Page 1

User Manual

Electronic Torque Limiting Control

Series 45

www.danfoss.com

Page 2

User Manual

S45 ETL Control

Revision history Table of revisions

Date Changed Rev

March 2015 First edition 0101

2 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 3

User Manual

S45 ETL Control

Contents

Overview

Purpose of this Manual...................................................................................................................................................................5

Before You Start................................................................................................................................................................................ 5

Literature References.................................................................................................................................................................5

General Electronic Torque Control Information

PLUS+1 Compliance........................................................................................................................................................................6

Electric Torque Limiting Control Principle.............................................................................................................................. 6

LS Signal Line Orifice..................................................................................................................................................................7

Electronic Torque Limiting Control Characteristic............................................................................................................... 7

System Considerations when Implementing ETL

Electronic Torque Limiting and Load Sense Signals............................................................................................................9

Electronic Torque Limiting and Margin Erosion....................................................................................................................9

General Angle Sensor Information

PLUS+1 Compliance......................................................................................................................................................................10

Angle Sensor Principle................................................................................................................................................................. 10

Angle Sensor Characteristics..................................................................................................................................................... 10

J & F-Frame (45-90cc) Angle Sensor Identification Convention:.............................................................................11

E-Frame (100-147cc) Angle Sensor Identification Convention:...............................................................................12

Angle Sensor Electrical Specifications....................................................................................................................................14

Sensor Connector and MC012 Microcontroller Pin Assignments................................................................................ 14

Angle sensor DTM04-4P connector pin assignments................................................................................................. 14

Pre-compiled MC012 Pin Assignments............................................................................................................................ 14

Potentiometers, Pressure Transducers, and the PumpTorqCalc Function Block....................................................15

General PLUS+1 ETL Service Tool Information

System Overview............................................................................................................................................................................18

Torque Limit Setpoint...................................................................................................................................................................18

Torque Limit Setpoint Parameters..................................................................................................................................... 18

ETL Service Tool Setup

Angle Sensor Calibration.............................................................................................................................................................19

Angle Sensor Calibration Parameters................................................................................................................................20

Establish the Minimum Pump Displacement.................................................................................................................20

Establish the Maximum Pump Displacement with Engine Off................................................................................21

Establish the Maximum Pump Displacement with Engine Running.....................................................................21

Pump Setup......................................................................................................................................................................................22

Pump Setup Parameters........................................................................................................................................................ 23

Define Pump Displacement..................................................................................................................................................23

RPM Input Setup.............................................................................................................................................................................24

RPM Input Parameters............................................................................................................................................................ 24

Perform RPM Input Setup......................................................................................................................................................24

Torque Potentiometer Calibration.......................................................................................................................................... 25

Torque Potentiometer Calibration Parameters............................................................................................................. 25

Calibrate Torque Potentiometer.........................................................................................................................................25

Pressure Sensor Setup..................................................................................................................................................................26

Pressure Sensor Setup Parameters.....................................................................................................................................26

Select Pressure Sensor Setup............................................................................................................................................... 26

Torque Limit Profile Setup..........................................................................................................................................................27

Torque Limit Profile Setup Parameters.............................................................................................................................28

Establish Torque Limit Profile with Torque Curve........................................................................................................ 28

Establish Torque Limit Profile without Torque Curve................................................................................................. 28

Adjust Torque Setpoints........................................................................................................................................................ 29

Considerations for Establishing the Torque Limit Profile.......................................................................................... 29

Additional Setup

Boost Mode...................................................................................................................................................................................... 30

Boost Mode Parameters.........................................................................................................................................................30

CAN Torque Setpoint Setup.......................................................................................................................................................30

Command Filter Setup.................................................................................................................................................................31

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 3

Page 4

User Manual

S45 ETL Control

Contents

Troubleshooting

Command Filter Setup Parameters....................................................................................................................................33

Pressure Setpoint Faults..............................................................................................................................................................34

Electrical Interface..........................................................................................................................................................................34

4 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 5

User Manual

S45 ETL Control

Overview

Purpose of this Manual

Before You Start

This manual is intended to be a reference for customers using Danfoss S45 Open Circuit Axial Piston

Electronic Torque Limiting (ETL) pumps in conjunction with the keyed ETL MC012 and PLUS+1® Guide

Subsystem Application Block. The setup and operation of the PLUS+1® ETL software will be illustrated

with S45 ETL pumps by utilizing the ETL PLUS+1® service screens.

Users setting up an ETL system with both PLUS+1® software and S45 Open Circuit ETL pumps should have

a working knowledge of basic hydraulic systems, principles, and PLUS+1® Service Tools.

Users should also have access to PLUS+1® and S45 technical literature.

Literature References

Useful technical information on pump displacements, controls specifications, software, and operating

condition requirements can be found in the following literature.

Literature references

Literature type Literature title Literature number

Technical Information Series 45 Axial Piston Open Circuit

Pumps

Service Manual Series 45 Frame J Open Circuit 520L0607

Series 45 Frame F Open Circuit 11005158

Series 45 Frame E Open Circuit 520L0606

Parts Manuals Series 45 Frame J 520L0585

Series 45 Frame F 11007197

Series 45 Frame E 520L0584

Repair Instructions Series 45 Frame J Open Circuit 520L0610

Series 45 Frame F Open Circuit 520L0821

Series 45 Frame E Open Circuit 520L0609

User Guide PLUS+1® Service Tool User Manual

Data Sheet PLUS+1® Controllers MC012-110 and

MC012-112

Product Electrical Installation MBS1250 Heavy Duty Pressure

Transmitter

520L0519

L1307770

(Also found under Help on toolbar)

L1301095

11062087

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 5

Page 6

P108779

S

M2

X

B

(ETL Signal

Port)

User Manual

S45 ETL Control

General Electronic Torque Control Information

PLUS+1 Compliance

All Series 45 Electric controls have met and passed the Danfoss PLUS+1 compliance standard testing, and

as such, this Series 45 control is PLUS+1 compliant. PLUS+1 compliance blocks are available on the

Danfoss website, within the PLUS+1 Guide section.

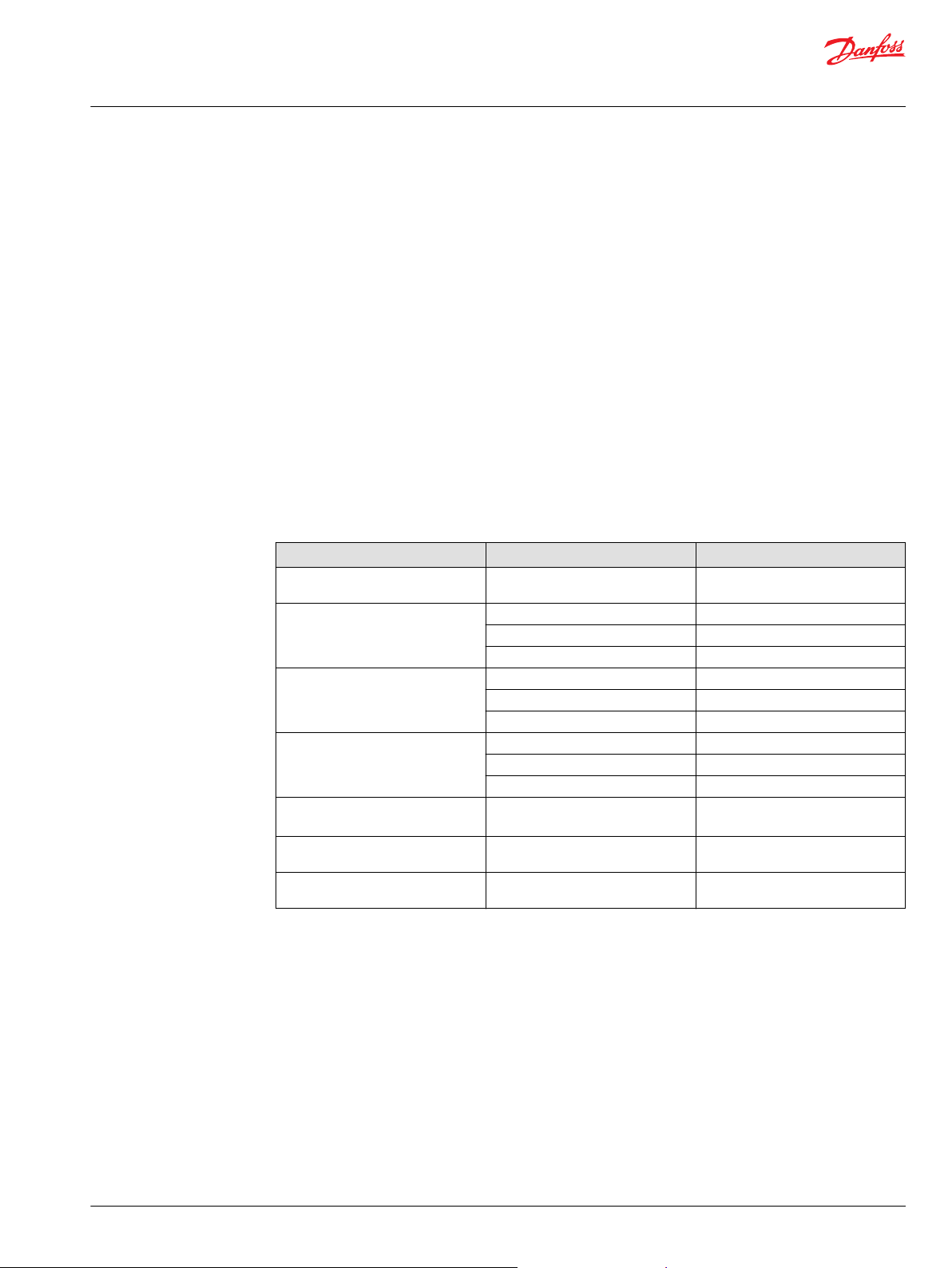

Electric Torque Limiting Control Principle

The Electronic Torque Limiting control consists of a normally closed proportional relief valve (PRV)

integrated into a Pressure Compensated/Load Sensing control. This control operates as a PC/LS control,

with the additional ability to limit load sense pressure using the integrated PRV by varying the current to

the solenoid. When combined with an angle sensor, this control allows for a PC/LS control with electronic

torque limiting.

J-frame pump with integrated ETL control

Pump torque consumption is a function of pump outlet pressure, pump displacement, and pump

mechanical efficiency. When pump mechanical efficiency is considered constant, the pump torque can

be limited when pump displacement is known and pump pressure is controlled. As pump displacement

increases, the pump outlet pressure can be limited using the PRV to result in a constant torque limit.

6 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 7

0

50

100

150

200

250

300

0 50 100 150 200

Pump Pressure (bar)

Pump Displacement (cc)

Electronic Torque Limiting

Speed 1

Speed 2

Speed 3

P108783

User Manual

S45 ETL Control

General Electronic Torque Control Information

Pump outlet pressure is equal to the load sense pressure, which is limited with the PRV, plus the margin

pressure setting of the pump.

LS Signal Line Orifice

S45 Electronic Torque Limiting Controls require the use of an LS signal line orifice. The LS signal line

orifice is used to enhance system stability, as well as allow the limiting of torque throughout the full

range of pump pressure and flow. The standard 0.8 mm orifice is best suited for use in a wide variety of

applications. Please contact your Danfoss representative for further information on the availability of

additional LS signal line orifice sizes.

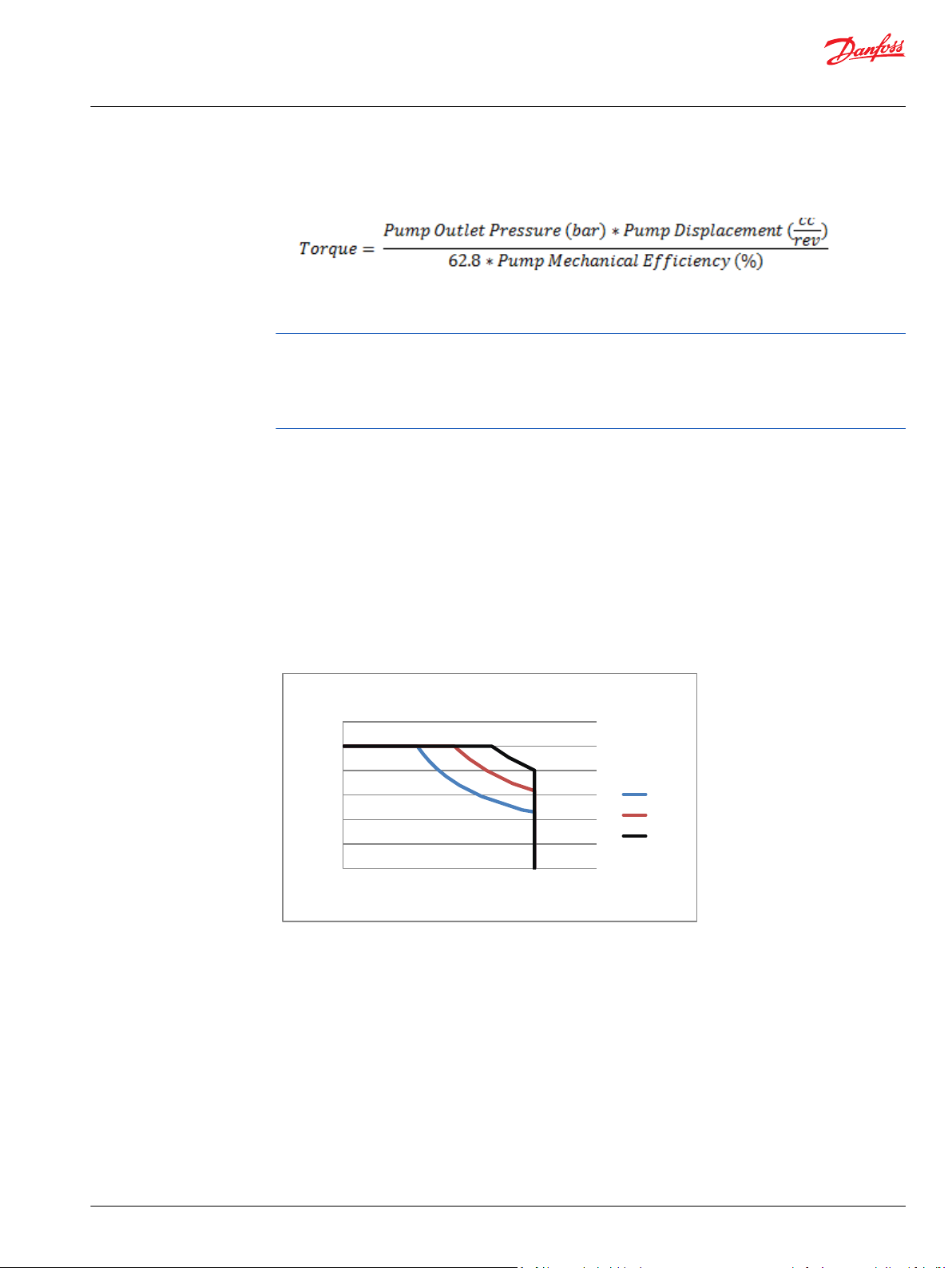

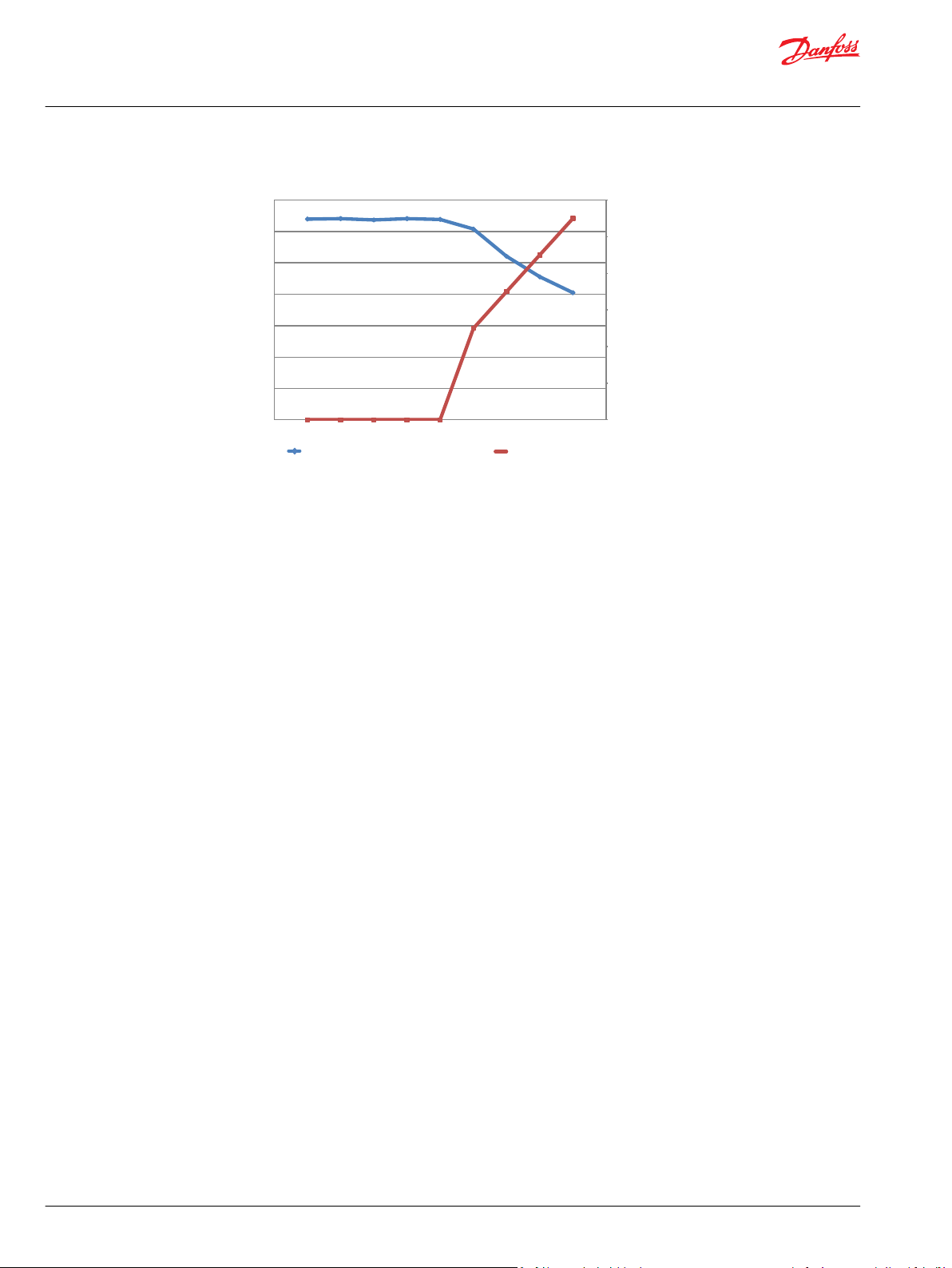

Electronic Torque Limiting Control Characteristic

The Electronic Torque Limiting control allows users to limit pump torque consumption electronically by

combining a pressure limiting PRV and angle sensor. This torque limit can be changed with varying

engine speeds (as shown in the Electronic Torque Limiting graph below), allowing the use of full engine

torque at all engine speeds and increasing machine productivity. A microcontroller is required to store

engine torque vs speed, receive the pump angle sensor signal, and then calculate and output the pump

outlet pressure limit. The basic torque limiting control logic for a single engine speed is shown below.

Danfoss offers a PLUS+1 subsystem application block for the Electronic Torque Limiting control option in

combination with keyed MC012-112 microcontroller hardware. The part number for the keyed

MC012-112 microcontroller is 11157484. Refer to graph Figure 1 for pressure vs. current information.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 7

Page 8

0

100

200

300

400

500

600

0

50

100

150

200

250

300

350

0 5 10 15 20 25 30 35 40 45

50

Basic ETL Control Logic

P108785

Current to Valve (mA)

Current to Valve (mA)

Maximum System Pressure - ETL Active (bar)

Pump Displacement (cc)

Maximum System Pressure (bar)

User Manual

S45 ETL Control

General Electronic Torque Control Information

8 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 9

User Manual

S45 ETL Control

System Considerations when Implementing ETL

When setting up an ETL system to function properly, you must account for LS signal line orificing and

margin erosion.

Electronic Torque Limiting and Load Sense Signals

Danfoss PVG valves, as well as many competitor valves, are manufactured with LS signal line orifices

installed in the pump inlet (PVP) module. These orifices enhance system stability by dampening the

highest load pressure signal before it is relayed to the open circuit pump. They also help limit the amount

of flow over the load sense relief valve inside the PVP.

It is important to ensure that when using these LS line orifices the highest resolved load sense pressure is

communicated to the pump or loss of some flow sharing functionality may occur. If you experience

symptoms of loss of flow sharing, some troubleshooting steps may include removing the LS line orifice in

the valve stack, or ensuring that the LS pressure rails are connected to each other when using two or

more different valve stacks. In this way, the highest load from the system is communicated to the pump.

Electronic Torque Limiting and Margin Erosion

A potential flow sharing problem may arise when several functions are actuated at the same time and

require a high flow demand from the pump. This problem may include a loss of movement in the highest

pressure function when many functions are actuated at the same time. This problem is margin erosion.

Margin erosion is caused when margin pressure is shifted from the operator-controlled valves to the LS

signal line orifice in the S45 pump. When this margin shifts too much, the valve cannot flow share

correctly. Danfoss PVG valve groups reduce this problem with compensator valves which remain open at

a very low margin pressure. This allows more aggressive torque limiting, particularly at low engine idle

speeds where torque limiting is most critical.

In addition to using valves with superior low pressure flow sharing characteristics, it is possible to use

calculations to identify problem areas where margin erosion can become a concern. Please contact your

Danfoss representative for more information on calculating and planning for margin erosion.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 9

Page 10

Swashplate

AMR Sensor

Magnet Carrier

Deutsch Plug

P108788

User Manual

S45 ETL Control

General Angle Sensor Information

PLUS+1 Compliance

The Electric Angle Sensor has met and passed the Danfoss PLUS+1 compliance standard testing, and as

such, this Angle Sensor is PLUS+1 compliant. PLUS+1 compliance blocks are available on the Danfoss

website, within the PLUS+1 Guide section.

Angle Sensor Principle

The Series 45 Angle Sensor option allows users to measure the angle of pump displacement. The angle

sensor is an electronic sensor mounted to the housing of the pump, which reads the pump stroke angle

based on the swashplate position. Interfacing with the angle sensor is achieved through a 4-pin Deutsch

DTM04-4P receptacle attached to a flexible connection cable (for a mating connector, use Deutsch® plug

DTM06-4S). The sensor is mounted to the pump within an aluminum housing to prevent magnetic

interference.

Angle Sensor Characteristics

The angle sensor package incorporates two sensor signals (primary & secondary), within a single sensor

housing. This allows for improved accuracy and troubleshooting. For the ‘Angle Sensor – Right’ order

code in the K module, the sensor is positioned according to the following conventions.

10 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 11

42.5

[1.67]

29.5

[1.16]

93.6

[3.68]

87.3

[3.44]

30.5

[1.2]

43.5

[1.71]

36

[1.417]

36

[1.417]

37.1

[1.462]

37.1

[1.462]

86.8

[3.417]

94.1

[3.704]

J Frame Angle Sensor Position

F Frame Angle Sensor Position

P108816

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Sensor Output (Volts)

Swashplate Angle (Degrees)

Sensor Output Voltage vs. Swashplate Angle

CW & CCW J & F-Frames (45-90cc)

Primary Output Voltage Secondary Output Voltage

User Manual

S45 ETL Control

General Angle Sensor Information

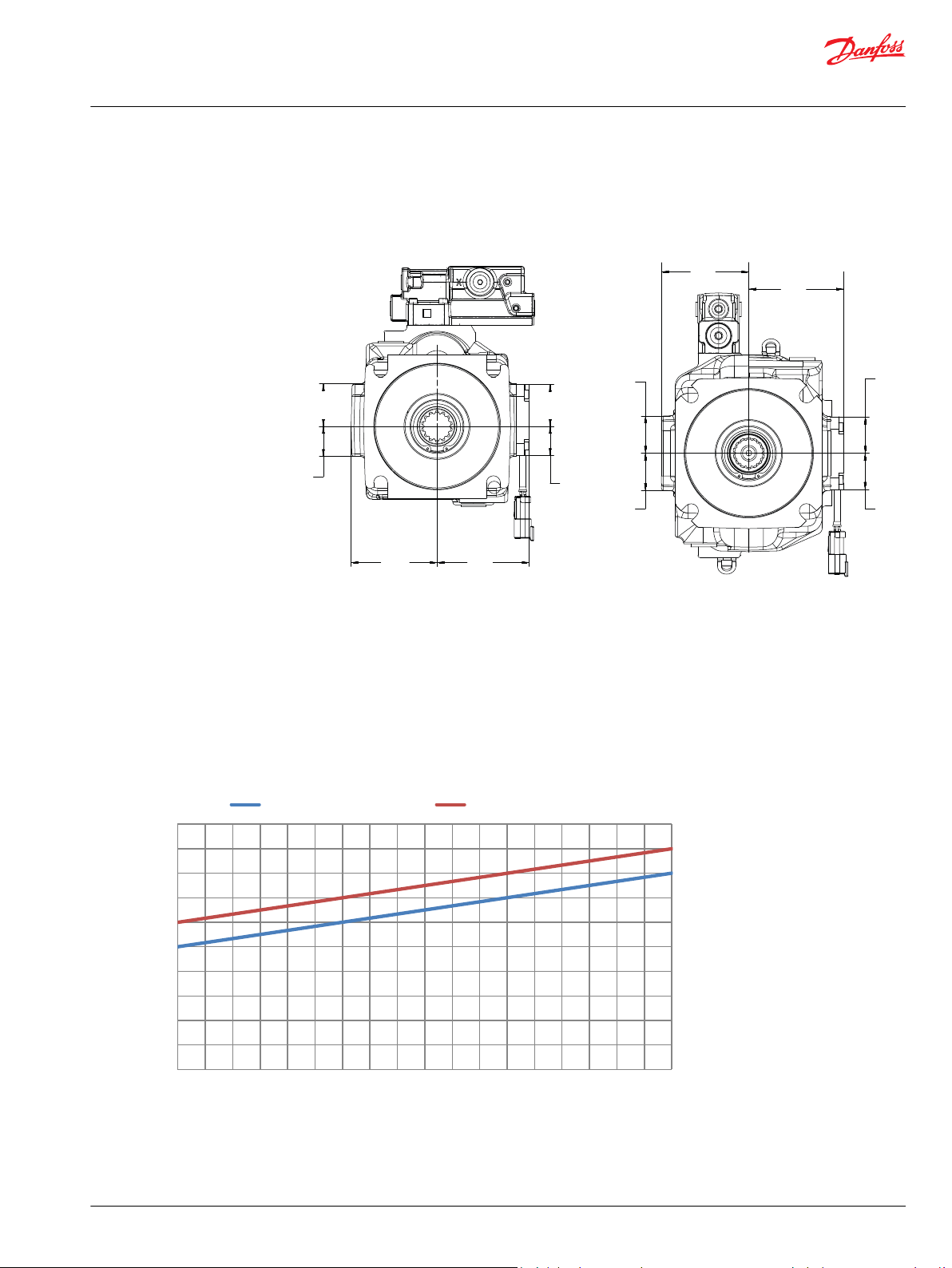

J & F-Frame (45-90cc) Angle Sensor Identification Convention:

When looking at the input shaft with the control on the ‘top’ side, the angle sensor will be viewed on the

right hand side. This convention is true for both Clockwise and Counter-clockwise rotation J & F-Frames.

This sensor location yields a unique voltage versus swashplate angle characteristic curve which is the

same for both Clockwise and Counter-clockwise rotation J & F-frames. Although each pair of curves will

be unique for individual pumps, a general example of what to expect is provided below for J & F units

with the ‘Right’ angle sensor position.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 11

Page 12

P108821

36

[1.42]

E Frame Angle Sensor Position

Outlet Port

36

[1.42]

59.4

[2.34]

126.9

[5.0]

120

[4.72]

Approximate

Wire Length

131.5

[5.18]

User Manual

S45 ETL Control

General Angle Sensor Information

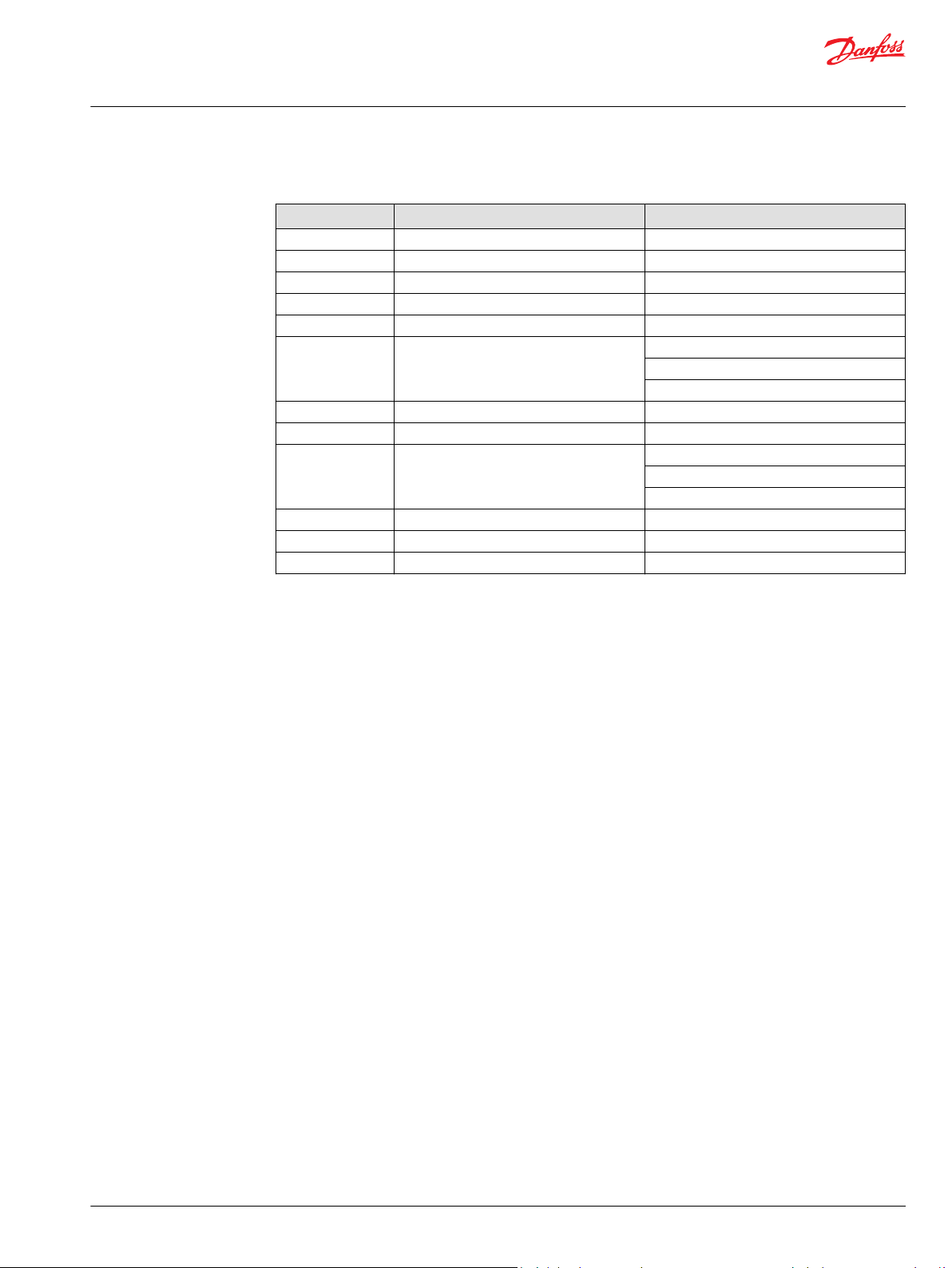

E-Frame (100-147cc) Angle Sensor Identification Convention:

The location convention for the E-Frame angle sensor is different from that of the J & F-Frame due to a

difference in design of the endcap and servo systems. When looking at the input shaft, the angle sensor

will be positioned on the same side as the outlet port of the endcap. The outlet port of the endcap is

always the smaller of the inlet and outlet ports, indicated below. This is the ‘right side’ order code

location, even though it appears on the left hand side from a frontal view.

Clockwise rotation E-frames appear with the control on the top side in this view. Counter-clockwise

rotation E-Frames appear with the control on the bottom side in this view.

This sensor location yields a unique voltage versus swashplate angle characteristic curve which is

different for Clockwise and Counter-clockwise rotation E-frames. Although each pair of curves will be

unique for individual pumps, a general example of what to expect is provided below for both Clockwise

and Counter-clockwise rotation units with the Right angle sensor position.

12 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 13

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Sensor Output (Volts)

Swashplate Angle (Degrees)

Sensor Output Voltage vs. Swashplate Angle

CW E-Frames (100-147cc)

Primary Output Voltage

Secondary Output Voltage

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0 1 2 3 4 5 6 7 8 9 10 11

12

13

14 15 16 17 18

Sensor Output (Volts)

Swashplate Angle (Degrees)

Sensor Output Voltage vs. Swashplate Angle

CCW E-Frames (100-147cc)

Primary Output Voltage Secondary Output Voltage

User Manual

S45 ETL Control

General Angle Sensor Information

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 13

Page 14

1

2

4

3

12111210394857

6

User Manual

S45 ETL Control

General Angle Sensor Information

Angle sensor electrical specifications

Electrical specifications

Description Minimum Typical Maximum Unit Note

Supply (V+) 4.75 5 5.25 Vdc Sensor is ratiometric in the voltage range

Supply protection — — 28 Vdc Sensor will switch off above 5.5 V

Supply current drawn — 22 25 mA Sensor supply at 5 V

Output short circuit current

(VDD to SIG 1/2 and GND to

SIG 1/2)

Sensitivity in sensing range at

calibration temperature for

primary and secondary sensor

Resolution — 0.03 — degree 11 bit output channel

Hysteresis — — — — Design of sensor eliminates any

Environment temperature

range

Operating temperature range 20 (68) 50 (122) 95 (203) °C (°F) Temperature of oil

Storage temperature -40 (-40) — 125 (257) °C (°F) —

Accuracy for primary and

secondary signals throughout

operating temperature range

when calibrated at 50 deg. C

Refresh rate of the sensor — — 100 μs Internal ADC refresh rate

— — 7.5 mA Additional 7.5 mA for each sensor signal,

70.02 78 85.8 mV —

-40 (-40) 80 (176) 104 (220) °C (°F) If temperature limits are exceeded, the

—

Primary: ±0.65

Secondary: ±0.85

— degree Includes linearity, temperature drift, and

total sensor 7.5x2+22=37 mA typical for

FSO

mechanical hysteresis

sensor will function at a reduced level of

performance

repeatability. Does not include the error

due to offsets and different ferrous

environment

Sensor Connector and MC012 Microcontroller Pin Assignments

Angle sensor DTM04-4P connector pin assignments

For a mating connector, use Deutsch® plug DTM06-4S.

Pin Assignment

1 Ground (GND)

2 Output signal 2 (SIG2) - Secondary signal

3 Output signal 1 (SIG1) - Primary signal

4 Supply (V+)

Pre-compiled MC012 Pin Assignments

12-pin connector

14 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 15

User Manual

S45 ETL Control

General Angle Sensor Information

Pre-compiled MC012 Pin Assignments

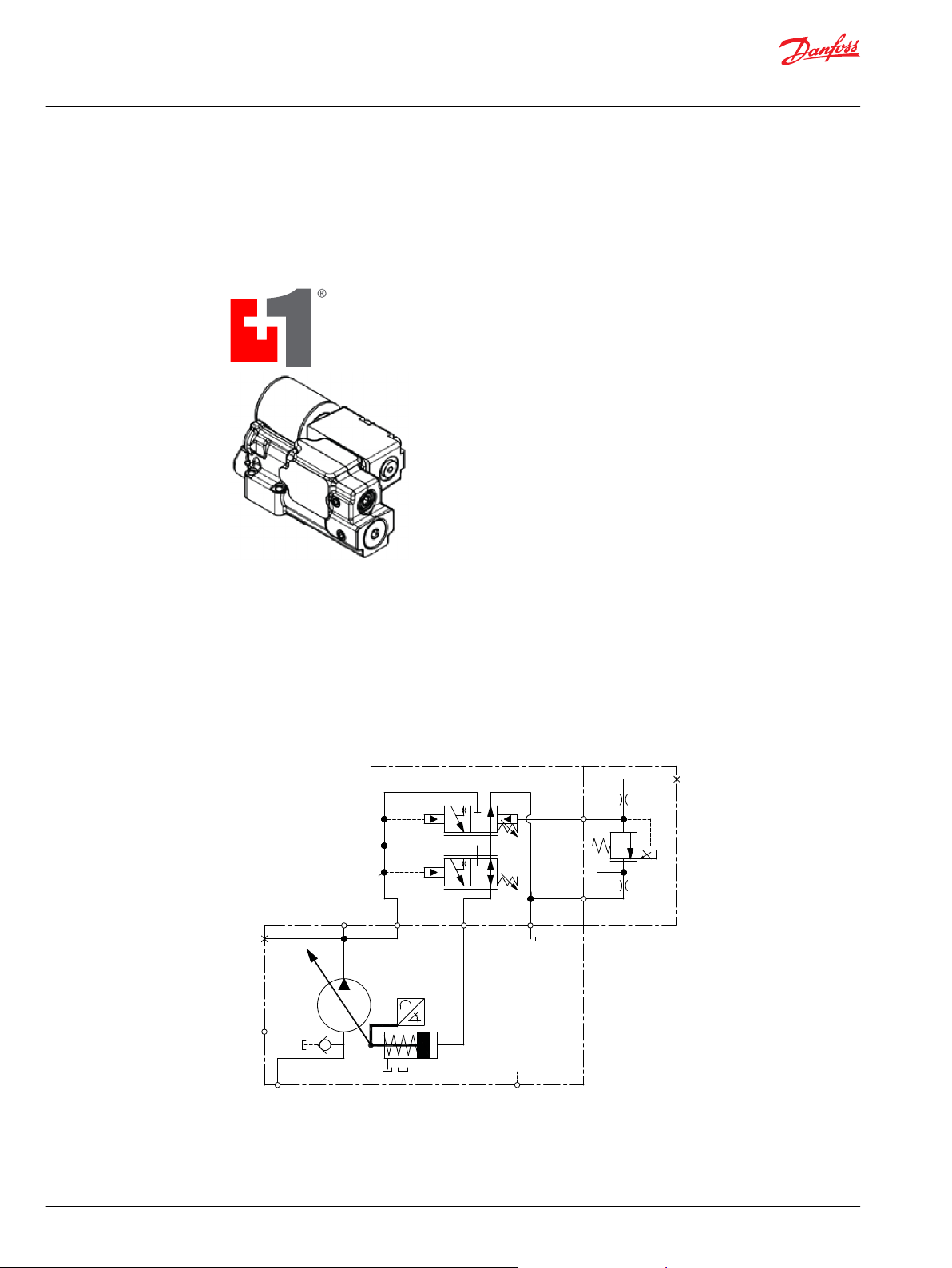

Pin callout Pin assignment type ETL function assigned

C1-P1 Power ground (–) Generic/sensor ground

C1-P2 Power supply (+) Machine power

C1-P3 CAN (+) CAN/J1939 High

C1-P4 CAN (–) CAN/J1939 Low

C1-P5 AIN/CAN shield Pressure transducer signal (optional)

C1-P6 5Vdc sensor power (+) Angle sensor power (mandatory)

C1-P7 Sensor power ground (–) Generic/sensor ground

C1-P8 DIN/AIN/FreqIN Angle sensor signal 1 (mandatory)

C1-P9 DIN/AIN/FreqIN Angle sensor signal 2 (optional)

C1-P10 DIN/AIN/FreqIN Potentiometer wiper (optional)

C1-P11 PWMOUT/DOUT/PVGOUT User function

C1-P12 PWMOUT/DOUT/PVGOUT Control coil current supply

Pressure transducer power (optional)

Torque potentiometer power (optional)

RPM speed ring pickup

Boost mode switch functionality

Potentiometers, Pressure Transducers, and the PumpTorqCalc Function Block

Potentiometer

It is possible to use a potentiometer to control the torque limiting signal for ETL setup purposes. Use a 1kohm potentiometer with a 120-ohm resistor on the +V and –V ends.

Pressure transducer

Using a pressure transducer allows the ETL service tool to report actual torque and power consumed by

the S45 pump via the PumpTorqCalc Funcion Block. The PumpTorqCalc function block is an optional part

of the ETL system, and it allows the user to report real-time data on a graphical display terminal to help

equipment operators understand and improve operating efficiencies or share data between subsystems

to coordinate power sharing.

For more detailed information on the PumpTorqCalc Function Block, see Work Function Control Blocks

Library (L1313265).

Danfoss recommends using the MBS1250 Heavy Duty Pressure Transducer with a measuring range of 0

to 400 bar [5800 psi]. For information on this transducer, see MBS1250 Heavy Duty Pressure Transmitter

Product Electrical Installation (11062087).

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 15

Page 16

User Manual

S45 ETL Control

General PLUS+1 ETL Service Tool Information

The Electronic Torque Limiting (ETL) Service Tool is used to set up the torque limiting functionality on a

machine. See ETL Service Tool Setup on page 19 for the steps required to set up an ETL system.

Typical ETL Service Tool Screen shows a typical ETL Service Tool screen. You can navigate the Service Tool

screens in two ways.

•

Diagnostic Navigator Panel (1), which allows you to view the hierarchy of all screens

•

Navigation buttons (2), which give you quick access to related screens

ETL functionality is listed under Diagnostic Navigator > Parameter Functions (3).

•

System Overview

Torque Limit Setpoint

‒

Torque Potentiometer Calibration

Torque Limit Profile Setup

Torque Setpoint

CAN Torque Setpoint Setup

Command Filter Setup

‒

Angle Sensor Calibration

‒

Boost Setup

‒

RPM Input Setup

‒

Pump Setup

‒

Pressure Sensor Setup

‒

Pressure Setpoint Faults

‒

Electrical Interface

‒

User-defined toggle inputs (4) appear with a blue background.

Parameter faults (5) are shown as green, if no fault is present, and red, if a fault is present.

Each screen includes navigation links back to the System Overview (6), bounded by red.

Outputs (7) appear on all ETL Service Tool screens.

16 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 17

User Manual

S45 ETL Control

General PLUS+1 ETL Service Tool Information

Typical ETL Service Tool Screen

Typical ETL Service Tool Outputs

Output Description

Torque Limit Setpoint Displays the real-time calculated torque limit for the real-time engine speed as a

Engine Speed Shows the real-time engine speed fed back from the machine. Engine speed feedback must

Pressure Setpoint Displays the real-time system pressure currently allowed by the ETL control system.

Control Current Displays real-time current in milliamps (mA) being sent to the pump’s control solenoid from

Torque Consumed Displays the real-time torque consumed by the pump as a calculated percentage of pump

Power Consumed Displays the real-time power consumed by the pump as a calculated percentage of pump

Displacement Displays the real time pump displacement in both percent of maximum displacement and

Pressure Indicates real-time system pressure based on a pressure transducer. Note that a pressure

percentage of maximum torque consumable by the pump. It is calculated based on the

curve fitted from the torque limit profile (discussed on torque limit profile page) or as an

input of the voltage from the Torque Potentiometer.

be wired to the microcontroller by the user using either the CAN High and CAN Low pins

(C1-P3 and C1-P4), or the RPM speed ring pickup pin (C1-P9) (see RPM Input Setup on page

24).

Displayed both as a percentage of Max Pump Pressure and in bar. It is calculated by

referencing current pump displacement and engine speed (torque available at engine).

the PLUS+1® microcontroller. A current of zero or near-zero mA indicates that the solenoid

is not being activated to limit torque.

maximum torque based on the Max Pump Displacement and Max Pump Pressure inputs.

maximum power based on the Max Pump Displacement, Max Pump Pressure, and Max

Pump Speed.

cm3/rev. This displacement depends directly on the minimum and maximum displacement

calibration points.

transducer must be added to the system by the user for this optional functionality.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 17

Page 18

User Manual

S45 ETL Control

General PLUS+1 ETL Service Tool Information

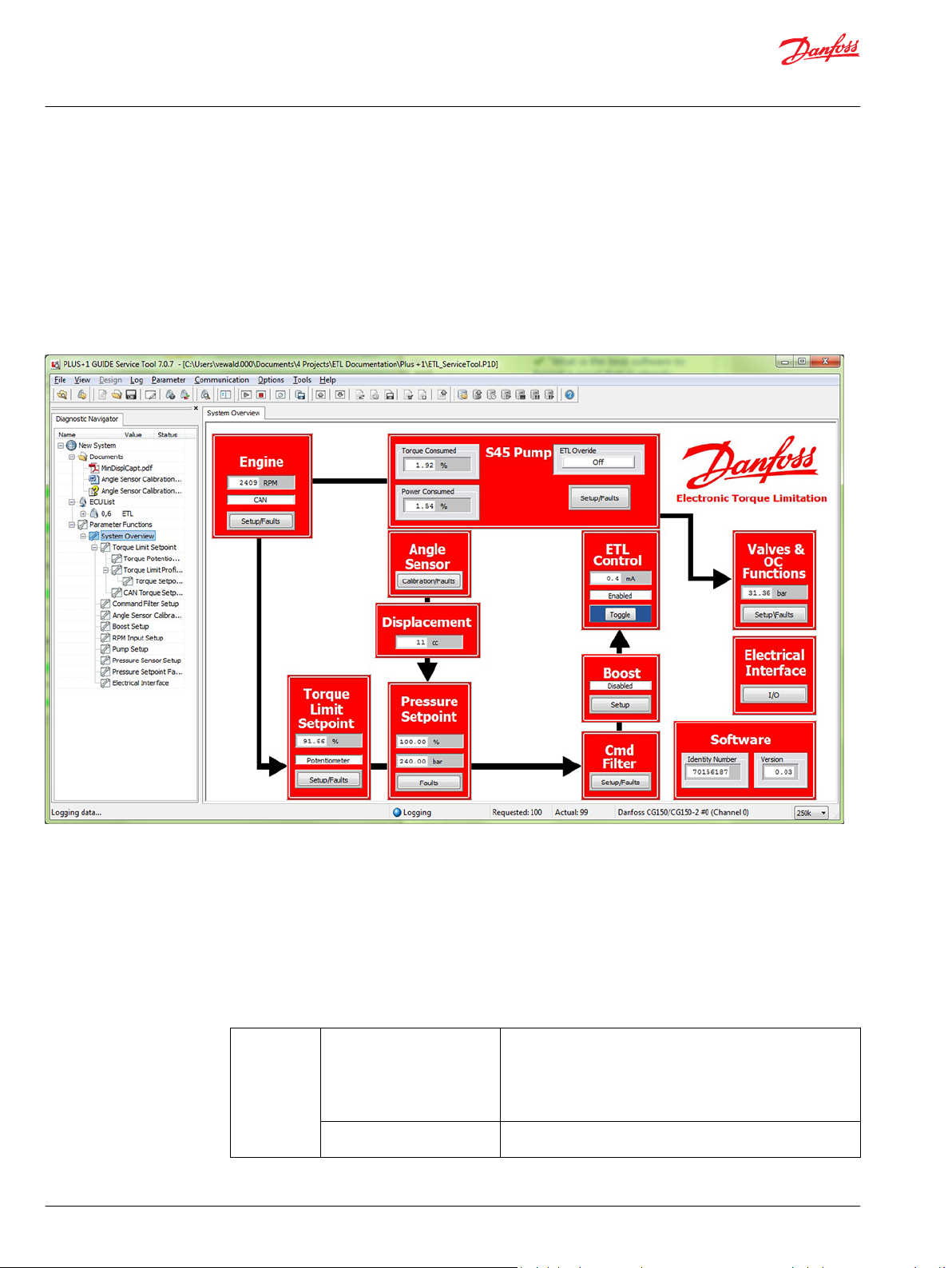

System Overview

The System Overview screen is the home screen for the ETL Service Tool. This screen shows a high-level

overview of how the S45 ETL software ties into the machine’s engine and hydraulic systems by reporting

real-time parameters.

You can also use the System Overview to do the following actions.

•

Navigate to each ETL functionality to tune changes or conduct diagnostics after the general setup

•

Enable or disable ETL Control using the Toggle button

ETL System Overview Screen

Torque Limit Setpoint

The Torque Limit Setpoint screen is important because it allows the user to select between two torque

limit input options (Torque Limit Profile or Torque Potentiometer).

This screen also provides quick navigation to the most frequently used setup screens.

Torque Limit Setpoint Parameters

Torque Limit Setpoint Parameters

Inputs Torque Limit Input Allows the user to select between two different forms of torque

Maximum Torque Allowed Allows the user to de-rate the whole Torque Limit Profile by a

limitation controls, Torque Profile and Potentiometer. The Torque

Profile is used when the seven limiting setpoints are finalized, and

the Potentiometer is used when first setting up ETL or conducting

diagnostics. These are discussed in detail in Torque Limit Profile

Setup on page 27.

common factor. The software sets the default value to 100%.

18 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 19

User Manual

S45 ETL Control

ETL Service Tool Setup

This section describes the ETL functions that are required for the ETL system to operate, including how to

set up each ETL function.

To set up each ETL function, you will make changes to each function's respective ETL Service Tool screen,

similar to the screen shown in Typical ETL Service Tool Screen.

The following steps are required in order for the ETL system to operate.

1. Calibrate Angle Sensor

a. Establish the Minimum Pump Displacement on page 20

b. Establish the Maximum Pump Displacement with Engine Off on page 21

or

Establish the Maximum Pump Displacement with Engine Running on page 21

2. Define Pump Displacement on page 23

3. Perform RPM Input Setup on page 24

4. Calibrate Torque Potentiometer on page 25

5. Select Pressure Sensor Setup on page 26

6. Establish Torque Limit Profile

•

Establish Torque Limit Profile with Torque Curve on page 28

or

Establish Torque Limit Profile without Torque Curve on page 28

Angle Sensor Calibration

A fundamental step in setting up ETL is to calibrate your angle sensor. The calibration will ensure accurate

angle sensor voltage readings based on maximum and minimum pump displacements (swashplate

angles).

Calibration does not inform the software what the physical maximum displacement of the pump is in

terms of engineering units. This is done in the Pump Setup Parameters screen, and the correct

calibration of the angle sensor is independent of the Max Pump Displacement input.

It is possible when calibrating the angle sensor that the Minimum Displacement Voltage is greater than

the Maximum Displacement Voltage. This is due to the different relationships between swashplate angle

and voltage for J and F-frames versus E-frame pumps. For more information, see the Angle Sensor

Characteristics on page 10.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 19

Page 20

User Manual

S45 ETL Control

ETL Service Tool Setup

Angle Sensor Calibration Screen

Angle Sensor Calibration Parameters

Angle Sensor Calibration Parameters

Calibration Minimum Pump Displacement Records the angle sensor signal voltage that corresponds to the

Maximum Pump Displacement Records the angle sensor signal voltage that corresponds to the

Inputs C1p08-Primary Signal Displays the real-time voltage signal from the primary sensor

C1p09-Secondary Signal Displays the real-time voltage signal from the secondary sensor

Faults Calibration/Parameter Faults

Sensor Input Faults Signal 1 input too low/high

pump’s lowest displacement condition

pump’s highest displacement condition

pickup

pickup, if enabled (optional)

Minimum/Maximum displacement not calibrated

Invalid setup/calibration

Parameter out of range

Signal 1 input at Sensor Power/Ground

Redundant signal indicates error

Establish the Minimum Pump Displacement

To establish the minimum displacement of the pump, you must operate the pump at either the Low

Pressure Standby Condition (LPSB) or the High Pressure Standby Condition (HPSB).

For the best results, calibrate and compare using both LPSB and HPSB to achieve the lowest (or highest,

for CW E-frame units) captured voltages.

20 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 21

User Manual

S45 ETL Control

ETL Service Tool Setup

It is important to compare the minimum displacement voltage readings at both LPSB and HPSB.

Generally, the swashplate angle is lower at LPSB because there are lower leakages at lower pressures, so

lower displacements are required to make up the leakages. This is not true when some flow is allowed

past the main valve block at LPSB. Then, HPSB conditions become preferred. Although the leakages are

higher at higher pressures, the increase in flow due to leakages is lower than the flow allowed by the

main valve.

1. Set the engine at full operating speed.

The engine must be operated at full speed to prevent an inaccurate displacement reading.

2. If the ETL is not disabled in the System Overview screen, toggle ETL Control to Disabled.

The control current should approximate 0 mA.

3. Operate the pump at one or both of the following conditions.

Condition When to use

Low Pressure Standby

Condition (LPSB)

High Pressure Standby

Condition (HPSB)

Use when the machine’s main valve block completely shuts off flow to any

downstream components (zero flow needed by machine functions/valves from

pump)

Use when the machine’s main valve block does not completely shut off flow to all

downstream components (some small flow needed by machine functions/valves

from pump at all times, even with no operator command)

a) If using LPSB, let the machine stand at full engine speed without operating any functions.

This allows the pump to de-stroke naturally because no flow is commanded from the pump, and

system pressures will be only slightly higher than the pump’s LS setting.

b) If using HPSB, operate a machine function over a hard-stop and reach full pressure compensator

(PC) setting with system pressure.

This allows the pump to de-stroke by porting high pressure oil to servo.

From the Angle Sensor Calibration screen while maintaining either LPSB or HPSB:

4. Click Minimum Pump Displacement > Capture Voltage.

Establish the Maximum Pump Displacement with Engine Off

1. Turn off the machine.

2. Momentarily jog the starter to turn the pump shaft a few revolutions, without actually running the

engine.

This allows the pump’s swashplate to return to its naturally spring biased full-stroke position by

overcoming residual pressure and friction in the swashplate and servo system.

From the Angle Sensor Calibration screen:

3. Click Maximum Pump Displacement > Capture Voltage.

Establish the Maximum Pump Displacement with Engine Running

The engine must be operated at full speed to prevent an inaccurate displacement reading.

1. Operate the pump in a full displacement, full flow, and low load machine condition.

a) Operate engine at full operating speed.

b) Command a single high flow function or multiple machine functions simultaneously while

remaining below the pump’s pressure compensator setting (low system pressure).

Do not reach or exceed the pressure compensator setting or the pump will begin to de-stroke and

reduce its displacement and render a bad maximum displacement reading.

From the Angle Sensor Calibration screen:

2. Click Maximum Pump Displacement > Capture Voltage.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 21

Page 22

User Manual

S45 ETL Control

ETL Service Tool Setup

Pump Setup

Pump Setup Screen

The pump setup function defines the pump displacement in PLUS+1® software. It also sets the maximum

system pressure and maximum pump speed to calculate the maximum pump torque and power.

Coil current thresholds are also set up based on the user's inputs.

22 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 23

User Manual

S45 ETL Control

ETL Service Tool Setup

Pump Setup Parameters

Pump Setup Parameters

Inputs Max Pump Pressure Defines the maximum desired system pressure created by the pump, in

Max Pump Speed Calculates power consumed by the pump. Generally, the highest engine

Max Pump

Displacement

LS pressure setting Defines the margin setting of the pump, in bar. This must be equal to the

Threshold current Defines the minimum current required for active torque limiting in the

Faults Parameter input faults Max Pump Pressure out of range

Input faults Displacement value too high or low

bar. This must be less than or equal to the Pressure Compensator (PC)

setting. This software setting DOES NOT override the pump’s factory set

mechanical Pressure Compensator setting. If the Max Pump Pressure is

higher than the PC setting, the pump will default to the physical PC

pressure of the pump and the ETL system will not function correctly.

operation speed of the machine should be used. See Series 45 Pumps

Technical Information (520L0519) for allowed pump operating speeds in

order to ensure conformance to recommended continuous operation

speeds. This input does not limit physical pump speed in any way.

Defines the true maximum displacement of the pump in terms of cm3/rev

and correlates it to the Maximum Captured Voltage.

Also known as nominal pump displacement, it can be determined by the

pump’s model code.

LS pressure setting as defined from the factory. This may be found on the

pump's identification tag.

control. It is based on the Max Pump (PC) Pressure, LS Pressure Setting,

and 12- vs. 24-volt coil characteristics. This is an interpolated value that

references control pressure vs. current curves.

Max Pump Speed out of range

Max Pump Displacement out of range

Speed value too high or low

Pressure value too high or low

Define Pump Displacement From the Pump Setup screen:

1. Set Pump Max Pressure to the desired maximum operating pressure.

The Pump Max Pressure setting must not exceed the Pressure Compensator (PC) setting of the

pump. It should be equal to or less than the PC setting, or else the system will lose power because the

pump will need to relieve pressure in a constant manner.

2. Set LS Pressure Setting to the pump's factory LS margin pressure.

3. Set Max Pump Speed to the maximum operating speed at which the pump will operate.

In general, you should use the highest engine operation speed of the machine. See Series 45 Pumps

Technical Information (520L0519) for allowed pump operating speeds to conform to the

recommended continuous operation speeds.

4. Set Max Pump Displacement to the physical maximum displacement of the pump in units of cm3/

rev.

5. Set Threshold Current.

a) Toggle Coil Setup to the correct coil voltage.

b) Set Max Pump (PC) Pressure and LS Pressure Setting.

The Recommended Threshold field will display the recommended threshold.

c) Select Use Recommended.

The recommended current threshold will transfer to the Threshold Current field.

Advanced users may reference a control pressure vs. current curve and enter their own threshold to

create a custom offset for the threshold setting.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 23

Page 24

User Manual

S45 ETL Control

ETL Service Tool Setup

RPM Input Setup

RPM Input Setup Screen

The RPM input limits the torque throughout an engine’s usable speed range. To set up this limit, you

must select the proper speed input, either CAN bus speed pickup or speed ring pulse pickup.

RPM Input Parameters

RPM Input Parameters

Inputs Speed Input Toggle switches between two different inputs: CAN bus and Speed ring

Pulse Per Revolution Sets the number of pulses per revolution of the Hall Effect Sensor when

C1p09 - MFIn Freq Displays the frequency at which the speed ring sensor is sensing pulses

Faults Parameter input faults PPR parameter is out of range (>10,000)

Perform RPM Input Setup From the RPM Input Setup screen:

1. Toggle your desired input to use for the engine speed pickup.

Speed ring

•

CAN bus

•

2. If a hall effect/speed ring type is used, indicate the number of pulses per revolution in Pulse Pickup

Calibration > Pulse Per Revolution.

The engine speed output will read the real-time speed when set up.

24 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

pulse pickup

Speed Ring is selected

Frequency is too high (>50,000)

Frequency is too low (=0)

Page 25

User Manual

S45 ETL Control

ETL Service Tool Setup

Torque Potentiometer Calibration

This section applies only if a potentiometer is used for ETL setup.

A potentiometer greatly reduces the Torque Limit Profile setup time by allowing quick adjustments to

the actual torque limit at any engine speed condition. In order for a potentiometer to be used for this

functionality, it must first be calibrated.

Torque Potentiometer Calibration Screen

Torque Potentiometer Calibration Parameters

Torque Potentiometer Calibration Parameters

Calibration C1p10 - Voltage Indicates the real-time signal voltage being input from the Torque

Minimum Captured Voltage Displays the minimum captured voltage created by the

Maximum Captured Voltage Displays the maximum captured voltage created by the

Auto Calibration Toggle Enables or disables the auto calibration feature

Clear Calibration Clears the minimum and maximum captured voltages from the

Potentiometer

potentiometer

potentiometer

previous calibration to establish a new calibration

Calibrate Torque Potentiometer

1. Connect a potentiometer to the indicated pins in the MC012 pin out.

From the Torque Potentiometer Calibration screen:

2. Toggle the auto calibration to Auto Cal Enabled.

This calibrates the potentiometer.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 25

Page 26

User Manual

S45 ETL Control

ETL Service Tool Setup

Pressure Sensor Setup

Pressure Sensor Setup Screen

3. Turn the potentiometer from lock to lock in a steady manner.

The auto calibration feature will automatically capture the minimum and maximum allowable

voltages registered while the Auto Cal is enabled. The proper voltage range will be attained when

using a 1k-ohm potentiometer with 120-ohm resistors on both the +V and -V ends.

4. After the minimum and maximum voltages are captured, toggle the auto calibration to Auto Cal

Disabled.

5. If the calibration did not cover the full range of the potentiometer, or if you need to use a new

potentiometer, click Clear Calibration.

This deletes the previously captured voltages to capture a new calibration.

The minimum and maximum voltages of the potentiometer will not be 0V or 5V. This is not allowed

for fault monitoring purposes.

The Pressure Sensor Setup screen allows the user to enable the use of a system pressure transducer. A

pressure transducer is helpful to diagnose the system and calculate power consumed by the pump.

Pressure Sensor Setup Parameters

Pressure Sensor Setup Parameters

Inputs Pressure Sensor Enable Enables or disables in-line pressure transducer functionality

Faults Parameter input faults Pin value too high (at sensor power)

Pin value too low (at sensor ground)

Select Pressure Sensor Setup

26 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 27

User Manual

S45 ETL Control

ETL Service Tool Setup

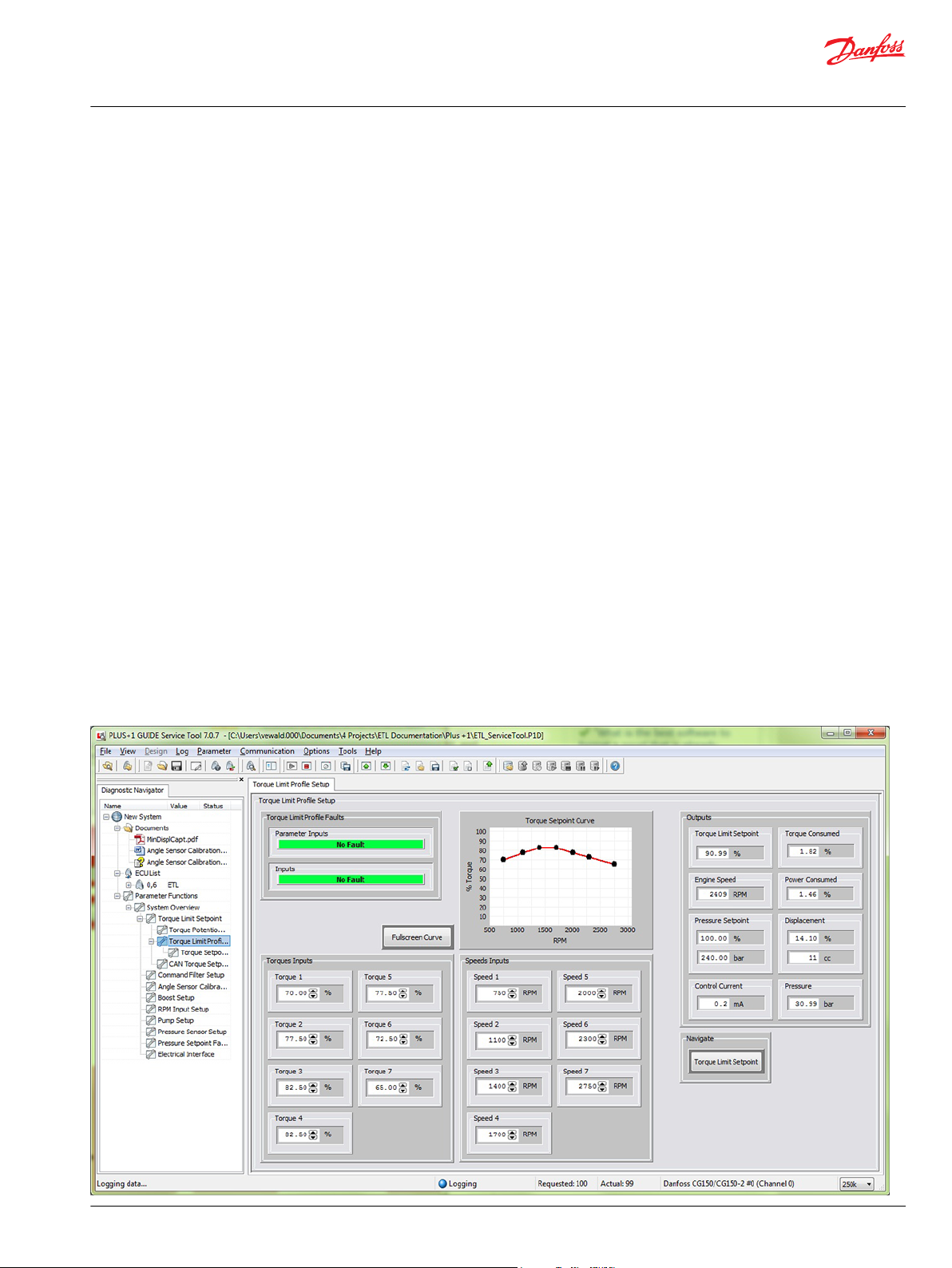

Torque Limit Profile Setup

Torque Limit Profile Setup Screen

1. After system pressure functionality is desired, hook up the recommended pressure transducer to the

recommended pins.

For pinout, see Pre-compiled MC012 Pin Assignments on page 14.

From the Pressure Sensor Setup screen:

2. Toggle Pressure Sensor Enable to Enabled.

The Torque Limit Profile is the heart of an ETL system. It is what defines how a machine reacts to torque

loads, and it has an infinite number of tuning possibilities. It allows you to define how the system limits

torque consumed by the open circuit hydraulic system.

The most basic torque profile will reference a graph of engine torque available vs. engine speed from the

engine manufacturer. However, this basic profile may not always be the best profile, and such detailed

engine information might be difficult to obtain.

It is important to realize that the user can tune the reactivity of the ETL system by how closely the 7 input

points match the actual torque available from the engine. Torque values which exactly match the

available torque from the engine may yield a system which allows for noticeable engine speed reactions

(engine bog or droop) as torque limiting takes over. This generally occurs because the pump’s input

torque requirements may increase much more rapidly than the engine’s torque output.

However, torque values which are set slightly lower than the actual available engine torque provide

some margin between the limited torque and the actual torque. This combats any reactivity from the

engine at all, and gives the operator the setup with the lowest potential for noticeable engine speed

changes.

The desired amount of engine reaction is subjective and can vary for different applications.

You can create a Torque Limit Profile with or without a torque curve. A torque curve is highly

recommended for best optimization, but it is not necessary.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 27

Page 28

Pump Torque Setpoint

n speed

[%] =

Engine Available Torque

n speed

Pump Torque Consumed

Max Pump Pressure, Displacement

User Manual

S45 ETL Control

ETL Service Tool Setup

Torque Limit Profile Setup Parameters

Torque Limit Profile Setup Parameters

Inputs Speed Inputs 1–7 These speed inputs correspond to 7 engine speed points on a torque

curve for which torque is to be limited

Torque Inputs 1–7 These torque inputs correspond to the 7 engine speed points on a torque

curve for which torque is to be limited

Faults Parameter inputs Speed [N] is less than or equal to Speed [N-1]

Speed [N], out of range

Torque [N], out of range

Inputs Actual engine input speed value too low or high

Establish Torque Limit Profile with Torque Curve

The following steps establish a torque limit profile if a known engine torque curve is available.

From the Torque Limit Profile Setup screen:

1. Set the engine Speed Inputs (Speed 1–7) at which you wish to limit torque.

For example, set the lowest engine idle speed, highest engine idle speed, and five equally spaced

points between the two.

2. Set the Torque Inputs (Torque 1–7).

To do this, normalize the engine's torque values to reflect the pump's maximum consumable torque.

That is, divide the available engine torque by the pump’s maximum consumable torque to get a

Pump Torque Setpoint percentage.

For example, if your engine’s available torque at 950 rpm is 196 N-m, and a 75cc J-frame pump

operating at a pressure limit of 240 bar will consume 302 N-m of torque, then 196 / 302 = 65%. This is

the Pump Torque Setpoint required at 950 rpm. Continue using this method for all 7 torque setpoints.

After establishing a torque limit profile, the torque setpoints may still require adjustment to achieve the

desired engine/machine reactivity. See Adjust Torque Setpoints on page 29.

Establish Torque Limit Profile without Torque Curve

The following steps establish a torque limit profile if an engine torque curve is not available. It uses a

guess-and-check method.

From the Torque Limit Profile Setup screen:

1. Set the engine Speed Inputs (Speed 1–7) at speeds which you wish to limit torque.

For example, set the lowest engine idle speed, highest engine idle speed, and five equally spaced

points between the two.

2. Set the Torque Inputs (Torque 1–7) .

The following steps are one suggestion.

a) Pick the lowest engine speed and set the machine at this condition.

b) Operate the machine through various high-torque consumption cycles.

c) Adjust the torque limit setpoint to achieve the desired level of torque limiting (some, or virtually

none, engine reaction/bog).

The reactiveness is affected by how close the pump’s allowed torque is relative to the engine’s

available torque.

After establishing a torque limit profile, the torque setpoints may still require adjustment to achieve the

desired engine/machine reactivity. See Adjust Torque Setpoints on page 29.

28 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 29

User Manual

S45 ETL Control

ETL Service Tool Setup

Adjust Torque Setpoints

After establishing a torque limit profile, the torque setpoints may still require adjustment to achieve the

desired engine/machine reactivity.

Adjust the torque setpoints using one of the following options.

Option Steps

Torque Inputs

Torque Setpoint Curve

Torque Potentiometer

The torque potentiometer has been shown to greatly reduce the process time to adjust torque

setpoints and fine tune the torque profile.

Considerations for Establishing the Torque Limit Profile

•

The amount of torque limiting required may be objective or subjective

Objective examples

‒

Killing the machine vs. not killing the machine

Not allowing the engine to droop more than ‘XXXX’ rpm below desired idle speed

Not allowing the engine to droop to a certain sound criteria

Allowing the engine to droop to a certain sound criteria

Not allowing the pump to drop below a certain flow requirement based on a pressure criteria

(necessary function speed under no load)

Subjective examples

‒

Operator must be able to experience some engine reactivity to perceive machine work

Operator skill allows for smaller margin between available engine torque and pump torque

consumed

Operator does not want machine to slow down too much

•

The amount of torque consumed by the open circuit pump system does not account for the torque

consumed by the closed circuit pump system

Propel vs. work functions

‒

•

A specific machine function may require more or less torque depending on environmental conditions

Cold weather vs. hot weather oil viscosity

‒

1. Set the Torque Inputs (Torque 1–7).

2. Download and check.

1. Click and drag the points in Torque Setpoint Curve.

2. Download and check.

1. Use a torque potentiometer to adjust the torque setpoints while operating the

machine.

2. Enter the setpoints into the Torque Limit Profile.

3. Download and check.

For questions on setting up the Torque Limit Profile for your machine, consult your Danfoss

representative.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 29

Page 30

User Manual

S45 ETL Control

Additional Setup

Boost Mode

Boost Setup Screen

The features in this section are not required for an ETL system to function. These features enhance or

adjust system performance and functionality.

Boost mode, or ETL override, allows the user to configure an operator interface to enable or disable ETL.

One example is a momentary switch incorporated into an interface such as a joystick.

The pre-keyed MC012 does not allow both the torque potentiometer and the boost mode functionality

to be used at the same time. To use boost mode, the potentiometer functionality must be disabled, and

vice versa. The engine will not be protected from stalling while boost mode is enabled.

One benefit of boost mode includes artificially creating a pressure setting that is lower than the pump’s

physical pressure compensator setting. As a result, you can achieve extra pressure capability on

command by enabling or disabling ETL and creating an extra power level.

Boost Mode Parameters

Boost Mode Parameters

Boost Enable

Input

Status

Allows or prevents the use of Boost Mode. When Disabled, Boost Mode cannot be used

even if an operator interface is present. If Enabled, Boost Mode can be used when not

using the Torque Potentiometer functionality.

Boost mode can be configured with a switch that is either Pull Up or Pull Down in

the electrical schematic. This toggle switches the logic between the two options.

Indicates whether Boost Mode is Off (ETL enabled) or Boost Enabled (ETL disabled).

CAN Torque Setpoint Setup

In CAN setpoint enable mode, the S45 pump responds to auxiliary command messages.

30 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 31

User Manual

S45 ETL Control

Additional Setup

CAN Torque Setpoint Setup Screen

When the CAN setpoint is enabled, you can remotely send a torque setpoint to the pump by identifying

an address on the CAN.

Please consult with your Danfoss representative for more information on setting up torque setpoints with

CAN messaging.

Command Filter Setup

The Command Filter Setup screen allows for possible filtering of control current signals if there are

pressure oscillations. The ETL system, by default, sets the command control filter to zero, which means it

is disabled.

If the command control filter is used, the filter values can be increased until the unwanted oscillations

reach an acceptable level.

Command filter setup is only necessary if unwanted instability or oscillations occur when ETL is active.

The time constant sets the cutoff frequency for a first order low pass exponential filter.

Determining the frequency of oscillations can help give you a starting point for the time constant: fc = 1/

(2*pi*t).

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 31

Page 32

User Manual

S45 ETL Control

Additional Setup

If the ETL control produces unwanted oscillations, and all time constant values are set to zero, use the

following table and the Command Filter Setup screen to reduce oscillations.

Are oscillations occurring when the load

is increasing?

Are oscillations only occurring when the

load is decreasing at high engine speed?

Yes Increase the Increasing input.

No Leave the Increasing input at zero.

Yes

No, there is no oscillation when the load is

decreasing at high engine speed

No, oscillations occur when the load is

decreasing at both high and low speeds

Set the High Speed input to the affected engine speed.

•

Increase the High Speed Decreasing input.

•

Leave the High Speed Decreasing input at zero.

•

Set the High Speed input to the high engine speed.

•

Ensure the High Speed and Low Speed inputs match the

•

engine tuning speeds before adjusting filter inputs.

Set the High Speed Decreasing and Low Speed

•

Decreasing inputs to the high and low engine setpoints.

32 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 33

User Manual

S45 ETL Control

Additional Setup

Command Filter Setup Screen

For questions on system stability and tuning with Command Filter time constants, consult your Danfoss

representative.

Command Filter Setup Parameters

Command Filter Setup Parameters

Inputs Low Speed Speed at which Low Speed Decreasing time constant is used for

High Speed Speed at which High Speed Decreasing time constant is used for

Low Speed Decreasing Low pass filter time constant to limit decrease in pressure setpoint. The

High Speed Decreasing Low pass filter time constant to limit decrease in pressure setpoint. The

Increasing Low pass filter time constant to limit increase in pressure setpoint.

Faults Parameter Fault High Speed out of range

Input Fault Displacement too low/high

filtering the torque setpoint output

filtering the torque setpoint output

actual used filter value is a scaled between High Speed Decreasing and

Low Speed Decreasing, depending on speed. Associated with Low

Speed.

actual used filter value is a scaled between High Speed Decreasing and

Low Speed Decreasing, depending on speed. Associated with High

Speed.

Low Speed out of range

Speed to low/high

Torque Demand too low/high

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 33

Page 34

User Manual

S45 ETL Control

Troubleshooting

Pressure Setpoint Faults

Pressure Setpoint Faults Screen

The Pressure Setpoint Faults screen is used for troubleshooting.

Electrical Interface

The Electrical Interface screen allows you to troubleshoot the electrical interface, including the status of

the input pins, output pins, and supply/sensor power.

34 | © Danfoss | March 2015 L1519202 | BC00000345en-000101

Page 35

User Manual

S45 ETL Control

Troubleshooting

ETL Electrical Interface Screen

©

Danfoss | March 2015 L1519202 | BC00000345en-000101 | 35

Page 36

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | March 2015 L1519202 | BC00000345en-000101

Loading...

Loading...