Page 1

PED 97/23/CE

Data sheet

Non return Valve - Danfoss NVD 802

Description

Features:

• Operating position : horizontal and vertical

• Easy to install and dismantle, space-saving

• Minimum head loss

• Does not generate hammering

•

Closing system : disc with parabolic edges with

return spring ; lateral guiding by 3 or 4 ribs (DN

32 to 100).

•

Closing system with back axial guiding and

return spring (DN 125 to 200).

• Metal/metal seal (machined trim)

• Usi n g t h es e ch ec k va l ve s on ne t wo r ks

equipped with piston pumps or compressors

is not recommended.

Main Data:

• DN 32 - 200

• kVS 18 - 546 m3/h

• PN 6/16

• Medium:

- Circulation water, drinking water or

chilled glycolic water up to 50%

• Medium Temperature:

- 10 … 200°C (DN65 to 200mm : 100°C)

• Mounting between langes PN6/16

• Compliance with Pressure Equipment

irective 2014/68/EU

D

• Flange drilling according to EN1092-2

• Approvals:

Ordering

Note:

The indicated pressure for the

different categories of fluids

(L1/L2/G1/G2) is under no condition

a guarantee of use.

Therefore, it is essential to validate

the use of products under given

operating conditions.

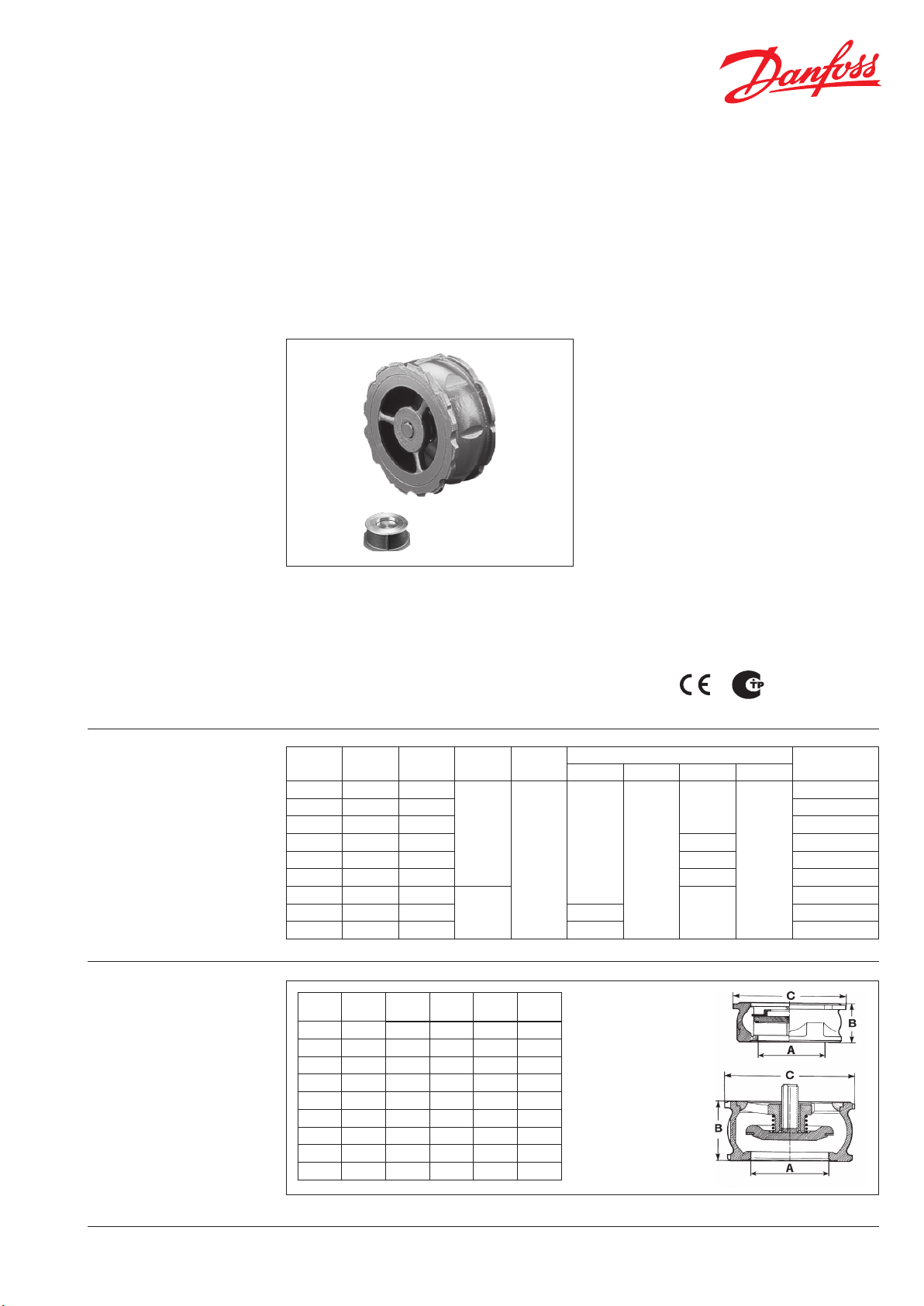

Dimensions

16

PS (bar)

Code No.

065B7520

16

16

065B7526

˝

1 ¼ 32 18

1 ½ 40 28 065 B7521

2 50 40 ,1 065B7522

2 ½ 65 72,5 15 065B7523

3 80 111 12 065 B7524

4 10 0 182 10 065B7525

5 12 5 302

6 15 0 370 13 065B7527

8 200 546 10 065B7528

1 ¼ 32 28

1 ½ 40

2 ½ 65

DN

A

˝

DNB(mm)C(mm)D(mm)

2 50

3 80

4 100

5 125

6 150

8 200

Kv

(m3/h)

31,5 88 94 0,52

40 98 109 0,73

46 118 129 1,52

50 134 14 4 2,17

60 15 4 162 3,35

90 - 194 8,55

106 - 218 12, 70

140 262 273 23,40

PN

6/16

16 0,5

78 84 0,35

PFA

(bar)

16

Weight

(kg)

L1 L2 G1 G2

16

DN 1”¼ to 4”

DN 5”to 8”

DEN-SMT/SI

VD.BO.O2

.02 © Danfoss 05/2019

1

Page 2

Data sheet Danfoss NVD 802

2

3

4

5

1

18

Design

Pos.

Description Material EURO ANSI

Casing DN32 to 50 Casing DZR brass CuZn35Pb2 Al-C

DN65 to 100 Cast iron + epoxy ex t. EN -G JL-2 50 ASTM A 48 35 B

1

Casing DN125 to 200 Cast iron + epoxy ext. EN-GJS-400 -15 ASTM A 536 60 -40-18

Closing system DN32 to 100 Stainless steel

2

Closing system DN125 to 200 Cast iron + epoxy EN -G JL-250 ASTM A 48 35 B

3

Spring Stainless steel X10Cr Ni18- 8 AISI 302

Stop guide DN32 Stainless steel

Stop guide DN4 0 to 100 Stainless steel X2CrNi18 -9 AISI 304L

4

Stop guide DN125 to 200 Cast iron + epoxy EN -G JL-250 ASTM A 48 35 B

5

Ring DN125 to 200 Bronze CuSn12 -C

X2 CrN iMo17-12-2

X2 CrN iMo17-12-2

AISI 316L

AISI 316L

DN 1”¼ to 4”

①

②

③

④

DN 5”to 8”

④

⑤

③

②

①

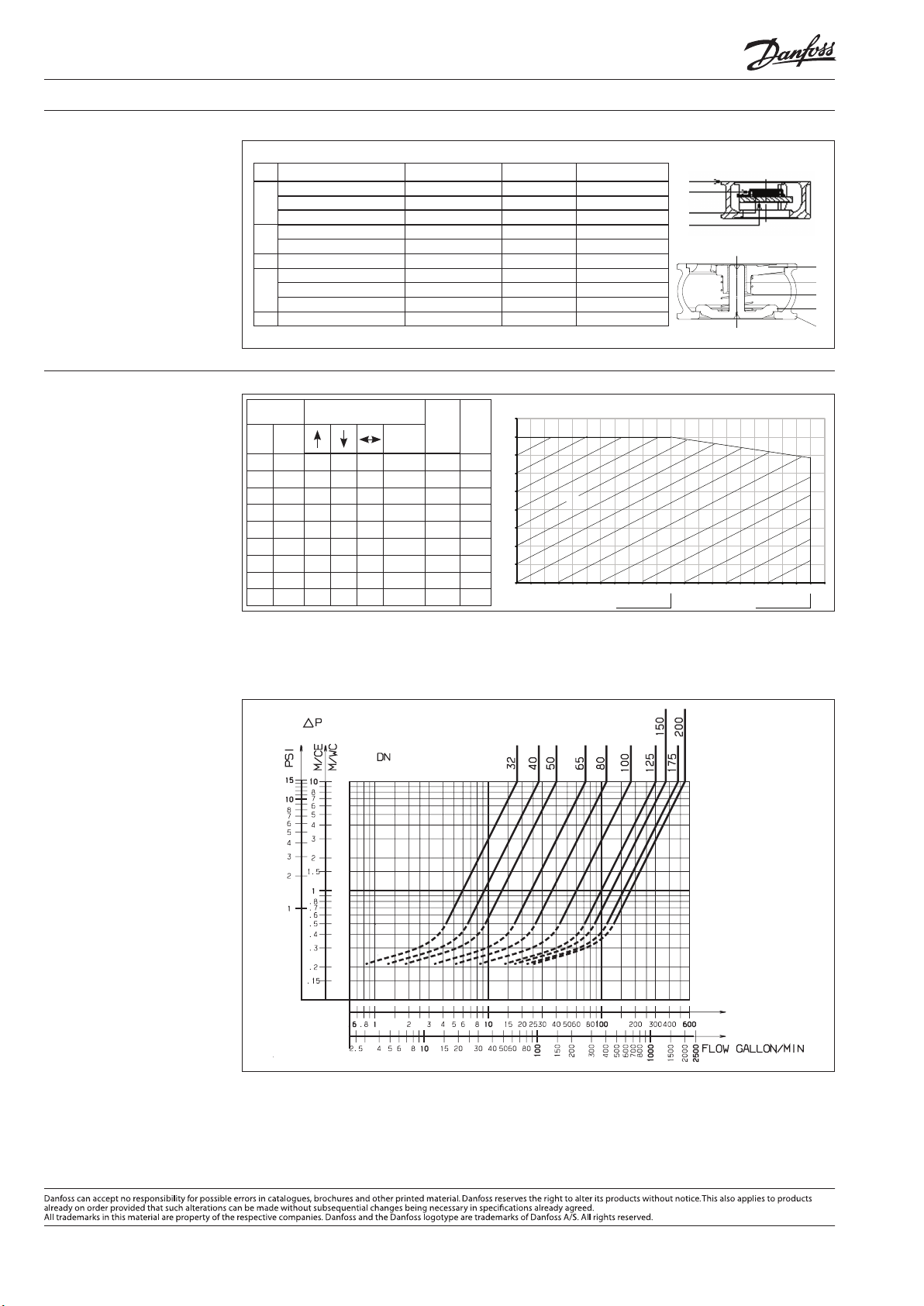

Headloss diagram

DN

˝

1 ¼ 32 190

1 ½ 40

2 50

2 ½ 65

3 80

4 100

5 125

6 150

8 200

Opening pressure

(mm)/WC

(mm)

Without

spring

130 160 30

200 120 160 40

210 110 155 50

210 100 155 55

226 95 160 65

235 75 205 80

335 75 205 130 302,00 4,2

360 70 215 145 370,00 5,8

515 105 310 205

K

V

(m3/h)

18,00 5,0

28,00 5 ,1

40 ,10 6,1

72,50 5,3

111, 00 5,2

182, 00 4,7

546,00

Direction for use :

• Solid line : Valve completely open

• Dotted line : opening stage of valve

Pressure/Temerature Diagram

ζ

16

14

12

8,4

10

8

Pressure (bar)

6

4

2

0

-10

0

WORKING AREA

Temperature (°C)

50 100 150 200 210

Maximum temperature

for DN65 -200mm

Maximum temperature

for DN32 -50mm

2

VD.BO.O

2.02

Produce d b

foss A/S © 052019

y Dan

Loading...

Loading...