Technical Information

MCHXXX

Control Handle

powersolutions.danfoss.com

Technical Information

MCHXXX

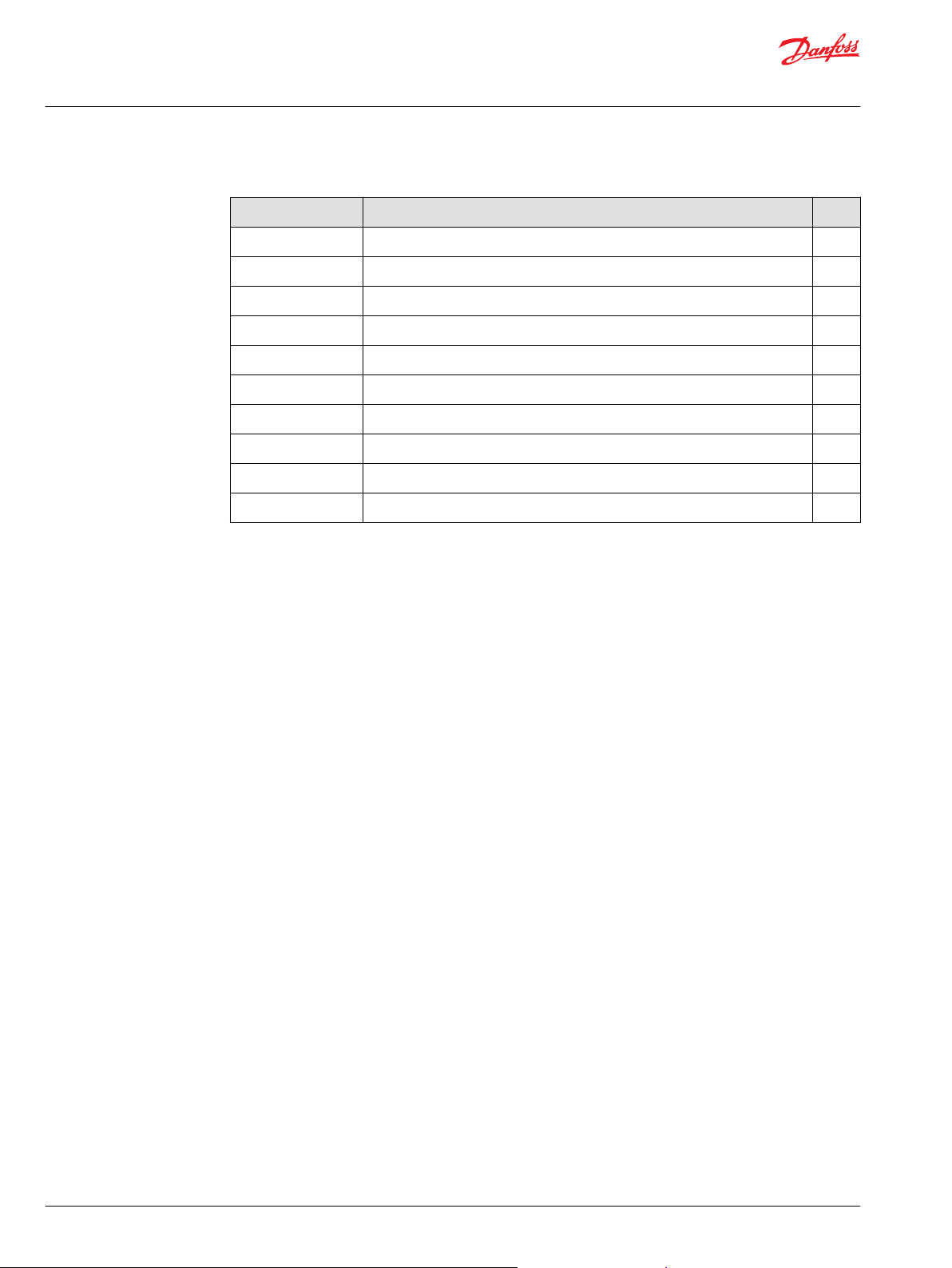

Revision history Table of revisions

Date Changed Rev

February 2017 MCHXXX Potentiometer Models with 1K Ohm table updated 0601

October 2016 Minor updates 0502

August 2016 Updated to Engineering Tomorrow design 0501

September 2013 Rebranded to Danfoss layout FA

January 2011 Various updates EA

May 2010 MCHXXX Potentiometer Models with 1K Ohm table updated DA

February 2010 MCHXXX Potentiometer Models with 1K Ohm table updated CA

August 2009 MCHXXX Potentiometer Models with 1K Ohm table updated BA

January 2009 Corrected operation and storage temperature AB

December 2008 First edition AA

2 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Technical Information

MCHXXX

Contents

Overview

Ordering information

Technical data

Installation

Connection diagrams

Device repair

Description..........................................................................................................................................................................................4

Features................................................................................................................................................................................................4

Ordering specification chart.........................................................................................................................................................5

Specifications.....................................................................................................................................................................................8

Environmental testing....................................................................................................................................................................9

Dimensions.......................................................................................................................................................................................10

Connectors....................................................................................................................................................................................... 10

Wiring.................................................................................................................................................................................................11

Potentiometer option ..................................................................................................................................................................14

Potentiometer option with 1K Ohm potentiometer ........................................................................................................14

PWM Option (primarily)...............................................................................................................................................................15

PWM option performance.....................................................................................................................................................16

Return to............................................................................................................................................................................................17

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 3

Technical Information

MCHXXX

Overview

Description

Features

The MCHXXX Single Axis Control Handle provides remote electrical actuation of Danfoss pumps/motors,

and or other electrically-actuated pump strokers for open loop control systems. The MCHXXX can

function as a setpoint for analog or microprocessor-controlled systems for controlling position, speed,

pressure, horsepower or other dynamic parameters.

Shock and vibration resistant

•

Choice of three mounting styles, with or without watertight case

•

Rugged components designed for the construction environment

•

High-torque handle actuation gives sure feel

•

Simple to install

•

Mechanical options include center-lock, spring-return, friction drag, uni/bi-directionality and optional

•

wire harness with a variety of electrical connectors

Electrical characteristics customized to the application

•

4 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Technical Information

MCHXXX

Ordering information

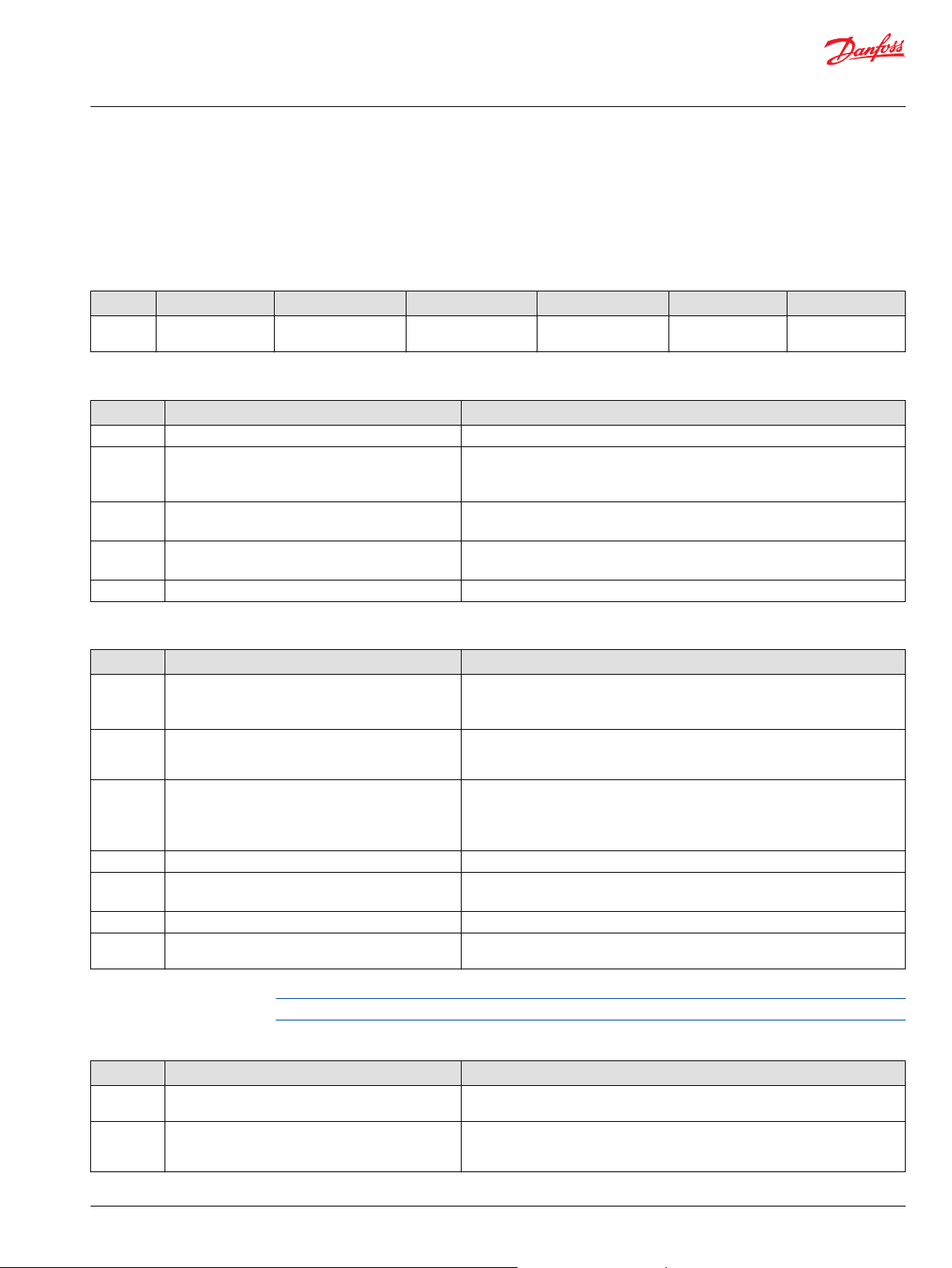

Ordering specification chart

A wide range of options to the basic control handle allow custom-tailoring to each application. The

following ordering specification chart is provided for assistance in determining model number. Other

options are possible, consult Danfoss with further questions.

Ordering specification chart

MCH X X X X X XXX

Mounting option Control knob type Handle actuation Electrical

characteristics

Mounting option

Code Description Detail

1 Base (surface) mount aluminum case Four screws connect to the flanges on the bottom of the metal case.

2 Top mount (drop in) with plastic case

3 Top mount (drop in) without case

4 Panel mount with plastic case

5 Panel mount without case Four screws connect to the top plate that holds the boot in place.

Two screws connect to an enlarged mounting plate.

Top mounting allows the entire handle to be removed from above the panel.

The case is made of black nylon plastic.

Two screws connect to an enlarged mounting plate.

Top mounting allows the entire handle to be removed from above the panel.

Four screws connect to the top plate that holds the boot in place.

The case is made of black nylon plastic.

Connector Factory assigned

Control knob option

Code Description Detail

1 Non-locking

2 Center lock The non-locking handle has a standard ballThe center lock handle has a

3 Non-locking, auxiliary push button switch

5 Non-locking, no knob The customer provides customized knob.

6 Three position maintained rocker switch

*

8

9 Three position momentary rocker switch This is the same as option 6, but the switch returns to the center position when

*

Unique configuration, for details contact your Danfoss representative.

Special (no handle or knob)

The friction-held handle detents with a springloaded ball to indicate null, while

the spring-return handle has a spring preload indicating null.The non-locking

handle has a standard ball knob.

cylindrical knob and provides a positive center lock that unlatches when the

operator pulls up on the knob.

This knob is teardrop shaped, with an auxiliary momentary push-button switch on

top.

The switch is wired through the handle shaft to the body with three wires

(common, normally open, and normally closed).

The cylindrical knob has a boot covering the three-position switch in the knob.

The switch, wired through the handle, is used for auxiliary functions.

released.

Reference Dimensions.

Handle actuation option

Code Description Detail

A Spring return, bi-directional This handle uses a torsion spring to return to the mechanical center position and

B Friction held, bi-directional This handle has an adjustable drag, set with a clamp-type brake that holds the

has 30 degrees of handle throw on either side of center.

handle at the set position and has 30 degrees of handle throw on either side of

the center detent.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 5

Technical Information

MCHXXX

Ordering information

Handle actuation option (continued)

Code Description Detail

C Friction held, uni-directional

D Special (friction held, center detent only, no brake)

Electrical characteristics option

Code Description Detail

A Proportional, no switches, 12 VDC

B Proportional, center off switch, 12 VDC, This handle has a center-off switch that ensures zero output voltage within ±3

C Proportional, center off switch, 24 VDC Same as option B except this handle runs on a supply voltage of 24 Volts.

D Proportional, center off and auxiliary switch, 12 VDC Same as option B except this handle has a second switch that actuates at +2 or -2

E Proportional, set-point potentiometer, 12 VDC Same as option B except this handle maintains the same polarity of signal in

F Step-plus-proportional, 12 VDC

G Step-plus-proportional, 24 VDC Same as option F, except this handle runs on a supply voltage of 24 Vdc.

H Switching This handle is non-proportional. Moving the handle off null activates switches

J Step-plus-proportional, full auxiliary switching, 12

K Proportional, unwired switch The customer uses the unwired center switch to operate an auxiliary function,

*

L

M Proportional, three switches The three switches are: a wired center switch; one unwired switch in forward; and

†

X

†

Y

†

Z

*

Option L, Electronic PWM auxiliary switching, 12 Vdc reached its end of life cycle in 2008 and is no longer available.

†

Unique configuration, for details contact your Danfoss representative.

VDC

Electronic PWM auxiliary switching, 12 Vdc

Special (no handle or knob)

Special

Special

This handle has 60 degrees of high-resolution of handle throw, rotating on only

one side of mechanical null, which is at full stroke.

It has no detent mechanism.

This handle’s output curve is fairly linear, with output voltage as a function of

handle stroke.

The supply voltage is 12 Volts, and there are no auxiliary function switches.

degrees of handle center position.

degrees.

forward or reverse.

This handle uses two switches to give the step-plus-proportional output current

on either side of null.

This overcomes deadbands in spool valves (see Specifications on page 8, StepPlus-Proportional-Control-Handle PWM option illustration).

Current beyond this step output is proportional through the rest of the handle

throw.

Full current output at 30 degrees handle stroke is maximum of 250 mA.

Step current is a maximum of 50% of full current output.

that power ON/OFF devices (for example, solenoid valves).

This handle uses the step switches for additional secondary functions.

Full current output at 30 degrees handle stroke is a maximum of 250 mA.

Step current is a maximum of 50% of full current output.

such as neutral start interlock.

This handle uses a printed circuit board that makes the step height and output

current fully adjustable, accommodating high current applications. It also has

pulse width modulation, that dithers the output to overcome hydraulic valve

stiction. Full current output at 30 degrees handle stroke is a maximum of 2 Amps

into a 5 Ohm load. Step current is a maximum 50% of full current output. Typical

dither frequencies (dependent on resistance of the load, specified in the suffix

number) are: 60 Hz for the HPI solenoid actuator, approximately 400 Hz for the

V7058 Hydrotransmission Valve and approximately 1000 Hz for the MCV101A/

MCV116A Pressure Control Pilot Valve.

one unwired switch in reverse.

6 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Technical Information

MCHXXX

Ordering information

Connector option

Code Description Detail

1 Terminal strip Electrical connections are made to a set of four internal or more screw terminals

2 Pigtail 1524 mm [60 in] without connector

3 Pigtail with unsealed Delphi connector

6 Pigtail with sealed Delphi connector, 4 pin male and

7 Pigtail sealed Delphi connector The wires from the case terminate in a sealed Delphi connector.

8 Pigtail sealed DEUTSCH connector The wires from the case terminate in a sealed DEUTSCH connector.

female

Pigtail (or leadwire) is routed from the control handle to a Delphi environmental connector. Pigtail

minimum length is 381 mm [15 in].

For optional connectors, contact your Danfoss representative.

Suffix number

The factory generates these final three numbers. To create the suffix number, supply the following

information:

•

Supply voltage

•

Number of additional switches needed and actuation angle of each with respect to null

•

Full current output

•

Resistance of the driven load

•

Step current needed (if necessary)

depending on the specific model.

Four wires extend from the handle case.

Reference Potentiometer option on page 14 for lengths.

The wires from the case terminate in a Delphi environmental connector.

Reference Potentiometer option on page 14.

There are two separate connectors, each connects to a separate potentiometer.

For details regarding unique configurations, contact your Danfoss representative.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 7

Output current

Adjustable

Adjustable

handle stroke

Dual-range

adjust option

1140B

30° 30°

Output current

Handle stroke

1139A

Technical Information

MCHXXX

Technical data

Specifications

Electrical

Operating voltage 11 to 15 Vdc (12 Volt models)

22 to 30 Vdc (24 Volt models)

*

Power

Load resistance

Switch current capability 3 Amps inductive at 28 Vdc

*

Customer specified. Reference Ordering specification chart on page 5.

*

Mechanical

Handle stroke ± 30º

Spring torque 1.2±.4 N•m [11±4 lbf•in] at center breakaway

2.0±.7 N•m [18±6 lbf•in] at full stroke

Detent torque (over and above friction drag) 1.1 N•m [10 lbf•in]

Friction drag

1.5±.3 N•m [13.5±3 lbf•in]

Friction is adjusted at the brake with a 5/32 inch internal hex

wrench and 3/8 inch open-end hex wrench.

Step-Plus-Proportional Control Handle: PWM option

PWM MCHXXX option reached its end of life cycle in 2008 and is no longer available.

Proportional Control Handle: Potentiometer option

8 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Technical Information

MCHXXX

Technical data

Environmental testing

Temperature

Operating -34º to 66ºC [-30º to 150ºF]

Storage -40º to 77ºC [-40º to 170ºF]

Humidity

After being placed in a controlled atmosphere of 95% humidity at 38ºC [100ºF] for 10 days, the control handle performs normally.

Rain

After being showered from all directions by a high pressure hose, the control handle performs normally (applied to cased models only). This test fulfills

NEMA 4 specifications (IP 65 equivalent).

Vibration

Withstands a vibration test designed for mobile equipment controls consisting of two parts:

1. Cycling from 5 to 2000 Hz in each of the 3 axes.

2. Resonance dwell for one million cycles for each resonance point in each of the 3 axes.

NEMA (National Electrical Manufacturer Association) NEMA 4 = Intended for indoor or outdoor use

primarily to provide a degree of protection against windblown dust and rain, splashing water, hosedirected water and external ice formation.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 9

149.1 max. [5.87]

136.4 ± 0.4 [5.37]

31.75

[1.25]

50.8 ± 0.4

[2.0]

63.76 max.

[2.51]

6.35

[0.25]

6.35

[0.25]

7.1 (4)

[0.279]

Panel cutout and

mounting plate

138.0

[5.43]

7.0

[0.275]

33.3

[1.31]

66.6

[2.62]

124.0 [4.88]

150.5 max. [5.93]

85.5 max.

[3.37]

4.5 ± 0.008 [2.0]

Mounting plate

Mounting plate

50.8

[2.0]

50.8

[2.0]

25.4

[1.0]

25.4

[1.0]

54.0

[2.12]

Remove burrs

from both sides of panel

to avoid damaging boot

6.2 (4)

[0.245]

Customer

panel

Customer

panel

251.5 max.

[9.9]

113 max.

[4.45]

29.5 [1.16]

60.4

[2.38]

60.4

[2.38]

121.3 max. [4.78] 121.3 max. [4.78]

Top (drop in)

mount

Customer

panel

Tapping

screws

(2)

30º ref. 30º ref. 30º ref. 30º ref. 30º ref. 30º ref. 30º ref. 30º ref.

302.0 max.

[11.88]

121.0 max. [4.76] 121.0 max. [4.76]

120.0 max.

[4.72]

14.2

[0.56]

27.0

[1.06]

269.2 max.

[10.6]

29.5 max.

[1.16]

Surface mount

96.0 max.

[3.78]

97.6 max.

[3.84]

120.0 max.

[4.72]

149.9 max.

[5.9]

114.6

max.

[4.51]

44.4

[1.75]

64.1 max.

[2.52]

Panel mount

Side view

of all

panel mount

Remove collar

that retains boot

and discard

29.5 [1.16]

1135D

3 or 4 pin Delphi Connector

Power +

Speed

Ground

Direction

A

B

C

D

3524A

4 pin Deutsch Plug DT Series Connector

A

Power +

C

Ground

B

Speed

D

Direction

3525

Technical Information

MCHXXX

Installation

Dimensions

MCHXXX Control Handle mounting dimensions in mm [in]

Connectors

10 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

W

Trim Terminal As Shown (2)

Shroud (Ref)

Terminals (6) (Ref)

Insulation Crimp*

Leadwire Crimp*

* Crimp before inserting terminal into body

1137B

Technical Information

MCHXXX

Installation

Wiring

For optional connectors, contact your Danfoss representative.

A barrier terminal strip inside the handle’s case provides connections to power, ground, and

potentiometers when no external cable is ordered. Run a cable from the strip through the strain relief

provided on the side or bottom of the case. Reference Potentiometer option on page 14. A clockwise

handle movement causes a current flow from terminal B to A when the terminal strip is facing you.

Warning

An unforeseen failure may cause an output which could activate a valve or pump. Unexpected vehicle or

mechanism movement can endanger people or damage equipment. Handles equipped with a center-off

switch will mitigate this condition. When an active neutral is necessary, provide an operator-presence

interlock and/or braking system sufficient to stop and hold the system or vehicle.

In most applications, auxiliary switches must be customer-wired, as shown in Potentiometer option on

page 14. When the switch is used as a center-off, power is connected from the external 12 Volt supply

to the terminal labeled common. The switch terminals are 3/16 inch quick-connect. PWM Option

(primarily) on page 15 shows a pre-wired control handle with center-off switch and Delphi connector,

exhibiting the handle phasing and color coding of the wires.

The following illustration shows how to assemble the mating Delphi connector (male shell, female

sockets) used in PWM Option (primarily) on page 15.

Delphi mating connector bag assembly (order seperately from handle)

Description Danfoss part number

Six sockets K03370

One plastic connector body

Unsealed Delphi mating connector assembly

For optional connectors, contact your Danfoss representative.

PWM MCHXXX option models are fitted with trim potentiometers for adjusting the output current. The

following illustration shows the location of the three trim potentiometers on the L handle. There are

either 3 or 4 trim potentiometers depending on the specific MCHXXX model. Reference Ordering

specification chart on page 5, Electrical characteristics option table, Code M—Proportional, three

switches.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 11

C

T

F

R

Step Current Adjust

Forward*

Reverse*

* Span adjust or full current output

1138B

Reverse threshold*

Forward full stroke*

Reverse full stroke*

Forward threshold*

2382

* Clockwise increases output

Technical Information

MCHXXX

Installation

Caution

Overcurrent could damage the control handle. Use a 1 Amp fuse in series for applications with low

current requirements to avoid damaging the control handle.

MCHXXX PWM option with trim potentiometer configurations

Handle adjustments

PWM MCHXXX option reached its end of life cycle in 2008 and is no longer available.

L control handles

Standard L

L with (2) threshold adjustments

12 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Threshold adjustment

Counter clockwise increases output

Forward full stroke

Clockwise increases output

Reverse full stroke

Clockwise increases output

Forward threshold

Counter clockwise increases output

Reverse threshold

Clockwise increases output

Forward full stroke

Clockwise increases output

Reverse full stroke

Clockwise increases output

Technical Information

MCHXXX

Installation

L control handles (continued)

L with acceleration/ deceleration Ramp

Threshold adjustment

Counter clockwise increases output

Forward full stroke

Clockwise increases output

Reverse full stroke

Clockwise increases output

Acceleration/deceleration ramp

Clockwise increases time

Option L, Electronic PWM auxiliary switching, 12 Vdc reached its end of life cycle in 2008 and is no longer

available.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 13

1224B

From Potentiometer +

From +

Torque Motor

12 or 24 VdcGround

-

B

A

+

NC

COM NO

EDC

A B

( + ) (A ) −

A D

B C

6

1 2 3

4

5

7

kwa1381515070607

Technical Information

MCHXXX

Connection diagrams

Potentiometer option

Direct EDC Control

Center-off switch assembly and wiring connections for the control handle.

MCHXXX potentiometer models having either two or single 200 Ohm pots are configured to directly

control Danfoss variable pumps with electrical displacement controls (EDCs). Whether two or single pots,

both require the same electrical connection to the EDC and only one of the dual coils needs to be

connected to achieve forward and reverse pump flow.

Potentiometer option with 1K Ohm potentiometer

Analog setpoint controller input

1. Red 5. 5 Vdc supply

2. Green 6. PLUS+1® controller

14 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

3. Black 7. Torque motor

4. Ground

Reverse Forward

1

2

3

4

5

6

7

toi1476734361490

Technical Information

MCHXXX

Connection diagrams

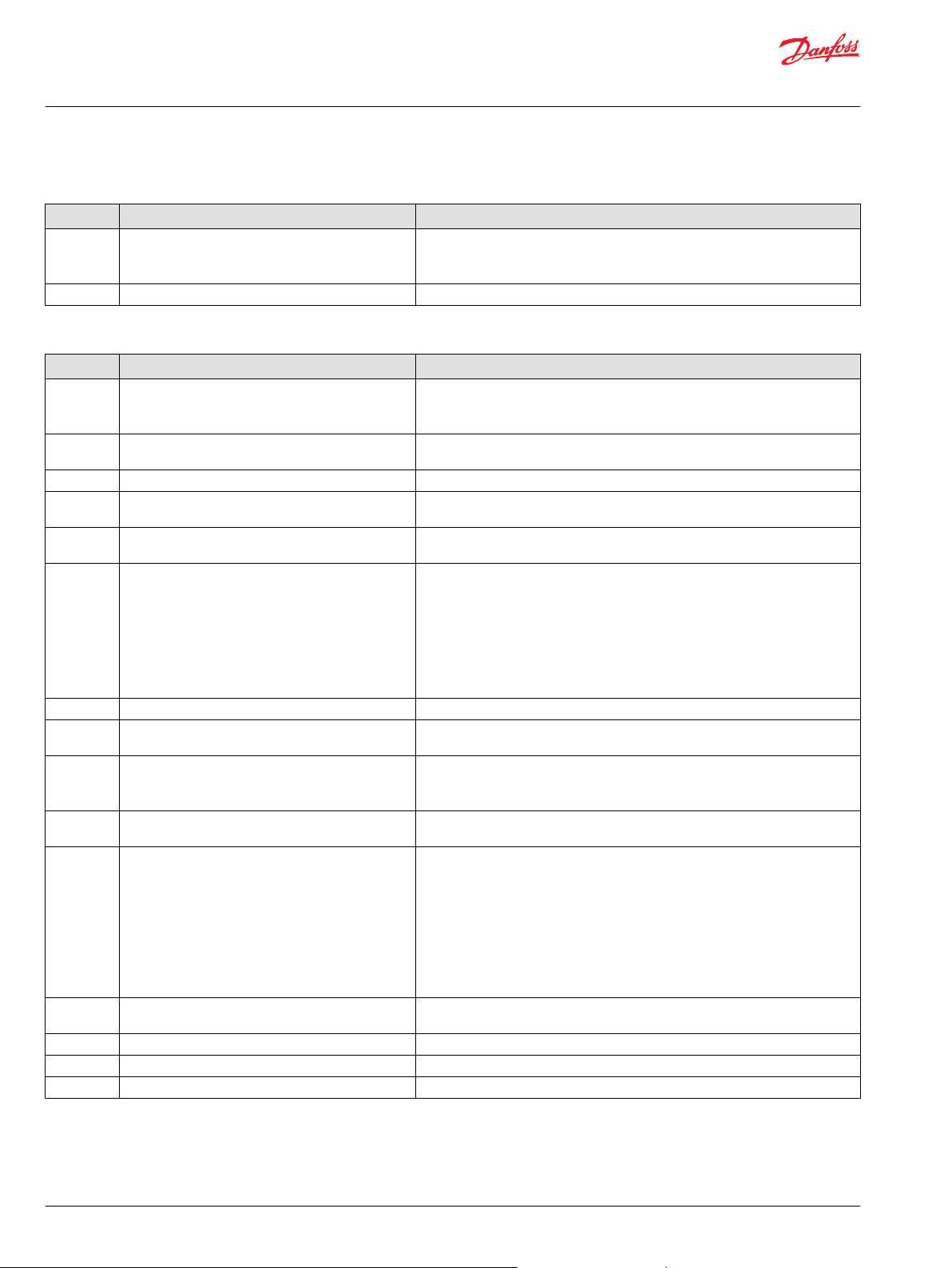

MCHXXX potentiometer models having a 1K Ohm pot are commonly used as analog input to a controller

(for example, SX or PLUS+1® MC200 Controllers). The supply voltage (5 VDC sensor supply) is usually

supplied from the controller.

MCHXXX potentiometer models typically used for a PLUS+1® input

Material

number

11090431 MCH19AM1649

11046484 MCH12AR1642 X X X X X X

10106017 MCH21CB1510 X X X X

11048497 MCH22AA1644 X X X X

11147104 MCH22AB1648 X X X X X

11068164 MCH22BB1648 X X X X X

11181083 MCH41BB1648 X X X X

11068165 MCH42BB1644 X X X X X

11017769 MCH51BB1535 X X X X

Model code Centerlock Spring

return

X X X X X X

Rocker 3-pos

momentary

MCH11CB1510 X X X X

MCH41BM1504 X X X X X X

MCH41AB1648 X X X X

MCH51AM1497 X X X X X X

MCH51BD1517 X X X X

MCH52BM1497 X X X X X X

Friction

hold

5 Vdc

supply

Terminal

strip

Microswitches

Forward Neutral Reverse

PWM Option (primarily)

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 15

PWM MCHXXX option reached its end of life cycle in 2008 and is no longer available.

Phasing and color scheme for handle with cable and connector

1. Blue Powered when handle is centered 5. White Valve drive, handle reverse

2. Red 12 ir 24 Vdc supply 6. Black Ground

3. Yellow Powered when handle is off center 7. 304.80 mm Cable length with connector

4. Green Valve drive, handle forward 1524.00 mm Cable length without connector

The blue and yellow wires provide optional functions.

Technical Information

MCHXXX

Connection diagrams

PWM option performance

Null current ±5 mA maximum if not switched (12 Vdc models)

±8 mA maximum if not switched (24 Vdc models)

Center deadband (optional) ±3º nominal

Full stroke current capability

Step current Step current occurs at end of deadband.

*

Customer specified. Reference Ordering Information.

*

16 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Technical Information

MCHXXX

Device repair

Return to

Danfoss

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

For devices in need of repair or evaluation, include a description of the problem

and what work you believe needs to be done, along with your name, address and telephone number.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 17

Technical Information

MCHXXX

18 | © Danfoss | February 2017 11022667 | BC00000033en-US0601

Technical Information

MCHXXX

©

Danfoss | February 2017 11022667 | BC00000033en-US0601 | 19

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | February 2017 11022667 | BC00000033en-US0601

Loading...

Loading...