Page 1

OperatingGuide

ECLComfort310,applicationP318

1.0TableofContents

1.0TableofContents...............................................1

1.1Importantsafetyandproductinformation.....................2

2.0Installation........................................................6

2.1Beforeyoustart.....................................................6

2.2Identifyingthesystemtype......................................29

2.3Mounting...........................................................30

2.4Placingthetemperaturesensors................................34

2.5Electricalconnections.............................................36

2.6InsertingtheECLApplicationKey..............................44

2.7Checklist............................................................50

2.8Navigation,ECLApplicationKeyA318.........................51

3.0Dailyuse.........................................................67

3.1Howtonavigate...................................................67

3.2Understandingthecontrollerdisplay..........................68

3.3Ageneraloverview:Whatdothesymbolsmean?...........69

3.4Monitoringtemperaturesandsystem

components........................................................70

3.5Influenceoverview................................................71

3.6Manualcontrol.....................................................72

3.7Schedule............................................................73

7.0Commoncontrollersettings............................114

7.1Introductionto‘Commoncontrollersettings’..............114

7.2Time&Date.......................................................115

7.3Inputoverview...................................................116

7.4Log.................................................................117

7.5Outputoverride..................................................118

7.6Keyfunctions.....................................................119

7.7System.............................................................121

8.0Miscellaneous................................................128

8.1ECA30/31setupprocedures.................................128

8.2Overridefunction................................................136

8.3Severalcontrollersinthesamesystem......................139

8.4Frequentlyaskedquestions....................................142

8.5Definitions........................................................144

8.6Type(ID6001),overview.......................................148

8.7Automatic/manualupdateoffirmware.....................149

8.8ParameterIDoverview..........................................150

4.0Settingsoverview............................................74

5.0Settings...........................................................76

5.1IntroductiontoSettings..........................................76

5.2Tanktemperature..................................................77

5.3X3control...........................................................81

5.4Flowtemperature..................................................82

5.5Returnlimit.........................................................84

5.6Controlparameters................................................88

5.7Flowmeter..........................................................97

5.8Application.........................................................99

5.9Anti-bacteria......................................................101

6.0Event.............................................................103

6.1IntroductiontoEvent...........................................103

6.2ChargeT...........................................................104

6.3DHWflowT.......................................................106

6.4Tanktemperature................................................108

6.5SupplyT...........................................................110

6.6Anti-bacteria......................................................111

6.7Tsensordefect...................................................112

6.8Eventoverview...................................................113

©Danfoss|2018.09VI.JM.Q5.02|1

Page 2

OperatingGuideECLComfort310,applicationP318

1.1Importantsafetyandproductinformation

1.1.1Importantsafetyandproductinformation

ThisOperatingGuideisassociatedwiththeECLApplicationKey

P318(codeno.087H3835).

TheECLApplicationKeyP318forDomesticHotWater(DHW)

temperaturecontrolcontains4subtypes:

•P318.1,bufferbasedtemperaturecontrol

•P318.2,bufferandmixingbasedtemperaturecontrol

•P318.10,advancedtemperaturecontrol

•P318.11,temperaturecontrolledflowsystemwithlayercontrol

andbuffercharging

SeetheInstallationGuideforapplicationdiagramsandelectrical

connections.

Theapplicationdiagramsshowmandatorytemperaturesensors

withanunderscore;exampleS3.

ThedescribedfunctionsarerealizedinECLComfort310whichalso

allowsM-bus,ModbusandEthernet(Internet)communication.

TheApplicationKeyP318complieswithECLComfort310

controllersasoffirmwareversion1.11.Thefirmware(controller

software)isvisibleatstart-upofthecontrollerandin'Common

controllersettings'in'System'.

UptotwoRemoteControlUnits,ECA30orECA31,canbe

connected.

TheapplicationP318workswithadditionalInternalI/Omodules:

•TheextensionmoduleECA32gives0-10Voltsignalforspeed

controlofcontrolpump,chargingpumpandcirculationpump.

•TheextensionmoduleECA35gives0-10Voltsignalforspeed

controlofcontrolpump,chargingpumpandcirculationpump.

ECA35canalsogivePWM*signalforspeedcontrolofthe

abovelistedpumptypes.

Apumpcanalsobeconsideredasacirculator.

TheECLComfort310workswitheitheroneECA32oroneECA

35.TheInternalI/Omoduleinquestionisplacedinthebasepart

oftheECLComfort310.

*PWM=PulseWidthModulation

TogetherwiththeECLComfort310theadditionalInternalI/O

modulescanalsobeusedforextradatacommunicationtoSCADA:

•Temperature,Pt1000(default)

•0-10voltsignals

•Digitalinput

Theset-upofinputtypecanbedonebymeansoftheDanfoss

Software"ECLTool".

Navigation:Danfoss.com>Products&Solutions>Products>

DistrictHeatingandCooling>Documentation>Tools&Software

>ECLTool.

TheURLis:https://www.danfoss.com/en/service-and-

support/downloads

ECLComfort310isavailableas:

•ECLComfort310,230volta.c.(codeno.087H3040)

•ECLComfort310B,230volta.c.(codeno.087H3050)

•ECLComfort310,24volta.c.(codeno.087H3044)

TheB-typehasnodisplayanddial.

2|©Danfoss|2018.09

VI.JM.Q5.02

Page 3

OperatingGuideECLComfort310,applicationP318

TheB-typeisoperatedbymeansoftheremotecontrolunit

ECA30/31:

•ECA30(codeno.087H3200)

•ECA31(codeno.087H3201)

InternalI/Omodules:

•ECA32(codeno.087H3202)

•ECA35(codeno.087H3205)

BasepartforECLComfort310,230voltand24volt:Codeno.

087H3230.

AdditionaldocumentationforECLComfort210and310,modules

andaccessoriesisavailableonhttp://heating.danfoss.com/.

Applicationkeysmightbereleasedbeforealldisplaytextsare

translated.InthiscasethetextisinEnglish.

SafetyNote

Toavoidinjuryofpersonsanddamagestothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocable

dimensionsandtypeofisolation(doubleisolatedat230V).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangesforECLComfortinoperationare:

ECLComfort210/310:0-55°C

ECLComfort296:0-45°C.

Exceedingthetemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thewarningsignisusedtoemphasizespecialconditionsthatshould

betakenintoconsideration.

Thissymbolindicatesthatthisparticularpieceofinformationshould

bereadwithspecialattention.

VI.JM.Q5.02

©Danfoss|2018.09|3

Page 4

OperatingGuideECLComfort310,applicationP318

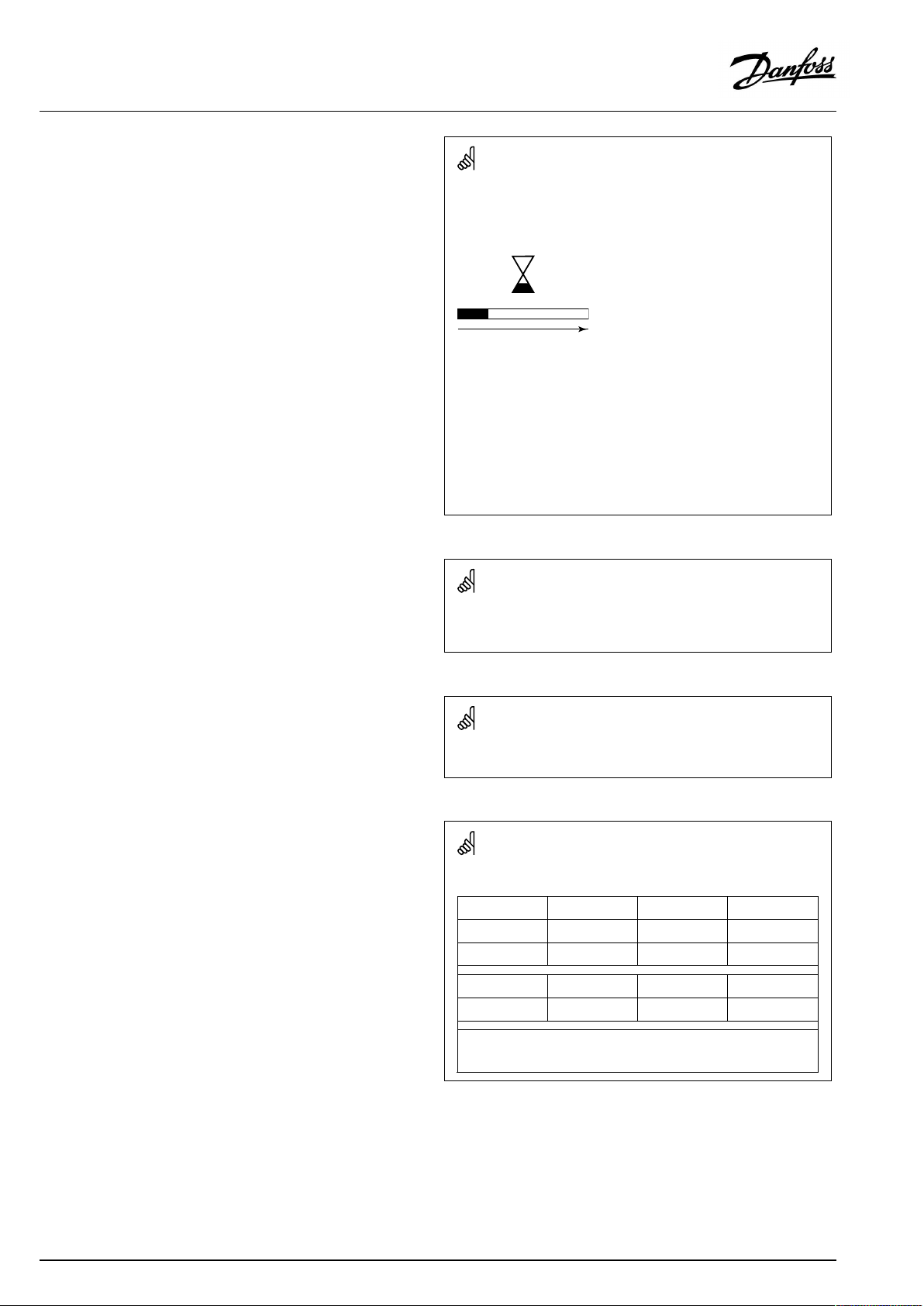

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

AsthisOperatingGuidecoversseveralsystemtypes,specialsystem

settingswillbemarkedwithasystemtype.Allsystemtypesareshown

inthechapter:'Identifyingyoursystemtype'.

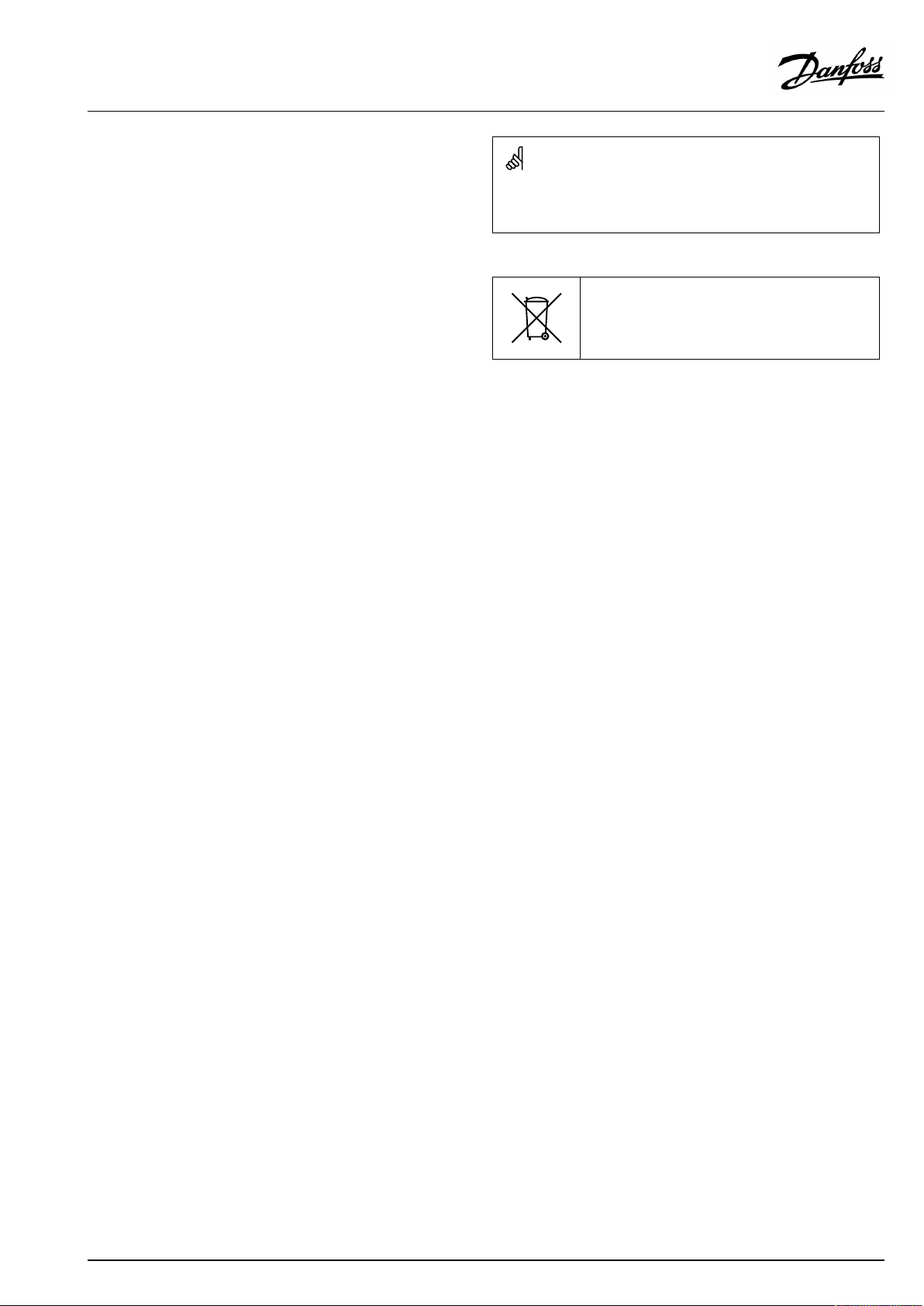

°C(degreesCelsius)isameasuredtemperaturevaluewhereasK

(Kelvin)oftenisusedfortemperaturedifferences.

TheIDno.isuniquefortheselectedparameter.

ExampleFirstdigitSeconddigitLastthreedigits

1117411174

-

12174

IfanIDdescriptionismentionedmorethanonce,itmeansthatthere

arespecialsettingsforoneormoresystemtypes.Itwillbemarked

withthesystemtypeinquestion(e.g.12174-A266.9).

1

-

Circuit1Parameterno.

2

Circuit2Parameterno.

174

4|©Danfoss|2018.09

VI.JM.Q5.02

Page 5

OperatingGuideECLComfort310,applicationP318

ParametersindicatedwithanIDno.like"1x607"meanauniversal

parameter.

xstandsforcircuit/parametergroup.

DisposalNote

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

VI.JM.Q5.02

©Danfoss|2018.09|5

Page 6

OperatingGuideECLComfort310,applicationP318

2.0Installation

2.1Beforeyoustart

TheECLapplicationkeyP318contains4subtypes,P318.1,P318.2,

P318.10andP318.11.

ThebasicprinciplesforapplicationP318.1:

TemperaturecontrolofDHWbuffer

ThedesiredDHWtemperatureatS6(setincircuit1,favorite

display1)determinesthebufferchargingprocedure.Thebuffer

temperaturesensorsS6andS8,thesupplytemperaturesensorS2

andthechargingtemperaturesensorS3arethemostimportant

sensorsandmustbeconnected.Ifoneofthementioned

temperaturesensorsisnotconnected,thecontrolvalveM1will

close;alternatively,thecontrolpumpP1/V1willstop.

ThechargingtemperatureatS3isbasedonthedesiredDHW

temperatureatS6andasetchargingdifference.

TheapplicationallowsinternalorexternalDHWcirculation.When

connectedforexternalcirculation,thedesiredS3temperatureis

thesameasthedesiredDHWtemperature,whenchargingisnot

inprogress.

Optional:TemperaturecontrolofthecirculationpipeatS9ensures

thedesiredtemperaturebymeansofON/OFFcontrolofpump

P3orspeedcontrolofpumpV3.Duringthechargingprocessthe

circulationpumpcanbeswitchedOFForrunataminimumspeed.

Startbufferchargingprocess:

1.BuffertemperatureS6temperaturegetslowerthan('Desired

DHWtemperature'+'Startdifference').

Anexample:60°C+(-5)=55°C

2.X1isswitchedON

3.M1openseitherfullyortoapresetposition(alternatively,P1/

V1isswitchedON/presetspeed)inordertoincreasethesupply

temperatureS2.Returntemperaturelimitationisrespected.

4.P2/V2isswitchedONwhensupplytemperatureS2getshigher

than('DesiredDHWtemperature'+'Pumpstartdiff.').

Anexample:60°C+3K=63°C

V2startswithminimumspeed,forexample20%.

5.M1(orP1/V1)controlsthechargingtemperatureatS3.

6.V2increasesthespeedaslongasthechargingtemperatureS3

ishigherthan(desiredchargingtemperature-2K).

Stopbufferchargingprocess:

1.BuffertemperatureS6temperaturegetshigherthan(2K+

'DesiredDHWtemperature'+'Startdifference)

AND

LowerbuffertemperatureS8getshigherthan('DesiredDHW

temperature'+'Stopdifference).

Anexample:S6temperaturehigherthan(2+60°C+(-5)=

57°C)AND(60°C+(-8)=52°C)

2.P2isswitchedOFF ,respecting'Char.Ppost-run'.V2changes

to0%.

NOTE:Post-runisnotrespectedifchargingtemperatureS3islower

thandesiredchargingtemperature.

3.X1isswitchedOFF.

4.M1closes(alternatively,P1/V1stops)ormaintainsthedesired

temperatureatS3.

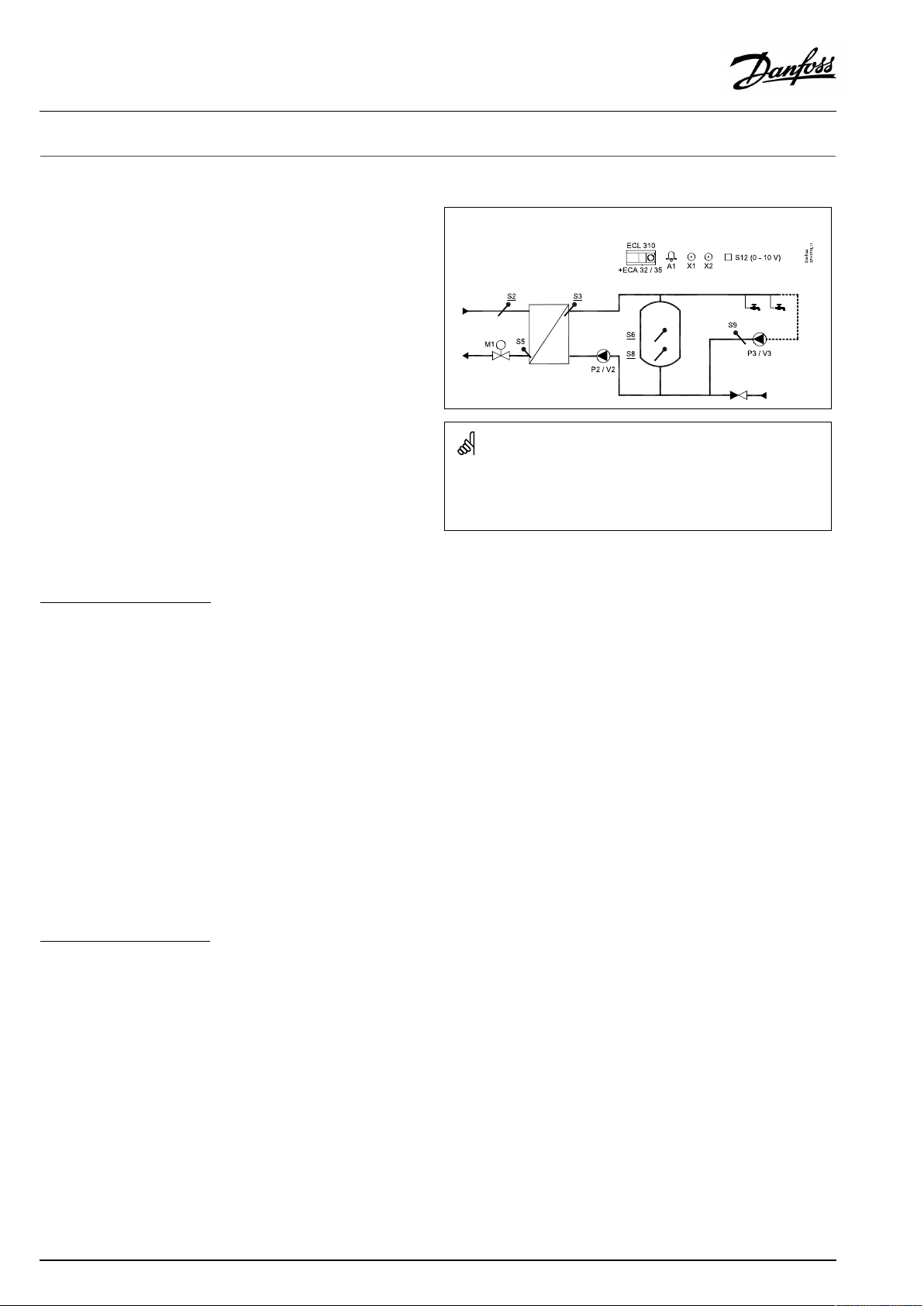

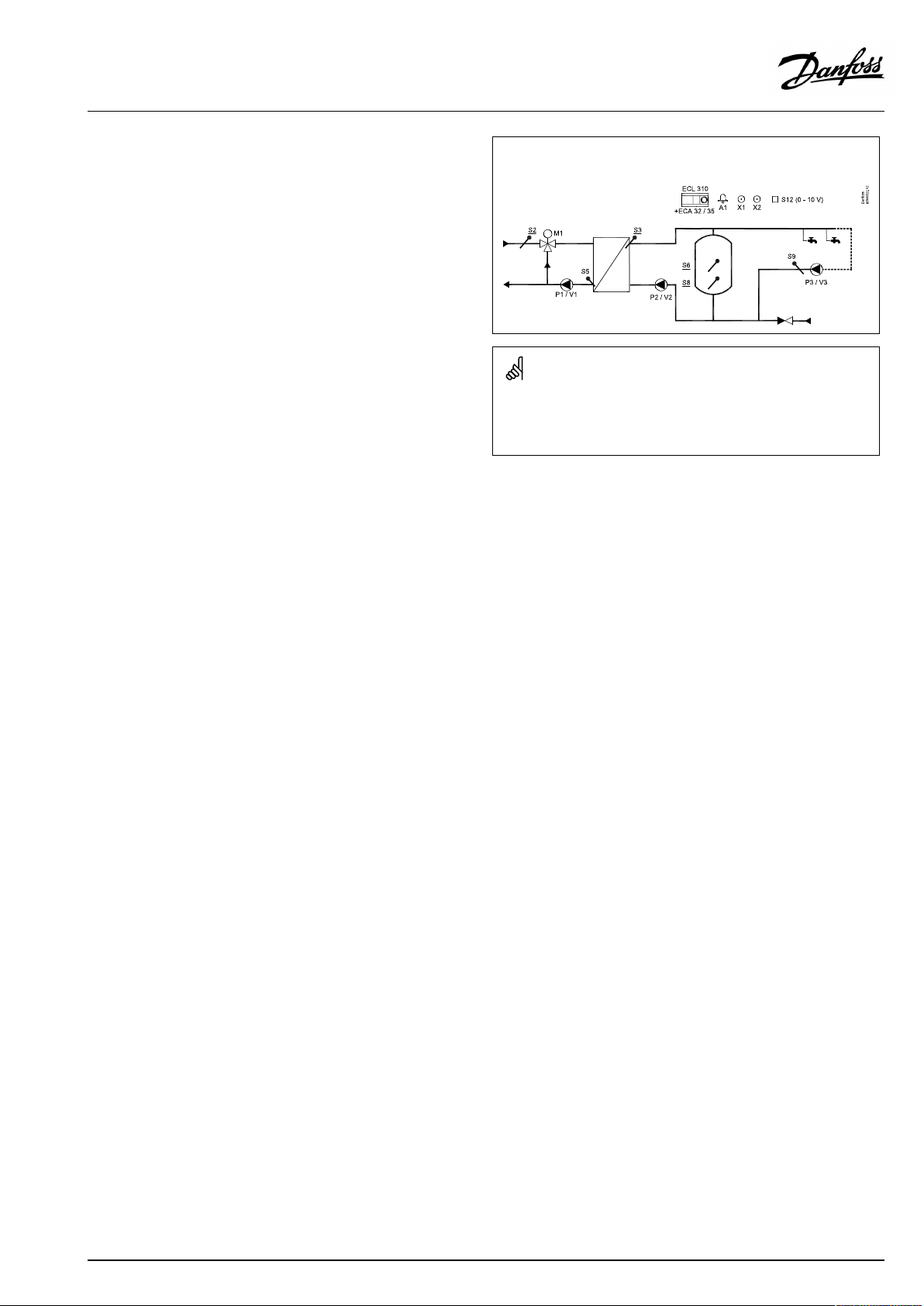

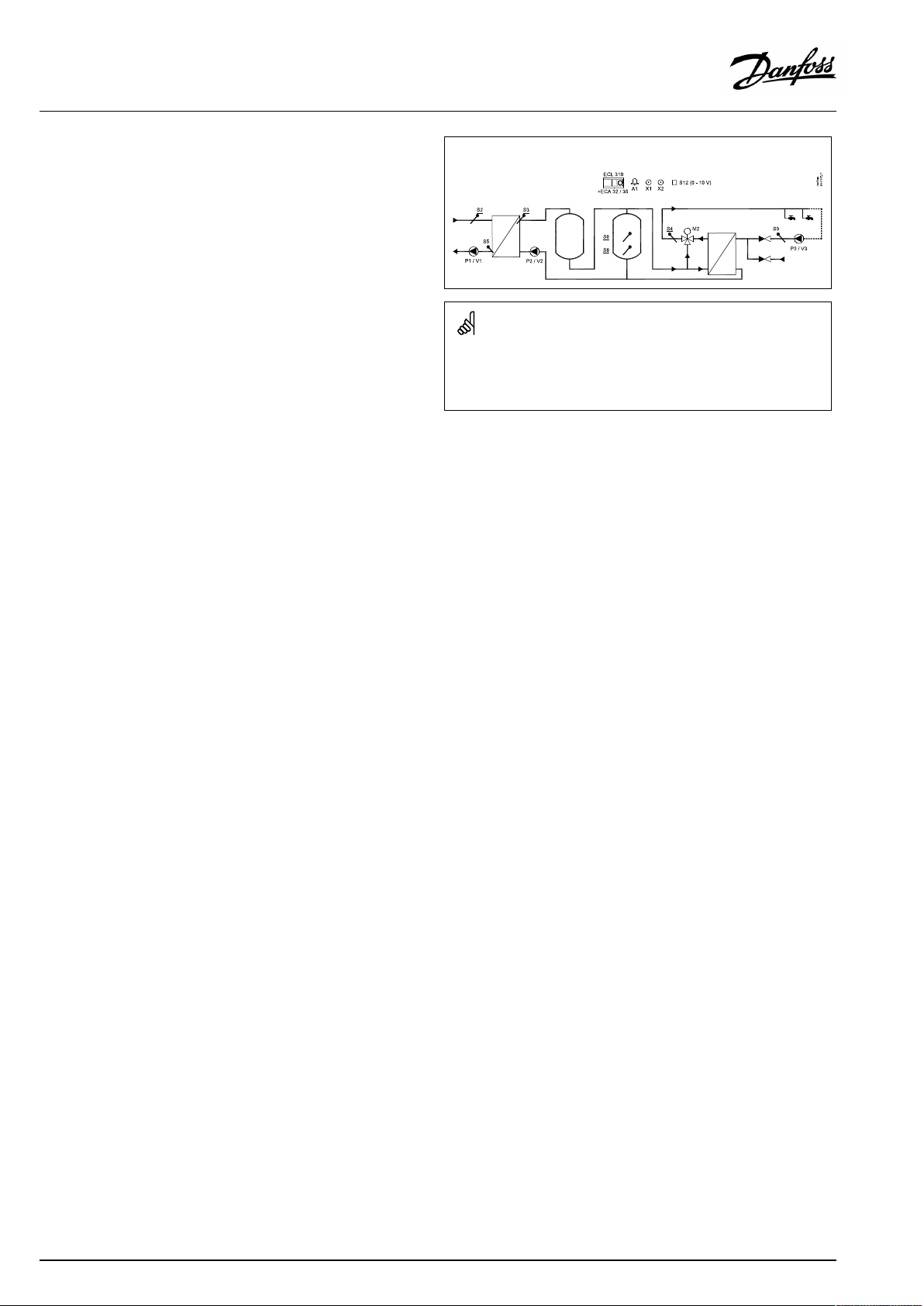

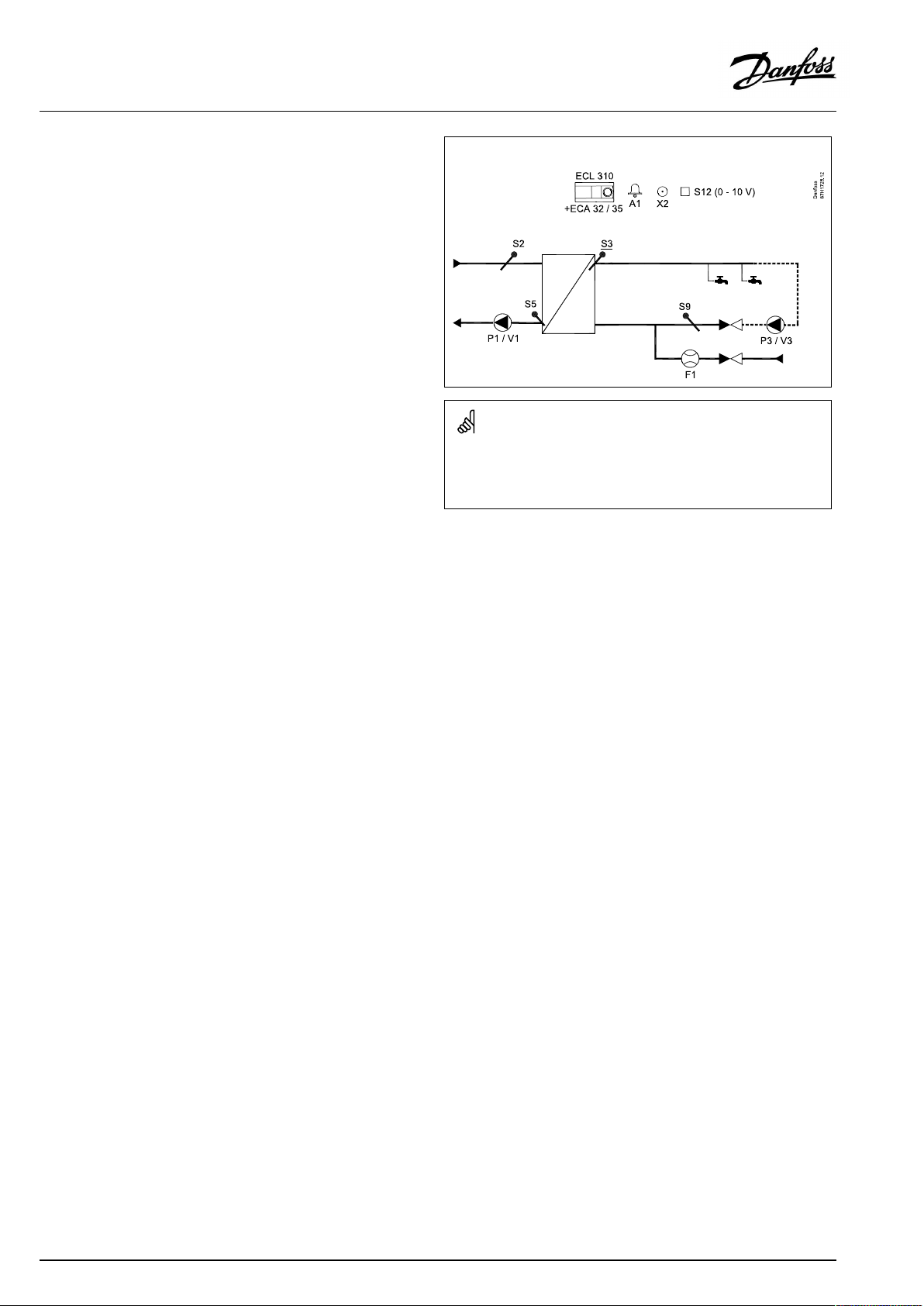

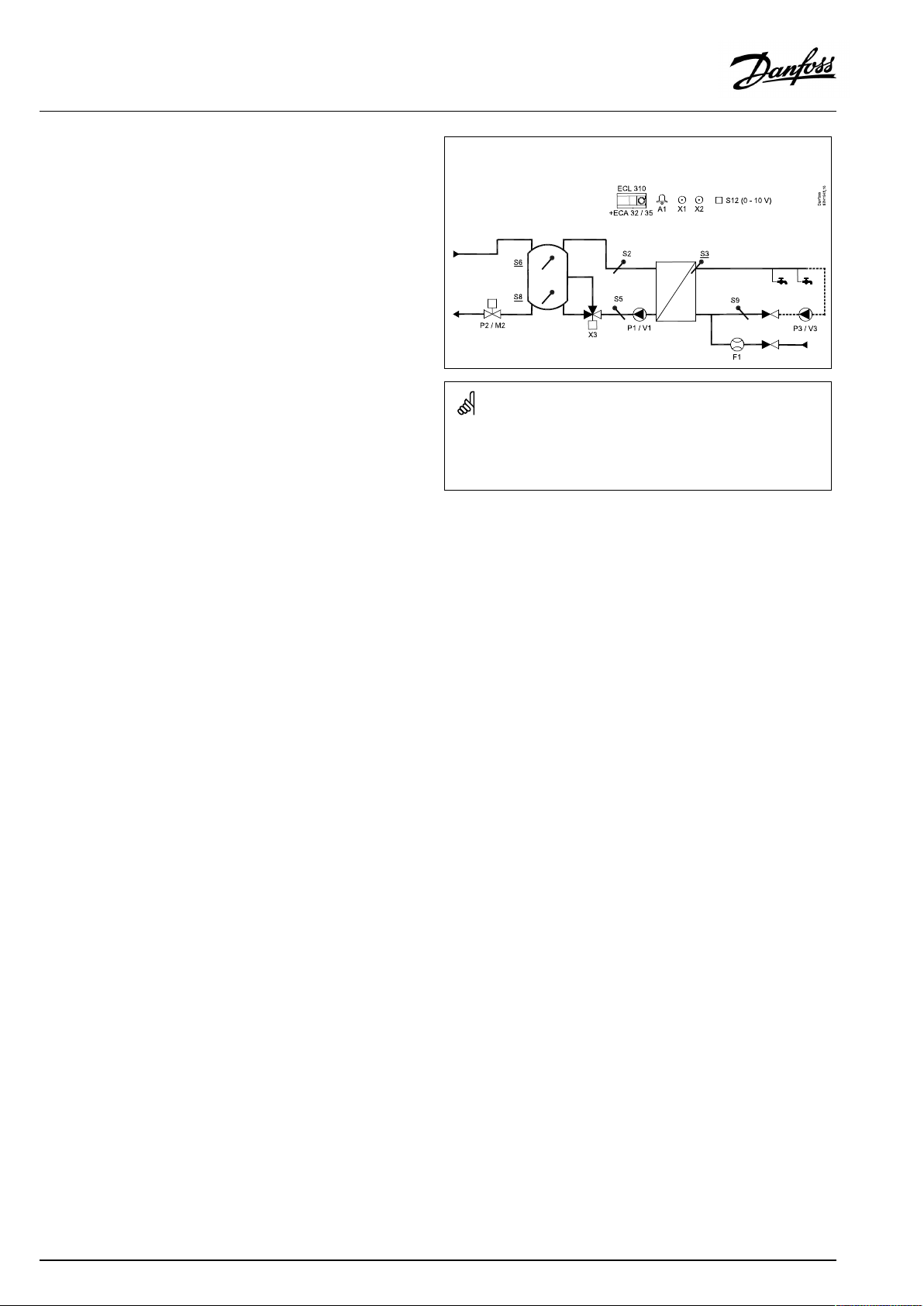

P318.1,ex.a,applicationwithcontrolvalveandinternalDHWcirculation:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

S2

S3

S5Returntemperaturesensor

S6

S8

S9

S12

P2

V2

P3

V3

M1

X1

X2

A1

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

Motorizedcontrolvalve(3-pointcontrolled)

Heatdemandsignal

Anti-bacteriafunctionisactive

Alarm

6|©Danfoss|2018.09

VI.JM.Q5.02

Page 7

OperatingGuideECLComfort310,applicationP318

Bymeansofaweekschedule,theDHWcirculationcanbeON/

OFFcontrolled.

ThemotorizedcontrolvalveM1isopenedgraduallywhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

Alternatively,thecontrolpumpP1/V1isincreasedinspeedwhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredchargingtemperatureatS3canbe

adjusted(typicallytoalowervalue);thisresultsinagradualclosing

ofthemotorizedcontrolvalveor,alternatively,alowerspeedof

thecontrolpump.

DHWcirculationtemperaturecontrol:

IfDHWcirculationreturntemperaturesensorS9isnotconnected,

theON-OFFcontrolledpumpwillbeON.Aspeedcontrolledpump

canbelimitedtoadesiredspeedbymeansofV.outmax.and

V.outminsettings.

TheON-OFFoutputX1isONatDHWheatingdemand.

Asanoption,thedesiredDHWtemperatureatS6canbeset

externally.Avoltagesignal(1-10Volt)canbeappliedtoinputS12

(ECA32/35).Thescaleforvoltageversustemperaturecanbeset.

Ananti-bacteriafunctionfortheDHWbufferisavailablefor

activationonselecteddaysoftheweek.

Theanti-bacteriafunctioncanbesettoincludetheDHW

circulation.

TheON-OFFoutputX2isONatactiveanti-bacteriafunction.

VI.JM.Q5.02

©Danfoss|2018.09|7

Page 8

OperatingGuideECLComfort310,applicationP318

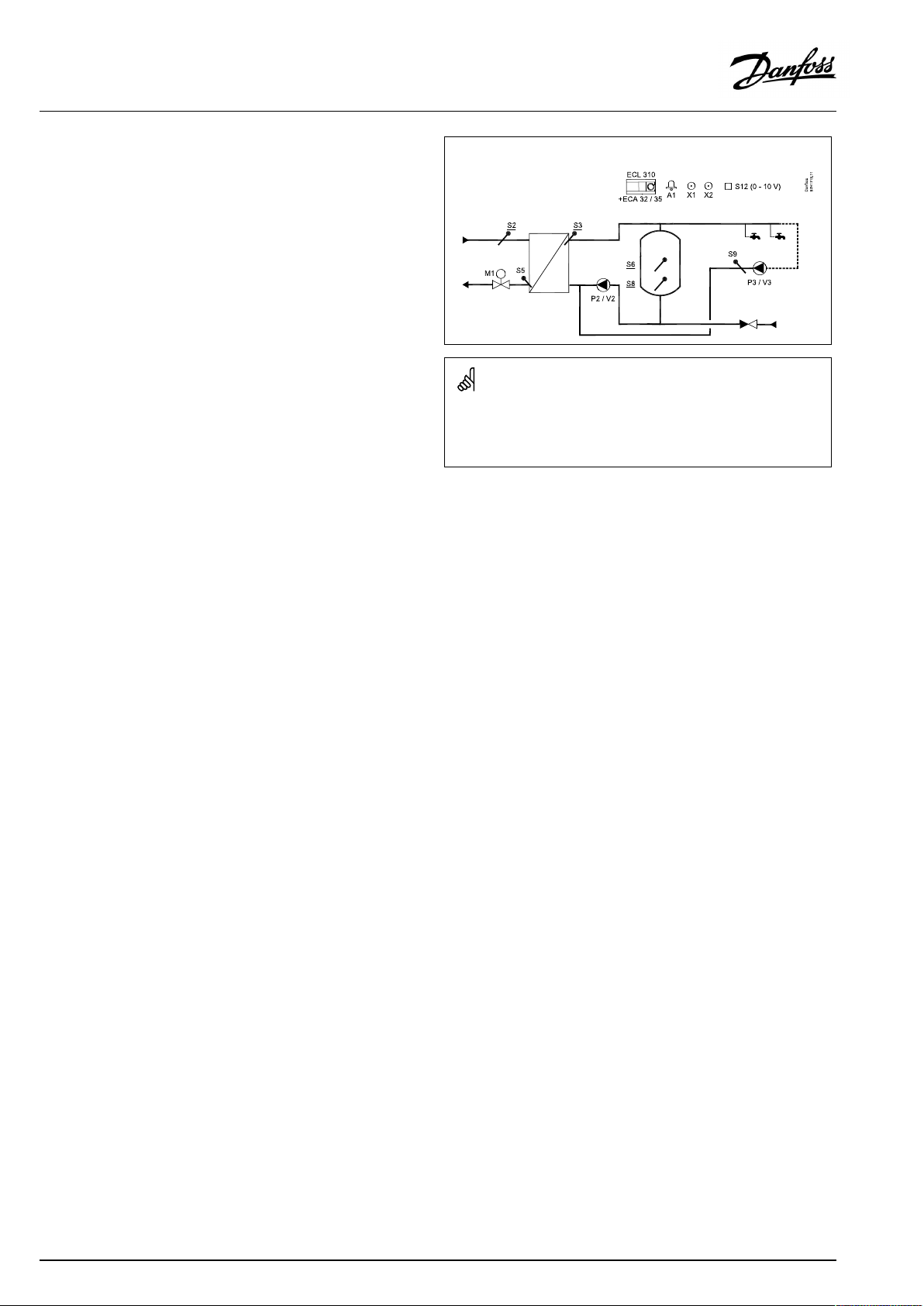

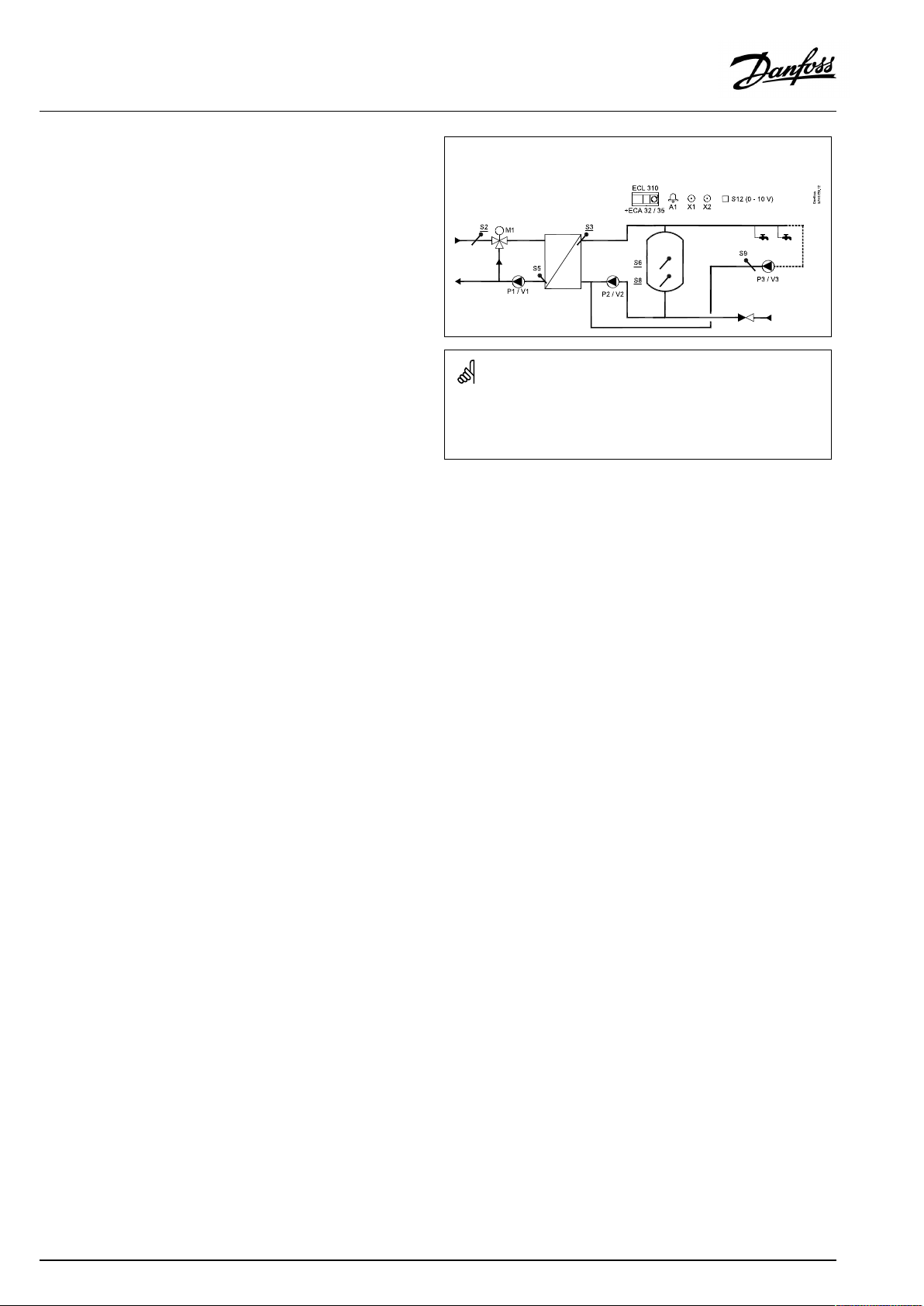

P318.1,ex.b,applicationwithcontrolvalveandexternalDHWcirculation:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

X1

X2

A1

Motorizedcontrolvalve(3-pointcontrolled)

Heatdemandsignal

Anti-bacteriafunctionisactive

Alarm

8|©Danfoss|2018.09

VI.JM.Q5.02

Page 9

OperatingGuideECLComfort310,applicationP318

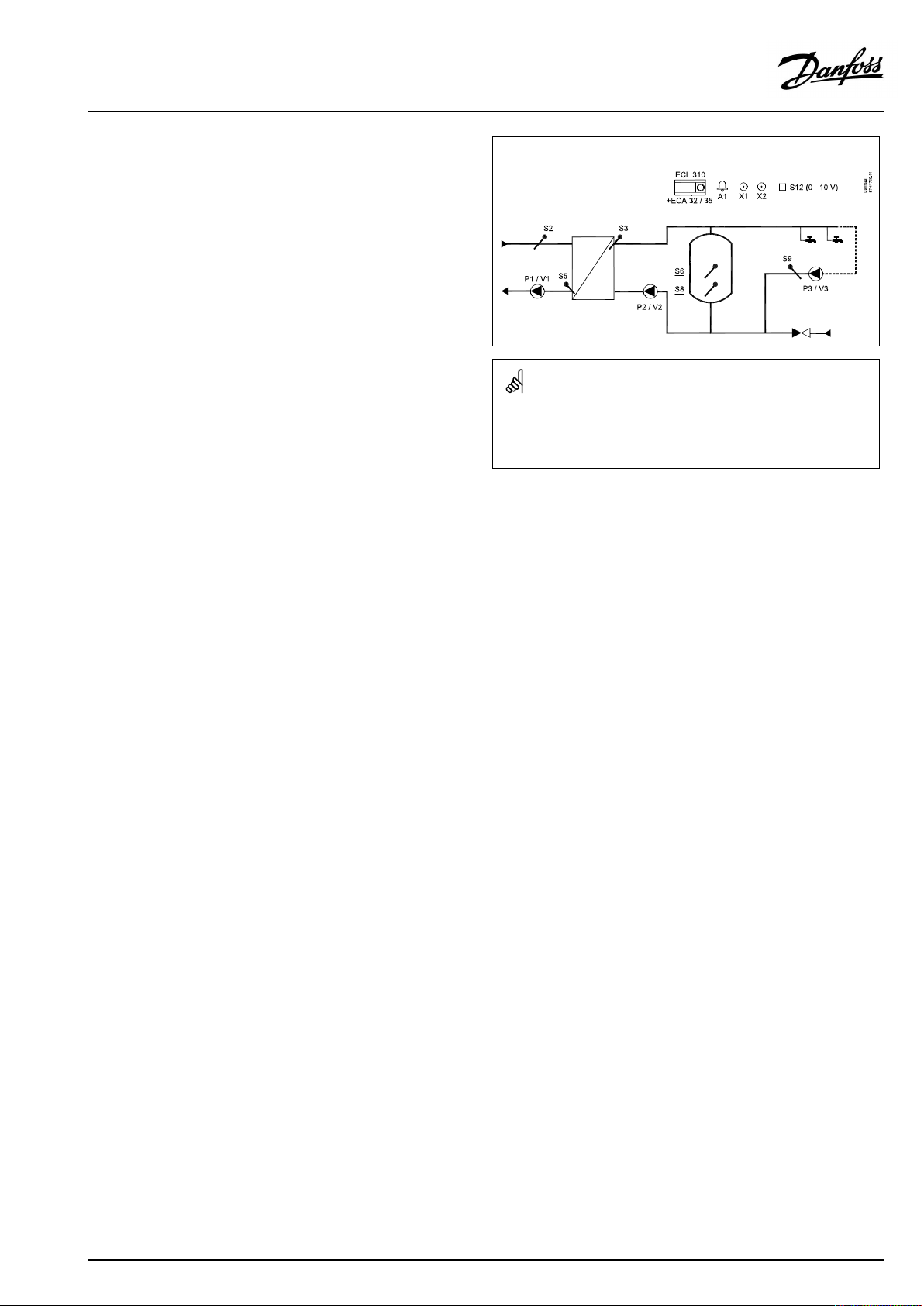

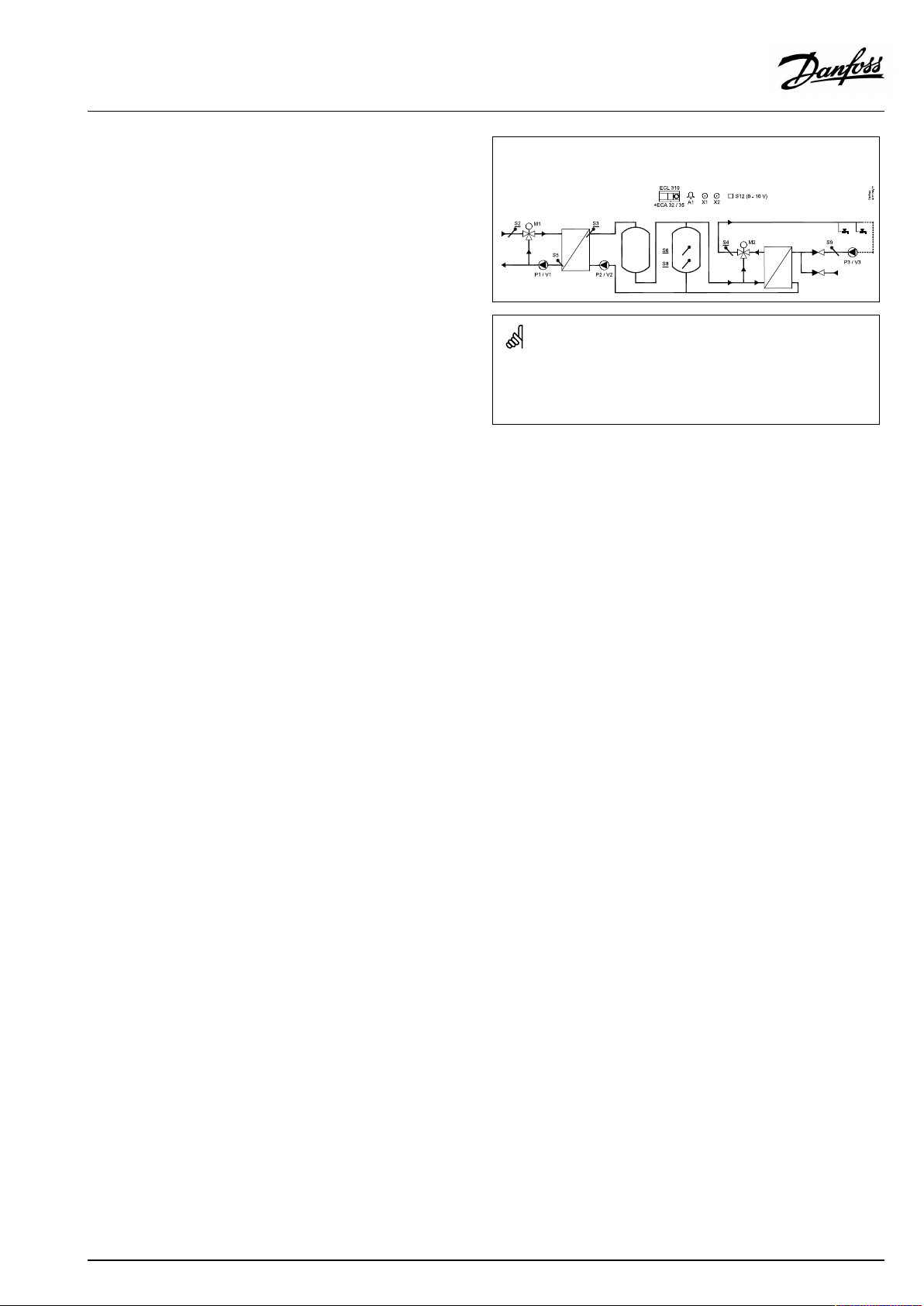

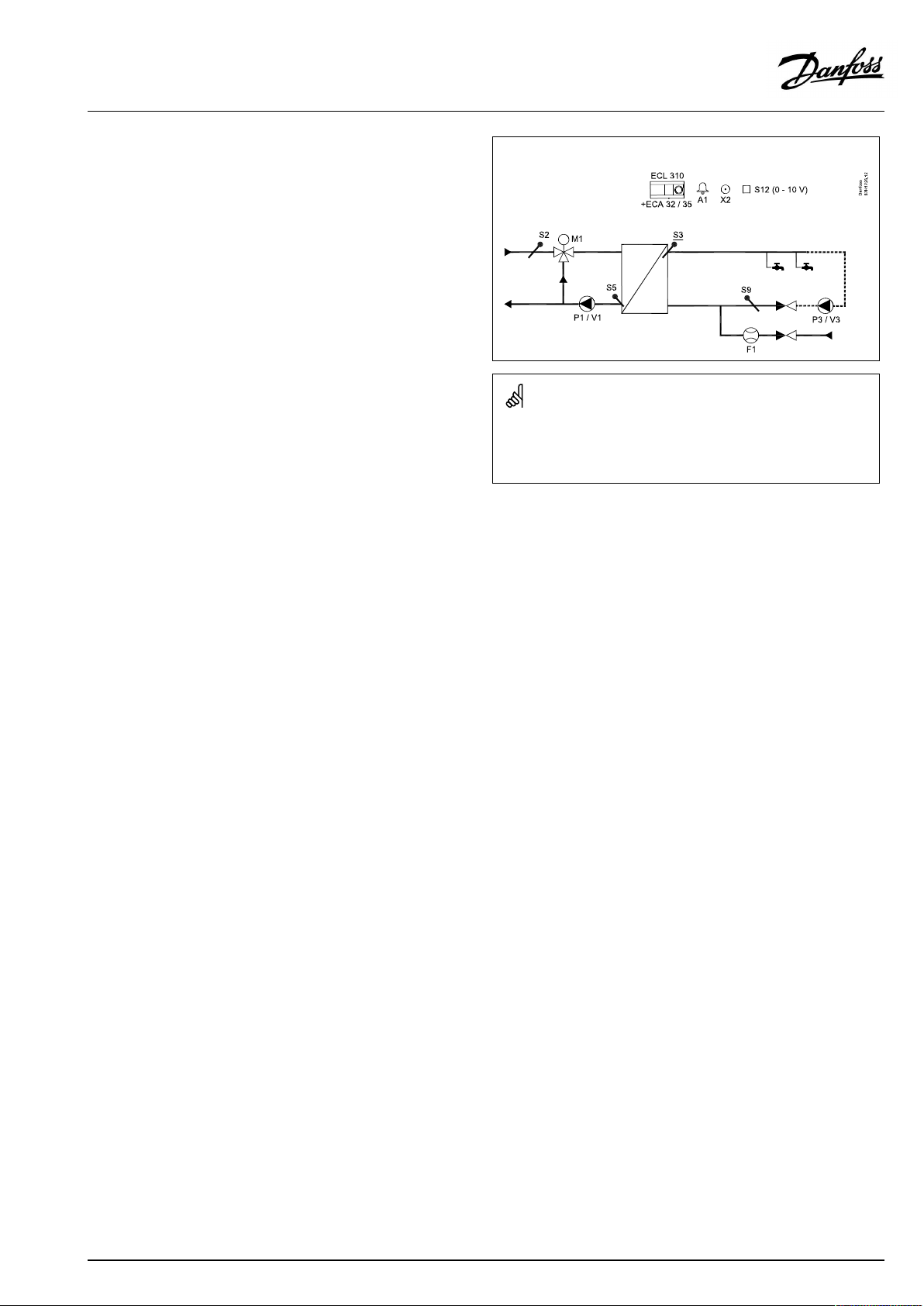

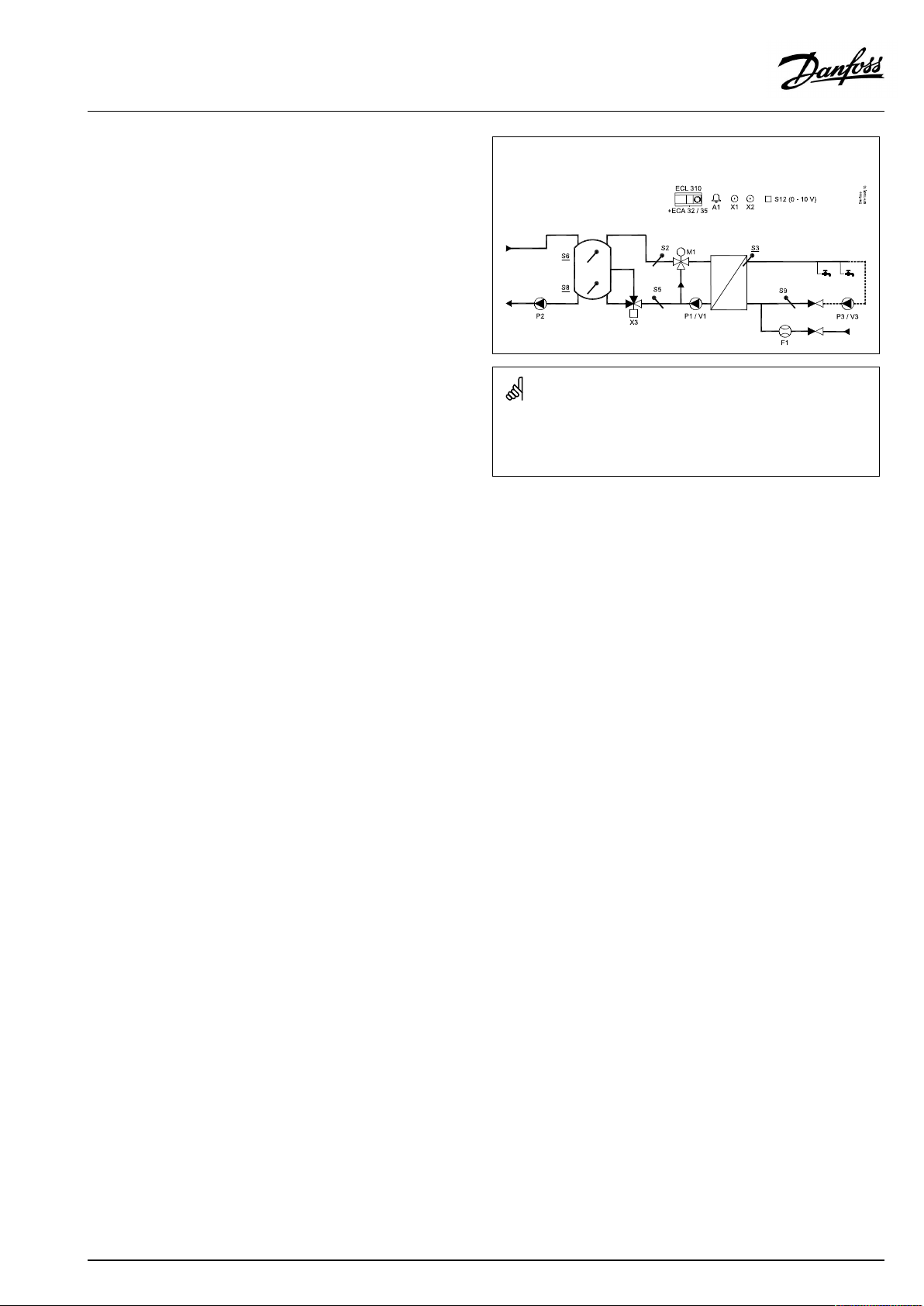

P318.1,ex.c,applicationwithcontrolpumpandinternalDHWcirculation:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

P1

V1

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0–10VorPWM)

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

X2

A1

Heatdemandsignal

Anti-bacteriafunctionisactive

Alarm

VI.JM.Q5.02

©Danfoss|2018.09|9

Page 10

OperatingGuideECLComfort310,applicationP318

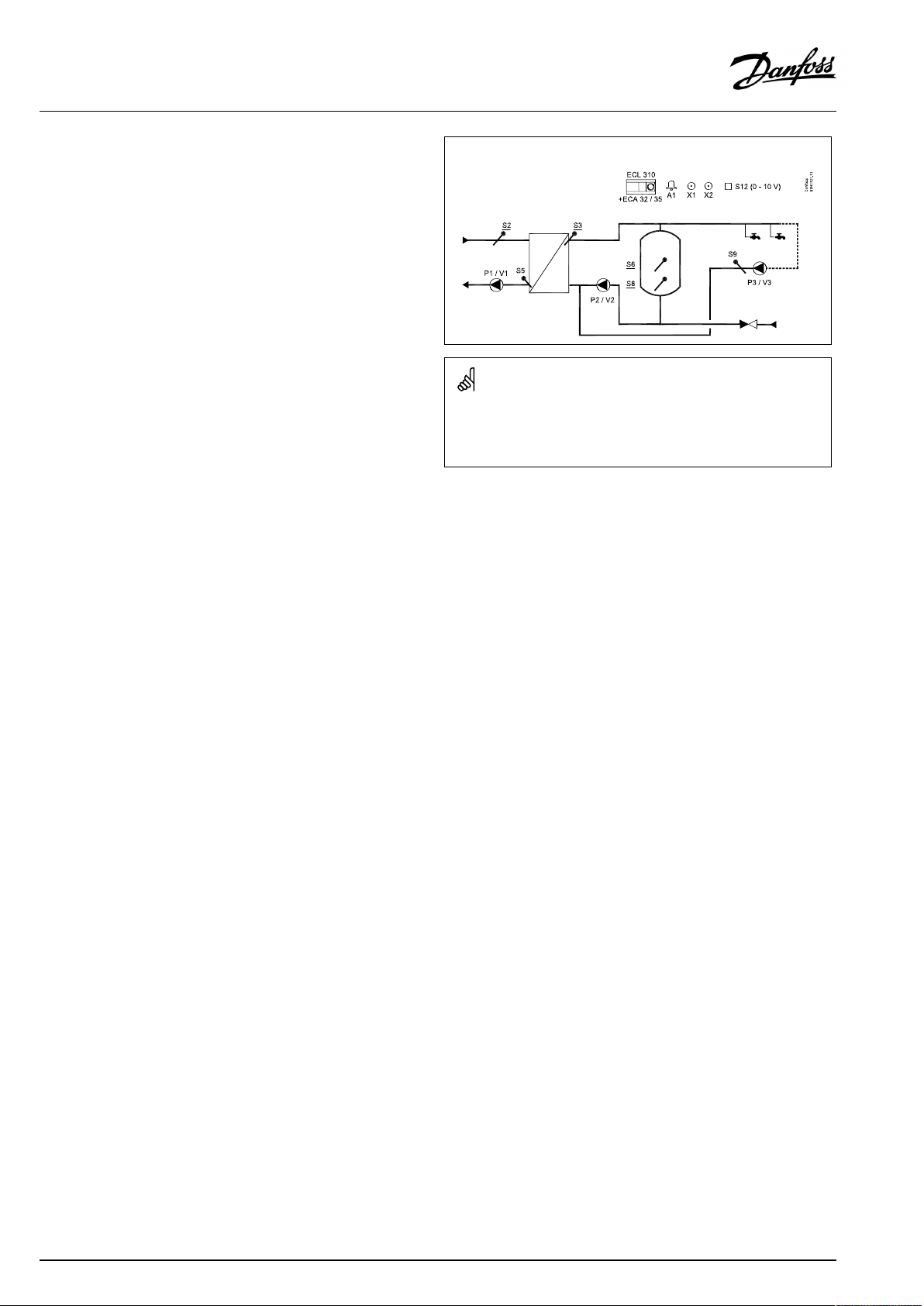

P318.1,ex.d,applicationwithcontrolpumpandexternalDHWcirculation:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

P1

V1

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0–10VorPWM)

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

X2

A1

Heatdemandsignal

Anti-bacteriafunctionisactive

Alarm

10|©Danfoss|2018.09

VI.JM.Q5.02

Page 11

OperatingGuideECLComfort310,applicationP318

P318.1,ex.e:Primarysideisacombinationofa3-portcontrolvalveanda

controlpump.InternalDHWcirculation:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

M1

P1

V1

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Motorized3-portcontrolvalve(3-pointcontrolled)

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0–10VorPWM)

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

X2

A1

Heatdemandsignal

Anti-bacteriafunctionisactive

Alarm

VI.JM.Q5.02

©Danfoss|2018.09|11

Page 12

OperatingGuideECLComfort310,applicationP318

P318.1,ex.f:Primarysideisacombinationofa3-portcontrolvalveanda

controlpump.ExternalDHWcirculation:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

M1

P1

V1

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Motorized3-portcontrolvalve(3-pointcontrolled)

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0–10VorPWM)

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

X2

A1

Heatdemandsignal

Anti-bacteriafunctionisactive

Alarm

12|©Danfoss|2018.09

VI.JM.Q5.02

Page 13

OperatingGuideECLComfort310,applicationP318

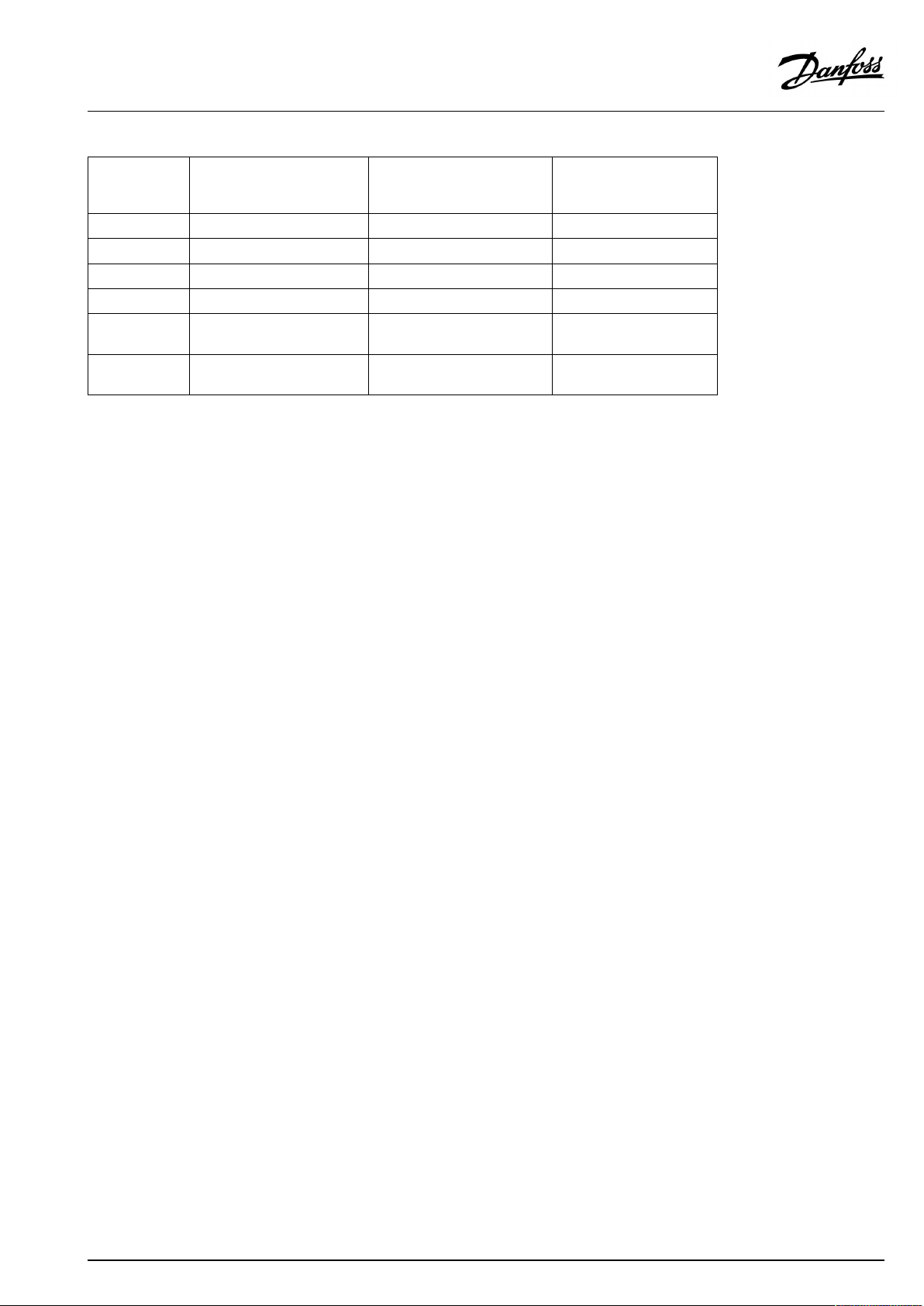

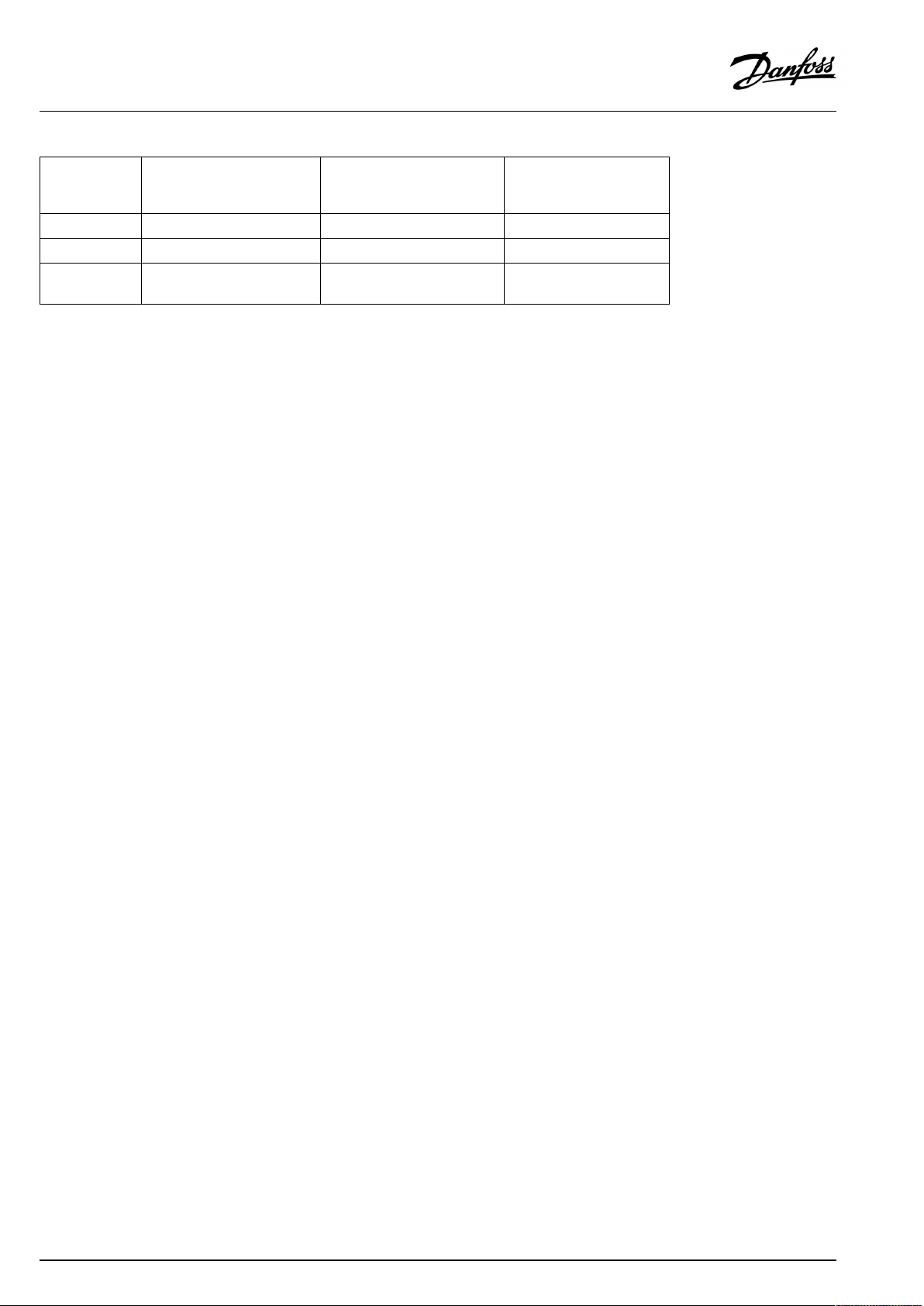

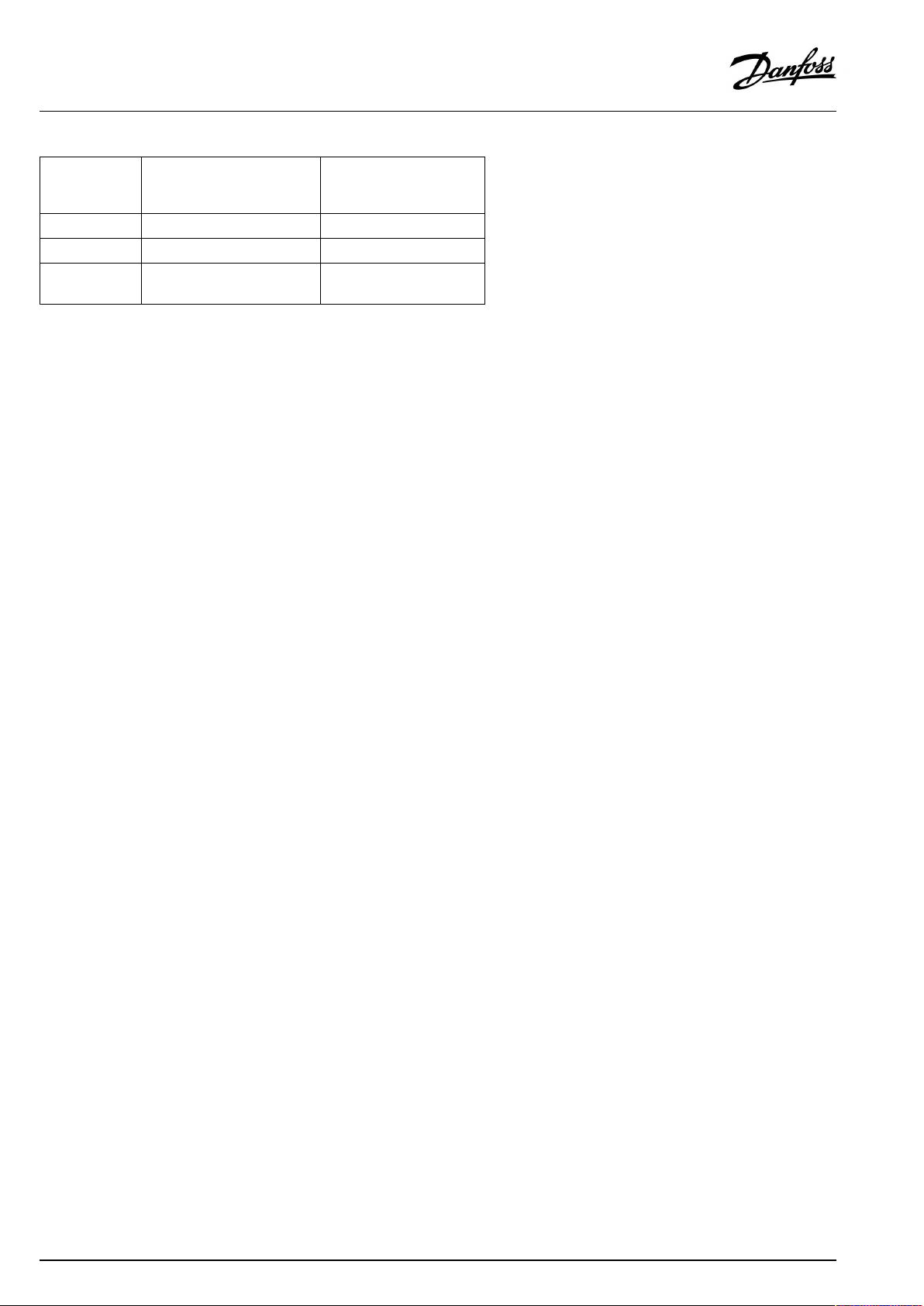

Recommendations/consideringsettings:

Int./Ext.DHWcirc.

"Cont.Tcontrol"(11054)*

P318.1,ex.a

P318.1,ex.b

P318.1,ex.c

P318.1,ex.d

P318.1,ex.e

P318.1,ex.f

*)

Circuit1>MENU>Settings>Application>

**)

Circuit1>MENU>Settings>Controlparameters1>

***)

Circuit1>MENU>Settings>Controlparameters1>

OFF

ON

OFF

ON

OFF

ON

Speed,P1/V1

"Voutmax. "/"Voutmin. "

(11165/11167)**

Max./min.tosamevalue

"Adapttime"(11065)*:OFF

Max./min.tosamevalue

"Adapttime"(11065)*:OFF

Actuatorrunningtime

"Mrun"(11186)***

X

X

X

X

VI.JM.Q5.02

©Danfoss|2018.09|13

Page 14

OperatingGuideECLComfort310,applicationP318

ThebasicprinciplesforapplicationP318.2:

DHWtemperatureandbuffercontrol

IfthemeasuredDHWtemperatureS4islowerthanthedesired

DHWtemperature(setincircuit1,favoritedisplay1),themotorized

controlvalveM2opensgraduallyformorewaterfromthebuffer

tank.

Coldtapwateris,viatheheat-exchanger,usedtocontroltheDHW

temperatureS4ifthetemperaturegetshigherandwillgradually

closethecontrolvalveM2.

TheDHWtemperaturesensorS4,thechargingtemperaturesensor

S3,thesupplytemperaturesensorS2andthebuffertemperature

sensorsS6andS8arethemostimportantsensorsandmustbe

connected.Ifoneofthementionedtemperaturesensorsisnot

connected,thecontrolvalveM1willclose;alternatively,thecontrol

pumpP1/V1willstop.

ThebufferchargingtemperatureatS3isbasedonthesetdesired

buffertemperatureatS6(setincircuit2,favoritedisplay1).

Optional:TemperaturecontrolofthecirculationpipeatS9ensures

thedesiredtemperaturebymeansofON/OFFcontrolofpump

P3orspeedcontrolofpumpV3.

Startbufferchargingprocess:

1.BuffertemperatureS6temperaturegetslowerthan('Desired

chargingtemperature'+'Startdifference').

Anexample:70°C+(-5)=65°C

2.X1isswitchedON

3.M1opens(alternatively,P1/V1isswitchedON/presetspeed)

inordertoincreasethesupplytemperature

S2.Returntemperaturelimitationisrespected.

4.P2/V2isswitchedONwhensupplytemperatureS2getshigher

than('Desiredchargingtemperature'+'Pumpstartdiff. ').

Anexample:70°C+3K=73°C

V2startswithminimumspeed,forexample20%.

5.M1(orP1/V1)controlsthechargingtemperatureatS3.

6.V2increasesthespeedaslongasthechargingtemperatureS3

ishigherthan(desiredchargingtemperature-2K).

Stopbufferchargingprocess:

1.BuffertemperatureS6temperaturegetshigherthan(2K+

'Desiredchargingtemperature'+'Startdifference)

AND

LowerbuffertemperatureS8getshigherthan('DesiredDHW

temperature'+'Stopdifference).

Anexample:S6temperaturehigherthan(2+70°C+(-5)=

67°C)

ANDS8temperaturehigherthan(70°C+(-8)=62°C).

2.P2isswitchedOFF ,respecting'DHWPpost-run' .V2changes

to0%.

NOTE:Post-runisnotrespectedifchargingtemperatureS3islower

thandesiredchargingtemperature.

3.X1isswitchedOFF.

4.M1closes(alternatively,P1/V1stops).

P318.2,ex.a,applicationwithcontrolvalveforbuffertemperaturecontrol:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

S4

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

M2

X1

X2

A1

Motorizedcontrolvalve(3-pointcontrolled)

Motorizedcontrolvalve(3-pointcontrolled)

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Alarm

14|©Danfoss|2018.09

VI.JM.Q5.02

Page 15

OperatingGuideECLComfort310,applicationP318

Bymeansofaweekschedule,theDHWcirculationcanbeON/

OFFcontrolled.

ThemotorizedcontrolvalveM1isopenedgraduallywhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

Alternatively,thecontrolpumpP1/V1isincreasedinspeedwhen

thechargingtemperatureislowerthanthedesiredcharging

temperatureandviceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredchargingtemperatureatS3canbe

adjusted(typicallytoalowervalue);thisresultsinagradualclosing

ofthemotorizedcontrolvalveor,alternatively,alowerspeedof

thecontrolpump.

Asanoption,thedesiredbuffertemperatureatS6canbeset

externally.Avoltagesignal(1-10Volt)canbeappliedtoinputS12

(ECA32/35).Thescaleforvoltageversustemperaturecanbeset.

TheON-OFFoutputX1isONatbufferheatingdemand.

Ananti-bacteriafunctionfortheDHWbufferisavailablefor

activationonselecteddaysoftheweek.

Theanti-bacteriafunctioncanbesettoincludetheDHW

circulation.

TheON-OFFoutputX2isONwhenanti-bacteriafunctionisactive.

VI.JM.Q5.02

©Danfoss|2018.09|15

Page 16

OperatingGuideECLComfort310,applicationP318

P318.2,ex.b,applicationwithcontrolpumpforbuffertemperaturecontrol:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

S4

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

P1

V1

M2

X1

X2

A1

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0–10VorPWM)

Motorizedcontrolvalve(3-pointcontrolled)

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Alarm

16|©Danfoss|2018.09

VI.JM.Q5.02

Page 17

OperatingGuideECLComfort310,applicationP318

P318.2,ex.c,applicationwithacombinationofa3-portcontrolvalveand

acontrolpumpforbuffertemperaturecontrol:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

S4

(mandatory)Supplytemperaturesensor

(mandatory)Chargingtemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

P2

V2

P3

V3

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS6

Chargingpump(ON-OFFcontrolled)

Speedcontrolofchargingpump(0-10VorPWM)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

P1

V1

M2

X1

X2

A1

Motorizedcontrolvalve(3-pointcontrolled)

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0–10VorPWM)

Motorizedcontrolvalve(3-pointcontrolled)

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Alarm

VI.JM.Q5.02

©Danfoss|2018.09|17

Page 18

OperatingGuideECLComfort310,applicationP318

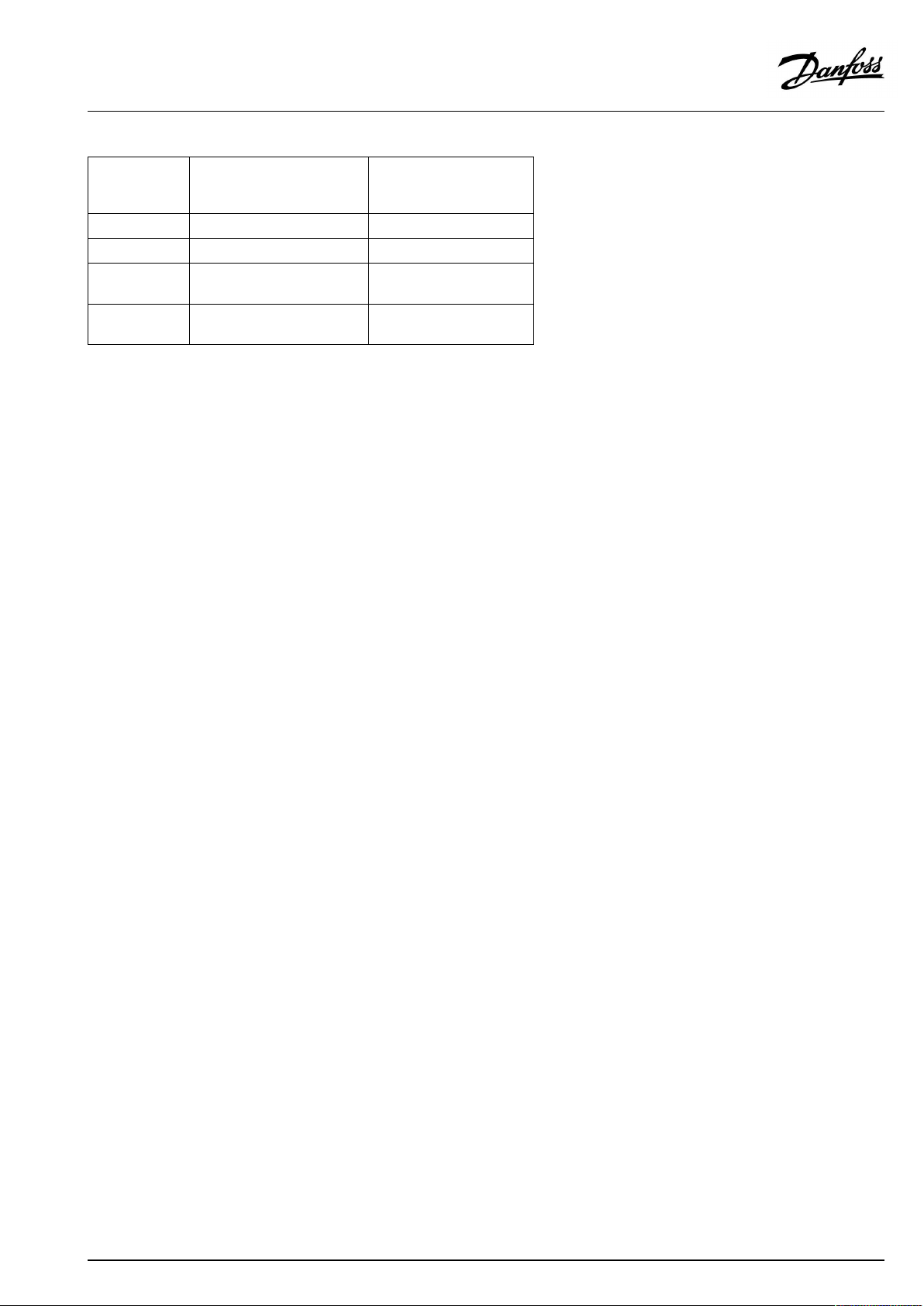

Recommendations/consideringsettings:

Speed,P1/V1

"Voutmax. "/"Voutmin. "

(11165/11167)*

P318.2,ex.a

P318.2,ex.b

P318.2,ex.c

*)

Circuit2>MENU>Settings>Controlparameters1>

**)

Circuit1>MENU>Settings>Controlparameters2>

***)

Circuit2>MENU>Settings>Controlparameters1>

Max./min.tosamevalue

"Adapttime"(11065)*:OFF

Actuatorrunningtime

M2"Mrun"

(14186)**

Actuatorrunningtime

M1"Mrun"

(11186)***

XX

X

XX

18|©Danfoss|2018.09

VI.JM.Q5.02

Page 19

OperatingGuideECLComfort310,applicationP318

ThebasicprinciplesforapplicationP318.10:

TemperaturecontrolofDHW

ThedesiredDHWtemperatureatS3(setincircuit1,favoritedisplay

1)determinesthetemperaturecontrol.

TheDHWflowtemperaturesensorS3isthemostimportantsensor

andmustbeconnected.IfS3isnotconnected,thecontrolvalve

M1willclose;alternatively,thecontrolpumpP1/V1willstop.

TemperaturecontroloftheDHWcirculationpipeatS9ensuresthe

desiredtemperaturebymeansofspeedcontrolofpumpP3/V3.

AweekscheduleforswitchingtheDHWcirculationpumpONand

OFFcanbeset.

IfDHWcirculationreturntemperaturesensorS9isnotconnected,

theON-OFFcontrolledpumpwillbeONregardlesstheschedule

status.

Aspeed-controlledpumpcanbelimitedtoadesiredspeedby

meansofV.outmax.andV.outminsettings.

ThemotorizedcontrolvalveM1isopenedgraduallywhenthe

DHWflowtemperatureislowerthanthedesiredDHWtemperature

andviceversa.

Alternatively,thecontrolpumpP1/V1isincreasedinspeedwhen

theDHWflowtemperatureislowerthanthedesiredDHWflow

temperatureandviceversa.

ThereturntemperatureS5canbelimited,forexamplenottobe

toohigh.Ifso,thedesiredDHWtemperatureatS3canbeadjusted

(typicallytoalowervalue);thisresultsinagradualclosingofthe

motorizedcontrolvalveor,alternatively,alowerspeedofthe

controlpump.

ThesupplytemperatureS2isusedtocompensatetheproportional

bandXpinordertoimprovethetemperaturecontrolatdifferent

supplytemperatures.

ThewaterflowsignalfromF1canbeusedtooverridethecontrol

valveinordertooptimizetheDHWtemperaturecontrol.This

pro-activefunctionalitycompensatesforthedelaybeforetheflow

temperaturesensorS3measuresachangeintemperature.

ThewaterflowsignalcanalsobeutilizedforcontroloftheS3

temperature,evenifthereisnoDHWcirculation.

Asanoption,thedesiredDHWtemperaturecanbesetexternally.

Avoltagesignal(1-10Volt)canbeappliedtoinputS12(ECA32/

35).Thescaleforvoltageversustemperaturecanbeset.

Ananti-bacteriafunctionfortheDHWcircuitisavailablefor

activationonselecteddaysoftheweek.Theanti-bacteriafunction

canbesettoincludetheDHWcirculation.

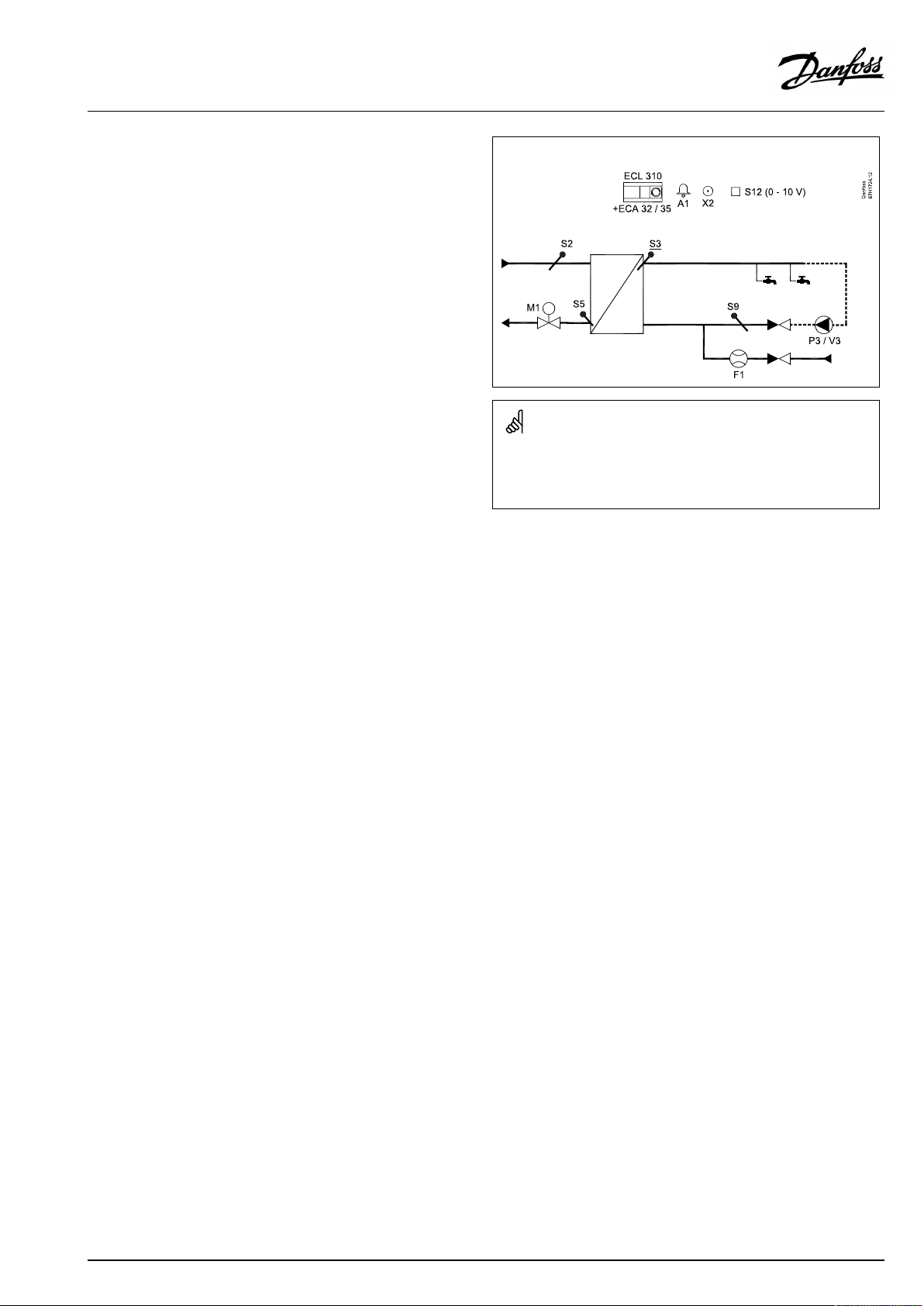

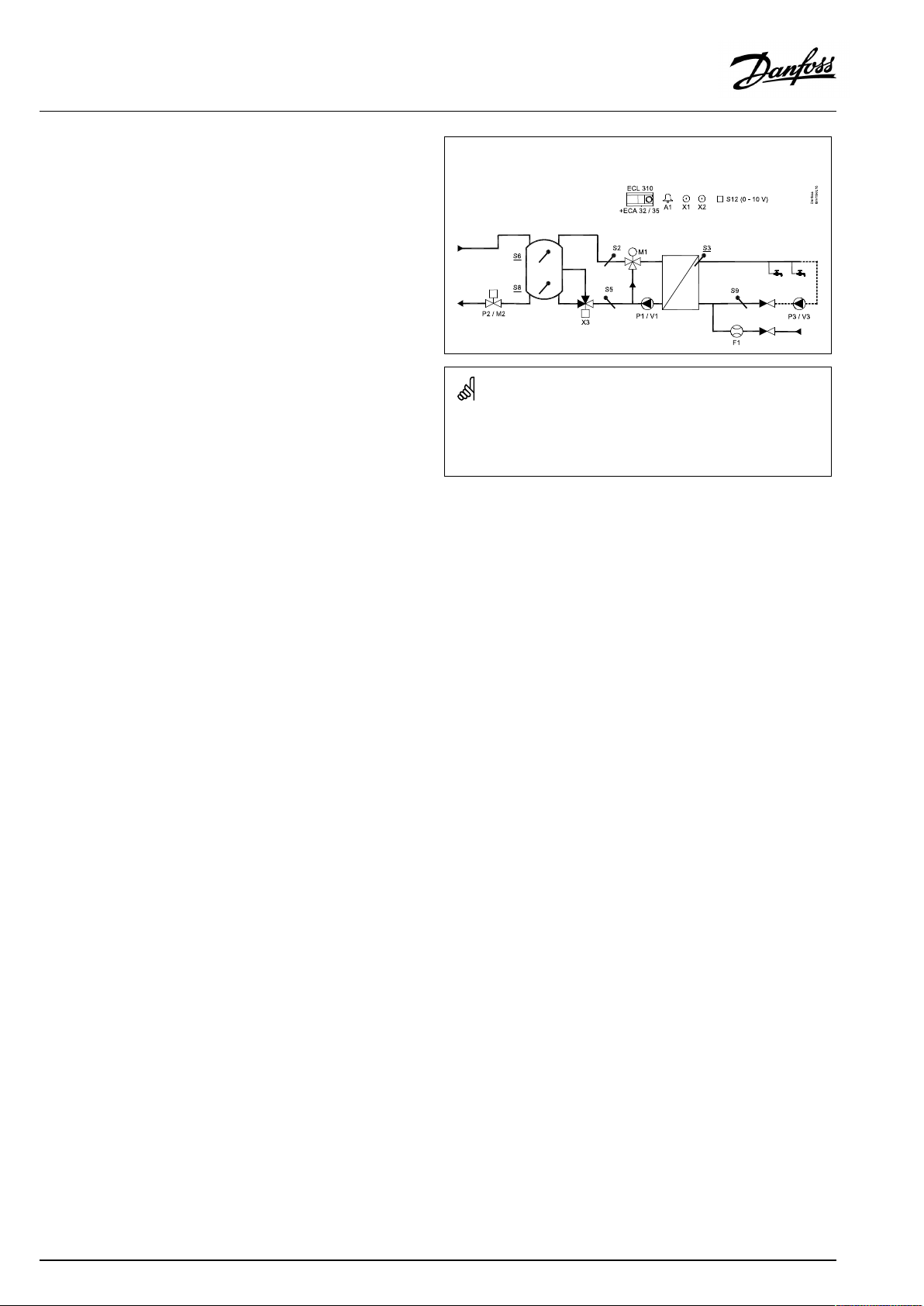

P318.10,ex.a,DHWapplicationwithcontrolvalve:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWflowtemperaturesensor

S5Returntemperaturesensor

S9

S12

F1

P3

V3

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

DHWcirculationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

X2

A1

Motorizedcontrolvalve(3-pointcontrolled)

Anti-bacteriafunctionisactive

Alarm

TheON-OFFoutputX2isONwhenanti-bacteriafunctionisactive.

VI.JM.Q5.02

©Danfoss|2018.09|19

Page 20

OperatingGuideECLComfort310,applicationP318

P318.10,ex.b,DHWapplicationwithcontrolpump:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWflowtemperaturesensor

S5Returntemperaturesensor

S9

S12

F1

P1

V1

P3

V3

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0-10VorPWM)

DHWcirculationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

X2

A1

Anti-bacteriafunctionisactive

Alarm

20|©Danfoss|2018.09

VI.JM.Q5.02

Page 21

OperatingGuideECLComfort310,applicationP318

P318.10,ex.c,DHWapplicationwithcontrolvalveandcontrolpump:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWflowtemperaturesensor

S5Returntemperaturesensor

S9

S12

F1

P1

V1

P3

V3

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

Controlpump(ON-OFFcontrolled)

Speedcontrolofcontrolpump(0-10VorPWM)

DHWcirculationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

X2

A1

Motorizedcontrolvalve(3-pointcontrolled)

Anti-bacteriafunctionisactive

Alarm

VI.JM.Q5.02

©Danfoss|2018.09|21

Page 22

OperatingGuideECLComfort310,applicationP318

Recommendations/consideringsettings:

Speed,P1/V1

"Voutmax. "/"Voutmin. "

(11165/11167)*

P318.10,ex.a

P318.10,ex.b

P318.10,ex.c

*)

Circuit1>MENU>Settings>Controlparameters1>

**)

Circuit1>MENU>Settings>Controlparameters1>

Max./min.tosamevalue

"Adapttime"(11065)*:OFF

Actuatorrunningtime

M1"Mrun"

(11186)**

X

X

22|©Danfoss|2018.09

VI.JM.Q5.02

Page 23

OperatingGuideECLComfort310,applicationP318

ThebasicprinciplesforapplicationP318.11:

AdvancedDHWtemperatureandbuffercontrol

ThedesiredDHWtemperatureatS3(setincircuit1,favoritedisplay

1)determinesthetemperaturecontrol.

TheDHWflowtemperaturesensorS3,thebuffertemperature

sensorsS6andS8arethemostimportantsensorsandmustbe

connected.IfS3isnotconnected,thecontrolpumpP1/V1will

stop;alternatively,thecontrolvalveM1(examplescandd)will

close.

TemperaturecontroloftheDHWcirculationpipeatS9ensuresthe

desiredtemperaturebymeansofspeedcontrolofpumpP3/V3.

AweekscheduleforswitchingtheDHWcirculationpumpONand

OFFcanbeset.

IfDHWcirculationreturntemperaturesensorS9isnotconnected,

theON-OFFcontrolledpumpwillbeONregardlesstheschedule

status.

Aspeed-controlledpumpcanbelimitedtoadesiredspeedby

meansofV.outmax.andV.outminsettings.

ThecontrolpumpP1/V1isincreasedinspeedwhentheDHW

flowtemperatureislowerthanthedesiredDHWflowtemperature

andviceversa.

Alternatively,themotorizedcontrolvalveM1(examplescandd)is

openedgraduallywhentheDHWflowtemperatureislowerthan

thedesiredDHWtemperatureandviceversa.

ThebufferisON/OFFcontrolledbymeansofP2orM2,operating

asON/OFFvalve,basedon3-pointcontrol.

Startbufferchargingprocess:

1.BuffertemperatureS6temperaturegetslowerthan('Desired

DHWtemperature'+'Startdifference').

Anexample:60°C+5)=65°C

2.X1isswitchedON

3.P2isswitchedON

Stopbufferchargingprocess:

1.BuffertemperatureS6temperaturegetshigherthan(2K+

'DesiredDHWtemperature'+'Startdifference)

AND

LowerbuffertemperatureS8getshigherthan('DesiredDHW

temperature'+'Stopdifference).

Anexample:

S6temperaturehigherthan(2+60°C+5)=67°C)

AND

S8temperaturehigherthan(60°C+(-3)=57°C).

2.P2isswitchedOFF

3.X1isswitchedOFF.

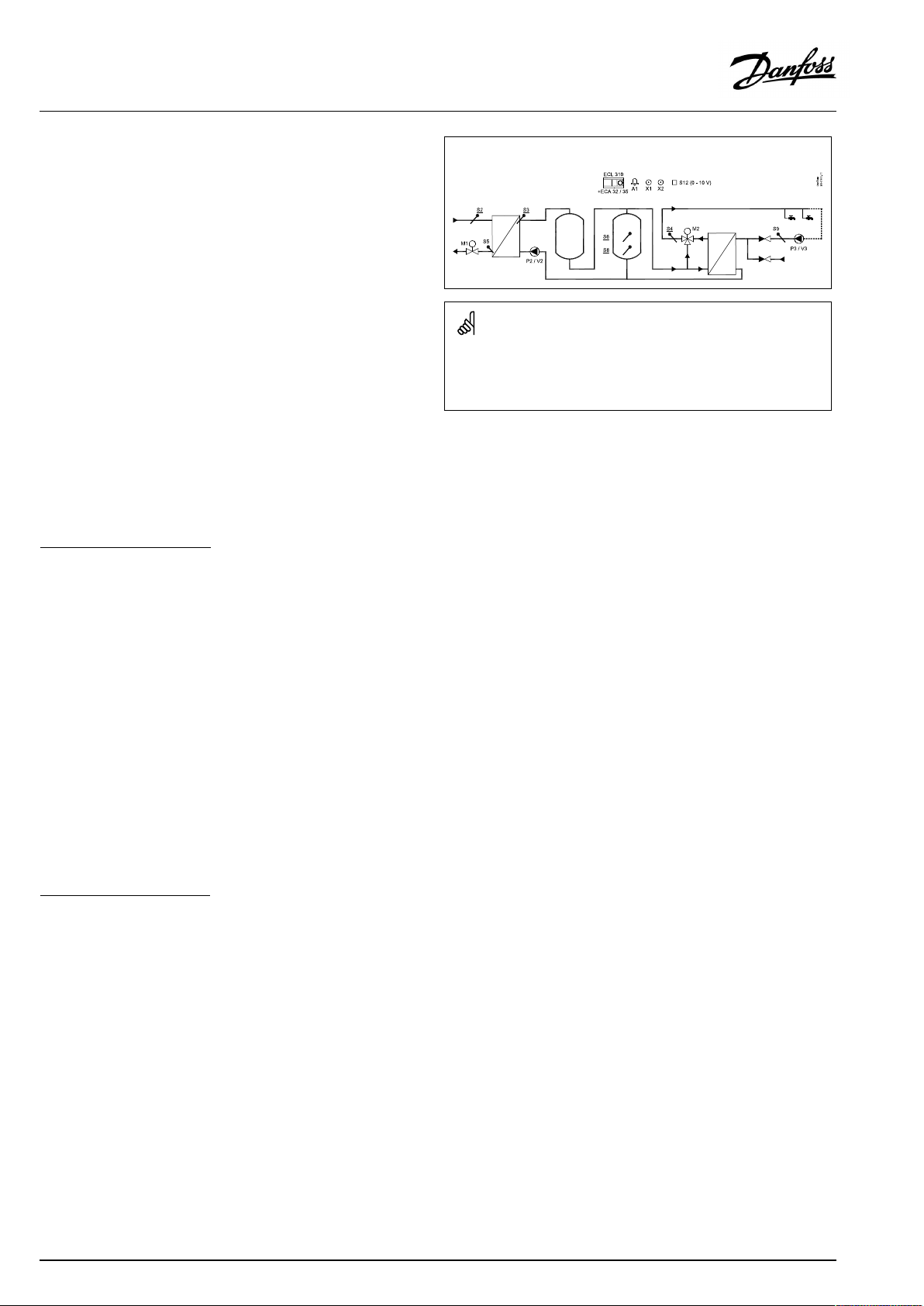

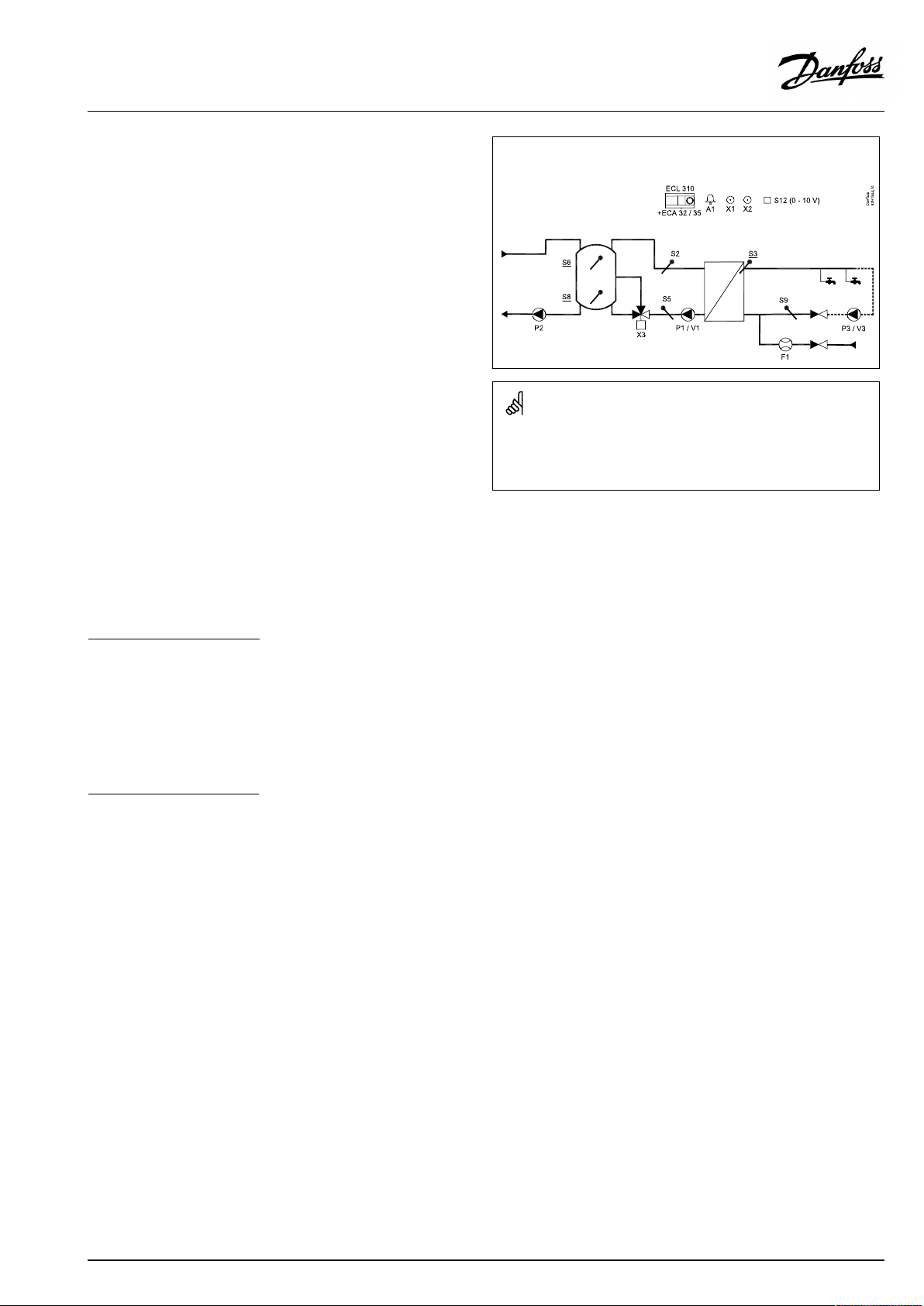

P318.11,ex.a,aapplicationwithDHWtemperaturecontrolandON/OFF

controlofbuffercharging.Inaddition,controlofreturnlayering:

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

F1

P1

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

DHWtemperaturecontrolpump(ON-OFF

controlled)

V1

SpeedcontrolofDHWtemperaturecontrolpump

(0-10VorPWM)

P2

P3

V3

X1

X2

X3

A1

Bufferchargingpump(ON-OFFcontrolled)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10VorPWM)

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Change-overvalve,layeringcontrol

Alarm

VI.JM.Q5.02

©Danfoss|2018.09|23

Page 24

OperatingGuideECLComfort310,applicationP318

ReturnwaterfromDHWheat-exchangertobuffercanbedirected

bythechange-overvalveX3,basedontemperaturerelationship

betweenS5andS8.

Thisreturnlayeringfunctiondirectslowtemperaturewaterto

buffer-bottomorhighertemperaturewatertobuffer-mid.

Differentialtemperaturesforlayeringcontrolcanbeset.

ThesupplytemperatureS2isusedtocompensatetheproportional

bandXpforimprovingthetemperaturecontrolatdifferentsupply

temperatures.

ThewaterflowsignalfromF1canbeusedtooverridethe

controlvalveforoptimizingtheDHWtemperaturecontrol.This

pro-activefunctionalitycompensatesforthedelaybeforetheflow

temperaturesensorS3measuresachangeintemperature.

ThewaterflowsignalcanalsobeutilizedforcontroloftheS3

temperature,evenifthereisnoDHWcirculation.

Asanoption,thedesiredDHWtemperaturecanbesetexternally.

Avoltagesignal(1-10Volt)canbeappliedtoinputS12(ECA32/

35).Thescaleforvoltageversustemperaturecanbeset.

TheON-OFFoutputX1isONatbufferheatingdemand.

Ananti-bacteriafunctionfortheDHWcircuitisavailablefor

activationonselecteddaysoftheweek.

Theanti-bacteriafunctioncanbesettoincludetheDHW

circulation.

TheON-OFFoutputX2isONwhenanti-bacteriafunctionisactive.

Bymeansofaweekschedule,theDHWcirculationcanbeON/OFF

controlled;thisispossiblewhenS9isconnected.

P318.11,ex.b,applicationwithDHWtemperaturecontrolandON/OFF

controlofbuffercharging.Inaddition,controlofreturnlayering.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

F1

P1

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

DHWtemperaturecontrolpump(ON-OFF

controlled)

V1

SpeedcontrolofDHWtemperaturecontrolpump

(0-10VorPWM)

P2/M2

P3

V3

Bufferchargingvalve(ON-OFFcontrolled)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

X1

X2

X3

A1

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Change-overvalve,layeringcontrol

Alarm

24|©Danfoss|2018.09

VI.JM.Q5.02

Page 25

OperatingGuideECLComfort310,applicationP318

P318.11,ex.c,applicationwithDHWtemperaturecontrolandON/OFF

controlofbuffercharging.Inaddition,controlofreturnlayering.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

F1

P1

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

DHWtemperaturecontrolpump(ON-OFF

controlled)

V1

SpeedcontrolofDHWtemperaturecontrolpump

(0-10VorPWM)

P2

P3

V3

Bufferchargingpump(ON-OFFcontrolled)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

X1

X2

X3

A1

Motorizedcontrolvalve(3-pointcontrolled)

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Change-overvalve,layeringcontrol

Alarm

VI.JM.Q5.02

©Danfoss|2018.09|25

Page 26

OperatingGuideECLComfort310,applicationP318

P318.11,ex.d,applicationwithDHWtemperaturecontrolandON/OFF

controlofbuffercharging.Inaddition,controlofreturnlayering.

Theshowndiagramisafundamentalandsimplifiedexampleanddoes

notcontainallcomponentsthatarenecessaryinasystem.

AllnamedcomponentsareconnectedtotheECLComfortcontroller.

Listofcomponents:

ECL310

ECA32

ECA35

ECLComfort310controller

Built-inextensionmodule,0-10Voutputs

Built-inextensionmodule,0-10Voutputsand

PWMoutputs

S2

S3

Supplytemperaturesensor

(mandatory)DHWtemperaturesensor

S5Returntemperaturesensor

S6

S8

S9

S12

F1

P1

(mandatory)Buffertemperaturesensor

(mandatory)Lowerbuffertemperaturesensor

DHWcirculationreturntemperaturesensor

0-10VinputfordesiredtemperatureatS3

ColdWatermeter(pulsesignal)

DHWtemperaturecontrolpump(ON-OFF

controlled)

V1

SpeedcontrolofDHWtemperaturecontrolpump

(0-10VorPWM)

P2/M2

P3

V3

Bufferchargingvalve(ON-OFFcontrolled)

Circulationpump(ON-OFFcontrolled)

Speedcontrolofcirculationpump(0-10Vor

PWM)

M1

X1

X2

X3

A1

Motorizedcontrolvalve(3-pointcontrolled)

Bufferheatingdemandsignal

Anti-bacteriafunctionisactive

Change-overvalve,layeringcontrol

Alarm

26|©Danfoss|2018.09

VI.JM.Q5.02

Page 27

OperatingGuideECLComfort310,applicationP318

Recommendations/consideringsettings:

Speed,P1/V1

"Voutmax. "/"Voutmin. "

(11165/11167)*

P318.11,ex.a

P318.11,ex.b

P318.11,ex.c

P318.11,ex.dMax./min.tosamevalue

*)

Circuit1>MENU>Settings>Controlparameters1>

**)

Circuit1>MENU>Settings>Controlparameters1>

P318,ingeneral

UptotwoRemoteControlUnits,ECA30/31,canbeconnectedto

oneECLcontrollerinordertocontroltheECLcontrollerremotely.

AdditionalECLComfortcontrollerscanbeconnectedviatheECL

485businordertoutilizecommonoutdoortemperaturesignal,

timeanddatesignals.TheECLControllersintheECL485bus

systemcanworkasmasterandslaves.TheapplicationP318can

workaloneorasaslave.

Max./min.tosamevalue

"Adapttime"(11065)*:OFF

"Adapttime"(11065)*:OFF

Actuatorrunningtime

M1"Mrun"

(11186)**

X

X

Heat-meters:

Upto5heat-meterscanbeconnectedtotheM-busterminals.

DatacanbetransferredtotheSCADAsystemviaModbusandTCP/

IPtotheECLPortal.

TheP318applicationhaseventindicationsfor

•Chargingtemperature

•Tank(buffer)temperature

•DHWflowtemperature

•Supplytemperature

•Anti-bacteria

Typically,aneventisregisteredifasettemperatureconditionis

notaccepted.Theeventscanbeprioritizedtobeindicatedas

informationoranalarm.

ThealarmA1(=relay6)canbeactivatedif:

•aneventoccurs

•atemperaturesensororitsconnectiondisconnects/short

circuits.(See:Commoncontrollersettings>System>Raw

inputoverview).

VI.JM.Q5.02

©Danfoss|2018.09|27

Page 28

OperatingGuideECLComfort310,applicationP318

PWM(PulseWidthModulation)

A200HzfrequencyisappliedtothePWMcontrolledpump.The

dutycycle(thepercentageoftheperiodtime)determinesthe

pumpspeed.

Pumpspeed,PWMor0–10Voltcontrolled

Sometypesofspeedcontrolledpumpsarelimitedtoaminimum

speed,forexample30%(PWMor3.0Volt).Eveniftheapplied

control%getslowerthan30%,thepumpspeedremainsonthe

minimumlevel*.

Furthermore,whentheappliedcontrol%getsbelow,forexample,

10%,thepumpswitchesOFF.Inordertogetthepumpswitched

ONagain,theappliedcontrol%mustexceed20%.

Thisbehaviorcan,atlowloadoratoobigpump,causeunstable

temperatureregulation.Toavoidthis,theP318hasafunction

wheretheappliedcontrolsignalisconvertedintoapulsedsignal.

Thepumpisshortlystoppedandthenstartedagain.Theresultisa

pumpspeedcontrolalsobelowtheminimumspeedlevel.

Theparameters"PWMperiod"(ID11565)and"Adapttime"(ID

11065)areusedforthisfunctionality.

*)Seethepumpmanufacturer'sdatasheet

Inputconfiguration

Inputs(asfromS7andup)whicharenotpartoftheapplicationcan

beconfiguredtobePt1000,0-10Volt,frequency(pulsecounter)

orDigitalinput.Thisfeaturemakesitpossibletocommunicate

extrasignals,suchastemperatures,pressures,ON/OFFconditions,

viaModbusandECLPortal.

TheconfigurationisdonebymeansoftheECLTool(freesoftware

fordownload)ordirectlyinadedicatedmenuintheECLPortalor

theconnectionforModbus(BMS/SCADA).

Commissioning

WhentheP318applicationhasbeenuploaded,theECLComfort

310controllerstartsinManualmode.Thiscanbeusedtoverify

correctconnectionsofinputrelatedcomponents,forexample

temperatureandpressuresensorsandflowmeters.

Inaddition,controlledcomponentscanbeverifiedforcorrect

functionality.

Theapplicationkeyisdeliveredwithfactorysettings.Depending

onsystemtype,itisrecommendedtochangesomeofthesettings

individuallyforoptimizingthefunctionality.

Thesesettingchanges,ifrequired,arelistedaftertheexplanation

ofeachsubtype(Seesection"Beforeyoustart")

Important:

Setthecorrectrunningtime"Mrun"ofMotorizedControlValve(s)

(CircuitX>MENU>Settings>Controlparameters>Mrun).

Theapplicationkeymustbeinsertedinordertochangesettings.

Thecontrollerispre-programmedwithfactorysettingsthatareshown

inthe‘ParameterIDoverview’appendix.

28|©Danfoss|2018.09

VI.JM.Q5.02

Page 29

OperatingGuideECLComfort310,applicationP318

2.2Identifyingthesystemtype

Sketchyourapplication

TheECLComfortcontrollerseriesisdesignedforawiderange

ofheating,domestichot-water(DHW)andcoolingsystemswith

differentconfigurationsandcapacities.Ifyoursystemdiffers

fromthediagramsshownhere,youmaywanttomakeasketch

ofthesystemabouttobeinstalled.Thismakesiteasiertouse

theOperatingGuide,whichwillguideyoustep-by-stepfrom

installationtofinaladjustmentsbeforetheend-usertakesover.

TheECLComfortcontrollerisauniversalcontrollerthatcanbe

usedforvarioussystems.Basedontheshownstandardsystems,

itispossibletoconfigureadditionalsystems.Inthischapteryou

findthemostfrequentlyusedsystems.Ifyoursystemisnotquite

asshownbelow,findthediagramwhichhasthebestresemblance

withyoursystemandmakeyourowncombinations.

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

applicationtypes/sub-types.

Adviceforsettings:

Factorysettingsinthesubtypesarerelatedtotheexamplesa.

Someoftheapplicationexamplesneedchangeofdedicated

settings.

Seethelistaftertheexplanationofeachsubtype(Seesection

"Beforeyoustart")

VI.JM.Q5.02

©Danfoss|2018.09|29

Page 30

OperatingGuideECLComfort310,applicationP318

2.3Mounting

2.3.1MountingtheECLComfortcontroller

SeetheInstallationGuidewhichisdeliveredtogetherwiththe

ECLComfortcontroller.

Foreasyaccess,youshouldmounttheECLComfortcontrollernear

thesystem.

ECLComfort210/296/310canbemounted

•onawall

•onaDINrail(35mm)

ECLComfort296canbemounted

•inapanelcut-out

ECLComfort210canbemountedinanECLComfort310basepart

(forfutureupgrade).

Screws,PGcableglandsandrawlplugsarenotsupplied.

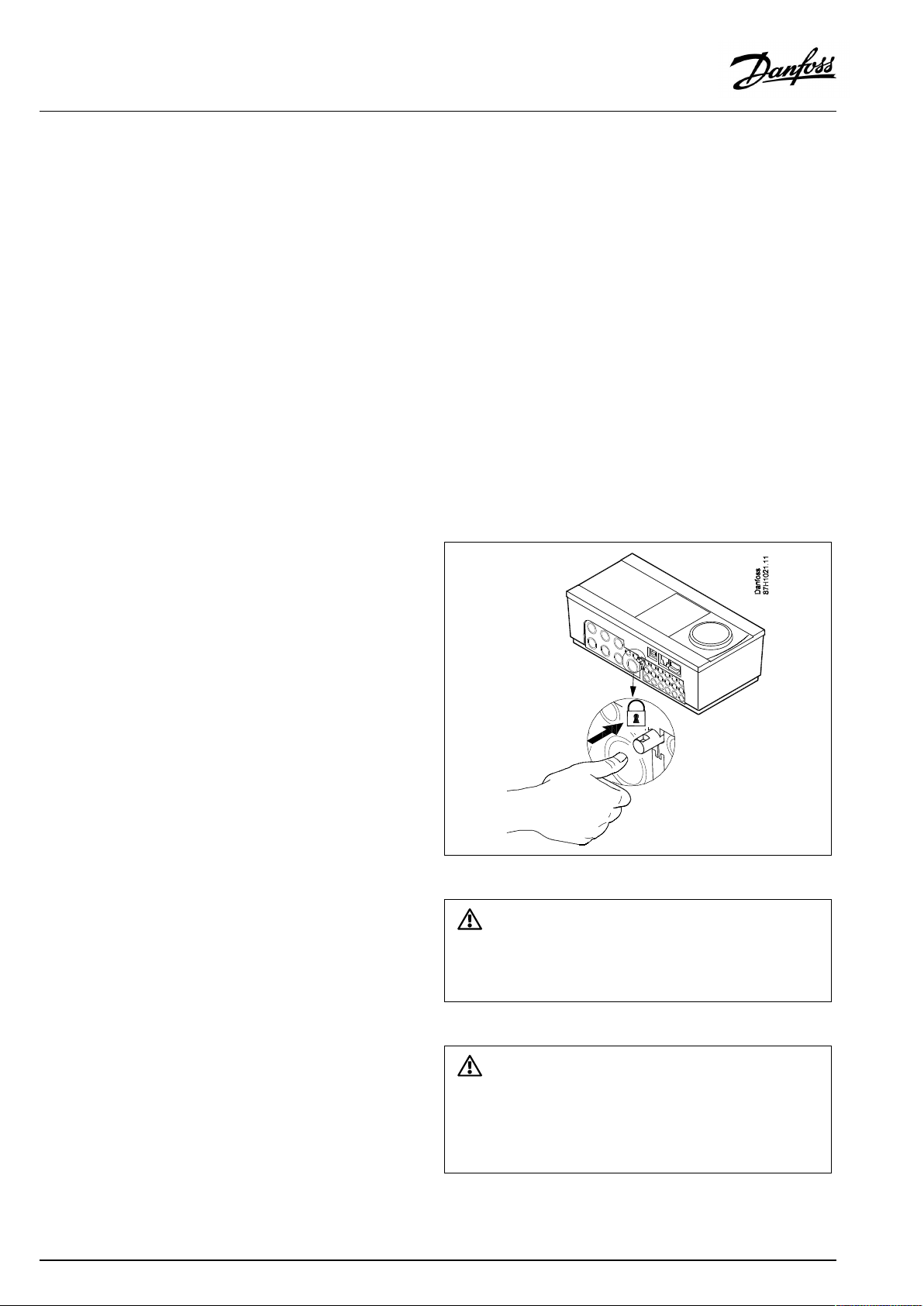

LockingtheECLComfort210/310controller

InordertofastentheECLComfortcontrollertoitsbasepart,secure

thecontrollerwiththelockingpin.

30|©Danfoss|2018.09

Topreventinjuriestopersonsorthecontroller,thecontrollerhasto

besecurelylockedintothebase.Forthispurpose,pressthelocking

pinintothebaseuntilaclickisheardandthecontrollernolonger

canberemovedfromthebase.

Ifthecontrollerisnotsecurelylockedintothebasepart,thereisarisk

thatthecontrollerduringoperationcanunlockfromthebaseandthe

basewithterminals(andalsothe230Va.c.connections)areexposed.

Topreventinjuriestopersons,alwaysmakesurethatthecontroller

issecurelylockedintoitsbase.Ifthisisnotthecase,thecontroller

shouldnotbeoperated!

VI.JM.Q5.02

Page 31

OperatingGuideECLComfort310,applicationP318

Mountingonawall

Mountthebasepartonawallwithasmoothsurface.Establishthe

electricalconnectionsandpositionthecontrollerinthebasepart.

Securethecontrollerwiththelockingpin.

MountingonaDINrail(35mm)

MountthebasepartonaDINrail.Establishtheelectrical

connectionsandpositionthecontrollerinthebasepart.Secure

thecontrollerwiththelockingpin.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

DismountingtheECLComfortcontroller

Inordertoremovethecontrollerfromthebasepart,pulloutthe

lockingpinbymeansofascrewdriver.Thecontrollercannowbe

removedfromthebasepart.

Theeasywaytolockthecontrollertoitsbaseorunlockitistousea

screwdriveraslever.

VI.JM.Q5.02

©Danfoss|2018.09|31

Page 32

OperatingGuideECLComfort310,applicationP318

2.3.2MountingtheRemoteControlUnitsECA30/31

Selectoneofthefollowingmethods:

•Mountingonawall,ECA30/31

•Mountinginapanel,ECA30

Screwsandrawlplugsarenotsupplied.

Mountingonawall

MountthebasepartoftheECA30/31onawallwithasmooth

surface.Establishtheelectricalconnections.PlacetheECA30/

31inthebasepart.

BeforeremovingtheECLComfortcontrollerfromthebasepart,ensure

thatthesupplyvoltageisdisconnected.

Mountinginapanel

MounttheECA30inapanelusingtheECA30framekit(ordercode

no.087H3236).Establishtheelectricalconnections.Securethe

framewiththeclamp.PlacetheECA30inthebasepart.TheECA

30canbeconnectedtoanexternalroomtemperaturesensor.

TheECA31mustnotbemountedinapanelifthehumidity

functionistobeused.

32|©Danfoss|2018.09

VI.JM.Q5.02

Page 33

OperatingGuideECLComfort310,applicationP318

2.3.3MountingtheinternalI/OmoduleECA32orECA35

TheECA32module(ordercodeno.087H3202)orECA35module

(ordercodeno.087H3205)canbeinsertedintotheECLComfort

310/310Bbasepartforadditionalinputandoutputsignalsin

relevantapplications.

ECA32

ECA35

VI.JM.Q5.02

©Danfoss|2018.09|33

Page 34

OperatingGuideECLComfort310,applicationP318

2.4Placingthetemperaturesensors

2.4.1Placingthetemperaturesensors

Itisimportantthatthesensorsaremountedinthecorrectposition

inyoursystem.

Thetemperaturesensormentionedbelowaresensorsusedforthe

ECLComfort210/296/310serieswhichnotallwillbeneeded

foryourapplication!

Outdoortemperaturesensor(ESMT)

Theoutdoorsensorshouldbemountedonthatsideofthebuilding

whereitislesslikelytobeexposedtodirectsunshine.Itshouldnot

beplacedclosetodoors,windowsorairoutlets.

Flowtemperaturesensor(ESMU,ESM-11orESMC)

Placethesensormax.15cmfromthemixingpoint.Insystems

withheatexchanger,DanfossrecommendsthattheESMU-typeto

beinsertedintotheexchangerflowoutlet.

Makesurethatthesurfaceofthepipeiscleanandevenwhere

thesensorismounted.

Returntemperaturesensor(ESMU,ESM-11orESMC)

Thereturntemperaturesensorshouldalwaysbeplacedsothatit

measuresarepresentativereturntemperature.

Roomtemperaturesensor

(ESM-10,ECA30/31RemoteControlUnit)

Placetheroomsensorintheroomwherethetemperatureistobe

controlled.Donotplaceitonoutsidewallsorclosetoradiators,

windowsordoors.

Boilertemperaturesensor(ESMU,ESM-11orESMC)

Placethesensoraccordingtotheboilermanufacturer’s

specification.

Airducttemperaturesensor(ESMB-12orESMUtypes)

Placethesensorsothatitmeasuresarepresentativetemperature.

DHWtemperaturesensor(ESMUorESMB-12)

PlacetheDHWtemperaturesensoraccordingtothemanufacturer’s

specification.

Slabtemperaturesensor(ESMB-12)

Placethesensorinaprotectiontubeintheslab.

ESM-11:Donotmovethesensorafterithasbeenfastenedinorderto

avoiddamagetothesensorelement.

ESM-11,ESMCandESMB-12:Useheatconductingpasteforquick

measurementofthetemperature.

ESMUandESMB-12:Usingasensorpockettoprotectthesensorwill,

however,resultinaslowertemperaturemeasurement.

34|©Danfoss|2018.09

VI.JM.Q5.02

Page 35

OperatingGuideECLComfort310,applicationP318

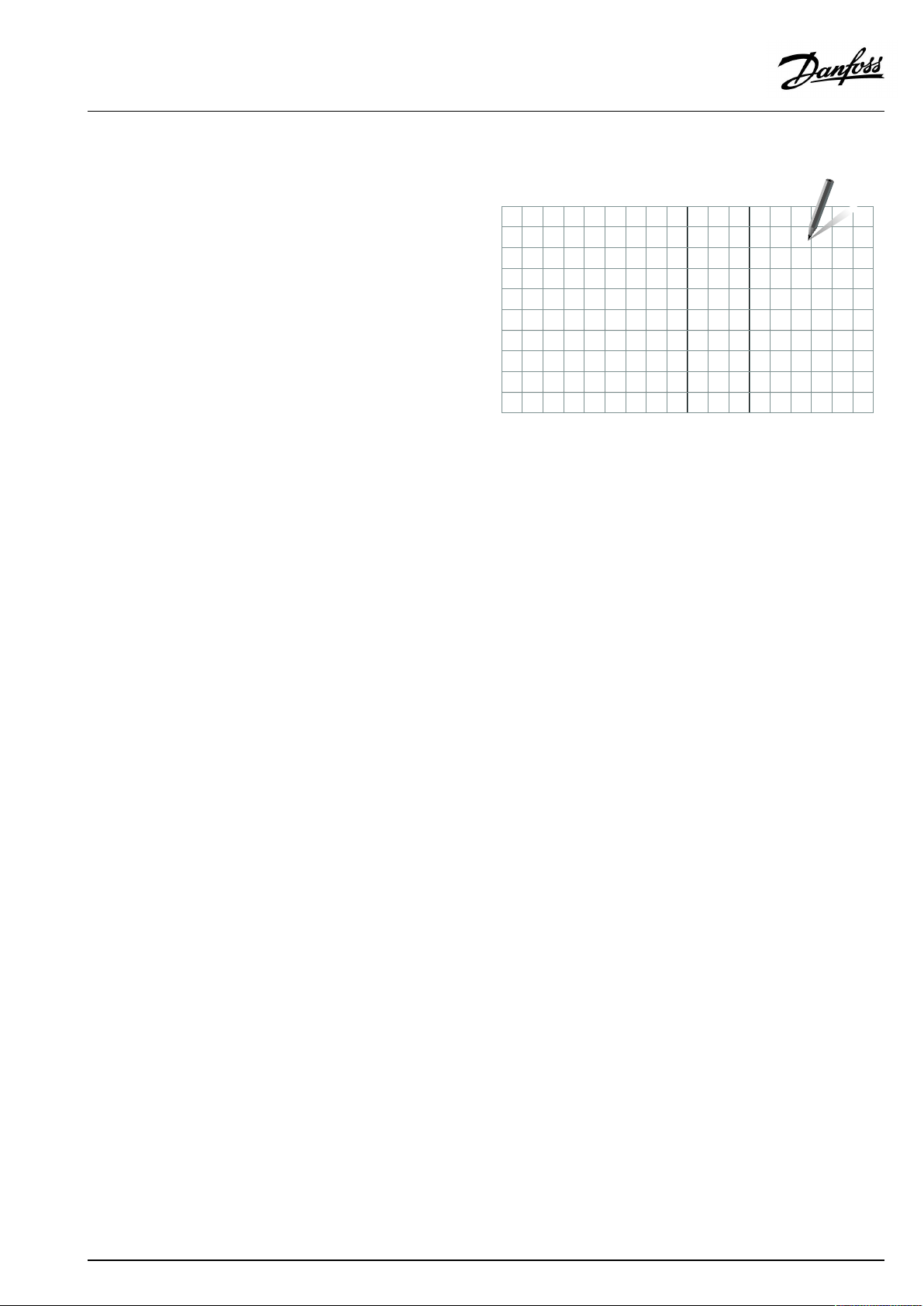

Pt1000temperaturesensor(IEC751B,1000Ω/0°C)

Relationshipbetweentemperatureandohmicvalue:

VI.JM.Q5.02

©Danfoss|2018.09|35

Page 36

OperatingGuideECLComfort310,applicationP318

2.5Electricalconnections

2.5.1Electricalconnections230Va.c.

SafetyNote

Necessaryassembly,start-up,andmaintenanceworkmustbe

performedbyqualifiedandauthorizedpersonnelonly.

Locallegislationsmustberespected.Thiscomprisesalsocablesize

andisolation(reinforcedtype).

AfusefortheECLComfortinstallationismax.10Atypically.

TheambienttemperaturerangefortheECLComfortinoperationis

0-55°C.Exceedingthistemperaturerangecanresultinmalfunctions.

Installationmustbeavoidedifthereisariskforcondensation(dew).

Thecommongroundterminalisusedforconnectionofrelevant

components(pumps,motorizedcontrolvalves).

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)

forapplicationspecificconnections.

ECL210/310

Wirecrosssection:0.5-1.5mm²

Incorrectconnectioncandamagetheelectronicoutputs.

Max.2x1.5mm²wirescanbeinsertedintoeachscrewterminal.

Maximumloadratings:

36|©Danfoss|2018.09

Relayterminals

Triac(=electronic

relay)terminals

4(2)A/230Va.c.

(4Aforohmicload,2Afor

inductiveload)

0,2A/230Va.c.

VI.JM.Q5.02

Page 37

OperatingGuideECLComfort310,applicationP318

Electricalconnections,ECA32/ECA35

Connections,ingeneral.

SeealsotheInstallationGuide(deliveredwiththeapplicationkey)forapplicationspecificconnections.

Maximumloadratings:

Terminals

ECA32ECA35

PWMOut1(52)

PWMOut2(53)

PWMOut3(54)

PWMOut4(55)

AnalogOut1(59)AnalogOut1(59)47kΩ*

AnalogOut2(60)AnalogOut2(60)47kΩ*

AnalogOut3(61)AnalogOut3(61)47kΩ*

*Thevalueisaminimum.

5kΩ*

5kΩ*

5kΩ*

5kΩ*

VI.JM.Q5.02

©Danfoss|2018.09|37

Page 38

OperatingGuideECLComfort310,applicationP318

2.5.2Electricalconnections,Pt1000temperaturesensorsandsignals

SeetheInstallationGuide(deliveredwiththeapplicationkey)for

sensorandinputconnections.

Applicationdiagramsshowmandatorytemperaturesensorswith

anunderscore;exampleS3.

P318

Sensor

S1

S2

S3*

S4*

S5Returntemperature

S6P318.1,P318.2,

S7

S8P318.1,P318.2,

S9

S10

Description

Notused

Supplytemperature

sensor

P318.1,P318.2:

Chargingtemperature

sensor

P318.10,P318.11:

DHWflowtemperature

sensor

P318.2:

DHWflowtemperature

sensor

sensor

P318.11:Upper

buffer-tank

temperaturesensor

P318.10:Notused

Notused

P318.11:Lower

buffer-tank

temperaturesensor

P318.10:Notused

DHWcirculation

temperaturesensor

Notused

Recommended

type

ESM-11/

ESMB/

ESMC/

ESMU

ESM-11/

ESMB/

ESMC/

ESMU

ESM-11/

ESMB/

ESMC/

ESMU

ESMB/

ESMU

ESMB/

ESMU

ESM-11/

ESMB/

ESMC/

ESMU

Temperaturesensorsmustbeconnectedinordertohavethe

desiredfunctionality.

*

Ifthesensorisnotconnectedorthesensorcableis

short-circuited,themotorizedcontrolvalveorcontrolpump

closes/stops(safetyfunction).

38|©Danfoss|2018.09

VI.JM.Q5.02

Page 39

OperatingGuideECLComfort310,applicationP318

Wirecrosssectionforsensorconnections:Min.0.4mm².

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

VI.JM.Q5.02

©Danfoss|2018.09|39

Page 40

OperatingGuideECLComfort310,applicationP318

2.5.3Electricalconnections,ECA30/31

Terminal

ECL

Terminal

ECA30/31

30

31

4

1

322

333

4

5

*

Afteranexternalroomtemperaturesensorhasbeenconnected,

Description

Twistedpair

Twistedpair

Ext.roomtemperature

sensor*

Type

(recomm.)

Cable2x

twistedpair

ESM-10

ECA30/31mustberepowered.

ThecommunicationtotheECA30/31mustbesetupintheECL

Comfortcontrollerin'ECAaddr.'

TheECA30/31mustbesetupaccordingly.

AfterapplicationsetuptheECA30/31isreadyafter2–5min.A

progressbarintheECA30/31isdisplayed.

Iftheactualapplicationcontainstwoheatingcircuits,itispossible

toconnectanECA30/31toeachcircuit.Theelectricalconnections

aredoneinparallel.

Max.2ECA30/31canbeconnectedtoanECLComfort310controller

ortoECLComfort210/296/310controllersinamaster-slavesystem.

SetupproceduresforECA30/31:Seesection‘Miscellaneous’ .

ECAinformationmessage:

‘Applicationreq.newerECA’:

Thesoftware(firmware)ofyourECAdoesnotcomplywiththe

software(firmware)ofyourECLComfortcontroller.Pleasecontact

yourDanfosssalesoffice.

Someapplicationsdonotcontainfunctionsrelatedtoactualroom

temperature.TheconnectedECA30/31willonlyfunctionasremote

control.

40|©Danfoss|2018.09

VI.JM.Q5.02

Page 41

OperatingGuideECLComfort310,applicationP318

ECA32/35

S12

Connectionofvoltagesignal(0–10V)forexternalcontrolofdesired

DHWtemperature.

Theappliedvoltagemust,asaminimum,be1Volt.

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

VI.JM.Q5.02

©Danfoss|2018.09|41

Page 42

OperatingGuideECLComfort310,applicationP318

2.5.4Electricalconnections,master/slavesystems

Thecontrollercanbeusedasmasterorslaveinmaster/slave

systemsviatheinternalECL485communicationbus(2xtwisted

paircable).

TheECL485communicationbusisnotcompatiblewiththeECL

businECLComfort110,200,300and301!

Terminal

31*

Description

30

Commonterminal

+12V*,ECL485communicationbus

32

B,ECL485communicationbus

33

A,ECL485communicationbus

*OnlyforECA30/31andmaster/slavecommunication

Type

(recomm.)

Cable2x

twistedpair

Totalcablelength:Max.200m(allsensorsincl.internalECL485

communicationbus).

Cablelengthsofmorethan200mmaycausenoisesensibility(EMC).

ECL485buscable

MaximumrecommendedlengthoftheECL485busiscalculatedlike

this:

Subtract"TotallengthofallinputcablesofallECLcontrollersinthe

master-slavesystem"from200m.

Simpleexamplefortotallengthofallinputcables,3xECL:

1xECL

3xECL

3xECLReturntemp.sensor:

3xECLRoomtemp.sensor:

Total:

MaximumrecommendedlengthoftheECL485bus:

200-81m=119m

Outdoortemp.sensor:

Flowtemp.sensor:

15m

18m

18m

30m

81m

42|©Danfoss|2018.09

VI.JM.Q5.02

Page 43

OperatingGuideECLComfort310,applicationP318

2.5.5Electricalconnections,communication

Electricalconnections,Modbus

ECLComfort210:Non-galvanicisolatedModbusconnections

ECLComfort296:GalvanicisolatedModbusconnections

ECLComfort310:GalvanicisolatedModbusconnections

Electricalconnections,M-bus

ECLComfort210:Notimplemented

ECLComfort296:Onboard

ECLComfort310:Onboard

Example,M-busconnections

(ECLComfort296/310and310Bonly)

VI.JM.Q5.02

©Danfoss|2018.09|43

Page 44

OperatingGuideECLComfort310,applicationP318

2.6InsertingtheECLApplicationKey

2.6.1InsertingtheECLApplicationKey

TheECLApplicationKeycontains

•theapplicationanditssubtypes,

•currentlyavailablelanguages,

•factorysettings:e.g.schedules,desiredtemperatures,

limitationvaluesetc.Itisalwayspossibletorecoverthefactory

settings,

•memoryforusersettings:specialuser/systemsettings.

Afterhavingpowered-upthecontroller,differentsituationsmight

beexisting:

1.Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

2.Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

3.Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

ECLComfort210/310

ECLComfort210/310

Usersettingsare,amongothers,desiredroomtemperature,desired

DHWtemperature,schedules,heatcurve,limitationvaluesetc.

Systemsettingsare,amongothers,communicationset-up,display

brightnessetc.

44|©Danfoss|2018.09

VI.JM.Q5.02

Page 45

OperatingGuideECLComfort310,applicationP318

Automaticupdateofcontrollersoftware(firmware):

Thesoftwareofthecontrollerisupdatedautomaticallywhenthekey

isinserted(asofcontrollerversion1.11(ECL210/310)andversion

1.58(ECL296)).Thefollowinganimationwillbeshownwhenthe

softwareisbeingupdated:

Progressbar

Duringupdate:

•DonotremovetheKEY

Ifthekeyisremovedbeforethehour-glassisshown,youhave

tostartafresh.

•Donotdisconnectthepower

Ifthepowerisinterruptedwhenthehour-glassisshown,the

controllerwillnotwork.

•Manualupdateofcontrollersoftware(firmware):

Seethesection"Automatic/manualupdateoffirmware"

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

VI.JM.Q5.02

©Danfoss|2018.09|45

Page 46

OperatingGuideECLComfort310,applicationP318

ApplicationKey:Situation1

Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

AnanimationfortheECLApplicationKeyinsertionisdisplayed.

InserttheApplicationKey.

ApplicationKeynameandVersionisindicated(example:A266

Ver.1.03).

IftheECLApplicationKeyisnotsuitableforthecontroller,a"cross"

isdisplayedovertheECLApplicationKey-symbol.

Action:Purpose:

Selectlanguage

Confirm

Selectapplication(subtype)

Somekeyshaveonlyoneapplication.

Confirmwith‘Yes’

Set'Time&Date'

Turnandpushthedialtoselectand

change'Hours' ,'Minutes','Date',

'Month'and'Year' .

Choose''Next'

Confirmwith‘Yes’

Goto‘Aut.daylight’

Choosewhether‘ Aut.daylight´*

shouldbeactiveornot

*‘Aut.daylight’istheautomaticchangeoverbetweensummer

andwintertime.

DependingonthecontentsoftheECLApplicationKey,procedure

AorBistakingplace:

A

TheECLApplicationkeycontainsfactorysettings:

Thecontrollerreads/transfersdatafromtheECLApplicationKey

toECLcontroller.

Examples:

YESorNO

Theapplicationisinstalled,andthecontrollerresetsandstartsup.

B

TheECLApplicationkeycontainschangedsystemsettings:

Pushthedialrepeatedly.

’NO’:

’YES*:

Ifthekeycontainsusersettings:

Pushthedialrepeatedly.

‘NO:

‘YES*:

*If‘YES’cannotbechosen,theECLApplicationKeydoesnot

containanyspecialsettings.

Choose‘Startcopying’andconfirmwith'Yes'.

46|©Danfoss|2018.09

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialsystemsettings(differingfromthefactory

settings)willbecopiedtothecontroller.

OnlyfactorysettingsfromtheECLApplicationKeywill

becopiedtothecontroller.

Specialusersettings(differingfromthefactorysettings)

willbecopiedtothecontroller.

VI.JM.Q5.02

Page 47

OperatingGuideECLComfort310,applicationP318

(Example):

The"i"intheupperrightcornerindicatesthat-besidesthefactory

settings-thesubtypealsocontainsspecialuser/systemssettings.

ApplicationKey:Situation2

Thecontrolleralreadyrunsanapplication.TheECLApplication

Keyisinserted,buttheapplicationneedstobechanged.

TochangetoanotherapplicationontheECLApplicationKey,the

currentapplicationinthecontrollermustbeerased(deleted).

BeawarethattheApplicationKeymustbeinserted.

Action:Purpose:

Choose‘MENU’inanycircuit

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose‘Commoncontrollersettings’

Confirm

Choose‘Keyfunctions’

Confirm

Choose‘Eraseapplication’

Confirmwith‘Yes’

Thecontrollerresetsandisreadytobeconfigured.

Followtheproceduredescribedinsituation1.

Examples:

VI.JM.Q5.02

©Danfoss|2018.09|47

Page 48

OperatingGuideECLComfort310,applicationP318

ApplicationKey:Situation3

Acopyofthecontrollerssettingsisneededforconfiguring

anothercontroller.

Thisfunctionisused

•forsaving(backup)ofspecialuserandsystemsettings

•whenanotherECLComfortcontrollerofthesametype(210,

296or310)mustbeconfiguredwiththesameapplicationbut

user/systemsettingsdifferfromthefactorysettings.

HowtocopytoanotherECLComfortcontroller:

Action:Purpose:

Choose‘MENU’

Confirm

Choosethecircuitselectoratthetop

rightcornerinthedisplay

Confirm

Choose'Commoncontrollersettings'

Confirm

Goto‘Keyfunctions’

Confirm

Choose‘Copy’

Confirm

Choose‘To’ .

‘ECL’or‘KEY’willbeindicated.Choose

’ECL’orKEY’

Pushthedialrepeatedlytochoose

copydirection

Choose‘Systemsettings’or‘User

settings’

Pushthedialrepeatedlytochoose

‘Yes’or‘No’in‘Copy’ .Pushtoconfirm.

Choose‘Startcopying’

TheApplicationKeyorthecontroller

isupdatedwithspecialsystemoruser

settings.

Examples:

*

’ECL’or‘KEY’ .

**

‘NO’or‘YES’

*

‘ECL’:

‘KEY’:

**

‘NO’:

‘YES’:

48|©Danfoss|2018.09

DatawillbecopiedfromtheApplicationKeytothe

ECLController.

DatawillbecopiedfromtheECLControllertothe

ApplicationKey.

ThesettingsfromtheECLcontrollerwillnotbecopied

totheApplicationKeyortotheECLComfortcontroller.

Specialsettings(differingfromthefactorysettings)will

becopiedtotheApplicationKeyortotheECLComfort

controller.IfYEScannotbechosen,therearenospecial

settingstobecopied.

VI.JM.Q5.02

Page 49

OperatingGuideECLComfort310,applicationP318

2.6.2ECLApplicationKey,copyingdata

Generalprinciples

Whenthecontrollerisconnectedandoperating,youcancheck

andadjustallorsomeofthebasicsettings.Thenewsettingscan

bestoredontheKey.

HowtoupdatetheECLApplicationKeyaftersettingshave

beenchanged?

AllnewsettingscanbestoredontheECLApplicationKey.

Factorysettingscanalwaysberestored.

Howtostorefactorysettinginthecontrollerfromthe

ApplicationKey?

PleasereadtheparagraphconcerningApplicationKey,Situation

1:Thecontrollerisnewfromthefactory,theECLApplicationKey

isnotinserted.

HowtostorepersonalsettingsfromthecontrollertotheKey?

PleasereadtheparagraphconcerningApplicationKey,Situation3:

Acopyofthecontrollerssettingsisneededforconfiguringanother

controller

Asamainrule,theECLApplicationKeyshouldalwaysremainin

thecontroller.IftheKeyisremoved,itisnotpossibletochange

settings.

Makeanoteofnewsettingsinthe'Settingsoverview'table.

DonotremovetheECLApplicationKeywhilecopying.Thedataon

theECLApplicationKeycanbedamaged!

ItispossibletocopysettingsfromoneECLComfortcontrollerto

anothercontrollerprovidedthatthetwocontrollersarefromthesame

series(210or310).

Furthermore,whentheECLComfortcontrollerhasbeenuploaded

withanapplicationkey,minimumversion2.44,itispossibletoupload

personalsettingsfromapplicationkeys,minimumversion2.14.

The“Keyoverview”doesnotinform—throughECA30/31—about

thesubtypesoftheapplicationkey.

Keyinserted/notinserted,description:

ECLComfort210/310,controllerversionslowerthan1.36:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;for20minutes

settingscanbechanged.

ECLComfort210/310,controllerversions1.36andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

ECLComfort296,controllerversions1.58andup:

-

Takeouttheapplicationkey;for20minutes

settingscanbechanged.

-

Powerupthecontrollerwithoutthe

applicationkeyinserted;settingscannotbe

changed.

VI.JM.Q5.02

©Danfoss|2018.09|49

Page 50

OperatingGuideECLComfort310,applicationP318

2.7Checklist

IstheECLComfortcontrollerreadyforuse?

Makesurethatthecorrectpowersupplyisconnectedtoterminals9and10(230Vor24V).

Makesurethecorrectphaseconditionsareconnected:

230V:Live=terminal9andNeutral=terminal10

24V:SP=terminal9andSN=terminal10

Checkthattherequiredcontrolledcomponents(actuator,pumpetc.)areconnectedtothecorrectterminals.

Checkthatallsensors/signalsareconnectedtothecorrectterminals(see'Electricalconnections').

Mountthecontrollerandswitchonthepower.

IstheECLApplicationKeyinserted(see'InsertingtheApplicationKey').

DoestheECLComfortcontrollercontainanexistingapplication(see'InsertingtheApplicationKey').

Isthecorrectlanguagechosen(see'Language'in'Commoncontrollersettings').

Isthetime&datesetcorrectly(see'Time&Date'in'Commoncontrollersettings').

Istherightapplicationchosen(see'Identifyingthesystemtype').

Checkthatallsettingsinthecontroller(see'Settingsoverview')aresetorthatthefactorysettingscomplywithyour

requirements.

Choosemanualoperation(see'Manualcontrol').Checkthatvalvesopenandclose,andthatrequiredcontrolled

components(pumpetc.)startandstopwhenoperatedmanually.

Checkthatthetemperatures/signalsshowninthedisplaymatchtheactualconnectedcomponents.

Havingcompletedthemanualoperationcheck,choosecontrollermode(scheduled,comfort,savingorfrostprotection).

50|©Danfoss|2018.09

VI.JM.Q5.02

Page 51

OperatingGuideECLComfort310,applicationP318

2.8Navigation,ECLApplicationKeyA318

Navigation,P318.1,circuits1and2(DHW)

Home

MENU

Schedule,Circ.P

Settings

IDnos.

TanktemperatureExt.desiredT(

11195Startdifference(

11194

11371

11152

Returnlimit

Controlpar.1

Controlpar.2

11030

11035

11036

11037

11184

11185

11186

11187

11165

11167

11189

11171

11330

11565

11065

12184

12185

12187

12165

12167

12171

12375

Function

Stopdifference

Pumpstartdiff.

Max.chargeT

Limit

Infl.-max.

Infl.-min.

Adapt.time

Xp

Tn

Mrun

Nz

Voutmax.

Voutmin.

Min.act.time

Reverseout

Wakeuplevel

PWMperiod

Adapttime

Xp

Tn

Nz

Voutmax.

Voutmin.

Reverseout

Reduceddes.T

P318.1

Circuit

1

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

(

2

(

VI.JM.Q5.02

©Danfoss|2018.09|51

Page 52

OperatingGuideECLComfort310,applicationP318

Navigation,P318.1,circuits1and2(DHW),continued

Home

MENU

Settings

Event

Influenceoverview

TankTReturnlim.

Circ.returnT

Controlpar.3

Application11054Cont.Tcontrol(

Anti-bacteria

ChargeT

Tanktemp.

SupplyT

Anti-bacteria

Tsensordefect

Eventoverview

Ext.override

Anti-bacteria

Ext.desiredT

Anti-bacteria

IDnos.

11041

11500

11145

11147

9022

11148