Page 1

Data sheet

Valves for Control of Fan Coils and Terminal Units

RA‑HC

Description

The RA-HC is a control valve applied together with

Danfoss self-acting or Danfoss electronic controls in

fan coil units and similar terminal units in any HVAC

system. When installed with Danfoss ASV, balancing

and control functions are combined representing the

complete dynamic hydraulic solution.

Combined with Danfoss thermo actuators (TWA) the

RA-HC valves provide On/Off control, control the

flow over the terminal unit and maintain optimum

temperatures based on room load requirements.

RA-HC valves have eight presettings, thus the correct

quantity of water flow is ensured for each circuit.

Ordering and Specification RA‑HC valve

Connection

Typ e

DN 15 G ⁄ yes 16 1.8 −10 … 100 003Z3931

DN 20 G ⁄ yes 16 1.8 −10 … 100 003Z3910

DN 25 G 1 yes 16 1. 8 −10 … 100 003Z3911

DN 15 G ⁄ no 16 1.8 −10 … 100 003Z3932

DN 20 G ⁄ no 16 1. 8 −10 … 100 003Z3920

DN 25 G 1 no 16 1.8 −10 … 100 003Z3921

The max. di fferential pressure spe cified is the maximum pre ssure at which the valves give satisfac tory regulation. As wi th any device

which imposes a p ressure drop on the system, no ise may occur under certain f low/pressure conditions.

RA‑HC accessories

Typ e

TWA-A NC

TWA-A NO 08 8H 3111

TWA-A NC

TWA-A NO 088H3113

Manual shut off knob - 013 G330 0

RA‑HC

without test plugs

Tes t

plugs

(“)

Connection

type

RA

RA‑HC

TWA ‑A

with test plugs

RA-HC matches high flow capacities and with its

compact design only little installation space is

required.

The RA-HC with TWA and ASV provide:

• Balancing and control function

• High flow capacity

• Compact design, requires small installation space

• Easy presetting, no tools required

• Measuring on ASV partner valve or optional on

RA-HC

• Shut-off (for isolation during system maintenance)

using manual shut off knob.

Max working pressure Max dif f. Pressure with TWA‑A Medium Temp

bar

Supply

Voltage

AC/DC

24 V

230 V

AC

Code No.

088H3110

088H3112

(°C)

Code No.

© Danfoss | 2020.02

Valve

DN 15 0.11 0.16 0.22 0.28 0.41 0.62 0.82 1.0 1.2 1.3 1.5 1.7 2.0 2.8 2.8

DN 20 0.29 0.34 0.43 0.68 0.88 1.1 1. 3 1.4 1.7 2.2 2.8 3.1 3.3 4.3 4.3

DN 25 0.35 0.41 0.58 0.79 1.0 1. 3 1.5 1.7 2.2 2.9 3.7 3.9 4.0 5.5 5.5

1)

The kv‑values show the f low (Q) in m3/h at a diffe rential pressure (∆p) of 1 bar throu gh the valve.

1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 N

Presettings, kv values

1)

AI175386404642en-000502 | 1

k

VS

Page 2

Data sheet RA‑HC Valves for Control of Fan Coils and Terminal Units

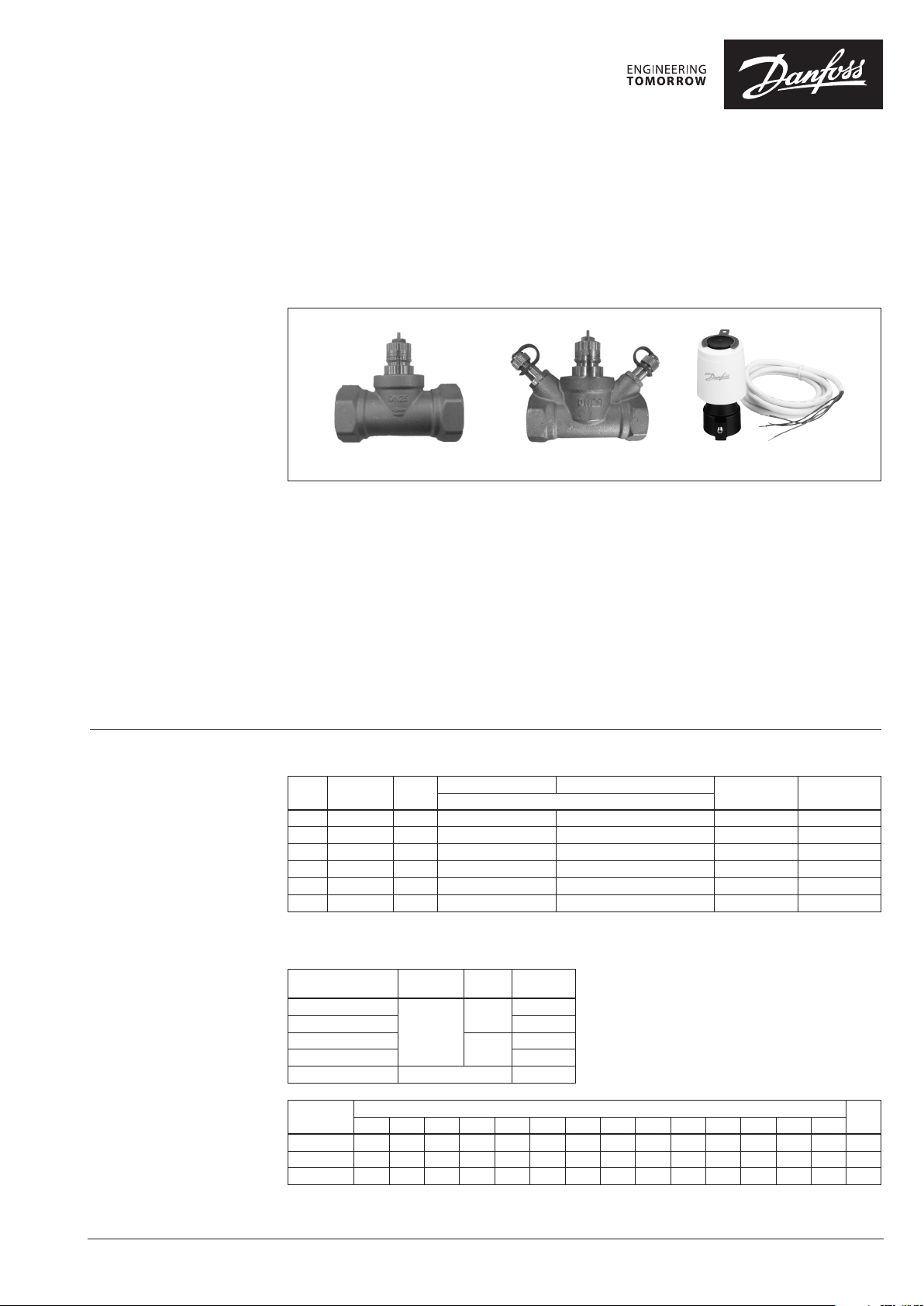

System and Flow

Verification

For RA-HC without test plugs, it is recommended to

do measuring and flow verification with Danfoss PFM

5001 or Danfoss flow indicator on the ASV-PV partner

valve.

For ASV-PV < DN 50 the recommended partner

valve is ASV-I or ASV-BD. For ASV-PV > DN 50 the

recommended partner valve is MSV-F2.

For RA-HC with test plugs, it is accepted to do

measuring and flow verification with Danfoss PFM

5001 or Danfoss flow indicator on the RA-HC valve

directly.

For ASV-PV < DN 50 the recommended partner valve

is ASV-M or ASV-BD.

For ASV-PV > DN 50 the recommended partner valve

is MSV-F2.

For detailed information on:

• ASV-PV data sheet

• PFM 5001 data sheet

• Flow indicator data sheet

For detailed information on:

• ASV-PV data sheet

• PFM 5001 data sheet

• Flow indicator data sheet

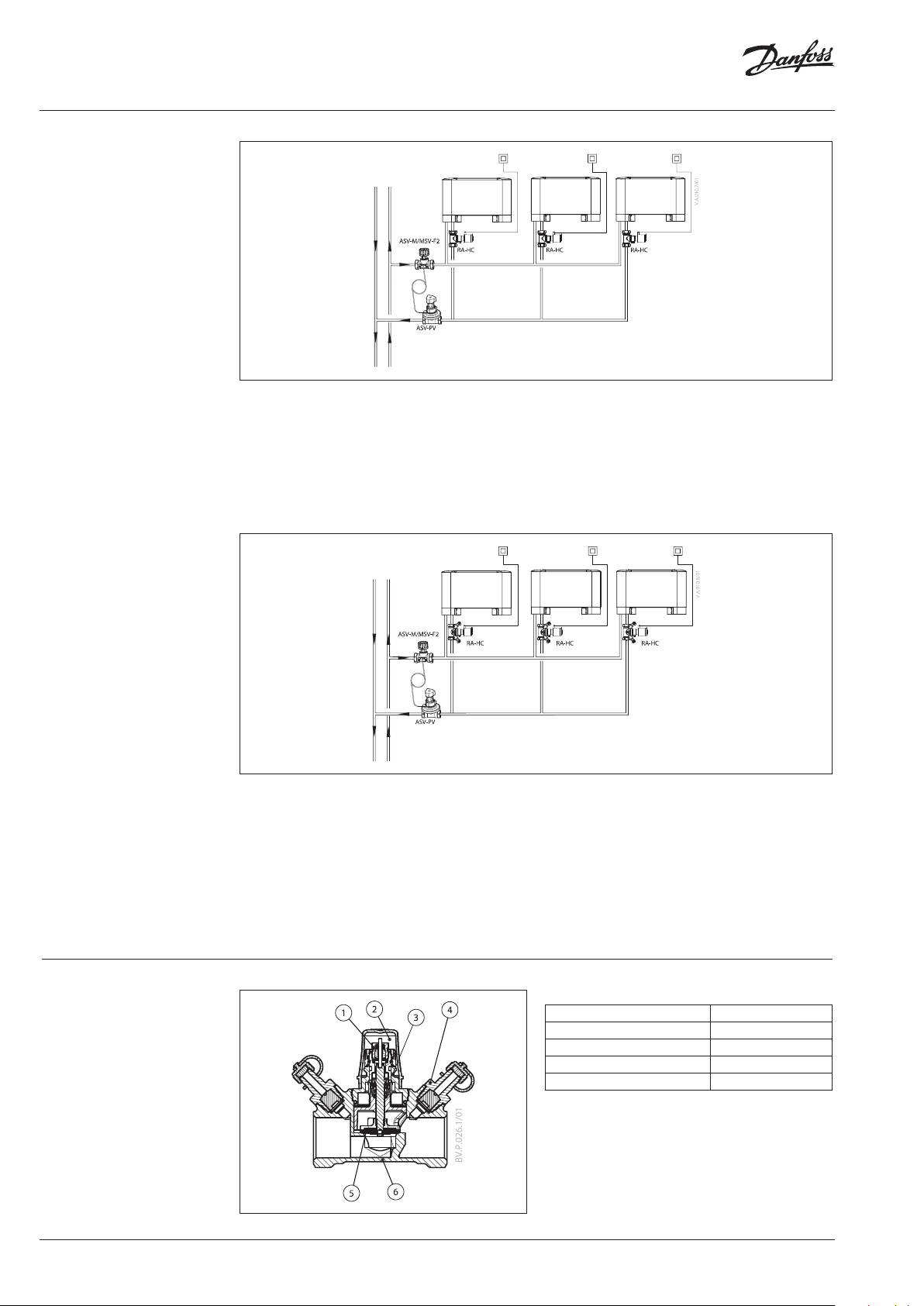

Design

1. Gland seal

2. Protection cap

3. Valve head

4. Test plugs

5. Sealing pad

6. Valve body

2 | AI175386404642en-000502

Materials in contact with flow medium

Valve body and other metal par ts DZR

Cone DZR

O-rings EPDM

Sealing pad NBR

kv-setting ring Ryton PPS

1)

Flow medium: water and water mixture s with secondary

coolants like gl ycols (regarding suitability an d usage especially

in not oxyge n tight systems please see the ins tructions given by

the coolant pro ducer) .

1)

© Danfoss | 2020.02

Page 3

Data sheet RA‑HC Valves for Control of Fan Coils and Terminal Units

Capacities

RA‑HC DN 15

© Danfoss | 2020.02

RA‑HC DN 20

RA‑HC DN 25

AI175386404642en-000502 | 3

Page 4

Data sheet RA‑HC Valves for Control of Fan Coils and Terminal Units

Presetting The calculated setting can be set easily and exactly

without using special tools:

• remove the protective cap or sensor element

• raise the setting ring

• turn the scale on the setting ring (anticlockwise)

until the required scale value faces the reference

mark *

• release the setting ring

* wthe fac tory setting of the val ve is N.

The presetting can be set at the values: 1-7 and N. At

setting N, the valve is completely open.

A setting in the shaded areas should be avoided.

When the sensor element is mounted, the presetting

is hidden, and is thus protected against alteration.

Settin g N = open valve

Presetting range

Pressure and Noise

Conditions

Dimensions

Special demands are made on the various

components of the system. This is due to water

temperature conditions, the chosen pipe types and

pipe dimensions of fancoils/induction units and the

structure of the cooling circuits.

In chilled ceilings and fancoils/induction-units

relatively large differential pressure and water flow are

often used compared to normal heating systems. This

may lead to noise nuisance.

1

H

D

S

L

1

Typ e Code no.

DN 15 003Z3931 G ⁄ 81 108 65.5 107 27

DN 20 003Z3910 G ⁄ 81 106 66 107 32

DN 25 003Z3911 G 1 91 112 66 107 41

DN 15 003Z3932 G ⁄ 81 - 65.5 107 27

DN 20 003Z3920

DN 25 003Z3921 G 1 91 - 66 107 41

1

H

S

D L

(inch) mm

G ⁄

The RA-HC valve has especially been designed to

correspond to these demands, no matter whether

self-acting or electronic controls are used.

L

2

2

H

D

L

1

L

1

81 - 66 107 32

H

2

H

1

S

2

4 | AI175386404642en-000502

© Danfoss | DHS-SRMT/SI | 2020.02

Loading...

Loading...