Page 1

Data sheet

CI-tronic™ Soft starters for Danfoss commercial

compressor applications

Type MCI 15C, MCI 25C, MCI 50CM-3 I-O

The MCI compressor soft starters are designed for

soft starting of 3 phase compressors.

During start the MCI will gradually increase the

voltage to the motor until it reaches full line

voltage.

The soft start ramp-up time and initial start

torque is preset to ensure a fast start and allow

easy and quick installation.

MCI compressor soft starters are ideal for use on

Danfoss Performer scroll and Maneurop

Reciprocating compressors. The starting current

can be reduced by up to 40% of the direct on line

value.

Features • Universal control voltage: 24 – 480 V AC/DC

• Automatic detection of missing phases

• LED Status indication.

• Automatic adaptation to 50/60 Hz

• Easy and quick installation

• Up to 12 start/stop operations per hour

• Built in varistor protection

• IP20 Protection

• Compact modular design

• DIN rail mountable

• Ramp-time max. 0.5 s (factory set-up)

• EN 60947-4-2

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.B3.02 | 1

Page 2

Data sheet | CI-tronic™ Soft starters for Danfoss commercial compressor applications, Type MCI 15C, MCI 25C, MCI 50CM-3 I-O

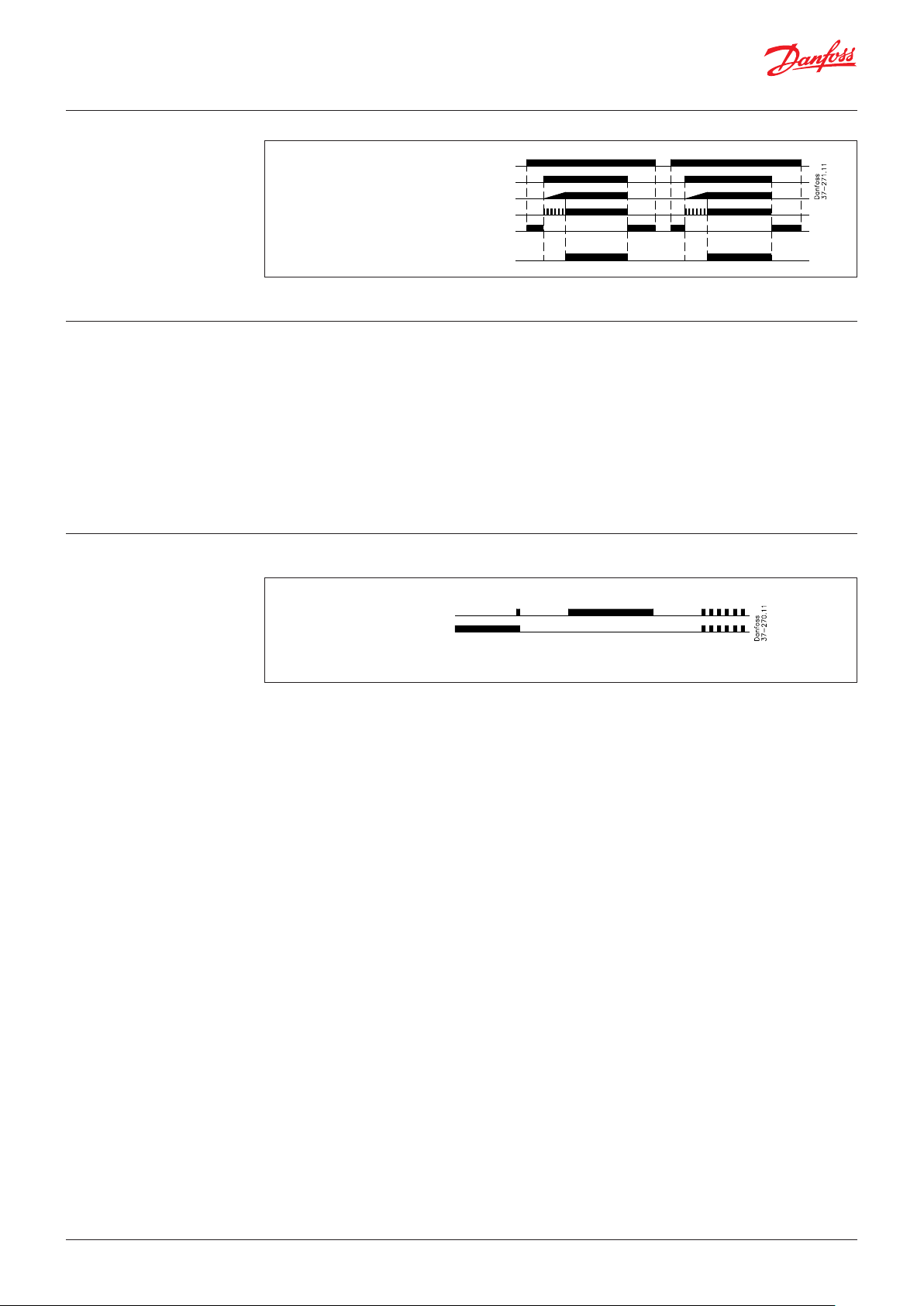

Functional diagram

Mains voltage, L1, L2, L3

Control voltage (A1, A2)

Motor voltage ( T1, T2, T3)

LED 1

LED 2

23-24 bypass (MCI 25C/MCI 50CM-3 I-O)

SCR contact:

Functional description

LED status indication

Start

During ramp-up the controller will gradually

increase the voltage to the motor from the preset

initial torque value until it reaches full line

voltage. The actual ramp time is digitally

calculated and will not be influenced by net

frequency or load variations.

LED 1

LED 2

Stand Ramp Full Line or

by up on load error

Bypass mode (contact 23-24, only MCI 25C/

MCI 50CM-3 I-O)

The auxiliary contacts are made possible by

means of SCR technology and will only switch

correctly on a.c. current. The contact is intended

for operating an external bypass contactor. The

contact will close when the controller is in steady

state operation, see application example page 7.

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.B3.02 | 2

Page 3

Data sheet | CI-tronic™ Soft starters for Danfoss commercial compressor applications, Type MCI 15C, MCI 25C, MCI 50CM-3 I-O

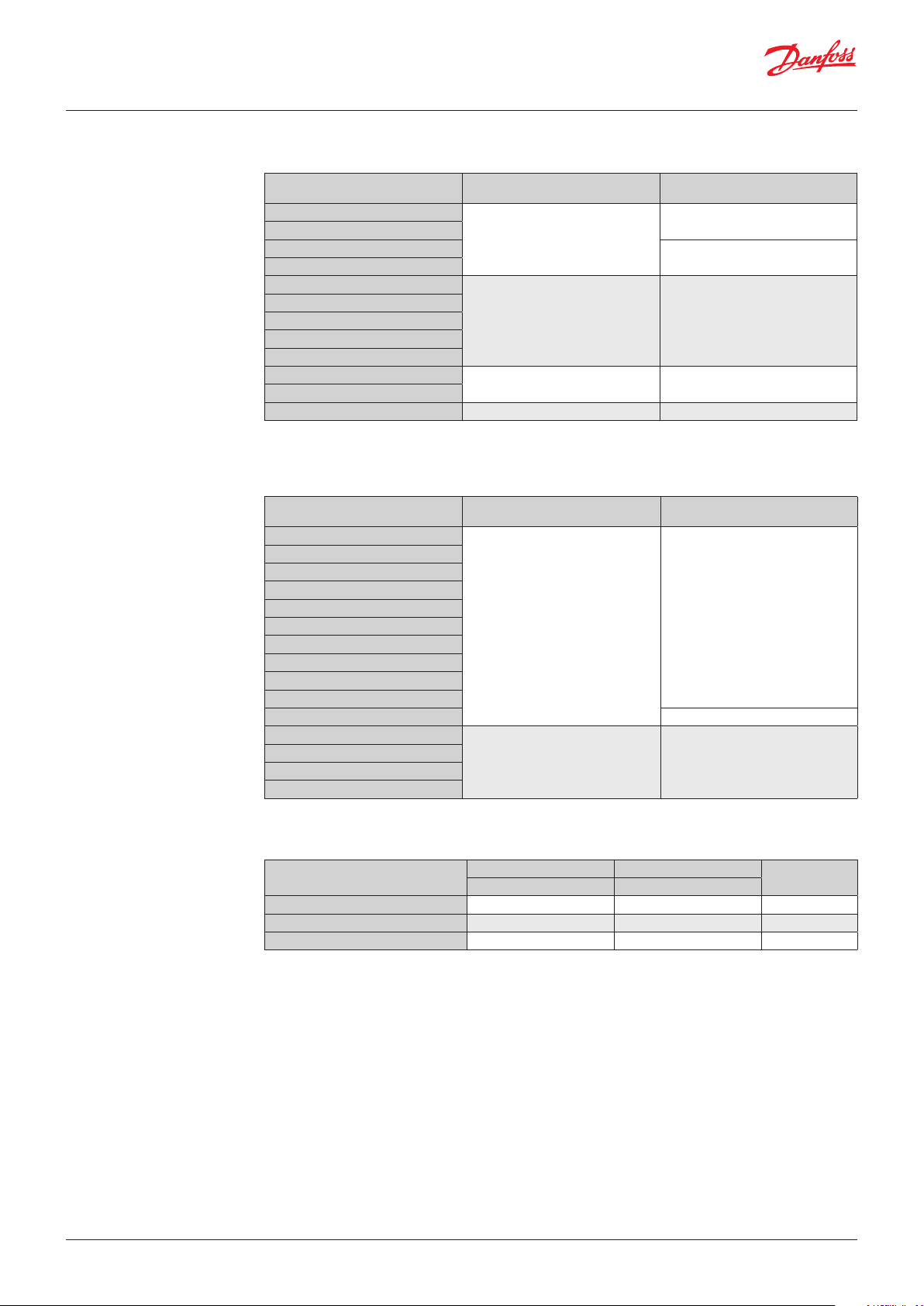

Soft starter selection guide

Performer® scroll compressors

Motor voltage code 4, 400 V - 3 phase - 50 Hz / 460 V - 3 phase - 60 Hz

Compressor model

SM/SZ 084

SM/SZ 090

SM/SZ 100

SM/SZ 110

SM/SZ 115-125

SM/SZ 120

SM/SZ 160

SM/SZ 148-161

SM/SZ 175-185

SY/SZ 240

SY/SZ 300

SZ 380 MCI 50CM-3 I-O 1) MCI 50CM-3 I-O 1)

) The controller must be by-passed in steady state mode. See application example page 7

Soft starter type

Ambient temp. max. 40 °C

MCI 15C

MCI 25C MCI 25C 1)

MCI 50CM-3 I-O 1) MCI 50CM-3 I-O 1)

Soft starter type

Ambient temp. max. 55 °C

MCI 15C

MCI 25C

Maneurop® compressors

Motor voltage code 4, 400 V - 3 phase - 50 Hz / 460 V - 3 phase - 60 Hz

Compressor model

MT/MTZ 18-22

MT/MTZ 28

MT/MTZ 32

MT/MTZ 36

MT/MTZ 40

MT/MTZ 44-50

MT/MTZ 45-51

MT/MTZ 56

MT/MTZ 57-65

MT/MTZ 64

MT/MTZ 72-73-80-81 MCI 25C

MT/MTZ 100

MT/MTZ 125

MT/MTZ 144

MT/MTZ 160

) The controller must be by-passed in steady state mode. See application example page 7

Soft starter type

Ambient temp. max. 40 °C

MCI 15C

MCI 25C MCI 25C 1)

Soft starter type

Ambient temp. max. 55 °C

MCI 15C

© Danfoss | DCS (az) | 2018.04

MCI C Soft Starter selection

Type

MCI 15C 380 – 480 45 037N0076

MCI 25C 380 – 480 90 037N0077

MCI 50CM-3 I-O 380 – 480 180 037N0401

Operational voltage Module dimensions

[V AC] [mm]

Code no.

IC.PD.C50.B3.02 | 3

Page 4

Data sheet | CI-tronic™ Soft starters for Danfoss commercial compressor applications, Type MCI 15C, MCI 25C, MCI 50CM-3 I-O

Technical data

Output specifications MCI 15C MCI 25C MCI 50CM-3 I-O

Operational voltage V AC 380 – 480 380 – 480 380 – 480

Operational current (AC-3, AC-53a, AC-53b) max. 15 A 25 A / 30 A 35 A / 50 A

Ramp up time (preset) max. 0.4 s 0.4 s 0.5 s

Leakage current max. 5 mA 5 mA 5 mA

Operational current min. 50 mA 50 mA 50 mA

Overload relay trip class Class 10 Class 10 Class 10

Semiconductor protection fusing:

Type 1 1) co-ordination 50 A gL/gG 100 A gL/gG 125 A gL/gG

Type 2 2) co-ordination I2t(t=10 ms) 1800 A2 S 6300 A2 S 25300 A2 S

Rating index:

AC-53a Asynchronous motors 3)

15A: AC-53a:

8-3: 100-3000

AC-53b Asynchronous motors with bypass -

1)

Type 1 coordination require that, under short-circuit conditions, the device shall cause no danger to persons or installation and

may not be suitable for further use without repair and replacement of parts

2)

Type 2 coordination require that, under short-circuit conditions, the device shall cause no danger to persons or installation and

shall be suitable for further use

3)

15A: AC-53a: 8-3:100-3000 means max. load 8x15A for 3 seconds. 100% ON-load factor or 3000 operations per hour

25A: AC-53a:

8-3: 100-3000

30A: AC-53b:

6-3: 30

35A: AC-53a:

6-6: 100-120

50A: AC-53b:

6-3: 30

Control circuit specifications

Control voltage range 24 – 480 V AC/DC

Pick-up voltage max. 20.4 V AC/DC

Drop-out voltage min. 5 V AC/DC

Control current for no operation max. 1 mA

Control current / power max. 15 mA / 2 VA

Response time max. 70 ms

SCR by-pass contact, optional

Voltage / current (AC-14, AC-15) max. 24 – 240 V / 0.5A 24 – 240 V / 0.5A 24 – 240 V / 1.0A

Fuse max. 10 A gL/gG, I2t max. 72 A2s

EMC immunity Meets requirements of EN 50082-1 and EN 500082-2

Insulation

Rated insulation voltage U

i

Rated impulse withstand voltage U

4 kV

imp

660 V AC

Installation category III

Thermal specification

Cooling method Natural convection

Mounting Vertical +/- 30°

Storage temperature range -20 °C – 80 °C

Enclosure degree / pollution degree IP20 / 3 IP20 / 3 IP10 / 3

Power dissipation, continuous duty max. 2 W/A 2 W/A 3 W/A

Power dissipation, intermittent duty max. 2 W/A × duty cycle 2 W/A × duty cycle 3 W/A × duty cycle

Materials

Housing self extinguishing PPO UL94V1

Heatsink aluminium Black anodized

Base Electroplated steel

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.B3.02 | 4

Page 5

Data sheet | CI-tronic™ Soft starters for Danfoss commercial compressor applications, Type MCI 15C, MCI 25C, MCI 50CM-3 I-O

Dimensions

MCI 15C MCI 25C

MCI 50CM-3 I-O

Mounting instructions

The controller is designed for vertical mounting.

If the controller is mounted horizontally the load

current must be reduced by 50%.

The controller needs no side clearance.

Clearance between two vertical mounted

controller must be minimum 80 mm (3.15”).

Clearance between controller and top and

bottom walls must be minimum 30 mm (1.2”).

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.B3.02 | 5

Page 6

Data sheet | CI-tronic™ Soft starters for Danfoss commercial compressor applications, Type MCI 15C, MCI 25C, MCI 50CM-3 I-O

Overload and short circuit

protection

Performer®

scroll compressors

Maneurop®

reciprocating compressors

Overload and short circuit protection is easily

achieved by installing a circuit breaker on the

line side of the motor controller. Select the circuit

breaker from the table below.

Motor voltage code 4 / 400 V - 3ph - 50 Hz / 460 V - 3ph - 60 Hz

Compressor type

SM/SZ 084 17 CTI 25M 047B3150

SM/SZ 090 17 CTI 25M 047B3150

SM/SZ 100 19 CTI 25M 047B3151

SM/SZ 110 20 CTI 25M 047B3151

SM/SZ 115 25 CTI 25M 047B3152

SM/SZ 120 29 CTI 25M 047B3152

SM/SZ 125 25 CTI 25M 047B3152

SM/SZ 148 32 CTI 45MB 047B3164

SM/SZ 161 32 CTI 45MB 047B3164

SM/SZ 160 29 CTI 25M 047B3152

SM/SZ 175 35 CTI 45MB 047B3164

SM/SZ 185 35 CTI 45MB 047B3164

SY/SZ 240 50 CTI 45MB 047B3165

Compressor type

MT/MTZ 18 5 CTI 25M 047B3147

MT/MTZ 22 6 CTI 25M 047B3148

MT/MTZ 28 7.5 CTI 25M 047B3148

MT/MTZ 32 8 CTI 25M 047B3149

MT/MTZ 36 9 CTI 25M 047B3149

MT/MTZ 40 10 CTI 25M 047B3149

MT/MTZ 44 9.5 CTI 25M 047B3149

MT/MTZ 45 9.5 CTI 25M 047B3149

MT/MTZ 50 12 CTI 25M 047B3150

MT/MTZ 51 11.5 CTI 25M 047B3149

MT/MTZ 56 12 CTI 25M 047B3150

MT/MTZ 57 12 CTI 25M 047B3150

MT/MTZ 64 15 CTI 25M 047B3150

MT/MTZ 65 14 CTI 25M 047B3150

MT/MTZ 72 15.5 CTI 25M 047B3150

MT/MTZ 73 17 CTI 25M 047B3150

MT/MTZ 80 18 CTI 25M 047B3151

MT/MTZ 81 19 CTI 25M 047B3151

MT/MTZ 100 22 CTI 25M 047B3151

MT/MTZ 125 27 CTI 25M 047B3152

MT/MTZ 144 30 CTI 45MB 047B3164

MT/MTZ 160 36 CTI 45MB 047B3164

Compressor max. current

[A]

Motor voltage code 4 / 400 V - 3ph - 50 Hz / 460 V - 3ph - 60 Hz

Compressor max. current

[A]

Be aware of the maximum prospective short

circuit current breaking capacity. For further

information please refer to the data sheet on the

circuit breaker.

Danfoss CTI

Type Code no.

Danfoss CTI

Type Code no.

Overheat protection If required, the controller can be protected

against overheating by inserting a thermostat in

the slot on the right-hand side of the controller.

Order: UP 62 thermostat, code no. 037N0050

For wiring connections see application examples

below.

© Danfoss | DCS (az) | 2018.04

IC.PD.C50.B3.02 | 6

Page 7

Danf

already on order pro

All trademarks in this material are property of the respec

Application examples

Overheat protection

The thermostat is connected in series with the

control circuit of the main contactor.

When the temp. of the heat sink exceeds 90 °C

the main contactor will be switched OFF.

This circuit requires manual reset to restart the

motor.

Line controlled soft start

When the contactor K1 is switched to the ONstate, the soft starter will start the motor,

according to the settings of the ramp-up time

and initial torque adjustments. When the

contactor K1 is switched to the OFF-state the motor will be switched off instantaneously.

In this application the contactor will have no load

during opertion.

The contactor will carry and break the nominal

motor current.

Danfoss

37N51

MCI 25 with bypass contactor

By means of the built-in auxiliary contact the

bypass function is easily achieved, see wiring

diagram from the side.

No heat is generated from the MCI.

As the contactor always switches in no-load

condition it can be selected on the basis of the

thermal current (AC-1).

(13-14 contact not applicable with MCI 25C and

MCI 50CM-3 I-O).

Input controlled soft start

When the control voltage is applied to A1 - A2,

the MCI soft starter will start the motor, according

to the settings of the Ramp-up time and Initial

torque adjustments. When the control voltage is

switched OFF, the motor will switch off

instantaneously.

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (az) | 2018.04

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

IC.PD.C50.B3.02 | 7

Loading...

Loading...