Technical Information

MP1 Axial Piston Motors

Size 20/24

www.danfoss.com

Technical Information

MP1 Axial Piston Motors Size 20/24

Revision history Table of revisions

Date Changed Rev

December 2021 additional notes for speed sensor 0113

June 2021 fixed available sensors 0112

April 2021 Corrected document number and other typos 0111

February 2021 Updated paint free coverage 0110

December 2020 Updated Speed limit in Operating Parameters 0109

November 2020 Updated Speed and Temperature Sensor 0108

April 2020 Minor revision 0107

March 2020 Minor revision 0106

March 2020 Minor revision 0105

February 2020 Fixed typo 0104

December 2019 Minor revision 0103

November 2019 Minor revision 0102

November 2019 First edition 0101

2 | © Danfoss | December 2021 BC290322888218en-000113

Technical Information

MP1 Axial Piston Motors Size 20/24

Contents

General Description

Overview..............................................................................................................................................................................................5

Features................................................................................................................................................................................................5

System Diagram................................................................................................................................................................................6

Schematic Diagram..........................................................................................................................................................................7

Technical Specification

Design Specifications......................................................................................................................................................................8

Technical Data................................................................................................................................................................................... 8

Operating Parameters.....................................................................................................................................................................9

Fluid Specifications..........................................................................................................................................................................9

Operation

Loop Flushing Valve......................................................................................................................................................................10

Anti-Cavitation and Shock Valve..............................................................................................................................................11

Speed and Temperature Sensor...............................................................................................................................................12

Available Sensors......................................................................................................................................................................12

Temperature Range.................................................................................................................................................................13

Protection Characteristics......................................................................................................................................................13

Mating Connectors...................................................................................................................................................................13

Speed Sensor 4.5 - 8 V.............................................................................................................................................................13

Speed Sensor 7 - 32 V..............................................................................................................................................................14

Sensor Position..........................................................................................................................................................................15

Output Pulses.............................................................................................................................................................................15

Operating Parameters

Overview........................................................................................................................................................................................... 16

Speed Ratings..................................................................................................................................................................................16

System Pressure..............................................................................................................................................................................16

Case Pressure...................................................................................................................................................................................17

Temperature.................................................................................................................................................................................... 17

Viscosity.............................................................................................................................................................................................17

System Design and Parameters

Installation........................................................................................................................................................................................18

Filtration............................................................................................................................................................................................ 18

Reservoir............................................................................................................................................................................................18

Overpressure Protection (Only for open circuit system)................................................................................................. 18

Summing System Pressure Conditions..................................................................................................................................19

Loop Flushing..................................................................................................................................................................................19

Case Pressure / Open Circuit Operation................................................................................................................................ 19

Redundant Braking System Requirement.............................................................................................................................19

Fluid selection................................................................................................................................................................................. 19

Case drain......................................................................................................................................................................................... 19

Bearing loads and life................................................................................................................................................................... 20

Shaft torque..................................................................................................................................................................................... 20

Shaft Loads.......................................................................................................................................................................................20

Duty Cycle and Bearing Life....................................................................................................................................................... 21

Hydraulic Equations Helpful for Motor Selection...............................................................................................................21

Determination of Nominal Motor Size................................................................................................................................... 22

Variables.......................................................................................................................................................................................22

Master Model Code

Model Code (B-C-D-E)...................................................................................................................................................................23

Model Code (K)................................................................................................................................................................................24

Model Code (L-M-N)......................................................................................................................................................................25

Features and Options

Shaft Options...................................................................................................................................................................................26

Installation drawings

Output Shafts: Option A (SAE A, B, 13 teeth)....................................................................................................................... 27

©

Danfoss | December 2021 BC290322888218en-000113 | 3

Technical Information

MP1 Axial Piston Motors Size 20/24

Contents

Output Shafts: Option C (SAE A, B, 15 teeth)........................................................................................................................28

Output Shafts: Option L (SAE B, 17 teeth).............................................................................................................................29

Output Shafts: Option E, F (SAE A, B, Straight Key Shaft: Long).................................................................................... 30

Output Shafts: Option J, K (SAE A, B, Straight Key Shaft: Middle).................................................................................31

Output Shafts: Option G, H (SAE A, B, Taper Key Shaft)....................................................................................................32

Output Shafts: Option A (Cartridge, 13 teeth).....................................................................................................................33

Output Shafts: Option C (Cartridge, 15 teeth).....................................................................................................................34

Output Shafts: Option L (Cartridge, 17 teeth)......................................................................................................................35

Output Shafts: Option E, F (Cartridge, Key Shaft : Long)..................................................................................................36

Output Shafts: Option J, K (Cartridge, Key Shaft : Middle).............................................................................................. 37

Output Shafts: Option G, H, (Cartridge, Taper key shaft).................................................................................................38

Motor Rotation................................................................................................................................................................................39

MP1M20/24: Mounting flange SAE-A.....................................................................................................................................40

MP1M20/24: Mounting flange SAE-B..................................................................................................................................... 42

MP1M20/24: Mounting flange Cartridge Style....................................................................................................................44

Gauge port "A", "B"........................................................................................................................................................................ 46

4 | © Danfoss | December 2021 BC290322888218en-000113

Technical Information

MP1 Axial Piston Motors Size 20/24

General Description

Overview

The MP1 motor is a fixed displacement axial piston motor and is intended for closed and open circuit

medium power applications. These motors are designed primarily to be combined with other products in

closed and open circuit systems to transfer and control hydraulic power. The MP1 motor consist of two

rotating groups (displacements) and three housing (mounting) configurations. An SAE-A two bolt, SAE-B

two-bolt and a cartridge style (for space optimized gear box mounting ) configurations.

The motor is ideally configured for installations requiring compact packaging and optimized plumbing

such as wheel ends. The standard porting configuration is twin radial (side) O-ring boss main ports.

Features

•

Two displacements allow the optimum selection of hydraulic motor for the lowest possible installed

cost.

•

SAE-A & B, two bolt, and cartridge style mounting configurations available.

•

Metric and inch O-ring boss system port interfaces.

•

Short and compact; fits into existing installation with improve porting.

•

Proven reliability and performance.

•

Worldwide sales and service.

Expanded Functionality

•

Open circuit fan drive application.

•

PLUS+1® Compliant speed sensor option.

•

Integrated flushing valve option available.

•

Anti-cavitation valve option available.

•

Shock valve option available.

©

Danfoss | December 2021 BC290322888218en-000113 | 5

Variable

Displacement

Pump

High pressure

relief/check valves

Loop flushing

valve

MP1

Axial piston

Motor

Filter

Reservoir

Heat

exchanger

Heat exchanger

bypass

Charge pressure

relief valve

Charge

pump

Suction flow

Case flow

Working Loop (High Pressure)

Working Loop (Low Pressure) and Charge Pressure

P400619

Technical Information

MP1 Axial Piston Motors Size 20/24

General Description

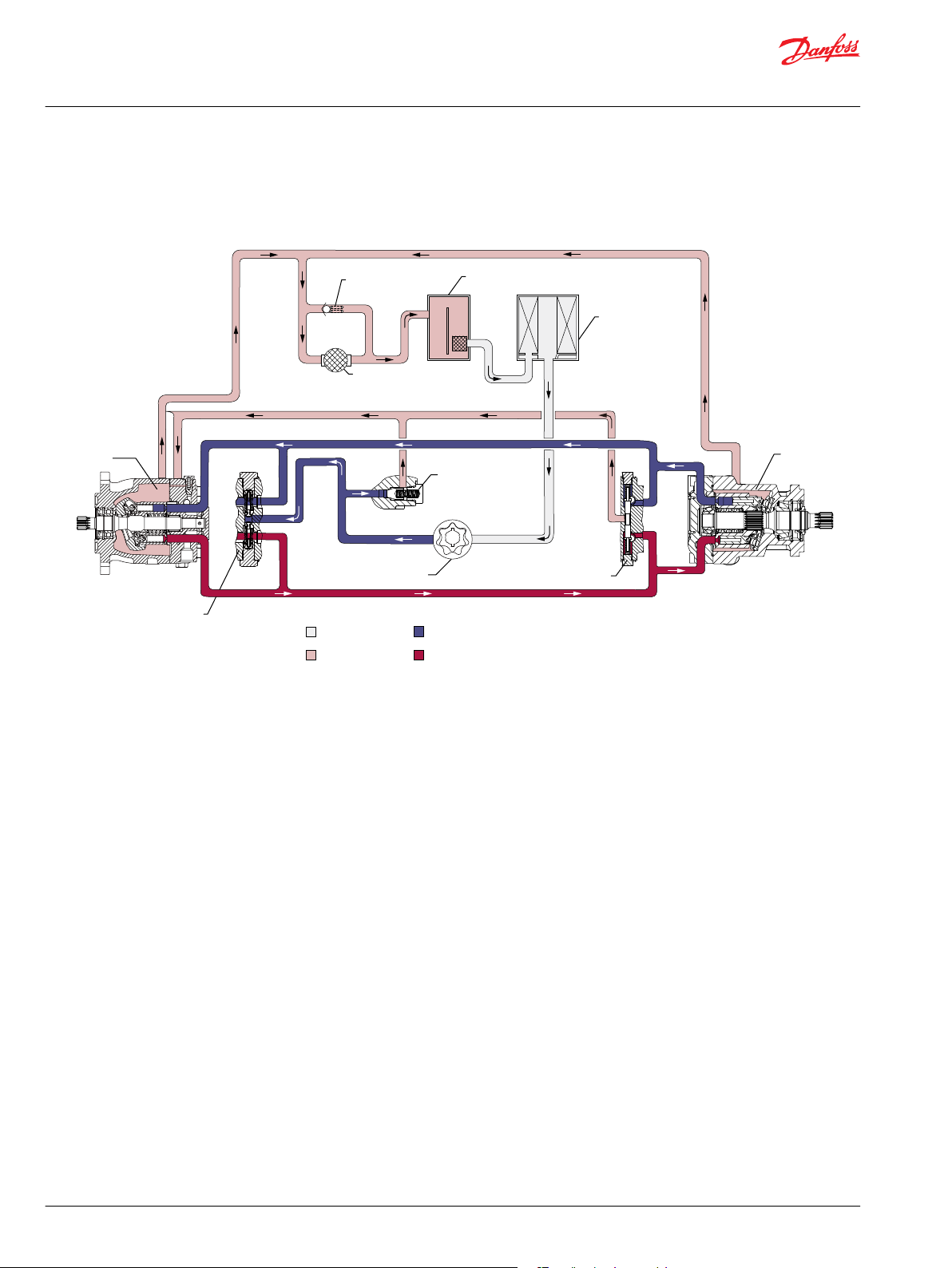

System Diagram

Pictorial system diagram

The system diagram above shows the MP1 motor in a simple closed-loop hydrostatic propel application.

The motor is driven by a variable displacement pump. The motor shows an integral loop flushing option

that will remove heat and contaminants from the main loop.

6 | © Danfoss | December 2021 BC290322888218en-000113

A

B

L2 N

L1

P400620

A

B

L2 N

L1

CCW

P400648

Technical Information

MP1 Axial Piston Motors Size 20/24

General Description

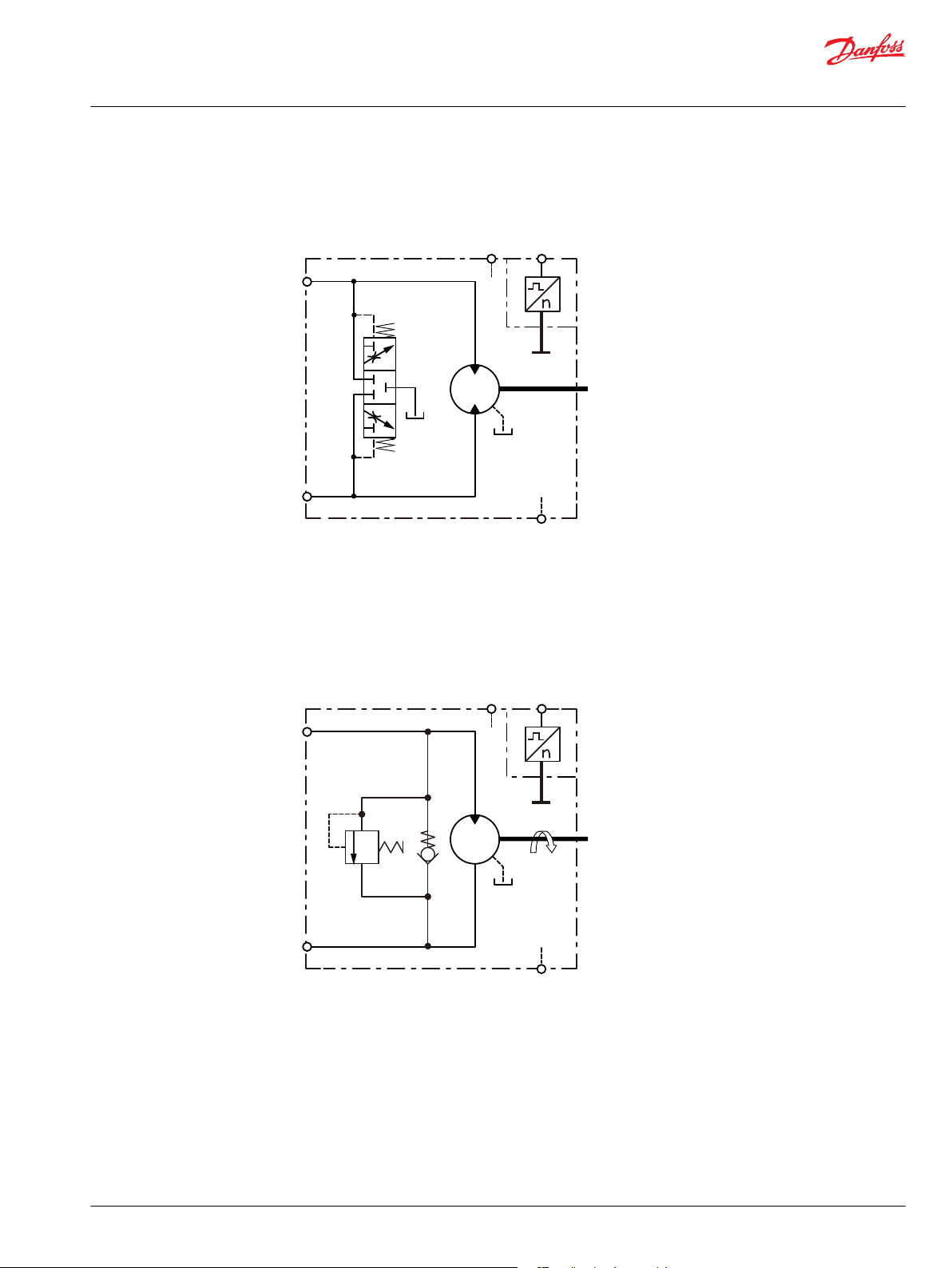

Schematic Diagram

Closed Circuit

For a close loop system, the system ports (A and B) connect to the high pressure work lines. The motor

receives pressurized fluid in its inlet port and discharges de-energized fluid through the outlet port.

Either port can act as inlet or outlet; flow is bidirectional. The motor has two case drains (L1 and L2). The

motor may include loop flushing. Loop flushing provides additional cooling and filtration capacity.

Open Circuit

An open circuit configuration is also possible for the motor and such a system is shown above. A shock

valve and an anti-cavitation valve is provided to protect the unit from sudden pressure surges as well as

cavitation. The flow path of pressurized fluid is from port A through port B. In this configuration, the

direction of rotation of the motor is counter clockwise as seen from shaft side. Similarly, if the anticavitation and shock valve is oriented in the reverse position, the direction of rotation will be clockwise.

Thus, pressurized fluid flow path is from port B through port A.

©

Danfoss | December 2021 BC290322888218en-000113 | 7

Technical Information

MP1 Axial Piston Motors Size 20/24

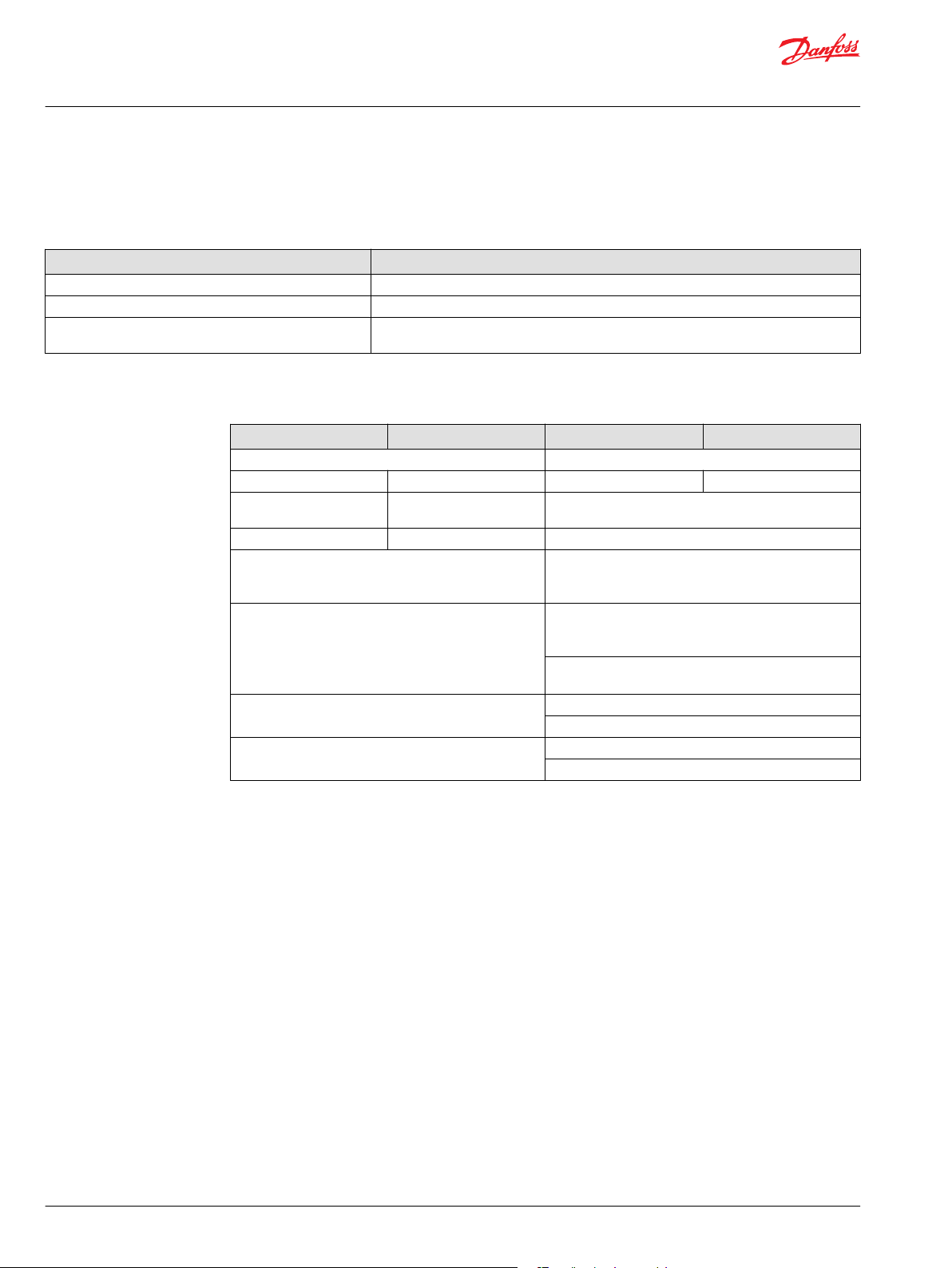

Technical Specification

Design Specifications

Features MP1 Motors

Design Axial piston motor with fixed displacement design.

Direction of output rotation (as seen from shaft side) Clockwise or counterclockwise

Recommended installation position

Technical Data

Feature Unit MP1M20 MP1M24

Model configuration Fixed displacement motor

Displacement cm3/rev [in3/rev] 20.0 [1.22] 24.0 [1.46]

Mass moment of inertia of

rotating components

Mass (Weight) dry kg [lb] 5.6 [12]

Mounting flange

Output shaft options

Main port configuration A, B

Case drain ports A, B

Motor installation position is discretionary, The housing must always be filled with

hydraulic fluid. Consult Danfoss for non-conformance to these guidelines.

kg•m2 [slug•ft2] 0.0010 [0.0007]

ISO 3019-1 flange 82-2 (SAE-A), 2 bolt

ISO 3019-1 flange 101-2 (SAE-B), 2 bolt

Cartridge mounting style

Spline 13T 16/32

Spline 15T 16/32

Spline 17T 24/48

Straight keyed 22.225 dia.

Tapered 22.225 dia. 1:8

ISO 11926-1, 7/8-14 (SAE O-ring boss) Twin port, radial

ISO 6149-1, M22x1.5 (Metric O-ring boss)

ISO 11926-1, 3/4-16 (SAE O-ring boss)

ISO 6149-1, M18x1.5 (Metric O-ring boss)

8 | © Danfoss | December 2021 BC290322888218en-000113

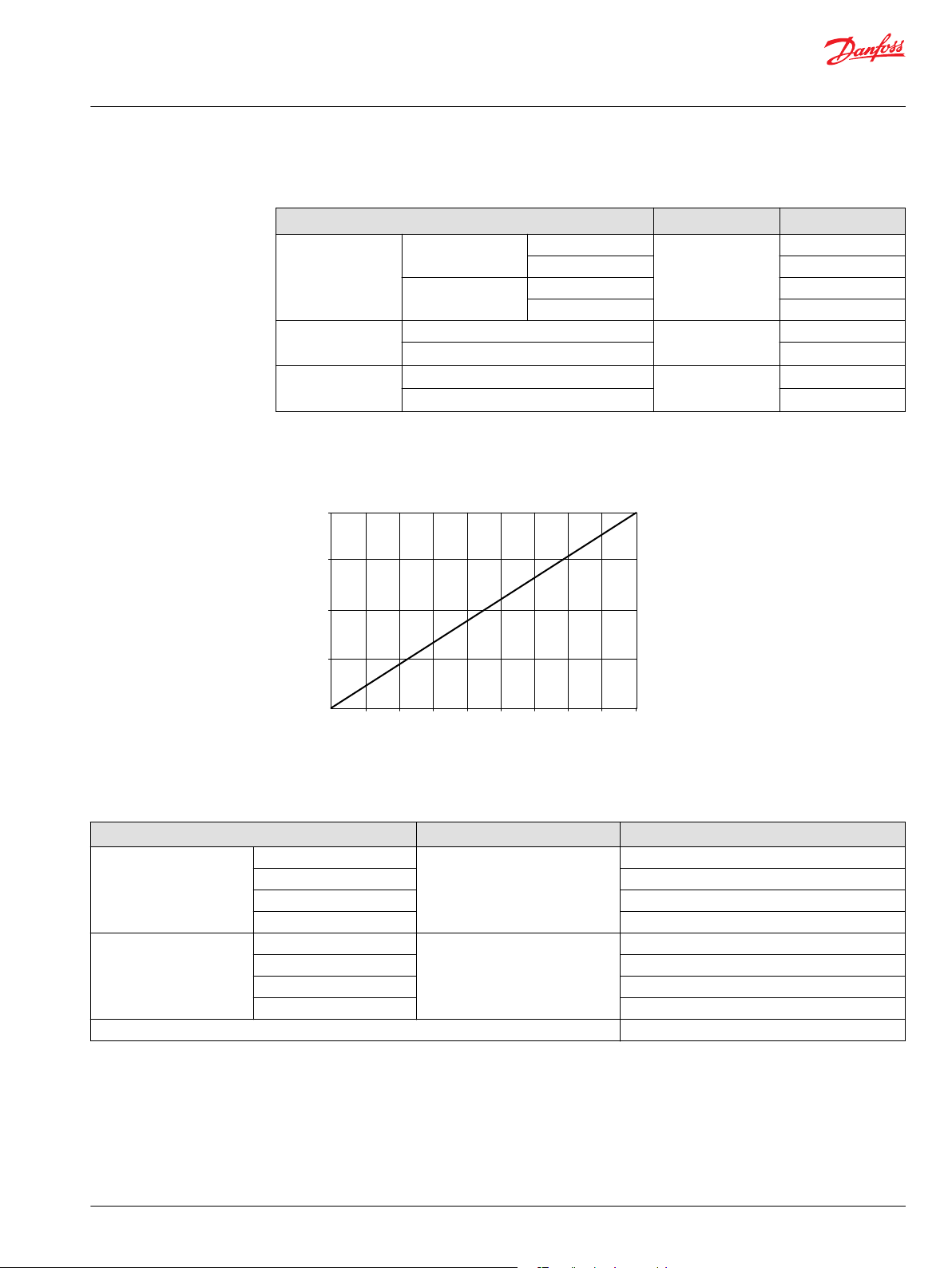

Output speed n/nmax

Outlet pressure [bar]

0.80

0.85

0.90

0.95

1.00

0 2 4 6 8 10 12 14 16 18

P400718

Technical Information

MP1 Axial Piston Motors Size 20/24

Technical Specification

Operating Parameters

Parameter Unit

Closed Circuit

1)

Speed limit

Open Circuit

System pressure

Case pressure

1)

At the limit speed, system minimum low pressure is 18 bar.

2)

Applied pressures above maximum working pressure requires Danfoss application approval.

Maximum working pressure

Maximum pressure

Rated

Maximum

Rated

Maximum 4700

Rated 3400

min-1(rpm)

Maximum 3800

2)

bar [psi]

bar [psi]

Motor speed limit in relation to output (low) pressure

20/24

4200

350 [5000]

380 [5429]

2 [29]

6 [87]

Fluid Specifications

Features Units 20/24

Intermittent

Viscosity

3

Temperature range

Cleanliness per ISO 4406 22/18/13 (as per ISO 4406)

1

Intermittent=Short term t <1 min per incident and not exceeding 2 % of duty cycle based load-life.

2

Cold start = Short term t < 3 min, p < 50 bar [725 psi], n < 1000 min-1 (rpm)

3

At the hottest point, normally case drain port.

©

Danfoss | December 2021 BC290322888218en-000113 | 9

Minimum 7 [49]

Recommended range 12 - 80 [66 - 370]

Maximum (cold start)

Minimum (cold start)

Recommended range 60 - 85 [140 - 185]

Maximum continuous 104 [220]

Maximum intermittent 115 [240]

1

5 [42]

mm2/sec. [SUS]

2

1600 [7500]

-40 [-40]

°C [°F]

A

B

L2 N

L1

P400637

Notch Spool

Spring guide

Spring

Plug

P400656

0

1

2

3

4

5

0 5 10 15 20 25

Flow [L/min]

System pressure _ low side [dbar]

1.5L - 50°C

0°C

3.6L - 5

Technical Information

MP1 Axial Piston Motors Size 20/24

Operation

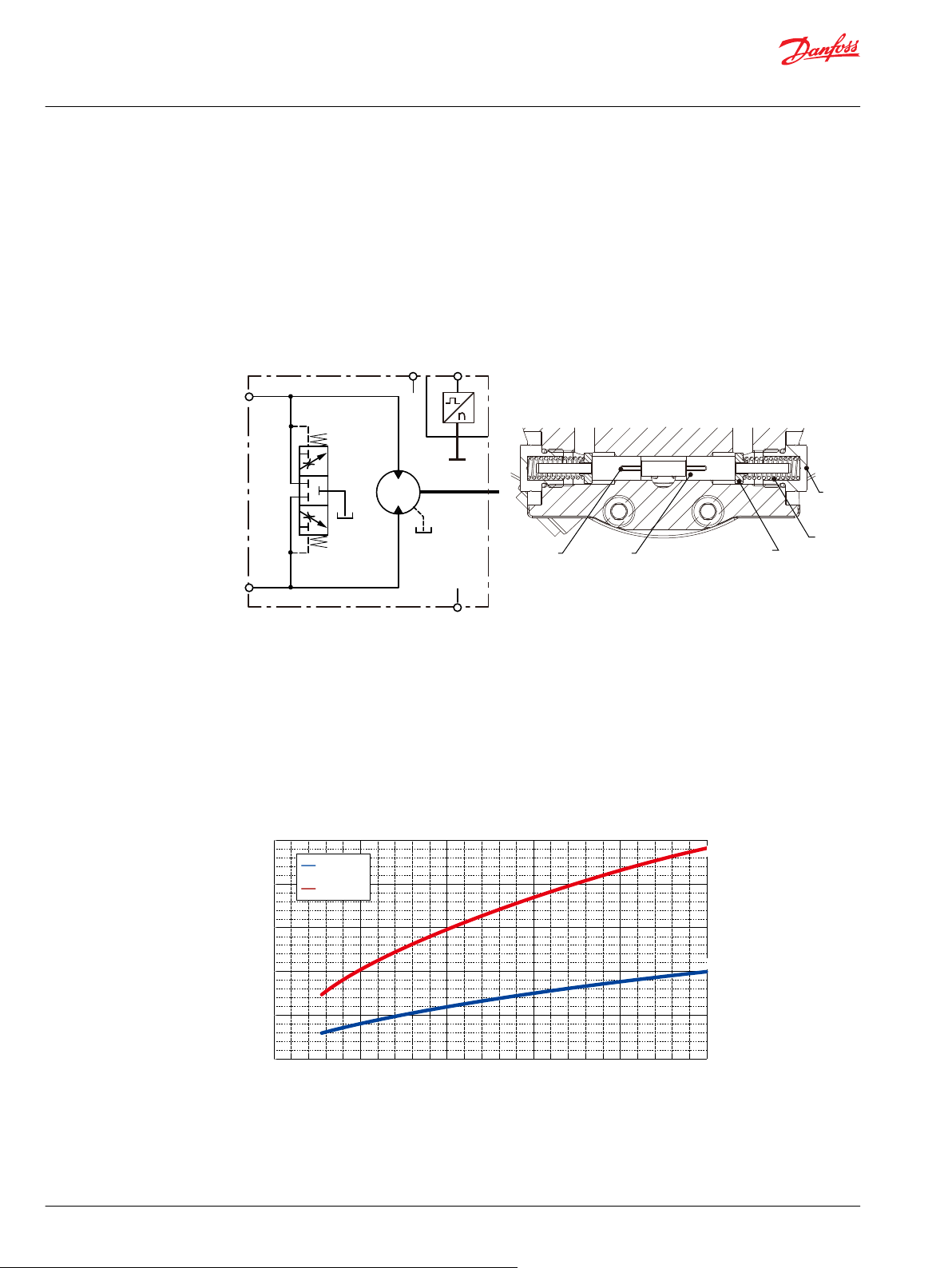

Loop Flushing Valve

Closed circuit systems may require loop flushing to meet temperature and cleanliness requirements. MP1

motors are available with an optional integral loop flushing. A loop flushing valve will remove heat and

contaminants from the main loop at a rate faster than otherwise possible.

The hydraulic circuit of an MP1 motor with loop flushing option is shown below. The MP1 motor loop

flushing design is a simple spring centered shuttle spool with an orifice notch.

A loop flush shuttle spool is used to separate system A and system B pressures. System delta pressure will

cause the shuttle spool to shift, allowing the low side system pressure to flow to the orifice towards the

case. The shuttle shifts at approximately 4 bar [57 psi]. The flushing flow is a function of the low loop

system pressure and the size of the notch.

Loop flush flow options of 1.5 & 3.6 l/min [0.4 & 1.0 gal/min] are available and are adequate for most

applications. Contact your Danfoss representative for assistance.

Loop flush characteristic curves

1.5 L and 3.6 L@15 bar, oil temp=50°C

When a MP1 pump is used with an external loop flushing shuttle valve, ensure that the charge setting of

the pump matches the setting of the loop flushing shuttle valve. Contact your Danfoss representative for

the availability of additional charge relief settings.

10 | © Danfoss | December 2021 BC290322888218en-000113

A

B

L2 N

L1

P400636

CW

Shock valve Anti-cavitation valve

P400658

Anti-cavitation and shock valve

Technical Information

MP1 Axial Piston Motors Size 20/24

Operation

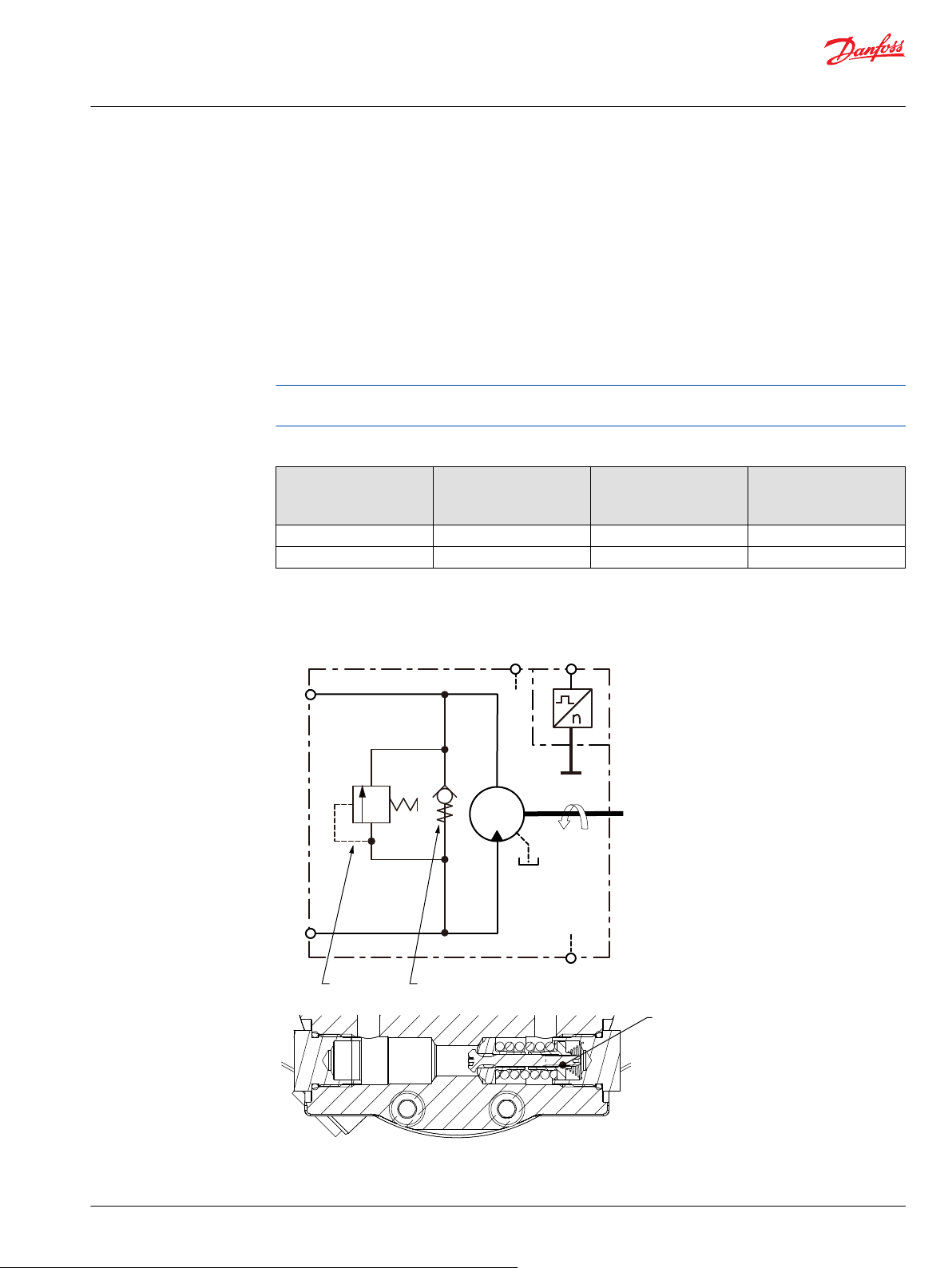

Anti-Cavitation and Shock Valve

The MP1M fixed motors are available with an anti-cavitation valve option. The key application for this

option is open circuit fan drives.

The anti cavitation valve function as a check valve within the same cavity which is integrated into the

endcap. The check valve function provides protection against cavitation that can occur upon

introduction of an overrunning load or due to loss of input flow. In such case, the system delta pressure

becomes negative and the check valve opens connecting the motor inlet and outlet, effectively shortcircuiting the motor. The shock valve function is intended to be used for system overpressure protection

events of limited duration only. It is not intended for continuous system pressure limitation.

The shock valve is available with 280 bar [4061 psi] or 345 bar [5004 psi] setting.

For this option the high pressure port needs to be defined upfront to get the correct motor rotation.

Reversing the motor is not possible with this option.

Flow direction

Motor shaft rotation (as

seen from shaft side)

Clockwise (CW) Out In MD1/MD2/SD1/SD2

Counterclockwise (CCW) In Out MC1/MC2/SC1/SC2

*

See Master Model Code on page 23

Port A Port B

System Port type, Loop

Flushing & Anticavitation

*

Anti cavitation and shock valve, Port B High Pressure, Clockwise rotation

©

Danfoss | December 2021 BC290322888218en-000113 | 11

P400635

A

B

L2 N

L1

CCW

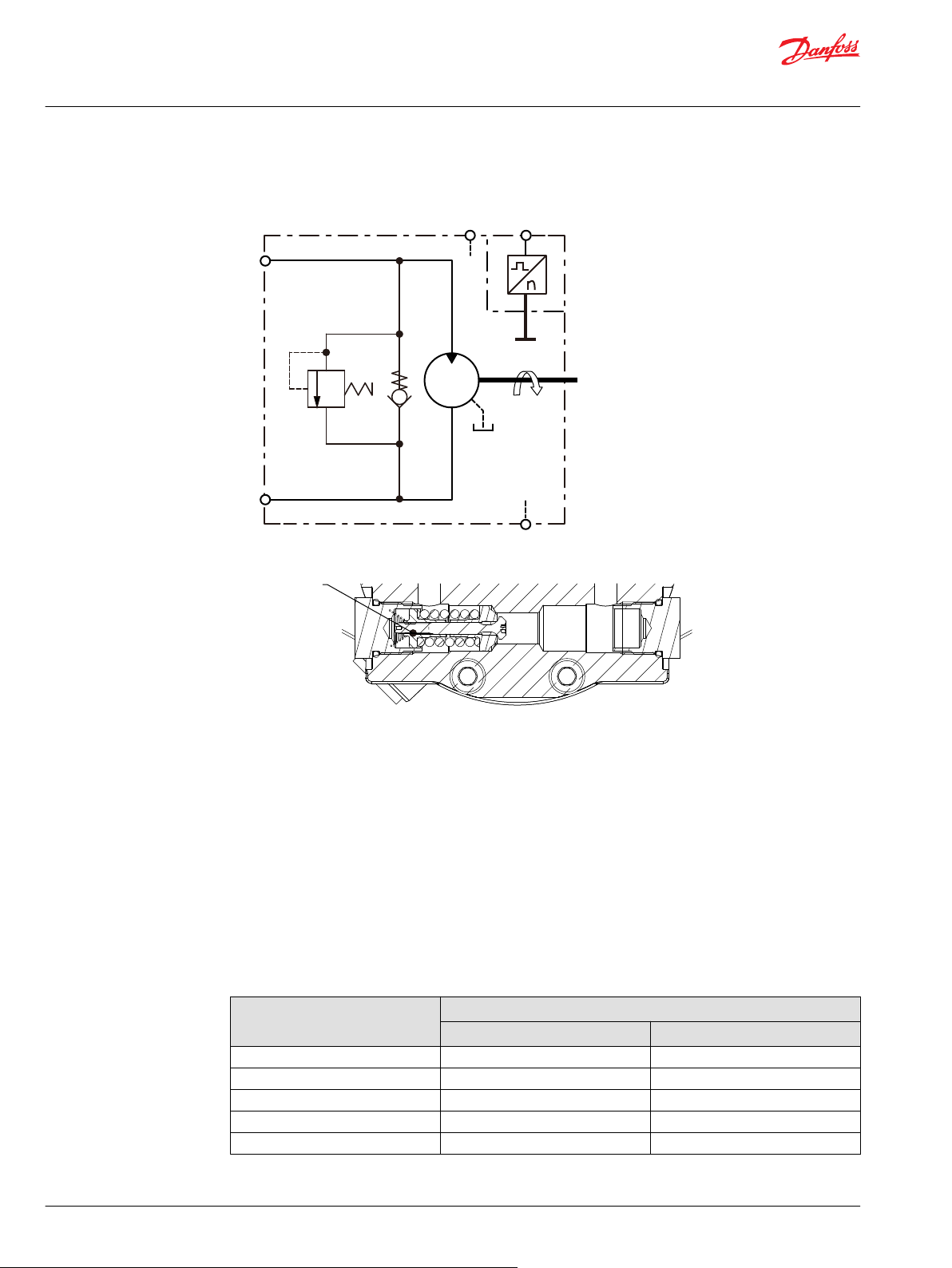

P400660

Anti-cavitation

and shock valve

Technical Information

MP1 Axial Piston Motors Size 20/24

Operation

Anti cavitation and shock valve, Port A High Pressure, Counter Clockwise rotation

Speed and Temperature Sensor

MP1 motors are available with an optional speed and temperature sensor. This hall-effect pulse pick-up is

located in the motor housing. The sensor accepts supply voltage and outputs a digital pulse signal in

response to the speed of the cylinder block. The output changes its high/low state as the target teeth

pass by the sensor's face. The digital (on-off-on-off) pulse train is fed to a controller, which interprets its

rate of change as a speed. A logic circuit decodes the two signals to provide an additional direction

indication (high or low) depending on direction).

The speed sensor is designed for rugged outdoor, mobile or heavy industrial speed sensing applications.

The detection of the speed is contactless and does not need any calibration or adjustments. There are

two optional sensors available.

Available Sensors

Description Order number

149055 11232698

Supply voltage 4.5 – 8 V 7 – 32 V

Speed signals Two, 90° Phase shift Two, 90° Phase shift

Direction signal One One

Temperature signal One One

PLUS+1 Compliance Yes No

12 | © Danfoss | December 2021 BC290322888218en-000113

4

3

2

1

5

6

P006035

Technical Information

MP1 Axial Piston Motors Size 20/24

Operation

Temperature Range

Parameter Minimum Maximum

Operation temperature range -40 °C 104 °C

115°C Intermittent = Short term; t < 1min per incident and not exceeding 2 % of duty cycle based loadlife.

Protection Characteristics

Parameter Data

Protection Code (IP class)

according IEC 60529 and DIN 40050

EMC Emission EN 61000-6-3

EMC Immunity (EMI) 100 V/m incl. 1 kHz AM 80 %; ISO 11452-5 and -2

ESD EN 61000-4-2

Vibration 30 G (294 m/s2)

Shock 50 G (490 m/s2)

Case maximum pressure 5 bar [72.5 psi]

IP 67 (without connector installed)

IP 69k (with connector installed)

Air discharge: 15 kV

Contact discharge: 8 kV

Mating Connectors

Ordering number

11033865 11033863

Assembly Bag, DEUTSCH DTM06-6S-E004; black, (24-20

AWG) 0.21 -0.52 mm²

Assembly Bag, DEUTSCH DTM06-6S, gray, (24-20 AWG)

0.21 -0.52 mm²

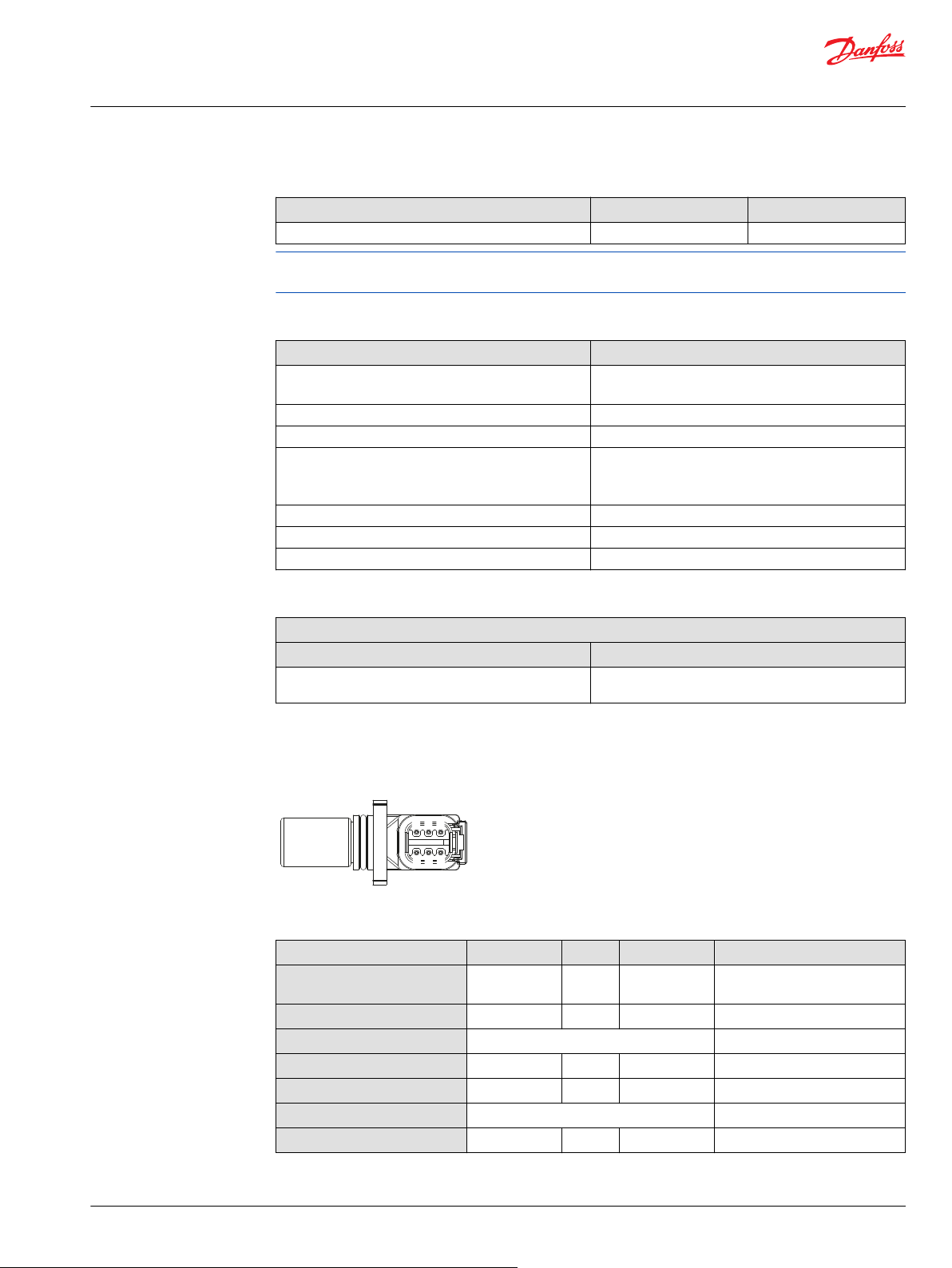

Speed Sensor 4.5 - 8 V

Speed sensor connector, 6-pin

Pinout:

1. Speed signal 2

2. Direction signal

3. Speed signal 1

4. Supply

5. Ground

6. Temperature

Technical data

Parameter Min. Nom. Max. Note

Supply voltage

Supply protection

Pulses per revolution

Max. required supply current

Max. output current

Operation mode

Temperature signal

4.5 V

DC

– – 30 V

NPN & PNP

– – 25 mA At supply voltage

– – 50 mA

NPN & PNP Push-Pull amplifier

-40°C = 2.318V – 100°C = 0.675V

5 V

8 V

DC

DC

DC

Regulated supply voltage.

Reverse polarity protected.

Shuts off above 9 V.

©

Danfoss | December 2021 BC290322888218en-000113 | 13

4

3

2

1

5

6

P006035

Technical Information

MP1 Axial Piston Motors Size 20/24

Operation

Technical data (continued)

Parameter Min. Nom. Max. Note

Output low speed signal

Output high speed signal

Detectable frequency range

Ordering number

Color of connector

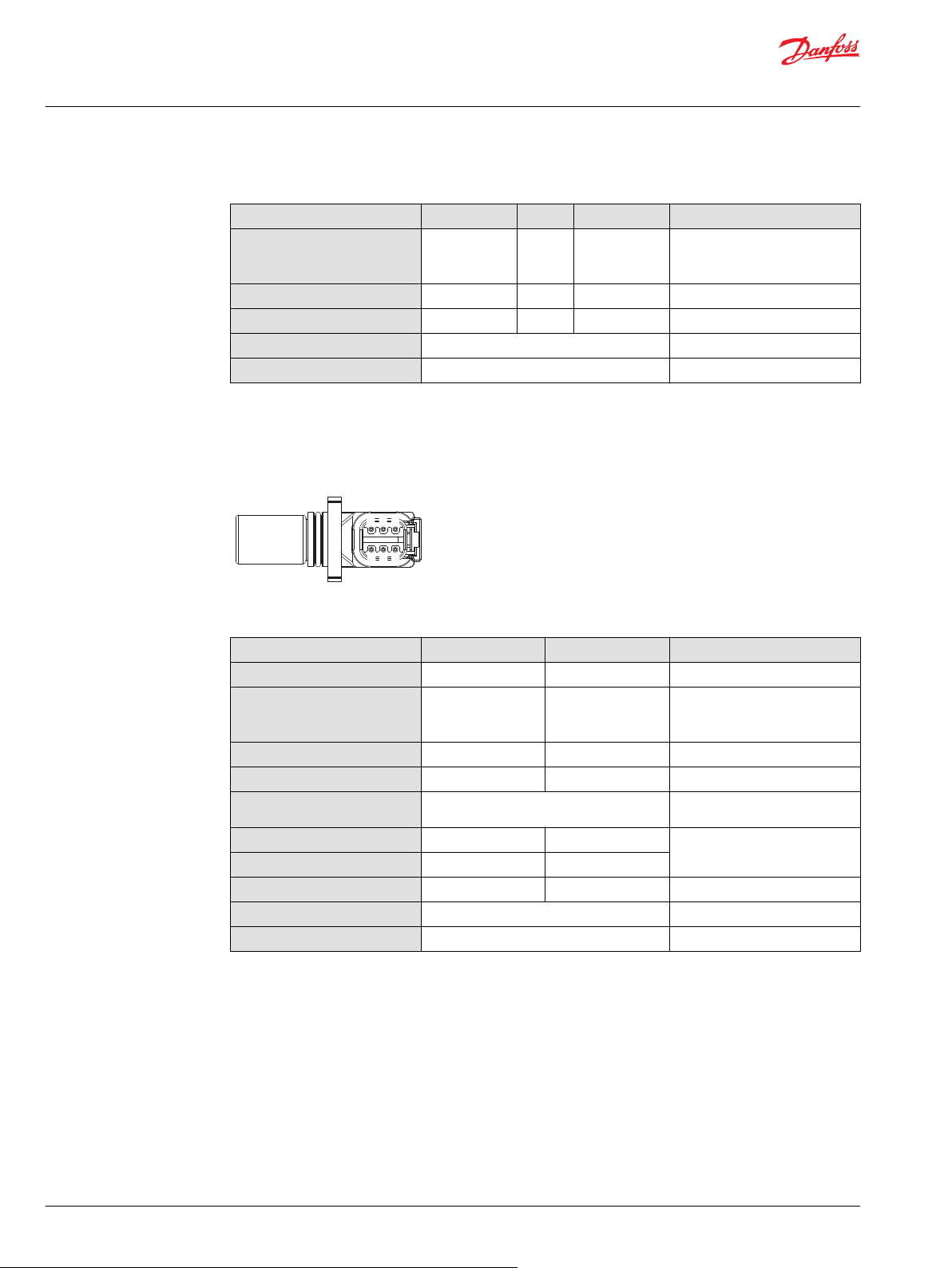

Speed Sensor 7 - 32 V

Speed Sensor 7 – 32 VDC technical data and information about connector.

5 % 8.5 % 12 %

88 % 91.5 % 95 %

1 Hz – 10 000 Hz

149055

Black

Ratiometric output voltage

Low state > 0 V to provide wire

fault detection

Speed sensor connector, 6-pin

Pinout:

1. Speed signal 2

2. Direction signal

3. Speed signal 1

4. Supply

5. Ground

6. Temperature signal

Technical data

Parameter Min. Max. Note

Supply voltage range

Supply protection

Max. required supply current

Max. output current

Operation mode

Output low signal range

Output high signal range

Detectable frequency range

Speed sensor order number

Color of connector

7 V

DC

– 36 V

– 30 mA

– 50 mA

NPN open collector Internal 2k7 pull-up resistor to

2 % 10 % Max. output voltage 24 V

55 % 85 %

1 Hz 10 000 Hz

11232698

Yellow

32 V

DC

DC

36 VDC over voltage protection

-36 VDC permanent reverse

polarity protection

supply

DC

For more information, see Speed and Temperature Sensor, Technical Information, BC152886482203.

14 | © Danfoss | December 2021 BC290322888218en-000113

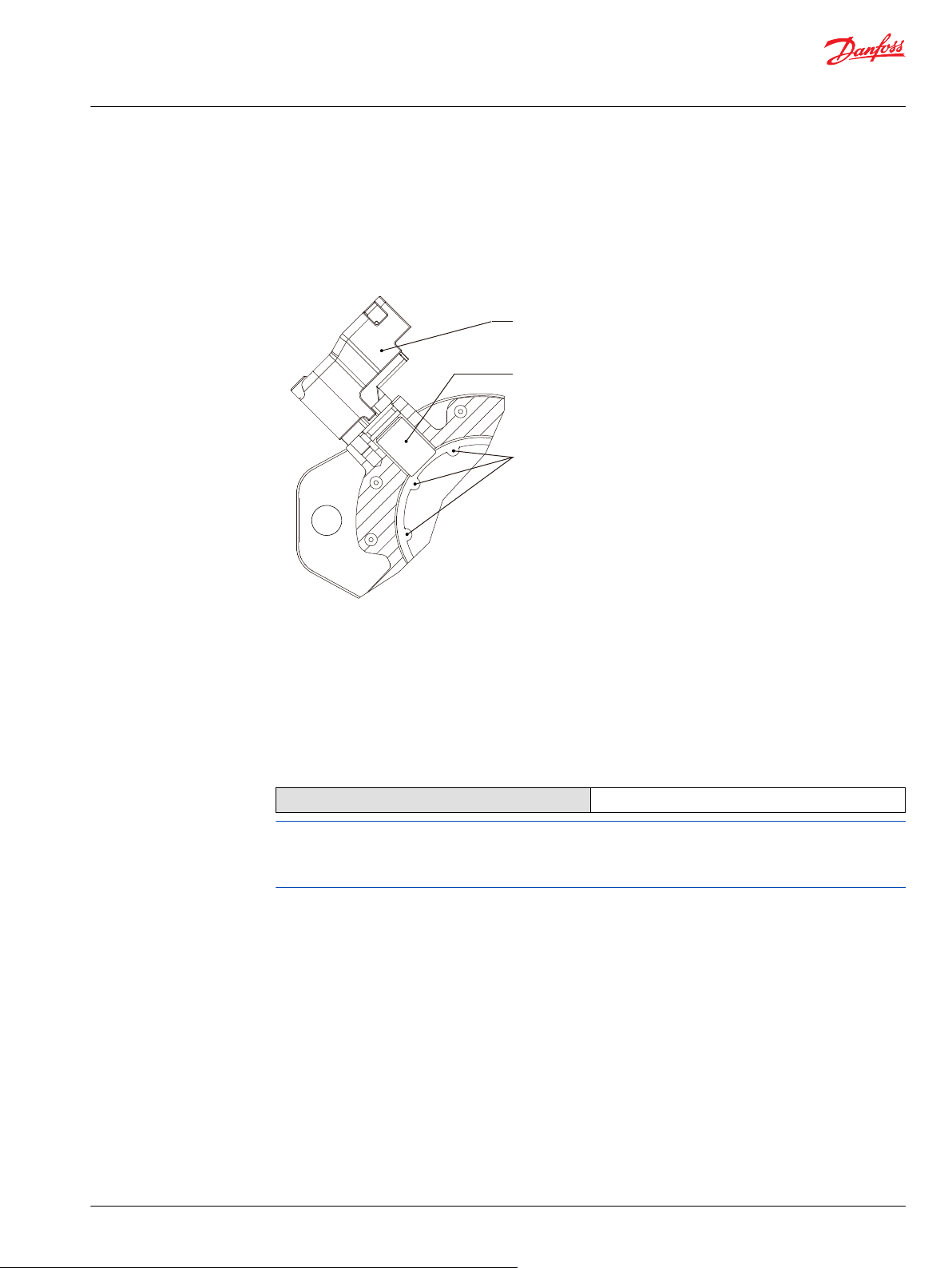

Speed sensor

P400649

Machined grooves

on cylinder block

Speed sensor

protection

Technical Information

MP1 Axial Piston Motors Size 20/24

Operation

Sensor Position

Sensor position in SAE and Cartridge housing.

SAE & Cartridge housing

Target block

Speed sensor target block has nine arc groove on cylinder block for detection of direction (CW/CCW) and

rotation.

Output Pulses

The expected number of output pulses per revolution is shown below.

The number of pulses (per rev)

9

Due to the number of target groove (9) for pulse pick up, the output signal resolution is lower than other

products (e.g.71 target teeth for H1B-60) in extra low speed.

For more technical information, please contact your Danfoss representative.

©

Danfoss | December 2021 BC290322888218en-000113 | 15

Loading...

Loading...