Page 1

Data sheet

Gasketed Plate Heat Exchangers (DN 200 / 8”)

S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229

Description

SONDEX® gasketed plate heat exchangers are

the ideal choice for a wide range of applications

across numerous market segments.

We have the largest plate portfolio in the

world, and we customize each heat exchanger

to meet your exact requirements. Innovative

technologies and smart design make our

gasketed plate heat exchangers a stellar

investment.

Benefits:

• Individually customized solution that

perfectly matches your requirements and

lowers your energy consumption.

• High performance and a low pressure

drop eliminate unnecessary burdens on

your system and optimize overall system

performance.

• The design results in a compact solution with

a small footprint, simple installation, and easy

access for maintenance.

Common applications:

• HVAC industry

• Marine/offshore industry

• Dairy/food/beverage industry

• Sugar industry

• Biogas industry

• Pulp and paper industry

• Heavy industry

• Mining industry

• Petrochemical industry

• Chemical industry DN 200

Main data:

• Min. temperature −10 °C

• Max. temperature 180 °C

• Max. working pressure 16 / 25 bar (6 / 10 bar

on request)

• Water and different fluids, steam

• Connection size DN 200 or 8”

Approvals:

• Please contact your local Danfoss/SONDEX®

sales representative for an overview of the

available approvals in your region

Construction standard:

• EN13445 (PED 2014/68/EU)

• ASME sec VIII, Div. 1

| 2019.07 VD.JQ.P1.02 | 1

Page 2

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Naming of units

S43-IS16-21-TKTL89

3)

1)

1)

Type of heat exchanger:

TKTL89 - Plate grouping

21 - Number of plates in the heat exchanger

16 - Design pressure of the heat exchanger

IS - Frame type

2)

43 – Type of heat exchanger

S – Gasketed heat exchanger

43 - …

Letter A shows type of the attachment of gasket to plate:

e.g. 43 (without A) – SonderLock

43A (with A) – Hang-on

AD - wider channel gap design

TY - asymmetric channel design

2)

Description of frame types:

There are few different frame types which can be offered for different applications and duties.

IS – with suspension roller,

IG – without suspension roller,

FS – food/sanitary with suspension roller,

FG - food/sanitary,

ST – simple design of frame with threaded connections

3)

Channel grouping:

In this example, the heat exchanger combines TK and TL channels. The share of TL channels equals

89% of the total number of channels.

The number of channels is defined as “the number of plates - 1”.

TK - short thermal length

TM - medium thermal length

TL - long thermal length

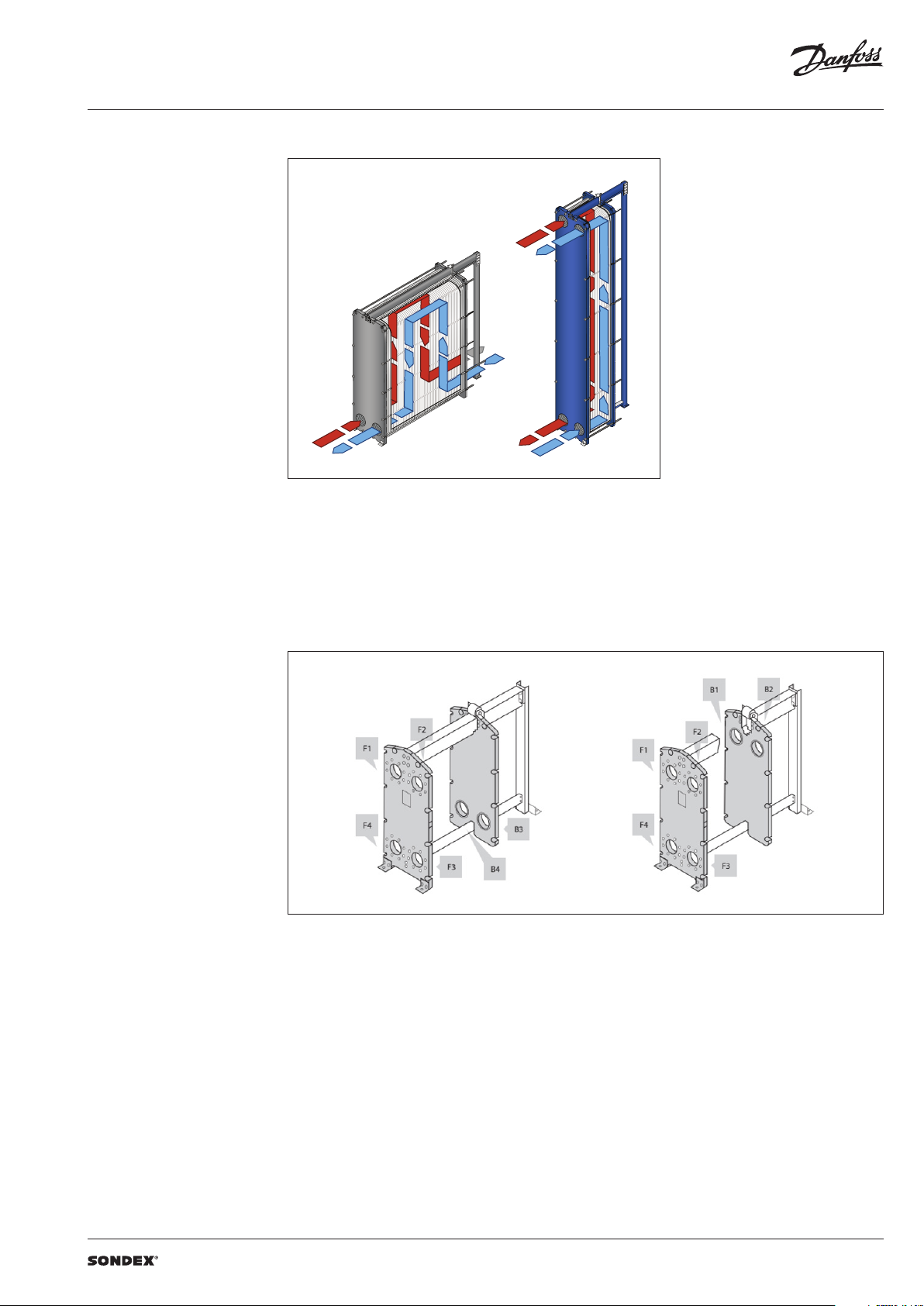

Heat exchanger design

Gasketed heat exchangers consist of

Carrying Bar

Plate Pack

Plate

Connections

Head

Flange Connections

Foundation Feet

Column

Follower

Tie Bolt

Guiding Bar

Anatomy of a SONDEX® plate heat exchanger - IS frame.

2 | VD.JQ.P1.02 | 2019.07

Page 3

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

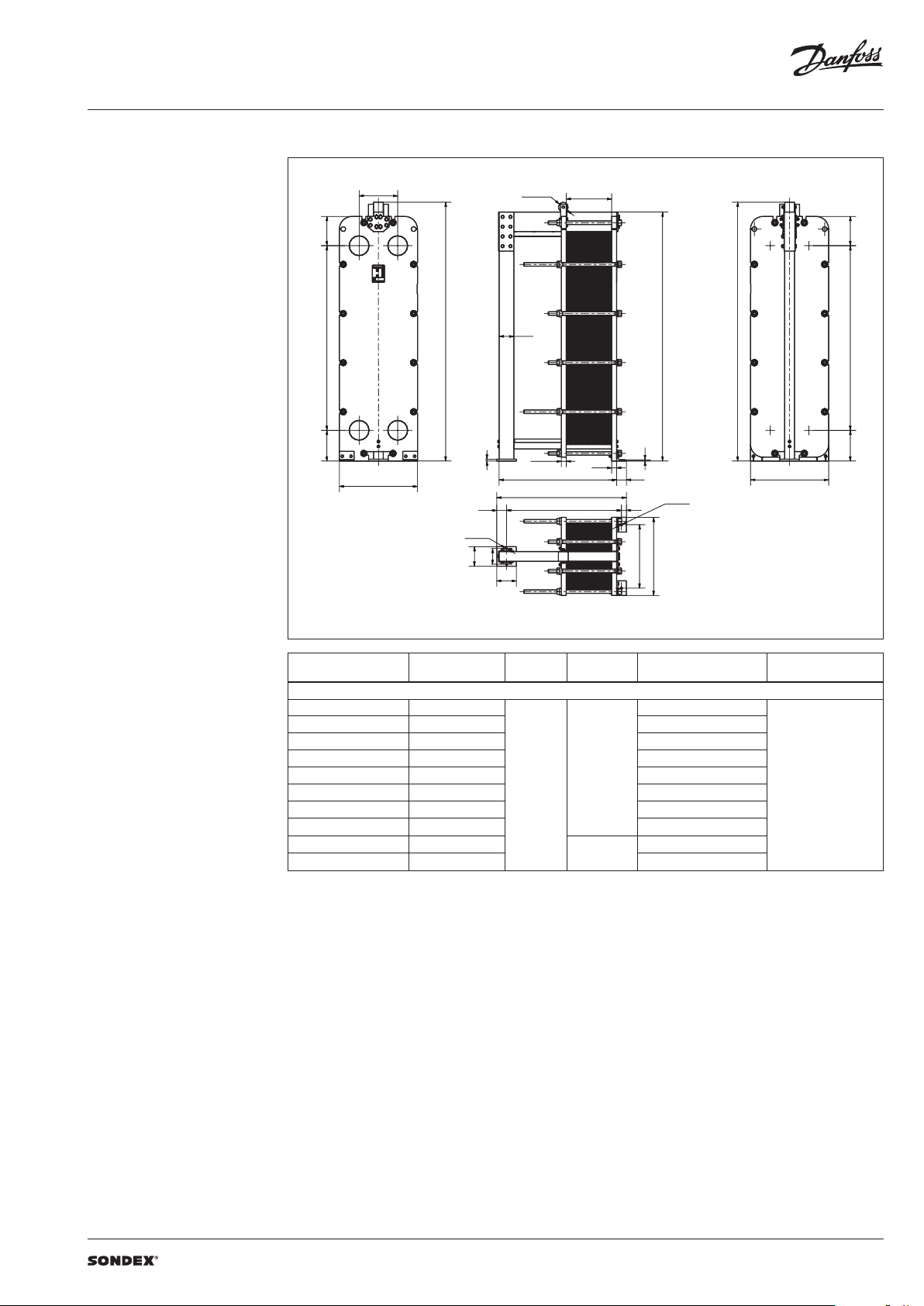

To the left: A multi-pass solution with connections

Heat exchanger design

(continued)

Multi-pass design

on the follower and the head.

To the right: A single-pass solution with

all connections on the head.

Connections

The heat exchanger may have connections on

both front and back end sides of the unit.

Connections on the front-end plate are marked

with F and connections on the back-end plate

are marked with B. The numbers 1, 2, 3 and 4

designate the position of the connection on the

end-plate from the top-left port clockwise.

VD.JQ.P1.02 | 3 | 2019.07

Page 4

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

SONDEX®

plate

range

Common

Technical data

Heat exchanger S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229

Typ e

Max. working

pressure

Max. operating

temperature

Min. operating

temperature

Flow medium Water and different fluids, steam

Volume / channel l 1.3 2.6 1.7 2. 38 4.23 2.92 / 1.84 3.4 8.6 4.03 5.9 11. 0

Connection size DN 200/ 8"

Connection type

Plate material

Plate thickness mm

Gasket material

Gasket attachment t ype Hang-on; Sonder Lock

Liners in connections

Frame

Frame painting

specification

1)

Not available f or all frame variations

2)

SonderSaf e – double plate

S43 S43AD S65 S100 S100A D S100T Y S130 S131 S152 S221 S229

PN

(bar)

°C

• DN 200/8” flanges. Carbon steel, rubberlined or cladded with AISI 316L (other materials available

on request)

Stainless steel EN 1.440 4 (AISI 316L), EN 1.4301 (AISI 304), SMO254, Hastelloy C276, titanium Gr.1

Other materials available on request

0.4; 0.5; 0.6; 0.71); 0.81) (ti)

2 x 0.4 SonderSafe plates

Other thicknesses available on request

NBR, EPDM, FKM

Certain gasket materials are not available for all frame sizes and/or variation

• Rubber NBR, EPDM, FKM

• Stainless steel EN 1.440 4 (AISI 316L), EN 1.4301 (AISI 304), SMO254, Hastelloy C276, titanium Gr.1

• Painted frame, color RAL 5010 (other colors available on request)

• Stainless steel frame, designed for the sanitary applications (e.g. food and dairy industries)

Painting available for corrosion categories C2L, C4M, C5M

1)

2)

(6)1), (10)1), 16, 25

Up to 180

-10

Using the right plate for each individual duty

is very important, as it greatly impacts the

efficiency of the entire installation.

It is important that the length of the plates and

the type of pattern match the requirements of

individual thermal duty.

We have developed a wide plate portfolio to

provide the perfect plate and connection size for

any duty.

No application is too small or too big for us - we

provide the optimal technical solution every

time.

Our extensive SONDEX® plate portfolio

includes plates that lie outside the commonly

manufactured plate sizes to cover all thermal

duties optimally.

plate

range

4 | VD.JQ.P1.02 | 2019.07

Page 5

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Accessories Insulation

Recommended applications:

The insulation jacket for the plate heat exchanger

is used in different applications with high

temperatures and cooling systems.

Application Heating Cooling

Material

Outer cap

Internal insulation 0.05 mm aluminium foil

Panel fixation Plastic rivets

Temperature 20 … 200 °C -50 … -80 °C

U-value 0.55 W/m2K 0.3 8 W/m2K

Insulation class 3

Heat loss 17.1 W/m

Please note:

Inlet and outl et temperatures in the exch anger have been based on 9 0/50 – 30/70 °C.

1)

The loss of he ating/cooling is stated per m2 surface on the insu lation jacket.

The bottom o f the heat exchanger is not insu lated and this fact has been e xcluded.

A possible loss of ve ntilation, largely dep endent on the mounting of the h eat exchanger, has not been take n into account either.

45 mm mineral wool

Not flammable

DIN EN 4102A2

1 mm aluminium

“Stucco” Embossed

1)

2

Drip trays

Recommended Applications:

The drip tray is available in two types. A “failsafe” solution which prevents water or liquid

from leaking onto the floor, or when the heat

exchangers is dismantled, or opened for

inspection and maintenance. And an insulated

drip tray for cooling applications, which

Materials

Drip tray consists of:

• 1 mm galvanized steel frame

• Hanging brackets in galvanized steel

• 60 mm Polyurethane insulation for cooling

applications

• Draining valve.

collects condensate formed outside of the plate

heat exchanger.

40 mm PU-foam

DIN 4102-1 B2

1)

4

-

Spare parts

Spare parts for gasketed heat exchangers, such

as plates, gaskets, frame parts can be ordered for

maintenance, repair, increasing heat exchanger

capacity, etc.

Selection and ordering Please contact your local SONDEX® or Danfoss

sales representative for the selection and / or

ordering of the heat exchangers, spare parts, and

accessories.

Please contact your local Danfoss or SONDEX®

sales representative to provide you with

information on spare parts available for gasketed

heat exchangers.

For contact information please visit

https://www.danfoss.com/en/contact-us.

VD.JQ.P1.02 | 5 | 2019.07

Page 6

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

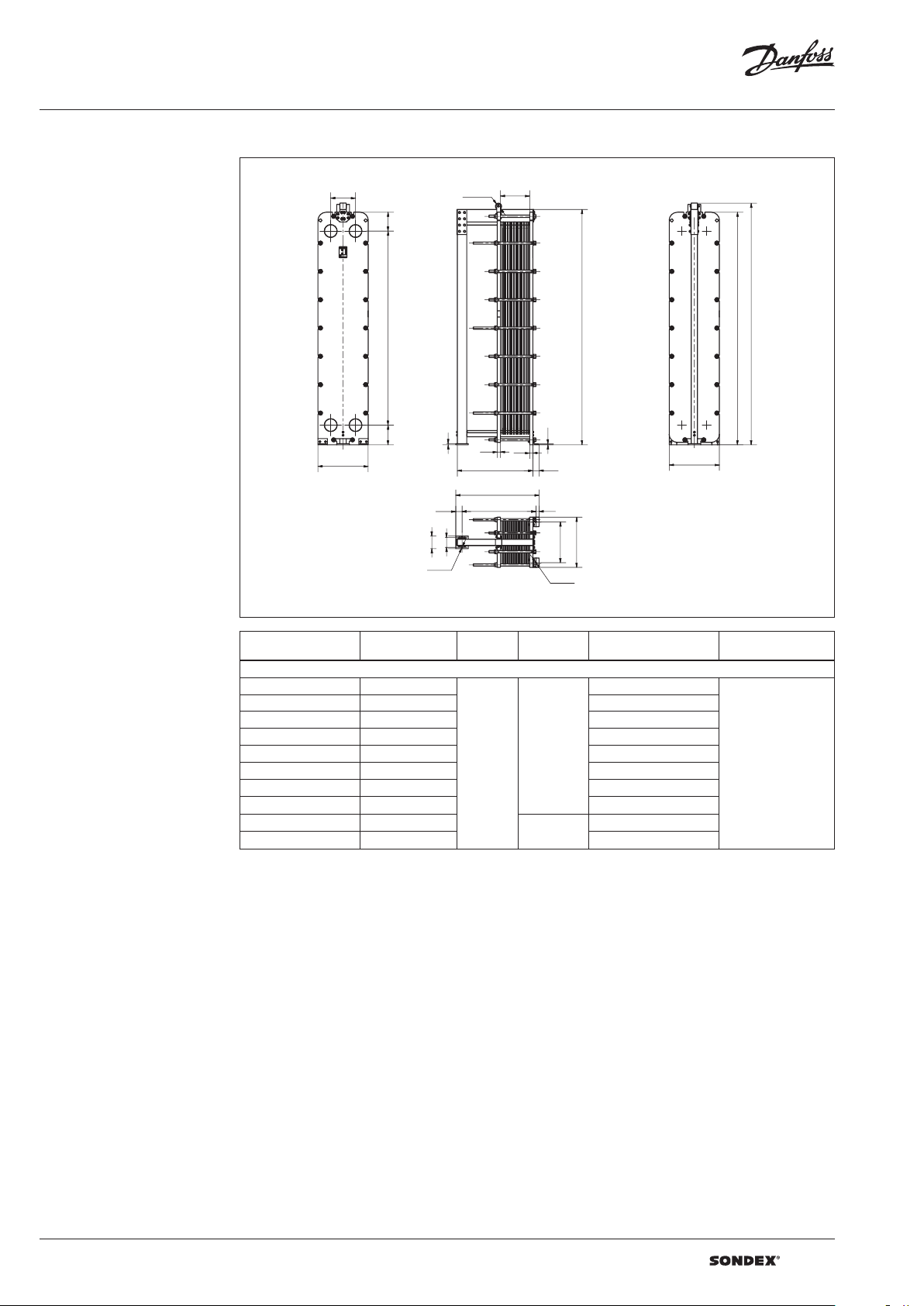

Dimensions

Non-sanitary applications

Any connection can be used for primary side in.

All the rest are made correspondingly.

S43 / S43AD frames

395

29 7,5791314

F2

F1

F3

F4

7

7

280

W

50

20

140

Ø18

110

Ø100

50

L

L + 150

L + 80

L1

1402, 5

280

B2 B1

B3

H

B4

14

60

100

W

50

W

620

Ø25

Drawing of S43 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S43 (S43AD) IS16

7 – 64 (7 - 54) 667

1161 (1276 )

65 – 137 (55 - 116) 1067 140 6 (1507)

138 – 191 (117 - 162) 1367 1591 (1678)

192 – 228 (163 - 193) 1567 172 2 (1793)

229 – 319 (194 - 270) 2067 2030 (2081)

320 – 410 (271 - 346) 2567 2345 (2365)

770

30 .31”

790

31.10 ”

1502 .5

59.15”

DN 200 flange or 8”

411 – 500 (347 - 423) 3067 2658 (2653)

501 – 682 (424 - 577) 4067 3290 (3228)

S43 IS25

7 − 62 677

1334

63 − 133 1077 1632

134 – 187 1377 1857

188 – 223 1577 2007

224 – 312 2077 2379

790

31.10 ”

1502 .5

59.15”

DN 200 flange or 8”

313 – 401 2577 2752

402 – 491 3077 312 8

492 – 669 4077 3873

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is avai lable on request

6 | VD.JQ.P1.02 | 2019.07

Page 7

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S65 frames

1702, 5

395

F1

F2

1091 297,5314

F3

F4

280

W

50

Ø100

L1

B1

B2

H

1702, 5

B3

7

7

50 60

14

100L

B4

280

W

L + 150

20

L + 80

50

Ø18

140

110

W

620

Ø25

Drawing of S65 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S65 IS16

7 − 64 667

1430

65 − 137 1067 173 7

138 – 191 1367 1971

192 – 228 1567 2137

229 – 319 2067 2523

770

30 .31”

1802 .5

70.96”

DN 200 flange or 8”

320 – 410 2567 2921

411 – 500 30 67 3316

501 – 682 4067 4114

S65 IS25

7 − 61 677

1690

62 − 133 1077 2050

134 – 186 1377 2326

187 – 222 1577 2521

223 – 311 2077 2991

790

31.10 ”

1802 .5

70.96”

DN 200 flange or 8”

312 – 400 2577 3443

401 – 490 3077 3919

491 – 668 4077 4862

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is avai lable on request

VD.JQ.P1.02 | 7 | 2019.07

Page 8

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S100 frames

29 7,51489314

395

F2

F1

Ø100

L1

2100,5

F3F4

280

7

7

50

60

L

14

60

100

W

L + 150

20

L + 80

50

395

B2

B1

H

B3

B4

280

W

Ø18

W

140

110

620

Ø25

Drawing of S100 IS16 frame

Number of plates

L (frame length)

1)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S100 I S16

7 – 64 6 67

1805

65 – 137 10 67 2194

138 − 191 1367 2489

192 − 228 1567 2689

229 − 319 2067 318 8

320 − 410 2 567 3692

770

30 .31”

2198

(86. 53”)

DN 200 Flange or 8”

411 − 500 30 67 4193

501 − 682 4067 5204

683 − 864 5210

865 − 1046 6210 7267

790

31.10 ”)

2505.5

(98.64”)

6214

S100 I S25

7 - 61 677

2019

62 – 133 1077 2505

134 – 186 1377 2864

187 − 222 1577 3108

223 – 311 2077 3710

312 − 400 2577 4312

790

31.10 ”

2200.5

86.63”

DN 200 Flange or 8”

401 − 490 3077 4921

491 − 668 4 077 6125

669 − 847 5220

848 − 1025 6220 8944

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is avai lable on request

790

31.10 ”

2505.5

98.64”

7686

8 | VD.JQ.P1.02 | 2019.07

Page 9

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S100AD / S100TY frames

395

29 7,51489314

F2

F1

F3F4

280

W

Ø100

L1

2100,5

7

7

50

60

L

14

60

100

L + 150

20

L + 80

50

395

B2

B1

H

B3

B4

280

W

Ø18

W

140

110

620

Ø25

Drawing of S100 IS16 frame

Number of plates

1)

L (frame length)

(mm)

W

(mm)

H

(mm)

Weight max,

2)

empty

(kg)

Connection type

S100A D IS16

7 – 64 667

1935

55 – 119 1067 2327

120 − 165 1367 2608

166 – 196 1567 2798

197 – 270 20 67 3252

271 – 350 25 67 3737

790

31.10 ”

2200.5

86.64”

DN 200 flange or 8”

351 – 426 30 67 4203

427 – 580 40 67 5143

581 – 734 5210 6084

735 – 888 6210 7023

S100T Y IS16

7 64 667

1977

65 – 140 1067 2 415

141 – 195 1367 2735

196 – 231 15 67 2945

232 – 319 20 67 3459

320 – 413 2567 4003

770

30 .31”

2198

86. 53”

DN 200 flange or 8”

414 – 504 30 67 4533

505 – 686 40 67 5591

687 – 868 5210

869 – 1050 6210 7708

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is avai lable on request

790

(31.10 ”)

2505.5

(98.64”)

6650

VD.JQ.P1.02 | 9 | 2019.07

Page 10

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S130 fra mes

315 1891 300

Ø100

F1

F2

L1

B1

B2

H

2506

2551

150

F4

F3

B4

B3

14

395

W

20

60

L

60

L + 125

100

160

200

L - 25

50

620

Ø25

Ø25

Drawing of S130 IS16 f rame

Number of plates

1)

L (frame length)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S130 IS16

7 – 64 810

2497

65 – 140 1210 3043

141 – 195 1510 34 41

196 – 231 1710 3703

232 – 319 2210 4344

320 – 413 2710 5022

770

30 .31”

2651

104.37 ”

DN 200 flange or 8”

414 – 504 3210 5681

505 – 686 4210 6854

687 – 868 5210

869 – 1050 6210 9337

2908

114 .4 9”

8048

S130 IS25

7 – 61 825

2276

62 - 133 122 5 2737

134 - 186 152 5 3114

187 - 222 17 25 3309

223 - 311 2225 3882

312 - 400 2725 4464

790

31.10 ”

2655

104.53 ”

DN 200 flange or 8”

401 - 490 3225 5036

491 - 668 4225 6191

669 - 847 5225

848 - 1025 6225 8491

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is avai lable on request

2907

114 .4 5”

7336

10 | VD.JQ.P1.02 | 2019.07

Page 11

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S131 f rames

1891 300315

395

F1

F1

F2

F2

H

F3

F3

F4

F4

W

100

Ø100

150

20

50

L

L + 125

L - 25

L1

B2

B2

B1

B1

2551

50

14

100

Ø25

50

H

1891 300315

B3

B3

B4

B4

W

Ø25

W

200

160

650

200

Drawing of S131 IS10 frame

Number of plates

1)

L (frame length)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S131 IS10

7 – 33 810

2276

34 – 70 1210 2737

71 – 98 1510 3 114

99 – 116 17 10 3309

117 – 162 2210 3882

163 – 209 2710 4464

800

31. 50”

2651

104.37 ”

DN 200 flange or 8”

210 – 255 3210 5036

256 – 348 4210 6191

349 – 440 5210

441 – 533 6210 8491

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

2908

114 .4 9”

7336

VD.JQ.P1.02 | 11 | 2019.07

Page 12

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S152 frame s

300315

2191

Ø100 L1

F2

F1

395

2806

F3

F4

150

20

W

100

60

L + 125

L - 25

60

L

100

50

2851

14

395

W

Ø25

H

Ø25

200

160

620

Drawing of S152 IS16 frame

Number of plates

1)

L (frame length)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S152 IS16

7 – 64 810

2804

65 – 137 1210 3402

138 – 191 1510 3845

192 – 228 17 10 4147

229 – 319 2210 4893

320 – 410 2710 5637

770

30 .31”

2951

116.18 ”

DN 200 flange or 8”

411 – 500 3210 6376

501 – 682 4210 7866

683 – 866 5225

867 – 1048 6225 108 61

3208

126 .30 ”

9370

S152 I S25

7 – 63 825

3053

64 – 134 1225 3687

135 – 188 152 5 4194

189 – 224 1725 4548

225 – 313 2225 5356

314 – 402 2725 6208

770

30 .31”

2950

116.14 ”

DN 200 flange or 8”

403 – 491 3225 7138

492 – 670 4225 8 878

671 – 850 5225

851 – 1029 6225 12071

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is avai lable on request

3208

126 .30 ”

1036 8

12 | VD.JQ.P1.02 | 2019.07

Page 13

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S221 frames

395

F1

F4

Drawing of S221 IS16 frame

Ø100

L1

395

300

B2

F2

3751

B1

H

150

F3

20

315 3091

W

60

14

60

100L

B4

B3

W

L + 125

100

200

160

Ø25

L - 25

50

W

620

Ø25

Number of plates

1)

L (frame length)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S221 IS16

7 – 64 810

3392

65 – 140 1210 4159

141 – 195 1510 4722

196 – 231 1710 510 6

232 – 319 2210 6005

320 – 413 2710 6967

770

30 .31”

3851

151.61

DN 200 flange or 8”

414 – 504 3210 8010

505 – 686 4210 9935

687 – 868 5210

869 – 1050 6210 13919

4108

(161.73” )

118 45

S221 IS25

7 – 61 825

4 411

62 – 133 1225 5316

134 – 186 1525 5986

187 – 222 1725 6439

223 – 311 2225 7561

312 – 400 2725 8682

790

31.10 ”

3849

151.53”

DN 200 flange or 8”

401 – 490 3225 9815

491 – 668 4225 12058

669 – 847 5225

848 – 1025 6225 16557

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

*)

PNclass 10 bar is availabl e on request

4107

161.69 ”

14313

VD.JQ.P1.02 | 13 | 2019.07

Page 14

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

Dimensions (continued)

Non-sanitary applications

S229 frames

F1

F4

Drawing of S229 IS10 frame

395

W

L1

Ø100

300

B1

F2

3091

F3

315

20

50

50

3751

14

L 100

B2

H

3706

B4

B3

W

L + 125

100

200

L - 25

160

50

W

650

Ø25

Ø25

Number of plates

1)

L (frame length)

(mm)

W

(mm)

H

(mm)

Weight max, empt y

(kg)

2)

Connection type

S229 IS10

7 – 33 800

3307

34 – 70 120 0 3980

71 – 98 150 0 4488

99 – 116 1700 4 815

117 – 162 2200 5651

163 – 209 2700 6503

800

31. 50”

3850

151.61”

DN 200 flange or 8”

210 – 255 3200 7340

256 – 348 4200 9027

349 – 440 5200

441 – 533 6200 123 87

1)

the indicate d maximum number of pla tes is based on the minimum plate thi ckness allowable for the PN le vel of the unit;

2)

the maximum w eight of the empty unit with t he maximum allowable nu mber of plates;

4108

161.73”

10700

14 | VD.JQ.P1.02 | 2019.07

Page 15

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

VD.JQ.P1.02 | 15 | 2019.07

Page 16

Data sheet S43 / S43AD / S65 / S100 / S100AD / S100TY / S130 / S131 / S152 / S221 / S229 (DN 200 / 8”)

| DHS-SRMT/SI | 2019.0716 | VD.JQ.P1.02

Loading...

Loading...