Page 1

User Manual

PLUS+1® Compliant

OX012-x10 Function Block

www.danfoss.com

Page 2

User Manual

PLUS+1® Compliant OX012-x10 Function Block

Revision history Table of revisions

Date Changed Rev

July 2018 Rebranding 0101

June 2009 AA

2 | © Danfoss | July 2018 11063396 | AQ00000105en-US0101

Page 3

User Manual

PLUS+1® Compliant OX012-x10 Function Block

Contents

OX012-x10 Function Block

Configure CAN...................................................................................................................................................................................4

Inputs – Power Supply....................................................................................................................................................................5

Inputs – CAN Shield......................................................................................................................................................................... 5

Inputs – MFOut Output Status.....................................................................................................................................................6

Outputs – Group...............................................................................................................................................................................6

Outputs – MultiFunction Outputs..............................................................................................................................................6

Inputs – CAN.......................................................................................................................................................................................7

Connections and Signal Overview............................................................................................................................................. 8

Configuring Communications..................................................................................................................................................... 9

Variable Addressing Mode.......................................................................................................................................................9

Predefined Addressing Mode.................................................................................................................................................9

Fixed Addressing Mode............................................................................................................................................................9

Volatile Parameters.....................................................................................................................................................................9

Non-Volatile Parameters...........................................................................................................................................................9

Timing Configurations.............................................................................................................................................................. 9

CAN Bus Load.............................................................................................................................................................................10

CAN Message Identifiers..............................................................................................................................................................10

Troubleshooting.............................................................................................................................................................................10

©

Danfoss | July 2018 11063396 | AQ00000105en-US0101 | 3

Page 4

User Manual

PLUS+1® Compliant OX012-x10 Function Block

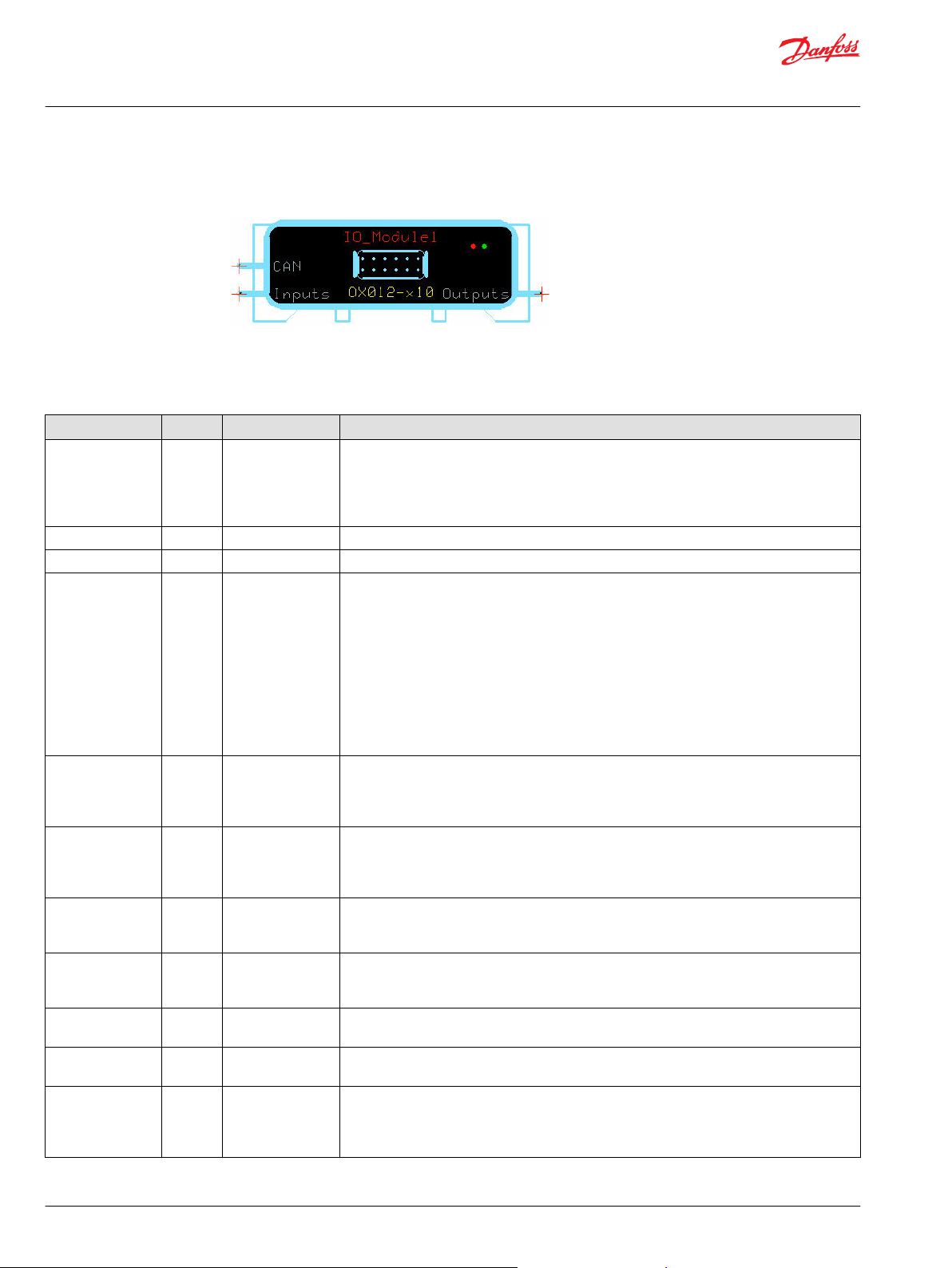

OX012-x10 Function Block

The IO_Module function block enables communication with the OX012-x10 expansion module so that

additional outputs can be used.

Configure CAN

Set up CAN so that CAN messages can be transmitted to and from the I/O module.

Input Type Range Description

CAN Bus —— In the GUIDE template, identify the CAN bus that contains CAN messages to and from the I/O

module. Route this bus to the CAN input on this function block.

CAN messages sent from the I/O module to the function block contain information about the

I/O modules’ inputs, outputs and configuration. CAN messages sent to the I/O module from the

function block set outputs and configurations.

Baudrate U32 50000–1000000 The Baudrate is the speed of the CAN Port.

Port Port —— Assigns the hardware CAN port that transmits the data.

AddrMode U8 0–2 I/O module addressing mode.

0: Variable ID addressing mode. The I/O module Tx and Rx message identifiers are determined

by the I/O module measuring the voltage on its CAN shield input and matching that value with a

predefined range and matching identifiers in the I/O Module CAN Message Identifiers table. The

CAN messages use 11 bit identifiers in this mode.

1: Predefined ID addressing mode. The I/O module Tx and Rx message identifiers are

determined by Node/N1. These identifiers are selected by matching to the N1 value in the I/O

Module CAN Message Identifiers table. The CAN messages use 11 bit identifiers in this mode.

2: Fixed ID addressing mode. The I/O module Tx and Rx message identifiers are determined

directly by setting Tx ID and Rx ID. The CAN messages use either 11 bit or 29 bit identifiers in

this mode, as determined by Frame.

Tx ID U32 0x00–0x1FFFFFFF Tx ID is the CAN message identifier used by the function block for sending messages to the I/O

module when using the Fixed ID addressing mode.

When using the service tool to configure the I/O module, this value corresponds to the Rx

parameter saved on the I/O module.

Rx ID U32 0x00–0x1FFFFFFF Rx ID is the CAN message identifier used by the function block for receiving messages from the

I/O module when using the Fixed ID addressing mode.

When using the service tool to configure the I/O module, this value corresponds to the Tx

parameter saved on the I/O module.

Frame U8 0–1 Sets CAN message identifier length when using the Fixed ID addressing mode.

0: 11 bit ID

1: 29 bit ID

Node/N1 U8 0–15 The KWP2000 node address used for communications between the I/O module and the PLUS+1

Service Tool is Node/N1 x 8. For Variable ID addressing mode and Predefined addressing mode

this value also determines the CAN.

Net U8 0–255 KWP2000 network used for communications between the I/O module and the PLUS+1® Service

Tool.

Enable BOOL —— Enables the function block to send CAN messages to the I/O module. An F/T transition or T at

power up starts initialization.

Enbl_RecheckCRC BOOL —— Determines if the I/O module CRC is periodically checked to ensure the device’s configuration

matches the function block’s configuration.

T: The CRC is requested from the I/O module and compared every 5 seconds.

F: The CRC is only requested from the I/O module during initialization.

®

4 | © Danfoss | July 2018 11063396 | AQ00000105en-US0101

Page 5

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

Input Type Range Description

Enbl_ResetTest BOOL —— Determines if the I/O module volatile memory is periodically checked to ensure the device has

not lost volatile configuration information due to temporary loss of power.

T: Volatile information is requested from the I/O module and compared every 1 second.

F: Volatile memory is not checked after initialization and temporary loss of power to the I/O

module may go undetected.

BusRecvryTm U16 0–65535 BusRecvryTm sets the time the I/O module CAN port waits after going into a “bus off” condition

before attempting to go back on the bus.

1000 is 1 ms.

DriverRecvryTm U16 0–65535 DriverRecvryTm sets the time the I/O module CAN port waits after a CAN error causes the

driver to reset before attempting to go back on the bus.

1000 is 1 ms.

RepTime_Supply U16 0–65535 Determines how often the Power, Sensor Power, and CAN Shield input values are transmitted

from the I/O module.

1000 is 1 ms.

RepTime_Status U16 0–65535 Determines how often the Output Status values are transmitted from the I/O module.

1000 is 1 ms.

RepTime_Outputs U16 0–65535 Determines how often the Output values are transmitted to the I/O module.

1000 is 1 ms.

TimeOut_Outputs U16 0–65535 Sets the maximum time allowed between commands for each output. If a command is not

received by the I/O module before the TimeOut_Outputs elapses then that output reverts to its

default output value and default pin configuration.

1000 is 1 ms.

Inputs – Power Supply

The status of power supply input on the connector and pin C1p02 is described.

Signal Type Direction Range Description

C1p02_Pwr Bus —— ——

AnIn U16 Input 0 – 32767 Analog input AD count.

Due to CAN message optimization, this value is approximated by scaling the Volt

signal.

Volt U16 Input 0 – 36000 Analog input voltage

100 is 100 mV.

Updated BOOL Input —— True when the AnIn and Volt signals are refreshed.

Inputs – CAN Shield

The status of analog and CAN0 shield inputs on the connector and pin C1p05 is described.

Signal Type Direction Range Description

C1p05_AnIn Bus —— ——

AnIn U16 Input 0 – 32767 Analog input AD count.

Due to CAN message optimization, this value is approximated by scaling the Volt

signal.

Volt U16 Input 0 – 5250 Analog input voltage.

100 is 100 mV.

Updated BOOL Input —— True when the AnIn and Volt signals are refreshed.

©

Danfoss | July 2018 11063396 | AQ00000105en-US0101 | 5

Page 6

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

Inputs – MFOut Output Status

The status of inputs for multifunction outputs on connectors and pins C1p06, C1p07, C1p08, C1p09,

C1p11, and C1p12 is described.

Signal Type Direction Range Description

Pin _Status Bus —— ——

FeedBackValue S16 Input -32768 –

32767

PinStatus U16 Input 0 – 2 Output pin status.

Updated BOOL Input —— True when the FeedBackValue and PinStatus signals are refreshed.

Outputs – Group

The status for two groups of outputs is described.

A pin group is for C1p06, C1p07 and C1p08.

Another pin group is for C1p09, C1p10 and C1p11.

Measured current flowing through the output pin.

1000 is 100 mA.

0: OK.

1: Incorrect pin configuration.

2: Overload detected.

Signal Type Direction Range Description

CurChgLim U16 Output 22 – 333 CurChgLim defines the maximum rate of change of current for the group of

outputs. This parameter is only used when the output’s PinConfig is 4 or 5.

111 is 11.1 mA/ms.

DitherFreq U16 Output 40 – 250 Sets dither frequency when output dither is enabled for the group.

40 is 40 Hz.

ReqFreq U16 Output 30 – 4000 Sets the base PWM frequency for the group.

30 is 30 Hz.

Outputs – MultiFunction Outputs

The output status of multifunction outputs on connectors and pins C1p06, C1p07, C1p08, C1p09, C1p10,

and C1p11 is described.

Signal Type Direction Range Description

Pin _MFOut Bus —— ——

Config Bus —— ——

PinConfig U16 Output 0 – 8 Output pin configuration

0: Digital Output, Push/Pull

1: Digital Output, Sourcing

2: Digital Output, Sinking

3: PWM Output, 0 – 10000 [0.01% positive duty]

4: PWM Output, 0 – 30000 [0.1 mA]

5: PWM Output, 0 – 30000 [0.1 mA] Dither Enabled

6: PVE Output, 0 – 10000 [0.01% of PVE Power]

7: HBridge Output, 0 – 10000 [0.01% positive duty]

8: PWM Output 0 – 30000 [0.1 mA] current control bidirectional

6 | © Danfoss | July 2018 11063396 | AQ00000105en-US0101

Page 7

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

Signal Type Direction Range Description

DefPinConfig U16 Output 0 – 8 Default Output pin configuration used at startup before the master/slave

communication initiates.

0: Digital Output, Push/Pull

1: Digital Output, Sourcing

2: Digital Output, Sinking

3: PWM Output, 0 – 10000 [0.01% positive duty]

4: PWM Output, 0 – 30000 [0.1 mA]

5: PWM Output, 0 – 30000 [0.1 mA] Dither Enabled

6: PVE Output, 0 – 10000 [0.01% of PVE Power]

7: HBridge Output, 0 – 10000 [0.01% positive duty]

8: PWM Output 0 – 30000 [0.1 mA] current control bidirectional

DefOutputValue U16 Output 0 – 10000 or

0 – 30000

DigOut BOOL Output —— Output command if PinConfig = 0, 1 or 2.

OutputValue U16 Output 0 – 10000 or

0 – 30000

DitherAmp U16 Output 0 – 5000 Amplitude of dither applied when dither is enabled.

Default Output value used when the I/O module has not received an output

command within the previous TimeOut_Output. The output range depends on

PinConfig.

1000 is 10.00%.

or

1000 is 100.0 mA.

Output command if PinConfig = 3, 4, 5, 6, 7 or 8. The output range depends on

PinConfig.

1000 is 10.00%.

or

1000 is 100.0 mA.

1000 is 100.0 mA.

Inputs – CAN

The following signals provide diagnostics and status about CAN communications with the I/O module.

The signals appear in both the Input and Output buses.

Signal Type Direction Range Description

CAN Bus —— ——

CommStatus U16 Input 1 – 8, 255 Current status of communication with the I/O module.

0: CAN message transmission is disabled. Outputs disabled.

1: Protocol Version request is being sent to the I/O module. Outputs disabled.

2: Waiting for protocol version and hardware information response Outputs

disabled.

3: The function block is sending all stored parameters to the I/O module. Outputs

disabled.

4: The function block is sending all volatile parameters to the I/O module. Outputs

disabled.

5: CRC request is being sent to the I/O module. Outputs are disabled except for

RecheckCRC.

6: Waiting for CRC response. Outputs are disabled except for RecheckCRC.

7: The I/O module is properly configured and in the normal operational state.

Outputs are enabled.

8: The function block’s output pin configurations have changed. The new

configurations are being transmitted to the I/O module. Outputs are disabled.

9 – 254: Undefined.

255: Incompatible protocol or hardware. Outputs are disabled and communication

to the I/O module is stopped.

Configured BOOL Input —— True when communication is established and the Outputs are enabled.

Incompat_HW BOOL Input —— The responding hardware does not match the I/O module application layer part

number expected by the function block. No more messages are sent to the I/O

module.

©

Danfoss | July 2018 11063396 | AQ00000105en-US0101 | 7

Page 8

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

Signal Type Direction Range Description

Incompat_Protocl BOOL Input —— The responding hardware uses an incompatible version of the I/O protocol. Either

the hardware’s firmware should be updated or a newer version of the function block

is required for proper communication. No more messages are sent to the I/O

module.

This version function block requires I/O hardware using protocol version 2.00 to 2.99.

ProtocolVersion U16 Input 0 – 65535 I/O Communication Protocol Version used by the I/O module hardware.

200 is version 2.00.

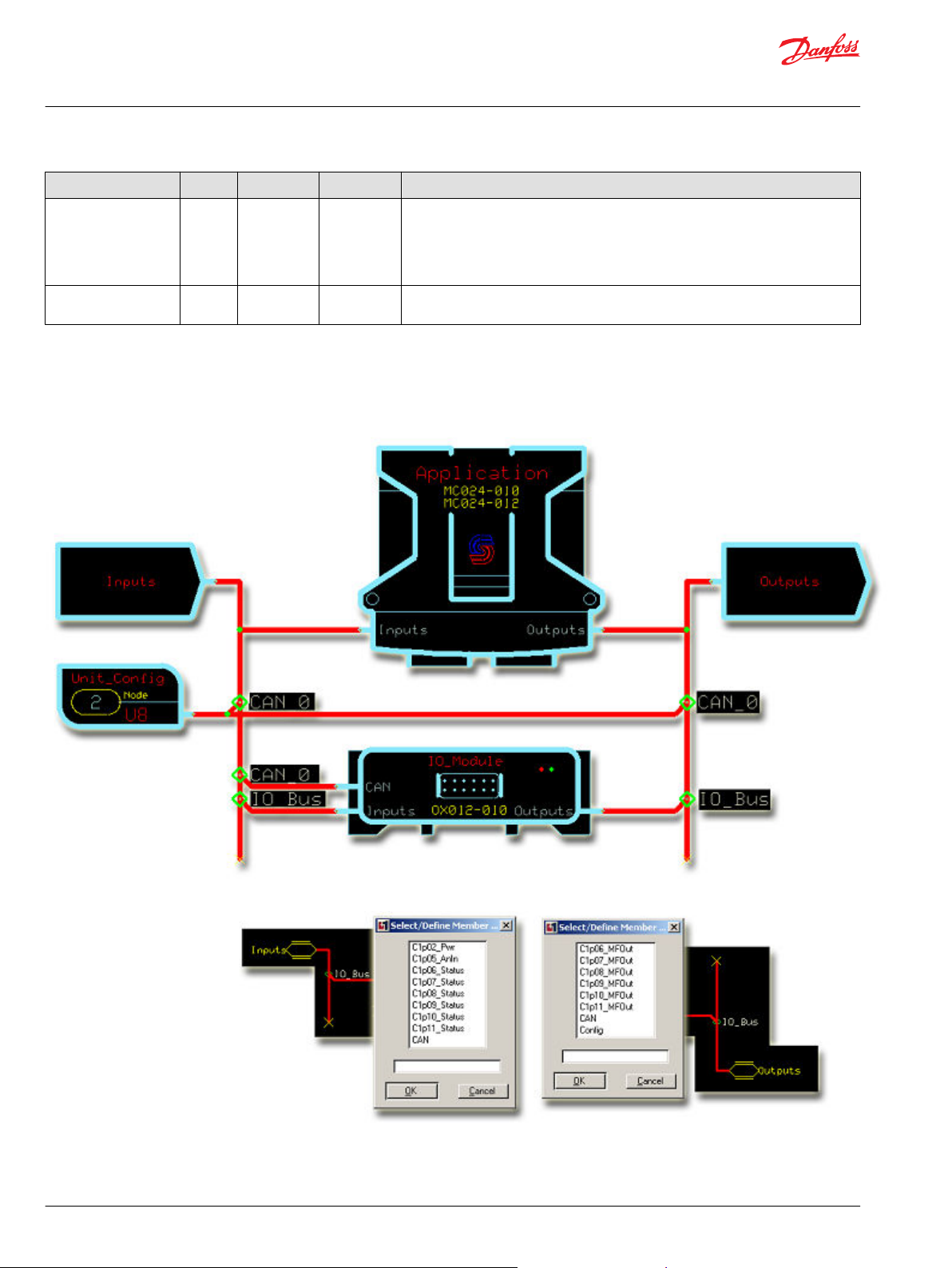

Connections and Signal Overview

When more than one I/O module is used in an application each block requires unique Inputs and Outputs

bus connections. For example, IO_Bus, IO_Bus1, IO_Bus2 are needed.

8 | © Danfoss | July 2018 11063396 | AQ00000105en-US0101

Page 9

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

Configuring Communications

The parameters that control the communication between a controller and an I/O module are described.

Variable Addressing Mode

Variable addressing mode is the default addressing mode of the I/O module, but it is not the default

mode for the function block.

When the device is powered, the CAN shield input voltage is measured. Communication parameters are

determined from the I/O Module CAN Message Identifiers table. For proper communication between the

function block and the I/O module, the corresponding N1 value from the table must be entered in the

function block and AddrMode must be set to 0.

Every time the device is powered, the CAN shield input voltage must be within the same N1 range for the

function block and device to reach the Configured status. After the device is powered, the CAN shield

input voltage has no effect on communication.

Predefined Addressing Mode

Predefined addressing mode is the default addressing mode for the function block, but it is not the

default mode for the I/O module.

In this mode, the I/O module reads the N1 value stored in non-volatile memory (EEPROM).

Because the function block and the I/O module use different default addressing modes, as long as the N1

value determined in the I/O module matches the N1 value set in the function block, the device is

configured using predefined addressing mode during all subsequent power cycles. As such, the proper

CAN shield voltage is only required during the first device initialization.

If setting the CAN shield voltage is not practical, use the PLUS+1® Service Tool to set the AddrMode to 1

and to set the required N1 value.

Fixed Addressing Mode

Fixed addressing mode allows for any pair of CAN message identifiers to be used for I/O module

communication.

In this mode, the I/O module relies on the RX_ID, TX_ID, and Frame parameters for communication with

the function block. Use the PLUS+1® Service Tool to set the proper values to match the function block and

to set the AddrMode.

Volatile Parameters

Once initial communication is established, all volatile parameter configuration messages are sent to the

I/O module.

Non-Volatile Parameters

After volatile parameters are configured, the function block sends a request for the configuration CRC to

the I/O module.

If this number matches the locally calculated value, then the configurations stored on the I/O module

match those set in the function block. If the numbers do not match, then all configuration commands are

sent and the CRC is requested again.

You can use the PLUS+1® Service Tool to access all non-volatile parameters on the I/O module.

Timing Configurations

Timing for messages to and from the I/O module is established after all other configurations are sent.

©

Danfoss | July 2018 11063396 | AQ00000105en-US0101 | 9

Page 10

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

CAN Bus Load

Adjust the average amount of message transmissions on the CAN bus to allow for bursts and other

increased message transmission situations.

Any CAN bus has a maximum message transmission capacity. So, to allow for situations that can cause

increases in messages, minimize the CAN bus load.

The CAN bus load is the average amount of message transmission on a CAN bus. Use the PLUS+1® CG150

USB/CAN gateway and CANKing software to view CAN bus loads.

PLUS+1® I/O modules communicate with their associated controllers over a CAN bus. System developers

can adjust I/O module RepTime and TimeOut parameters to manage CAN bus loading. Increasing these

times reduces the CAN bus load. Decreasing these times increases CAN bus load.

CAN Message Identifiers

The function block uses the following message identifiers to enable communication between the

controller and the I/O module.

I/O Module CAN Message Identifiers

CAN Shield Voltage [mV] N1 KWP2000 Node Tx ID Rx ID

0 – 299 0 0 0x180 0x300

300 – 599 1 8 0x188 0x308

600 – 899 2 16 0x190 0x310

900 – 1199 3 24 0x198 0x318

1200 – 1499 4 32 0x1A0 0x320

1500 – 1799 5 40 0x1A8 0x328

1800 – 2099 6 48 0x1B0 0x330

2100 – 2399 7 56 0x1B8 0x338

2400 – 2699 8 64 0x1C0 0x340

2700 – 2999 9 72 0x1C8 0x348

3000 – 3299 10 80 0x1D0 0x350

3300 – 3599 11 88 0x1D8 0x358

3600 – 3899 12 96 0x1E0 0x360

3900 – 4199 13 104 0x1E8 0x368

4200 – 4499 14 112 0x1F0 0x370

4500 – 15 120 0x1F8 0x378

Troubleshooting

Find out how to ensure the outputs of the I/O module function properly, and make sure your changes to

parameters are saved.

Problem Cause Solution

Outputs of I/O module do not

function as expected. Configured is

always false.

The I/O module is using variable address mode

and the CAN shield voltage does not fall within

the range matching the function block’s N1

value.

Use the I/O Module CAN Message Identifiers table to find the

correct voltage and ensure it is applied to the CAN shield

during power up.

Change the N1 value in the function block to match the

voltage applied to the CAN shield.

10 | © Danfoss | July 2018 11063396 | AQ00000105en-US0101

Page 11

User Manual

PLUS+1® Compliant OX012-x10 Function Block

OX012-x10 Function Block

Problem Cause Solution

When changing the I/O module ’s

parameters with the PLUS+1® Service

Tool, those changes are not properly

saved.

Incompat_HW is true. The function block is

communicating with a device other than the I/O

module.

Incompat_Protocl is true. The firmware on the

I/O module uses a version of the I/O Protocol less

than 2.00.

Incompat_Protocl is true. The firmware on the

I/O module uses a version of the I/O Protocol

later than version 2.99.

A function block detects the changes and resets

the parameters to the values specified in the

function block.

Ensure the proper addressing mode and corresponding

communication parameters are set on both the I/O module

and the function block.

It is possible the I/O module is correctly configured, but a

second I/O module has a similar configuration. Review

configuration and make changes to the other I/O modules.

Update the I/O module with the latest firmware.

Replace the function block by using the latest available

HWD file.

Disconnect the function block’s controller before making

parameter changes. If the changes do not result in different

CAN message identifiers for the I/O module, then

reconnecting the controller results in the parameters

reverting back to the values set in the function block.

©

Danfoss | July 2018 11063396 | AQ00000105en-US0101 | 11

Page 12

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | July 2018 11063396 | AQ00000105en-US0101

Loading...

Loading...