Page 1

Data Sheet

Pressure regulating valve

Type OFV and OFV-SS 20-25

Ecient control of defrosting pressure

OFV are angle-way pressure regulating valves,

which have ajustable opening pressure and

cover the dierential pressure range (ΔP): 2 - 8

bar (29 ‑ 116 psi). The valve can be closed

manually, e.g. during plant service and have

backseating, enabling the spindle seal to be

replaced with the valve still under pressure.

The valves are especially designed to prevent

uttering due to low velocity and/or low

density. In consequence it is possible to apply

the valves with wide uctuations in capacity

demands, i.e. from maximum performance to

part load. A exible O-ring provides perfect

sealing over the seat.

Features

• Applicable to HCFC, HFC, R717(Ammonia)

and R744 (CO2).

• Full temperature range packing gland -50 °C /

+150 °C (-58 °F / +302 °F)

• Maximum operating pressure: 40 bar (580

psig)

• Three functions in one valve. The OFV valve

combines the functions of a pressure

reegulating valve, a check valve and a shut-

o valve

• Classication: DNV, CRN, BV, EAC etc. To get

an updated list of certication on the

products please contact your local Danfoss

Sales Company.

• Special features for OFV-SS

◦ Low temperature stainless steel housing

and bonnet

◦ Low temperature packing gland -60 °C /

+150 °C (-76 °F / +302 °F)

◦ Maximum operating pressure 52 bar (754

psig)

AI234986440301en-000601

Page 2

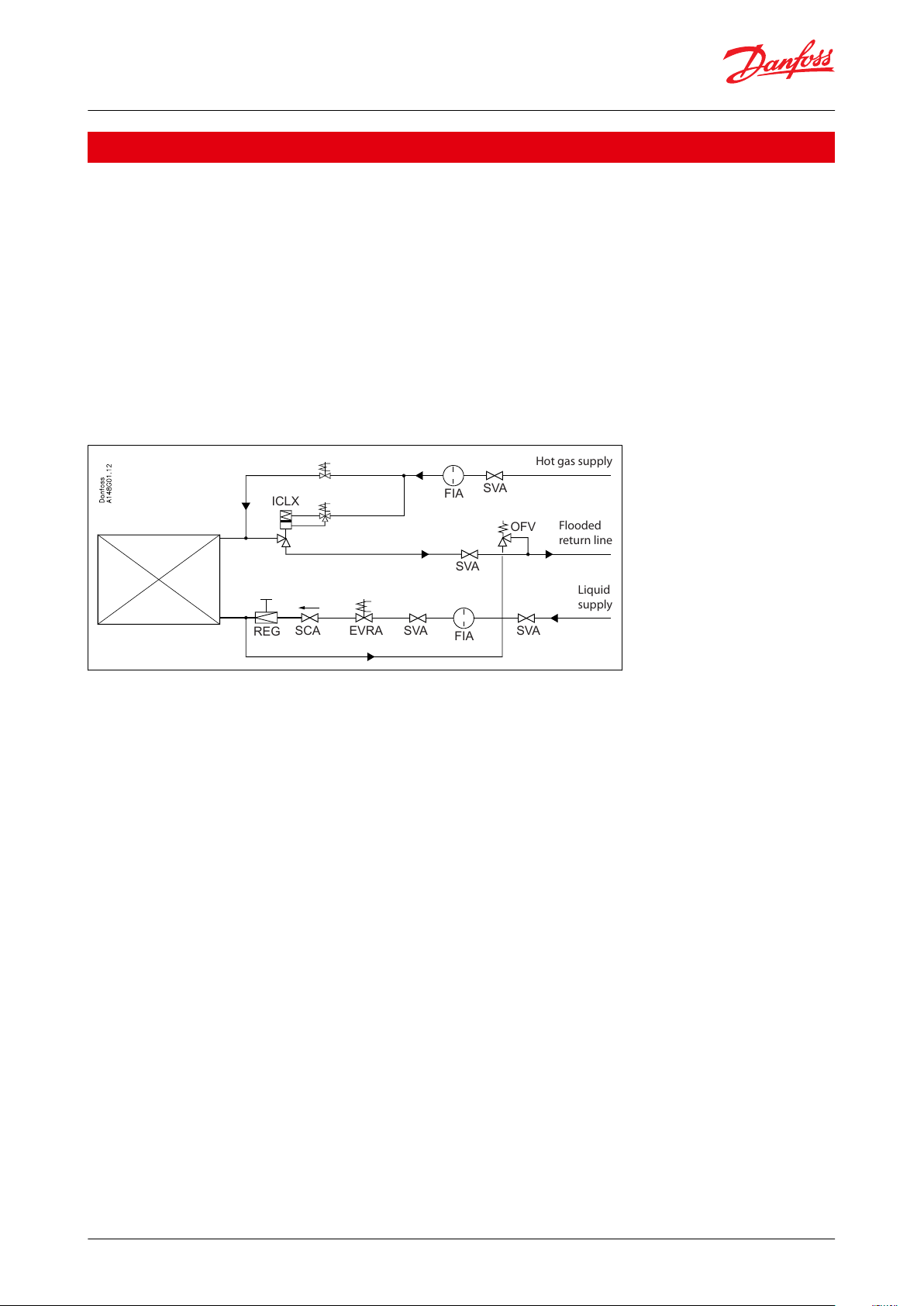

Hot gas supply

Flooded

return line

Liquid

supply

SVA

FIA

OFV

SVA

SVA

FIA

SVAEVRASCA

REG

ICLX

Pressure regulating valve, type OFV and OFV-SS 20-25

Application

Pressure/temperature control during hot gas defrosting

In order to obtain ecient hot gas defrosting the temperature (pressure) must be increased to approx. 10°C (50°F).

The OFV is the optimal solution for controlling the defrosting pressure and thus the corresponding temperature. It is

recommended to start the defrosting cycle by closing the ICLX valve in the liquid supply line and allowing some of

the cold liquid contained in the evaporator to return to the liquid separator.

Close the ICLX valve in the suction line and after a delay open the solenoid valve in the hot gas supply in order to

build up the defrosting pressure in the evaporator. When the defrosting pressure reaches the set OFV-pressure, the

OFV will open and the defrosting pressure will increase to the working pressure ΔP

After defrosting, it is normal practice to open the ICLX in the return line to equalize the pressure to the suction side

before opening to the pump side.

Figure 1: Pressure/temperature control

set

+ ΔP

over

.

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 2

Page 3

Pressure regulating valve, type OFV and OFV-SS 20-25

Media

Refrigerants

Applicable to HCFC, HFC, R717(Ammonia) and R744 (CO2).

Flammable hydrocarbons are not recommended. For further information please contact your local Danfoss Sales

Company.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 3

Page 4

Description

Values

Temperature range

OFV: -50/+150 °C (-58/+302 °F)

OFV-SS: -60/+150 °C (-76/+302 °F)

Maximum operating pressure

OFV: 40 bar (580 psig)

OFV-SS: 52 bar (754 psig)

Set pressure (Δp)

2 - 8 bar (29 - 116 psi)

Pressure regulating valve, type OFV and OFV-SS 20-25

Product specication

Design

Packing gland OFV

The “full temperature range” packing gland consists of a double O-ring sealing arrangement combined with

permanent lubrication from a grease reservoir. This ensures perfect tightness throughout the whole range: -50/+150

°C (-58/+302 °F).

Flexible O-ring provides perfect sealing over the seat.

Packing gland OFV-SS

The stainless steel packing gland comprises a spring loaded seal packing gland which ensures a perfect tightness in

the range: -60/+150 °C (-76/+302 °F).

The packing glands are equipped with a scraper ring to prevent penetration of dirt and ice into the packing gland.

Installation

The valve is designed to resist very high internal pressure, but as to the pipe system in general, hydraulic pressure

caused by thermal expansions in entrapped refrigerants should be avoided. For further information please see OFV

installation instruction.

Figure 2: Example of Marking

Ring, Valve type OFV.

Pressure and temperature data

Table 1: Pressure and temperature range

Understanding the OFV in practice

(when working in a defrosting application)

How the OFV works

The opening pressure of the OFV can be adjusted to a specic dierential pressure ΔP

indirectly determines the defrosting pressure.

As illustrated in Figure 3: Pressure and temperature the OFV will work at a pressure somewhat higher than ΔP

namely the ΔP

which will be situated somewhere in the area marked with grey in Figure 3: Pressure and

total

temperature.

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 4

by turning the spindle. ΔP

set

set

,

set

Page 5

min. temperature

Condensing temperature/pressure

∆P

total

∆P

over

∆P

set

+ ∆P

over

Evaporating temperature/pressure

∆P

set

max. temperature

(defrosting temperature)

Pressure regulating valve, type OFV and OFV-SS 20-25

Figure 3: Pressure and temperature

As ΔP

adjusting the opening dierential pressure ΔP

is plant specic, it follows that the total working pressure (ΔP

over

it is possible to adjust the working pressure ΔP

set

total

= ΔP

set

+ ΔP

) is plant specic too. By

over

set

+ ΔP

over

until you

get the required defrosting pressure.

Defrosting pressure ≈ Evaporating pressure + ΔP

IMPORTANT:

set

+ ΔP

over

.

The OFV valve is back pressure dependent.

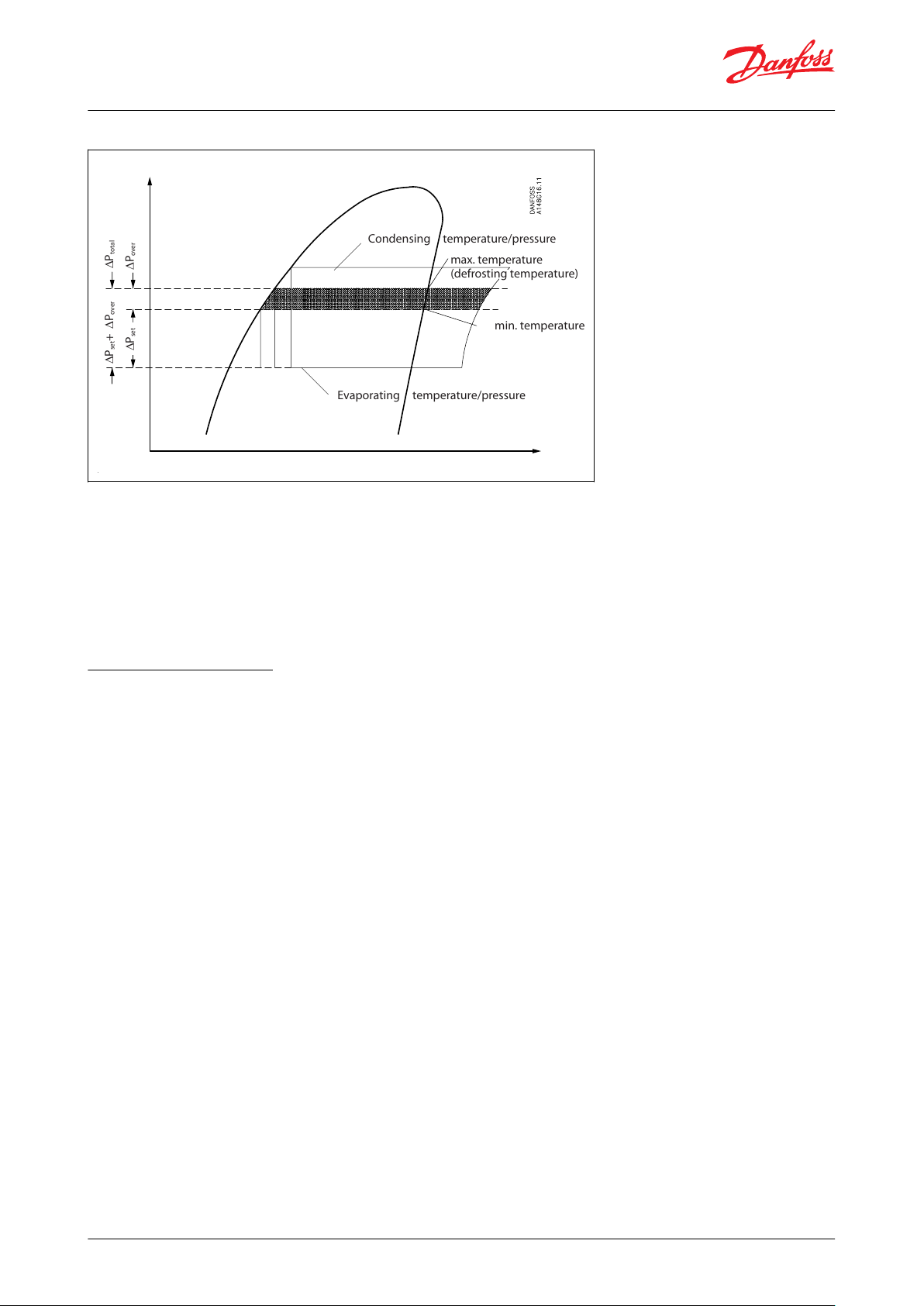

Adjusting set pressure

The set pressure is the pressure at which the valve starts to open.

The set pressure is adjustable in the range 2 ‑ 8 bar dierential pressure. When the valve is delivered, a distance

piece is supplied seperately with the valve. The distance piece can be mounted under the spring, thus increasing the

initial tension of the spring. Therefore the valve covers the complete range 2 - 8 bar dierential pressure, as follows:

2 bar - 6.5 bar dierential pressure without distance piece. 3.5 bar - 8 bar dierential pressure with distance piece.

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 5

Page 6

Spindle turns

[bar]P

Set

Pressure Set with distance piece (element 23)

Pressure Set without distance piece (element 23)

p

over

(bar)

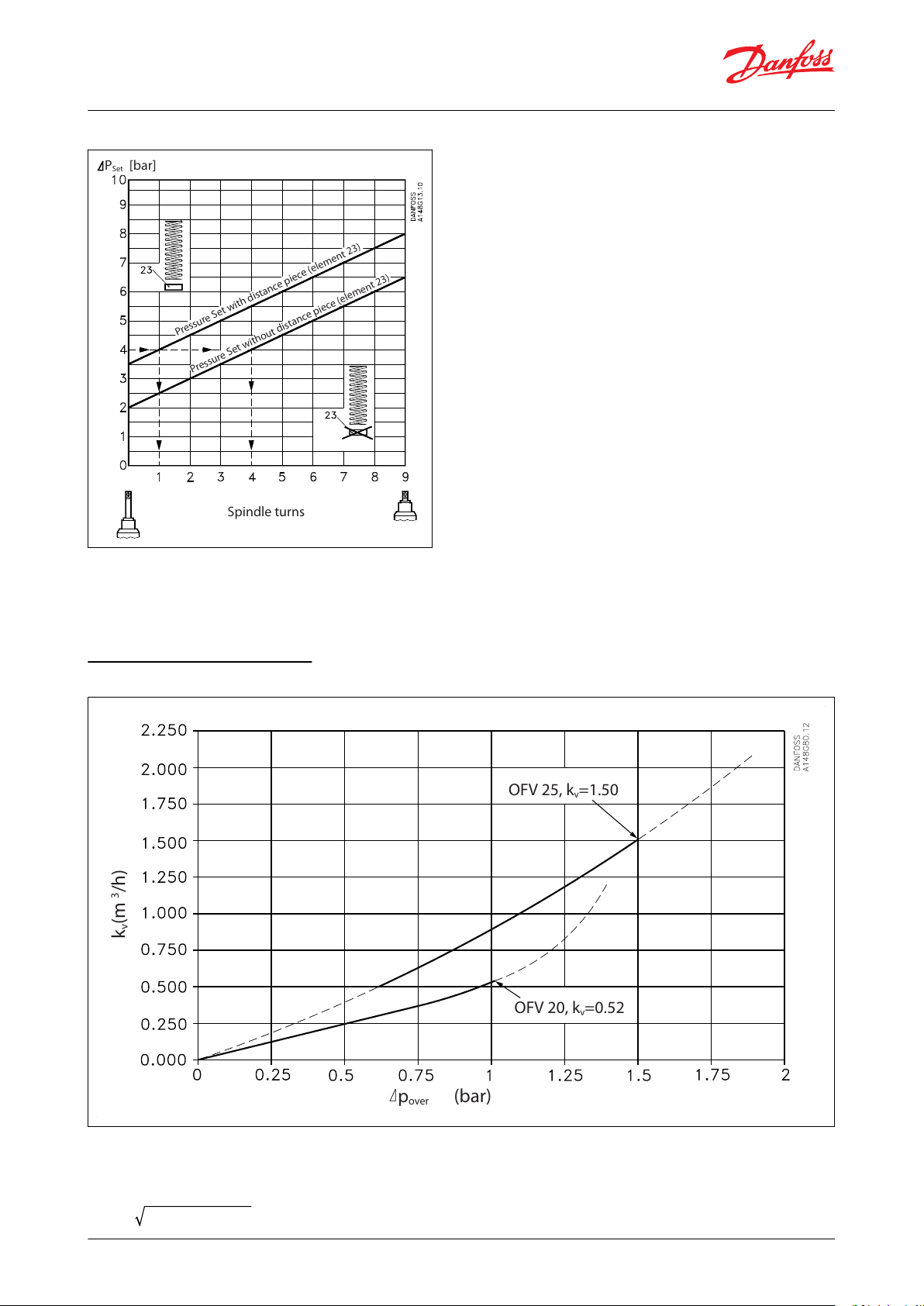

k

v

(m

3

/h)

OFV 20, kv=0.52

OFV 25, kv=1.50

Pressure regulating valve, type OFV and OFV-SS 20-25

Figure 4: Adjusting set pressure

Illustrated gure shows set pressure as a function of the spindle turns

NOTE:

See material specication and installation an maintenance instruction for OFV.

Computation and selection

Figure 5: kv values for OFV 20 - 25

The capacity of the OFV valves can be calculated by the following formulas:

Liquids without phase change

r × ΔP

G = k

v

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 6

total

× 1000

Page 7

Evaporating temperature

–10°C

–20°C

–30°C

–40°C

–50°C

Defrosting temperature

10°C

Mass ow G

OFV

20 (kg/h)

(ΔP

over

= 1 bar , kv = 0.52 m3/h)

577

661

714

747

768

Mass ow G

OFV

25 (kg/h)

(ΔP

over

= 1.5 bar , kv = 1.5 m3/h)

1666

1906

2059

2156

2216

Evaporating temperature

–10°C

–20°C

–30°C

–40°C

–50°C

Mass

ow G0 (kg/h)

2.780 × Q

0

2.712 × Q

0

2.651 × Q

0

2.595 × Q

0

2.544 × Q

0

Pressure regulating valve, type OFV and OFV-SS 20-25

Liquids with phase change (e.g. pressure control during defrost)

G = kv × 0.78 r × ΔP

total

× 1000

G: mass ow (kg/h)

kv: ow rate (m3/h) (the kv value is dependent on ΔP

, see Figure 5: kv values for OFV 20 - 25).

over

ρ: density, liquid (kg/m3)

ΔP

= dierential pressure (bar)

bar

ΔP

= ΔP

bar

Defrosting pressure ≈ Evaporating pressure + ΔP

set

+ ΔP

over

set

+ ΔP

over

Capacity calculation for defrost pressure regulating

Table 2: Max. mass ow (G

Table 3: OFV 20

Table 4: OFV 25

NOTE:

The calculation is based on formula for "liquids with phase change" in the paragraph "Computation and selection".

) for OFV 20 and OFV 25 with R717

OFV

Table 5: Calculating of refrigerant mass ow G

0

Q0: Capacity of the evaporator (kW)

NOTE:

The calculation is based on pump circulating system (Liquid temperature = Evaporating temperature)

Guide line: Defrost capacity G

~ (2 – 3) × G

OFV

0

Example:

An evaporator in a refrigerant plant has a capacity of Qo = 150 kW and a evaporating temperature of -40 °C.

The defrosting temperature has to be controlled with an OFV valve.

Table 2: G0= 2.595 × Q0 = 389 kg/h

The defrosting capacity in this example is 2.5 × G0.

G

≥ 2.5 × 389 = 972 kg/h.

OFV

OFV 25 is selected (G

OFV 25 max.

= 2156 kg/h (Table 2: Max. mass ow (G

) for OFV 20 and OFV 25 with R717)).

OFV

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 7

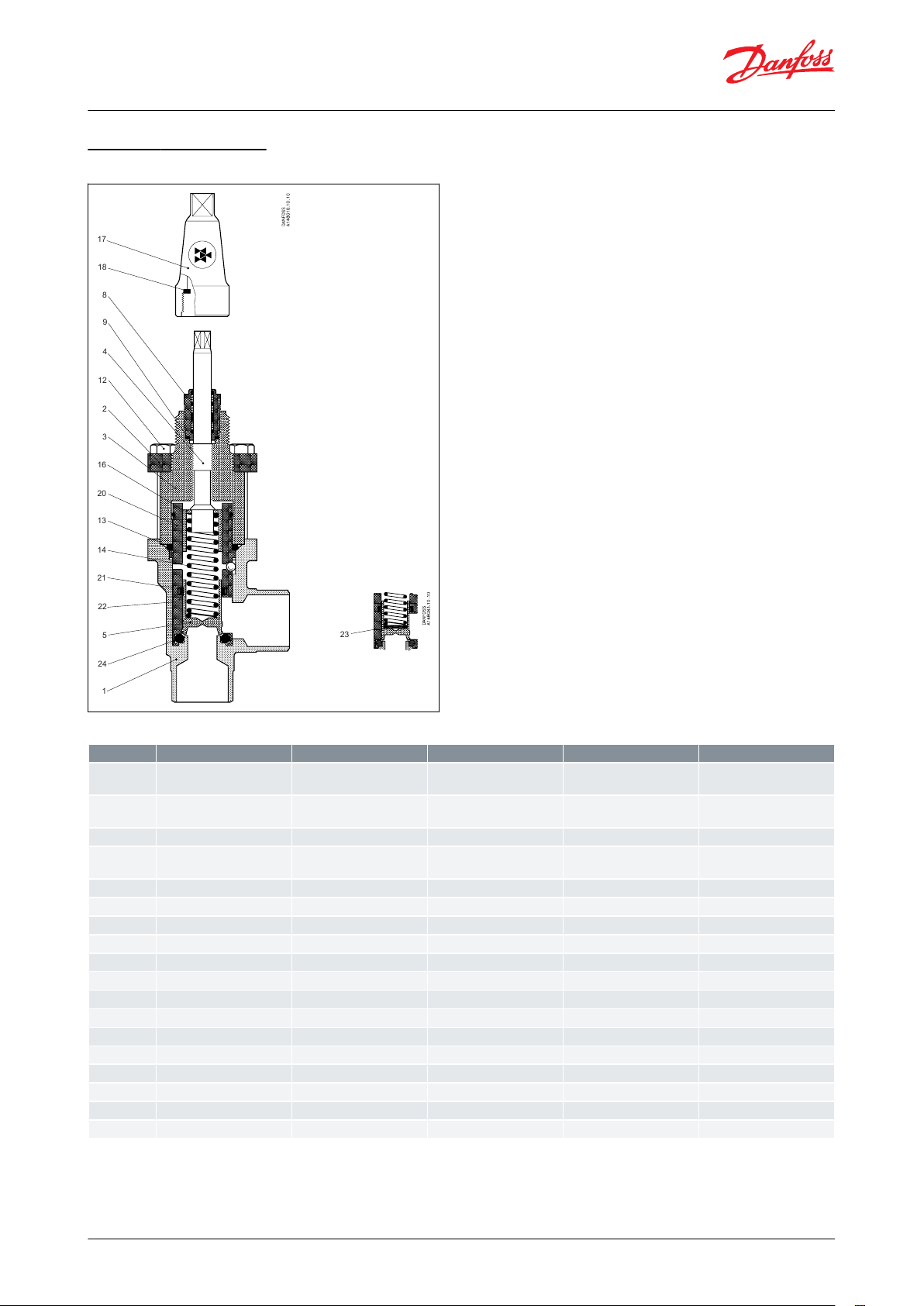

Page 8

1

24

5

22

21

14

13

20

16

3

2

12

4

9

8

18

17

23

No.

Part

Material

EN

ISO

ASTM

1

Housing

Steel

P285 QH

EN10222-4

LFA350

2

Bonnet, Flange

Steel

P275 NL1

EN10028-3

3

Bonnet, Insert

Steel

4

Spindle

Stainless steel

X10 CrNi S18-9

17440

Type 17

683/13

AISI 303

5

Cone

Steel8Packing gland

Steel9Packing washer

Aluminium

12

Bolts

Stainless steel

A2-70

A2-70

Type 308

13

O-ring

Cloroprene (Neoprene)

14

Spring

Steel16Spring washer

Steel17Cap

Aluminium

18

Gasket for cap

Nylon20Guide piece

Steel21O-ring

Cloroprene (Neoprene)

22

Sealing ring

PTFE (Teon)

23

Distance piece

Steel24O-ring

Cloroprene (Neoprene)

Pressure regulating valve, type OFV and OFV-SS 20-25

Material specication

Figure 6: OFV

Table 6: Material and part list

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 8

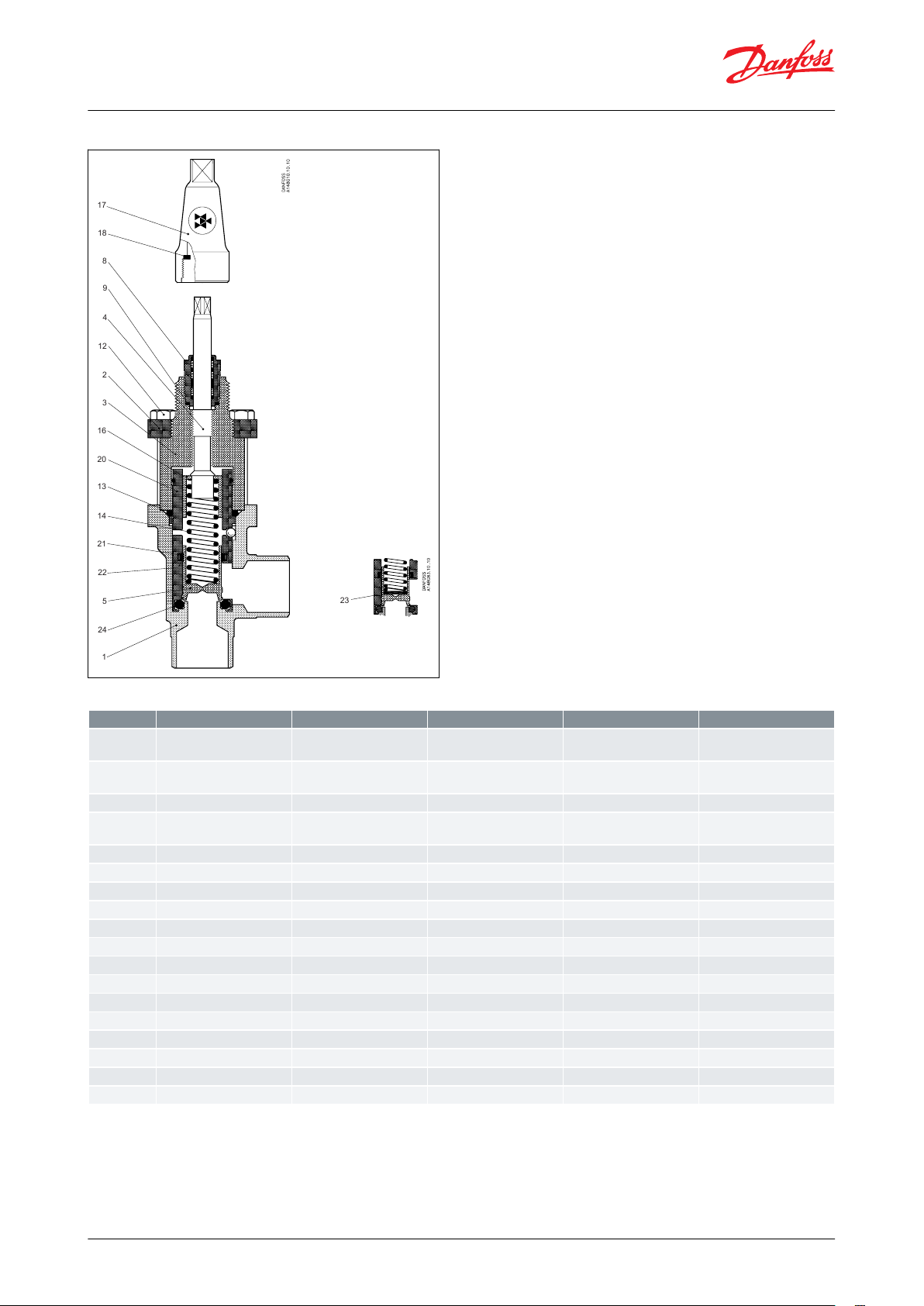

Page 9

1

24

5

22

21

14

13

20

16

3

2

12

4

9

8

18

17

23

No.

Part

Material

EN

ISO

ASTM

1

Housing

Stainless steel

X5CrNi18-10

EN10088

AISI 304

2

Bonnet, Flange

Stainless steel

X5CrNi18-10

EN10088

AISI 304

3

Bonnet, Insert

Stainless steel

4

Spindle

Stainless steel

X8CrNiS18-9

DIN 17440

Type 17

683/13

AISI 303

5

Cone

Steel

9SMn28

Type 2

12138Packing gland

Stainless steel

9

Packing washer

Non asbestos

12

Bolts

Stainless steel

A2-70

A2-70

Type 308

13

O-ring

Cloroprene (Neoprene)

14

Spring

Steel16Spring washer

Steel

Steel17Spindle seal cap

Aluminium

18

Seal cap gasket

Nylon20Guide piece

Steel21O-ring

Cloroprene (Neoprene)

22

Sealing ring

PTFE (Teon)

23

Distance piece

Steel24O-ring

Cloroprene (Neoprene)

Pressure regulating valve, type OFV and OFV-SS 20-25

Figure 7: OFV-SS 20 - 25 (¾ - 1")

Table 7: Material and part list

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 9

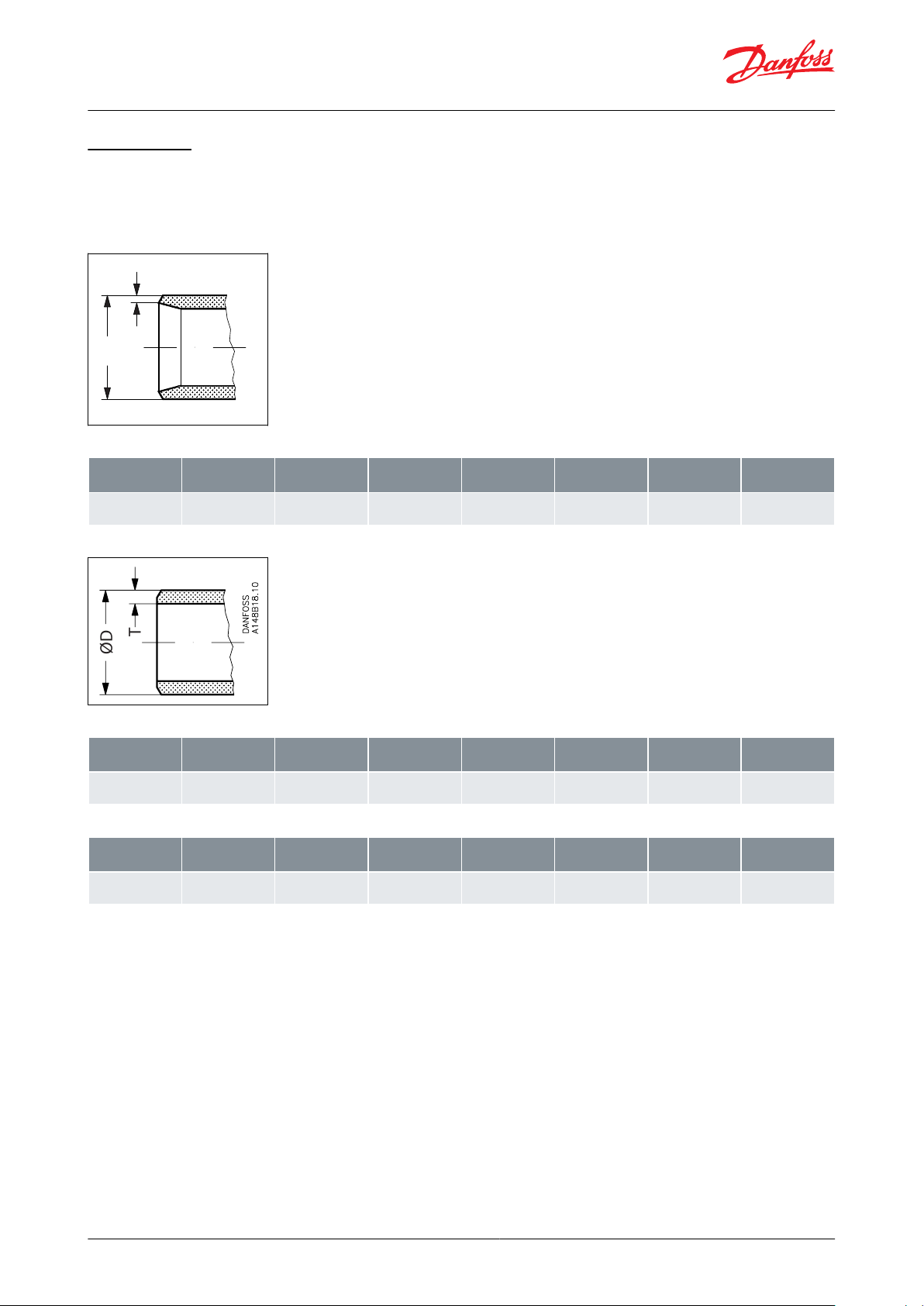

Page 10

T

ØD

Danfoss

A148B15.10

SizemmSize

in.ODmmTmmODin.Tin.

kv-angle

m3/h

Cv-angle

USgal/min

2025¾126.9

33.7

2.3

2.6

1.06

1.33

0.09

0.10

0 - 0.52

0 - 1.50

0 - 0.60

0 - 1.74

T

ØD

SizemmSize

in.ODmmTmmODin.Tin.

kv-angle

m3/h

Cv-angle

USgal/min

2025¾126.9

33.7

4.0

4.6

1.06

1.33

0.16

0.18

0 - 0.52

0 - 1.50

0 - 0.60

0 - 1.74

SizemmSize

in.ODmmTmmODin.Tin.

kv-angle

m3/h

Cv-angle

USgal/min

2025¾126.9

33.7

2.9

3.5

1.06

1.33

0.11

0.14

0 - 0.52

0 - 1.50

0 - 0.60

0 - 1.74

Pressure regulating valve, type OFV and OFV-SS 20-25

Connections

Available with the following connections:

• Welding DIN (EN 10220)

• Welding ANSI (B 36.19M)

Figure 8: DIN

Table 8: Butt-weld DIN (EN 10220)

Figure 9: ANSI

Table 9: Butt-weld ANSI (B 36.10M)

Table 10: Butt-weld ANSI (B 36.19M, SCHEDULE 40)

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 10

Page 11

G

G

C

D

Cmin.

H

Valve size

G

C

C

min

∅DHWeight

OFV 20 (¾

mm

in.451.77

230

9.1

290

11.4381.5602.4

2.0 kg

4.4 lb

OFV 25 (1 in.)

mm

in.451.77

230

9.1

290

11.4381.5602.4

2.0 kg

4.4 lb

Pressure regulating valve, type OFV and OFV-SS 20-25

Dimensions and weights

Figure 10: OFV 20 - 25

Table 11: OFV 20 - 25

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 11

Page 12

Valve type

OFV

OFV-SS

Over Flow Valve in carbon steel

Over Flow Valve in stainless steel

Nominal size in mm

20

25

DN 20

DN 25

Connections

D

A

Butt-weld connection: DIN EN 10220

Butt-weld connection: ANSI B 36.19M

Valve housing

1

Angle ow

Materials

3

Housing: P285 QH, Bonnet: P275 NL1

Other equipment

3

Cap, short spindle with Cloroprene (Neoprene) O-ring

OFV25D13

3

Size

Type

Code No.

mm

in

20

¾

OFV 20 A 133

2412+185

20

¾

OFV 20 D 133

2412+183

20

¾

OFV-SS 20 D ANG OVER FLOW VALVE 52 bar

148G3194

25

1

OFV 25 A 133

2412+186

25

1

OFV 25 D 133

2412+184

25

1

OFV-SS 25 A ANG OVER FLOW VALVE 52 bar

148G3843

25

1

OFV-SS 25 D ANG OVER FLOW VALVE 52 bar

148G3195

Pressure regulating valve, type OFV and OFV-SS 20-25

Ordering

How to order

The table below is used to identify the valve required.

Please note that the type codes only serve to identify the valves, some of which may not form part of the standard

product range.

For further information please contact your local Danfoss Sales Company.

Table 12: Type codes

Table 13: Example for type codes

IMPORTANT:

Where products need to be certied according to specic certication societies or where higher pressures are

required, the relevant information should be included at the time of order.

Table 14: Opening dierential pressure 2 - 8 bar (29 - 116 psi):

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 12

Page 13

OFV valves are approved and CE-marked in accordance with the Pressure Equipment Directive - 97/23/EC.

OFV

Nominal bore

DN≤ 25 mm (1 in.)

Classied for

Fluid group I

Category

Article 3, paragraph 3

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

033F0686.AH

Manufacturers Declaration

PED

Danfoss

033F0473.AD

Manufacturers Declaration

ATEX

Danfoss

19.10327.266

Marine - Safety Certicate

-

RMRS

Pressure regulating valve, type OFV and OFV-SS 20-25

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 15: Pressure Equipment Directive (PED)

For further details / restrictions - see Installation Instruction

Table 16: OFV

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 13

Page 14

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI234986440301en-000601 | 14

Loading...

Loading...