Application guidelines

2018

Optyma

TM

Optyma™ Plus INVERTER

Stepless capacity modulation from 30 to 100 rps in a simple plug and play package

cc.danfoss.com

EcoDesign

by Danfoss

Application Guidelines

Content

Important information/Safety ................4

1.1 Symbols are shown left of the text ............. 4

Product description .................................5

2.1 Optyma™ Plus INVERTER condensing unit ... 5

2.2 Exploded view Optyma

2.3 Condensing unit nomenclature system ... 7

2.4 Label ...................................................................... 7

2.5 Approvals and certificates ............................ 8

2.6 Technical specifications .................................. 8

2.7 Spare part codes ............................................... 8

2.8 Cooling capacities, sound data, power

consumption .............................................................9

2.9 Layout .................................................................. 13

™

Plus INVERTER ..... 6

Application range...................................14

3.1 Main applications ............................................ 14

3.2 Condensing unit selection ..........................14

3.3 Application envelopes ................................. 15

3.4 Ambient conditions ....................................... 16

3.5 Limits for voltage supply ............................. 16

Installation .............................................. 17

4.1 Location & fixings ............................................ 17

4.2 Electrical connection .................................... 18

4.2.1 Power supply protection ..............................18

4.2.2 Protection and features ................................18

4.3 Wiring diagrams .............................................. 19

4.3.1 Emergency running without controller 20

4.4 Electrical protection standard (protection

class) ...........................................................................23

4.5 EMC compliance .............................................. 23

4.5.1 Warning when touching unit

when OFF .................................................................23

4.6 Phase sequence .............................................. 24

4.7 Brazed connections........................................24

4.8 High pressure transmitter connection....25

System design recommendations .......26

5.1 Piping design ..................................................26

5.2 Evacuation ......................................................... 27

5.3 Refrigerant charge ..........................................28

5.4 Oil level ...............................................................29

5.5 Check before start .......................................... 29

5.6 Startup of the unit .......................................... 30

5.7 Check after start .............................................. 30

Condensing unit controller ...................31

6.1 Advantages ........................................................31

6.2 Controller’s regulation logic ....................... 31

6.3 Functions ........................................................... 31

6.4 Regulation reference for condensing

temperature ............................................................. 31

6.5 Fan operation ................................................... 31

6.6 Compressor control ....................................... 31

6.7 Maximum discharge gas temperature ....32

6.8 High pressure monitoring ........................... 32

6.9 Low pressure monitoring .............................32

6.10 Pump down limit ...........................................32

6.11 Data communication ................................... 32

6.12 Controller settings ........................................ 33

Service and maintenance ......................36

7.1 General recommendations .........................36

7.2 Condenser .........................................................36

7.3 Service and safety advice .............................36

7.4 Access ports ...................................................... 37

Transportation, handling and storage 38

8.1 Unpacking ..........................................................38

8.2 Transportation and handling ..................... 38

8.3 Disposal Instruction ....................................... 38

Warranty .................................................39

9.1 Warranty conditions ....................................... 39

9.2 Unauthorized changes ..................................39

Data collected during start up ..............40

3AB241186442766en-000801

WARNING

CAUTION

NOTICE

Application Guidelines

Important information/Safety

1.1 Symbols are shown

left of the text

There are 3 symbols, used for different degrees of

danger:

Warning! Risk of serious injury or death to person!

Caution! Danger which can lead to serious

damages!

Notice! Risk of damage to equipment!

This guideline is intended to enable users to

ensure the safe installation, starting, operation

and maintenance of Optyma

condensing units. This guideline is not intended

to replace the system expertise available from

system manufacturers.

In addition to this instruction application

instructions of compressor drive, controller and

other internal components must be taken into

consideration as well.

™

Plus INVERTER

4 AB241186442766en-000801

Application Guidelines

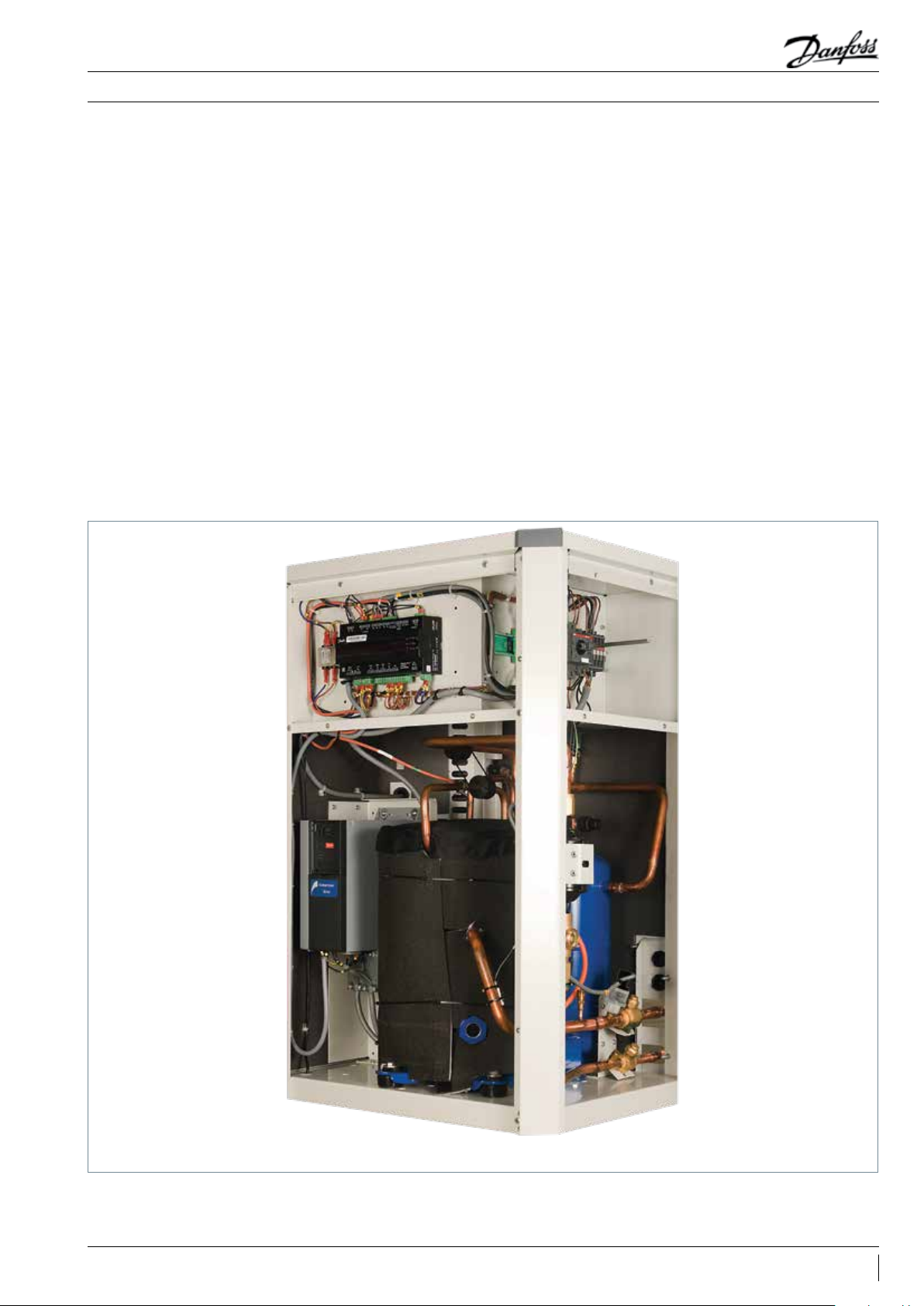

Product description

2.1 Op t y m a™ Plus INVERTER

condensing unit

Optyma™ Plus INVERTER combines our market

leading expertise in condensing unit design with

the unique benefits of stepless inverter scroll

technology. The result is 20-30% higher energy

efficiency in a flexible plug-and-play package,

for medium and high temperature refrigeration

applications in the range of 2kW to 9kW.

Standard equipment features:

• Variable speed compressor (scroll) with acoustic

housing and crankcase heater

• Compressor drive (with EMI filter)

• MCHX condenser

• Condenser fan motor

• Oil separator with oil heater

• Receiver with stop valve

• Ball valves

• Sight glass

• HP and LP switches

• Filter drier

™

• Optyma

• Circuit Breaker MCB, compressor contactor with

overload relay

• Robust weather proof housing

Plus controller

5AB241186442766en-000801

ITEM NAME DESCRIPTION QTY

1

023U8007

2

009G7053

3

009G7054

4

118A0614

5

118A0639C

6

118A0615

7

HUSKY_118U3455_LEG

8

061F8492

9

014F0174

10

134N4263

11

MLZ026_HOOD

12

DIGITAL_DISPLY_2

13

118A0679

14

023Z8045

15

118U3202

16

061F7283

17

021F0075

18

118U3259

19

118U3243

20

118U3256

21

118U3258

22

118U3887

23

118U3255

24

118U3261

25

118U3241-02

26

118U3264

27

MANIFOLD_A6E500AJ0302

28

118A0632001

29

118A05930001

30

118U3431001

31

118U34320002

32

118A06310001

33

PRESSURE_TRANSDUCER

34

VZH028_035_044_INVERTER_SCROLL_

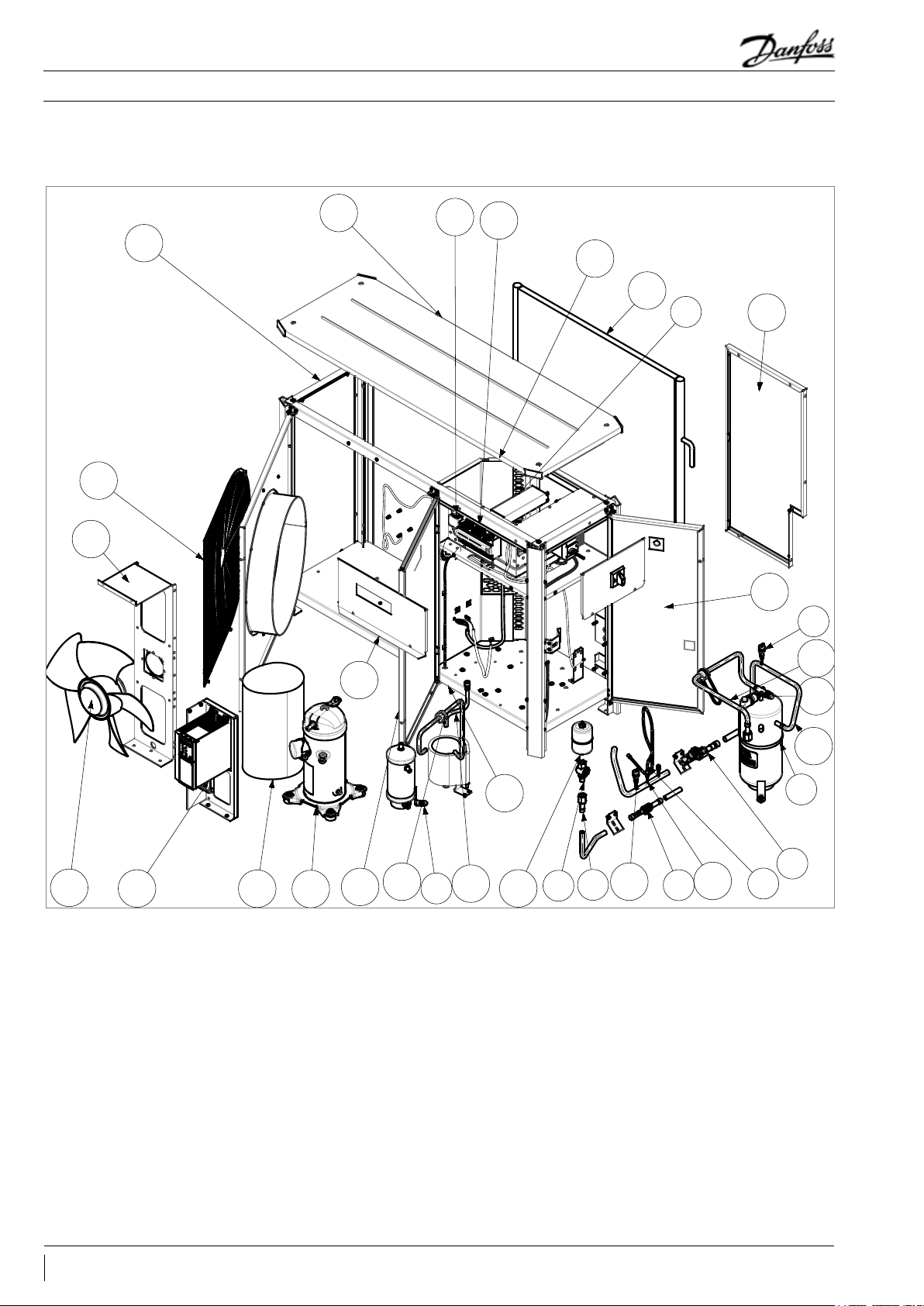

Application Guidelines

Product description

2.2 Exploded view

Optyma

™

Plus INVERTER

21

15

22

27

10

Legend:

1: FSA Adaptor

2: Liquid line valve (with schrader)

3: Suction line valve + Extra service

connection

4: EMI filter (drive)

5: Oil return pipe

6: Oil separator

7: Receiver

8: High pressure switch

9: Sight glass

10: Compressor drive

11: Acoustic hood

6 AB241186442766en-000801

11

26

13

19

34

12: Optyma

20

28

™

Plus controller

29

6

13: EMI filter (controller)

14: Refrigerant filter

15: Fan guard

16: Low pressure switch

17: Microchannel heat exchanger

18: Right side door

19: E-box cover

20: Front door, right side

21: Unit frame

22: Fan bracket

23: Separation panel

12

25

14

23

17

16

1

9

24: Back panel

25: Base plate

26: Top panel

27: Fan assembly

28: Discharge pipe

29: Condenser outlet pipe

30: Receiver outlet pipe

31 Oil separator outlet pipe

32: Suction line

33: Rotalock valve

34: Compressor

4

32

2

24

18

8

30

33

31

7

3

5

2018

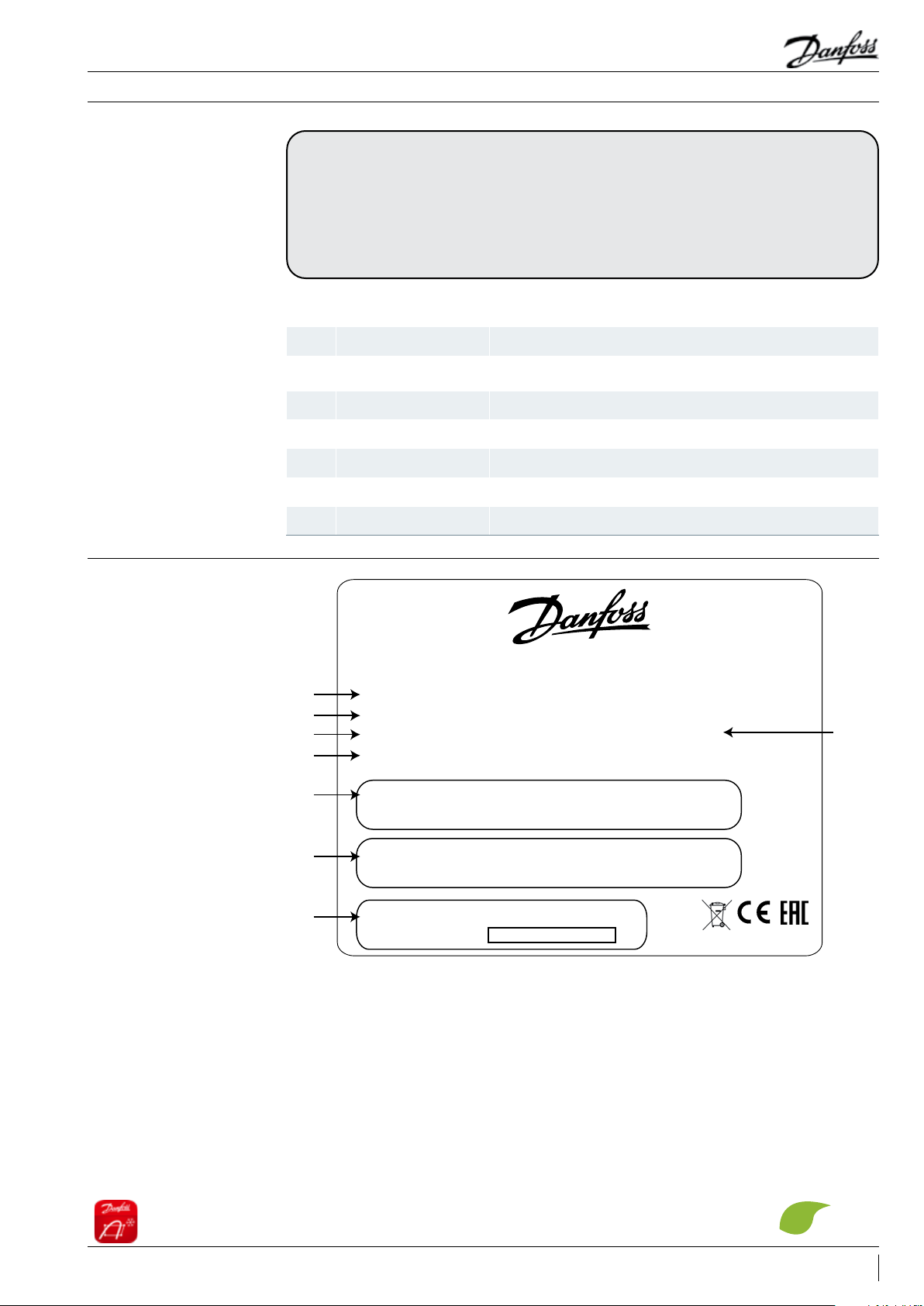

Application Guidelines

2.3 Condensing unit

nomenclature system

Product description

OP - M P L M 028 VVL P01 E

1 2 3 4 5 6 7 8

1 Application M = MBP

2 Design P = Packaged units

3 Refrigerant

4 Condenser type

5 Displacement 028 = 28 cm

6 Compressor platform VVL = variable speed scroll VLZ compressor

7 Version P01

8 Electrical code E = Compressor 400 V/3 phase/50 Hz, fan 230 V/1 phase/ 50 Hz

L = R404A, R407A, R407F

P= R404A, R407A, R407F, R448A, R449A

M = Standard with micro channel heat exchanger

Tambient max 43 deg C

3

/rev

2.4 Label

MADE IN INDIA

A

B

C

D

OP-MPPM044VVLP01E

Code Number.: 114X4334

Application MBP IP 54

Refrigerant (1) R448A/R449A/R407F

R407A/R404A (2)

E

M.W.P HP (1) 28 bar (2)

LP (1) 7 bar (2)

F

Voltage 380V-400V~3N~50Hz

LRA Inverter Driven MCC 12.1 A

G

A: Model

B: Code number

C: Application

D: Refrigerant

E: Housing Service Pressure

F: Supply voltage, M§aximum Current Consumption

G: Serial Number and bar code

H: Protection

Serial No. 123456CG1015

H

Serial-no.: XXXXXXCGWWYY

XXXXXX = ascending number

CG = manufacturing plant

WW = week of production

YY = year of production

For more information related to EcoDesign compliance, please refer to Coolselector®

coolselector.danfoss.com or contact Danfoss

EcoDesign

7AB241186442766en-000801

NOTICE

Application Guidelines

Product description

2.5 Approvals and

certificates

2.6 Technical

specifications

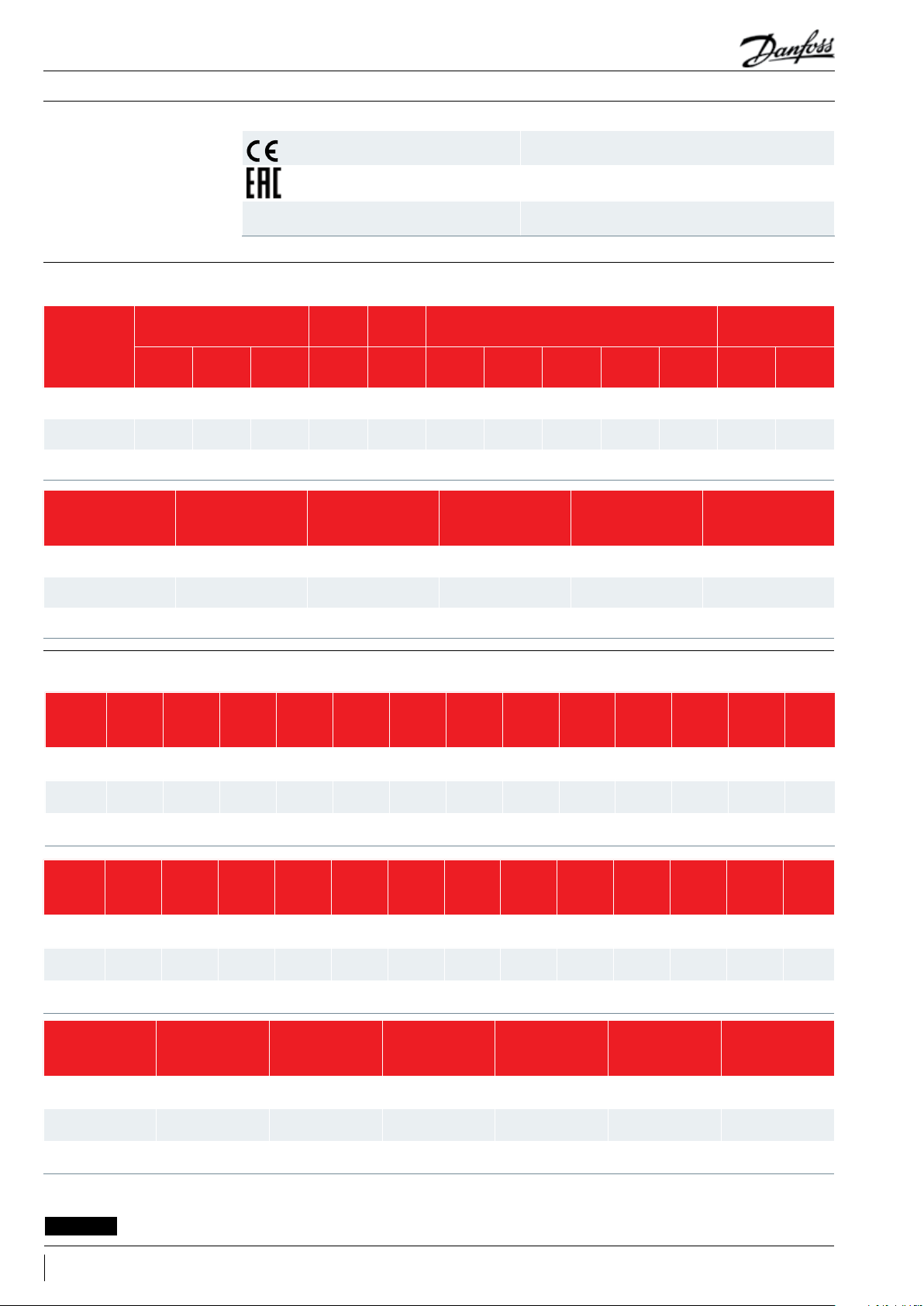

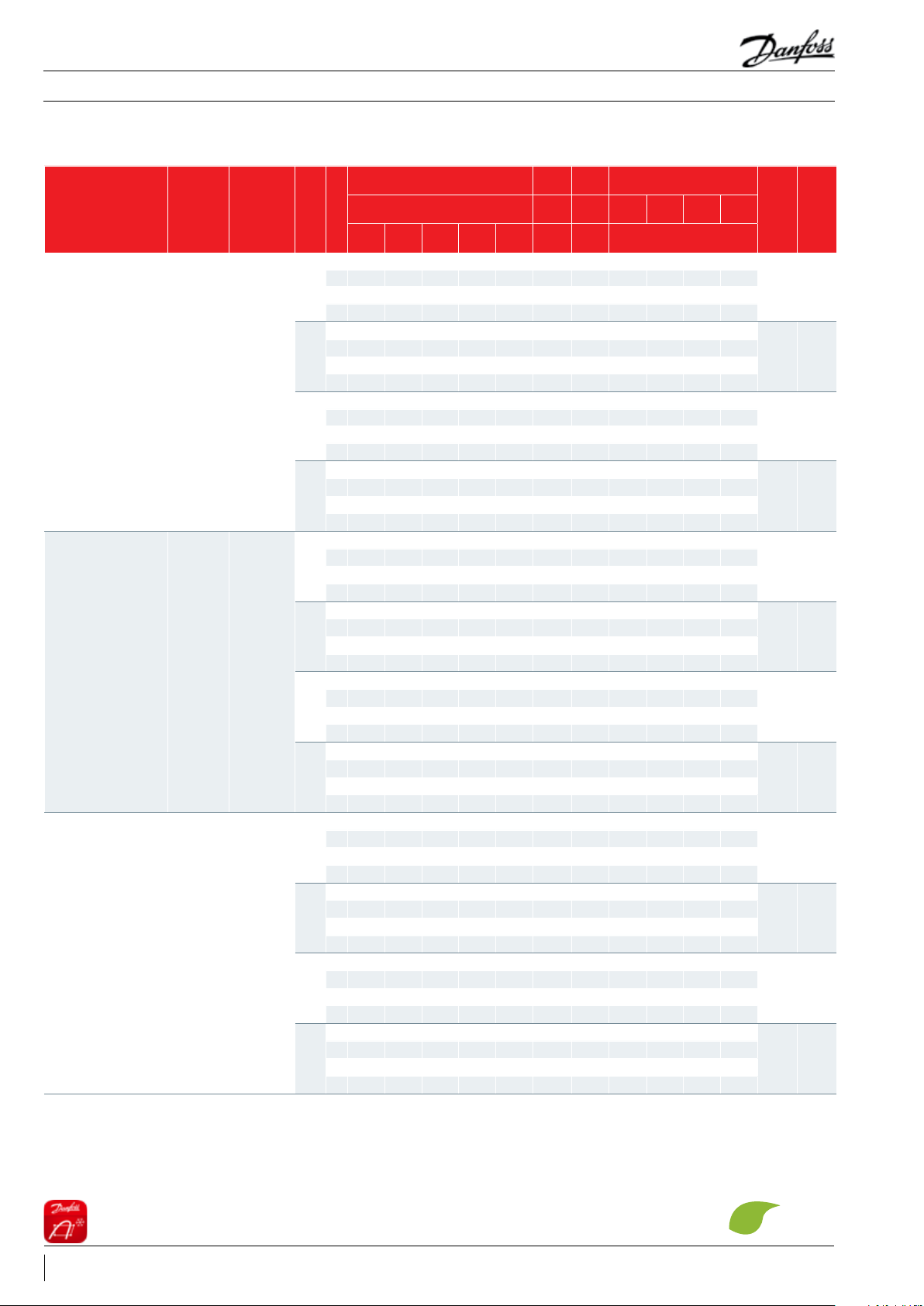

Unit

Typ e

OP-MPLM028

OP-MPPM028

OP-MPLM035

OP-MPPM035

OP-MPLM044

OP-MPPM044

Unit

OP-MPLM028

OP-MPPM028

OP-MPLM035

OP-MPPM035

OP-MPLM044

OP-MPPM044

G7 5200 1.62 1x50 0 6.2 481 14 06 965 3/4" 5/8" 150 124

G7 5200 1.62 1x50 0 6.2 481 14 06 965 3/4" 5/8" 151 125

G7 5200 1.62 1x50 0 6.2 481 14 06 965 3/4" 5/8" 151 125

All models OP-MPLM, OP-MPPM

All models OP-MPLM, OP-MPPM

Other Contact Danfoss

[dm3]

Condenser

fan

Fan blade

Ø [mm]

Max cont. power

consumption [kW]

Receiver Dimensions Weight [kg]

Volume [L]

(without

valve)

Depth

D

[mm]

Width

W

[mm]

MCC Fan

[A]

230 V/1 phase

Height

H

[mm]

Suction line Liquid line Gross Net

Fan power

output

[W]

Condenser coil

Air flow

[m

MCC compressor

40 0V/3ph ase

Internal

volume

3

/h]

[A]

8.1 3.98 0.96 1x130 1x220

9.8 4.94 0.96 1x13 0 1x220

12. 0 6.33 0.96 1x13 0 1x220

Fan power

consumption

[W]

2.7 Spare part codes

Unit Compressor Condenser

OP-M PLM028

OP-M PPM028

OP-MPLM035

OP-MPPM035

OP-MPLM044

OP-MPPM044

Unit Controller* Main switch

OP-M PLM028

OP-M PPM028

OP-MPLM035

OP-MPPM035

OP-MPLM044

OP-MPPM044

120 G0162 118 U349 4 118 U382 9 118 U3 476 023Z5 04591 014F0174 009 G7053 009G7054 118U 40 21 118 U4 025 084N0003 084N2007 118 U3 48 5

120 G0159 11 8U34 94 118 U38 29 118 U3 476 023Z504591 014F0174 009G7053 0 09G7054 118U 40 21 118 U4 025 084N0003 084N2007 118 U3485

120 G0156 11 8U34 94 118 U382 9 118 U3 476 023Z504591 014F0174 009G7053 009G7054 118 U4 021 11 8U4 025 084N0003 084N2007 118U 34 85

118 U3465

118 U3465

118 U3465

Unit Top panel Fan Panel Back panel Front panel Access panel Left side panel

OP-MPLM028

OP-MPPM028

OP-MPLM035

OP-MPPM035

OP-MPLM044

OP-MPPM044

118 U38 52

118 U38 54

118 U38 52

118 U38 54

118 U38 52

118 U38 54

118 U513 1 118 U513 2 118 U5133 118 U513 4 118 U51 35 118 U51 65

118 U513 1 118 U513 2 118 U5133 118 U513 4 118 U51 35 118 U51 65

118 U513 1 118 U513 2 118 U5133 118 U513 4 118 U51 35 118 U51 65

Fan

assembly

Compressor

contact

118 U38 47 118 U38 58 120Z5 040 118U3718 118U 3720 120Z 5043 118U3973 118U3972 118U3974

118 U38 47 118 U38 58 120Z5 040 118U3718 118U 3720 120Z 5043 118U3973 118U3972 118U3974

118 U38 47 118 U38 58 120Z5 040 118U3718 118U 3720 120Z 5043 118U3973 118U3972 118U3974

Receiver Filter

Door

handle

Crankcase

heater

Sight

glass

High

pressure

switch

Liquid

line

valve

Low

pressure

switch

Suction

line

valve

Acoustic

hood

High

pressure

transmitter

Compres-

sor drive

CDS803

Low

pressure

transmitter

EMI

filter

(Drive)

* For service replacement of controller in Optyma™ Plus INVERTER only new version of controller can be used: code number on the

controller is 084B8080.

For service purpose original components (spare parts) recommended by Danfoss should be used.

Suction

and

ambient

temperature

EMI filter

(Controller)

Discharge

temperature

sensor

Compressor

oil

120Z5 034

120Z0 648

120Z5 034

120Z0 648

120Z5 034

120Z0 648

separator

118U3981

118U3981

118U3982

Fan gr ill

Oil

8 AB241186442766en-000801

2018

Application Guidelines

Product description

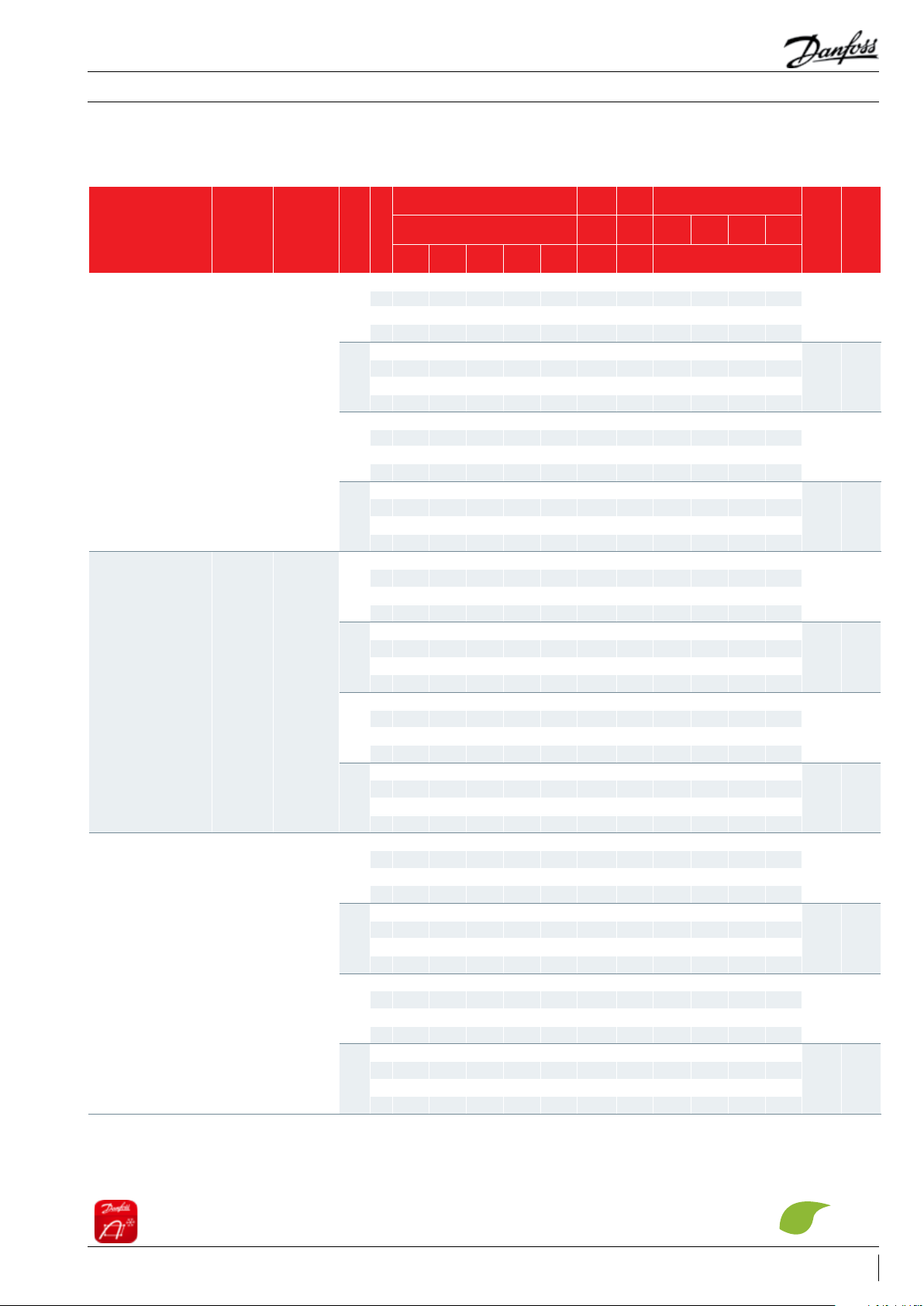

2.8 Cooling capacities, sound data, power consumption

Optyma™ Plus INVERTER, R407A

Cooling capacity Q [kW] P [kW] EcoDesign (2)

Model number

OP-M PPM028V VLP01E 114X4302 VLZ028TGA

OP-M PPM035V VLP01E 114X4316 VLZ035TGA

OP-M PPM044V VLP01E 114X4334 VLZ044TGA

[1] Nominal conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Superheat 10K.

[2] Rated conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Return Gas Temperature 20°C

Code

number

Compressor

Te [°C]

Tamb [° C]

speed, rps

Compressor

-15 C -10 C -5 C 0 C 5 C -10 °C

27 1435 1797 2227 2732 3320

32 1345 1686 2092 2570 3128 899 1.88

30

38 - 1557 1934 2380 2902

43 - - - - 27 2382 2994 37 11 4543 5499

32 2243 2829 3515 4310 5224 1333 2.12

50

38 - 2622 3267 4 015 4876

43 - 2442 3050 3757 4571

27 3499 4412 5470 6686 8069

32 3306 4177 5183 6339 7654 2005 2.08

75

38 - 3879 4821 5901 7131

43 - 3618 4503 5519 6676

27 4549 574 0 7106 8660 10413

32 4313 5438 6726 8192 9847 2830 1.92 5539 2834 1.95 3.49

100

38 - 5067 6261 7621 9158

43 - 4747 5864 7135 8575

27 1806 2259 2796 3426 4157

32 1692 2119 2626 3223 3916 1057 2.00

30

38 - 1956 2427 2983 3632

43 - - - - 27 2988 3751 4643 5674 6854

32 2812 3542 4393 5378 6504 1599 2.22

50

38 - 3279 4079 5003 6061

43 - 3051 3803 4674 5674

27 4374 5503 6805 8291 9973

32 4128 5203 6439 7849 9443 2445 2.13

75

38 - 4824 5977 7292 8779

43 - 4492 5573 6806 8201

27 5666 7124 8782 10652 12744

32 5367 6741 8302 1006 4 12035 3488 1.93 6876 3494 1.97 3.63

100

38 - 6270 7715 9345 11172

43 - 5864 7212 8734 10442

27 2303 2877 3556 4350 5268

32 2159 2699 3339 4091 4962 1278 2 .11

30

38 - 2491 3085 3785 4600

43 - - - - 27 3796 4757 5876 7163 8629

32 3569 4487 5553 6779 8175 1974 2.27

50

38 - 4148 5146 6294 7602

43 - 3852 4790 5870 7101

27 5527 6933 8542 10363 124 05

32 5208 6543 8067 9790 11720 3073 2.13

75

38 - 6052 7468 9069 10862

43 - 5620 6944 8440 10117

27 712 5 8914 10926 13170 156 49

32 6738 8 421 10311 12419 14750 4434 1.90 8612 4446 1.94 3.71

100

38 - 7813 9557 11502 13656

43 - 7288

8911 10721 12728

COP

Q [kW] P [kW] COPASEPR

(1)

SEPR, Seasonal Energy Performance Ratio

level dB(A)

Sound power

Sound pressure

72.8 41.8

73.4 42.4

74.0 43.0

75.3 44.3

71.7 40.7

72.3 41.3

72.9 41.9

74. 6 43.6

72.6 41.6

73.1 43.1

73.7 43.7

74.4 43.4

Q [W], Cooling Capacity

P [W], Power Input

level 10 m dB(A)

For more information related to EcoDesign compliance, please refer to Coolselector®

coolselector.danfoss.com or contact Danfoss

EcoDesign

9AB241186442766en-000801

2018

Application Guidelines

Product description

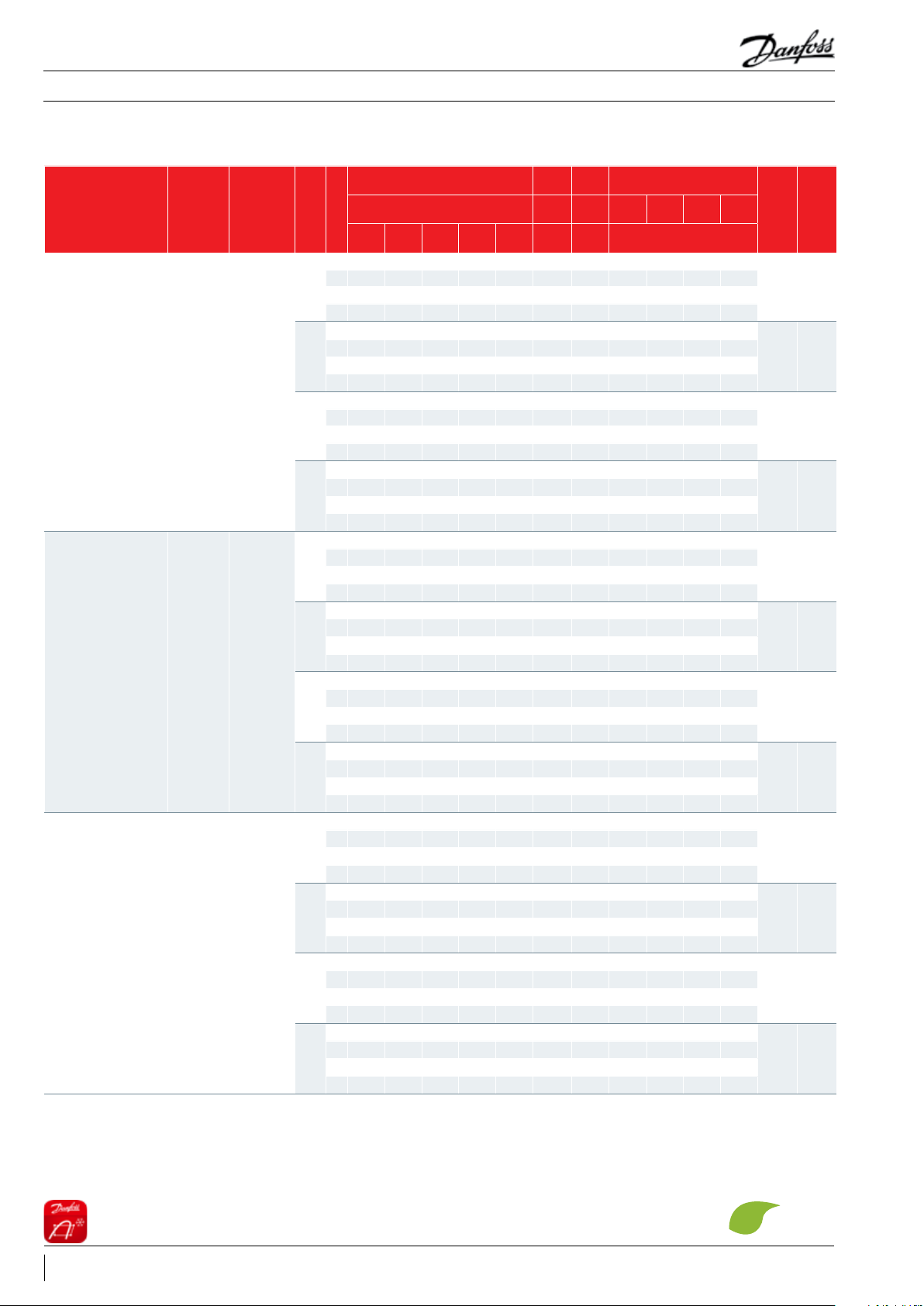

Optyma™ Plus INVERTER, R407F

Cooling capacity Q [kW] P [kW] EcoDesign (2)

Model number

OP-M PPM028V VLP01E 114X4302 VLZ028TGA

OP-M PPM035V VLP01E 114X4316 VLZ035TGA

OP-M PPM044V VLP01E 114X4334 VLZ044TGA

[1] Nominal conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Superheat 10K.

[2] Rated conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Return Gas Temperature 20°C

Code

number

Compressor

Te [°C]

Tamb [° C]

speed, rps

Compressor

-15 C -10 C -5 C 0 C 5 C -10 °C

27 1534 1915 2363 2888 3496

32 1447 1808 2234 2733 3313 945 1.91

30

38 - 1679 2078 2547 3092

43 - - - - 27 2598 3258 4022 4900 5902

32 2450 3083 3815 4655 5613 1410 2.19

50

38 - 2862 3555 4349 5254

43 - 2669 3328 4083 4943

27 3826 4792 5901 7163 8590

32 3612 4539 5600 6806 8169 2121 2.14

75

38 - 4220 5223 6362 7647

43 - 3942 4895 5977 7197

27 4950 6174 7573 9158 10939

32 4689 5857 7191 8703 10400 2977 1.97 5905 2979 1.98 3.58

100

38 - 5470 6724 8145 9742

43 - 5141 6327 7671 9182

27 1931 2408 2969 3623 4380

32 1820 2272 2805 3428 4149 1115 2.04

30

38 - 2110 2609 3193 3871

43 - - - - 27 3258 4080 5029 6116 7351

32 3069 3858 4766 5804 6984 1698 2.27

50

38 - 3577 4435 5416 6529

43 - 3330 4147 5078 6135

27 4776 5970 7334 8878 10 612

32 4503 5648 6951 8425 10079 2594 2.18

75

38 - 5242 6472 7860 9 417

43 - 4888 6055 7372 8847

27 6156 7655 9358 11274 134 09

32 5825 7254 8876 10699 12731 3679 1.97 7326 3682 1.99 3.71

100

38 - 6764 8286 9996 11902

43 - 6347 7783 9397 11198

27 2464 3068 3778 4603 5555

32 2322 2895 3568 4354 5260 1353 2.14

30

38 - 2686 3316 4052 4903

43 - - - - 27 4135 5170 6359 7714 9244

32 3891 4882 6019 7311 8771 2105 2.32

50

38 - 4519 5591 6809 818 4

43 - 4200 5218 6374 7677

27 6024 7510 9195 110 89 1319 6

32 5670 7092 8700 10503 1250 9 3271 2.17

75

38 - 6567 8080 9774 116 58

43 - 6107 7540 9143 10924

27 7723 9567 11641 13951 16 496

32 7298 9052 1102 3 13215 15631 4694 1.93 9164 4701 1.95 3.78

100

38 - 8421 10265 12315 14574

43 - 7884

9618 115 48 13675

COP

Q [kW] P [kW] COPASEPR

(1)

SEPR, Seasonal Energy Performance Ratio

level dB(A)

Sound power

Sound pressure

71.7 40.7

72.3 41.3

72.9 41.9

74. 2 43.2

71.2 40.2

71.9 40.9

72.5 41.5

73.55 42.5

72 41

72.6 41.6

73.2 42.2

74 43

Q [W], Cooling Capacity

P [W], Power Input

level 10 m dB(A)

For more information related to EcoDesign compliance, please refer to Coolselector®

coolselector.danfoss.com or contact Danfoss

10 AB241186442766en-000801

EcoDesign

2018

Application Guidelines

Product description

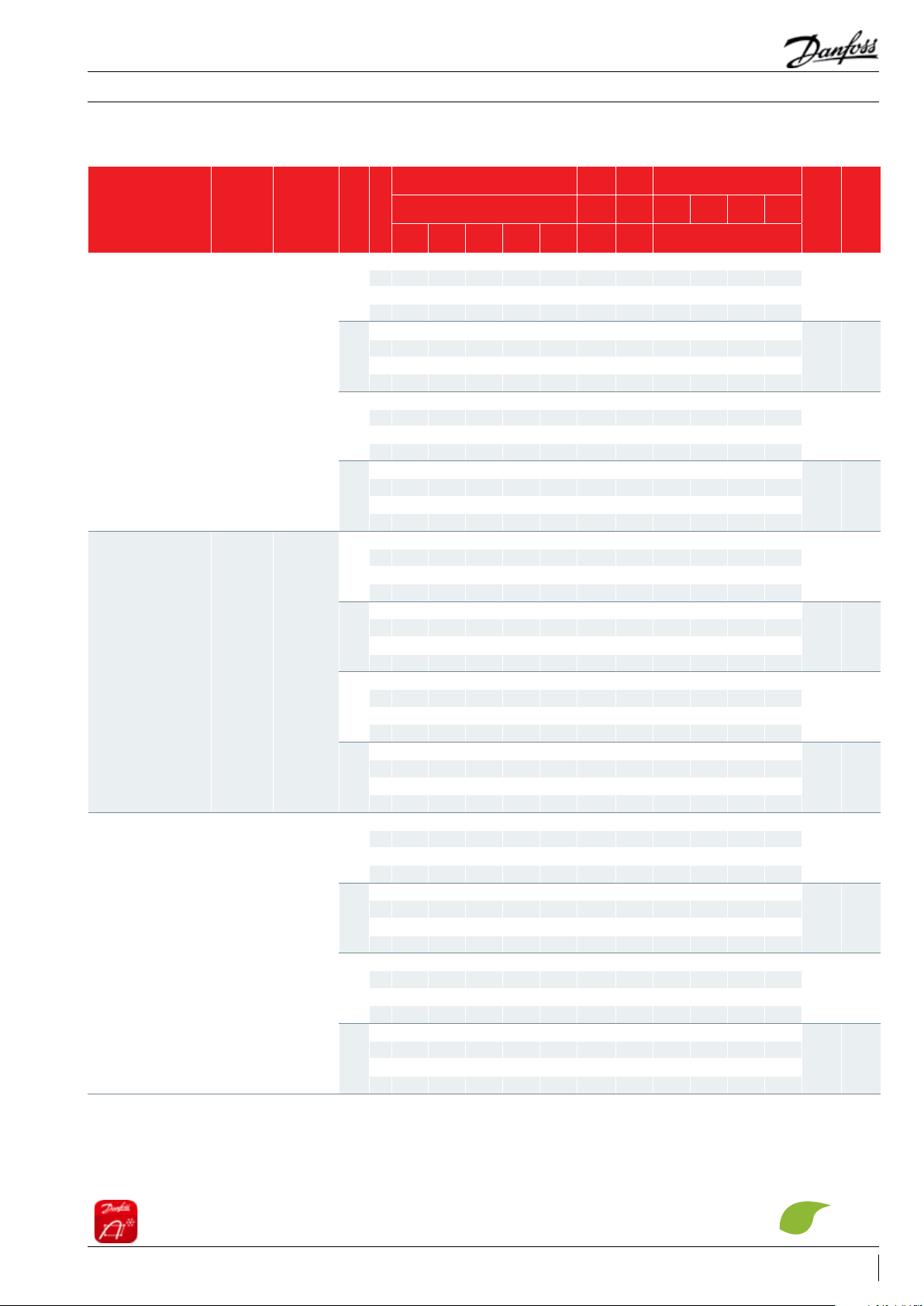

Optyma™ Plus INVERTER, R404A

Cooling capacity Q [kW] P [kW] EcoDesign (2)

Model number

OP-M PPM028V VLP01E 114X4302 VLZ028TGA

OP-M PPM035V VLP01E 114X4316 VLZ035TGA

OP-M PPM044V VLP01E 114X4334 VLZ044TGA

[1] Nominal conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Superheat 10K.

[2] Rated conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Return Gas Temperature 20°C

Code

number

Compressor

Te [°C]

Tamb [° C]

speed, rps

Compressor

-15 C -10 C -5 C 0 C 5 C -10 °C

27 1597 199 0 2446 2972 3573

32 148 4 185 4 2284 2780 3349 10 02 1.85

30

38 - - - - 43 - - - - 27 2700 3340 4080 4929 5894

32 2505 310 6 3802 4601 5510 1537 2.02

50

38 2266 2820 3168 419 8 5039

43 2060 2574 3168 3853 4636

27 3994 4916 5976 7181 8542

32 3707 4574 5569 6701 7981 2349 1.95

75

38 3354 4151 4633 6110 7290

43 3048 3785 4633 5600 6698

27 5202 6381 7724 9241 10939

32 4832 5939 7198 8620 10214 3317 1.79 6250 3328 1. 88 3.47

100

38 4368 5384 5965 7845 9310

43 3962 4899 5965 7171 8528

27 2027 2 517 3085 3739 4485

32 1878 2339 2875 3491 419 6 1159 2.02

30

38 - - - - 43 - - - - 27 3402 4193 5108 6153 7338

32 3158 3899 4755 5735 6846 179 4 2 .17

50

38 2854 3533 3937 5215 6236

43 2590 3215 3937 4766 57 11

27 4962 6087 7381 8853 10511

32 4610 5659 6866 8240 9790 2813 2.01

75

38 4169 5126 5672 74 81 8899

43 3784 4662 5672 6826 8133

27 6354 7768 9389 11226 13287

32 5901 7218 8727 10438 1236 0 4070 1.77 7614 4088 1.86 3.77

100

38 5331 6529 7183 9460 11214

43 4828 5926 7183 8614 10227

27 2620 3236 3949 4767 5698

32 2426 3008 3681 4453 5334 1391 2.16

30

38 - - - - 43 - - - - 27 4322 5303 6426 7700 913 4

32 4012 4932 5987 7183 8532 2288 2.16

50

38 3623 4 470 4964 6541 7784

43 3284 4067 4964 5985 7139

27 6267 7656 9231 10997 12960

32 5812 7111 8583 10234 12 070 3618 1.97

75

38 5243 6432 7078 9289 10972

43 4744 5839 7078 8472 10027

27 8008 9755 11715 13888 16273

32 740 6 9033 10856 12879 15102 5190 1.74 9560 5220 1.83 3.76

100

38 6648 8128 8852 11626 13651

43 5980 7335

8852 10539 1239 9

COP

Q [kW] P [kW] COPASEPR

(1)

SEPR, Seasonal Energy Performance Ratio

level dB(A)

Sound power

Sound pressure

71.2 40.2

71.9 40.9

72.5 41.5

73.7 42.7

73.1 4 2.1

73.8 42.8

74. 4 43.4

75.4 44.4

73.1 4 2.1

73.9 42.9

74. 5 43. 5

75.5 44.5

Q [W], Cooling Capacity

P [W], Power Input

level 10 m dB(A)

For more information related to EcoDesign compliance, please refer to Coolselector®

coolselector.danfoss.com or contact Danfoss

EcoDesign

11AB241186442766en-000801

2018

Application Guidelines

Product description

Optyma™ Plus INVERTER, R448A/R449A

Cooling capacity Q [kW] P [kW] EcoDesign (2)

Model number

OP-M PPM028V VLP01E 114X4302 VLZ028TGA

OP-M PPM035V VLP01E 114X4316 VLZ035TGA

OP-M PPM044V VLP01E 114X4334 VLZ044TGA

[1] Nominal conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Superheat 10K.

[2] Rated conditions, Evaporating temperature -10°C. Ambient air temperature +32°C. Return Gas Temperature 20°C

Code

number

Compressor

Te [°C]

Tamb [° C]

speed, rps

Compressor

-15 C -10 C -5 C 0 C 5 C -10 °C

27 1465 1839 2276 2783 3365

32 1375 1732 2149 2633 3190 939 1.84

30

38 - - - - 43 - - - - 27 2494 3107 3816 4629 5553

32 2346 2930 3605 4379 5259 1415 2.07

50

38 - 2706 3338 4064 4891

43 - 2510 3106 3790 4571

27 3656 4527 5536 6695 8 013

32 3443 4270 5226 6324 7573 2159 1.98

75

38 - 3949 4842 5866 7032

43 - 3670 4509 5472 6569

27 4686 57 74 7041 8502 10171

32 4421 5451 6648 8028 9605 3054 1.78 5548 3058 1. 81 3.38

100

38 - 5056 6170 7454 8922

43 - 4713 5761 6967 8346

27 1836 2301 2845 3476 4201

32 1722 216 6 2684 3284 3974 1081 2.00

30

38 - - - - 43 - - - - 27 3091 3846 4713 5699 6 812

32 2896 3616 4442 5381 6441 174 8 2.07

50

38 - 3327 4102 4983 5977

43 - 3076 3806 4637 5577

27 4505 5569 6792 8183 9752

32 4227 5238 6396 7713 9200 2718 1.93

75

38 - 4827 5907 7136 8523

43 - 4472 5487 6 641 7945

27 5773 7090 8615 10361 12338

32 5439 6683 8119 9765 11631 3839 1.74 6814 3837 1.78 3.29

100

38 - 6185 7518 9045 10779

43 - 5757 7006 8436 10061

27 2364 2954 3637 4 422 5317

32 2213 2776 3429 4180 5037 1316 2.11

30

38 - - - - 43 - - - - 27 3894 4834 5915 7145 8532

32 3650 4544 5570 6739 8058 2051 2.22

50

38 - 4185 514 4 6238 7473

43 - 3876 4779 5808 6973

27 5674 7003 8510 10203 12087

32 5308 6572 8003 9609 11397 3243 2.03

75

38 - 6034 7371 8873 10544

43 - 5566 6825 8237 9810

27 7289 8959 10828 1289 9 15173

32 6786 8375 10149 12112 14265 4739 1.77 8558 4753 1.8 3.73

100

38 - 7634 9291 11123 13130

43 - 6982

8539 10260 12145

COP

Q [kW] P [kW] COPASEPR

(1)

SEPR, Seasonal Energy Performance Ratio

level dB(A)

Sound power

Sound pressure

71.2 40.2

71.9 4 0.9

72.5 41. 5

73.7 42.7

73.1 4 2.1

73.8 42.8

74. 4 43.4

75.4 44.4

73.1 4 2.1

73.9 42.9

74. 5 43. 5

75.5 44.5

Q [W], Cooling Capacity

P [W], Power Input

level 10 m dB(A)

For more information related to EcoDesign compliance, please refer to Coolselector®

coolselector.danfoss.com or contact Danfoss

12 AB241186442766en-000801

EcoDesign

Application Guidelines

Product description

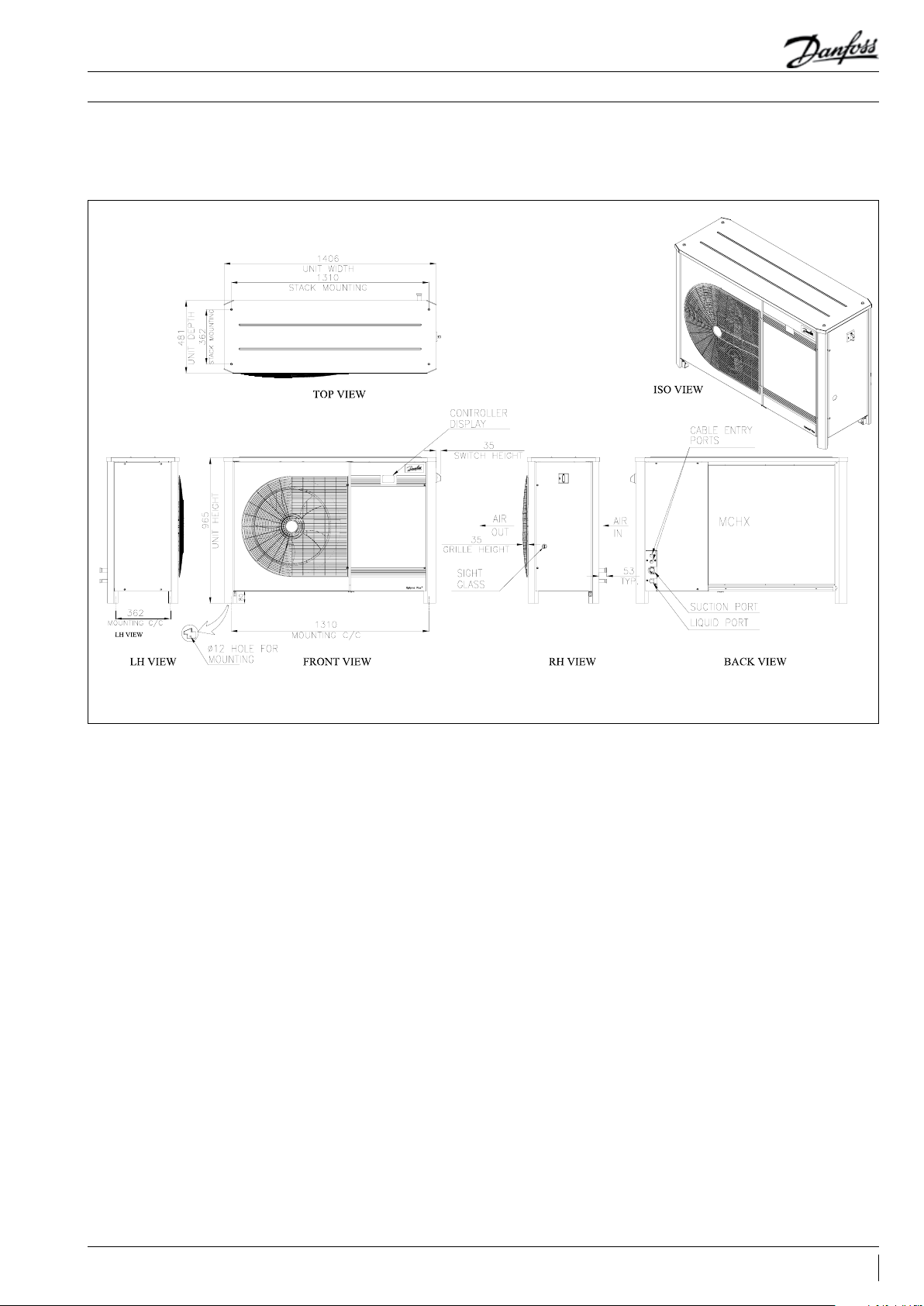

2.9 Layout

OP-MPLM028-035-044, OP-MPPM028-035-044

13AB241186442766en-000801

NOTICE

NOTICE

Application Guidelines

Application range

3.1 Main applications

3.2 Condensing unit

selection

Optyma™ Plus INVERTER is a perfect cooling

solution for typical MBP applications like food

retail, petrol forecourt sites, cold rooms ,and

display cases. All units are fully wired and factory

tested. They have one cabinet sizes and are

equipped with one fan.

Inverter technology offers more flexibility in

condensing unit selection than fixed-speed units.

Selection of the right inverter condensing unit

size can be made by next method:

Select a condensing unit size which achieves the

peak load system cooling capacity demand at its

maximum speed.

It is compulsory to secure that

condensing unit capacity at minimum speed

(30 rps) will not be higher than necessary

cooling capacity for the smallest evaporator!

In case minimum (at 30 rps) condensing unit

capacity is higher than capacity of smallest

evaporator it can cause work of condensing

unit outside its application envelope and as

consequence reduce lifetime.

Example1 (evaporating temperature -10 °C,

ambient temperature 32 °C, R404A):

Evaporator1= 3 kW

Evaporator2= 3 kW

Evaporator3= 3 kW

Total Q = 9 kW (maximum cooling capacity)

Minimum cooling capacity = minimum

evaporator capacity = minimum evaporating

capacity = 3kW

According to the capacities at evaporating -10 °C,

ambient 32 °C and refrigerant R404A condensing

unit OP-MPPM044 (maximum capacity 9 kW)

achieves the peak load system cooling capacity

(9,3 kW) demand at its maximum speed and

at the same time condensing unit capacity at

minimum speed (minimum capacity 3 kW) is not

higher than necessary cooling capacity for the

smallest evaporator (3 kW).

Optyma

units are released for R448A/R449A, R407A/F and

R404A.

Evaporator1= 1 kW

Evaporator2= 2,1 kW

Evaporator3= 2,5 kW

Evaporator4=1,5 kW

Total Q = 7,1 kW (maximum cooling capacity)

Minimum cooling capacity = minimum

evaporator capacity = Evaporator1 = 1 kW.

According to the capacities at evaporating -10 °C,

ambient 32 °C and refrigerant R404A condensing

unit OP-MPPM035 (maximum capacity 7,2 kW)

achieves the peak load system cooling capacity

(7,1 kW) demand at its maximum speed but

at the same time condensing unit capacity at

minimum speed (minimum capacity 2,3 kW) is

higher than necessary cooling capacity for the

smallest evaporator (1 kW).

In this case it is recommended to connect

few evaporators together (regulated by one

thermostat) to achieve smallest required capacity

higher than minimum capacity of condensing

unit: by managing Evaporator1 and Evaporator4

via one thermostat minimum required capacity

will be 2,5 kW (Evaporator2) which is higher than

minimum capacity of condensing unit at low

speed (2,3 kW).

INVERTER is equipped with a IPM (Interior

Permanent Magnet) motor. The compressor

cannot operate without frequency converter.

It will be destroyed immediately if connected

directly to public network. The applied frequency

from the inverter will be 60 Hz for 30 rps (1800

rpm) up to 200 Hz for 100 rps (6000 rpm).

Please refer to the table below

™

Plus INVERTER outdoor condensing

Compressor of Optyma™ Plus

14 AB241186442766en-000801

Example2 (evaporating temperature -10 °C,

ambient temperature 32 °C, R404A):

Compressor speed Min Max

rps 30 100

rpm 1800 6000

Drive output frequency Hz 60 200

0

10

20

30

40

50

60

5

15

25

35

45

55

Ambient temperature (°C)

Operating Map (R407F/A)

-20 -10 0 10 20-25 -15 -5 5 15

Evaporating temperature (°C)

30 rps-100 rps

SH10K

50 rps-100 rps

°C

(Te -10°C, Tamb 43°C)

0

10

20

30

40

50

60

5

15

25

35

45

55

Ambient temperature (°C)

Operating Map (R404A)

-20 -10 0 10 20-25 -15 -5 5 15

Evaporating temperature (°C)

30 rps-100 rps

SH10K

50 rps-100 rps

°C

(Te -15°C, Tamb 43°C)

0

10

20

30

40

50

60

5

15

25

35

45

55

Ambient temperature (°C)

Operating Map (R448A/R449A)

-20 -10 0 10 20-25 -15 -5 5 15

Evaporating temperature (°C)

30 rps-100 rps

SH 10K

50 rps-100 rps

°C

(Te -10°C, Tamb 43°C)

Application Guidelines

Application range

3.3 Application envelopes

The operating envelopes of Optyma™ Plus

INVERTER are given in the figures below, where

the ambient and evaporating temperatures

represent the range for steady state operation.

The figures below show the operating envelopes

for condensing units with refrigerants R448A/

R449A, R407A/F and R404A. The operating limits

serve to define the envelopes within which

reliable operation of the condensing units are

guaranteed.

15AB241186442766en-000801

Application Guidelines

Application range

Red line on the application envelope indicates

maximum safe ambient temperature for low load

(30-50 rps) and high ambient conditions (above

32 °C for R448A/R449A, 32 °C for R404A and

above 40 °C for R407A/F.

In case low unit capacity required (30-50 rps)

at high ambient temperatures controller will

increase compressor speed up to minimum safe

Minimum and maximum evaporating and

condensing temperatures as per the operating

Other operating limits: Recommendation

Discharge gas temperature

Evaporator outlet superheat above 6K (to avoid liquid flood back)

Suction gas superheat at compressor inlet within the limits shown on the application envelope

Special attention to suction line insulation will

have to be secured in order to:

• Avoid too high superheat during high ambient

conditions that can create too high discharge

gas temperature.

speed at high temperature. This minimum safe

speed at high temperature is factory preset to

50 rps (controller parameter c47: Start speed

of the compressor). It is not recommended to

decrease setting of parameter c47 below 50 rps

as this can lead to work of compressor at low

speed during high ambient conditions which can

reduce lifetime of the unit.

envelopes – compressor should work inside

application envelope.

125

°C maximum

• Avoid too low superheat during low ambient

conditions that can create condensation of

refrigerant in suction line.

3.4 Ambient conditions

3.5 Limits for voltage

supply

Optyma™ Plus INVERTER units can be used with

ambient temperature from -15°C to 43°C. For

altitudes above 2000 m, contact Danfoss. The

other working conditions should be within the

limits of application envelope.

To assure that the unit can start during cold

conditions the parameter “c94 LpMinOnTime” can

be used. If this parameter is set to a value that

is higher than 0 and the ambient temperature

(Tamb) is below 5°C, the internal transmitter “LP

switch c75” and “pump down limit c33” will be

overridden for the number of seconds defined

in “c94 LpMinOnTime”. And the value for Min on

time for the compressor will be set to the largest

of the values of “c94 MinLpOnTime” and “c01 Min.

on time”.

Voltage limits: Min: 360 V Max 440 V

Phase asymmetry: ±3%

Frequency limits: 50Hz ±1%

The CDS803 drive forces the compressor to 50rps

(see Optyma Controller parameter c47) for 30s

always at compressor start, to ensure proper oil

return at low load and short runtimes. The start

delay time can be modified via drive parameter

1-71, if a proper oil return is always ensured

without or by modifying this start delay function.

In order to change 1-71, a separate LCP panel

needs used to change the settings on the drive,

the LCP panel has the ordering code 120Z0581.

When changing 1-71, a value not lower as 10

seconds should get applied.

16 AB241186442766en-000801

CAUTION

NOTICE

Application Guidelines

Installation

4.1 Location & fixings

Optyma™ Plus INVERTER unit

has to be installed by competent authorized

The unit is to be placed in such a way that it is

not blocking or expose an obstacle for walking

areas, doors, windows etc. The foundation where

the unit is to be placed upon has to be strong

enough to carry the entire weight, see unit

data. Ensure adequate space around the unit

for air circulation. Avoid installing the unit in

locations which are exposed to direct sunshine

daily for long periods. Unit has to be placed on

a horizontal surface - less than 3° slope, which

has to be strong and stable enough to eliminate

vibrations and interference. It is recommended to

install the unit on rubber grommets or vibration

dampers (not part of the Danfoss supply).

Installation of unit shall not be done in aggressive

and dusty environments.

Furthermore the installation of the unit shall not

be done in facilities containing flammable gasses

or in installation containing flammable gasses.

Special attention should be paid if

unit needs to be installed close to the sea as this

can reduce unit lifetime due to corrosion of metal

parts.

personnel and the installation shall comply to

applicable local laws and rules.

Where multiple units are to be installed in the

same location, please consider each individual

case carefully. Air by-pass around each condenser

and between the units should be avoided at all

times.

Optyma

™

Plus INVERTER condensing units can

also be used for wall mounting on suitable

brackets. Wall mounting brackets are not

supplied by Danfoss.

Another factor to consider in finding a good

installation site is the direction of the prevailing

wind. For example if the air leaving the condenser

faces the prevailing wind, the air flow through

the condenser can be impeded, causing high

condensing temperatures, improper functioning

of the unit and ultimately resulting in reducing

the life of the unit. A baffle is a remedy for this

situation.

Q

W

ZY

R

X

Picture 1: Minimum mounting distances

Q: Air in R: Air out

Unit

Housing 3 250 760 580 580

W

[mm]X [mm]Y [mm]Z [mm]

17AB241186442766en-000801

WARNING

Application Guidelines

Installation

4.2 Electrical connection

Ensure that power supply

cannot be switched on during installation.

Below table lists recommended wiring sizes for

the condensing unit power supply cables. These

wiring sizes are valid for a cable length up to 30 m.

Model Cable size, mm2 (from network to unit main switch)

OP-MPLM028

OP-MPPM028

OP-MPLM035

OP-MPPM035

OP-MPLM044

OP-MPPM044

Note: 1.The wire size here is the guideline. In

each specific case required cable size should be

specified by the installer depending on the system

design, ambient temperature, the wire material,

current, etc.

In order to ensure a safe and problem free

operation of the unit it is recommended to:

- Ensure that the power supply corresponds to

the unit and that the power supply is stable (see

nominal values on unit label and power supply

found in the wiring diagram. Wiring diagram can

be found in front door of unit. Unit is equipped

with high and low pressure switches, which

directly cuts the power supply of the compressor

contactor in case of activation.

Unit is equipped with an electronic controller and

compressor drive.

The controller and compressor drive are preprogrammed with parameters ready for use with

the actual unit.

4

4

4

limits in paragraph 3.5).

As standard the parameters for operation with

- Make the power supply according to present

norm and legal requirements. Ensure that the

unit is properly connected to ground.

refrigerant R449A set. If another refrigerant is

to be used refrigerant parameter (o30) needs to

be changed (refer to description in Controller

application manual). Parameters for high and

The unit is equipped with a main switch with

overload protection. Overload protection is preset

from factory. Value for overload protection can be

low pressure cut outs are preset in the controller

adapted to the compressor and refrigerant

installed in the unit.

4.2.1 Power supply

protection

4.2.2 Protection and

features

You should use only original circuit breaker,

min. short circuit breaking capacity needs to

- Electronic thermal compressor protection against

overload.

- Temperature monitoring of the heat sink ensures

that the frequency converter trips in case of

overtemperature.

- The frequency converter is protected against

short-circuits between compressor terminals

U, V, W.

- When a compressor phase is missing, the

frequency converter trips and issues an alarm.

- When a mains phase is missing, the frequency

converter trips or issues a warning (depending

on the load).

be 100kA. Please refer to spare part section for

selection of components for service replacement.

- Monitoring of the intermediate circuit voltage

ensures that the frequency converter trips, when

the intermediate circuit voltage is too low or too

high.

- The frequency converter is protected against

ground faults on compressor terminals U, V, W.

- Occurring alarms will be shown in the controller

display and by the red LED in front of the

frequency converter.

- The root cause of an individual alarm can be

shown with an optional LCP (local control panel,

code 120Z0581) or the MCT10 setup software.

18 AB241186442766en-000801

Application Guidelines

Installation

4.3 Wiring diagrams

OP-MPLM028-035-044, OP-MPPM028-035-044

A1 : EMC/RFI Filter (Compressor) A2 : Frequency Converter A3 : EMI Filter (Controls) A4 : Optyma™ Plus Controller

B1 : Condensing Pressure Transducer B2 : Suction Pressure Transducer B3 : High Pressure Switch B4 : Low Pressure Switch

C1 : Run Capacitor (Fan) F1 : Fuse (Control Circuit) K1 : Contactor M1 : Compressor

M2 : Fan Motor Q1 : Main Switch R1 : Ambient Temp. Sensor R2 : Discharge Temp. Sensor

R3 : Suction Temp. Sensor R4,R5 : Auxiliary Temp. Sensor (optional) R6 : Crankcase Heater R7 : Oil Separator Heater

S1 : Room Thermostat (optional) X1 : Terminal

Supply : Supply Fan : Fan Alarm : Alarm Comp. : Compressor

CCH : Crankcase Heater Aux : Auxiliary

19AB241186442766en-000801

Application Guidelines

Installation

4.3.1 Emergency running

without controller

In case of controller failure, the condensing unit

can still be operated when the controller standard

wiring (WD1) is modified into a temporary wiring

(WD2) as described below.

This modification may be done by authorized

electricians only. Country legislations have to be

followed.

Disconnect the condensing unit from power

supply (turn hardware main switch off).

• Contact of Room Thermostat must be possible to

switch 250VAC.

• Remove wire 22 (safety input DI3) and wire 6 (fan

supply) and put them together. A fan pressure

switch (e.g. KP5) or a fan speed controller (e.g.

XGE) can be connected in series to wire 6.

• Remove wire 10 (drive start) and wire 24 (room

thermostat) and put them together.

• Remove wire 11 (drive start) and wire 25 (room

thermostat) and put them together.

• Remove wire 53 and 55 from drive terminals and

connect the attached 10kOhm potentiometer

(R8) as below:

wire 1 to drive terminal 55

wire 2 to drive terminal 53

wire 3 to drive terminal 50

• Turn the knob of the potentiometer to middle

position, which corresponds approximately

compressor speed 50rps.

• Remove wire 14 (crankcase and oil separator

heaters) and connect it to the compressor

contactor terminal 22.

• Remove wire 12 (supply crankcase and oil

separator heaters), extend this wire by using an

250 Vac 10mm² terminal bridge and 1,0mm²

brown cable and connect it to compressor

contactor terminal 21.

• Remove the large terminal block from the

controller terminals 10 to 19.

• Connect the condensing unit to power supply

(turn hardware main switch on).

• Adjust the potentiometer to get the desired

speed.

• Replace the controller as soon as possible.

20 AB241186442766en-000801

Application Guidelines

Installation

OP-MPLM028-035-044, OP-MPPM028-035-044- Emergency Wiring

A1 : EMC/RFI Filter (Compressor) A2 : Frequency Converter A3 : EMI Filter (Controls) A4 : Optyma™ Plus Controller

B1 : Condensing Pressure Transducer B2 : Suction Pressure Transducer B3 : High Pressure Switch B4 : Low Pressure Switch

B5* : Fan Speed Controller / Pressure Switch C1 : Run Capacitor (Fan) F1 : Fuse (Control Circuit) K1 : Contactor

M1 : Compressor M2 : Fan Motor Q1 : Main Switch R1 : Ambient Temp. Sensor

R2 : Discharge Temp. Sensor R3 : Suction Temp. Sensor R4,R5 : Auxiliary Temp. Sensor (optional) R6 : Crankcase Heater

R7 : Oil Separator Heater R8 : Compressor Speed S1 : Room Thermostat (optional) X1 : Terminal

Potentiometer

Supply : Supply Fan : Fan Alarm : Alarm Comp. : Compressor

CCH : Crankcase Heater Aux : Auxiliary

21AB241186442766en-000801

Application Guidelines

Picture1. Normal wiring

Installation

Picture2. Emergency

wiring

22 AB241186442766en-000801

WARNING

WARNING

CAUTION

Application Guidelines

Installation

4.4 Electrical protection

standard (protection

class)

4.5 EMC compliance

4.5.1 Warning when

touching unit when

OFF

- Scroll compressors: IP22

- Fan: IP54

- Controller: IP20

- Drive: IP20

- Complete unit: IP54

All necessary actions are taken to secure EMC

compliance of complete condensing unit!

DC-link capacitors that can remain charged even

when the frequency converter is not powered. To

avoid electrical hazards, disconnect AC mains and

wait 15 min for the capacitors to fully discharge

before performing any service or repair work.

Failure to wait the specified time after power has

been removed before doing service or repair could

result in death or serious injury.

The digital inputs are not a safety switch. They do

not disconnect the frequency converter from the

mains.

Do not remove mains connections, compressor

connections or other power connections while the

frequency converter is connected to power.

The ground leakage current from the frequency

converter exceeds 3.5 mA. According to IEC 618005-1 a reinforced Protective Earth connection

Frequency converters contain

Leakage Current

Power connections under

voltage and can cause danger by electrical shock.

Optyma™ Plus INVERTER units are fully wired and

factory tested. Electrical connection compromises

only power supply.

must be ensured with a min. 10 mm2 Cu or an

additional PE wire – with the same cable crosssection as the mains wiring - must be terminated

separately.

Residual Current Device

This product can cause a DC current in the

protective conductor. Where a residual current

device (RCD) is used for extra protection, only an

RCD of Type B (time delayed) shall be used on the

supply side of this product.

Recommended Brand & Model Number :

Make RCCB Model Number

Doepke DFS 4B SK, Type B

ABB F 804 B, Type B

ABL RA4403, Type B

Protective earthing of the frequency converter and

the use of RCDs must always follow national and

local regulations.

23AB241186442766en-000801

NOTICE

Application Guidelines

Installation

4.6 Phase sequence

4.7 Brazed connections

Optyma™ Plus INVERTER units are equipped with

variable speed scroll compressors for which

proper phase sequence is compulsory in order to

secure rotation in right direction and therefore

compression.

Refrigerant connections, brazing and

flange connections has to be done by a

qualified installer according to EN378.

The unit is supplied with an positive protective

pressure of Nitrogen (1 bar).

The use of substances containing chlorine, mineral

oil or other chemicals is not allowed.

Piping has to be designed to avoid vibrations,

either through flexibility or piping

brackets. Furthermore piping has to be done in

such a way that oil return for the

compressor is ensured and the risk of liquid slug

over in compressor is eliminated.

Only use clean and dehydrated refrigeration grade

copper tubing. Tube-cutting must be

carried out so as not to deform the tubing

roundness and to ensure that no foreign debris

remains within the tubing. Only refrigerant grade

fittings should be used and these must be of

both a design and size to allow for a minimum

pressure drop through the completed assembly.

Follow the brazing instructions bellow. Never drill

holes into parts of the pipe-work where filings

and particles cannot be removed. Even during

installation, if the system is left for

any reasonable period of time (say 1 hour), pipes

should be re-capped to prevent moisture and

contaminant from entering the system.

Liquid/suction tubes are extended from

the condensing unit housing, therefore we

recommend to isolate the housing by using a heat

shield and/or a heat-absorbent compound (e.g.

wet cloth) on the copper tubing. Use a doubletipped torch.

heat shield

The phase sequence has to be secured between

the drive and compressor.

(The phase sequence between network and unit

drive is of no influence on the compressor rotation

direction).

For brazing the suction and liquid line

connections, the following procedure is advised:

• Make sure that no electrical wiring is connected

to the compressor.

• Use brazing material with a minimum of 5% silver

content.

• Fit the copper tube into the unit tube.

• Apply heat evenly to area A until the brazing

temperature is reached. Move the torch to

area B and apply heat evenly until the brazing

temperature has been reached there as well, and

then begin adding the brazing material. Move

the torch evenly around the joint, in applying

only enough brazing material to flow the full

circumference of the joint.

• Move the torch to area C only long enough to

draw the brazing material into the joint.

• Remove all remaining flux “once the joint has

been soldered” with a wire brush or a wet cloth.

Remaining flux would cause corrosion of the

tubing. Ensure that no flux is allowed to enter into

the tubing. Flux is acidic and can cause substantial

damage to the internal parts of the system and

compressor.

The polyolester oil used in VLZ compressors

is highly hygroscopic and will rapidly absorb

moisture from the air. Condensing unit must

therefore not be left open to the atmosphere for

a long period of time. Unit fitting plugs shall be

removed just before brazing. Condensing unit

should always be the last component brazed into

the system.

Before eventual unbrazing of the compressor or

any system component, the refrigerant charge

must be removed from both the high- and

low-pressure sides. Failure to do so may result in

serious personal injury. Pressure gauges must be

used to ensure all pressures are at atmospheric

level.

For more detailed information on the appropriate

materials required for brazing or soldering, please

contact the product manufacturer or distributor.

For specific applications not covered herein, please

contact Danfoss for further information.

24 AB241186442766en-000801

C

A

B

It is compulsory to braze with a protective

atmosphere of nitrogen inside the piping.

Nitrogen displaces the air and prevents the

formation of copper oxides in the system.

NOTICE

NOTICE

WARNING

WARNING

Application Guidelines

Installation

4.8 High pressure

transmitter

connection

(Copper oxide could block capillary tubes, thermal

expansion valves and generate damage of

compressor).

Furthermore it is recommended to insulate the

suction pipe up to the compressor inlet.

Do not open the receiver Rotalock

valve entirely, it must be turned 1 round (360°) to

the closed direction to provide system pressure to

the transmitter!

(Insulation should be at least 19 mm thick and is

not a part of Danfoss supply). Use only dry pipes

and components in order to avoid moisture in the

system.

Maximum test pressure is 28 bar.

1. Valve In (from receiver).

2. Valve Out (to evaporator).

3. Service port (for safety devices).

4. Service port (for transmitter or service only).

Fig A: Fully closed Condition

Port 2 and 3 is fully open

port 4 is fully closed

Transmitter failure: Valve shall be opened entirely to disconnect transmitter port from

the others.

Rotolock spindle should be rotated by 5.5 turns/rotation in anticlockwise(from valve

fully closed position) to open the valve.

Fig B: Fully Opened Condition

Port 3 and 4 is fully open

port 2 is fully closed

Fig C: Partially Opened

Condition

Port 2, 3, 4 is fully opened.

25AB241186442766en-000801

NOTICE

Application Guidelines

System design recommendations

5.1 Piping design

Connection sizes! Unsuitable refrigerant flow

rate!

Do not assume that the liquid/

suction connection sizes on the unit are in fact

the correct sizes to run your interconnecting

refrigeration pipes!

The pipes should be sized to ensure optimum

performance and good oil return. The sizing must

also take into account the full capacity range

through which this particular unit will need to

operate.

Tube size Distance between 2 clamp supports

12 mm (1/2") 1 m

16 mm (5/8") 1,5 m

19 mm (3/4") 1,8 m

22 mm (7/8") 2 m

The suction line should:

• secure gentle slope towards the unit

(recommended slope minimum 0,5/100).

• have P traps, double risers and reduced pipe

diameters where long vertical risers cannot be

avoided.

Pipe runs should be kept as short as possible,

using the minimum number of directional

changes. Use large radius bends and avoid

trapping of oil and refrigerant. This is particularly

important for the suction line.

All pipes should be adequately supported to

prevent sagging which can create oil traps. The

recommended pipe clamp support distance is

shown in Table below:

The suction gas velocity must be sufficient to

ensure a good oil return, within 8 to 12 m/s in

vertical risers. In horizontal pipes this velocity

can decrease down to 4 m/s. The use of U-trap

and double suction risers is often required. These

suction risers must always be fitted with a U-trap

at the bottom and a P-trap at the top and never be

higher than 4 m unless a second U-trap system is

fitted.

26 AB241186442766en-000801

8 to 12 m/s at minimum speed

8 to 12 m/s at minimum speed

If the evaporator lies above the CU, a pump-down

cycle is strongly recommended. If a pump-down

cycle were to be omitted, the suction line must

have a loop at the evaporator outlet to prevent

refrigerant from draining into the compressor

during off-cycles. If the evaporator are situated

below the CU, the suction riser must be trapped

so as to prevent liquid refrigerant from collecting

at the outlet of the evaporator while the system is

idle, which would mislead the expansion valve’s

sensor (thermal bulb) at start-up.

Maximum safety length of pipes between CU and

last evaporator is 20 m.

If pipes length is more than 20 m special

adjustment of complete system is needed (oil

and refrigerant charge adjustments).

NOTICE

NOTICE

CAUTION

CAUTION

Application Guidelines

System design recommendations

5.2 Evacuation

Diameter of separate suction lines from

evaporators to condensing unit manifold should

be with appropriate size according evaporator

capacity (securing recommended speed for proper

oil return). Common manifold tube should be as

close as possible to condensing unit.

Moisture obstructs the proper functioning of both

the compressor and the refrigeration system. Air

and moisture reduce service life and increase

condensation pressure, which causes abnormally

high discharge temperatures that are then capable

of degrading the lubricating properties of the oil.

The risk of acid formation is also increased by air

and moisture, and this condition can also lead

to copper plating. All these phenomena may

cause both mechanical and electrical compressor

failures. The typical method for avoiding such

problems is a vacuum pump-down executed

with a vacuum pump, thus creating a minimum

vacuum of 500 microns (0.67 mbar).

The evacuation procedure is based

upon achieving an actual system Vacuum standard

and is NOT TIME DEPENDENT!

Evacuate the installation down to 0,67 mbar to

ensure quality vacuum.

It is recommended to evacuate on both high and

low pressure side to achieve fast and uniform

vacuum in the entire refrigeration system.

The installer is responsible for the

installation of the unit and complete refrigeration

system design according particular conditions

of each application as this is not scope of current

Guideline.

When the vacuum level has been reached, the

system must be isolated from the pump.

A vacuum of 0.67mbar has to be reached and

maintained for 4 hours. This pressure is to be

measured in the refrigeration system, and not at

the vacuum pump gauge.

If pressure increases rapidly, the system is not

airtight. Locate and repair leaks. Restart the

vacuum procedure.

If pressure increases slowly, the system contains

moisture inside. Break the vacuum with nitrogen

gas and restart the vacuum process again.

Do not use a megohmmeter nor

apply power to the compressor while it is under

vacuum as this may cause internal damage.

Leak detection must be carried

out using a mixture of nitrogen and refrigerant or

nitrogen and helium. Never use other gasses such

as oxygen, dry air or acetylene as these may form

an inflammable mixture. Pressurize the system on

HP side first then LP side.

27AB241186442766en-000801

Application Guidelines

System design recommendations

5.3 Refrigerant charge

For the initial charge condensing must not run

and eventual service valves must be closed.

Charge refrigerant as close as possible to the

nominal system charge before starting the

compressor. As maximum safe refrigerant charge

for compressor is 3,6 kg initial charge can be

considered close to 4 kg (will depend on tube

sizes, lengths of each individual system). This initial

charging operation must be done in liquid phase

as far away as possible from the compressor.

Never start the compressor under vacuum, ensure

a progressive charge of the system to 4– 5 bar.

For the initial refrigerant charge service port on

liquid line ball valve can be used. This port is

equipped with Schrader valve.

For the adjustment of refrigerant charge port on

the suction line can be used (located between oil

return port and suction ball valve port). This port is

also equipped with Schrader valve.

Refrigerant charge should secure stable work

at minimum and maximum heat load within

the limits of condensing unit application

envelope!

The remaining charge is done until the installation

has reached a level of stable nominal condition

during operation.

Next steps can be followed for proper charging or

the system:

- keep system working under the max load

conditions (all evaporators working, maximum

air/liquid flow via evaporator(s)).

- slowly throttling liquid in on the low pressure

side as far away as possible from the compressor

suction connection by default via the port on

suction line as described before.

- keep under the control evaporating pressure,

condensing pressure, suction superheat.

- charge system until reaching suction superheat

6-12 K at desired evaporating temperature.

Suction superheat as well as suction, condensing

pressures (temperatures) can be read from

controller display.

To avoid system overcharging (which can cause

higher energy consumption, high pressure alarms)

maximum refrigerant charge can be calculated as

follows:

Mmax = (Vrec + VliqL) * 0.9,

Where

Mmax = approximate maximum refrigerant

charge, kg

Vrec = receiver volume, L, for Optyma

™

Plus

INVERTER 6,2 L

VliqL = internal volume of liquid line, L (specific for

each system)

0.9 – correlation coefficient due to refrigerant

density.

Liquid line – Dimension Liquid line - Volume

OD

[inch]

3/8 9.5 7.9 0.05 0.5

1/2 12. 7 11.1 0.10 1.0

5/8 15.9 14.1 0.16 1.6

3/4 19.1 17.3 0.23 2.3

7/8 22.2 19.9 0.31 3.1

OD [mm] ID [mm]

VliqL

[L /1m]

VliqL

[L/10m]

28 AB241186442766en-000801

NOTICE

CAUTION

Application Guidelines

System design recommendations

5.4 Oil level

During all of the charge procedure keep the

oil heaters ON and keep an eye on the oil sight

glass, so that it doesn’t change color, density

or appearance and it doesn’t start foaming.

Refrigerant charge quantity must be suitable for

maximum load conditions as well as for minimum

load conditions for both summer and winter

operations.

It means that refrigerant charge should be enough

to feed all evaporators during the peak load

conditions and condenser should not be flooded

by liquid refrigerant during minimum load

conditions.

Receiver and liquid lines should be able to contain

remaining refrigerant during low load conditions.

Optyma™ Plus INVERTER condensing units are

supplied with POE oil, the oil separator is precharged with 0,3l oil. In case of adding oils always

use original Danfoss POE oil from new cans.

After commissioning, the oil level should be

checked and topped up if necessary.

When the compressor is running under stabilized

conditions, the oil level must be visible in the

sight glass. The presence of foam filling in the

sight glass indicates large concentration of

refrigerant in the oil and / or presence of liquid

returning to the compressor. The oil level can also

be checked a few minutes after the compressor

stops, the level must be between ¼ and ¾ of

sight glass. When the compressor is off, the

level in the sight glass can be influenced by the

presence of refrigerant in the oil.

Only refrigerant for which the unit is designed for

has to be charged, see unit data.

In case of refrigerant blend charging has to be

done in liquid form in order to avoid chemical

changes of the refrigerant.

Don’t judge the refrigerant charge by

the liquid sight glass as 100% correct way. It may

mislead you!

When Optyma™ Plus INVERTER unit

has to be scraped, refrigerant has to be disposed

for destruction. Local laws and rules have to be

followed for disposal of refrigerant.

In installations with good oil return and line

runs up to 20 m, no additional oil is required. If

installation lines exceed 20 m, additional oil may

be needed. Oil charge has to be adjusted based

on the oil level in the compressor sight glass.

Top-up the oil while the compressor is idle. Use

the schrader connector or any other accessible

connector on the compressor suction line and a

suitable pump.

The oil fills connection and gauge port is a 1/4”

male flare connector incorporating a Schrader

valve.

Oil changing is not normally necessary for

package units.

5.5 Check before start

1. Compliance between unit and power supply.

2. Check that valves are opened.

Remark: Do not open receiver valve entirely to

get correct pressure to the discharge pressure

transmitter. Turn valve spindle one round (360°) in

close direction.

3. Check that crankcase and oil separator heaters

are working.

4. Check that fan can rotate freely.

5. Check for possible faults in the installation.

6. Check main switch overload protection setting.

29AB241186442766en-000801

Application Guidelines

System design recommendations

5.6 Startup of the unit

After below steps are completed:

1) System is completely installed.

2) All electrical connections are done.

3) System is charged.

Next steps are needed to start the unit:

The controller of the condensing unit is set for

R449A. If this factory setting of refrigerant as well

as other factory settings of parameters fits for the

requirement of your application, no controller

parameter must be changed.

• For a refrigerant change go into the parameter

menu (press upper button 5 seconds).

• Select parameter “r12” (software main switch)

with a short press on lower button.

• Activate parameter “r12” with middle button and

change the value to 0 (zero).

• Confirm the value with a short press on the

middle button (the 3 LED’s start flashing).

• Go to the parameter “o30” (Refrigerant).

• Change the value of parameter “o30” to 21 if

R407A, 37 if R407F will be used.

• Confirm the value with a short press on the

middle button.

Press short the upper (or lower) button to go to

the next Parameter of the Parameter menu, e.g.

Parameter r23 for suction pressure setpoint or r82

for Min Condensing Pressure. Scroll fast through

the Parameters with a long press on these buttons.

• Press short the middle button to show the value

of the selected Parameter.

• Press afterwards the upper (or lower) button to

change the value of the selected parameter. A

long press on these buttons will change the value

fast

• Select parameter “r12” again.

• Change the value to 1 (one).

• Confirm the value with a short press on the

middle button (the 3 LED-signs stop flashing and

the condensing unit will start if required).

• After 20 seconds the display returns to the

evaporation temperature in °C, the new refrigerant

and all relevant parameters are changed.

It is compulsory to energize crankcase and oil

separator heaters at least 1 hour before initial

start-up and start-up after prolonged shutdown

to remove refrigerant in liquid phase from the

compressor.

Condensing unit is factory preset for quick

installation and start up. Compressor drive is

fully managed by condensing unit controller and

therefore all parameters settings should be done

only via condensing unit controller.

5.7 Check after start

After a couple of hours of stable operation

following has to be checked via service

parameters U :

1. Unit current consumption.

2. Rotation of fan (suction through condenser).

3. Check for leakages in refrigerant system.

4. Check superheat.

5. Check oil level.

6. Check for abnormal noises.

7. Check for abnormal vibrations.

8. Suction and discharge pressures.

30 AB241186442766en-000801

Application Guidelines

Condensing unit controller

6.1 Advantages

6.2 Controller’s

regulation logic

6.3 Functions

In order to provide the highest level of compressor

protection, energy efficiency and adaptation to

• Condensing pressure control in relation to

outside temperature.

• Fan speed regulation.

• On/off and variable speed regulation of the

compressor.

• Crankcase heating element control.

• Day/night controller operation.

The controller receives a signal for demanded

cooling, and it then starts the compressor.

If compressor is controlled by variable speed, the

suction pressure (converted to temperature) will

be controlled according to the set evaporating

temperature.

Condenser pressure regulation is performed

following a signal from the ambient temperature

• Control of condensing temperature.

• Control of fan speed.

• On/off control or speed regulation of the

compressor.

• Control of heating element in crankcase.

• Liquid injection into economizer port.

variable conditions condensing unit is equipped

with specific controller.

• Built-in clock function with power reserve .

• Built-in Modbus data communication.

• Monitoring discharge temperature td.

• Oil return management control at variable speed

operation.

sensor and the set reference corresponding to

difference between condensing and ambient

temperatures. The controller will then control the

fan, which allows the condensing temperature to

be maintained at the desired value. The controller

can also control the heating element in the

crankcase so that oil is kept separate from the

refrigerant.

• Raising the condenser pressure regulation

reference during night operation.

• Both internal and external start/stop cooling.

• Safety cut-out activated via signal from

automatic safety control.

6.4 Regulation reference

for condensing

temperature

6.5 Fan operation

6.6 Compressor control

The controller controls the condensing

temperature in relation to the ambient

temperature. This difference is preset in the

The controller will control the fan so that the

condensing temperature is maintained at the

desired value above the ambient temperature.

The compressor is controlled by a signal at the

DI1 input. The compressor will start once the

input is connected. Three restrictions have been

implemented to avoid frequent start/stops:

- minimum ON time.

- minimum OFF time.

- time elapsed between two starts.

These three restrictions have the highest priority

during regulation, and the other functions will

wait until they are complete before regulation

can continue. When the compressor is ‘locked’

controller. It can also, via another parameter, get

increased at night.

by a restriction, this can be seen in a status

notification. DI3 input is used as a safety stop for

the compressor, an insufficient input signal will

immediately stop the compressor. The compressor

is speed-controlled with a voltage signal at the

AO2 output.

If the compressor has been running for a long

period at low speed, the speed is increased for a

short moment for the purpose of oil return.

31AB241186442766en-000801

Application Guidelines

Condensing unit controller

6.7 Maximum discharge

gas temperature

6.8 High pressure

monitoring

6.9 Low pressure

monitoring

6.10 Pump down limit

The temperature is recorded by sensor Td.

If variable speed control is chosen for the

compressor, this control will initially reduce the

compressor capacity if the Td temperature

approaches the set maximum value. If higher

temperature is detected than the set max.

temperature, the fan’s speed will be set to 100%.

If this does not cause the temperature to drop,

and if the temperature remains high after the

During regulation, the internal high pressure

monitoring function is able to detect an over the

limit condensing pressure so that the regulation

can continue.

However, if the C73 setting is exceeded, the

compressor will be stopped.

During regulation, the internal low pressure

monitoring function will cut out the compressor

upon detecting a suction pressure that falls below

the lower limit, but only once the minimum ON

The compressor will be stopped if a suction

pressure that falls below the set value is registered,

but only once the minimum ON time is exceeded.

set delay time, the compressor will be stopped.

The compressor will only be re-started once the

temperature is 10 K lower than the set value. The

above mentioned re-start restrictions must also

be complete before the compressor can start once

again. If the delay time is set to ‘0’, the function

will not stop the compressor. The Td sensor can be

deactivated (o63).

If, on the other hand, the signal comes from the

interrupted safety circuit connected to DI3, the

compressor will immediately be stopped and the

fan will be set to 100%.

When the signal is once again ‘OK’ at the DI3 input,

the regulation will resume.

time is exceeded. An alarm will be issued. This

function will be time delayed, if the compressor

starts at low ambient temperature.

6.11 Data communication

The controller is delivered with built-in MODBUS

data communication and can be connected to

an ADAP KOOL® network. If a different form of

data communication is requested, a LON RS-485

module can be inserted in the controller.

The connection will then be made on terminal RS

485.

Important:

All connections to the data communication

must comply with the requirements for data

communication cables.

All condensing units are delivered with controllers

which are factory pre-set.

See below table with factory setting of controllers

integrated into condensing units and controllers

supplied separately for service replacement

(when controller is supplied as spare part for

service replacement its factory settings are slightly

different and should be adjusted according to

controller unit specific settings in paragraph 6.12

and application specific requirements).

32 AB241186442766en-000801

Application Guidelines

Condensing unit controller

6.12 Controller settings

NOTE! In case of controller replacement beware that unit controller settings are different from default controller factory settings!

Function Code Min.value Max.value

Normal operation

Set point Tc (regulation reference follows the number of degrees above the outside

temperature Tamb)

Regulation

Select SI or US display. 0=SI (bar and °C). 1=US (Psig and °F) r05 0/ °C 1/ F 0/ °C

Internal Main Switch. Manual and service = - 1, Stop regulation = 0, Start regulation =1 r12 -1 1 0 1

Offset during night operation. During night operation the reference is raised by this

value

Set point for suction pressure Ts r23 -25 °C 10°C -7°C

Readout of reference for Tc r29 - - Thermostat cut-in value for an external heating element (069=2 and o40=1) r71 -30.0°C 0.0°C -25°C

Min. condensing temperature (lowest permitted Tc reference) r82 0°C 40°C 30°C

Max. condensing temperature (highest permitted Tc reference) r83 20°C 50°C 40°C

Max. discharge gas temperature Td r84 50°C 140°C 12 5°C 125°C

Alarms

Alarm time delay on signal on the DI2 input A28 0 min. 240 min. 30 min.

Alarm for insufficient cooling in condenser. Set temperature difference. A70 3.0 K 20.0 K 10.0 K

Delay time for A70 alarm A71 5 min. 240 min. 30 min.

Compressor

Min. ON-time c01 1 s 240 s 5 s

Min. OFF-time c02 3 s 240 s 12 0 s

Min. time between compressor starts c07 0 min. 30 min. 5 min.

Pump down limit at which the compressor is stopped (setting 0.0 = function

dis-activated)

Min. compressor speed c46 30 rps 70 rps 30 rps

Start speed for compressor and min. speed for high condensing temperatures c47 30 rps 70 rps 50 rps

Max. compressor speed c48 50 rps 100 rps 10 0 rps

Max. compressor speed during night operation (% value of c48) c69 50% 100% 70%