Page 1

Data Sheet

Pressure switch

Type KPU

The KPU pressure switches are designed for use

in refrigeration and air-conditioning systems to

protect the systems from excessively low

suction pressure or too high discharge

pressure. They can also be applied to start and

stop compressors and the fans of air-cooled

condensers.

The KPU pressure switches, in single and dual

versions cover a comprehensive range of

applications, and are designed for use with

HCFC and non-ammable HFC refrigerants.

Features:

• Snap action electrical contacts minimize

chatter, bounce, and wear, and ensure

longterm electrical and mechanical reliability

• The fail-safe dual bellows used in KPU 6 and

KPU 16 prevent refrigerant loss and enable

premature cut-out when a fault occurs

• SPDT or SPST switch a in single control

models. SPST or SPDT with high-low pressure

signal in dual control models

• Manual trip function (electrical contact

function can be tested without the use

of tools)

• Easily replaces Johnson Controls and Ranco

products

• Wide pressure range:from low pressure KPU 2

with narrow dierential to KPU 6 and KPU 16

for high pressure refrigerants (R410A, R744)

• Automatic, manual or convertible reset

versions available

• Vibration and shock resistant

AI216886432210en-000901

Page 2

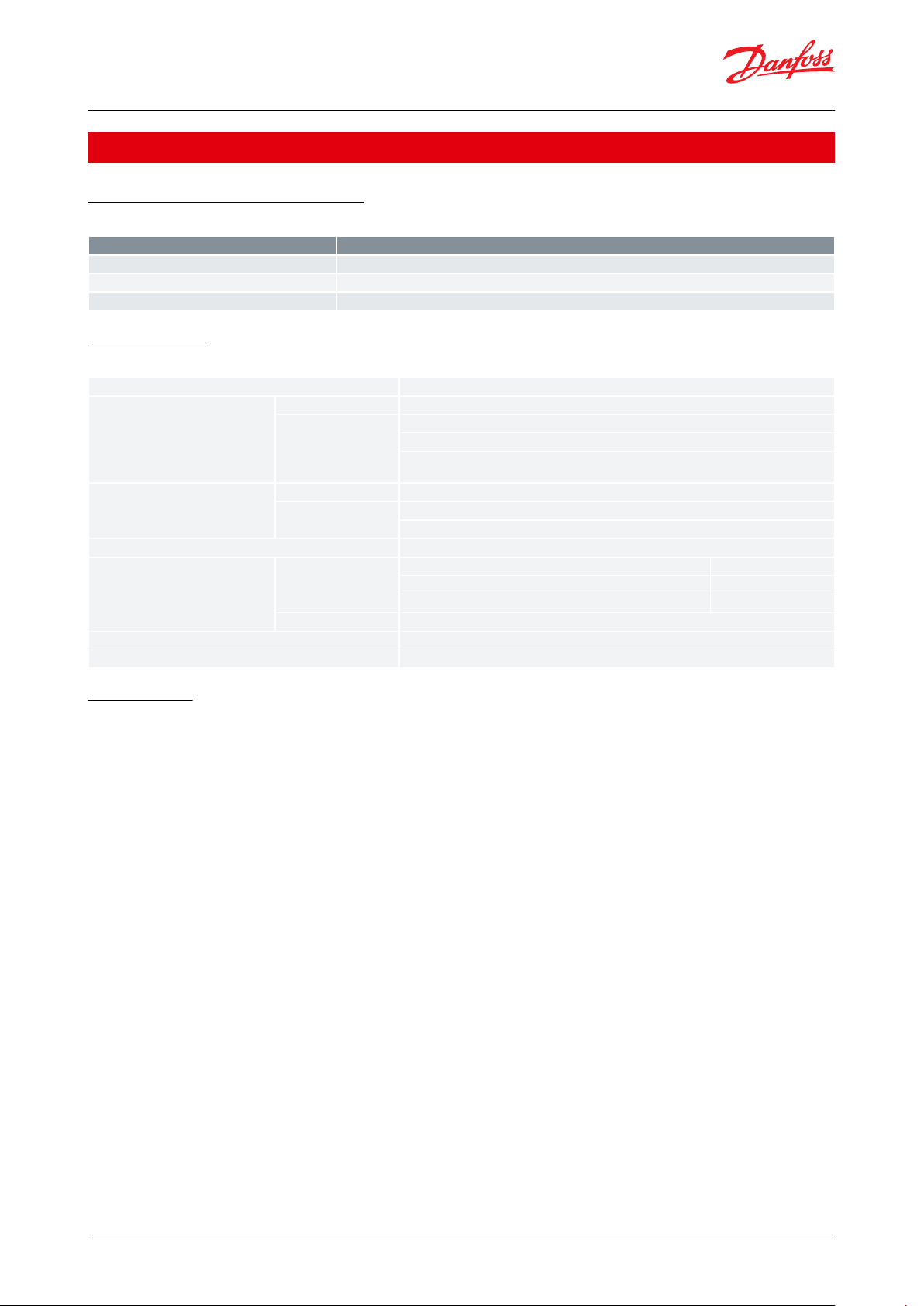

Unit type

Material

KPU 1, KPU 2, KPU 5, KPU 15

Tin bronze, no. CW452K, EN 1652 Nickel plated free cutting steel, no. 1.0737/ 1.0718 to EN 10277

KPU 6, KPU 16

Stainless steel bellows

KPU with capillary tube

Copper SF-CU no. 2.0090 to DIN 1787

Ambient temperature

-40 – 122 °F (175 °F for max 2 hours)

Maximum working pressure

Low pressure (LP)

KPU 1, KPU 2 and LP side of KPU 15, KPU 16: 250 psig

High pressure (HP)

KPU 5 and KPU 15 on HP side: 510 psig

KPU 6 and KPU 16 on HP side: 675 psig

KPU 6 and KPU 16 on HP side: 610 psig for products used according to 2014/68/EU PED directive

Maximum testing pressure

Low pressure (LP)

KPU 1, KPU 2 and LP side of KPU15, KPU16: 290 psig

High pressure (HP)

KPU 5 and KPU 15 on HP side: 530 psig

KPU 6 and 16 on HP side: 725 psig

Cable entry

7

⁄8 in cable entry for 1⁄2 in male pipe thread connection (conduit boss)

Contact load

Alternating current

FLA = 24 A @ 120 V AC

24 A @ 240 V AC

LRA = 144 A @ 120 V AC

144 A @ 240 V AC

LRA is rated for make only

Direct current

240 V DC: 12W pilot duty

Wire dimension

10 AWG maximum

Enclosure

~NEMA 1

Pressure switch, KPU

Product specication

Materials in contact with medium

Table 1: Materials

Technical data

Table 2: Technical data

Terminology

Set point

A predetermined value to which a switch is adjusted and at which it performs its intended function.

Reset

1. Manual reset

A unit with manual reset can only be restored to operational mode by activating the external reset button.

2. Automatic reset

A unit with automatic reset is restored to operational mode automatically.

3.Convertible reset

A unit with convertible reset can be adjusted for either automatic or manual reset.

Maximum working pressure

The maximum permissible pressure for safe functioning of a refrigeration system or any of its parts.

Maximum test pressure

The maximum pressure applied in strength or leakage tests on refrigeration systems or components thereof.

Dierential

Dierential is the number of psi (or bar) by which cut-in and cut-out set points are separated.

Snap function

A specic contact force is maintained until snap is initiated. The time over which contact force reaches zero is a few

milliseconds; therefore, contact bounce cannot occur as a result, for example, of slight vibrations before cut-out. The

snap-action contact system will continue to function even when micro-welds are created between the contacts

during cut-in. The force created to separate the contacts is strong, and instantly shears o all contact surface welds

that have been created as the result of cut-in action. These design features ensure that the cut-out point of the KPU

switch remains very accurate and completely independent of the magnitude of the current load.

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 2

Page 3

Pressure switch, KPU

Fail-safe switch

A switch is fail-safe if it has the capability to remain in a safe condition or transition to a safe condition when a fault

occurs.

FLA – Motor Full Load Amperes

The current rating, in amperes, of the motor when a full load is applied to it for work being done.

LRA – Locked Rotor Amperes

The current drawn, in amperes, by an electric motor with the shaft or rotor stopped and locked in position.

Setting

Cut-in and cut-out pressures for both LP and HP sides of the system should always be checked with an

accurate pressure gauge.

Low Pressure setting for switches with automatic reset

1.

Set the LP cut-in pressure on the “CUT-IN” scale (range scale). One rotation of the low pressure spindle ~ 5.2 psi

for KPU 2 and ~6.8 psi for KPU 1.

2.

Set the LP dierential on the “DIFF” scale. One rotation of the dierential spindle ~ 3.2 psi for KPU 2 and 2.9 psi

for KPU 1.

NOTE:

The LP cut-out pressure is LP cut-in pressure minus dierential value. The LP cut-out pressure must be above

absolute vacuum (Pe = 29.5 in Hg).

High Pressure setting for switches with automatic reset

1.

Set the HP cut-out pressure on the “CUT-OUT” scale. One rotation of the HP spindle ~ 22 psi for KPU 5 and ~ 28

psi for KPU 6.

2.

Set the HP dierential on the “DIFF” scale. One rotation of the dierential spindle ~ 5.3 psi for KPU 5 and ~ 8.6 psi

for KPU 6.

NOTE:

The HP restart pressure is equal to HP cut-out pressure minus dierential.

Pressure switches with manual reset Set the cut-out pressure on the “CUT-OUT” scale (range scale). Low Pressure

switches can be manually reset when the pressure is above the cut-out pressure plus the dierential. High Pressure

switches can be manually reset when the pressure is below cut-out minus dierential.

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 3

Page 4

1

2

345678910111213141516171819

Pressure switch, type KPU

KPU single (KPU 1, KPU 2, KPU 5, KPU 6) without front cover

KPU dual (KPU 15, KPU 16) without front cover

Low pressure (LP) setting

spindle

High pressure (HP) setting

spindle

Dierential

Low pressure main spring

High pressure main spring

Dierential spring

Ground terminal

Cable entry

Bellows

LP connection

HP connection

Control terminals

Reset button

Arm

Switch

Tumbler

Locking plate

Contact housing

Damping device

Pressure switch, KPU

Design and Function

Table 3: KPU types

Switch function

The switch in KPU control has a snap-action function and the bellows moves only when cut-in or cut-out set point is

reached.

This design has following advantages:

• high contact load

• ultra-short bounce time

• long mechanical and electrical lifetime

• high resistance to pulsation and vibrations

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 4

Page 5

123

Pressure connection

Regulating bellows

Outer bellows

KPU single

KPU dual

0.47 in.

3.01 in.

1.17 in.

3.52 in. 1.83 in.

1.83 in.5.22 in.

0.47 in.

1.17 in.

3.01 in.

Approx. net weight: 0.765 lbs

Approx. net weight: 1.19 lbs

KPU single

KPU dual

6.75 in.

3.01 in.

3.52 in.

1.83 in.

3.01 in.

6.75 in.

1.83 in.5.22 in.

Approx. net weight: 0.91 lbs

Approx. net weight: 1.5 lbs

Pressure switch, KPU

Figure 1: Fail-safe bellows concept in KPU 6 and high pressure side of KPU 16

KPU 6 and high pressure side of KPU 16 have double bellows: an outer bellow and a regulating bellow. When system

pressure exceeds the set value, the KPU will automatically stop the system. The double bellows system prevents the

loss of charge in the event of bellows rupture. Rupture in the outer bellows causes the control cut-out pressure to

fall about 40 psi under the set value, thus providing fail-safe function.

Reset

Version with automatic reset cut-in again automatically when the pressure falls or rises to the set point minus

dierential. Version with manual reset have to be cut in manually with external reset button when the pressure in

KPU 1 rises min. 10 psi above the set point value, and in KPU 6 falls min. 60 psi under the set point value. All KPU

pressure switches operate independently of changes in ambient temperature around the switch. Therefore the

setting for cut-out pressure and dierential stay constant unless the permissible ambient temperature is exceeded.

Dimensions and weight

Table 4: KPU with are connection

Table 5: KPU with capillary tube

All switches are supplied with universal mounting bracket and mounting screws as standard accessory.

Approximate weight of the bracket and mounting screws: 0.615 lbs

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 5

Page 6

Pressure

Control type

Low pressure (LP)

High pressure (HP)

Reset

Contact type

Code no.

Range

[inHg][psig]

Dierential

[psi]

Range

[psig]

Dierential

[psi]

Low

pressure

(LP)

High

pressure

(HP)

Connection

¼ in male

are

36 in cap.

tube w. ¼ in

are nut

Low

KPU 1

6 – 108

10 – 60––

Auto–A

060-5231

060-5233

Low

KPU 1

6 – 108

10 – 60––

Auto–B

060-5236–Low

KPU 1B

28 – 10010––Man. (Min.)–A

060-5232

060-5234

Low

KPU 2

6 – 73

6 – 30––

Auto–B

060-5237

060-5235

Low

KPU 2

6 – 73

6 – 30––

Auto–A

060-5239

060-5240

Fan cycling

KPU 5––

100 – 465

25 – 85–Auto

B

060-5241

060-5242

Dual

KPU 15

6 – 108

10 – 60

100 – 465

60

Auto

Auto

C

060-5247

060-5248

Dual

KPU 15B

6 – 108

10 – 60

100 – 465

60

Auto

Man. (Max.)

C

060-5249

060-5250

Pressure

Control type

Low pressure (LP)

High pressure (HP)

Reset

Contact type

Code no.

Range

[inHg] [psig]

Dierential

[psi]

Range

[psig]

Dierential

[psi]

Low

pressure

(LP)

High

pressure

(HP)

Connection

¼ in male

are

36 in cap.

tube w. ¼ in

are nut

High

KPU 6W––

100 – 600

58 – 145–Auto

A

060-5243

060-5245

High

KPU 6B––

100 – 60060–

Man. (Max.)

A

060-5244

060-5246

Dual

KPU 16W

6 – 108

10 – 60

100 – 600

60

Auto

Auto

D

060-5251

060-5252

Dual

KPU 16B

6 – 108

10 – 60

100 – 600

60

Min. Conv.

Max. Conv.

D

060-5253

060-5254

Switch type

Switch action

Application

FW

SPDT

1. Terminals 1-4 close high and open low. Terminals

1-2 can be used as low pressure alarm.

1. Low pressure cut-out.

2. Terminals 1-2 open high and close low Terminals

1-4 can be used as high pressure alarm.

2. High pressure cut-out.

SPST (NO)

Terminals 1-4 close high and open low

1. Low pressure cut-out.

2. Condenser fan cycling control.

FW

SPST (NO + NC)

Dual Pressure switch employs an SPST switch that is

open when either high or low pressure beyond the

control setting is sensed on the two bellows sensing

elements of the switch.

Dual Pressure switch Protects the system against too

low suction pressure and against too high discharge

pressure.

FW

SPDT + SPST (NO)

Contact opens on pressure drop below LP set point

(turns on the LP signal light) and on pressure rise

above HP set point (turns on HP signal light). Contact

action is controlled by two bellows sensing elements.

Note: max. contact D rating is 50 VA

Dual Pressure switch. Protects the system against too

low suction pressure (LP cut-out signal on terminal B)

and against too high discharge pressure (HP signal on

terminal D).

Pressure switch, KPU

Ordering

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

Table 6: For R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R438A, R448A, R449A, R450A, R452A, R507A, R513A

Table 7: Fail-safe switches for high pressure refrigerants (R410A, R744) PED 2014/68/EU approved according to EN 12263

During standstill the ambient temperature cannot be higher than 82 °F for R410A and higher than -11 °F for R744 as

the LP side bellows MWP (250 psig) will be exceeded.

Contact system and application

Table 8: Contact system and application

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 6

Page 7

Load

Signal option

Bellows movement on pressure rise

Bellows movement on pressure drop

Low pressure

Manual reset.

(1)

Automatic reset

Automatic reset

Manual reset

High pressure

Manual reset.

(1)

Manual reset

Automatic reset

Automatic reset

File name

Document type

Document topic

Approval authority

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

UL E31024

Certicate

Electrical - Safety

Certicate

-ULTÜV 01 202 PL-Q-11 0004

Quality - Assurance

Certicate

-

PED

Pressure switch, KPU

Pressure switch setting with convertible reset

Table 9: Pressure switch setting with convertible reset

(1)

(1)

Factory setting

Factory setting

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 10: Certicates, declarations, and approvals

UL listed for USA and Canada, E31024

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 7

Page 8

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI216886432210en-000901 | 8

Loading...

Loading...