Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

Modbus RTU

Page 2

Contents Modbus RTU Operating Instruction

Contents

1 Safety and Conformity

1.1 Safety Precautions

1.1.1 Safety Precautions - Continued 3

1.2.1 Caution 4

1.3.1 Software Version 4

1.4 CE Labelling

1.4.1 CE Conformity and Labelling 5

1.4.2 What Is Covered 5

1.4.3 Danfoss Frequency Converter and CE Labelling 5

1.4.4 Compliance with EMC Directive 2004/108/ECEMC Directive 2004/108/EC 6

1.5.1 Air Humidity 6

1.5.2 Aggressive Environments 6

1.5.3 Vibration and Shock 6

2 Introduction

2.1 Introduction

2.1.1 Modbus RTU Overview 8

3

3

5

8

8

3 RS-485 Installation and Set-up

3.1.1 Overview 9

3.1.2 Cable Specifications 9

3.1.5 EMC Precautions 11

4 Modbus RTU Message Framing Structure

4.1.1 Frequency Converter with Modbus RTU 12

4.1.2 Timing Constraints 12

4.1.3 Modbus RTU Message Structure 13

4.1.4 Start/Stop Field 13

4.1.5 Address Field 13

4.1.6 Function Field 13

4.1.7 Data Field 13

4.1.8 CRC Check Field 13

4.1.9 Coil and Register Addressing 14

4.1.10 Function Codes Supported by Modbus RTU 14

4.1.11 Coil Addresses 14

4.1.12 Register Addresses 16

9

12

4.1.13 Parameter Handling 16

4.1.14 Storage of Data 16

4.1.15 IND 16

4.1.16 Text Blocks 16

MG92B102 - VLT® is a registered Danfoss trademark 1

Page 3

Contents Modbus RTU Operating Instruction

4.1.17 Conversion Factor 17

4.1.18 Parameter Values 17

5 How to Control the Frequency Converter

5.1 How to Control the Frequency Converter

5.2 Parameter for Modbus RTU

5.2.1 Important Parameters for Modbus RTU 18

5.2.2 Access via PCD write/read 18

5.2.3 Mapping the Holding Registers to Drive Parameters 19

5.2.4 Mapping the Holding Registers to Drive Parameters, 32 bits 20

6 Function Code Examples

6.1 Examples

6.1.2 Force/Write Single Coil (05 HEX) 21

6.1.3 Force/Write Multiple Coils (0F HEX) 21

6.1.4 Read Holding Registers (03 HEX) 22

6.1.5 Preset Single Register (06 HEX) 22

6.1.6 Preset Multiple Registers (10 HEX) 23

7 FC Control Profile

7.1.1 Control Word According to FC Profile (8-10 Protocol = FC profile) 24

18

18

18

21

21

24

8 Parameters

8.1 Parameters: 8-** Communications and Options

8.1.3 8-3* FC Port Settings 30

8.1.4 8-4* FC MC protocol set 31

9 Troubleshooting

9.1.1 Modbus Exception Codes 35

9.1.2 8-80 Bus Message count 35

9.1.3 8-81 Bus Error Count 35

9.1.4 8-82 Slave Messages Rcvd 35

9.1.5 8-83 Slave Error 36

Index

28

28

35

37

2 MG92B102 - VLT® is a registered Danfoss trademark

Page 4

Safety and Conformity Modbus RTU Operating Instruction

1 Safety and Conformity

1.1 Safety Precautions

WARNING

The voltage of the frequency converter is dangerous

whenever connected to mains. Incorrect installation of the

motor, frequency converter or fieldbus may cause death,

serious personal injury or damage to the equipment.

Consequently, the instructions in this manual, as well as

national and local rules and safety regulations, must be

complied with.

Safety Regulations

1. The mains supply to the frequency converter

must be disconnected whenever repair work is to

be carried out. Check that the mains supply has

been disconnected and that the necessary time

has elapsed before removing motor and mains

supply plugs.

2. The [Off] button on the control panel of the

frequency converter does not disconnect the

mains supply and consequently it must not be

used as a safety switch.

3. The equipment must be properly earthed, the

user must be protected against supply voltage

and the motor must be protected against

overload in accordance with applicable national

and local regulations.

4. The earth leakage current exceeds 3.5 mA.

5. Protection against motor overload is not included

in the factory setting. If this function is desired,

set 1-90 Motor Thermal Protection to data value

ETR trip 1 [4] or data value ETR warning 1 [3].

6. Do not remove the plugs for the motor and

mains supply while the frequency converter is

connected to mains. Check that the mains supply

has been disconnected and that the necessary

time has elapsed before removing motor and

mains plugs.

7. Note that the frequency converter has more

voltage sources than L1, L2 and L3, when load

sharing (linking of DC intermediate circuit) or

external 24 V DC are installed. Check that all

voltage sources have been disconnected and that

the necessary time has elapsed before

commencing repair work.

1.1.1

Safety Precautions - Continued

Warning against unintended start

1. The motor can be brought to a stop with digital

commands, bus commands, references or a local

stop, while the frequency converter is connected

to mains. If personal safety considerations (e.g.

risk of personal injury caused by contact with

moving machine parts following an unintentional

start) make it necessary to ensure that no

unintended start occurs, these stop functions are

not sufficient. In such cases the mains supply

must be disconnected or the Safe Stop function

must be activated.

2. The motor may start while setting the

parameters. If this means that personal safety

may be compromised (e.g. personal injury caused

by contact with moving machine parts), motor

starting must be prevented, for instance by use

of the Safe Stop function or secure disconnection

of the motor connection.

3. A motor that has been stopped with the mains

supply connected, may start if faults occur in the

electronics of the frequency converter, through

temporary overload or if a fault in the power

supply grid or motor connection is remedied. If

unintended start must be prevented for personal

safety reasons (e.g. risk of injury caused by

contact with moving machine parts), the normal

stop functions of the frequency converter are not

sufficient. In such cases the mains supply must be

disconnected or the Safe Stop function must be

activated.

NOTE

When using the Safe Stop function, always follow the

instructions in the section Safe Stop of the Design Guide.

4. Control signals from, or internally within, the

frequency converter may in rare cases be

activated in error, be delayed or fail to occur

entirely. When used in situations where safety is

critical, e.g. when controlling the electromagnetic

brake function of a hoist application, these

control signals must not be relied on exclusively.

1 1

MG92B102 - VLT® is a registered Danfoss trademark 3

Page 5

Safety and Conformity Modbus RTU Operating Instruction

11

WARNING

1.2.1 Caution

High Voltage

Touching the electrical parts may be fatal - even after the

equipment has been disconnected from mains.

Also make sure that other voltage inputs have been

disconnected, such as external 24 V DC, load sharing

(linkage of DC intermediate circuit), as well as the motor

connection for kinetic back up.

Systems where frequency converters are installed must, if

necessary, be equipped with additional monitoring and

protective devices according to the valid safety regulations,

e.g law on mechanical tools, regulations for the prevention

of accidents etc. Modifications on the frequency converters

by means of the operating software are allowed.

CAUTION

The DC link capacitors remain charged after power has

been disconnected. Be aware that there may be high

voltage on the DC link even when the Control Card LEDs

are turned off. A red LED is mounted on a circuit board

inside the frequency converter to indicate the DC bus

voltage. The red LED will stay lit until the DC link is 50 V

DC or lower. To avoid electrical shock hazard, disconnect

the frequency converter from mains before carrying out

maintenance. When using a PM-motor, make sure it is

disconnected. Before doing service on the frequency

converter wait at least the amount of time indicated

below:

NOTE

Hazardous situations shall be identified by the machine

builder/integrator who is responsible for taking necessary

preventive means into consideration. Additional

monitoring and protective devices may be included, always

according to valid national safety regulations, e.g. law on

mechanical tools, regulations for the prevention of

accidents.

NOTE

Crane, Lifts and Hoists:

The controlling of external brakes must always have a

redundant system. The frequency converter can in no

circumstances be the primary safety circuit. Comply with

relevant standards, e.g.

Hoists and cranes: IEC 60204-32

Lifts: EN 81

Protection Mode

Once a hardware limit on motor current or DC link voltage

is exceeded the frequency converter will enter “Protection

mode”. “Protection mode” means a change of the PWM

modulation strategy and a low switching frequency to

minimize losses. This continues 10 s after the last fault and

increases the reliability and the robustness of the

frequency converter while re-establishing full control of the

motor.

In hoist applications “Protection mode” is not usable

because the frequency converter will usually not be able to

leave this mode again and therefore it will extend the time

before activating the brake – which is not recommendable.

The “Protection mode” can be disabled by setting

14-26 Trip Delay at Inverter Fault to zero which means that

the frequency converter will trip immediately if one of the

hardware limits is exceeded.

Voltage [V] Power [kW] Waiting Time [min]

380-500 0.25-7.5 4

11-75 15

90-200 20

250-800 40

525-690 11-75 (frame

size B and C)

37-315 (frame

size D)

355-1000 30

15

20

1.2.2 Protection Mode

Equipment containing electrical

components may not be disposed of

together with domestic waste.

It must be separately collected with

electrical and electronic waste according

to local and currently valid legislation.

1.3.1 Software Version

Design Guide

Software version: 6.4x

This Design Guide can be used for all frequency converters with

software version 6.4x.

The software version number can be seen from 15-43 Software

Version.

NOTE

It is recommended to disable protection mode in hoisting

applications (14-26 Trip Delay at Inverter Fault = 0)

4 MG92B102 - VLT® is a registered Danfoss trademark

Page 6

Safety and Conformity Modbus RTU Operating Instruction

1.4 CE Labelling

1.4.1 CE Conformity and Labelling

The machinery directive (2006/42/EC)

Frequency converters do not fall under the machinery

directive. However, if a frequency converter is supplied for

use in a machine, Danfoss provide information on safety

aspects relating to the frequency converter.

What is CE Conformity and Labelling?

The purpose of CE labelling is to avoid technical trade

obstacles within EFTA and the EU. The EU has introduced

the CE label as a simple way of showing whether a

product complies with the relevant EU directives. The CE

label says nothing about the specifications or quality of

the product. Frequency converters are regulated by two EU

directives:

The low-voltage directive (2006/95/EC)

Frequency converters must be CE labelled in accordance

with the low-voltage directive of January 1, 1997. The

directive applies to all electrical equipment and appliances

used in the 50 - 1000 V AC and the 75 - 1500 V DC voltage

ranges. Danfoss CE-labels in accordance with the directive

and issues a declaration of conformity upon request.

The EMC directive (2004/108/EC)

EMC is short for electromagnetic compatibility. The

presence of electromagnetic compatibility means that the

mutual interference between different components/

appliances does not affect the way the appliances work.

The EMC directive came into effect January 1, 1996.

Danfoss CE-labels in accordance with the directive and

issues a declaration of conformity upon request. To carry

out EMC-correct installation, see the instructions in this

Design Guide. In addition, Danfoss specify which standards

our products comply with. Danfoss offer the filters

presented in the specifications and provide other types of

assistance to ensure the optimum EMC result.

The frequency converter is most often used by professionals of the trade as a complex component forming part

of a larger appliance, system or installation. The EMC

directive (2004/108/EC)

What Is Covered

1.4.2

The EU "Guidelines on the Application of Council Directive

2004/108/EC" outline three typical situations of using a

frequency converter. See below for EMC coverage and CE

labelling.

1. The frequency converter is sold directly to the

end-consumer. The frequency converter is for

example sold to a DIY market. The end-consumer

is a layman. Installing the frequency converter for

use with a hobby machine, a kitchen appliance,

etc. For such applications, the frequency

converter must be CE labelled in accordance with

the EMC directive.

2. The frequency converter is sold for installation in

a plant. The plant is built up by professionals of

the trade. It could be a production plant or a

heating/ventilation plant designed and installed

by professionals of the trade. Neither the

frequency converter nor the finished plant has to

be CE labelled under the EMC directive. However,

the unit must comply with the basic EMC

requirements of the directive. This is ensured by

using components, appliances, and systems that

are CE labelled under the EMC directive.

3. The frequency converter is sold as part of a

complete system. The system is being marketed

as complete and could e.g. be an air-conditioning

system. The complete system must be CE labelled

in accordance with the EMC directive. The

manufacturer can ensure CE labelling under the

EMC directive either by using CE labelled

components or by testing the EMC of the system.

If only CE labelled components are used, it is

unneccessary to test the entire system.

Danfoss Frequency Converter and CE

1.4.3

Labelling

CE labelling is a positive feature when used for its original

purpose, i.e. to facilitate trade within the EU and EFTA.

However, CE labelling may cover many different specifications. Check what a given CE label specifically covers.

The covered specifications can be very different and a CE

label may therefore give the installer a false feeling of

security when using a frequency converter as a component

in a system or an appliance.

Danfoss CE labels the frequency converters in accordance

with the low-voltage directive. This means that if the

frequency converter is installed correctly, we guarantee

compliance with the low-voltage directive. Danfoss issues a

declaration of conformity that confirms our CE labelling in

accordance with the low-voltage directive.

The CE label also applies to the EMC directive provided

that the instructions for EMC-correct installation and

filtering are followed. On this basis, a declaration of

conformity in accordance with the EMC directive is issued.

The Design Guide offers detailed instructions for installation to ensure EMC-correct installation. Furthermore,

1 1

MG92B102 - VLT® is a registered Danfoss trademark 5

Page 7

Safety and Conformity Modbus RTU Operating Instruction

11

Danfoss specifies which our different products comply

with.

Danfoss provides other types of assistance that can help to

obtain the best EMC result.

1.4.4 Compliance with EMC Directive

2004/108/ECEMC Directive

IP54/55. As an extra protection, coated printed circuit

boards can be ordered as an option.

Airborne Particles such as dust may cause mechanical,

electrical, or thermal failure in the frequency converter. A

typical indicator of excessive levels of airborne particles is

dust particles around the frequency converter fan. In very

dusty environments, use equipment with enclosure rating

IP54/55 or a cabinet for IP00/IP20/TYPE 1 equipment.

2004/108/EC

In environments with high temperatures and humidity,

As mentioned, the frequency converter is mostly used by

professionals of the trade as a complex component

forming part of a larger appliance, system, or installation.

Note that the responsibility for the final EMC properties of

the appliance, system or installation rests with the installer.

As an aid to the installer, Danfoss has prepared EMC installation guidelines for the Power Drive system. The standards

and test levels stated for Power Drive systems are

complied with, provided that the EMC-correct instructions

for installation are followed, see the section EMC Immunity

in the Design Guide.

Air Humidity

1.5.1

The frequency converter has been designed to meet the

IEC/EN 60068-2-3 standard, EN 50178 pkt. 9.4.2.2 at 50° C.

corrosive gases such as sulphur, nitrogen, and chlorine

compounds cause chemical processes on the frequency

converter components.

Such chemical reactions rapidly affect and damage the

electronic components. In such environments, mount the

equipment in a cabinet with fresh air ventilation, keeping

aggressive gases away from the frequency converter.

An extra protection in such areas is a coating of the

printed circuit boards, which can be ordered as an option.

NOTE

Mounting frequency converters in aggressive environments

increases the risk of stoppages and considerably reduces

the life of the converter.

Aggressive Environments

1.5.2

A frequency converter contains a large number of

mechanical and electronic components. All are to some

extent vulnerable to environmental effects.

CAUTION

The frequency converter should not be installed in

environments with airborne liquids, particles, or gases

capable of affecting and damaging the electronic

components. Failure to take the necessary protective

measures increases the risk of stoppages, thus reducing

the life of the frequency converter.

Degree of protection as per IEC 60529

The Safe Stop function may only be installed and operated

in a control cabinet with degree of protection IP54 or

higher (or equivalent environment). This is required to

avoid cross faults and short circuits between terminals,

connectors, tracks and safety-related circuitry caused by

foreign objects.

Liquids can be carried through the air and condense in the

frequency converter and may cause corrosion of

components and metal parts. Steam, oil, and salt water

may cause corrosion of components and metal parts. In

such environments, use equipment with enclosure rating

Before installing the frequency converter, check the

ambient air for liquids, particles, and gases. This is done by

observing existing installations in this environment. Typical

indicators of harmful airborne liquids are water or oil on

metal parts, or corrosion of metal parts.

Excessive dust particle levels are often found on installation cabinets and existing electrical installations. One

indicator of aggressive airborne gases is blackening of

copper rails and cable ends on existing installations.

D and E enclosures have a stainless steel back-channel

option to provide additional protection in aggressive

environments. Proper ventilation is still required for the

internal components of the frequency converter. Contact

Danfoss for additional information.

1.5.3

Vibration and Shock

The frequency converter has been tested according to the

procedure based on the shown standards:

The frequency converter complies with requirements that

exist for units mounted on the walls and floors of

production premises, as well as in panels bolted to walls or

floors.

6 MG92B102 - VLT® is a registered Danfoss trademark

Page 8

Safety and Conformity Modbus RTU Operating Instruction

IEC/EN 60068-2-6: Vibration (sinusoidal) - 1970

•

IEC/EN 60068-2-64: Vibration, broad-band random

•

1 1

MG92B102 - VLT® is a registered Danfoss trademark 7

Page 9

Introduction Modbus RTU Operating Instruction

2 Introduction

22

confirming the action taken, any data to be returned, and

2.1 Introduction

This manual explains how to physically establish and

configure communication between the Danfoss FC Series

and a controller using the Modbus RTU protocol.

This instruction is intended to be used for both instruction

and reference. It only briefly touches on the basics of the

Modbus protocol whenever necessary to gain an

understanding of the Modbus RTU. This instruction is also

intended to serve as a guideline to specify and optimise

the communication system. Even experienced Modbus

programmers, should read these entire operating

instructions before starting programming since important

information can be found in all sections.

Modbus RTU Overview

2.1.1

Regardless of the type of physical communication

networks, the Modbus RTU Overview describes the process

a controller uses to request access to another device. This

process includes how the Modbus RTU responds to

requests from another device, and how errors are detected

and reported. It also establishes a common format for the

layout and contents of message fields.

During communications over a Modbus RTU network, the

protocol determines:

an error-checking field. If an error occurs in receipt of the

message, or if the slave is unable to perform the requested

action, the slave constructs an error message, and sends it

in response, or a time-out occurs.

How each controller learns its device address

Recognizes a message addressed to it

Determines which actions to take

Extracts any data or other information contained

in the message

If a reply is required, the controller constructs the reply

message and sends it.

Controllers communicate using a master-slave technique in

which only one device (the master) can initiate

transactions (called queries). The other devices (slaves)

respond by supplying the requested data to the master, or

by taking the action requested in the query.

The master can address individual slaves, or can initiate a

broadcast message to all slaves. Slaves return a message

(called a response) to queries that are addressed to them

individually. No responses are returned to broadcast

queries from the master. The Modbus RTU protocol

establishes the format for the master’s query by placing

into it the device (or broadcast) address, a function code

defining the requested action, any data to be sent, and an

error-checking field. The slave’s response message is also

constructed using Modbus protocol. It contains fields

8 MG92B102 - VLT® is a registered Danfoss trademark

Page 10

Wire # 1

Wire # 2

Data In Data Out

175ZB021.10

Wire #1

Wire #2

175ZB028.10

130BA060.11

68 69 68 69 68 69

RS 485

RS 232

USB

+

-

RS-485 Installation and Set... Modbus RTU Operating Instruction

3 RS-485 Installation and Set-up

3.1.1 Overview

The Modbus RTU protocol is based on the built-in RS-485

(EIA-485) interface on the FC Drive series control card.

RS-485 is a two-wire bus-interface that allows multi-drop

network topology i.e. nodes can be connected as a bus

(daisy chain), or via drop cables from a common trunk line.

Danfoss uses the two-wire system where the communication between master and slave is half-duplex, i.e. it

cannot transmit and receive at the same time.

Each signal uses one twisted-pair line — two wires twisted

around themselves. This is known as balanced data

transmission or differential voltage transmission (see

Illustration 3.1). The signal on one wire is ideally the exact

opposite of the signal on the second wire. In other words,

if one wire is transmitting a high, the other wire transmits

a low, and vice versa (see Illustration 3.2).

Since RS-485 is a multipoint communication system, all

devices are connected to the single twisted-pair cable.

3.1.2 Cable Specifications

When choosing a transmission line for RS-485, it is

necessary to examine the required distance of the cable

and the data rate of the system. Losses in a transmission

line are a combination of AC losses (skin effect), DC

conductor loss, leakage, and AC losses in the dielectric. In

high-quality cable, the conductor losses and the dielectric

losses are on the same order of magnitude.

The recommended maximum Modbus cable length

between the frequency converter and the Controller must

not exceed 30 m (100 feet). While the RS-485 specification

does not specify cabling, the recommendation is 0.25

mm2/24 AWG shielded twisted-pair cable with a shunt

capacitance of 16 pF/ft and 100 Ω impedance. Another

choice is the same cable commonly used in the twistedpair Ethernet cabling. This cable is commonly referred to

as Category 5 cable. The cable has a maximum capacitance

of 17 pF/ft (14.5 pF/ft typical) and characteristic impedance

of 100 Ω.

Network Connection

3.1.3

3

3

Illustration 3.1 Balanced Data Transmission

Illustration 3.2 Differential Concept

The Modbus RTU uses master/slave architecture, where

each slave device has its unique address and responds

only to packets addressed to this device.

The packets are generated by the master (Controller),

which periodically polls all connected slave devices. Data

travels over the single line in both directions.

According to the EIA-485 specification a total number of

32 nodes can be connected to one Modbus RTU network

segment, and a total of 247 nodes in a network are

supported. Network segments are divided with repeaters.

NOTE

Each repeater counts for a node in each segment it is

installed. Every node connected to the same network must

have a unique nodes address, across all segments.

One or more frequency converters can be connected to a

control (or master) using the RS-485 standardized interface.

Terminal 68 is connected to the P signal (TX+, RX+), while

terminal 69 is connected to the N signal (TX-,RX-).

If more than one frequency converter is connected to a

master, use parallel connections.

MG92B102 - VLT® is a registered Danfoss trademark 9

Page 11

130BB021.10

12 13 18 19 27 29 32

33 20 37

Remove jumper to enable Safe Stop

61 68 69 39 42 50 53 54 55

130BT310.10

1

2

N O

V LT

BUS TER.

OFF-ON

A53 A54

U- I U- I

3

RS-485 Installation and Set... Modbus RTU Operating Instruction

Illustration 3.3 Control Card Terminals

RS-485 Bus Termination

3.1.4

The RS-485 bus terminate by a resistor network at both

ends only. For this purpose, set switch S801 on the control

card for "On".

10 MG92B102 - VLT® is a registered Danfoss trademark

Page 12

Fieldbus cable

Min.200mm

90° crossing

130BA080.11

RS-485 Installation and Set... Modbus RTU Operating Instruction

3.1.5 EMC Precautions

The following EMC precautions are recommended to

achieve interference-free operation of the RS-485 network.

Relevant national and local regulations, for example

regarding protective earth connection, must be observed.

The RS-485 communication cable must be kept away from

motor and brake resistor cables to avoid coupling of high

frequency noise from one cable to another. Normally a

distance of 200 mm (8 inches) is sufficient, but keeping the

greatest possible distance between the cables is generally

recommended, especially where cables run in parallel over

long distances. When crossing is unavoidable, the RS-485

cable must cross motor and brake resistor cables at an

angle of 90o.

3

3

MG92B102 - VLT® is a registered Danfoss trademark 11

Page 13

at least 3.5 char

t

0

at least 3.5 char

3.5 char

4.5 char

Frame 1 Frame 2 Frame 3

175ZB026.10

Frame 1 OK

≤ 1.5 char

t

0

> 1.5 char

Frame 2 NOK

175ZB027.10

Modbus RTU Message Framing ... Modbus RTU Operating Instruction

4 Modbus RTU Message Framing Structure

4.1.1 Frequency Converter with Modbus

RTU

The controllers are set up to communicate on the Modbus

network using RTU (Remote Terminal Unit) mode, with

44

each byte in a message containing 8-bit hexadecimal

Bits Per Byte 1 start bit

8 data bits, least significant bit sent first

1 bit for even/odd parity; no bit for no

parity

1 stop bit if parity is used; 2 bits if no parity

characters. The format for each byte is shown in Table 4.1.

Start

bit

Table 4.1 The Format for each Byte

Data byte Stop/

parity

Stop

4.1.2 Timing Constraints

The Modbus Standard specifies two timing constraints.

Table 4.1 illustrates the inter-character timing which

determines that a message has been received.

NOTE

if the baud rate is greater than 19200, then the 3.5

character time is replaced by a timeout time of 1.75 ms.

NOTE

It is very important that the controller wait at least 3.5

character length otherwise the nodes can not separate the

telegrams.

There is an additional timing constraint, the framing error

time, as shown in Illustration 4.1. The Modbus specification

states that if a framing error occurs, the message should

frequency converter notes the occurrence of framing errors

and maintains a counter for them, but it does not discard

the message.

be considered invalid and discarded. The variable speed

12 MG92B102 - VLT® is a registered Danfoss trademark

Page 14

Modbus RTU Message Framing ... Modbus RTU Operating Instruction

4.1.3 Modbus RTU Message Structure

The transmitting device places a Modbus RTU message

into a frame with a known beginning and ending point.

This allows receiving devices to begin at the start of the

message, read the address portion, determine which

device is addressed (or all devices, if the message is

broadcast), and to recognise when the message is

completed. Partial messages are detected and errors set as

a result. Characters for transmission must be in

hexadecimal 00 to FF format in each field. The frequency

converter continuously monitors the network bus, also

during ‘silent’ intervals. When the first field (the address

field) is received, each frequency converter or device

decodes it to determine which device is being addressed.

Modbus RTU messages addressed to zero are broadcast

messages. No response is permitted for broadcast

messages. A typical message frame is shown in Table 4.2.

Start Address Function Data CRC

T1-T2-T3-T48 bits 8 bits N x 8

bits

check

16 bits T1-T2-T3-

End

T4

address in this address field to let the master know which

slave is responding.

4.1.6 Function Field

The function field of a message frame contains 8 bits. Valid

codes are in the range of 1-FF. Function fields are used to

send messages between master and slave. When a

message is sent from a master to a slave device, the

function code field tells the slave what kind of action to

perform. When the slave responds to the master, it uses

the function code field to indicate either a normal (errorfree) response, or that some kind of error occurred (called

an exception response). For a normal response, the slave

simply echoes the original function code. For an exception

response, the slave returns a code that is equivalent to the

original function code with its most significant bit set to

logic 1. In addition, the slave places a unique code into the

data field of the response message. This tells the master

what kind of error occurred, or the reason for the

exception. Also refer to the sections 4.1.10 Function Codes

Supported by Modbus RTU and 9.1.1 Modbus Exception

Codes.

4 4

Table 4.2 Typical Modbus RTU Message Structure

Start/Stop Field

4.1.4

Messages start with a silent period of at least 3.5 character

intervals. This is implemented as a multiple of character

intervals at the selected network baud rate (shown as Start

T1-T2-T3-T4). The first field to be transmitted is the device

address. Following the last transmitted character, a similar

period of at least 3.5 character intervals marks the end of

the message. A new message can begin after this period.

The entire message frame must be transmitted as a

continuous stream. If a silent period of more than 1.5

character intervals occurs before completion of the frame,

the receiving device flushes the incomplete message and

assumes that the next byte will be the address field of a

new message. Similarly, if a new message begins before

3.5 character intervals after a previous message, the

receiving device considers it a continuation of the previous

message. This causes a time-out (no response from the

slave), since the value in the final CRC field is not valid for

the combined messages.

4.1.5

Address Field

The address field of a message frame contains 8 bits. Valid

slave device addresses are in the range of 0 – 247 decimal.

The individual slave devices are assigned addresses in the

range of 1 – 247. (0 is reserved for broadcast mode, which

all slaves recognize.) A master addresses a slave by placing

the slave address in the address field of the message.

When the slave sends its response, it places its own

Data Field

4.1.7

The data field is constructed using sets of two hexadecimal

digits, in the range of 00 to FF hexadecimal. These are

made up of one RTU character. The data field of messages

sent from a master to slave device contains additional

information which the slave must use to take the action

defined by the function code. This can include items such

as coil or register addresses, the quantity of items to be

handled, and the count of actual data bytes in the field.

CRC Check Field

4.1.8

Messages include an error-checking field, operating on the

basis of a Cyclical Redundancy Check (CRC) method. The

CRC field checks the contents of the entire message. It is

applied regardless of any parity check method used for the

individual characters of the message. The CRC value is

calculated by the transmitting device, which appends the

CRC as the last field in the message. The receiving device

recalculates a CRC during receipt of the message and

compares the calculated value to the actual value received

in the CRC field. If the two values are unequal, a bus timeout occurs. The error-checking field contains a 16-bit

binary value implemented as two 8-bit bytes. When this is

done, the low-order byte of the field is appended first,

followed by the high-order byte. The CRC high-order byte

is the last byte sent in the message.

MG92B102 - VLT® is a registered Danfoss trademark 13

Page 15

Modbus RTU Message Framing ... Modbus RTU Operating Instruction

4.1.9 Coil and Register Addressing

In Modbus, all data are organized in coils and holding

registers. Coils hold a single bit, whereas holding registers

hold a 2-byte word (i.e. 16 bits). All data addresses in

Modbus messages are referenced to zero. The first

occurrence of a data item is addressed as item number

zero. For example: The coil known as ‘coil 1’ in a

programmable controller is addressed as coil 0000 in the

44

data address field of a Modbus message. Coil 127 decimal

is addressed as coil 007EHEX (126 decimal).

Holding register 40001 is addressed as register 0000 in the

data address field of the message. The function code field

already specifies a ‘holding register’ operation. Therefore,

the ‘4XXXX’ reference is implicit. Holding register 40108 is

addressed as register 006BHEX (107 decimal).

See 4.1.11 Coil Addresses for details regarding Coil

Addresses and 4.1.12 Register Addresses for details

Function

Read coils 1 hex

Read holding registers 3 hex

Write single coil 5 hex

Write single register 6 hex

Write multiple coils F hex

Write multiple registers 10 hex

Get comm. event counter B hex

Report slave ID 11 hex

Function Function

Code

Diagnostics 8 1 Restart communication

Subfunction

code

2 Return diagnostic register

10 Clear counters and

11 Return bus message

regarding Register Addresses

12 Return bus communi-

4.1.10

Danfoss FC Series Modbus RTU supports use of the

Function Codes Supported by

Modbus RTU

13 Return bus exception

14 Return slave message

following function codes in the function field of a

Function Code

Sub-function

diagnostic register

count

cation error count

error count

count

message.

4.1.11 Coil Addresses

Table 4.3 shows the coils addresses. Notice that the coil

known as ‘coil 1’ in a programmable controller is

addressed as coil 0000 in the data address field of a

Modbus message.

Coil Number Description Signal Direction

1-16

17-32 Frequency converter speed or set-point reference Range 0x0 – 0xFFFF (-200% ...

33-48

49-64 Open loop mode: Frequency converter output frequency Closed loop mode:

65 Parameter write control (master to slave) Master to slave

66-65536 Reserved

Table 4.3 Coil Addresses

Frequency converter control word (see Table 4.4)

~200%)

Frequency converter status word (see Table 4.5)

frequency converter feedback signal

0 = Parameter changes are written to the RAM of the frequency

converter

1 = Parameter changes are written to the RAM and EEPROM of the

frequency converter.

Master to slave

Master to slave

Slave to master

Slave to master

14 MG92B102 - VLT® is a registered Danfoss trademark

Page 16

Modbus RTU Message Framing ... Modbus RTU Operating Instruction

Control Word (FC profile)

Coil 0 1

00 Reference value External selection lsb

01 Reference value External selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output frequency Use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data invalid

11 Relay 01 open Relay 01 active

12 Relay 02 open Relay 02 active

13 Parameter set-up Selection lsb

15 No function Reverse

Table 4.4 Control Word (FC profile)

Status Word (FC profile)

Coil 0 1

00 Control not ready Control ready

01 Drive not ready Drive ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved 06 No error Triplock

07 No warning Warning

08 Speed # reference Speed = reference

09 Local operation Bus control

10 Out of frequency limit Frequency limit OK

11 No operation In operation

12 Drive OK Stopped, auto start

13 Voltage OK Voltage exceeded

14 Torque OK Torque exceeded

15 TImer OK Timer exceeded

4 4

Table 4.5 Status Word (FC profile)

See 7 FC Control Profile for detail on the Control word,

reference, status word and Main Actual Value. The Coil 65

decimal determines whether data written to the frequency

converter are stored in EEPROM and RAM (coil 65 = 1) or

only in RAM (coil 65 =0). Notice that coil 65 needs to be

set On before writing to register are stored in EEPROM.

MG92B102 - VLT® is a registered Danfoss trademark 15

Page 17

Modbus RTU Message Framing ... Modbus RTU Operating Instruction

4.1.12 Register Addresses

Table 4.6 shows the register addresses.

Holding registers

Modbus Register Number Description

00001-00006 Reserved

00007 Last error code from an FC data object interface

44

00008 Reserved

00009 Parameter index*

00010-00099 000 parameter group (parameters 001 through 099)

00100-00199 100 parameter group (parameters 100 through 199)

00200-00299 200 parameter group (parameters 200 through 299)

... ...

02810-02873

02910-02973

... ...

00300-00399 300 parameter group (parameters 300 through 399)

00400-00499 400 parameter group (parameters 400 through 499)

... ...

28000-28999 2800 parameter group (parameters 2800 through 2899)

... ...

50000 Control word (CTW)

50010 Bus reference (Ref)

50200 Status word (STW).

50210 Main Actual Value (MAV)

Write data block (PCD Write via 8-42 PCD write configuration)

Read data block (PCD Read via 8-43 PCD read configuration)

4.1.13 Parameter Handling

Each parameter number is translated to a register address.

The parameter number is translated to Modbus holding

address as parameter number x 10 DECIMAL.

Notice that holding register 40001 is addressed as register

0000 in the data address field of the message. The

function code field already specifies a ‘holding register’

operation. Therefore, the ‘4XXXX’ reference is implicit.

Example: 3-41 Ramp 1 up time is address as holding

register 3410. In the message field of the telegram it will

be addressed as register 2809 (D51 Hex).

4.1.14

The Coil 65 decimal determines whether data written to

the frequency converter are stored in EEPROM and RAM

(coil 65=1) or only in RAM (coil 65=0).

Storage of Data

NOTE

Coil 65 needs to be set On before changed parameters are

stored in EEPROM and after a Power cycle coil 65 is set

back to default Off, meaning only in RAM.

4.1.15 IND

The array index is set in holding register 9 and used when

accessing array parameters. Some parameters like 8-43 PCD

read configuration have structures of an index and the

Modbus protocol does not support index parameters in

the telegram frame. To read or write to those parameters

requires that register 009 Parameter index contains the

index number, before a read or write is done. Example:

Setup 8-43 PCD Read Configuration index 2 to the value

[1613] Frequency.

1. Write [2] to register 009 Parameter index

2. Write [1613] to holding register 8430

3. Write [0] to register 009 Parameter index to set it

back to default 0

Notice after a power cycle register 009 Parameter index is

set it back to default 0.

4.1.16

Parameters stored as text strings are accessed in the same

way as the other parameters. The maximum text block size

is 20 characters. If a read request for a parameter is for

more characters than the parameter stores, the response is

truncated. If the read request for a parameter is for fewer

Text Blocks

16 MG92B102 - VLT® is a registered Danfoss trademark

Page 18

Modbus RTU Message Framing ... Modbus RTU Operating Instruction

characters than the parameter stores, the response is space

filled.

NOTE

Text blocks are only used together with Function code 11

hex Report slave ID.

4.1.17 Conversion Factor

Since a parameter value can only be transferred as a whole

number, a conversion factor must be used to transfer

decimals.

The conversion index for each parameter can be found in

the Programming guide.

Example: 4-12 Motor Speed Low Limit [Hz] has a conversion

factor of 0.1. To set the Motor Speed Low Limit frequency

to 10 Hz, transfer the value 100. A conversion factor of 0.1

means that the value transferred is multiplied by 0.1. The

value 100 is thus perceived as 10.0.

Conversion index Conversion factor

100

75

74

67

6 1000000

5 100000

4 10000

3 1000

2 100

1 10

0 1

-1 0.1

-2 0.01

-3 0.001

-4 0.0001

-5 0.00001

-6 0.000001

-7 0.0000001

UNSIGNED32 and SIGNED32

An unsigned and signed integer of 4 bytes fills two

registers with the following byte mapping.

Register 1 Register 2

Byte 3 Byte 2 Byte 1 Byte 0

Example:

Register Address: 40201–Value 0x0102

Register Address: 40202–Value 0x0304

A read of an UNSIGNED32/SIGNED32 from Modbus register

40201 with the quantity of 2, is: 0x01020304.

UNSIGNED16 and SIGNED16

An unsigned and signed integer of 2 bytes fills one

register with the following byte mapping.

Register 1

Byte 1 Byte 0

Example:

Register Address: 40201–Value 0x0102

A read of an UNSIGNED16 from register 40201 with the

quantity of 1, is: 0x0102.

UNSIGNED8 and SIGNED8

An unsigned and signed integer of 1 byte fills one register

with the following byte mapping.

Register 1

0x00 Byte 0

The data type for each parameter can be found in the

Programming guide.

4 4

Table 4.6 Conversion Table

4.1.18

Parameter Values

One Modbus holding register is specified as a 16 bit

register, i.e. the data range goes from 0–65535. Some

parameters in the frequency converterhave data types of

32 bit, so to be able the read or write to these parameters

two registers need to be accessed to have the correct data

value read or written.

In order to read and write the different supported data

types, the following conversions must be used.

MG92B102 - VLT® is a registered Danfoss trademark 17

Page 19

How to Control the Frequenc... Modbus RTU Operating Instruction

5 How to Control the Frequency Converter

5.1 How to Control the Frequency Converter

Modbus RTU provides access to control the frequency

converter via the Control Word like start/stop and to

control the speed of the frequency converter via a bus

reference. In the same way it also provides information of

Control Method Address Function Code (hex)

55

Coils

Register 50000 group

Register 28-1x and 29-10 group

1-16 Control word 05 Write single coil

17-32 Reference 0F Write Multiple coils

33-48 Status word

49-64 Main Actual Value

65 Parameter Write Control

50000 Control Word

50010 Reference

50200 Status word

50210 Main Actual Value

2810 Control word

2811 Reference

2812-2873

2910 Status word

2911 Main Actual Value

2912-2973

Register write via 8-42 PCD Write configuration

Register read via 8-43 PCD Read configuration

the frequency converter status like running, alarm etc. via

the Status Word and the Main Actual Value, i.e. the actual

running speed.

01 Read coils

05 Write single coil

01 Read coils

06 Write single register

03 Read holding register

06 Write single register

0F Write Multiple register

03 Read holding register

NOTE

Danfoss recommends only using one of the three

mentioned ways to control the frequency converter!

NOTE

Danfoss recommends register 2810-2873 and 2910-2973 to

control the frequency converter ensuring compatibility

with all controllers.

5.2 Parameter for Modbus RTU

5.2.1 Important Parameters for Modbus

RTU

Set the following parameters to enable the Modbus RTU

for the frequency converter.

Parameter no. Setting

8-30 Protocol

8-31 Address

8-32 FC Port Baud Rate

8-33 Parity / Stop Bits

Modbus RTU [2]

1-247

2400-19200

Even parity, 1 Stop Bit [0] default

Odd Parity, 1 Stop Bit [1]

No Parity, 1 Stop Bit [2]

No Parity, 1 Stop Bits [3]

NOTE

8-32 FC Port Baud Rate and 8-33 Parity / Stop Bits should

match the setting on the controller and other slaves on

the network.

Other important parameters to setup are how the control

of the frequency converter should be established and what

should happen with the motor control in case of bus time

out.

See also 8 Parameters.

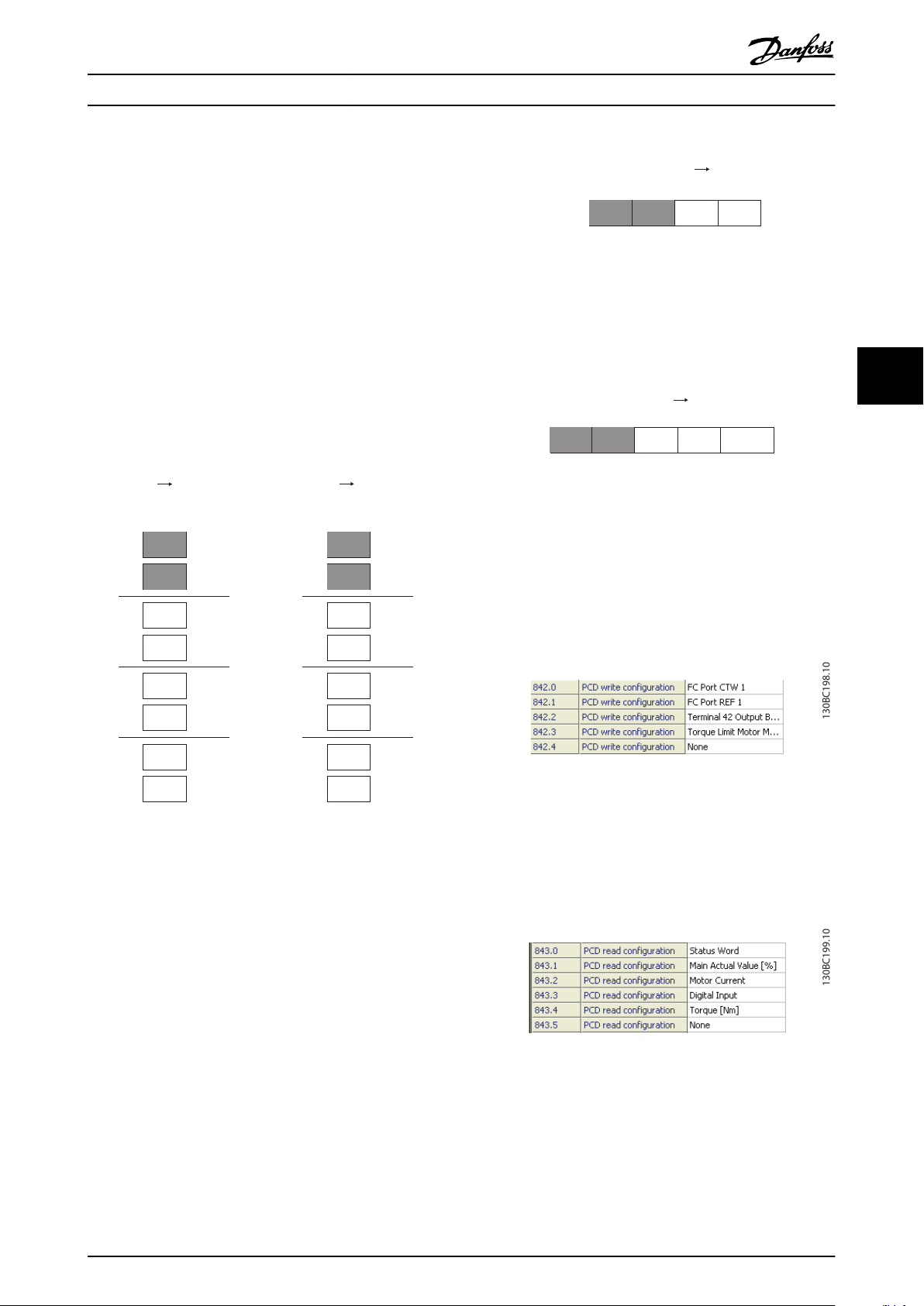

5.2.2 Access via PCD write/read

The advantage of using the PCD write/read configuration

is that the controller can write or read more data in one

telegram. Up to 63 registers can be read or written to via

the Function code Read Holding register or Write Multiple

Registers in one telegram. The structure is also flexible so

that only two registers can be written to and 10 registers

can be read from the controller.

The PCD write list is data send from the controller to the

frequency converter like Control word, Reference and

application dependent data like Minimum reference and

Ramp times.

18 MG92B102 - VLT® is a registered Danfoss trademark

Page 20

CTW

Holding

Register

2810

Write

Master Frequency Converter

Read

Frequency

Converter Master

Controlled by

Parameter

Holding

Register

Controlled by

Parameter

8-42 [0]

REF

2811

8-42 [1]

2812

8-42 [2]

PCD 2

write

2813

8-42 [3]

PCD 3

write

2814

8-42 [4]

PCD 4

write

2815

8-42 [5]

PCD 5

write

...

...

...

write

2873

8-42 [63]

PCD 63

write

STW

2910

8-43 [0]

MAV

2911

8-43 [1]

2912

8-43 [2]

PCD 2

read

2913

8-43 [3]

PCD 3

read

2914

8-43 [4]

PCD 4

read

2915

8-43 [5]

PCD 5

read

...

...

...

read

2919

8-43 [63]

PCD 63

read

130BC048.10

CTW

REF

Analog

output 42

Torque

limit

Register 2810

2811

2812

2813

Write

Frequency Converter Drive

CTW = Parameter 16-85,

Analog output = Parameter 6-52,

REF = Parameter 16-86,

Torque limit Motor mode = 4-16

130BC049.10

Motor

current

Digital

inputs

Actual

Torque [Nm]

Register 2910

2911

2912

2913

2914

Read

Frequency Converter Master

STW

MAV

130BC050.10

STW = Parameter 16-03,

Motor Current = Parameter 16-14,

Actual Torque [Nm]

MAV = Parameter 16-05,

Digital Inputs = Parameter 16-60

130BC198.10

130BC199.10

How to Control the Frequenc... Modbus RTU Operating Instruction

NOTE

The Control word and Reference is always sent in the list

from the controller to the frequency converter.

The PCD write list is setup in 8-42 PCD write configuration.

The PCD read list is data send from the frequency

converter to the controller like Status word, Main Actual

Value and application dependent data like Running Hours,

Motor current and Alarm word.

Example:

The frequency converter sends status word, main actual

value, actual motor current, digital inputs and torque [Nm]

NOTE

The Status word and Main Actual Value is always sent in

the list from the frequency converter to the Controller.

NOTE

The boxes marked in grey are not changeable, they are the

default values.

5 5

Example, continued

The input and output data of the Modbus RTU has to be

mapped to the Parameter of the frequency converter. This

is done in 8-42 PCD write configuration and 8-43 PCD read

configuration.

NOTE

Grey lines are fixed, red are user selectable.

Following parameters has to be set up in the frequency

converter:

NOTE

32 bit parameters must be mapped inside the 32 bit

boundaries, (PCD2 & PCD3 or PCD4 & PCD5 etc.) where the

parameter number is mapped twice to8-42 PCD write

configuration or 8-43 PCD read configuration.

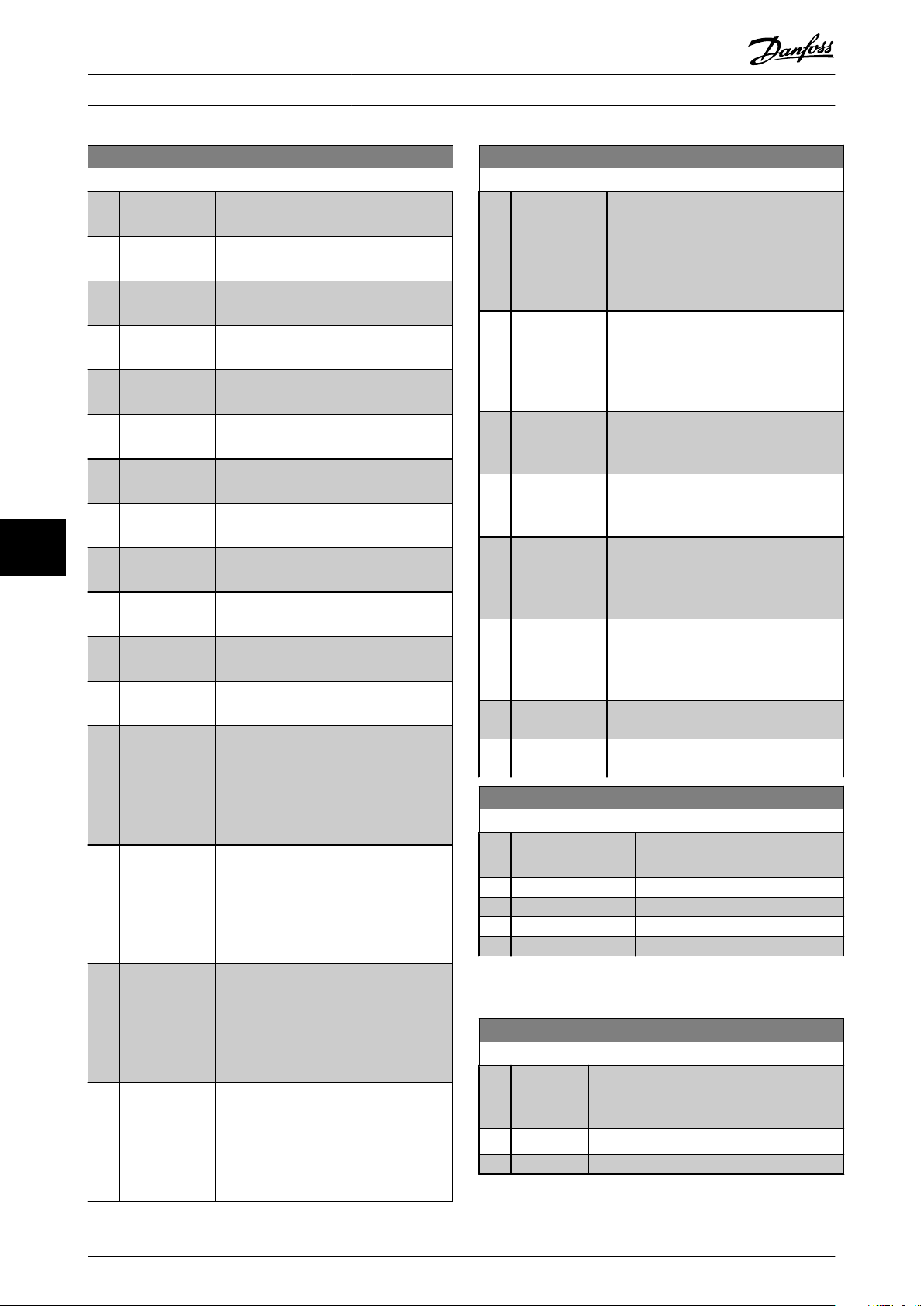

5.2.3 Mapping the Holding Registers to

Drive Parameters

Example:

The PLC sends control word, reference, set the analog

output 42 and set the torque limit

NOTE

The motor current in 16-14 Motor Current is 32 bit. This

mapping is only mapping the lower 16 bit, so the

maximum motor current readout is 327 Amps.

For higher Amp readout, user 32 bit readout.

MG92B102 - VLT® is a registered Danfoss trademark 19

Page 21

CTW

REF

Ramp 1

Ramp up Time

Register 2810

2811

2812

2813

Write

Master Frequency Converter

CTW = Parameter 16-85,

Ramp 1 Ramp up time 3-41,

REF = Parameter 16-86,

130BC053.10

Ramp 1

Ramp up Time

Motor

current

Digital

inputs

Register 2910

2911

2912

2913

2914

Read

Frequency Converter Master

STW

MAV

130BC054.10

STW = Parameter 16-03,

Motor Current = Parameter 16-14,

MAV = Parameter 16-05,

Digital Inputs = Parameter 16-60

Motor

current

130BC200.10

How to Control the Frequenc... Modbus RTU Operating Instruction

Mapping a 32 bit parameter as 16 bit always accesses the

16 lower bits.

5.2.4 Mapping the Holding Registers to

Drive Parameters, 32 bits

Example:

The PLC sends control word, reference and Ramp 1 Ramp

up Time

55

Example:

The frequency converter sends status word, main actual

value, actual motor current and digital inputs

Example 32 bit, continued

Following parameters has to be set up in the frequency

converter:

NOTE

The motor current in parameter 16-14 is mapped as 32 bit.

Motor current can be readout up to 42949672 Amps.

20 MG92B102 - VLT® is a registered Danfoss trademark

Page 22

Function Code Examples Modbus RTU Operating Instruction

6 Function Code Examples

NOTE

6.1 Examples

The following examples illustrate various Modbus RTU

commands. If an error occurs, refer to 9.1.1 Modbus

Exception Codes.

Coils and registers are addressed explicit with an off-set of

-1 in Modbus.

I.e. Coil 33 is addressed as Coil 32.

6.1.2 Force/Write Single Coil (05 HEX)

6.1.1 Read Coil Status (01 HEX)

Description

This function reads the ON/OFF status of discrete outputs

(coils) in the frequency converter. Broadcast is never

supported for reads.

Query

The query message specifies the starting coil and quantity

of coils to be read. Coil addresses start at zero, i.e. coil 33

is addressed as 32.

Example of a request to read coils 33-48 (Status Word)

from slave device 01.

Field Name Example (HEX)

Slave Address 01 (frequency converter address)

Function 01 (read coils)

Starting Address HI 00

Starting Address LO 20 (32 decimals) Coil 33

No. of Points HI 00

No. of Points LO 10 (16 decimals)

Error Check (CRC) -

Response

The coil status in the response message is packed as one

coil per bit of the data field. Status is indicated as: 1 = ON;

0 = OFF. The LSB of the first data byte contains the coil

addressed in the query. The other coils follow toward the

high order end of this byte, and from ‘low order to high

order’ in subsequent bytes.

If the returned coil quantity is not a multiple of eight, the

remaining bits in the final data byte will be padded with

zeros (toward the high order end of the byte). The Byte

Count field specifies the number of complete bytes of

data.

Field Name

Slave Address 01 (frequency converter address)

Function 01 (read coils)

Byte Count 02 (2 bytes of data)

Data (Coils 40-33) 07

Data (Coils 48-41) 06 (STW=0607hex)

Error Check (CRC) -

Example (HEX)

Description

This function forces the coil to either ON or OFF. When

broadcast the function forces the same coil references in

all attached slaves.

Query

The query message specifies the coil 65 (parameter write

control) to be forced. Coil addresses start at zero, i.e. coil

65 is addressed as 64. Force Data = 00 00HEX (OFF) or FF

00HEX (ON).

Field Name Example (HEX)

Slave Address 01 (frequency converter address)

Function 05 (write single coil)

Coil Address HI 00

Coil Address LO 40 (64 decimal) Coil 65

Force Data HI FF

Force Data LO 00 (FF 00 = ON)

Error Check (CRC) -

Response

The normal response is an echo of the query, returned

after the coil state has been forced.

Field Name

Slave Address 01

Function 05

Force Data HI FF

Force Data LO 00

Quantity of Coils HI 00

Quantity of Coils LO 01

Error Check (CRC) -

Example (HEX)

6.1.3 Force/Write Multiple Coils (0F HEX)

This function forces each coil in a sequence of coils to

either ON or OFF. When broadcast the function forces the

same coil references in all attached slaves.

The query message specifies the coils 17 to 32 (speed setpoint) to be forced.

6

6

MG92B102 - VLT® is a registered Danfoss trademark 21

Page 23

Function Code Examples Modbus RTU Operating Instruction

6

NOTE

Coil addresses start at zero, i.e. coil 17 is addressed as 16.

Field Name Example (HEX)

Slave Address 01 (frequency converter address)

Function 0F (write multiple coils)

Coil Address HI 00

Coil Address LO 10 (coil address 17)

Quantity of Coils HI 00

Quantity of Coils LO 10 (16 coils)

Byte Count 02

Force Data HI

(Coils 8-1)

Force Data LO

(Coils 16-9)

Error Check (CRC) -

Response

The normal response returns the slave address, function

code, starting address, and quantity of coils forced.

Field Name Example (HEX)

Slave Address 01 (frequency converter address)

Function 0F (write multiple coils)

Coil Address HI 00

Coil Address LO 10 (coil address 17)

Quantity of Coils HI 00

Quantity of Coils LO 10 (16 coils)

Error Check (CRC) -

6.1.4 Read Holding Registers (03 HEX)

Description

This function reads the contents of holding registers in the

slave.

Query

The query message specifies the starting register and

quantity of registers to be read. Register addresses start at

zero, i.e. registers 1-4 are addressed as 0-3.

Example: Read 3-03 Maximum Reference, register 03030.

20

00 (ref. = 2000 hex)

Response

The register data in the response message are packed as

two bytes per register, with the binary contents right

justified within each byte. For each register, the first byte

contains the high order bits and the second contains the

low order bits.

Example: Hex 0016E360=1.500.000=1500 RPM.

Field Name Example (HEX)

Slave Address 01

Function 03

Byte Count 04

Data HI

(Register 3030)

Data LO

(Register 3030)

Data HI

(Register 3031)

Data LO

(Register 3031)

Error Check

(CRC)

00

16

E3

60

-

6.1.5 Preset Single Register (06 HEX)

Description

This function presets a value into a single holding register.

Query

The query message specifies the register reference to be

preset. Register addresses start at zero, i.e. register 1 is

addressed as 0.

Example: Write to 1-00 Configuration Mode, register 1000.

Field Name

Slave Address 01

Function 06

Register Address HI 03 (Register address 999)

Register Address LO E7 (Register address 999)

Preset Data HI 00

Preset Data LO 01

Error Check (CRC) -

Example (HEX)

Field Name

Slave Address 01

Function 03 (read holding registers)

Starting Address HI 0B (Register address 3029)

Starting Address LO D5 (Register address 3029)

No. of Points HI 00

No. of Points LO 02 - (Par. 3-03 is 32 bits long, i.e.

Error Check (CRC) -

22 MG92B102 - VLT® is a registered Danfoss trademark

Example (HEX)

2 registers)

Response

The normal response is an echo of the query, returned

after the register contents have been passed.

Page 24

Function Code Examples Modbus RTU Operating Instruction

Field Name Example (HEX)

Slave Address 01

Function 06

Register Address HI 03

Register Address LO E7

Preset Data HI 00

Preset Data LO 01

Error Check (CRC) -

6.1.6 Preset Multiple Registers (10 HEX)

Description

This function presets values into a sequence of holding

registers.

Query

The query message specifies the register references to be

preset. Register addresses start at zero, i.e. register 1 is

addressed as 0. Example of a request to preset two

registers (set parameter 1-24=738 (7.38 A)):

6

6

Field Name Example (HEX)

Slave Address 01

Function 10

Starting Address HI 04

Starting Address LO D7

No. of Registers HI 00

No. of registers LO 02

Byte Count 04

Write Data HI

(Register 4: 1049)

Write Data LO

(Register 4: 1049)

Write Data HI

(Register 4: 1050)

Write Data LO

(Register 4: 1050)

Error Check (CRC) -

00

00

02

E2

Response

The normal response returns the slave address, function

code, starting address, and quantity of registers preset.

Field Name

Slave Address 01

Function 10

Starting Address HI 04

Starting Address LO D7

No. of Registers HI 00

No. of registers LO 02

Error Check (CRC) -

Example (HEX)

MG92B102 - VLT® is a registered Danfoss trademark 23

Page 25

Speed ref.CTW

Master-slave

130BA274.10

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit

no.:

FC Control Profile Modbus RTU Operating Instruction

7 FC Control Profile

7.1.1 Control Word According to FC Profile

(8-10 Protocol = FC profile)

Bit 02, DC brake

Bit 02 = ’0’ leads to DC braking and stop. Set braking

current and duration in 2-01 DC Brake Current and 2-02 DC

Braking Time.

Bit 02 = ’1’ leads to ramping.

Bit 03, Coasting

Bit 03 = ’0’: The frequency converter immediately "lets go"

of the motor, (the output transistors are "shut off") and it

coasts to a standstill.

Bit Bit value = 0 Bit value = 1

00 Reference value external selection lsb

01 Reference value external selection msb

02 DC brake Ramp

77

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output

frequency

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 Relay 01 open Relay 01 active

12 Relay 02 open Relay 02 active

13 Parameter set-up selection lsb

15 No function Reverse

use ramp

Bit 03 = ’1’: The frequency converter starts the motor if the

other starting conditions are met.

Make a selection in 8-50 Coasting Select to define how Bit

03 gates with the corresponding function on a digital

input.

Bit 04, Quick stop

Bit 04 = ’0’: Makes the motor speed ramp down to stop

(set in 3-81 Quick Stop Ramp Time).

Bit 05, Hold output frequency

Bit 05 = ’0’: The present output frequency (in Hz) freezes.

Change the frozen output frequency only with the digital

inputs (5-10 Terminal 18 Digital Input to 5-13 Terminal 29

Digital Input) programmed to Speed up = 21 and Slow down

= 22.

Explanation of the Control Bits

Bits 00/01

Bits 00 and 01 are used to choose between the four

reference values, which are pre-programmed in 3-10 Preset

Reference according to the Table 7.1.

Programmed ref.

value

1

2

3

4

Table 7.1 Control bits

NOTE

Make a selection in 8-56 Preset Reference Select to define

how Bit 00/01 gates with the corresponding function on

the digital inputs.

24 MG92B102 - VLT® is a registered Danfoss trademark

Parameter Bit 01 Bit 00

3-10 Preset Reference [0]

3-10 Preset Reference [1]

3-10 Preset Reference [2]

3-10 Preset Reference [3]

0 0

0 1

1 0

1 1

NOTE

If Freeze output is active, the frequency converter can only

be stopped by the following:

Bit 03 Coasting stop

•

Bit 02 DC braking

•

Digital input (5-10 Terminal 18 Digital Input to

•

5-13 Terminal 29 Digital Input) programmed to DC

braking = 5, Coasting stop = 2, or Reset and

coasting stop = 3.

06, Ramp stop/start

Bit

Bit 06 = ’0’: Causes a stop and makes the motor speed

ramp down to stop via the selected ramp down parameter.

Bit 06 = ’1’: Permits the frequency converter to start the

motor, if the other starting conditions are met.

Make a selection in 8-53 Start Select to define how Bit 06

Ramp stop/start gates with the corresponding function on

a digital input.

Page 26

Output freq.STW

Bit

no.:

Slave-master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

130BA273.10

FC Control Profile Modbus RTU Operating Instruction

Bit 07, Reset Bit 07 = ’0’: No reset.

Bit 07 = ’1’: Resets a trip. Reset is activated on the signal’s

leading edge, i.e. when changing from logic ’0’ to logic ’1’.

Bit 08, Jog

Bit 08 = ’1’: The output frequency is determined by

3-11 Jog Speed [Hz].

Bit 09, Selection of ramp 1/2

Bit 09 = "0": Ramp 1 is active (3-41 Ramp 1 Ramp up Time

to 3-42 Ramp 1 Ramp Down Time).

Bit 09 = "1": Ramp 2 (3-51 Ramp 2 Ramp up Time to

3-52 Ramp 2 Ramp down Time) is active.

Bit 10, Data not valid/Data valid

Tell the frequency converter whether to use or ignore the

control word.

Bit 10 = ’0’: The control word is ignored. Bit 10 = ’1’: The

control word is used. This function is relevant because the

telegram always contains the control word, regardless of

the telegram type. Turn off the control word if not wanting

to use it when updating or reading parameters.

Bit 11, Relay 01

Bit 11 = "0": Relay not activated.

Bit 11 = "1": Relay 01 activated provided that Control word

bit 11 = 36 is chosen in 5-40 Function Relay.

Bit 12, Relay 02

Bit 12 = "0": Relay 02 is not activated. Bit 12 = "1": Relay 02

is activated provided that Control word bit 12 = 37 is

chosen in 5-40 Function Relay.

Bit 13, Selection of set-up

Use bit 13 to choose from the 2 menu set-ups according

to the table.

Set-up

1 0

2 1

Bit 13

7.1.2

Status Word According to FC Profile

(STW) (8-30 Protocol = FC profile)

Bit Bit = 0 Bit = 1

00 Control not ready Control ready

01 Drive not ready Drive ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved 06 No error Triplock

07 No warning Warning

08

09 Local operation Bus control

10 Out of frequency limit Frequency limit OK

11 No operation In operation

12 Drive OK Stopped, auto start

13 Voltage OK Voltage exceeded

14 Torque OK Torque exceeded

15 Timer OK Timer exceeded

Speed ≠ reference

Explanation of the Status Bits

Bit 00, Control not ready/ready

Bit 00 = ’0’: The frequency converter trips.

Bit 00 = ’1’: The frequency converter controls are ready but

the power component does not necessarily receive any

power supply (in case of external 24 V supply to controls).

Bit 01, Drive ready

Bit 01 = ’1’: The frequency converter is ready for operation

but the coasting command is active via the digital inputs

or via serial communication.

Speed = reference

7 7

The function is only possible when Multi Set-Ups = 9 is

selected in 0-10 Active Set-up.

Make a selection in 8-55 Set-up Select to define how Bit 13

gates with the corresponding function on the digital

inputs.

Bit 15 Reverse

Bit 15 = ’0’: No reversing.

Bit 15 = ’1’: Reversing. In the default setting, reversing is

set to digital in 8-54 Reversing Select. Bit 15 causes

reversing only when Ser. communication, Logic or Logic

and is selected.

Bit 02, Coasting stop

Bit 02 = ’0’: The frequency converter releases the motor.

Bit 02 = ’1’: The frequency converter starts the motor with

a start command.

Bit 03, No error/trip

Bit 03 = ’0’ : The frequency converter is not in fault mode.

Bit 03 = ’1’: The frequency converter trips. To re-establish

operation, press [Reset].

Bit 04, No error/error (no trip)

Bit 04 = ’0’: The frequency converter is not in fault mode.

Bit 04 = “1”: The frequency converter shows an error but

does not trip.

MG92B102 - VLT® is a registered Danfoss trademark 25

Page 27

Actual output

freq.

STW

Slave-master

Speed ref.CTW

Master-slave

16bit

130BA276.10

FC Control Profile Modbus RTU Operating Instruction

Bit 05, Not used

Bit 05 is not used in the status word.

Bit 12 = ’1’: The inverter stops because of over

temperature but the unit does not trip and will resume

operation once the over temperature stops.

Bit 06, No error / triplock

Bit 06 = ’0’: The frequency converter is not in fault mode.

Bit 06 = “1”: The frequency converter is tripped and locked.

Bit 13, Voltage OK/limit exceeded

Bit 13 = ’0’: There are no voltage warnings.

Bit 13 = ’1’: The DC voltage in the frequency converter’s

Bit 07, No warning/warning

intermediate circuit is too low or too high.

Bit 07 = ’0’: There are no warnings.

Bit 07 = ’1’: A warning has occurred.

Bit 14, Torque OK/limit exceeded

Bit 14 = ’0’: The motor current is lower than the torque

Bit 08, Speed≠ reference/speed = reference

Bit 08 = ’0’: The motor is running but the present speed is

different from the preset speed reference. It might e.g. be

limit selected in 4-18 Current Limit.

Bit 14 = ’1’: The torque limit in 4-18 Current Limit is

exceeded.

the case when the speed ramps up/down during start/

stop.

Bit 08 = ’1’: The motor speed matches the preset speed

reference.

77

Bit 15, Timer OK/limit exceeded

Bit 15 = ’0’: The timers for motor thermal protection and

thermal protection are not exceeded 100%.

Bit 15 = ’1’: One of the timers exceeds 100%.

Bit 09, Local operation/bus control

Bit 09 = ’0’: [Off/Reset] is activate on the control unit or

Bus Speed Reference Value

7.1.3

Local control in F-02 Operation Method is selected. It is not

possible to control the frequency converter via serial

communication.

Bit 09 = ’1’ It is possible to control the frequency converter

via the fieldbus/serial communication.

Speed reference value is transmitted to the frequency

converter in a relative value in %. The value is transmitted

in the form of a 16-bit word; in integers (0-32767) the

value 16384 (4000 Hex) corresponds to 100%. Negative

figures are formatted by means of 2’s complement. The

Bit 10, Out of frequency limit

Bit 10 = ’0’: The output frequency has reached the value in

Actual Output frequency (MAV) is scaled in the same way

as the bus reference.

4-12 Motor Speed Low Limit [Hz] or 4-14 Motor Speed High

Limit [Hz].

Bit 10 = "1": The output frequency is within the defined

limits.

Bit 11, No operation/in operation

Bit 11 = ’0’: The motor is not running.

Bit 11 = ’1’: The frequency converter has a start signal or

the output frequency is greater than 0 Hz.

Bit 12, Drive OK/stopped, autostart:

Bit 12 = ’0’: There is no temporary over temperature on

the inverter.

The reference and MAV are scaled as follows:

26 MG92B102 - VLT® is a registered Danfoss trademark

Page 28

Reverse Forward

Par.3-00 set to

(1) -max- +max

Max reference Max reference

Par.3-00 set to

(0) min-max

Max reference

Forward

Min reference

100%

(4000hex)

-100%

(C000hex)

0%

(0hex)

Par.3-03 0 Par.3-03

Par.3-03

(4000hex)(0hex)

0% 100%

Par.3-02

130BA277.10

FC Control Profile Modbus RTU Operating Instruction

7 7

MG92B102 - VLT® is a registered Danfoss trademark 27

Page 29

Parameters Modbus RTU Operating Instruction

8 Parameters

8-03 Control Word Timeout Time

8.1 Parameters: 8-** Communications and

Options

8.1.1 8-0* General Settings

8-01 Control Site

Option: Function:

The setting in this parameter overrides

the settings in 8-50 Coasting Select to

8-56 Preset Reference Select.

[0] * Digital and

ctrl.word

[1] Digital only Control by using digital inputs only.

[2] Controlword only Control by using control word only.

Control by using both digital input and

control word.

88

8-02 Control Word Source

Select the source of the control word: one of two serial interfaces

or four installed options. During initial power-up, the frequency

converter automatically sets this parameter to [3] Option A if it

detects a valid Fieldbus option installed in slot A. If the option is

removed, the frequency converter detects a change in the

configuration, sets 8-02 Control Word Source back to default

setting RS-485, and the frequency converter trips. If an option is

installed after initial power-up, the setting of 8-02 Control Word

Source does not change, but the frequency converter trips and

displays: Alarm 67 Option Changed.

When retrofitting a bus option into a frequency converter, that

did not have a bus option installed to begin with, take an

ACTIVE decision to move the control to Bus based. This is done

for safety reasons in order to avoid an accidental change.

Option: Function:

[0] None

[1] * FC RS485

[2] FC USB

[3] Option A

[4] Option B

[5] Option C0

[6] Option C1

[30] External Can

NOTE

This parameter cannot be adjusted while the motor is

running.

Range: Function:

1.0 s* [Application

dependant]

Enter the maximum time expected to

pass between the reception of two

consecutive telegrams. If this time is

exceeded, it indicates that the serial

communication has stopped. The

function selected in 8-04 Control Word

Timeout Functionis then carried out. A