Page 1

Data sheet

CI-tronic™ Reversing contactor

Type RCI

RCI reversing contactors are designed for

demanding forward/reverse control of

three-phase AC motors. The zero cross

switching method ensures very fast and precise

motor control and virtually eliminates EMC

emission. The RCI reversing contactor is ideal

where fast switching capability and long life are

essential. Typical applications are conveyors,

thread cutting machines, packaging lines and

other applications where fast reversing

capabilities are needed.

Features • Compact modular design complete with

heat sink

• DIN-rail mountable

• Built-in varistor protection

• Operational current up to 10 A (AC-3)

• Line voltage up to 480 V AC

• Built-in interlock

• Universal control voltage

• Burst firing (zero cross)

• LED status indicator

• IP 20 protection

• Problem-free specification according to

industry standard

• Easy and quick installation

• EN 60947-4-2 and UL-C

© Danfoss | DCS (mw) | 2017.10

IC.PD.C50.D3.02 | 520B3036 | 1

Page 2

Data sheet | Reversing contactor, type RCI

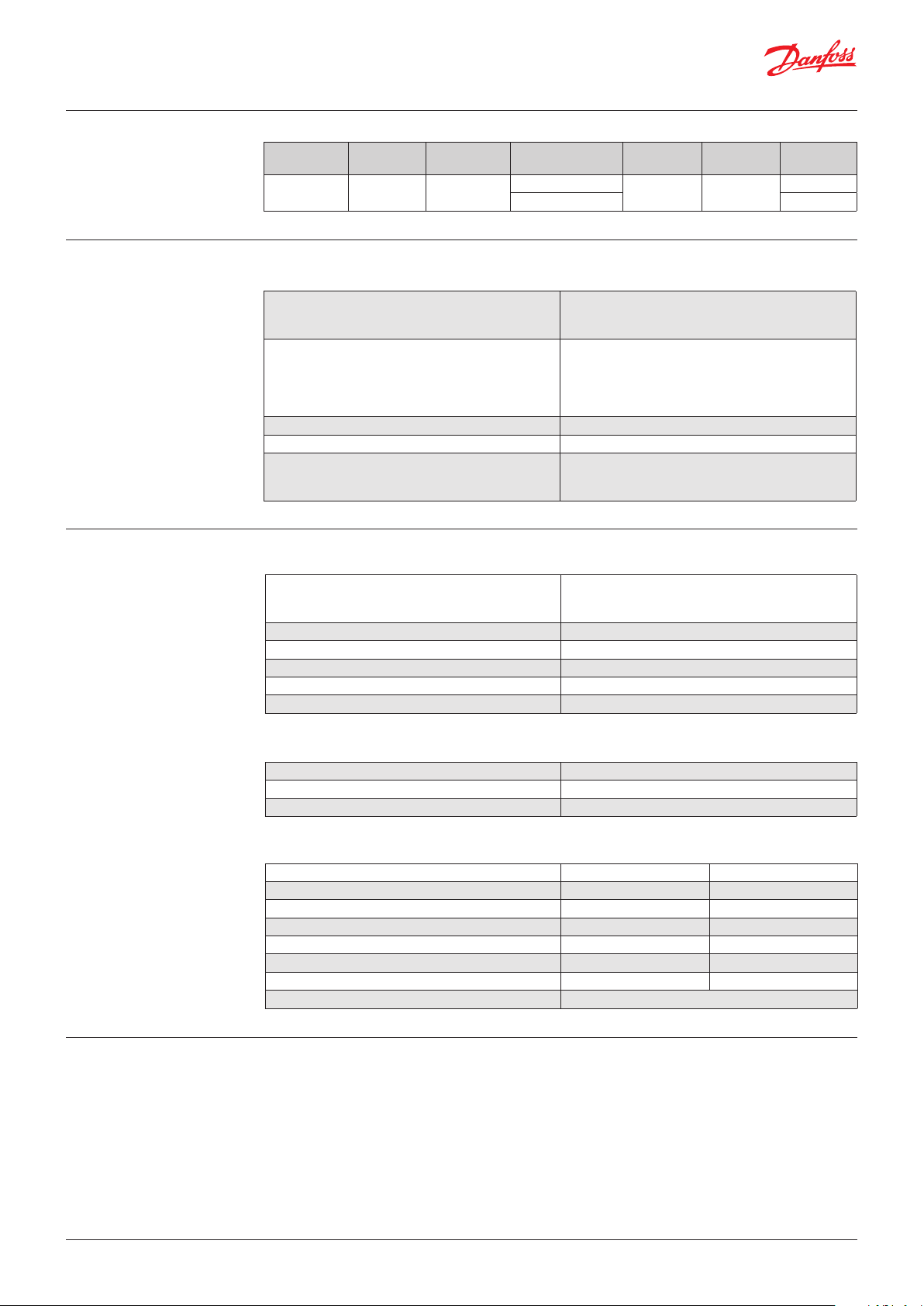

Selection guide

Technical data

Technical data (continued)

Operational

voltage

24 – 480 V AC 10 A 4 kW / 5.5 HP

Max. motor

current

Max. motor

power

Control

voltages

5 – 24 V DC

24 – 230 V AC / DC 037N0043

Dimensions Type Code no.

45 mm

module

RCI 10

Output specifications

Operational current

AC-3 (motor load)

AC 4 (motor load)

Motor size at

208 – 240 V AC (50 / 60 Hz)

400 – 480 V AC (50 / 60 Hz)

Leakage current max. 1 mA

Operational current min. 10 mA

Semiconductor protection fusing

Type 1 coordination

Type 2 coordination

AC-3: 0.1 – 2.2 kW (0.18 – 3 HP)

AC-4: 0.1 – 1.5 kW (0.18 – 2 HP)

AC-3: 0.1 – 4 kW (0.18 – 5.5 HP)

AC-4: 0.1 – 3 kW (0.18 – 4 HP)

10 A

8 A

50 A gL / gG

450 A2s

Thermal specification and environment

Power dissipation

Continuous duty

Intermittend duty

Ambient temperature range −5 °C to 60 °C

Cooling method Neutral convection

Mounting Vertical (± 30°)

Storage temperature range 20 °C to 80 °C

Enclosure degree / pollution degree IP 20/3

2.0 W/A

2.0 W/A x duty cycle

037N0044

Functional description

Insulation

Rated insulation voltage, U

Rated impulse withstand voltage, U

Installation category III

i

imp

660 V AC

4 kV

Control circuit specifications

037N0044 037N0043

Control voltage range (±10%) 5 – 24 V DC 24 – 230 V AC / DC

Pick up voltage max. 4.25 V DC 20.4 V AC / DC

Drop-out voltage min. 1.5 V DC 7.2 V AC / DC

Control current / power max. 25 mA at 4 V DC 6 mA / 1.5 VA at 24 V DC

Response time max. ½ cycle 1 cycle

Interlock delay time (min. / max.) 30 ms / 80 ms 60 ms / 150 ms

EMC immunity Meets requirements of EN 60947-4-2

When control circuit A1 – A2 is ON, the motor will

rotate forward. With control circuit A3 – A4 ON

the motor will rotate in reverse direction. If both

control circuits are switched ON the motor will

rotate in the direction determined by the circuit

which was switched ON first. A delay time

(interlock) between forward and reverse running

is incorporated.

© Danfoss | DCS (mw) | 2017.10

IC.PD.C50.D3.02 | 520B3036 | 2

Page 3

Data sheet | Reversing contactor, type RCI

Functional diagram

Mains voltage (L1, L2, L3)

Control voltage, “F” (A1, A2)

Control voltage, “R” (A3, A4)

Delay F-R

Delay R-F

Motor forward

LED “F”

Motor reverse

LED “R”

Wiring

Motor overload and short

circuit protection

Motor full load current

[A]

Danfoss CTI 25M / CTI 25MB

circuit breaker, code no.

0 – 0.16 047B3140

0.16 – 0.25 047B3141

0.25 – 0.4 047B3142

0.4 – 0.63 047B3143

0.63 – 1.0 047B3144

1.0 – 1.6 047B4145

1.6 – 2.5 047B3153

2.5 – 4.0 047B3154

4.0 – 6.3 047B3155

6.0 – 10.0 047B3156

© Danfoss | DCS (mw) | 2017.10

IC.PD.C50.D3.02 | 520B3036 | 3

Page 4

Data sheet | Reversing contactor, type RCI

Dimensions

Mounting

The controller is designed for vertical mounting.

If the controller is mounted horizontally the load

current must be reduced by 50%. Controllers

mounted side by side need no clearance.

Controllers mounted vertically on top of another

need a clearance of minimum 80 mm (3.15 in.).

Clearance between controller top and “ceiling”

and between controller bottom and “floor” must

be at least 30 mm (1.2 in.)

© Danfoss | DCS (mw) | 2017.10

IC.PD.C50.D3.02 | 520B3036 | 4

Page 5

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Overheat protection

If required the controller can be protected

against overheating by inserting a thermostat in

the slot on the right-hand side of the controller.

Order: UP 62 thermostat 037N0050

The thermostat is connected in series with the

control circuit of the main contactor.

When the temperature of the heat sink exceeds

100 °C the main contactor will be swtiched OFF.

A manual reset is necessary to restart this circuit.

For wiring connections see application

examples.

Application examples

Combined reversing contactor and soft starter

Soft start & soft stop

A soft reversing of a motor can easily be achieved

by connecting a reversing contactor to the soft

starter.

The reversing contactor, type RCI, will determine

the direction of rotation, forward or reverse and

the soft starter, type MCI, will perform soft

starting and soft stopping of a motor.

Soft start only

If soft stop is not required, the application can be

simplified by connecting the control circuit of the

soft starter to the main terminals.

A delay of approx. 0.5 sec. between forward and

reverse control signal must be allowed to avoid

influence from the voltage generated by the

motor during turn-off.

© Danfoss | DCS (mw) | 2017.10

IC.PD.C50.D3.02 | 520B3036 | 5

Loading...

Loading...