Page 1

Data sheet

Oil Nozzles Type H, S-S and B

Application

Identification The nozzles are marked with the following

information (example):

0.65

Stampe d on the flats

0.65 GPH at 100 psi, (~ 7 bar) 35 SSU (2.7 cSt)

60°B Spray angle and pattern: B Solid, S -S Semi Solid and H Hollow

SOLID SOLID for “Solid” spray pattern. Only on B nozzles

123 45 Batch code

SOLID60°B

12345

Danfoss Hago oil nozzles are designed for

domestic and commercial high pressure oil

burners operating with light or heavy fuel.

An optimal combustion process is only achieved

by a perfect match between nozzle capacity and

spray pattern, air supply and air distribution and

the design of combustion chamber.

Danfoss Hago offers a very broad range of

nozzles with different capacity and spray

patterns – which means that it is possible to

cover all demands in the market.

Features: Light and heavy fuel.

Technical Data

© Danfoss | 2019.05 VD.CE.Y3.02 | 1

Material and construction

Nozzle tip and disc AISI 416 grade stainless steel

filters size dependent

Recommended and maximum tightening

torque

Recommended 200-310 in-lbs (25-30 Nm) and

max. 310 in-lbs (35 Nm).for steel and nickel

plated adapters.

Recommended 130-180 in-lbs (15-20 Nm) and

max. 220 in-lbs (25 Nm).for brass adapters.

Filters

Capacity 0.40 – 1.35 GPH

30-40 μm sintered bronze filter

Capacity from 1.50 GPH

120 mesh stainless steel strainer

Page 2

Data sheet Oil Nozzles Type H, S-S and B

A BC D

A BC D

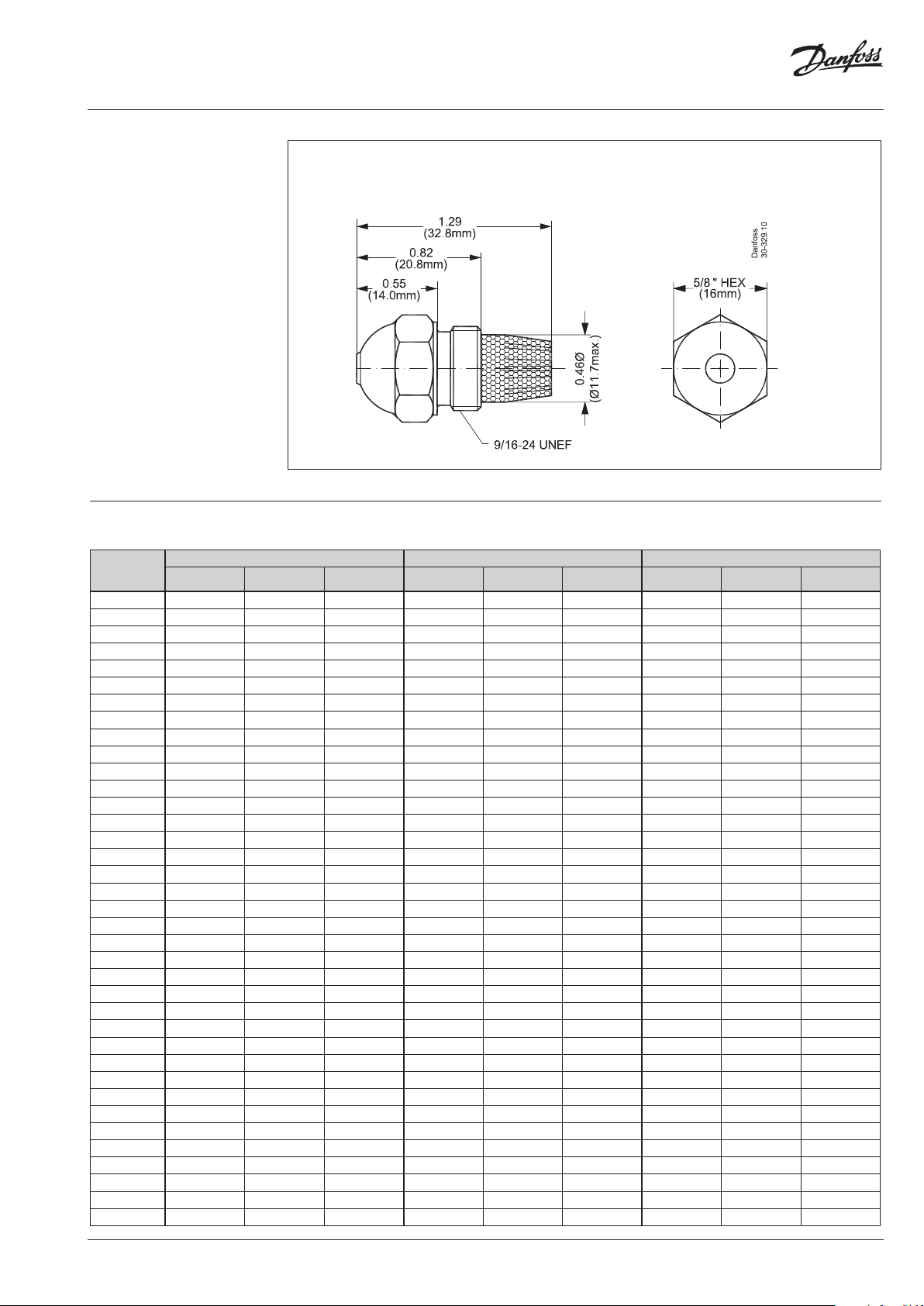

Design and dimensions

A: Tip

B: Disc

C: Bronze lter or strainer

D: Locknut

Available spray patterns:

H: Hollow Cone (red caps)

Hollow spray pattern with higher volume

concentration in the periphery of the spray.

Well suited for low firing rates and burners with

hollow air pattern.

S-S: Semi Solid Cone (blue caps)

Semi solid spray pattern which is the optimal

choice for applications where exact air pattern or

spray pattern requirements can’t be established.

B: Solid Cone (black caps)

Even distributed spray pattern – well suited for

burners with even distributed air pattern. Well

suited for high static pressure flame retention

burners.

Spray angles Schematic spray patterns

45

60

80

H series S-S series

to 2.00 USgal/h

B series 0.50

B series 2.25

to 6.00 USgal/h

2 | VD.CE.Y3.02 © Danfoss | 2019.05

Page 3

Data sheet Oil Nozzles Type H, S-S and B

Design and dimensions

(continuous)

Dimensions for reference only.

Program

Reference

capacity

(Usgal/h)

0.50 - - - - - - - 030G6408 030G6508

0.60 - - - - - - 030G6312 030G6412 030G6512

0.65 030G6014 030G6114 030G6214 030G6614 030G6714 030G6814 030G6314 030G6414 030G6514

0.70 030G6015 030G6115 030G6215 - - - - - -

0.75 030G6016 030G6116 030G6216 030G6616 030G6716 030G6816 03 0G6316 030G6416 030G6516

0.85 030G6018 030G6118 030G6218 030G6618 030G6718 030G6818 030G6318 030G6418 030G6518

0.90 - - - - - - 030G6319 030G6419 030G6519

1.00 030G6020 030G6120 030G6220 030G6620 030G6720 030G6820 030G6320 030G6420 030G6520

1.10 030G6022 030G6122 030G6222 030G6622 030G6722 030G6822 030G6322 030G6422 030G6522

1.20 - - - 030G6623 030G6723 030G6823 - - -

1.25 030G6024 030G6124 030G6224 030G6624 030G6724 030G6824 030G6324 030G6424 030G6524

1.35 - - - - - - 030G6326 030G6426 030G6526

1.50 030G6028 030G6128 030G6228 030G6628 030G6728 030G6828 030G6328 030G6428 030G6528

1.65 030G6029 030G6129 030G6229 - 030G6729 030G6829 - - -

1.75 030G6030 030G6130 030G6230 030G6630 030G6730 030G6830 030G6330 030G6430 030G6530

2.00 030G6032 030G6132 030G6232 030G6632 030G6732 030G6832 030G6332 030G6432 030G 6532

2.25 030G6034 030G6134 030G6234 030G6634 030G6734 030G6834 030G6334 030G6434 030G6534

2.50 030G6036 030G6136 030G6236 030G6636 030G6736 030G6836 030G6336 030G6436 030G6536

2.75 - - - 030G6638 030G6738 030G6838 030G6338 030G6438 030G6538

3.00 030G6040 030G6140 030G6240 030G6640 030G6740 030G6840 030G6340 030G6440 030G6540

3.25 - - - 030G6641 030G6741 030G6841 030G6341 030G6441 030G6541

3.50 030G6042 030G6142 030G6242 030G6642 030G6742 030G6842 030G6342 030G6442 030G6542

3.75 - - 030G6243 - - - 030G6343 030G6443 030G6543

4.00 030G6044 030G6144 030G624 4 030G6644 030G6744 030G6844 030G6344 030G6444 030G6544

4.50 030G6046 030G6146 030G6246 030G6646 030G6746 030G6846 030G6346 030G6446 030G6546

5.00 030G6048 030G6148 030G6248 030G6648 030G6748 030G6848 030G6348 030G6448 030G6548

5.50 030G6050 030G6150 030G6250 030G6650 030G6750 030G6850 030G6350 030G6450 030G6550

6.00 030G6052 030G6152 030G6252 030G6652 030G6752 030G6852 030G6352 030G6452 030G6552

6.50 - - - 030G6653 030G6753 - - - -

7.0 0 - - - 030G6654 030G6754 030G6854 - - -

7.50 - - - 030G6655 030G6755 - - - -

8.00 - - - 030G6656 030G6756 030G6856 - - -

8.50 - - - 030G6657 030G6757 - - - -

9.00 - - - 030G6658 030G6758 030G6858 - - -

10.0 - - - 030G6660 030G6760 030G6860 - - -

11. 0 - - - 030G6662 030G6762 030G6862 - - -

12. 0 - - - 030G6664 030G6764 030G6864 - - -

45° 60° 80° 45° 60° 80° 45° 60° 80°

Hollow Semi Solid Solid

VD.CE.Y3.02 | 3© Danfoss | 2019.05

Page 4

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet Oil Nozzles Type H, S-S and B

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all Danfoss l ogotypes are trademarks of Danfoss A/S. All rights reserve d.

© Danfoss | DHS-SDBT/DK | 2019.054 | VD.CE.Y3.02

Loading...

Loading...