Data sheet

D

B

PED 97/23/CE

Non return Valve - Danfoss NVD 402

Description

Ordering

Note:

The indicated pressure for the

different categories of fluids (L1/

L2/G1/G2) is under no condition a

guarantee of use.

Therefore, it is essential to validate

the use of products under given

operating conditions.

• Closing system: long back axial guiding for

reduced displacement

• Sealing guaranteed by a flat seal

• Return spring

Main Data:

• DN 40 - 500

• kVS 47 - 6914 m3/h

• PN 16 (10)

• Medium: - Circulation water, drinking water or

chilled glycolic water up to 50 %

Features:

• Operates in any position

• Minimum head loss

• Silent, reliable sealing, compact

• Exceptional robustness

• Notch provided for cable to submerged

pumps until DN 100.

˝

1 ½ 40 47

2 50 99 06 5B7471

2 ½ 65 159 15 065B7472

3 80 222 12 06 5B7473

4 10 0 396 10 0 65B7474

5 12 5 619 0.5 06 5B7475

6 15 0 890 13 0.5 06 5B7476

8 200 1120 10

10 250 2010 10 065B7478

12 300 2459 10 065 B7479

14 350 2843 10

16 400 4370 10 06 5B748 1

20 500 6914 10 06 5B748 2

DN

Kv

(m3/h)

PN

10/16 16

PFA

(bar)

10

10 0.5

• Medium Temperature: - 10 … 100 °C

• Flanged connection

• Compliance with Pressure Equipment

Directive 2014/68/EU

• Flange drilling according to EN1092-2

• Approvals:

PS (bar)

L1 L2 G1 G2

16

16

10 10

16

10

16

10

Code No.

06 5B7470

06 5B7477

06 5B748 0

Dimensions

A

˝

DNB(mm)C(mm)D(mm)

40 85 80 150 4.2

1 ½

50 100 97 165 5.8

2

65 120 125 185 8 .1

2 ½

80 14 0 150 200 10.2

3

100 170 187 220 14.5

4

125 200 220 250 24

5

150

6

8

10

12

14

16

20

230 250 285 32

200

289 340 340 53

250

354 420 405 94

300

396 490 460 140

350

473 586 533 225

400

560 680 597 312

500

750 880 670 540

Weight

(kg)

A

C

© Danfoss | 2019.04 VD.BO.M2.02 | 1

Data sheet Danfoss NVD 402

Design

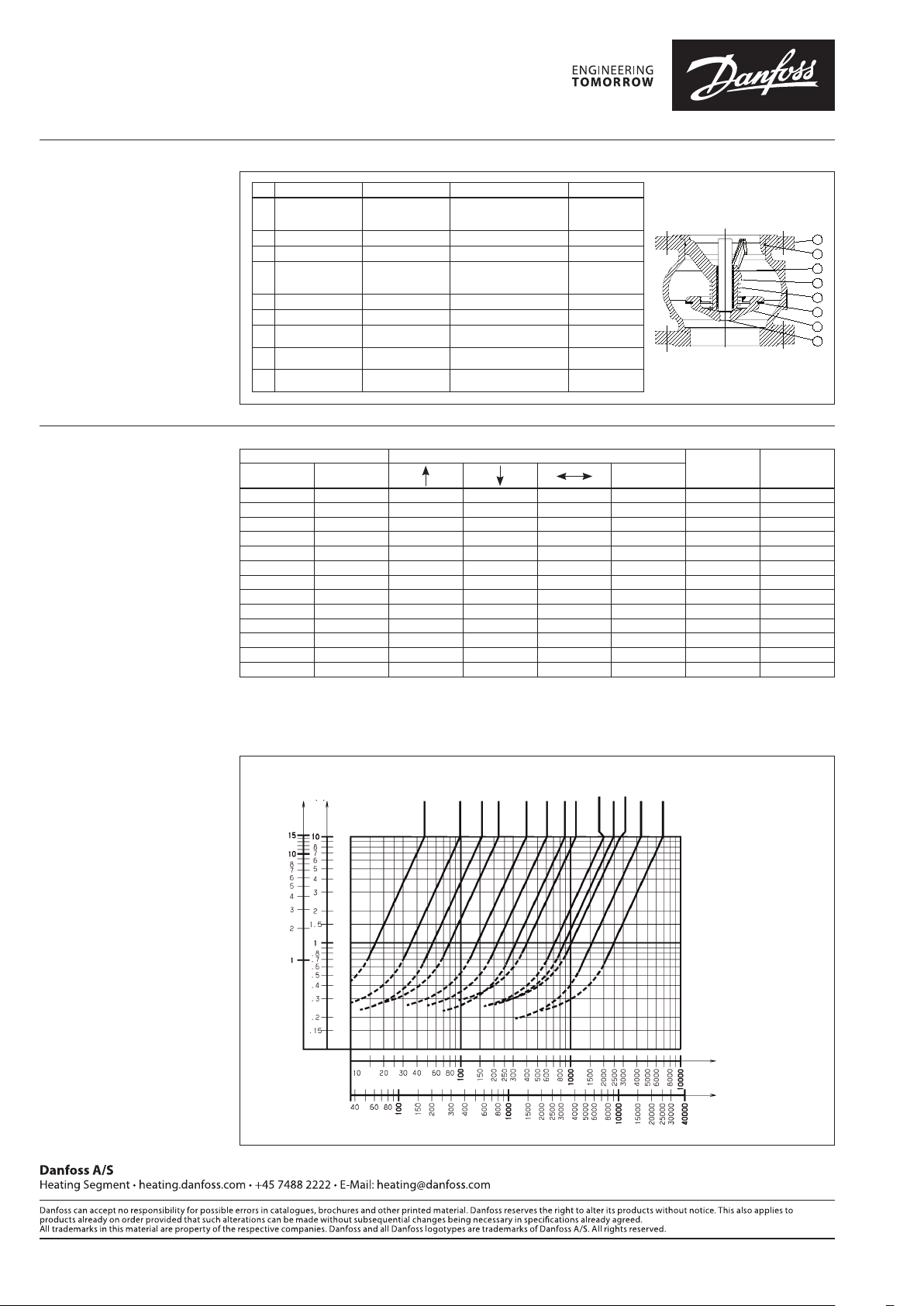

Headloss diagram

Pos.

Description Material EURO ANSI

Casing DN 4 0-400

1

Casing DN 50 0

2 Ring seal D N 40-250 EPDM - -

3 Ring Bronze EN 1982 CuSn12-C GS -

Guide DN5 0

4

DN 40&60-400

DN 500

5 Spring Stainless steel EN 10270 -3 X10CrN i18-8 AISI 302

6 Seal EPDM - -

Closing s ystem

7

DN 40, DN 50 -65

DN 80- 400 Stem

7-8

Check-Va lve

DN 500 Stem

7-8

Check-Va lve

Cast iron / e poxy

Ductil e iron / epoxy

Bronze

Cast iron / e poxy

Ductil e iron / epoxy

Brass

Bronze

Bronze

Ductil e iron / epoxy

Bronze

Ductil e iron / epoxy

EN 1561 EN-GJL-250

EN 15 63 EN -G JS- 400 -15

EN 1982 CuSn5Zn5Pb2-C GS

EN 1561 EN-GJL-250

EN 15 63 EN -G JS- 400 -15

EN 12164 CuZn40Pb2 R360

EN 1982 CuSn5Zn5Pb2-C GS

EN 1982 CuSn5Zn5Pb2-C GS

EN 1561 EN-GJL-250

EN 1982 CuSn12-C GS

EN 15 63 EN -G JS- 400 -15

ASTM A 48 35 B

ASTM A 536

65-45-12

ASTM A 48 35 B

ASTM A 536

65-45-12

-

-

ASTM A 48 35 B

DN Opening pressure in mm/CE

˝

1 ½

2

2 ½

3

4

5

6

8

10

12

14

16

20

mm

40 440 210 320 120 47 1.8

50 440 220 330 110 99 1

65 450 190 320 130 159 1.1

80 450 19 0 320 130 222 1.3

100 500 240 370 130 396 1

125 510 210 360 150 619 1

150

200

250

300

350

400

500

550 210 380 170 890 1

590 210 400 19 0 1120 2

710 210 460 250 2010 1.5

820 90 460 365 2459 2.1

860 100 480 380 2843 2.9

800 50 410 390 4370 2 .1

1030 0 430 580 6914 2.05

without spring

K

V

(m3/h)

1

2

3

4

5

6

7

8

ζ

Direction for use:

• Solid line: Valve completely open

• Dotted line: opening stage of valve

∆P

PSI

M/WC

M/CE

DN

40

50

65

80

200

125

150

100

250

350

300

500

400

Debit m

3

/h

Flow gallon/min

© Danfoss | DHS-SRMT/SI | 2019.042 | VD.BO.M2.02

Loading...

Loading...