proportional Electric Control, 12 Vdc, 32 bar

FD Non Feedback Proportional Electric Control, 24 Vdc, 32 bar

FG Non Feedback Proportional Electric Control, 12 Vdc, 32 bar

FH Non Feedback Proportional Electric Control, 24 Vdc, 32 bar

FK Non Feedback Proportional Electric Control, 12 Vdc, 25 bar

FL Non Feedback Proportional Electric Control, 24 Vdc, 25 bar

FM Non Feedback Proportional Electric Control, 12 Vdc, 32 bar

FN Non Feedback Proportional Electric Control, 24 Vdc, 32 bar

Only certain control options for the Series 90 pump utilize the Non Feedback Proportional Control (NFPE).

Please refer to the pump's nomenclature to determine if the pump is equipped with the proper option.

The nomenclature can be found on the pump's name tag.

11023289 • Rev BA • August 2015 5

"0"

Signal Current

Displacemen

t

100 %

100 %

W

Electrical Installation

Product overview

Theory of operation

S90 NFPE

The Non Feedback Proportional Electric (NFPE) control is an electrical automotive control in which an

electrical input signal activates one of two proportional solenoids that port charge pressure to either side

of the pump servo cylinder. The NFPE control has no mechanical feedback mechanism.

The pump displacement is proportional to the solenoid signal current, but it also depends upon pump

input speed and system pressure. This characteristic also provides a power limiting function by reducing

the pump swashplate angle as system pressure increases.

Signal current versus displacement

Hydrostatic drive line power

Warning

Unintended vehicle or machine movement hazard. The loss of hydrostatic drive line power, in any mode

of operation (forward, neutral, or reverse) may cause the system to lose hydrostatic braking capacity. You

must provide a braking system, redundant to the hydrostatic transmission, sufficient to stop and hold the

vehicle or machine in the event of hydrostatic drive power loss.

6 11023289 • Rev BA • August 2015

B

A

M5

M4

M3

M1

M2

L1

S

L2

M6

P003 174

Electrical Installation S90 NFPE

Product overview

Hydraulic schematics

Non feedback proportional electric (NFPE)

Electrical specifications

S90 NFPE electrical specifications

Voltage

Start current

End current

Maximum current

Coil resistance at 20 °C [70 °F]

Recommended PWM frequency**

Minimum PWM frequency

*

PWM signal required for optimum control performance.Verify the PWM frequency is set correctly in the PLUS+1

controller. The default is set at 4000 Hz which will significantly reduce EDC performance.

12V 24V

440 mA 220 mA

1290 mA 645 mA

1500 mA 750 mA

4.98 Ω 20.60 Ω

200 Hz

80 Hz

®

11023289 • Rev BA • August 2015 7

2 1

W

Electrical Installation S90 NFPE

Electrical installation

Pinout

AMP Junior Power Timer connector

Pin location

Pinout

Pin Function

1 PWM signal

2 Ground

Pinout (alternative)

Pin Function

1 Ground

2 PWM signal

Pin compatibility

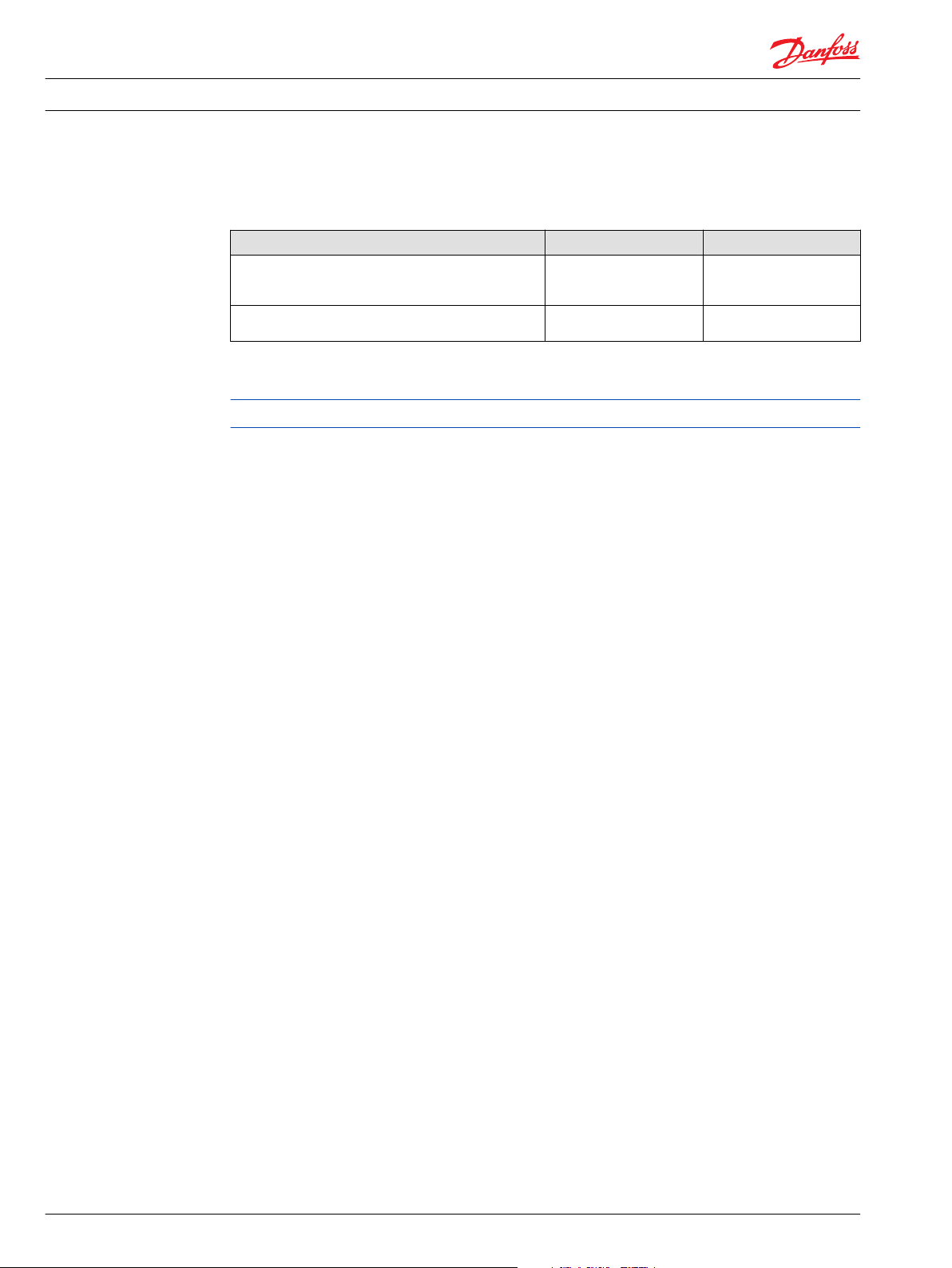

S90 NFPE input/output matrix

PLUS+1® module pin type

Pin Function

1, 2 PWMOUT/DOUT/PVG Power supply

1, 2 PWMOUT/DOUT/PVGOUT

1, 2 Power ground

*

Use output pins with configurable PWM frequency.

*

*

Warning

Unintended vehicle or machine movement hazard. Verify the wiring harness to ensure the correct PLUS

+1® pin is properly connected to each control pin.

Shaft rotation

Active solenoid

Port A flow

Port B flow

Servo cylinder

Clockwise Counterclockwise

A B A B

Out In In Out

In Out Out In

M5 M4 M5 M4

8 11023289 • Rev BA • August 2015

Electrical Installation S90 NFPE

Electrical installation

Mating connector

AMP connector parts list

Description Quantity Ordering number

Two pin connector 1 Tyco Electronics 282189-1

Contacts 2 Tyco Electronics 929940-1

Seal plugs 2 Tyco Electronics 828904-1

Mating connector kit 1 Danfoss K19815

11023289 • Rev BA • August 2015 9

Electrical Installation S90 NFPE

10 11023289 • Rev BA • August 2015

Electrical Installation S90 NFPE

11023289 • Rev BA • August 2015 11

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11023289 • Rev BA • August 2015 www.danfoss.com

Local address:

©

Danfoss A/S, 2015

Loading...

Loading...