Page 1

Installation Guide

Pressure regulating valve

OFV, OFV-SS 20-25 (52 bar version)

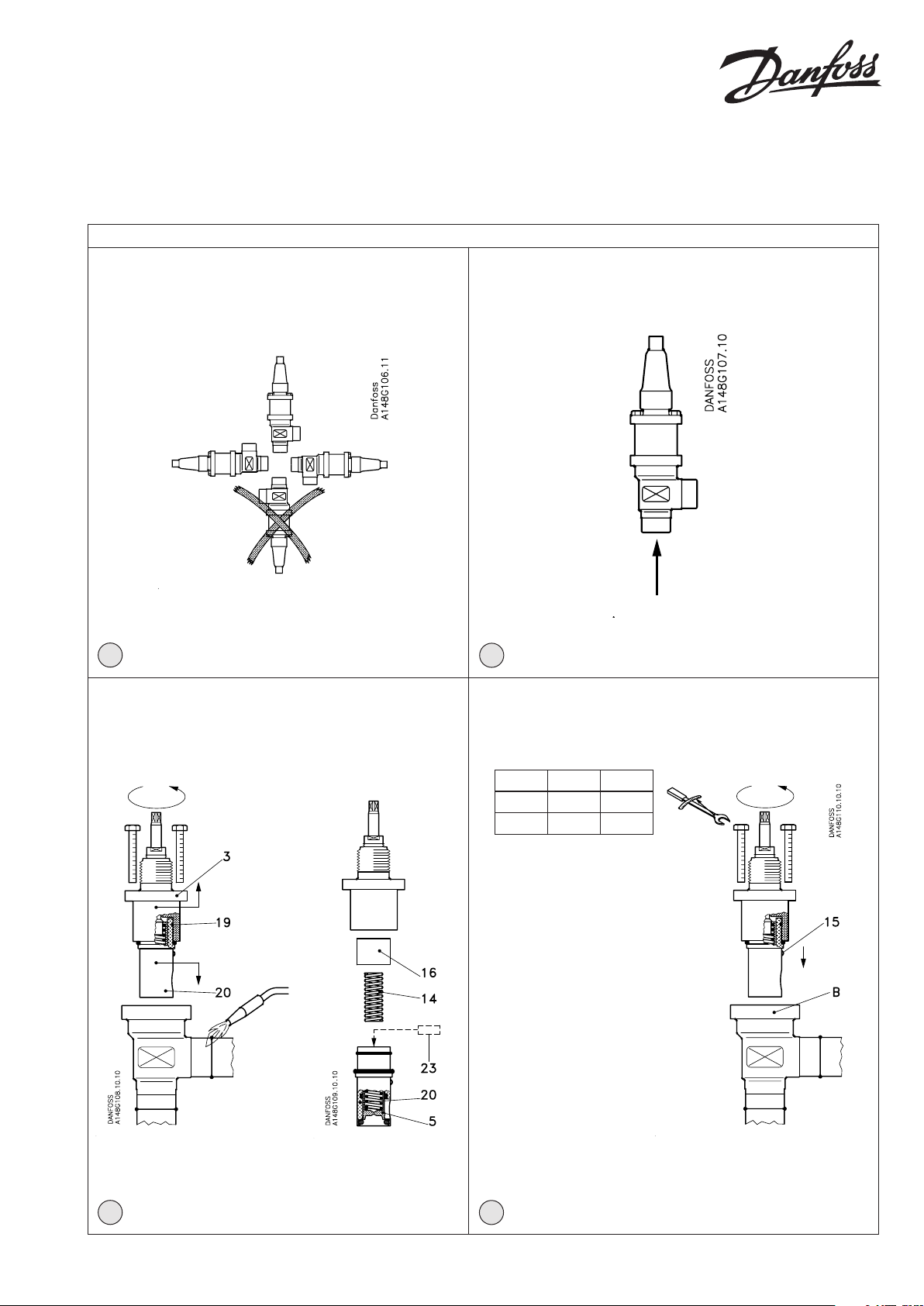

Installation

148R 9537

1

2

148R 9537

Nm LB-feet

DN 20 18 13

DN 25 18 13

3

4

© Danfoss A/S (MWA), 2015-02 DKRCI.PI.HX0.A4.02 / 520H0768 1

Page 2

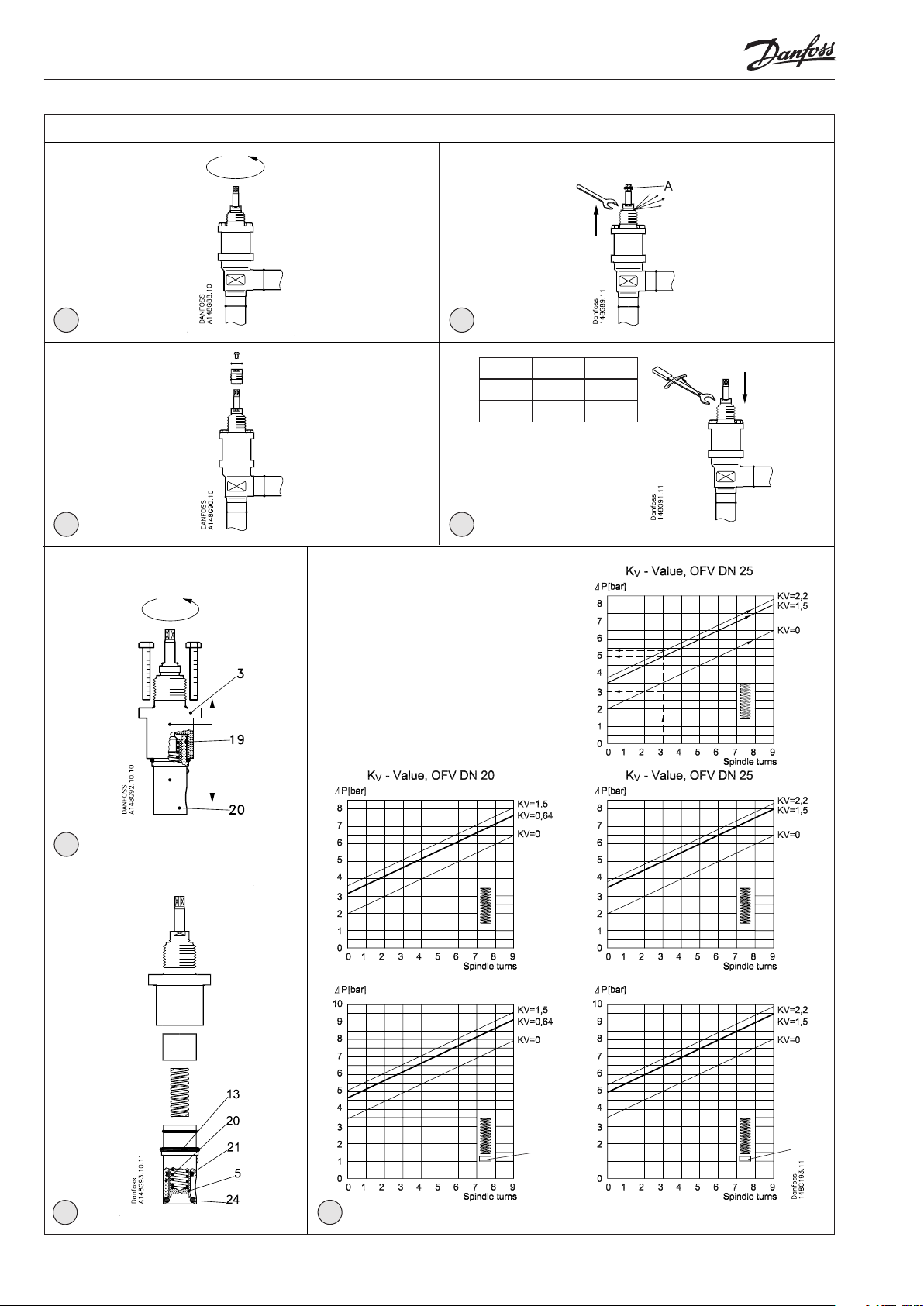

Maintenance

5 6

7 8

Nm LB-feet

DN 20 50 37

DN 25 50 37

9

23

10

11

2 DKRCI.PI.HX0.A4.02 / 520H0768 © Danfoss A/S (MWA), 2015-02

23

Page 3

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC, R717(Ammonia)

and R744 (CO2).

Flammable hydrocarbons are not

recommended. The valve is only

recommended for use in closed circuits. For

further information please contact Danfoss.

Temperature range

OFV: –50/+150°C (–58/+302°F)

OFV-SS: –60/+150°C (–76/+302°F)

Pressure range

The valves are designed for a max. working

pressure of 52 bar g (554 psi g).

Installation

The valve must be installed with the

spindle vertically upwards or in horizontal

position (g. 1). Valves should be opened

by hand according to the guidelines

in the datasheet. The valve is designed

to withstand a high internal pressure.

However, the piping system should be

designed to avoid liquid traps and reduce

the risk of hydraulic pressure caused by

thermal expansion. It must be ensured

that the valve is protected from pressure

transients like “liquid hammer” in the

system.

Recommended ow direction

Direct the ow towards the cone as

indicated by the arrow placed on the valve

housing (g. 2). The force used to open and

close the valve must not exceed the force

of an ordinary handwheel.

Welding

The bonnet should be removed before

welding (g. 3) to prevent damage to

the O-rings in the packing gland and

between the valve body and bonnet, as

well as the teon gasket in the valve seat.

Only materials and welding methods,

compatible with the valve housing

material, must be welded to the valve

housing. The valve should be cleaned

internally to remove welding debris on

completion of welding and before the

valve is reassembled.

Avoid welding debris and dirt in the

threads of the housing and the bonnet.

Removing the bonnet can be omitted

provided that:

The temperature in the area between the

valve body and bonnet during welding

does not exceed +150°C/+302°F. This

temperature depends on the welding

method as well as on any cooling of the

valve body during the welding itself.

(Cooling can be ensured by, for example,

wrapping a wet cloth around the valve

body.)

Make sure that no dirt, welding debris

etc. get into the valve during the welding

procedure.

Be careful not to damage the teon cone

ring.

The valve housing must be free from

stresses (external loads) after installation.

Opening pressure

From factory the OFV will be covering

dierential pressure (∆P) 2-6.5 bar (29-94.3

psig).

Adjust the dierential pressure by turning

the spindle as shown in g. 11. If the above

range is satisfactory please continue with

“Assembly”.

Alternatively, by mounting the distance

piece, (pos. 23) the following range can be

obtained: ∆P = 3.5-8 bar (50.8-116 psig).

Mounting of distance piece (g. 3)

Valve bonnet and guide are held together

by O-ring (pos. 19). Separate the bonnet

(pos. 3) and the guide (pos. 20) by

pulling the pieces from each other. Now

springshoe (pos. 16) and spring (pos. 14)

can be removed. Then mount the distance

piece (pos. 23), supplied separately

together with the installation instruction,

in the cone (pos. 5) at the bottom of the

guide (pos. 20).

NB: Do not take cone and guide apart.

OFV valves must not be mounted in

systems where the outlet side of the valve

is open to atmosphere. The outlet side of

the valve must always be connected to the

system or properly capped o, for example

with a welded-on end plate.

Assembly

Remove welding debris and any dirt from

pipes and valve body before assembly.

Check that the cone has been fully screwed

back towards the bonnet before it is

replaced in the valve body (g. 4).

Tightening

Tighten the bonnet with a torque wrench,

to the values indicated in the table (g. 4).

Colours and identication

The OFV valves are painted with a red oxide

primer in the factory. Stainless steel valves

are not painted. Precise identication of

the valve is made via the ID ring at the top

of the bonnet, as well as by the stamping

on the valve body. The external surface of

the painted OFV valve housing must be

prevented against corrosion with a suitable

protective coating after installation and

assembly.

Protection of the ID ring when repainting

the valve is recommended.

Maintenance

Packing gland

When performing service and maintenance, replace the complete packing gland

only, which is available as a spare part.

As a general rule, the packing gland must

not be removed if there is internal pressure

in the valve.

However, if the following precautionary

measures are taken, the packing gland

can be removed with the valve still under

pressure:

Backseating (g. 5)

To backseat the valve, turn the spindle

counter-clockwise until the valve is fully

open.

Pressure equalization (g. 6)

In some cases, pressure forms behind

the packing gland. Hence a handwheel

or similar should be fastened on top of

the spindle (pos. A) while the pressure is

equalized. The pressure can be equalized

by slowly screwing out the gland.

Removal of packing gland (g. 7)

Cap and packing gland can now be

removed.

Dismantling the valve (g. 10)

Do not remove the bonnet while the valve

is still under pressure.

- Check that the O-rings (pos. 13 & 24)

have not been damaged.

- Check that spindle and cone (pos. 5) are

free of scratches and impact marks.

- If the sealing ring (pos. 21) has been

damaged, the whole cone assembly

must be inspected carefully and maybe

replaced.

Replacement of O-ring (g. 10)

O-ring (pos. 24) seals between seat and

cone. Therefore, it has to be changed if

the valve is leaking. Use a pointed tool to

dismount the O-ring (pos. 24). Check that

cone (pos. 5) and guide (pos. 20) are not

worn out. If these parts are worn out it is

necessary to change the complete guide

which consists of all wearing parts.

Assembly

Remove any dirt from the body before the

valve is assembled. Check that the cone

has been screwed back towards the bonnet

before it is replaced in the valve body (g.

4).

Tightening

Tighten the bonnet with a torque wrench,

to the values indicated in the table (g. 4).

Tighten the packing gland with a torque

wrench, to the values indicated in the table

(g. 6).

Use only original Danfoss parts, including

packing glands, O-rings and gaskets for

replacement. Materials of new parts are

certied for the relevant refrigerant. In

cases of doubt, please contact Danfoss.

Danfoss accepts no responsibility for

errors and omissions. Danfoss Industrial

Refrigeration reserves the right to make

changes to products and specications

without prior notice.

© Danfoss A/S (MWA), 2015-02 DKRCI.PI.HX0.A4.02 / 520H0768 3

Page 4

4 DKRCI.PI.HX0.A4.02 / 520H0768 © Danfoss A/S (MWA), 2015-02

Loading...

Loading...