Page 1

Data Sheet

Check and Stop valve

Type OFC

For Oil Free Refrigerants, Fits Turbocor TTS/TGS/TTH/TGH Compressors

OFC type check and stop valve are designed for

delivering a discharge solution that improves

performance and reliability of oil-free

centrifugal compressors with magnetic

bearings by incorporating a damped check

valve, while reliably and eciently

incorporating stop and diuser functions.

Features

• Nozzle check valve closes quickly if backow

• PTFE protects against reverse refrigerant

migration; compatible with oil-free

applications

• Gas damper and special opening

characteristic prevents from violent

movements in surge conditions

• Damped nozzle check valve reduces

chattering noises

• Decoupled stop function from check function

allows faster access and improves reliability of

sealing

• Lock ring design prevents from unintentional

closing of the valve

• Built-in sight glass gives direct visibility to

proper valve functioning and refrigerant ow

• Built-in pressure port provides connection to

high pressure cut out

• Built-in staging port

• Optimized ow path enhances ow capacity

with lower pressure drop

• Bolt on to all TTS/TGS/TTH/TGH compressor

discharge ports

• Multiple orientations possible

AI391918642123en-000101

Page 2

Image

Compressor type

Refrigerant

TTS300: 60-90 TR

R134a R513A

TTS350: 70-120TR

TTS400: 90-150 TR

TTS700: 130-200 TR

TTH375: 75-115 TR

TGS230: 40-70 TR

R1234ze R515B

TGS310: 60-90 TR

TGS390: 70-120 TR

TGS490: 110-140 TR

TTGS520: 90-150 R

TGH285: 70-90 TR

Check and Stop valve, Type OFC

Functions

The OFC is intended for use on Turbocor compressors up to size TTS700 as a combined diuser elbow, shut o valve

and check valve with integrated staging port and pressure port (Schrader valve). The device contains:

Integrated stop function

Damped check valve function

Integrated diuser elbow

Integrated staging port

Table 1: Used for Danfoss Turbocor® Compressors:

Figure 1: Fit on compressor

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 2

Page 3

Motor Cooling

Port

Suc!on

Port

Economizer

Port

Discharge Port

*

*

*

Sight

Glass

Sight

Glass

Filter/

Drier

Filter/

Drier

Evaporator

Expansion

Valve

Expansion

Valve

Staging

Valve

Staging

Valve

Load

Balancing

Valve

Load

Balancing

Valve

**

Condenser with

Subcooler

Filter/

Drier

Filter/

Drier

Sight

Glass

*

**

*

Check

Valve

Danfoss

32Z8201

Check and Stop valve, Type OFC

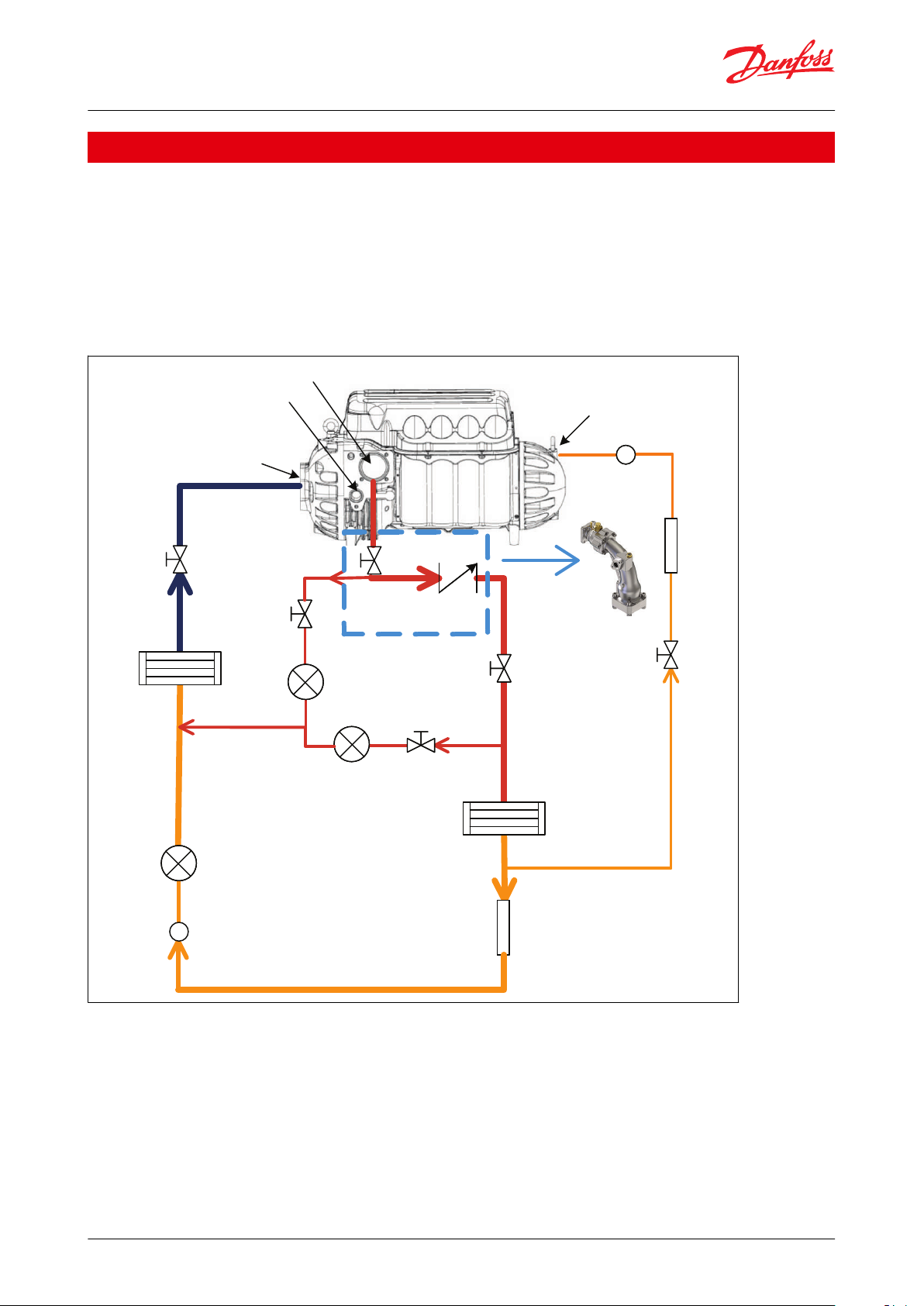

Applications

Typical applications for OFC valves are:

Only for oil free system

• Air-Cooled Chiller

• Water-Cooled Chiller

• Water-to-Water Heat Pump

• Air-to-Water Heat Pump

Figure 2: Application Diagram

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 3

Page 4

Check and Stop valve, Type OFC

Media

UL listed for R134a, R513A and R515B. CE approved for uid group 2, including R1234ze(E)For other refrigerants, visit

http://store.danfoss.com/ and search for individual code, where refrigerants are listed as part of product details.

Oil: OFC valve is designed for an oil-free environment

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 4

Page 5

Technical data

Values

Max. working pressure

23 bar / 334 psig

Media temperature range

Min. 0 ⁰C / 32 ⁰F

Max. 90 ⁰C / 194 ⁰F, short term up to 100⁰C / 212⁰F

Operating ambient temperature

-15°C to +51°C (5°F to 124°F)

Storage ambient temperature

-30°C to +51°C (5°F to 124°F)

Humidity

5-95% (Non-Condensing)

Flow direction

Single-ow

Valve direction

Angleway

Liquid detection

SGR socket sight glass in elbow

State of Delivery

With spring for vertical installation mounted. Ball valve is open. Included outlet

ange and alternative springs packed separately

Orientation

(1)

Three dierent orientations: Horizontal, 45° down and Vertical down

Serviceable

Check valve spare parts

Compressor interface

to t directly on outlet of the listed Turbocor compressors(see page 2)

Connection: Ø54 mm (2 1/8”)

Flange thickness: 17 mm

(Bolt is not included)

Staging port

O-ring groove: OD ø41.1 mm, ID 32,9mm, width 4.1mm

(O-ring is not included)

Thread depth: 24mm

Tube Brazing and ange connection

Ø80 mm (3 1/8”) Outlet steel ange for brazing of 3-1/8" copper pipe

4 1/8” is available as spare part and shall be purchased separately

Support bracket

Thread: 2 x M10

Thread depth: 18mm

Vertical down

Blue spring

(as delivered)

45° down

Yellow spring

Horizontal

Red spring

45° down

Yellow spring

Horizontal

Red spring

Danfoss

20R01

Check and Stop valve, Type OFC

Product specication

Technical data

Table 2: Technical data

(1)

(1)

Check valve spring must be exchanged if elbow is mounted horizontal or 45° down

Check valve spring must be exchanged if elbow is mounted horizontal or 45° down

Orientation and Spring Selection

Figure 3: Available orientations

Available orientations

Lifetime and functionality are compromised if used in other orientation than specied and/or not in accordance to

the mounted spring.

At delivery, ball valve actuating axle is orientated same way on all versions as shown.

Ball valve clocking may be changed by removing bolts and rotating ball valve housing without retracting the ball

valve assembly away from the elbow.

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 5

Page 6

Vertical: Blue spring. Mounted at delivery

45° down: Yellow spring

Horizontal: Red spring

45° up

Not allowed

45° up

Not allowed

Vertical up

Not allowed

Box label

Product label

Position

Inscription

Explanation

Box label; Product label

Check and Stop valve

Product name

Box label; Product label

020-5420

Code number for ordering

Box label; Product label

OFC 80s

Product type

Check and Stop valve, Type OFC

Table 3: Check valve spring

Impossible orientations

45° up as well as vertical up orientations are not allowed. Using these positions will result in improper valve

operation and can cause premature valve failure.

Figure 4: Impossible orientations

NOTE:

For more detailed information about OFC mounting, please refer to OFC installation guide.

Identication

Relevant product data is available on the product and box label. An example of a box label and product label are

shown, including an explanation of the content.

Table 4: Box label & product label (example)

Table 5: Product and label text

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 6

Page 7

Position

Inscription

Explanation

Box label

Angleway

Direction

Box label

Flange 3 1/8 in-80,00 mm

Connection size and type

Box label; Product label

PS 23 bar/MWP 334 psig

Max. working pressure in bar and psig

Box label

292021

Code for production time: week 29, year 2021

Product label

020-5420N341A00203

Code for production place and time:

• 020-5420 = code number

• N = Nordborg

• 381D = week 38, year 2021, Thursday) (A-B-C-D-EF-G is used for weekdays)

• 00241 = serial number

Box label; Product label

MADE IN DENMARK

Manufacturing site acc. to EN standards

Box label

EAN code

Barcode for individual code no. identication according to EAN standard

Product label

TS: 0 - 100 °C/32-212F

Media temperature range, min and max.

Product label

DN80

Connection size

Product label

Fluid group:2

PED category

Box label; Product label

Additional information: Relevant approval authority

logos

A

A

1

2

4

5

9-10-11

8

12

13

6

14

15

16

17-18-19-20

21

22

23

7

3

Danfoss

32Z8202

Position

Description

Material

1

Elbow housing

Aluminum

2

Ball valve housing

Aluminum

3

Steel

ange

Steel4Ball

Stainless steel

5

Seat

PTFE6Spindle

Brass, rubber, PTFE

7

Cap

Brass, PTFE

8

Stop ring

Stainless Steel

9

Plain washer

Stainless Steel

10

Spring washer

Stainless Steel

Check and Stop valve, Type OFC

Design and Materials

Straight through, 90 degree diuser elbow. Integration of all functions into diuser elbow dimensions:

• Ball valve placed at inlet before staging port

• Sight glass function into 90 degree diuser elbow

• Check valve function placed at outlet after staging port

• Pressure tap at inlet before ball valve

Figure 5:

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 7

Page 8

Position

Description

Material

11

Bolt

Stainless Steel

12

Schrader valve

Brass, rubber

13

O-ring

Rubber

14

Check valve stationary part

Aluminum, bronze, brass, steel, rubber

15

Check valve moving part

Aluminum, steel, PTFE

16

Spring

Steel17Bolt

Stainless Steel

18

Plain washer

Stainless Steel

19

Nut

Stainless Steel

20

Spring washer

Stainless Steel

21

O-ring

Rubber

22

Sight Glass

Brass, glass

23

O-ring

Rubber

5

4

m

m

[

Ø

2

1

/

8

i

n

]

74 mm

[2.91 in]

7

4

m

m

[

2

.

9

1

i

n

]

300

mm

[11.81 in

]

2

9

6

.

8

m

m

[

1

1

.

6

9

i

n

]

80 mm

[ 3 1/8 in]

2

7

.

5

m

m

[

1

.

0

8

i

n

]

6

9

.

9

m

m

[

2

.

7

5

i

n

]

83 mm

[

3

.

2

7 in]

5

5

m

m

[

2

.

1

7

i

n

]

3

4

.

8

m

m

[

1

.

3

7

i

n

]

M

10x1.5

Depth

18

[0.71 i

n]

M10x1.5

D

e

pth 24

[

0.94 in)

1

40

mm

[

5.

51 in]

8

5

m

m

[

3

.

3

i

n

]

Danfoss

32Z

8

203

Ø

Ø

Ø

Ø

Ø

Check and Stop valve, Type OFC

Dimensions

You will nd downloadable dimension drawings for individual code numbers on Danfoss store as part of the Visuals

tab for individual code numbers.

Figure 6: Dimensions and Weights

NOTE:

Net weight: 9.6 Kg

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 8

Page 9

Type

Code no.

Single

pack

Connection

Flange

Kv

(1)

Cv

(1)

Max.

working

pressure:

PS/MWP

Media temperature range

(2)

PED

category

[Fluid

Group 1]

PED

category

[Fluid

Group 2]

Inlet

Outlet

[in.]

[mm]

[in.]

[mm]

[m3/h]

[gal/min]

OFC 80s

020-5420

2 1⁄8543 1⁄880270

312

23 bar /

334 psig

0 °C - 90 °C /

32 °F - 194 °F, short term up

to 100⁰C / 212⁰F

Art. 4.3

Art. 4.3

Type

Used for product

Multi pack Quantity per packing [pcs]

Code no.

Check Valve kit

OFC 80s

4

020-5427

Type

Valve connection size

Used for product

Multi pack Quantity per

packing [pcs]

Code no.

[inch]

[mm]

Flange kit 3 1/8 in

3 1⁄880OFC 80s

4

020-5428

Flange kit 4 1/8 in

4 1⁄8

105

OFC 80s

4

020-5429

Check and Stop valve, Type OFC

Ordering

Figure 7: Ordering

Table 6: Ordering

(1)

(1)

Calculated based on uid dynamic equations. Does not include elbow.

Calculated based on uid dynamic equations. Does not include elbow.

(2)

(2)

For short term use in high temperature application, please consult Danfoss

For short term use in high temperature application, please consult Danfoss

Spare parts

Figure 8: Check Valve kit

Figure 9: Flange kit

Table 7: Flange kit

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 9

Page 10

File name

Document type

Document topic

Approval authority

Д-DK.РА01.B.02567_19

EAC Declaration

Machinery & Equipment

EAC RU

Д-DK.БЛ08.B.02139_19

EAC Declaration

PED

EAC RU

033F5420.AB

EU Declaration

PED

Danfoss

033F5420.AB

Manufacturers Declaration

RoHS

Danfoss

UL SA7200

Mechanical - Safety Certicate

UL

UL

Check and Stop valve, Type OFC

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: Certicates, declarations and approvals

NOTE:

Note: EAC is under progress. For further information please contact Danfoss.

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.09 AI391918642123en-000101 | 11

Loading...

Loading...