Page 1

OperatingGuide

ECLComfort310,applicationP318.21

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................6

2.1Beforeyoustart.....................................................6

2.2Electricalconnections..............................................8

3.0Dailyuse.........................................................12

3.1Understandingthecontrollerdisplay..........................12

3.2Descriptionoffunctions..........................................13

3.3Ageneraloverview:Whatdothesymbolsmean?...........14

3.4Navigation,ECLApplicationKeyP318.21......................15

4.0Settingsoverview............................................16

5.0Settings...........................................................17

5.1IntroductiontoSettings..........................................17

5.2Flowtemperature..................................................18

5.3Controlparameters(1)............................................19

5.4Flowmeter..........................................................22

5.5Application.........................................................23

6.0Commoncontrollersettings..............................24

6.1Introductionto‘Commoncontrollersettings’................24

7.0Appendix........................................................25

7.1Applicationupload................................................25

7.2Commissioning....................................................26

7.3Powerdown/power-up..........................................27

7.4Language...........................................................28

7.5ParameterIDoverview............................................29

©Danfoss|2020.12AQ356837161168en–010102|1

Page 2

OperatingGuideECLComfort310,applicationP318.21

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisOperatingGuideisassociatedwiththeECLApplication

KeyP318(codeno.087H3835)andisonlyfocusingonsubtype

P318.21.

FordetailedinformationaboutECLComfort310,handling,setting

etc.,pleaseseetheP318OperatingGuide.

P318.21runsanadvancedDomesticHotWater(DHW)temperature

control.Asoption,aheatingcircuitcanbecontrolled.

SeetheInstallationGuideforapplicationdiagramsandelectrical

connections.

Theapplicationdiagramsshowmandatorytemperaturesensors

withanunderscore;exampleS3.

ThedescribedfunctionsarerealizedinECLComfort310whichalso

allowsM-bus,ModbusandEthernet(Internet)communication.

TheApplicationKeyP318complieswithECLComfort310

controllersasoffirmwareversion1.11.Thefirmware(controller

software)isvisibleatstart-upofthecontrollerandin'Common

controllersettings'in'System'.

UptotwoRemoteControlUnits,ECA30orECA31,canbe

connected.

TheapplicationP318.21workswiththeadditionalInternalI/O

moduleECA35.

TheextensionmoduleECA35givesPWM(=PulseWidth

Modulation)signalforcontrolvalvesandON-OFFsignalfor

FlushingandHeatingcircuit.

Alternatively,ECA35gives0-10Voltsignalforcontrolvalves.

TheECLComfort310workswithoneECA35whichisplacedinthe

basepartoftheECLComfort310.

TogetherwiththeECLComfort310theadditionalInternalI/O

modulescanalsobeusedforextradatacommunicationtoSCADA:

•Temperature,Pt1000(default)

•0-10voltsignals

•Digitalinput

Theset-upofinputtypecanbedonebymeansoftheDanfoss

Software"ECLT ool"orfromtheECLPortal.

TheECLPortal(seehttps://ecl.portal.danfoss.com)isan

Internet-basedtoolformonitoringandremotecontrolofECL

controllers.

Documentation

Navigation:Danfoss.com>Products&Solutions>Products>

DistrictHeatingandCooling>Documentation>Tools&Software

>ECLTool.

TheURLis:

https://www.danfoss.com/en/service-and-support/downloads

ECLComfort310isavailableas:

•ECLComfort310,230volta.c.(codeno.087H3040)

•ECLComfort310B,230volta.c.(codeno.087H3050)

•ECLComfort310,24volta.c.(codeno.087H3044)

TheB-typehasnodisplayanddial.

2|©Danfoss|2020.12

AQ356837161168en–010102

Page 3

OperatingGuideECLComfort310,applicationP318.21

TheB-typeisoperatedbymeansoftheremotecontrolunit

ECA30/31:

•ECA30(codeno.087H3200)

•ECA31(codeno.087H3201)

InternalI/Omodules:

•ECA35(codeno.087H3205)

BasepartforECLComfort310,230voltand24volt:Codeno.

087H3230.

AdditionaldocumentationforECLComfort210and310,modules

andaccessoriesisavailableonhttp://heating.danfoss.com/.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

AQ356837161168en–010102

©Danfoss|2020.12|3

Page 4

OperatingGuideECLComfort310,applicationP318.21

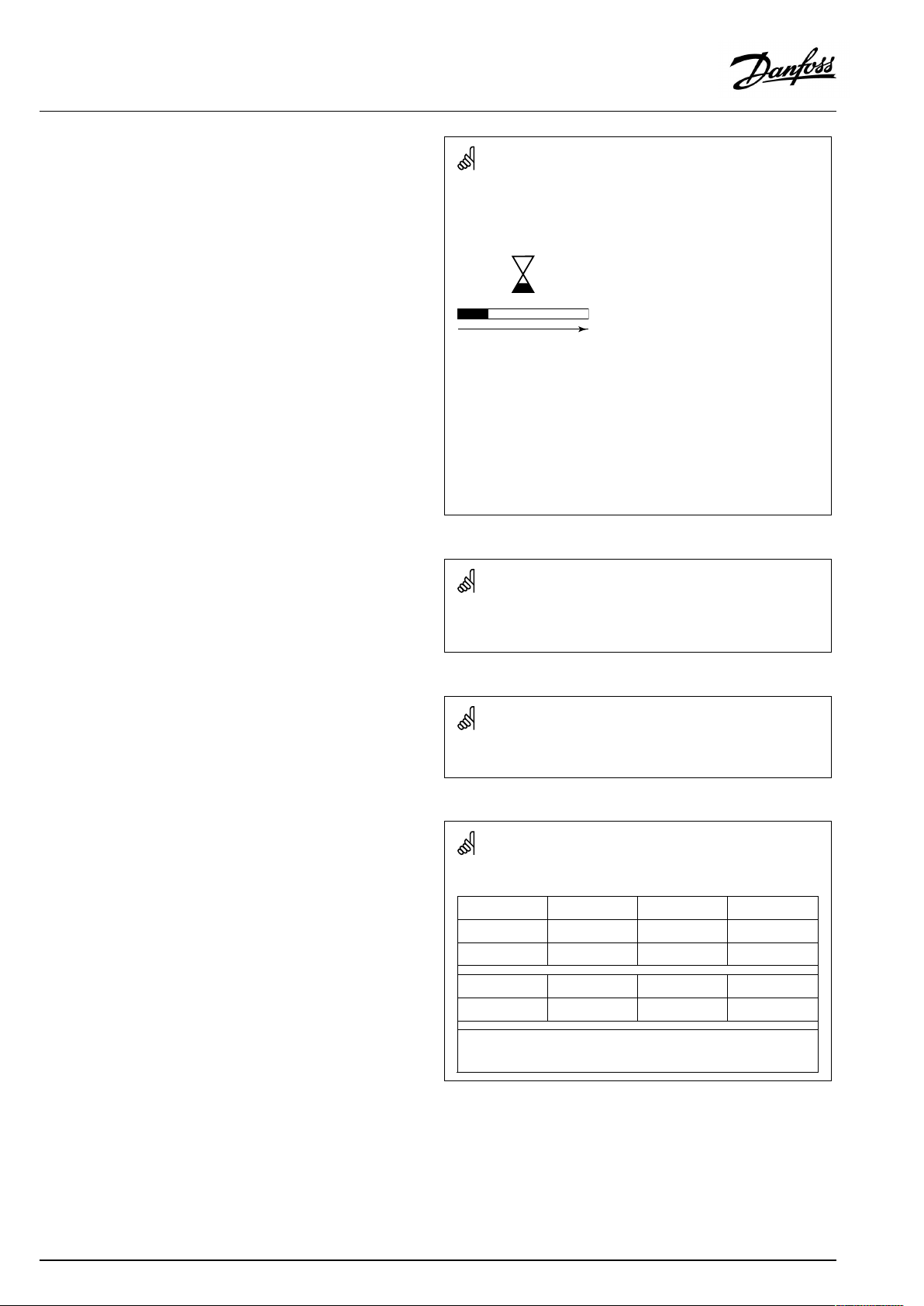

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter .

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

12174

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

1

-

Circuit1Parameterno.

2

Circuit2Parameterno.

174

4|©Danfoss|2020.12

AQ356837161168en–010102

Page 5

OperatingGuideECLComfort310,applicationP318.21

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DisposalNote

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

AQ356837161168en–010102

©Danfoss|2020.12|5

Page 6

OperatingGuideECLComfort310,applicationP318.21

2.0Installation

2.1Beforeyoustart

Description,ingeneral

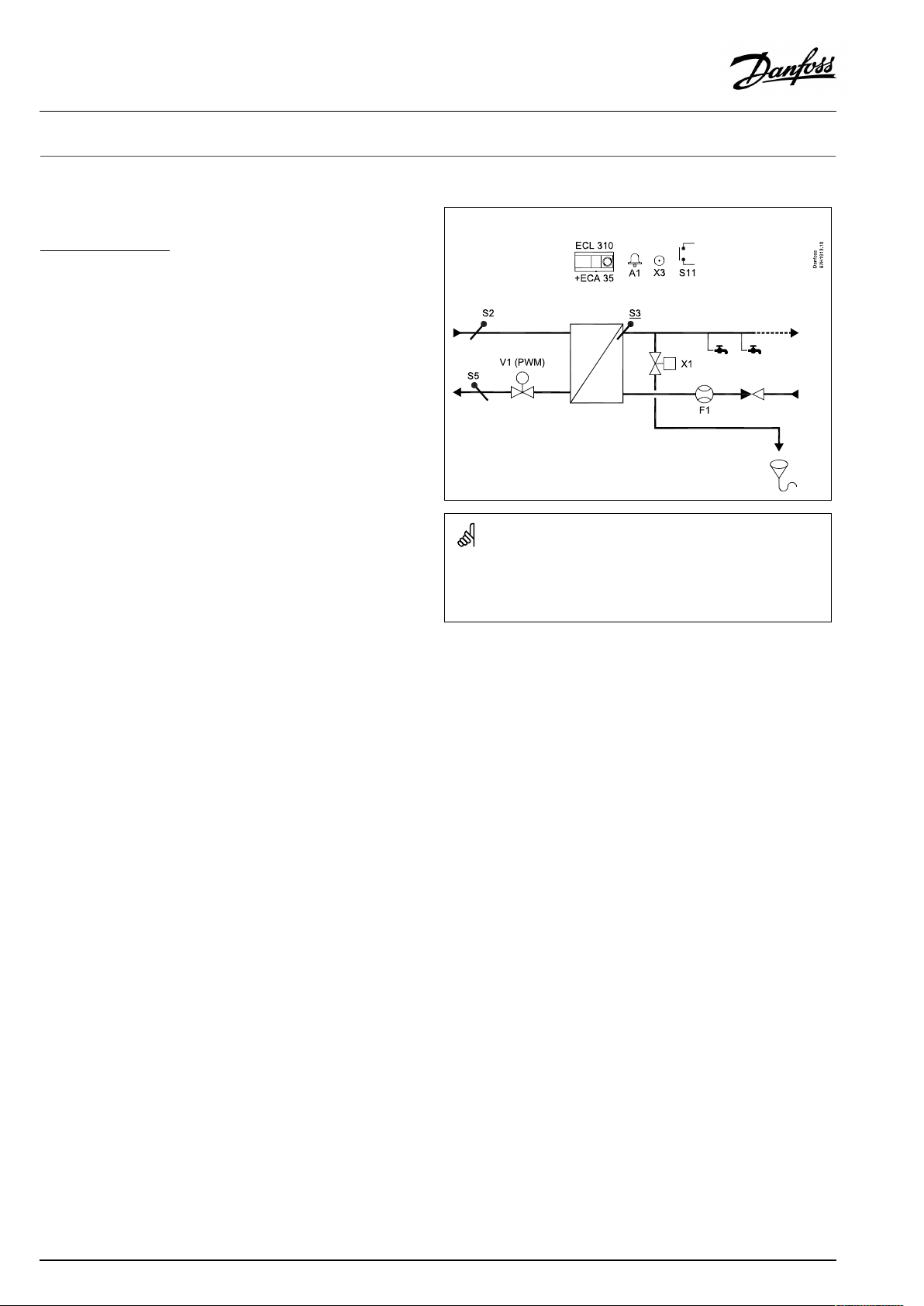

SubtypeP318.21ex.a

ControloftheflowtemperatureinanindirectlyheatedDHW

(DomesticHotWater)system.ThetemperaturesensorS3mustbe

connectedandthetemperaturecontrolis,amongothers,basedon

theflowsignalfromflowmeterF1.ThisflowispresentwhenDHW

istakenfromthetap.Thecontrolvalveisoperatedbyastepper

motorviatheV1output,whichisaPWMsignal.Withcontrolby

meansofasteppermotor(=quickoperating),thecontrolvalve

controlstheflowforcorrecttemperatureatS3.

ThemeasuredtemperatureatS2canchangetheXpvalue

(proportionalband)foroptimumDHWtemperaturecontrol.

ReturntemperatureS5isformonitoringonly.

ABypassfunctioncanmaintainadesiredtemperatureatS2.This

helpstoreducetheheat-uptimeforDHWifDHWhasnotbeen

takenfromthetapforalongertime.

BasedonthemeasuredtemperatureatS2,thecontrolvalve

V1canbeopenedperiodicallytoasetposition.ECLawaitsthe

temperaturetoreachasettemperatureandV1closesagain.A

schedule("Schedule,bypass")canbesetforhavingBypassactive

insetperiods.

Aflushfunction,activatinganON-OFFvalveviaoutputX1,can

avoidtheheatexchangertobetoowarmwhennoDHWistaken

fromthetap.

P318.21,ex.a:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller .

Listofcomponents:

ECL310

ECA35

S2

S3

S5

S11

F1

V1

X1

X3

A1

ECLComfort310controller

Extensionmodule,placedinthebasepartof

ECL310

Supplytemperaturesensor(usedforBypass

functionandcompensatedXp)

(mandatory)DHWtemperaturesensor

Returntemperaturesensor(monitoringpurpose

only)

Input(potentialfree)forroomthermostat,

seeex.b

Flowsensor(connectedtoS7)

Actuator,PWMcontrolled,forcontrolvalve

ON-OFFflushvalve

Seeexampleb

Alarm

6|©Danfoss|2020.12

AQ356837161168en–010102

Page 7

OperatingGuideECLComfort310,applicationP318.21

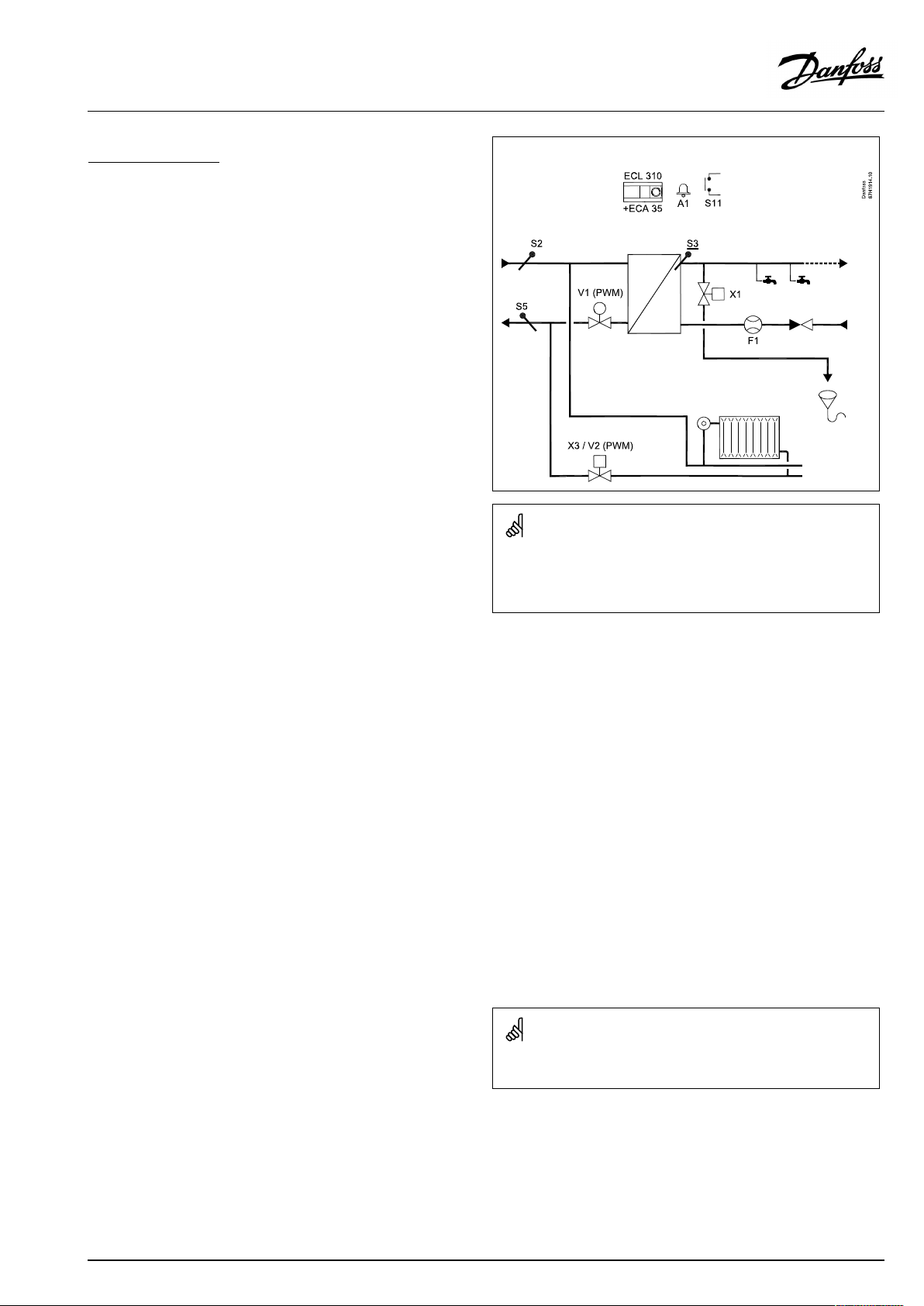

SubtypeP318.21ex.b

Inadditiontothedescriptionofexamplea,thesubtypecan

furthermorecontrolaheatingcircuit.

TheON-OFFvalveX3(=solenoidvalve=magneticvalve)is

operatedbyeithertheX3outputortheV2output,whichisthe

PWMsignalforcontrolofasteppermotor.Inthiscasethestepper

motoreitherfullyopensorclosestheX3valve.

Theweekschedule("Schedule")determinestheperiods(Comfort)

wheretheheatingcircuitisswitchedin.

Aroomthermostat,potentialfree(=voltfree)connectedatinput

S11,canalsoswitchintheheatingif"Schedule"isinSavingmode.

Theheatingcircuitisswitchedoff(=closed)duringDHWheating.

P318.21,ex.b:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller .

Listofcomponents:

ECL310

ECA35

ECLComfort310controller

Extensionmodule,placedinthebasepartof

ECL310

S2

Supplytemperaturesensor(usedforBypass

functionandcompensatedXp)

S3

S5

(mandatory)DHWtemperaturesensor

Returntemperaturesensor(monitoringpurpose

only)

S11

F1

V1

V2

X1

X3

A1

Input(potentialfree)forroomthermostat

Flowsensor(connectedtoS7)

Actuator,PWMcontrolled,forcontrolvalve

Actuator,PWMcontrolled,forheatingON-OFF

ON-OFFflushvalve

OutputforheatingON-OFF .AlternativetoV2

Alarm

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

AQ356837161168en–010102

©Danfoss|2020.12|7

Page 8

OperatingGuideECLComfort310,applicationP318.21

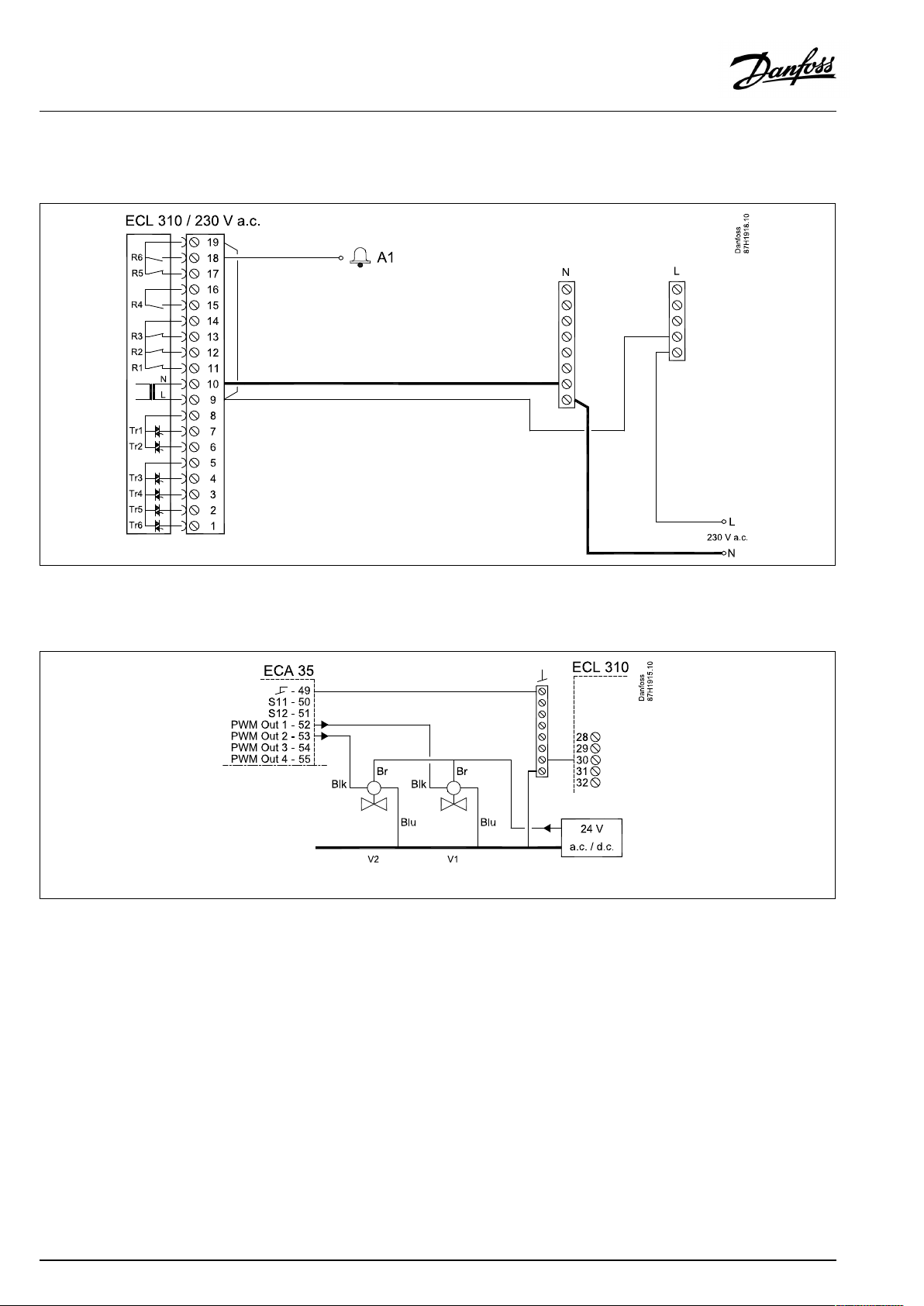

2.2Electricalconnections

ECL310,powersupplyandalarmconnections

ECA35,outputconnections

V1,V2

Blk=Black,Blu=Blue,Br=Brown

8|©Danfoss|2020.12

AQ356837161168en–010102

Page 9

OperatingGuideECLComfort310,applicationP318.21

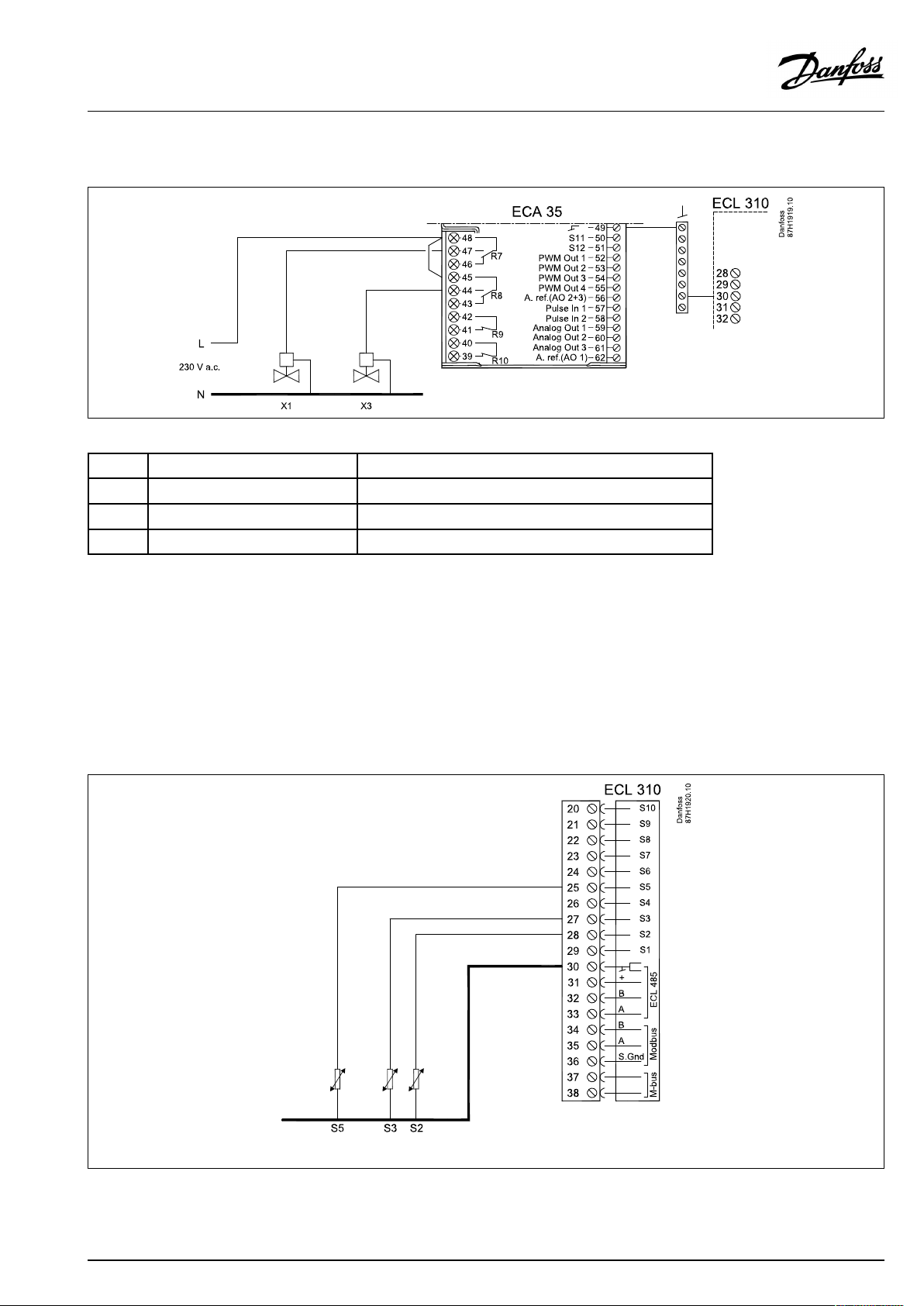

ECA35,outputconnections

X1,X3

Sensor

S2

S3

S5Returntemperaturesensor

*)

Theflowtemperaturesensormustalwaysbeconnectedinordertohavethedesiredfunctionality.

Ifthesensorisnotconnectedorthecableisshort-circuited,themotorizedcontrolvalvecloses(safetyfunction).

**)

ThesupplytemperaturesensormustbeconnectedforenablingtheBypassfunction.

ECL310,inputconnections

S2,S3,S5

Description

Supplytemperaturesensor**ESM-11,ESMB,ESMC,ESMU(allPt1000types)

Flowtemperaturesensor*

Recommendedtype

ESMU(Pt1000type)

ESM-11,ESMB,ESMC,ESMU(allPt1000types)

Note:S3mustbeconnected

AQ356837161168en–010102

©Danfoss|2020.12|9

Page 10

OperatingGuideECLComfort310,applicationP318.21

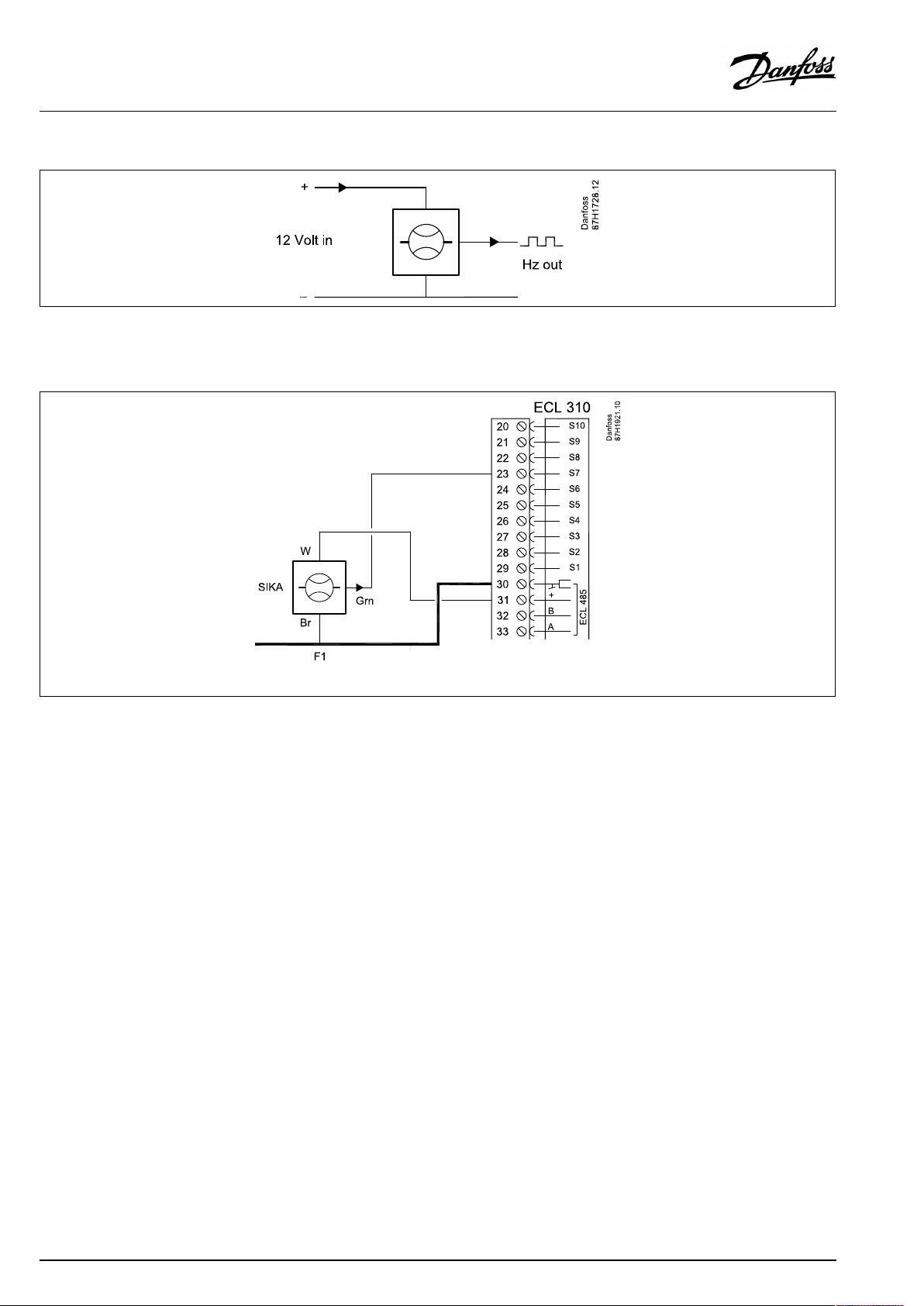

Flowsensor,F1

ECL310,inputconnections

FlowsensorconnectiontoS7

Br=Brown,Grn=Green,W=White

10|©Danfoss|2020.12

AQ356837161168en–010102

Page 11

OperatingGuideECLComfort310,applicationP318.21

ECA35,Inputconnections

S11

Inputconnections,ECA35

S11(Roomthermostat)

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

SafetyNote

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocablesize

andisolation(reinforcedtype).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangefortheECLComfortinoperationis

0-55°C.Exceedingthistemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

AQ356837161168en–010102

©Danfoss|2020.12|11

Page 12

OperatingGuideECLComfort310,applicationP318.21

3.0Dailyuse

3.1Understandingthecontrollerdisplay

Favoritedisplay1:

20.10.2020:

46.3:

16.51

50°C:

Favoritedisplay2:

V1:

X1:

V2:

X3:

54°C:

(--):

46°C:

(--):

Date

ActualDHWtemp.atS3

Actualtime

DesiredDHWtemp.

Openingin%ofV1

Flushactivity;shownOFF

HeatingvalveON-OFFcontrol

(0%=closed,100%=open)

HeatingvalveON-OFFcontrol;

shownON

Supplytemp.S2

Desiredbypasstemp.

DHWtemp.S3

(heatexchangertemp.)

DesiredDHWtemp.

40°C:

0.0l/h

Thedisplayisupdatedevery5thsecond.

WhenoperatingtheECLwiththedial,thedisplayis

immediatelyupdated.

Settingsandnavigationinmenus:

SeesectionsNavigationandSettings

Returntemp.S5

Actualwaterflow

Theindication(--)showsthatthe

relatedfunctionisnotactive.

12|©Danfoss|2020.12

AQ356837161168en–010102

Page 13

OperatingGuideECLComfort310,applicationP318.21

3.2Descriptionoffunctions

DHWtemperaturecontrol

DesiredDHWtemperatureissetintheFavoritedisplay1,

forexample50°C.

Thecold-waterflowsignalfromF1isusedtooptimizetheDHW

temperaturecontrol.

Thispro-activefunctionalitycompensatesforthedelaybeforethe

flowtemperaturesensorS3measuresachangeintemperature.

Bypassfunction

Forhavinganacceptabletemperature(supplytemperature)

presentattheinstallation,theBypassfunctionisusefulfor

minimizingtheDHWheat-uptime.

ThesupplytemperaturesensorS2isusedfortheBypassfunction.

AdesiredtemperaturefortheBypassfunctioncanbeset.

Furthermore,aweekschedule("Schedule,bypass")canbesetto

activatetheBypassinsetperiods.

(Navigation:MENU>Schedule,bypass)

Flushfunction

ThisfunctionisactiveonlyifnoDHWistakenfromthetap.

IfthetemperatureatS3getshigherthan"DHWmax.T" ,theFlush

isactivated(=X1opens)inperiods,setby"Delay" .

TheECLawaitstheS3temperaturetodrop,andFlushis

de-activatedwhentheS3temperatureis"DHWmax.diff"below

"DHWmax.T".

TheFlushfunctioncanbedisabledbysetting"DHWmax.T"toOFF .

Alarm

Analarmfunctionisonlyimplementedforsensorconnections.

SeetheP318OperatingGuidefordetails.

Flowsensor

SIKAVTY20flowsensorintheCWlinehasapulserateof119pulses

/liter.Theflowrangeis1...60l/min.Theflowsignal(pulses)is

senttotheECLforcontrollingtheDHWtemperatureatS3.

Steppermotorindicationsfromclosedtoopenposition

•redtriangle=fullyclosed(0%)

•redtriangle+bluerectangle

•bluerectangle

•bluerectangle+yellowcircle

•yellowcircle=fullyopened(100%)

Settingsfordailyuse

Normally,thesetvalueforDHWtemperatureissetonce.

AQ356837161168en–010102

©Danfoss|2020.12|13

Page 14

OperatingGuideECLComfort310,applicationP318.21

3.3Ageneraloverview:Whatdothesymbolsmean?

Symbol

Description

Outdoortemp.

Relativehumidityindoor

Roomtemp.

DHWtemp.

Positionindicator

Scheduledmode

Comfortmode

Savingmode

Frostprotectionmode

Manualmode

Standby

Coolingmode

Symbol

Temperature

Mode

Description

Alarm

Letter

Event

Monitoringtemperaturesensor

connection

Displayselector

Max.andmin.value

Trendinoutdoortemperature

Windspeedsensor

Sensornotconnectedornotused

Sensorconnectionshort-circuited

Fixedcomfortday(holiday)

Activeinfluence

Heatingactive(+)

Coolingactive(-)

Activeoutputoverride

Optimizedstartorstoptime

Heating

Cooling

DHW

Commoncontrollersettings

PumpON

PumpOFF

FanON

FanOFF

Actuatoropens

Actuatorcloses

Actuator,analoguecontrol

signal

Pump/fanspeed

DamperON

Circuit

Controlled

component

Numberofheatexchangers

Additionalsymbols,ECA30/31:

Symbol

InECA30/31onlythesymbolsthatarerelevanttotheapplicationin

thecontrolleraredisplayed.

Description

ECARemoteControlUnit

Connectionaddress(master:15,slaves:1-9)

15

Dayoff

Holiday

Relaxing(extendedcomfortperiod)

Goingout(extendedsavingperiod)

14|©Danfoss|2020.12

DamperOFF

AQ356837161168en–010102

Page 15

OperatingGuideECLComfort310,applicationP318.21

3.4Navigation,ECLApplicationKeyP318.21

Navigation(1)

Menu

Schedule

Schedule,bypass

Settings

InfluenceoverviewInfoifBypassisactive

WeekscheduleforHeatingcircuit

WeekscheduleforBypassfunction

AQ356837161168en–010102

©Danfoss|2020.12|15

Page 16

OperatingGuideECLComfort310,applicationP318.21

4.0Settingsoverview

Forfactorysettingsandsettingrange,seeappendix“ParameterIDoverview” .

ParametersindicatedwithanIDno.like"1x607"meanauniversalparameter.xstandsforcircuit/parametergroup.

Xpactual

"Emptyline”

BYPASS

Awaittime

Actual

DHWdeact.time

Delay

SupplyT(idle)

Pulse

Units

Voutmax.

Reverseout

Tn

Nz

Td

Wakeuplevel

Level

CWinfluence

Controldelay

SenddesiredT

DHWmax.T

DHWmax.diff.

SettingIDPage

1104518

1108018

1109720

11114

11115

1116519

11171

1118519

1118719

1119719

1133021

1135320

1135420

1136421

1150023

1158018

1158118

Factorysettingsincircuit(s)

1

19

20

20

21

22

22

22

20

16|©Danfoss|2020.12

AQ356837161168en–010102

Page 17

OperatingGuideECLComfort310,applicationP318.21

5.0Settings

5.1IntroductiontoSettings

Settings

Flowtemperature

Controlpar.1

Flowmeter

Application

Flushfunctionrelatedsettings

ParametersforDHWtemp.controlandBypassfunction

Parametersrelatedtoflowsensor

UsediftheECLisasub-controllerinanECLsystem

AQ356837161168en–010102

©Danfoss|2020.12|17

Page 18

OperatingGuideECLComfort310,applicationP318.21

5.2Flowtemperature

(Flushfunctionrelatedsettings)

MENU>Settings>Flowtemperature

DHWmax.T

SeeAppendix“ParameterIDoverview”

OFF:

Value:

Flushfunctionisdisabled

FlushfunctionisenabledifDHWtemp.atS3isabove

setvalue.

MENU>Settings>Flowtemperature

DHWmax.diff.

FlushfunctionisstoppedwhenDHWtemp.atS3getsbelow"DHWmax.T"

+setvalue.

SeeAppendix“ParameterIDoverview”

Example:

DHWmax.T=40°C,DHWmax.diff=-4K.

Result:FlushstopswhenDHWtemp.atS3getsbelow

36°C.

MENU>Settings>Flowtemperature

Delay

FlushstartsinintervalswithsetvaluewhenDHWtemp.atS3isabove"DHW

max.T"

11580

11581

11080

SeeAppendix“ParameterIDoverview”

MENU>Settings>Flowtemperature

DHWdeact.time

DHWdeactivationtime

SeeAppendix“ParameterIDoverview”

OFF:

Deactivationdisabled.

Flushingisaccordingto"DHWmax.diff."and"Delay" .

IftheDHWtemp.atS3doesnotgetbelow"DHW

max.T",flushisautomaticallystoppedafter100sec.

Value:

Flushingtime.DHWheatingisdeactivatedafterflush

hasstartedaccordingto"DHWmax.T"andsettime.

11045

18|©Danfoss|2020.12

AQ356837161168en–010102

Page 19

OperatingGuideECLComfort310,applicationP318.21

5.3Controlparameters(1)

MENU>Settings>Controlparameters(1)

Xpactual

Read-outoftheactualXp(proportionalband)basedonthesupply

temperatureS2.

SeeAppendix“ParameterIDoverview”

Xpisdeterminedbysettingsrelatedtothesupplytemperature.

Typically,thehigherthesupplytemperature,thehighertheXp

mustbetogetastabletemperaturecontrol.

ClickthemenuandseethescaleforXpat50and90°C.

Changesettingsifrequired.

IfthesupplytemperaturesensorS2isnotconnected,theXpvalue

isthevaluesetat50°C.

MENU>Settings>Controlparameters(1)

Tn

Integrationtime

11185

SeeAppendix“ParameterIDoverview”

Setahighintegrationtimeconstant(inseconds)toobtainaslow,

butstablereactiontotemperaturedeviations.

Alowintegrationtimeconstantwillmakethecontrollerreactfast,

butwithlessstability.

MENU>Settings>Controlparameters(1)

Td

Timederivative(Differentiationtime).

TheTdrelatedfunctioncanavoidatooaggressivereactioninthe

temperaturecontrol.

11197

SeeAppendix“ParameterIDoverview”

0:

Noinfluence

Lowvalueswillcauseminorinfluence,whereashigh

valueswillcausemajorinfluence.

MENU>Settings>Controlparameters(1)

Nz

Neutralzone.

SymmetricallytemperaturebandarounddesiredS3temperature.

WhentheS3temperatureisinsidetheNeutralzonetheregulationmakesno

changeoftheV1position.

SeeAppendix“ParameterIDoverview”

AQ356837161168en–010102

11187

©Danfoss|2020.12|19

Page 20

OperatingGuideECLComfort310,applicationP318.21

MENU>Settings>Controlparameters(1)

Voutmax.

Settingthemaximumopeningofthecontrolvalve.

SeeAppendix“ParameterIDoverview”

MENU>Settings>Controlparameters(1)

Reverseout

SeeAppendix“ParameterIDoverview”

NO:

Controlsignal(%)risesformoreopeningofthecontrol

valve.

YES:

Controlsignal(%)fallsformoreopeningofthecontrol

valve.

MENU>Settings>Controlparameters(1)

CWinfluence

Cold-Waterinfluence.

Thecold-waterflowsignalfromF1optimizestheDHWtemperaturecontrol.

Thevalueexpresseshowmany%of100liters/hourwilldoaninfluenceon

themotorizedcontrolvalve.

Lowvalueswillcauseminorinfluence,whereashighvalueswillcausemajor

influence.

11165

11171

11354

SeeAppendix“ParameterIDoverview”

MENU>Settings>Controlparameters(1)

Level

Changeinwaterflowmorethansetvaluewillmakefurtheractivationof

thecontrolvalve.

SeeAppendix“ParameterIDoverview”

MENU>Settings>Controlparameters(1)

"Emptyline”

MENU>Settings>Controlparameters(1)

BYPASS

(groupheadlineonly)

11353

20|©Danfoss|2020.12

AQ356837161168en–010102

Page 21

OperatingGuideECLComfort310,applicationP318.21

MENU>Settings>Controlparameters(1)

SupplyT(idle)

SeeAppendix“ParameterIDoverview”

OFF:

Bypassfunctionisdisabled.

Value:DesiredtemperaturetobemaintainedatS2.

MENU>Settings>Controlparameters(1)

Wakeuplevel

The%-valuereflectshowmuchV1opensthecontrolvalveatBypass.

Thecontrolvalvemustbeopenedproperlytoensureanacceptablewater

flowinthesupplypipe;readjustthesetting,ifneeded.

SeeAppendix“ParameterIDoverview”

MENU>Settings>Controlparameters(1)

Controldelay

SeeAppendix“ParameterIDoverview”

OFF:

V1opensthecontrolvalvewhenthetemperature

getsmorethan5Kbelow"SupplyT(idle)" .

V1closesthecontrolvalvewhenthetemperature

getsabove"SupplyT(idle)" .

ON:

Adaptiveadjustment.

Anadaptivefunctiondetectstheprogressofthe

supplytemperatureandmakeschangeoftheperiod

(Awaittime)betweentwoBypassactivities.

11097

11330

11364

MENU>Settings>Controlparameters(1)

Awaittime

Read-outvalue

Validonlywhen"Controldelay"issettoON.Itindicatesthenumberof

minutesthecontrolvalveisclosedbetweentwoBypass-basedopenings.

SeeAppendix“ParameterIDoverview”

Initialtimeatpower-upis15minutes.Iftimegetshigher,the

settingof"Wakeuplevel"shouldbeincreasedorthesettingof

"SupplyT(idle)"shouldbedecreased.

CalculatedAwaittimecannotberesetto15minuteswithout

re-poweringtheECL.

AQ356837161168en–010102

©Danfoss|2020.12|21

Page 22

OperatingGuideECLComfort310,applicationP318.21

5.4Flowmeter

MENU>Settings>Flowmeter

Actual

Read-outofactualflowintheColdWaterflowsensor.

Thevalueisbasedonappliedpulsesignalandthesettings"Pulse"and

"Units".

SeeAppendix“ParameterIDoverview”

MENU>Settings>Flowmeter

Pulse

Numberofpulsesfor1milli-literor1literofwaterflowthroughflowsensor

F1.

SeeAppendix“ParameterIDoverview”

MENU>Settings>Flowmeter

Units

SeeAppendix“ParameterIDoverview”

ml,l/h:

Numberofpulses("Pulse")representsoneml;

flowread-outinl/h

l,l/h:

Numberofpulses("Pulse")representsonel;

flowread-outinl/h

ml,m3/h:

Numberofpulses("Pulse")representsoneml;

flowread-outinm3/h

l,m3/h:

Numberofpulses("Pulse")representsonel;

read-outinm3/h

11114

11115

22|©Danfoss|2020.12

AQ356837161168en–010102

Page 23

OperatingGuideECLComfort310,applicationP318.21

5.5Application

MENU>Settings>Application

SenddesiredT

WhentheECLactsasaslavecontrollerinamaster/slavesystem,

informationaboutthedesiredflowtemperaturecanbesenttothemaster

controllerviatheECL485bus.

SeeAppendix“ParameterIDoverview”

OFF:

Informationaboutthedesiredflowtemperatureisnot

senttothemastercontroller.

ON:

Informationaboutthedesiredflowtemperatureissent

tothemastercontroller.

11500

AQ356837161168en–010102

©Danfoss|2020.12|23

Page 24

OperatingGuideECLComfort310,applicationP318.21

6.0Commoncontrollersettings

6.1Introductionto‘Commoncontrollersettings’

Navigationto"Commoncontrollersettings":

MENU(1)>Circuit1>Commoncontroller.

SeetheOperatingGuideforP318fordescriptioningeneral.

CommonController

Time&Date

Inputoverview

Log

Outputoverride

KeyfunctionsInfoaboutapplications.Copyfunctions

System

SettingTimeanddate

Actualvaluesfor:

DHWflowtemp.

Primaryreturntemp.

Supplytemp.

Logfeaturesfor:

DHWflowtemp.

Primaryreturntemp.

Supplytemp.

Overridepossibilityforselectedoutputs:

V1,X1,V2,X3,A1

Furthersystemrelatedinfoandcommunicationsettings

24|©Danfoss|2020.12

AQ356837161168en–010102

Page 25

OperatingGuideECLComfort310,applicationP318.21

7.0Appendix

7.1Applicationupload

Theapplicationuploadprocedureisthefollowingafterhaving

powereduptheECLComfortcontroller:

1.InserttheapplicationkeyP318

2.Selectlanguage.Info:Seesection7.4,Language

3.SelectsubtypeP318.21

4.SetTimeandDate

TheECLComfortcontrollerinstallstheapplication,initializesand

restarts.Outputrelaysareactivated/de-activated(click-sounds

fromthiscanbeheard).Thisalsomeansthat,forexample,Flush

andHeatingvalvecanbeswitchedONandOFFshortly.

AQ356837161168en–010102

©Danfoss|2020.12|25

Page 26

OperatingGuideECLComfort310,applicationP318.21

7.2Commissioning

WhentheP318.21applicationhasbeenuploadedtheECLComfort

controllerstartsinManualmode.Thiscanbeusedtoverifycorrect

connectionsoftemperatureandflowsensors.Alsoverifyingthe

controlledcomponents(valveactuators)forcorrectfunctionality

canbedone.

Theapplicationkeyisdeliveredwithfactorysettings.

Dependingonsystemtype,itmightbenecessarytochangesome

factorysettingsindividuallyinordertooptimizethefunctionality.

Theapplicationkeymustbeinsertedinordertochangesettings.

26|©Danfoss|2020.12

AQ356837161168en–010102

Page 27

OperatingGuideECLComfort310,applicationP318.21

7.3Powerdown/power-up

WhenthepowersupplytotheECLComfortcontrolleris

disconnected(powerdown),theoutputrelaysgotode-activated

position.

Thismeansthat,forexample,valveactuatorscanbeswitchedON.

SeetheelectricalconnectiondiagramsintheInstallationGuide.

Allrelaycontactsareshowninde-activatedsituation.Somerelay

contactsareclosed,somerelaycontactsareopen.

WhenthepowersupplytotheECLComfortcontrolleris

re-established(power-up),theoutputrelaysareactivated/

de-activated(click-soundsfromthiscanbeheard).Thisalsomeans

that,forexample,valveactuatorscanbeswitchedONandOFF

shortly.

AQ356837161168en–010102

©Danfoss|2020.12|27

Page 28

OperatingGuideECLComfort310,applicationP318.21

7.4Language

Language

Atapplicationupload,alanguagemustbeselected.*

IfanotherlanguagethanEnglishisselected,theselectedlanguage

ANDEnglishwillbeuploadedintotheECLcontroller.

ThismakesserviceeasyforEnglishspeakingservicepeople,just

becausetheEnglishlanguagemenuscanbevisiblebychanging

theactualsetlanguageintoEnglish.

(Navigation:MENU>Commoncontroller>System>Language)

Iftheuploadedlanguageisnotsuitable,theapplicationmustbe

erased.UserandSystemsettingscanbesavedontheapplication

keybeforeerasing.

Afternewuploadwithpreferredlanguage,theexistingUserand

Systemsettingscanbeuploaded.

*)

(ECLComfort310,24Volt)Iflanguagecannotbeselected,the

powersupplyisnota.c.(alternatingcurrent).

28|©Danfoss|2020.12

AQ356837161168en–010102

Page 29

OperatingGuideECLComfort310,applicationP318.21

7.5ParameterIDoverview

P318.x—xreferstothesubtypeslistedinthecolumn.

IDParameterNameP318.xSettingrangeFactoryUnitOwnsettings

11045DHWdeact.time21OFF ,1...250OFFSec

11080Delay212...20045Min

11097SupplyT(idle)21OFF ,10...100OFF°C

11114Pulse211...9999119

11115Units21

11165Voutmax.1,2,5,10,11,210...100100%

11171Reverseout1,2,5,10,11,21NO;YESNO

Xp215...25045/45K

11185Tn21OFF ,1...99910Sec

11187Nz10,11,210...91K

11197Td210.0...25.00.0Sec

11330Wakeuplevel210...1000%

11353Level210...25020l/h

11354

11364Control,delay21

11500SenddesiredT1,2,5,10,11,21

11580DHWmax.T21OFF,10...11040°C

11581

CWinfluence

DHWmax.diff.

21

21-20...-1

ml,l/h;l,l/h;ml,

m3/h;l,m3/hl,l/h

OFF,0.1...100.0

OFF;ONON

OFF;ONON

7.0%

-4

K

AQ356837161168en–010102

©Danfoss|2020.12|29

Page 30

OperatingGuideECLComfort310,applicationP318.21

Installer:

By:

Date:

30|©Danfoss|2020.12

AQ356837161168en–010102

Page 31

OperatingGuideECLComfort310,applicationP318.21

*087H9333*

AQ356837161168en–010102

2020.12|©Danfoss|31

Loading...

Loading...