Page 1

PLUS+1™ GUIDE

Software

PLUS+1 Compliant S90 EDC Control Function Block User Manual

142.0 mm

[5.59]

97.0 mm

[3.82]

144.5 mm

5.69

158.2 mm

6.23

PIN #1

INDICATED

2x 25.2 mm

[1.0]

2x ∅7.0

[.28]

MOUNTING

DIRECTION

#2

LED INDICATO R

LIGHTS

TM

COMPLIANT

CONNECTOR MATES

WITH DEUTCH

CONNECTOR #D TM-06-125A

51.6 mm

47.1 mm

[1.85]

[2.03]

1

12

6

7

1

6

12

7

CONNECTOR MATES

WITH DEUTCH

CONNECTOR #DTM-06-125A

Page 2

PLUS+1 Compliant S90 EDC Control Function Block

T

User Manual

About this Manual

Organization

and Headings

o help you quickly find information in this manual, the material is divided into sections,

topics, subtopics, and details, with descriptive headings set in red type. Section titles

appear at the top of every page in large red type.

In the PDF version of this document, clicking an item underlined in blue italic type

you to the referenced page in the document.

Special Text Formatting Controls and indicators are set in bold black type.

Table of Contents

A Table of Contents (TOC) appears on the next page. In the PDF version of this document,

the TOC entries are hyperlinked.

Revision History

Revision Date Comment

Rev CA October 2011

jumps

©2011 Sauer-Danfoss. All rights reserved.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer-Danfoss reserves the right to alter its products without prior notice. This also applies to products already

ordered provided that such alterations can be made without affecting agreed specifications.

All trademarks in this material are properties of their respective owners.

PLUS+1, GUIDE, and Sauer-Danfoss are trademarks of the Sauer-Danfoss Group. The PLUS+1 GUIDE, PLUS+1

2

Compliant, and Sauer-Danfoss logotypes are trademarks of the Sauer-Danfoss Group.

11022912 · Rev CA · October 2011

Page 3

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

Contents

S90_EDC Function Block ............................................................................................................................... 4

Overview .................................................................................................................................................... 4

Inputs ........................................................................................................................................................... 4

Function Block Internal Constants ..................................................................................................... 5

Function Block Parameters .................................................................................................................. 6

Outputs ....................................................................................................................................................... 8

About Function Block Connections .................................................................................................. 9

Status and Fault Logic.......................................................................................................................... 10

Configuration Values ............................................................................................................................ 12

About Modifying the Config_Data Page ....................................................................................... 15

About the Relationship between the Function Block Input and Output Signals ............ 17

MC Controller—Output Configuration .......................................................................................... 18

How to Configure an MFOut ..................................................................................................... 18

SC Controller—Output Configuration ........................................................................................... 20

How to Configure an MFOut ..................................................................................................... 20

How to Calibrate the Function Block .............................................................................................. 21

How to Calibrate an Individual Parameter ............................................................................ 23

About Manual Calibration .......................................................................................................... 24

About the Name Space Feature ....................................................................................................... 25

How to Enter a Name Space Value .......................................................................................... 25

11022912 · Rev CA · October 2011

3

Page 4

Overview

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

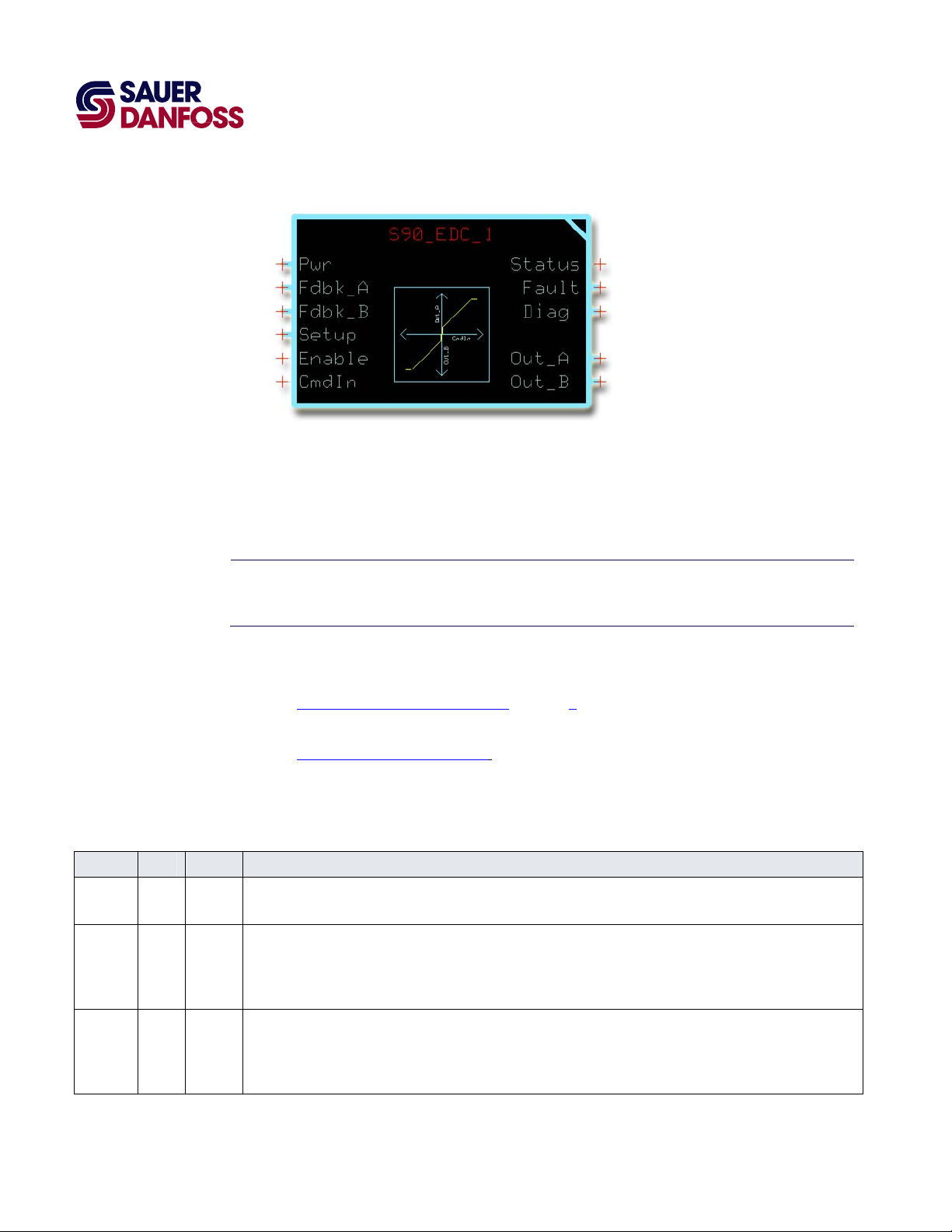

S90_EDC Function Block

The output of an S90_EDC function block interfaces between your application and a

Sauer-Danfoss S90 EDC (Electronic Displacement Control). The output of this function

block drives the coils that control flow direction and magnitude through a pump’s A and B

ports.

T PLUS+1 I/O modules do not have the fault-checking feedback signals that are needed

by this function block. An application that uses this function block to control an I/O

module will fail to compile.

See:

• About Function Block Connections on page 9 for an overview of this function block’s

connections and signals.

• About the Name Space Feature on page 25 if you are using more than one of these

function blocks in your application.

Inputs

S90_EDC Function Block Inputs

Input Type Range Description

Pwr —— —— Reports controller power supply voltage.

The function block uses this voltage when it calculates the measured resistance of the control circuit.

Fdbk_A —— —— Reports the status of the MFOut (Multifunction Output) block that receives the function block’s Out_A (Output A)

bus.

Each MFOut block in the Outputs page has a corresponding MFOut block in the Inputs page that reports on its

status through a Status bus. The Inputs bus on the Application page contains these Status buses.

Fdbk_B —— —— Reports the status of the MFOut (Multifunction Output) block that receives the function block’s Out_B (Output B)

bus.

Each MFOut block in the Outputs page has a corresponding MFOut block in the Inputs page that reports on its

status through a Status bus. The Inputs bus on the Application page contains these Status buses.

4

11022912 · Rev CA · October 2011

Page 5

C

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

S90_EDC Function Block Inputs

Input Type Range Description

Setup —— —— Allows common configuration to be applied to multiple function blocks.

See About Modifying the Config_Data Page on page 15 for more information.

Enable BOOL —— Enables the OutputValue signals in the Out_A and Out_B buses.

– T = OutputValue signals follow the CmdIn signal.

– F = Holds both OutputValue signals at zero.

– F/T = Clears latched faults if CmdIn is zero.

CmdIn S16 ±10000 Specifies the requested speed and direction.

– +10000 = Requests maximum Out_A speed.

– 0 = Requests neutral (stop).

– –10000 = Requests maximum Out_B speed.

Function Block Internal Constants

The following table lists constant values that are provided in the function blocks for

setting limits. These constants cannot be edited.

S90_ED

Constant Value Description

MaxCrnt 100 mA The maximum current for displacement or proportional control.

Nominal Ω 18.0 Ω The resistance of the load normally connected to Out_A and Out_B.

Internal Constants

11022912 · Rev CA · October 2011

5

Page 6

C

Function Block Parameters

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

Warning

Using the PLUS+1 Service Tool program download new parameter values to an

application can result in unexpected and sudden machine movements.

Unexpected and sudden machine movements can result in personal injury and

equipment damage.

Always secure your machine against unexpected and sudden movements before you

use the Service Tool program download new parameter values.

The following table lists function block parameters that are stored in the controller’s nonvolatile memory.

You can change these values by:

• Execution of the calibration process.

• Direct access to serial EE memory using the PLUS+1 Service Tool.

• Recalling default values.

S90_ED

Parameter Type Range Description

A.EE_Thld,

B.EE_Thld

A.EE_EndCrnt

B.EE_EndCrnt

A.EE_CalFlg,

B.EE_CalFlg

Function Block Parameters

U16 CalThldMin to CalThldMax Calibrated threshold values for Out_A and Out_B.

U16 Thld + 1 to MaxCurrent Calibrated end current values for Out_A and Out_B.

U8 —— Calibration flags for Out_A and Out_B.

– Bit 1 = 1 (0x0001)—Threshold is not calibrated.

– Bit 2 = 1 (0x0002)—End current is not calibrated.

The CalFlg signal in the Diag bus contains both pairs of flags, with the Out_B bits

shifted to positions 3 and 4.

These parameters determine the values used as threshold and end current for each

direction during normal operation. However, the values actually applied might be

different because:

• Thld and EndCrnt are both subject to range limits.

• Thld is modified by the ThldMult value.

6

11022912 · Rev CA · October 2011

Page 7

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

The following intermediate values represent the values that are actually applied:

• EndCrntApplied = MIN(EE_EndCrnt, MaxCrnt).

• ThldApplied = MIN((EE_Thld × ThldMult), EndCrntApplied).

This assures that:

• EndCrntApplied never exceeds MaxCrnt.

• ThldApplied never exceeds EndCrntApplied.

Also note that, while the CalTask value is set to select a calibration task:

• EndCrntApplied = MaxCrnt.

• ThldApplied = 1.

The applied values are available in the Diag bus as Thld_A, Thld_B, EndCrnt_A, and

EndCrnt_B.

11022912 · Rev CA · October 2011

7

Page 8

C

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

Outputs

S90_ED

Output Type Range Description

Status U16 —— Reports the function block’s status conditions.

Fault —— —— Reports the function block’s fault conditions.

Diag —— —— Outputs a bus with the following signals:

Out_A U16 0-8500 Has an OutputValue signal that drives the A coil.

Out_B U16 0-8500 Has an OutputValue signal that drives the B coil.

8

Function Block Outputs

This output uses the standard bitwise scheme described in the Basic Function Blocks Library User’s Manual.

For more information about status logic, see Status and Fault Logic on page 10.

This output uses the standard bitwise scheme described in the Basic Function Blocks Library User’s Manual.

For more information about fault logic, see Status and Fault Logic on page 10.

Fault_A U16 —— Reports fault conditions for the A output.

Fault_B U16 —— Reports fault conditions for the B output.

– CalFlg (Calibration Flag).

– EndCrnt_A (End Current A).

– FltTmr_A (Fault Timer A).

– MeasOhm (Ohm A).

– Thld_A (Threshold A).

– EndCrnt_B (End Current B).

– FltTmr_B (Fault Timer B).

– MeasOhm_B (Ohm B).

– Thld_B (Threshold B).

The Diag bus also has Config and Define sub-buses that report the configuration and setup values used

by the function block.

Use these signals for troubleshooting.

CalFlg U8 —— The CalFlg signal is a bitmask value that indicates the state of calibration values.

– Bit 1 = 1 (0x0001)—Threshold A is not calibrated.

– Bit 2 = 1 (0x0002)—End current A is not calibrated.

– Bit 3 = 1 (0x0004)—Threshold B is not calibrated.

– Bit 4 = 1 (0x0008)—End current B is not calibrated.

Use these flags to manage the calibration process.

EndCrnt_A,

EndCrnt_B

FltTmr_A,

FltTmr_B

MeasOhm_A,

MeasOhm_B

U16 —— Report the active end current value for the A and B outputs.

During:

– Normal operation, end current values equal A.EE_EndCrnt and B.EE_EndCrnt.

– Calibration, the active end current values equal MaxCrnt.

U16 —— Reports the value of the forward fault delay timer.

U16 —— Indicate the measured resistance of the control circuits that drive the pump’s coils.

11022912 · Rev CA · October 2011

Page 9

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

About Function Block Connections

Function Block Connections

Item Description

1 Controller power supply voltage.

2 Status of Out_A.

3 Status of Out_B.

4 Input for configuration values from an external source.

5 T enables Out_A and Out_B.

6 Commands direction and speed.

7 Reports the status of the function block.

8 Reports the faults of the function block.

9 Diagnostic signals.

10 Drives the A and B coils.

11022912 · Rev CA · October 2011

9

Page 10

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

Status and Fault Logic

The following table lists function block status codes. These codes indicate the calibration

state of the function block.

Status Logic

Status Bit* Reported While

Block is not calibrated. 1 Any CalFlg bit is set to 1.

Calibration active. 2 Enable is T and the CalTask = –2, –1, +1, or +2.

Parameters are corrupt. 3 (EE_EndCrnt > MaxCrnt) or (EE_Thld × ThldMult) > EndCrntApplied) for either direction A or direction B.

The actual tests in the software are:

– (EndCrntApplied ≠ EE_EndCrnt)—happens when (EE_EndCrnt > MaxCrnt). It means that EndCrntApplied

= MaxCrnt.

– (ThldApplied = EndCrntApplied)—happens when ((EE_Thld × ThldMult) ≥ EndCrntApplied).

Invalid setup/calibration. 4 Any of the following setup and configuration values are not within their valid ranges:

– CalThldMin.

– CalThldMax.

– ThldMult.

– FltDelay.

– CalTask.

Also reported while PinStatus reports a configuration error (value =1).

Value too low. 7 Threshold calibration is active and the OutputValue < CalThldMin for the calibration direction.

Value too high. 8 Threshold calibration is active and the OutputValue > CalThldMax for the calibration direction.

*Position of set bit in a 16 bit fault code or status code. Bit 1 is the least significant bit. Bit 16 set to 1 identifies a standard Sauer-Danfoss status code

or fault code.

10

11022912 · Rev CA · October 2011

Page 11

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

The function block’s Out_A bus contains an OutputValue signal that drives a forward EDC

coil, while its Out_B bus contains an OutputValue signal that drives a reverse EDC coil.

The following table lists function block faults and how they affect the two OutputValue

signals.

Fault Logic

Fault Cause Bit* Response Delay† Latch‡ Correction

Input value too low. CmdIn < –100000. 1

Input value too high. CmdIn > +10000. 2

Open circuit. Measured Ω > (Nominal Ω × 3).§ 3

Short circuit. Measured Ω < (Nominal Ω ÷ 3).§ 4

Hardware.

General.

*Position of set bit in a 16 bit status or fault code. Bit 1 is the least significant bit. Bit 16 set to 1 identifies a standard Sauer-Danfoss status code or

fault code.

†

A delayed fault gets reported if the detected fault condition persists for a specified delay time. A delayed fault cannot be cleared until the fault

condition remains undetected for the delay time.

‡

A latched fault report maintains until the latch is released. A release is attempted each time that Enable becomes T while CmdIn is 0.

§

The nominal Ω value is an internal constant of each function block. It can be viewed, with other defined constants, in the Define sub-bus of the

Diag bus. The other constants specify the maximum current and the range limits for configuration values.

Current exceeds continuous or

peak rating.

Current flow between Out_A and

Out_B. Possible cause is loss of a

common ground connection.

OutputValue

held at 0.

6 Correct cause of overload.

7 Correct open ground connection.

No. No. Fix CmdIn.

Check for open circuit or high resistance

between output pin and ground.

Check for short circuit or low resistance

between output pin and ground.

Yes. Yes.

11022912 · Rev CA · October 2011

11

Page 12

Configuration Values

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

The default Config_Data page contains constant values that set the function block’s

operating characteristics. Typically, you do not have to change any of these values for the

correct operation of the function block.

Optionally, you can:

• Modify the constant values on this page.

• Replace some or all the constant values on this page with signals brought in on the

Setup bus, which is connected to the function block’s Setup input. See About

Modifying the Config_Data Page on page 15 for more information.

12

11022912 · Rev CA · October 2011

Page 13

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

Config_Data Function Block Configuration Values

Input Type Range Description

CalTask S16 –2 to +3 Selects a calibration process.

– –2 = Calibrate the B end current.

– –1 = Calibrate the B threshold.

– 0 = Not in the calibration mode.

– +1 = Calibrate the A threshold.

– +2 = Calibrate the A end current.

– +3 = Applies default calibration values for both outputs on a transition to +3. The default value of +3

applies default values each time the controller powers up and allows normal operation.

StoreCalVal BOOL —— While calibration is active, a StoreCalVal (Store Calibration Value) F/T transition writes the selected

calibration value to memory and sets the CalFlg to indicate this value as calibrated.

The CalFlg in the Diag bus reports the status of each calibration value.

– T = Not calibrated.

– F = Calibrated.

SetCalReqd BOOL —— A SetCalReqd (Set Calibration Required) F to T transition sets all CalFlg bits to 1 to mark all calibration

values as uncalibrated.

ClrCalReqd BOOL —— A ClrCalReqd (Clear Calibration Required) F to T transition clears all CalFlg bits to 0 to mark all calibration

values as calibrated.

CalThldMin U16 0–89 Sets the lower limit of the valid range for the threshold parameter.

10000 = 1000 mA.

CalThldMax U16 90–300 Sets the upper limit for of the valid range for the threshold parameter.

10000 = 1000 mA.

ThldMult U16 0–10000 The function block multiplies the Out_A and Out_B thresholds by the ThldMult (Threshold Multiplier) to

calculate the applied threshold.

Enter a value of less than 10000 to reduce the applied threshold. For example, a value of 7500 reduces

both the Out_A and Out_B thresholds by 25%.

10000 = 100.00%.

DfltThld_A U16 CalThldMin

to

CalThldMax

DfltThld_B U16 CalThldMin

to

CalThldMax

DfltEndCrnt_A U16 0–100 When the CalTask becomes +3, the Out_A end current parameter resets to equal the DfltEndCrnt_A

DfltEndCrnt_B U16 0–100 When the CalTask becomes +3, the Out_B end current parameter resets to equal the DfltEndCrnt_B

When the CalTask becomes +3, the Out_A threshold parameter resets to equal the DfltThld_A (Default

Threshold A).

10000 = 1000 mA.

When the CalTask becomes +3, the Out_B threshold parameter resets to equal the DfltThld_B (Default

Threshold B).

10000 = 1000 mA.

(Default End Current A).

10000 = 1000 mA.

(Default End Current B).

10000 = 1000 mA.

11022912 · Rev CA · October 2011

13

Page 14

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

Config_Data Function Block Configuration Values

Input Type Range Description

FltDet BOOL —— The FltDet (Fault Detection) signal enables the detection of open and short conditions, based on the

measured resistance of the EDC control circuit.

– T = Enable fault detection.

– F = Disable fault detection.

FltDetectTm U16 100–2000 Sets the time before the fault detection logic reports or clears fault conditions.

This value specifies how long a fault condition must be detected before it is reported. It also specifies how

long the fault condition must remain undetected before the report can be cleared.

1000 = 1000 ms.

FltDetThld U16 —— For each direction, the open and short faults are only detected while the OutputValue exceeds the

FltDetThld (Fault Detect Threshold).

Typically, set this value below the Out_A and Out_B threshold values.

If you set the value too:

– Low, you get nuisance faults.

– High, you turn off fault detection for some or all of the output range.

NegCrntThld U16 —— Negative feedback current in an uncommanded direction must be greater than the NegCrntThld

(Negative Current Threshold) value to set a fault.

Typically, this fault results when the A and B outputs drive coils that share a common ground and their

connection to the controller ground is lost.

FdbkFltrTime U16 —— Sets the time constant for the exponential filtering applied to the current measurement used to detect a

fault caused by negative feedback in an uncommanded direction.

14

11022912 · Rev CA · October 2011

Page 15

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

About Modifying the Config_Data Page

Modify the Config_Data page to control the configuration process with signals routed

into the function block from an application.

The preceding figure shows an unmodified Config_Data page. This Config_Data page

has all the values that are needed to configure the function block.

11022912 · Rev CA · October 2011

15

Page 16

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

The preceding figure shows the changes made to a Config_Data page to allow an

application to control the configuration process using signals routed via the Setup bus.

16

11022912 · Rev CA · October 2011

Page 17

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

About the Relationship between the Function Block Input and Output Signals

The function block’s Out_A and Out_B buses each contain an OutputValue signal.

The following figure plots the relationship between the function block’s CmdIn and

OutputValue signals.

• The Thld_A value sets the Out_A OutputValue of the block when it receives a CmdIn

of +1.

• The Thld_B value sets the Out_B OutputValue of the block when it receives a CmdIn

of –1.

• The EndCrnt_A value sets the Out_A OutputValue of the block when it receives a

CmdIn of +10000.

• The EndCrnt_B value sets the Out_B OutputValue of the block when it receives a

CmdIn of –10000.

11022912 · Rev CA · October 2011

17

Page 18

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

MC Controller—Output Configuration

If you have an SC controller, see SC Controller—Output Configuration on page 20.

You route the function block’s Output bus to an MFOut.

How to Configure an MFOut

You must configure an MFOut to receive the signals in an Output bus.

1. In the GUIDE template, enter the Outputs block.

18

2. In the Group that receives the signals in an Output bus, make the changes that are

shown in the preceding figure.

11022912 · Rev CA · October 2011

Page 19

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

3. In the individual MFOut that receives the signals in an Output bus, make the changes

that are shown in the preceding figure.

11022912 · Rev CA · October 2011

19

Page 20

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

SC Controller—Output Configuration

If you have an MC controller, see MC Controller—Output Configuration on page 18.

You route the function block’s Output bus to an MFOut.

How to Configure an MFOut

You must configure the MFOut to receive the signals in an Output bus.

1. In the GUIDE template, enter the Outputs block.

20

2. In the MFOut that receives the signals in an Output bus, make the changes that are

shown in the preceding figure.

11022912 · Rev CA · October 2011

Page 21

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

How to Calibrate the Function Block

See About Modifying the Config_Data Page on page 15 for an example of a Config_Data

page that has been modified to allow an application program to control the calibration

process.

1. Prepare to calibrate.

A. Set the SetCalReq signal to F.

B. Set the ClrCalReq signal to F.

C. Set the StoreCalVal signal to F.

D. Toggle the SetCalReq signal from F to T.

2. Set the Enable signal to T.

Toggling sets the “not calibrated” bits in the CalFlag signal to 1.

3. Calibrate the Out_A threshold parameter.

A. Set the CalTask signal to +1.

B. Gradually modify the CmdIn signal in a positive (0 to +10000) direction to find the

minimum command that causes motion.

In the Status signal, monitor bit 7—Value too low and bit 8—Value too high to

make sure that the OutputValue signal is within the valid threshold range.

C. Toggle the StoreCalVal signal from F to T to write the OutputValue to memory.

In the CalFlag signal, check that bit 1 clears to 0, to verify that the controller has

written the Out_A threshold parameter to memory.

4. Calibrate the reverse threshold parameter.

A. Set the CalTask signal to –1.

B. Gradually modify the CmdIn signal in a negative (0 to –10000) direction to find

the minimum command that causes motion.

In the Status signal, monitor bit 7—Value too low and bit 8—Value too high to

make sure that the OutputValue signal is within the valid threshold range.

C. Toggle the StoreCalVal signal from F to T to write the OutputValue to memory.

In the CalFlag signal, check that bit 3 clears to 0, to verify that the controller has

written the Out_B threshold parameter to memory.

11022912 · Rev CA · October 2011

21

Page 22

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

5. Calibrate the Out_A end current parameter.

A. Set the CalTask signal to +2.

B. Gradually modify the CmdIn signal in a positive direction to find the command

that produces the desired maximum pump flow.

C. Toggle the StoreCalVal signal from F to T to write the OutputValue to memory.

In the CalFlag signal, check that bit 2 clears to 0, to verify that the controller has

written the Out_A end current parameter to memory.

6. Calibrate the Out_B end current parameter.

A. Set the CalTask signal to –2.

B. Gradually modify the CmdIn signal in a negative direction to find the command

that produces the desired maximum pump flow.

C. Toggle the StoreCalVal signal from F to T to write the OutputValue to memory.

In the CalFlag signal, check that bit 4 clears to 0, to verify that the controller has

written the Out_B end current parameter to memory.

7. End the calibration process.

A. Set the CalTask signal to 0.

B. In the CalFlag signal, verify that all bits are now 0.

C. Verify that no Status or Fault conditions are reported.

D. Set the ThldMult signal to the desired value.

22

11022912 · Rev CA · October 2011

Page 23

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

How to Calibrate an Individual Parameter

Partial calibration allows you to calibrate an individual parameter while leaving the values

of other parameters unchanged.

1. Prepare to calibrate.

A. Set the SetCalReq signal to F.

B. Set the ClrCalReq signal to F.

C. Set the StoreCalVal signal to F.

D. Toggle the SetCalReq signal from F to T.

Toggling sets all the “not calibrated” bits in the CalFlag signal to 1.

2. Set the Enable signal to T.

3. Use the CalTask signal to select the parameter to be calibrated.

4. Calibrate the parameter.

A. Toggle the StoreCalVal signal from F to T to write the OutputValue to memory.

B. In the CalFlag signal, check that the calibration bit for the selected parameter

clears to 0, to verify that the controller has written the parameter to memory.

5. End the calibration process.

A. Set the CalTask signal to 0.

B. Toggle the ClrCalReqd signal from F to T.

C. In the CalFlag signal, verify that all bits are now 0.

D. Verify that no Status or Fault conditions are reported.

11022912 · Rev CA · October 2011

23

Page 24

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

About Manual Calibration

Warning

Using the PLUS+1 Service Tool program download new parameter values to an

application can result in unexpected and sudden machine movements.

Unexpected and sudden machine movements can result in personal injury and

equipment damage.

Always secure your machine against unexpected and sudden movements before you

use the Service Tool program download new parameter values.

You can manually calibrate the function block using the PLUS+1 Service Tool program to

download calibration parameters.

When you manually calibrate, make sure that the:

• Calibration parameters are valid. If the values are out of range for a given direction,

the block limits the values of ThldApplied, EndCrntApplied or both for that

direction. This condition is indicated by the “Parameters are corrupt” status and can

produce unintended output commands.

• Status signal indicates normal status conditions.

24

11022912 · Rev CA · October 2011

Page 25

PLUS+1 Compliant S90 EDC Control Function Block

User Manual

S90_EDC Function Block

About the Name Space Feature

If you use this function block more than once in an application, you must change each

function block’s Name Space value to avoid compiler errors.

These function blocks allocate memory using memory names (“aliases”). Identical function

blocks have identical memory names. Identical memory names will cause a compiler error.

The Name Space value adds a unique prefix to each memory name to avoid memory

allocation errors. Keep Name Space values short to save controller memory.

How to Enter a Name Space Value

1. In the PLUS+1 GUIDE menu bar, click the Query/Change button.

2. Click the function block’s page name to display the Edit Page window.

3. In the Edit Page window, enter a meaningful Name Space value.

4. Press /.

5. Repeat these steps to enter unique Name Space values for other identical function

blocks.

11022912 · Rev CA · October 2011

25

Page 26

p

Products we offer:

• Bent Axis Motors

• Closed Circuit Axial Piston Pumps

and Motors

• Displays

• Electrohydraulic Power Steering

• Electrohydraulics

• Hydraulic Power Steering

• Integrated Systems

• Joysticks and Control Handles

• Microcontrollers and Software

• Open Circuit Axial Piston Pumps

• Orbital Motors

• PLUS+1™ GUIDE

• Proportional Valves

• Sensors

• Steering

Sauer-Danfoss is a global manufacturer and supplier of highquality hydraulic and electronic components. We specialize in

providing state-of-the-art technology and solutions that excel in

the harsh operating conditions of the mobile off-highway market.

Building on our extensive applications expertise, we work closely

with our customers to ensure exceptional performance for a broad

range of off-highway vehicles.

We help OEMs around the world speed up system development,

reduce costs and bring vehicles to market faster.

Sauer-Danfoss—Your Strongest Partner in Mobile Hydraulics.

Go to www.sauer-danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Sauer-Danfoss.

We offer expert worldwide support for our customers, ensuring the

best possible solutions for outstanding performance. And with an

extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Transit Mixer Drives

•

Members of the Sauer-Danfoss Group:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-inverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Sauer-Danfoss-Daikin

www.sauer-danfoss-daikin.com

Please contact the Sauer-Danfoss re

Local address:

Sauer-Danfoss Inc.

3500 Annapolis Lane North

Minneapolis, MN 55447, USA

Phone: +1 763 509-2000

Fax: +1 763 559-5769

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000

Fax: +1 515 239-6618

Sauer-Danfoss GmbH & Co. OHG

Postfach 2460, D-24531 Neumünster

Krokamp 35, D-24539 Neumünster,

Germany

Phone: +49 4321 871-0

Fax: +49 4321 871 122

resentative nearest you.

Sauer-Danfoss ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444

Fax: +45 7488 4400

Sauer-Danfoss-Daikin LTD

Shin-Osaka TERASAKI 3rd Bldg. 6F

1-5-28 Nishimiyahara, Yodogawa-ku

Osaka 532-0004, Japan

Phone: +81 6 6395 6066

Fax: +81 6 6395 8585

11022912 ● Rev CA ● October 2011

www.sauer-danfoss.com

Loading...

Loading...