Page 1

Data sheet

Electronic Oil Burner Control OBC 82.12

Description

Function

The microprocessor based control OBC 82.12

offers stable and precise timings independent of

variations in supply voltage and ambient

temperature.

The control is undervoltage protected.

The OBC 82.12 controls the cut-in and cut-out of

the oil burner’s components and monitors that

the combustion cycle is performed safely.

When the boiler thermostat (TR) cuts in, heating

of the oil in the oil preheater (OFV) will begin.

Once the release temperature is reached and the

oil preheater’s thermostat (OTR) cuts in, the

burner motor will start the pre-purge and power

will simultaneously be applied to the ignition

(TT). Following the pre-ignition and pre-purge

time, the oil will be released by valve V1 being

opened and subsequently V2 will be opened.

When the boiler thermostat opens after the

heating period power will be cut off and all

relays at the outputs will open and be ready for

the next start-up cycle.

Operating information

OBC 82.12 is equipped with a two-coloured LED

which displays both the operating status and can

indicate the causes of errors leading to lockout.

In the event of operating lockout, the cause of

error can be read out as a flash code by holding

down the reset button for at least 5 seconds and

then releasing it. Undervoltage will, however, be

displayed automatically. Reset can be performed

directly in alarm mode (constant red light) or in

flash code mode by pressing the reset button for

at least 0.5 seconds, but no more than 3 seconds.

In flash code mode it is possible to return to

alarm mode by holding down the reset button

again for at least 5 seconds.

In case of undervoltage the control will prevent

the burner from starting and simultaneously

show a flash code. Besides this, up to five other

fault types can be read out as flash codes when

the control is in lockout.

The design complies with the requirements of

the RoHS and WEEE directive.

Application and features

• For 2 stage burners up to 30 kg/h

• For burners with or without preheater

• Precise and reproducible timings

• Limitation at 3 restarts by flame failure within

the same operating period

• Limitation of 10 min. on preheating time

• Remote alarm output

• Indication of reason for lockout

• Indication of preheating and operation

Normal operation

When the boiler thermostat (TR) cuts in, the reset

button flashes green. As soon as the preheater

thermostat (OTR) cuts in, the reset button lights

up constant green. When the boiler thermostat

cuts out, the green light turns off.

Errors during operation (flash codes):

• If the mains voltage falls below 176 V before

start-up, the control will be blocked from

starting. If the mains voltage falls below 165 V

during operation, the oil supply and burner

will be stopped. In both cases, the reset

button will automatically flash 8 times.

When the mains voltages reaches 176 V, the

control will restart as normal. Please note

that the control cannot be reset if the mains

voltage is below 165 V.

• If the mains voltage exceeds 264 V, the control

will automatically enter alarm mode.

The purpose of the overvoltage cut out is

not simply to protect the electronics in the

control, but also the other components in

the burner.

• If light is registered in the final stage of the

pre-purge time, the control will not release

oil and will enter alarm mode.

• If no flame is established at the start, i.e. by

the end of the safety time, the control will

enter alarm mode.

© Danfoss | 2019.10

VD.HN.C1.02 | 1

Page 2

Data sheet Electronic Oil Burner Control OBC 82.12

• In the event of a flame failure during

operation, the oil supply will be cut off after

no more than 1 second and the control will

restart the burner. If flame failure occurs more

than three times in the same operating period

(TR connected), the control will enter alarm

mode.

• If the release temperature in the preheater is

not reached within 10 minutes, the control

will enter alarm mode.

The OBC 82.12 processor also monitors the

outputs at TT, V1 and V2. If errors like electrical

noise (EMC) are registered at the outputs, the

control will enter alarm mode.

Note:

OBC 82.12 can only be reset while the sup ply voltage is connected.

Flash codes

Event Code

False light 2 flashes

No flame when safety time elapses 3 flashes

More than three restar ts in the same

cycle

Max. waiting time on preheater overrun

(10 mi n)

Supply voltage above 264 V a.c. 6 flashes

Undervoltage <170 V (automatic) 8 flashes

Application failure (EMC)

4 flashes

5 flashes

constant

flashes

2 | © Danfoss | 2019.10

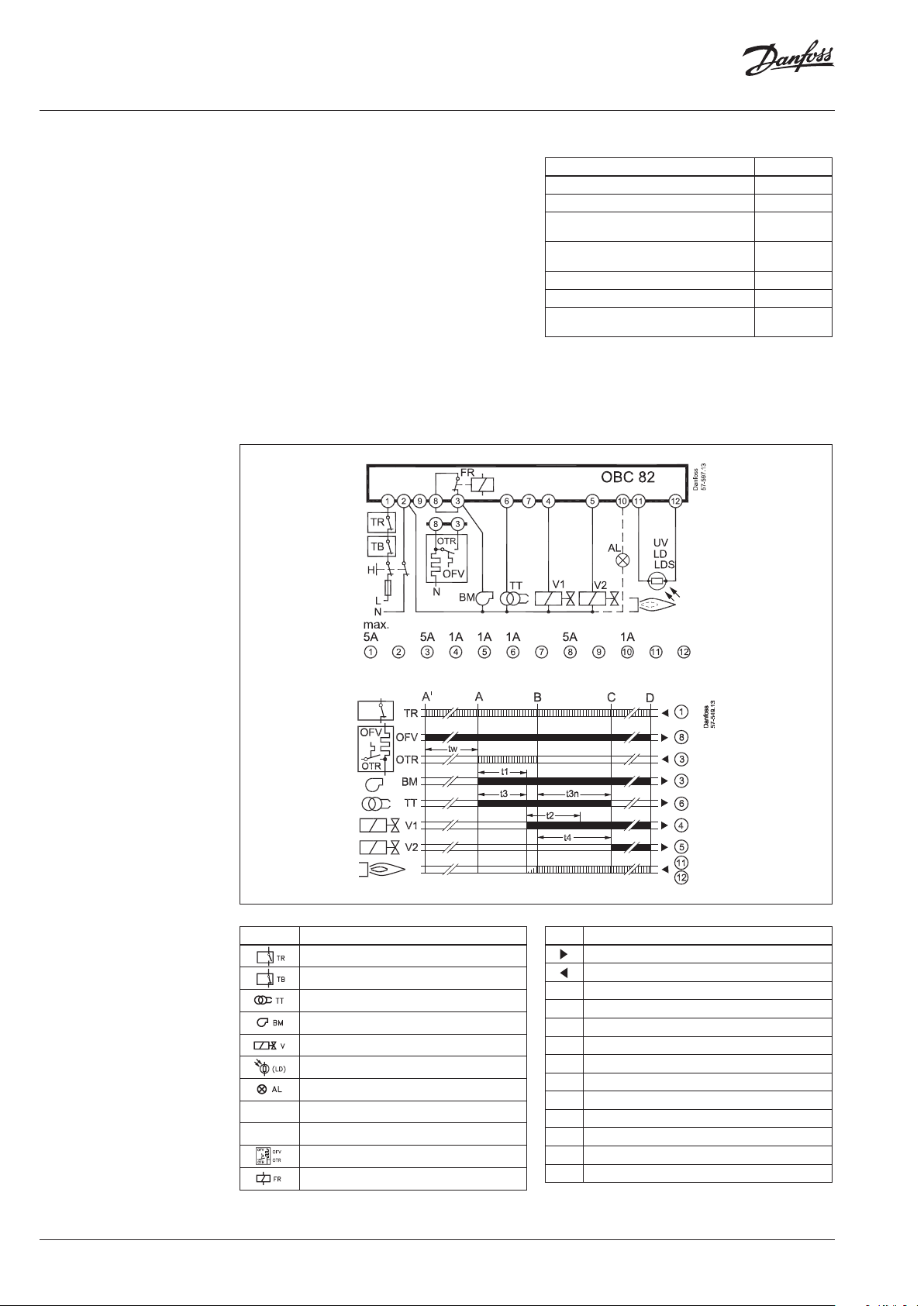

Symbols

Boiler thermostat

High temperature cutout

Ignition unit

Burner motor

Solenoid valve

Photo unit or UV sensor

External alarm

L Phase wire

N Neutral wire

Oil preheater ⁄ Oil preheater thermostat

Hold relay

* Due to the initia lisation of the electroni cs it may take up to two secon ds before ignition is enabl ed

Time function/explanation

Output signals of control

Required input signals

A’ Initiation of burners with oil preheater OFV

A Initiation of burners without oil preheater

B Flame formation

C Operation position

D Burner stop

tw Heating of oil preheater until OTR switches on

t1 Pre-purge 13 s

t2 Safety time 10 s

t3* Pre-ignition 13 s

t4 Inter val V1-V2 15 s

t3n Post-ignition 15 s

VD.HN.C1.02

Page 3

Data sheet Electronic Oil Burner Control OBC 82.12

Technical data

Ordering

Rated voltage 230 V~

Operating range 195-253 V~

Frequency 50-60 Hz ± 6%

Consumption 6 VA

Reset Immediately

Reaction time on flame failure Max. 1 s

Undervoltage protection <165 V +/- 2 V

Protection class II

Pollution degree 2

Main fuse (terminal load, see electrial diagram) Max. 10 A

Cable connection Plate for 5 PG 11 screwed connections or plate with knockouts

Ambient temperature -20 to +60°C

Installation Any position

Enclosure IP40

Flame monitoring UV, LD or LDS

Required flame signal

Max. cable length between OBC and UV, LD/LDS 20 m (installed separately)

Description Weight Code no.

OBC 82.12 200 g 057H 8716

Base BHB 70 g 057H7010

Front plate for BHB, 5 × PG 11 12 g 05 7H7 011

Front plate for BHB, 8 × knockouts 12 g 057H7012

No flame / dark ≤5 A

Flame / light ≥65 A

Please note!

The OBC 82.12 does not meet the requirements of

EN 298 regarding level of undervoltage protection

and is hereby not CE compliant, for the same

reason the level of CO2 shall not exceed 12% on

the exhaust.

The EN 298 demand for undervoltage protection

applies only for burner controls used in the EU

and associated countries and it is not requested

in other countries.

This control box cannot be sold into countries as

a standalone product or mounted on oil burners

where EN 298 is requested to be fulfilled.

Please note that the control box is designed in the

manner that it does fulfil all other requirements

within the Low Voltage Directive (LVD) and Electromagnetic Compatibility Directive (EMCD).

VD.HN.C1.02

© Danfoss | 2019.10 | 3

Page 4

Data sheet Electronic Oil Burner Control OBC 82.12

Dimensions

Additional documentation on burner components is available on http://heating.danfoss.com/ or https://store.danfoss.com/

4 | © Danfoss | DHS-SDBT/DK | 2019.10

VD.HN.C1.02

Loading...

Loading...