Page 1

Data sheet

Gasketed Plate Heat Exchangers (DN 300 / 12”)

S81 / S121 / S188 / S251

Description

SONDEX® gasketed plate heat exchangers are

the ideal choice for a wide range of applications

across numerous market segments.

We have the largest plate portfolio in the

world, and we customize each heat exchanger

to meet your exact requirements. Innovative

technologies and smart design make our

gasketed plate heat exchangers a stellar

investment.

Benefits:

• Individually customized solution that

perfectly matches your requirements and

lowers your energy consumption.

• High performance and a low pressure

drop eliminate unnecessary burdens on

your system and optimize overall system

performance.

• The design results in a compact solution with

a small footprint, simple installation, and easy

access for maintenance.

Common applications:

• HVAC industry

• Marine/offshore industry

• Dairy/food/beverage industry

• Sugar industry

• Biogas industry

• Pulp and paper industry

• Heavy industry

• Mining industry

• Petrochemical industry

• Chemical industry

Main data:

• Min. temperature −10 °C

• Max. temperature 180 °C

• Max. working pressure 16 / 25 bar (10 bar on

request)

• Water and different fluids, steam

• Connection size DN 300 or 12”

Approvals:

• Please contact your local Danfoss/SONDEX®

sales representative for an overview of the

available approvals in your region

Construction standard:

• EN13445 (PED 2014/68/EU)

• ASME sec VIII, Div. 1

| 2019.07 VD.JQ.R1.02 | 1

Page 2

Data sheet S81 / S121 / S188 / S251 (DN 300)

Naming of units

S81-IS16-21-TKTL89

3)

1)

1)

Type of heat exchanger:

TKTL89 - Plate grouping

21 - Number of plates in the heat exchanger

16 - Design pressure of the heat exchanger

IS - Frame type

2)

81 – Type of heat exchanger

S – Gasketed heat exchanger

81 - …

Letter S81 shows type of the attachment of gasket to plate:

e.g. 81 (without A) – SonderLock

81A (with A) – Hang-on

2)

Description of frame types:

There are few different frame types which can be offered for different applications and duties.

IS – with suspension roller,

IG – without suspension roller,

FS – food/sanitary with suspension roller,

FG - food/sanitary,

ST – simple design of frame with threaded connections

3)

Channel grouping:

In this example, the heat exchanger combines TK and TL channels. The share of TL channels equals

89% of the total number of channels.

The number of channels is defined as “the number of plates - 1”.

TK - short thermal length

TM - medium thermal length

TL - long thermal length

Heat exchanger design

Gasketed heat exchangers consist of

Carrying Bar

Plate Pack

Plate

Connections

Head

Flange Connections

Foundation Feet

Column

Follower

Tie Bolt

Guiding Bar

Anatomy of a SONDEX® plate heat exchanger - IS frame.

2 | VD.JQ.R1.02 | 2019.07

Page 3

Data sheet S81 / S121 / S188 / S251 (DN 300)

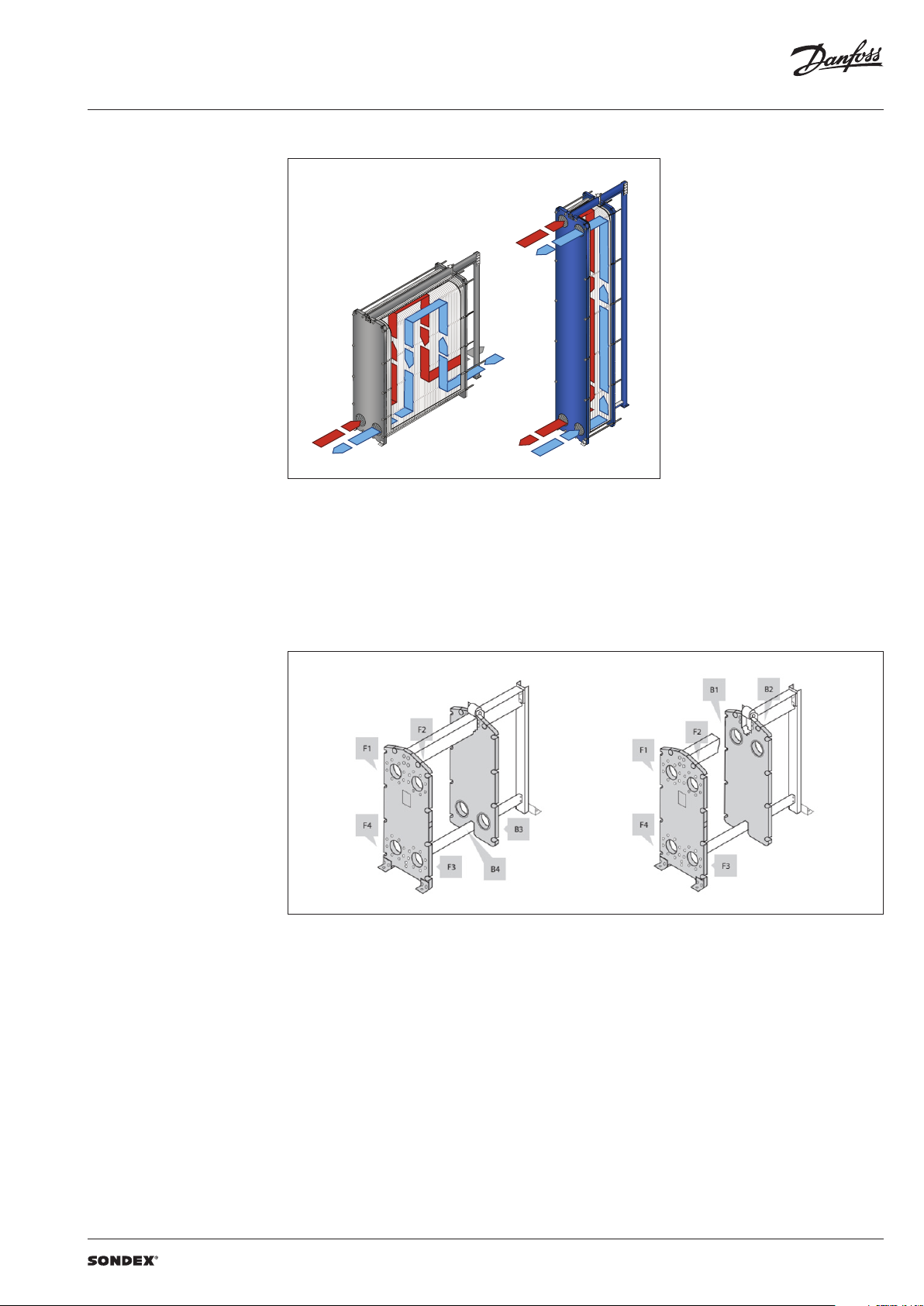

To the left: A multi-pass solution with connections

Heat exchanger design

(continued)

Multi-pass design

on the follower and the head.

To the right: A single-pass solution with

all connections on the head.

Connections

The heat exchanger may have connections on

both front and back-end sides of the unit.

Connections on the front-end plate are marked

with F and connections on the back-end plate

are marked with B. The numbers 1, 2, 3 and 4

designate the position of the connection on the

end-plate from the top-left port clockwise.

VD.JQ.R1.02 | 3 | 2019.07

Page 4

Data sheet S81 / S121 / S188 / S251 (DN 300)

SONDEX®

plate

range

Common

Technical data Heat exchanger S67 / S113 / S155

Typ e S81 S121 S188 S251

Max. working pressure

Max. operating temperature

Min. operating temperature -10

Flow medium Water and different fluids, steam

Volume / channel l 3.1 4.7 7.3 9. 8

Connection size DN 300 / 12”

Connection type

Plate material

Plate thickness mm

Gasket material

Gasket attachment t ype Sonder Lock

Liners in connections

Frame

Frame painting specification Painting available for corrosion categories C2L, C4M, C5M

1)

Not available f or all frame variations

2)

SonderSaf e - double plate

PN

(bar)

°C

• DN 300/12” flanges. Carbon steel, rubberlined or cladded with AISI 316L

(other materials available on request)

Stainless steel EN 1.440 4 (AISI 316L), EN 1.4301 (AISI 304), SMO254, Hastelloy C276,

titanium Gr.1

Other materials available on request

0.4; 0.5; 0.6; 0.7

2 x 0.4 SonderSafe plates

Other thicknesses available on request

NBR, EPDM,

Other materials available on request

• Rubber NBR, EPDM,

• Stainless steel EN 1.440 4 (AISI 316L), EN 1.4301 (AISI 304), SMO254, Hastelloy C276,

titanium Gr.1

• Painted frame, color RAL 5010 (other colors available on request)

• Stainless steel frame, designed for the sanitary applications (e.g. food and dairy

industries)

(10)1), 16, 25

Up to 180

1)

2)

Using the right plate for each individual duty

is very important, as it greatly impacts the

efficiency of the entire installation.

It is important that the length of the plates and

the type of pattern match the requirements of

individual thermal duty.

We have developed a wide plate portfolio to

provide the perfect plate and connection size for

any duty.

No application is too small or too big for us - we

provide the optimal technical solution every

time.

Our extensive SONDEX® plate portfolio

includes plates that lie outside the commonly

manufactured plate sizes to cover all thermal

duties optimally.

plate

range

4 | VD.JQ.R1.02 | 2019.07

Page 5

Data sheet S81 / S121 / S188 / S251 (DN 300)

Accessories Insulation

Recommended applications:

The insulation jacket for the plate heat exchanger

is used in different applications with high

temperatures and cooling systems.

Application Heating Cooling

Material

Outer cap

Internal insulation 0.05 mm aluminium foil

Panel fixation Plastic rivets

Temperature 20 … 200 °C -50 … -80 °C

U-value 0.55 W/m2K 0.3 8 W/m2K

Insulation class 3

Heat loss 17.1 W/m

Please note:

Inlet and outl et temperatures in the exch anger have been based on 9 0/50 – 30/70 °C.

1)

The loss of he ating/cooling is stated per m2 surface on the insu lation jacket.

The bottom o f the heat exchanger is not insu lated and this fact has been e xcluded.

A possible loss of ve ntilation, largely dep endent on the mounting of the h eat exchanger, has not been take n into account either.

Drip trays

Recommended applications:

The drip tray is available in two types. A “failsafe” solution which prevents water or liquid

from leaking onto the floor, or when the

heat exchanger is dismantled, or opened for

inspection and maintenance. And an insulated

drip tray for cooling applications, which

collects condensate formed outside of the plate

heat exchanger.

45 mm mineral wool

Not flammable

DIN EN 4102A2

40 mm PU-foam

DIN 4102-1 B2

1 mm aluminium

“Stucco” Embossed

1)

2

1)

4

-

Materials

Drip tray consists of:

• 1 mm galvanized steel frame

• Hanging brackets in galvanized steel

• 60 mm Polyurethane insulation for cooling

applications

• Draining valve.

Spare parts

Spare parts for gasketed heat exchangers, such

as plates, gaskets, frame parts can be ordered for

maintenance, repair, increasing heat exchanger

capacity, etc.

Selection and ordering Please contact your local SONDEX® or Danfoss

sales representative for the selection and / or

ordering of the heat exchangers, spare parts, and

accessories.

Please contact your local Danfoss or SONDEX®

sales representative to provide you with

information on spare parts available for gasketed

heat exchangers.

For contact information please visit

https://www.danfoss.com/en/contact-us.

VD.JQ.R1.02 | 5 | 2019.07

Page 6

Data sheet S81 / S121 / S188 / S251 (DN 300)

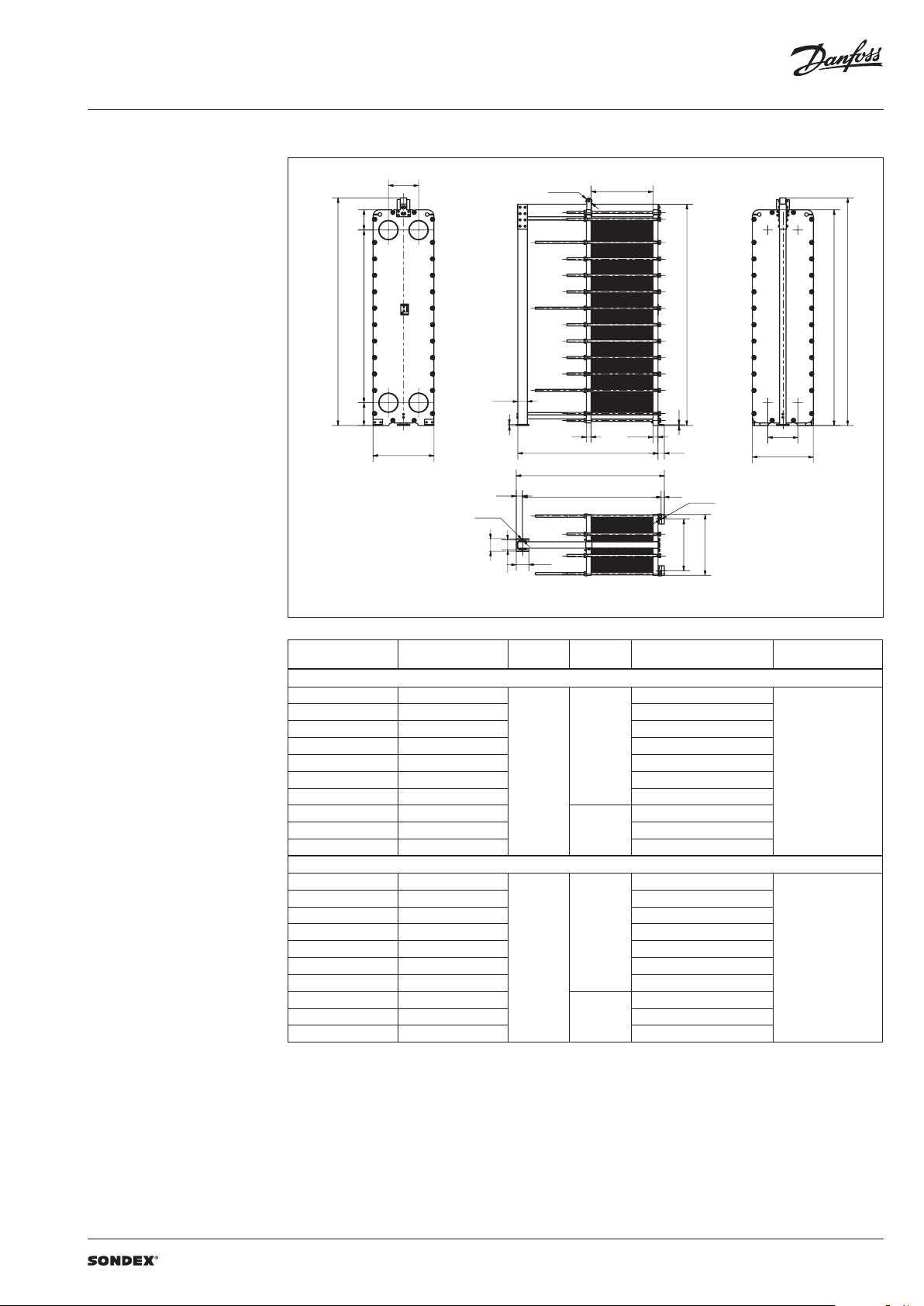

Dimensions

Non-sanitary applications

Any connection can be used for primary side in.

All the rest are made correspondingly.

S81 frames

Ø100 L1

323

F1

F2

7

H

1080

F4

F3

363

480

W

1806

7

50

20

Ø18

140

75

L

L + 150

L+ 80

323

B1

B2

H

1806

B3

7

14

80

100

50

Ø25

W

820

480

W

1080

B4

363

Drawing of S81 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S81 I S16

7 29 687

30 95 1087 2498

96 145 1387 2806

146 179 1587 3024

180 262 2087 3546

263 348 2740

970

38.19”

349 431 3240 5109

432 598 4240 6240

599 765 5240

766 931 624 0 8497

190 6

(75.0 4”)

1956

(7 7.01“ )

2208

(86.93“)

2108

DN 300 flange or 12”

4546

7370

S81 IS 25

7 31 697

32 96 1097 2939

97 − 145 1397 3323

146 178 1597 3581

179 260 2097 4222

261 342 2 740

1030

(40. 55”)

343 424 3240 5504

425 588 4240 6786

589 752 5240

753 916 6240 9 351

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PN class 6 bar / 10 bar is a vailable on request.

190 6

(75.0 4”)

1956

(7 7.01“ )

2208

(86.93“)

2430

DN 300 flange or 12”

4863

8068

flange

flange

6 | VD.JQ.R1.02 | 2019.07

Page 7

Data sheet S81 / S121 / S188 / S251 (DN 300)

Dimensions (continued)

Non-sanitary applications

S121 frames

H

Ø100

F1

F2

1490 323363

F3

F4

150

L1

B1B2

2265

2176

B3 B4

14

480

W

20

75

L

80

100

W

L + 125

100

L - 25

50

Ø25

Ø25

200

160

W

820

200

Drawing of S121 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S121 IS16

7 - 29 830

2713

30 - 95 123 0 3229

96 - 145 1530 3634

146 - 179 17 30 3929

180 - 262 2230 4585

263 - 345 2730 5273

970

38.19”

2366

(93 .15”)

DN 300 flange or 12”

346 - 429 3230 6037

430 - 595 423 0

596 - 762 5230 8 911

763 - 929 6230 10332

2618

(103. 07“)

7433

S121 I S25

7 - 26 850

4171

27 - 91 125 0 4820

92 - 140 1550 5309

141 - 173 17 50 5637

174 - 255 2250 6 456

256 - 337 2750 7273

1030

(40. 55”)

2366

93 .15”

DN 300 flange or 12”

338 - 419 3250 8091

420 - 583 425 0

584 - 747 5260 113 62

748 - 911 6260 129 97

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PN class 6 bar / 10 bar is a vailable on request.

2618

(103. 07“)

9726

flange

flange

VD.JQ.R1.02 | 7 | 2019.07

Page 8

Data sheet S81 / S121 / S188 / S251 (DN 300)

Dimensions (continued)

Non-sanitary applications

S188 frames

2806

480

L1

Ø 100

323

F1

F2

H

2120

F4

F3

2895

150

363

20

75

14

80

B1B2

H

B4

B3

L 100

W

L + 125

100

L - 25

50

Ø25

Ø25

200

160

200

W

820

Drawing of S188 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S188 I S16

7 - 29 830

3553

30 - 95 123 0 4226

96 - 145 1530 4752

146 - 179 17 30 5132

180 - 262 2230 5988

263 - 345 2730 6878

970

38.19”

2996

(117. 95” )

DN 300 flange or 12”

346 - 429 3230 7848

430 - 595 423 0

596 - 762 5230 11554

763 - 929 6230 134 63

3248

(12 7.87“ )

9652

S188 I S25

7 - 26 850

4540

27 - 91 125 0 5323

92 - 140 1550 5958

141 - 173 17 50 6 412

174 - 255 2250 7435

256 - 337 2750 8590

1030

(40. 55”)

2996

(117. 95” )

DN 300 flange or 12”

338 - 419 3250 9693

420 - 583 425 0

584 - 747 5250 14230

748 - 911 6250 16437

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PN class 10 bar is avail able on request.

3248

(12 7.87“ )

118 96

flange

flange

8 | VD.JQ.R1.02 | 2019.07

Page 9

Data sheet S81 / S121 / S188 / S251 (DN 300)

Dimensions (continued)

Non-sanitary applications

S251 frames

H

323

2750

363

480

F1 F2

F4

W

Ø100

F3

150

20

75

L1

B2

B1

3525

B3 B4

H

3436

14

80

L

100

480

W

L + 125

100

L - 25

50

Ø25

Ø25

200

200

160

W

820

Drawing of S251 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S251 IS16

7 - 29 830

4393

30 - 95 123 0 5222

96 - 145 1530 5869

146 - 179 17 30 6332

180 - 262 2230 7386

263 - 345 2730 8479

970

38.19”

3626

(142. 76”)

DN 300 flange or 12”

346 - 429 3230 9666

430 - 595 423 0

596 - 762 5230 14249

763 - 929 6230 164 85

3878

(152.68“)

118 61

S251 IS25

7 - 26 850

5603

27 - 91 125 0 6 541

92 - 140 1550 7353

141 - 173 17 50 7910

174 - 255 2250 917 3

256 - 337 2750 10578

1030

(40. 55”)

3626

(142. 76”)

DN 300 flange or 12”

338 - 419 3250 11932

420 - 583 425 0

584 - 747 5250 1708 6

748 - 911 6250 19623

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PN class 10 bar is avail able on request.

3878

(152.68“)

144 83

flange

flange

VD.JQ.R1.02 | 9 | 2019.07

Page 10

Data sheet S81 / S121 / S188 / S251 (DN 300)

10 | VD.JQ.R1.02 | 2019.07

Page 11

Data sheet S81 / S121 / S188 / S251 (DN 300)

VD.JQ.R1.02 | 11 | 2019.07

Page 12

Data sheet S81 / S121 / S188 / S251 (DN 300)

| DHS-SRMT/SI | 2019.0712 | VD.JQ.R1.02

Loading...

Loading...