General Data Sheet

Oil Nozzles Type LE

For specific information on this product, please contact Danfoss Burner Components

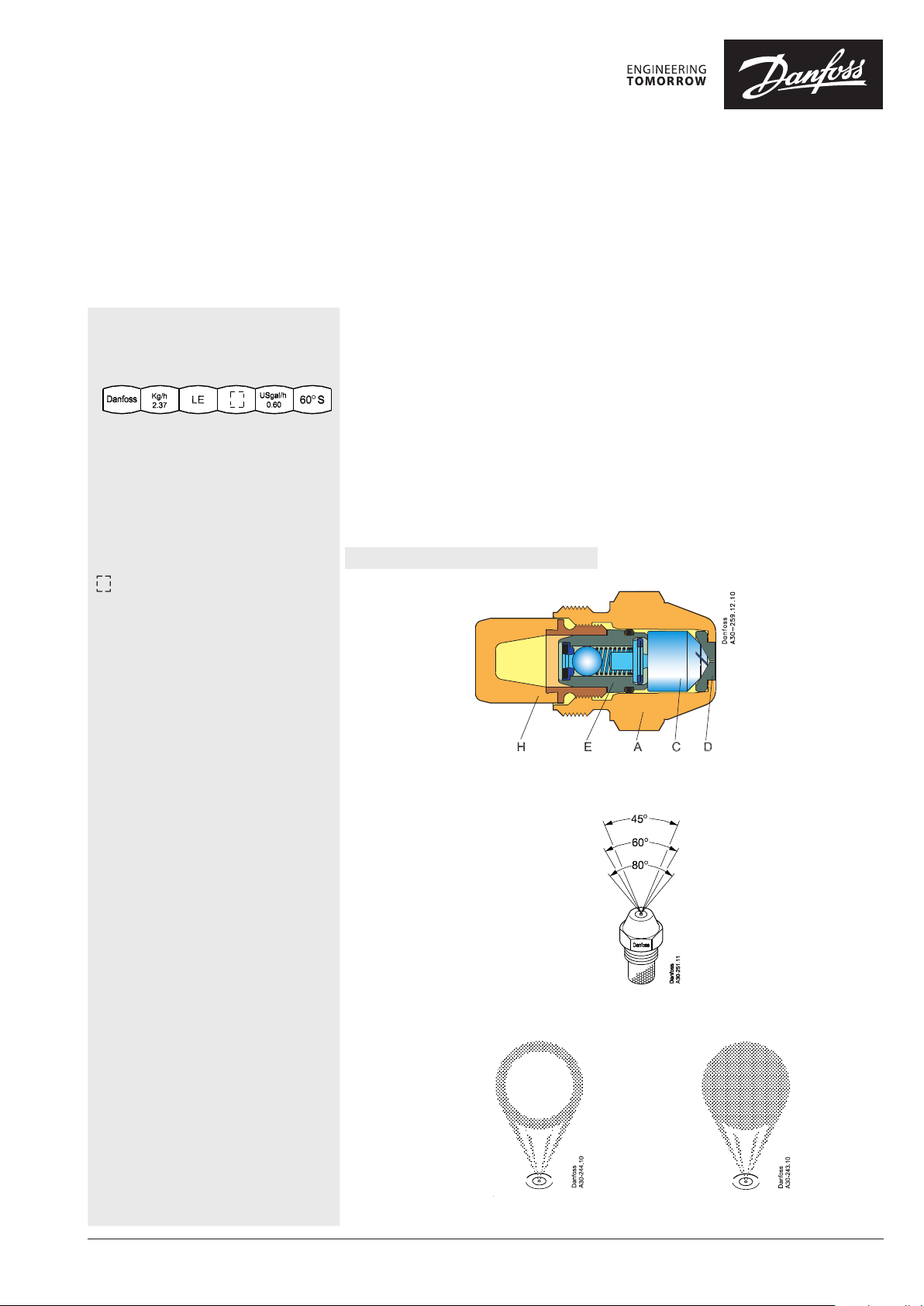

Identification

The nozzle is marked with the following

information:

2.37 Specified capacity (kg/h)

Specification 1160 kPa (11.6 bar),

point 3.4 cSt., 840 kg/m3

[10 bar + 1.6 bar = 11.6 bar]

Capacity tolerance: ± 6%

LE Type (Low Emission)

Serial number for

internal use

0.60 Reference capacity

(USgal/h)

Reference 860 kPa (8.6 bar), 3.4 cSt.,

specification 820 kg/m

point [7.0 bar + 1.6 bar = 8.6 bar]

60° S Spray angle & pattern

(S = Solid)

(H = Hollow)

3

Oil nozzles type LE are special versions

of standard nozzles type OD with built-in

cut-off valve. In combination with an oil

pump with LE-function (e.g. BFP 21 LE)

the LE nozzle prevents drop formation

when preheating and from oil expansion

in the nozzle line at burner stop.

Alternatively the LE-function can be

obtained by using a preheater with incorporated LE-valve (FPHB-LE) in combination with an OD-nozzle.

Design

A Nozzle housing

C Nozzle cone

D Orifice disc

E LE-valve

H Filter

LE nozzles are available with 3 spray angles, 2

spray patterns and capacities from 0.40 to 2.0

Usgal/h. The nozzles are equipped with sintered

bronze filter.

Application and Features

• Light oil

• Low Emission

• 100% test of capacity and

performance

© Danfoss | 2019.10

Spray angles

Spray patterns H S

Hollow Solid

BD.CB.P1.02 1

General Data Sheet Oil Nozzles Type LE

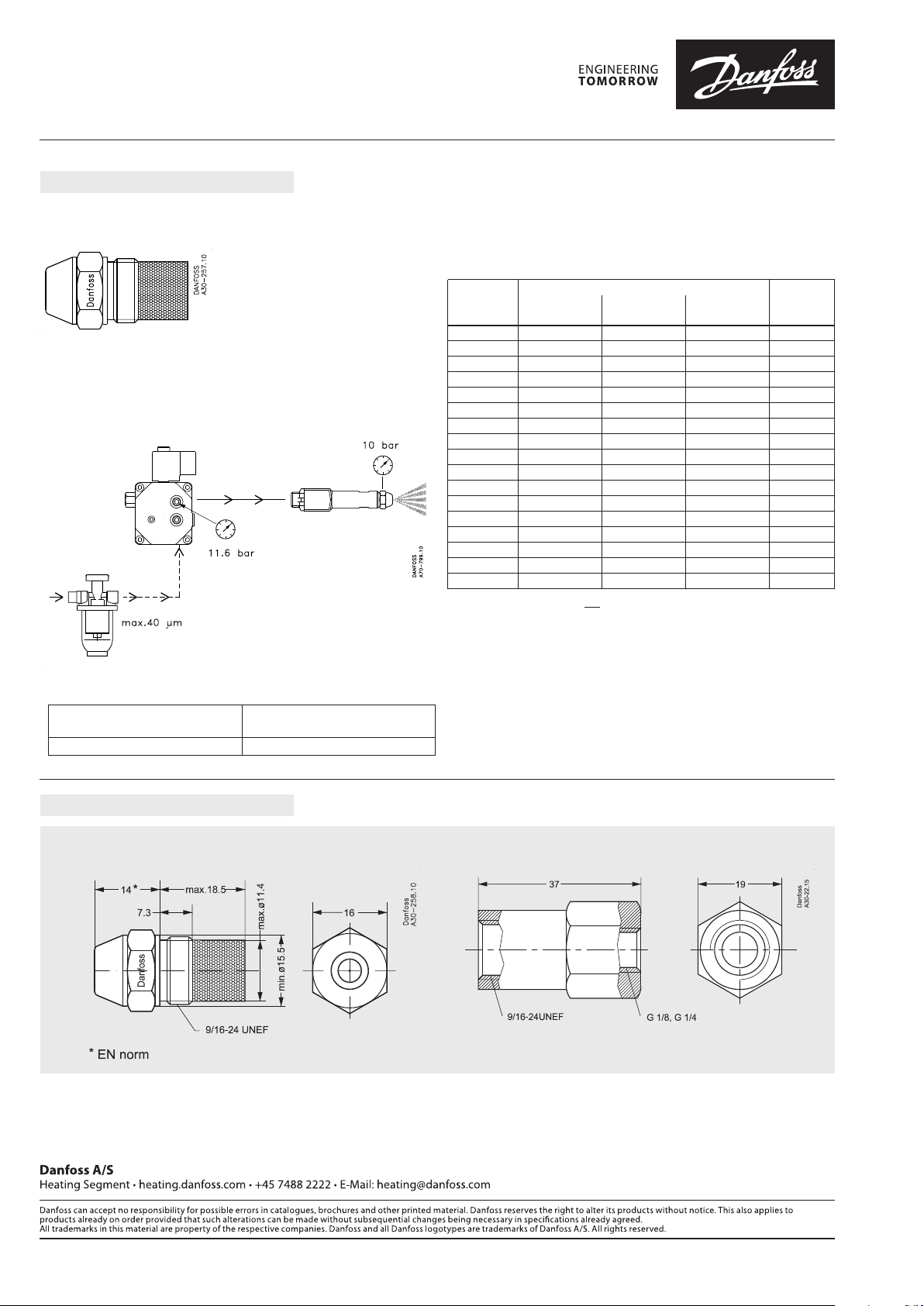

Technical Data

Filters

Capacity 0.40-2.0 USgal/h:

30 μm sintered bronze

Note! The LE-function must be protected by an effective pre-filter

(max. 40 μm)

Oil Nozzles Type LE

The capacity and spray pattern is precisely the same as on an OD

nozzle. I.e. an 0.5 USgal/h, 60°S LE-nozzle is identical to an 0.5 USgal/h,

60°S OD-nozzle. The difference is that the pressure on the pump must

be increased by 1.6 bar in order to get the same capacity from an LE as

from an OD.

Reference Spray angles /patterns Specified

capacity capacity

USgal/h 45° 60° 80° kg/h

0.40 * S H S H S 1.46

0.45

S H S H S 1.66

*

0.50 H S H S H S 1.87

0.55 H S H S H S 2.11

0.60 H S H S H S 2.37

0.65 H S H S H S 2.67

0.75 H S H S H S 2.94

0.85 H S H S H S 3.31

1.00 H S H S H S 3.72

1.10 H S H S H S 4.24

1.20 H S H S H S 4.45

1.25 H S H S H S 4.71

1.35 H S H S H S 5.17

1.50 H S H S H S 5.84

1.65 H S H S H S 6.08

1.75 H S H S H S 6.55

2.00 H S H S H S 7.42

This nozzle capacity should not be used for oil with viscosities lower than

*

1.6 cSt.

Tightening torques

Recommended

tightening torque

Max. tightening torque 25 Nm (2.5 kpm)

15 to 20 Nm

(1.5 to 2.0 kpm)

Dimensions

Nozzle holder

Additional documentation on burner components is available on http://heating.danfoss.com/ or https://store.danfoss.com/

2 | © Danfoss | DHS-SDBT/DK | 2019.10

BD.CB.P1.02

Loading...

Loading...