Page 1

Data Sheet

Differential pressure switch

Type MP 55E

MP 55E oil dierential pressure switches

are used as safety switches

MP 55E oil dierential pressure switches are

used as safety switches to protect refrigeration

compressors against low lubricating oil

pressure.

If the oil pressure fails the oil dierential

pressure control stops the compressor.

MP 55E for HCFC, HFC and HC refrigerants are

equipped with gold-plated SPDT contacts,

which react directly on the dierential pressure

without time delay.

The units are designed to operate in explosive

zones acc. to 2014/34/EU, Atex directive,

explosive zone 2, surface equipment, category

3.

MP 55E are delivered with ¼ inch solder

connections to ensure a hermetic installation.

Features

• Wide regulating range,

• Can be used for deep freeze, refrigeration and

air conditioning plant,

• Can be used for HCFC, HFC and HC

refrigerants,

• Electrical connection at the front of the unit,

• Screwed cable entry for cables from 6 – 14

mm diameter,

• Small contact dierential

AI217686432357en-001001

Page 2

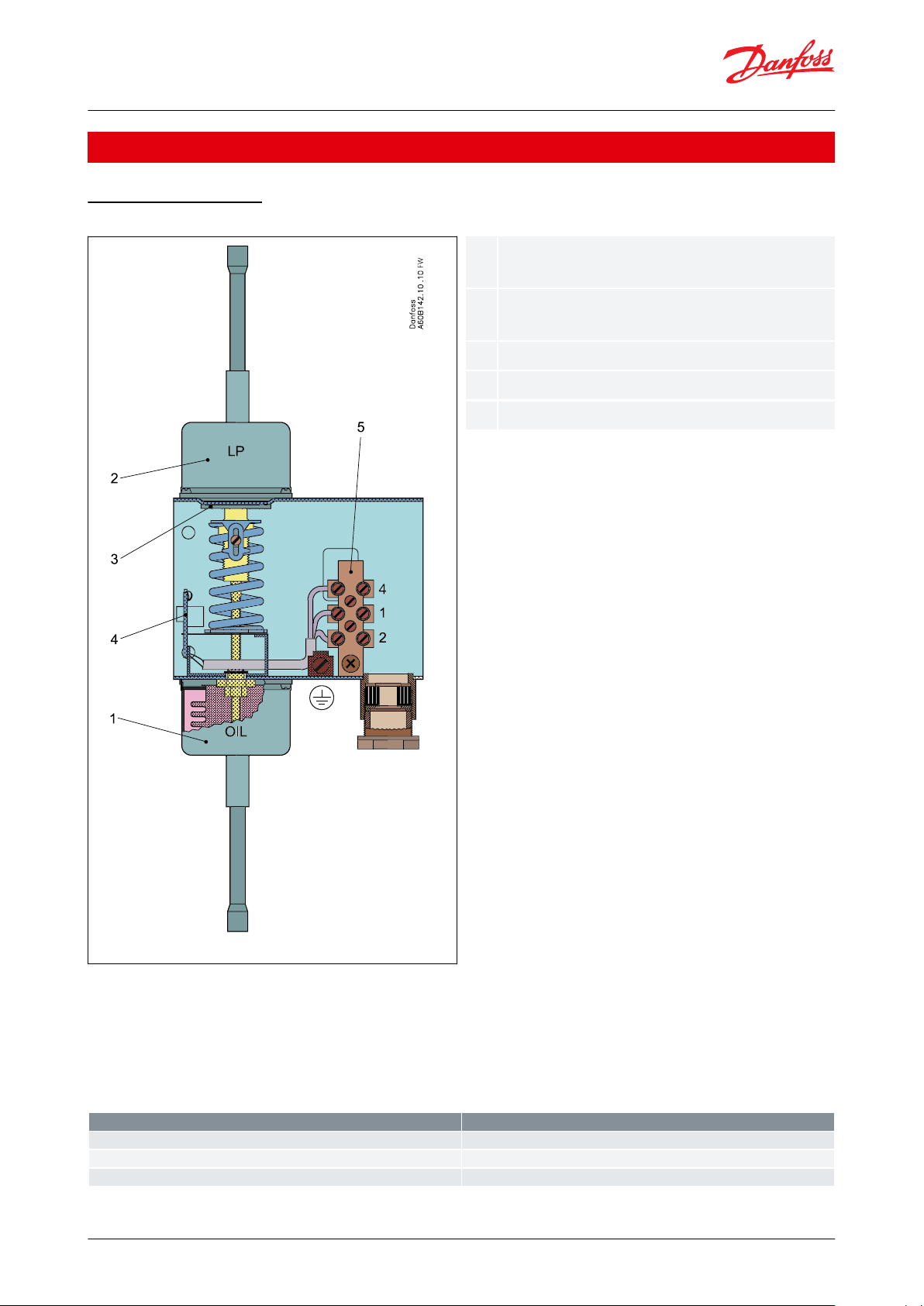

1

2

345

Connection to oil pressure side of lubrication

system, OIL

Connection to suction side of refrigeration plant,

LP

Setting disc

Test device

Terminals

Features

Specication

Stainless steel

19/11, no. 1.4306 to EN 10088

Deep-drawn steel plate

no. 1.0338 to EN 10130

Free cutting steel

no. 1.0401 to EN 10277

Dierential pressure switch, Type MP 55E

Product specications

Design and Materials

Figure 1: Design for Type MP 55E

The MP 55E pressure control only switches the dierential pressure, i.e. the dierence in pressure between the two

counteracting bellows, and it is virtually independent of the absolute pressure acting on both bellows.

The MP 55E can be set for dierent dierential pressures by the setting disc (3).

The set dierential pressure can be read from the internal scale.

Table 1: Materials in contact with the medium

© Danfoss | Climate Solutions | 2021.02 AI217686432357en-001001 | 2

Page 3

Features

Specication

Ambient temperature

-20 – 60 °C

Max. working pressure

PS/MWP = 17 bar

Max. test pressure

Pe = 22 bar

Screwed cable entry

Pg 13.5

Cable diameter

6 – 14 mm

Max. media temperature

80 °C

Enclosure

IP20 to EN 60529 / IEC 60529

Contact rating

Pi max: 1 W

Ui max: 30 V

Ii max: 0.1 A

Ci max: 0.5 nF

Li max: 0.2 μH

EX - zone

Non EX - zone

Electrical data for intrinsically safe specication

(for all MP 55E types):

EX certified

Zenner barrier

Pi max: 1 W

Ui max: 30 V

Ii max: 0.1 A

Ci max: 0.5 nF

Li max: 0.2 µH

Dierential pressure switch, Type MP 55E

Technical data

Table 2: Technical data for MP 55E

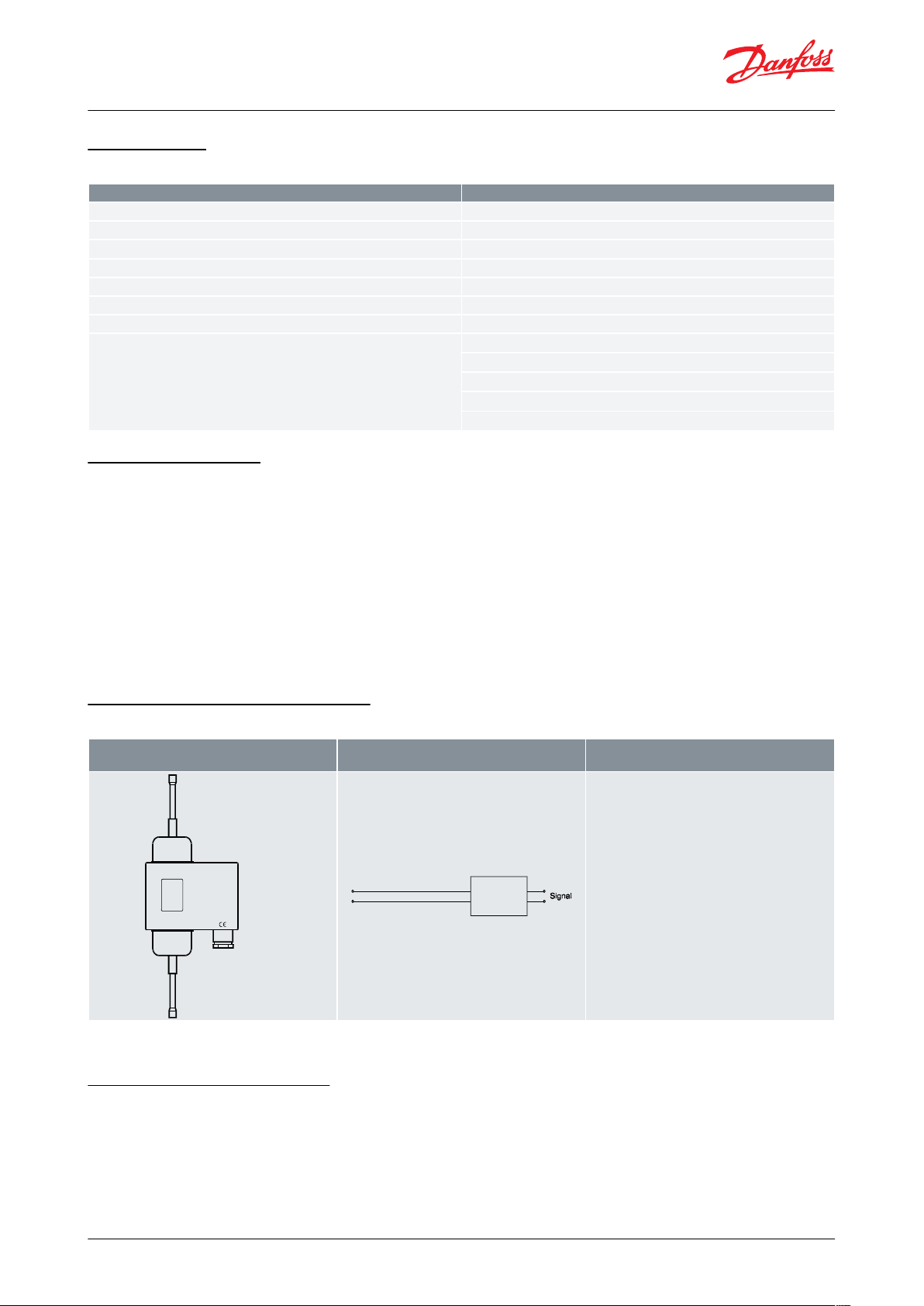

Electrical connection

The MP 55E pressure switch placed in explosive zone must always be wired through reliable Ex zener barrier, placed

outside ex-zone, to ensure insucient energy supply to cause the ignition of surrounding atmosphere by an

electrical spark or the heating of components of circuitry.

The equipment to be used for electrical load limiting must always be approved for use in the zone concerned.

Cables and cable entries approved for the application must be used and can not be in contact with sharp edges.

Cables must be connected with adequate stress relief that way that pulling forces can not be carried throug the

cable to the terminal.

NOTE:

A particular system can be classied in dierent zones, for dierent parts of the system.

Intrinsic safety protection method

Table 3: Intrinsic safety protection method

Must be used with certied Ex ic barrier (product matching) satisfying the input parameters.

Installation and maintenance

Only authorised persons, who are certied in installing and maintaining the systems may do the installation,

maintenance and change of the switch.

In the event of strong pulsation in the system, bellows must be protected against fatigue failure by use of damping

coil.

© Danfoss | Climate Solutions | 2021.02 AI217686432357en-001001 | 3

Page 4

Net weight approx. 0.8 kg

Dierential pressure switch, Type MP 55E

The cycle frequency of the MP 55E switch must be kept as low as possible. The vibration level must be kept as low as

possible.

Any overload of the MP 55E switch must be prevented. Overloaded or damaged apparatus must be exchanged.

Safety requirements

The MP-E can be applied on systems with R1270, R290, R600, R600a as the working uid. For countries where safety

standards are not an indispensable part of the safety system Danfoss recommend the installer to get a third party

approval of the system containing ammable refrigerant.

: Please follow specic selection criteria stated in the datasheet for these particular refrigerants.

MP 55E pressure switches comply with the requirements for explosive atmosphere 2014/34/EU, acc. to ATEX, zone 2.

Only apparatus designed, constructed and released by Danfoss must be used for application concerned. Danfoss

can accept no responsibility in case of alterations made on the switches or the use of them against the Danfoss

instructions.Original Danfoss spare parts approved for use in explosive atmosphere can only be used.

The application covers systems that must be located within the EU or EFTA and comply with the existing EU

legislation, such as the directive concerning potential explosive atmosphere (ATEX) 2014/34/EU, and other related

EU standards. The system where MP 55E is mounted must always comply with local directives, legislation or any

other regulation applying in the area of installation. The Danfoss products comply with the requirements of ATEX

directive, but Danfoss takes no responsibility for the classication of explosive zone.

Dimension and weight

Figure 2: Dimension and weight for MP 55E

© Danfoss | Climate Solutions | 2021.02 AI217686432357en-001001 | 4

Page 5

Type

Dierential

range ∆p

Switch

dierential max. ∆p

Operation range LP side

Code no.

[bar]

[bar]

[bar]

Connection

1

⁄4 in. ODF solder

MP 55E

0.3 – 4.5

0.2

-1 – 12

060B530091

Dierential pressure switch, Type MP 55E

Ordering

Figure 3: Ordering for MP 55E

For R32, R290, R600, R600a, R1270

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

This product is validated in accordance to EN 60079-0:2012 + A11:2013. Ignition risk is evaluated in accordance to

EN 60079-11:2012. See safety requirements at the end of instruction.

Table 4: Ordering for MP 55E

© Danfoss | Climate Solutions | 2021.02 AI217686432357en-001001 | 5

Page 6

Document type

Approval authority

UA declaration (EMCD/LVD)

LLC CDC EURO TYSK

EU declaration (ATEX/ ROHS)

Danfoss

Manufacturer declaration for China ROHS

Danfoss

Dierential pressure switch, Type MP 55E

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 5: Certicates, declarations and approvals

© Danfoss | Climate Solutions | 2021.02 AI217686432357en-001001 | 6

Page 7

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI217686432357en-001001 | 7

Loading...

Loading...