MAKING MODERN LIVING POSSIBLE

Technical Information

Speed Sensor

KPP Pulse Pickup (PPU)

powersolutions.danfoss.com

Technical Information KPP PPU

Revision

Revision History

Table of Revisions

Date Page Changed Rev.

09 Jul 2013 7 Corrected illustration title to Non-adjustable Wire Conguration (at

end and conical end)

10 Aug 2009 6, 9-12, 18 Various content updated; Ordering Information; PPU Quick Reference

table; Connector Pin Assignments

25 Sep 2008 Various pages Updated BLN-95-9045 to Technical Information (TI) format; updated

Part Number Quick Reference table and various content

BB

BA

AA

11029257 • Rev BB • July 20132

Technical Information KPP PPU

Contents

Product Overview

Ordering Information

Product Installation Procedures for Flat End and Conical End Models ....................................................................................................... 14

Description .................................................................................................................................................................................. 4

Features ........................................................................................................................................................................................ 4

Technical Data ............................................................................................................................................................................ 4

Theory of Operation ................................................................................................................................................................ 5

Improvements ............................................................................................................................................................................ 6

D Revision (June 1996) ...................................................................................................................................................... 6

E Revision (September 1996) .......................................................................................................................................... 6

F Revision (June 1999) ....................................................................................................................................................... 6

G Revision (February 2002) .............................................................................................................................................. 6

Dimensions .................................................................................................................................................................................. 7

Considerations ........................................................................................................................................................................... 8

Supply Voltage ..................................................................................................................................................................... 8

Directional versus Non-directional KPPs ................................................................................................................... 8

Housings ................................................................................................................................................................................. 8

4-wire KPP .............................................................................................................................................................................. 8

Ordering Nomenclature ......................................................................................................................................................... 9

Ordering Nomenclature Codes and Denitions .......................................................................................................... 10

PPU Quick Reference ............................................................................................................................................................. 11

Speed Rings ............................................................................................................................................................................... 13

Procedure A ........................................................................................................................................................................ 14

Procedure B: ........................................................................................................................................................................ 14

Procedure C ......................................................................................................................................................................... 15

Procedure D ........................................................................................................................................................................ 15

Procedure E ......................................................................................................................................................................... 15

Installation Diagrams ............................................................................................................................................................. 16

System Wiring Guidelines .................................................................................................................................................... 17

Connector Pin Assignments................................................................................................................................................ 18

Troubleshooting Steps .......................................................................................................................................................... 18

11029257 • Rev BB • July 2013 3

Technical Information KPP PPU

Product Overview

Description

Features

The KPP pulse pickup accepts a supply voltage and, in response to the speed of a permanently

magnetized speed ring on the motor’s cylinder block or shaft, outputs a digital pulse signal. The

output changes its high/low state as the north and south poles of the speed ring pass by the sensor’s

face. Because the output is digital, the KPP is ideal for low-speed measurement.

The KPP is designed for rugged outdoor, mobile, or heavy industrial speed-sensing applications that

do not allow contact with the rotating shaft. It is custom-designed for Sauer-Danfoss pumps and

motors.

y Choice of directional or non-directional devices

y Choice of Delphi/Packard Weather-Pack®, Turck Eurofast® or Deutsch® connectors

y Rugged housing designed to withstand extreme environments

y You can order pre-mounted in Sauer-Danfoss pumps and motors

y You can use with digital or analog controllers

y Suitable for zero speed measurements

Technical Data

Electrical and Environmental Data

Electrical

Supply voltage (two ranges)

Regulated 4.5 to 8.5 Vdc Battery 7 to 32 Vdc

Maximum operating current

20 mA at 1 Hz and 5 Vdc supply

Required current

12 mA at 5 Vdc (no load)

Output voltage in high state

Supply voltage minus 0.5 Vdc minimum (no load)

Output voltage in low state

0.5 Vdc, maximum (no load)

Maximum frequency

15 k Hz

Load

15 kΩ to both ground and supply

Peak transient voltage

80 Vdc for 2 milliseconds,

4.5 to 8.5 Vdc models

Peak reverse voltage

-15 Vdc continuous, 4.5 to 8.5 Vdc models -32 Vdc continuous, 7 to 32 Vdc models

Environmental

Operating and storage temperature

-40° to 110° C [-40° to 230° F]

300 Vdc for 2 milliseconds,

7 to 32 Vdc models

200 Vdc for 100 milliseconds,

7 to 32 Vdc models

11029257 • Rev BB • July 20134

Technical Information KPP PPU

Speed signal B

2190

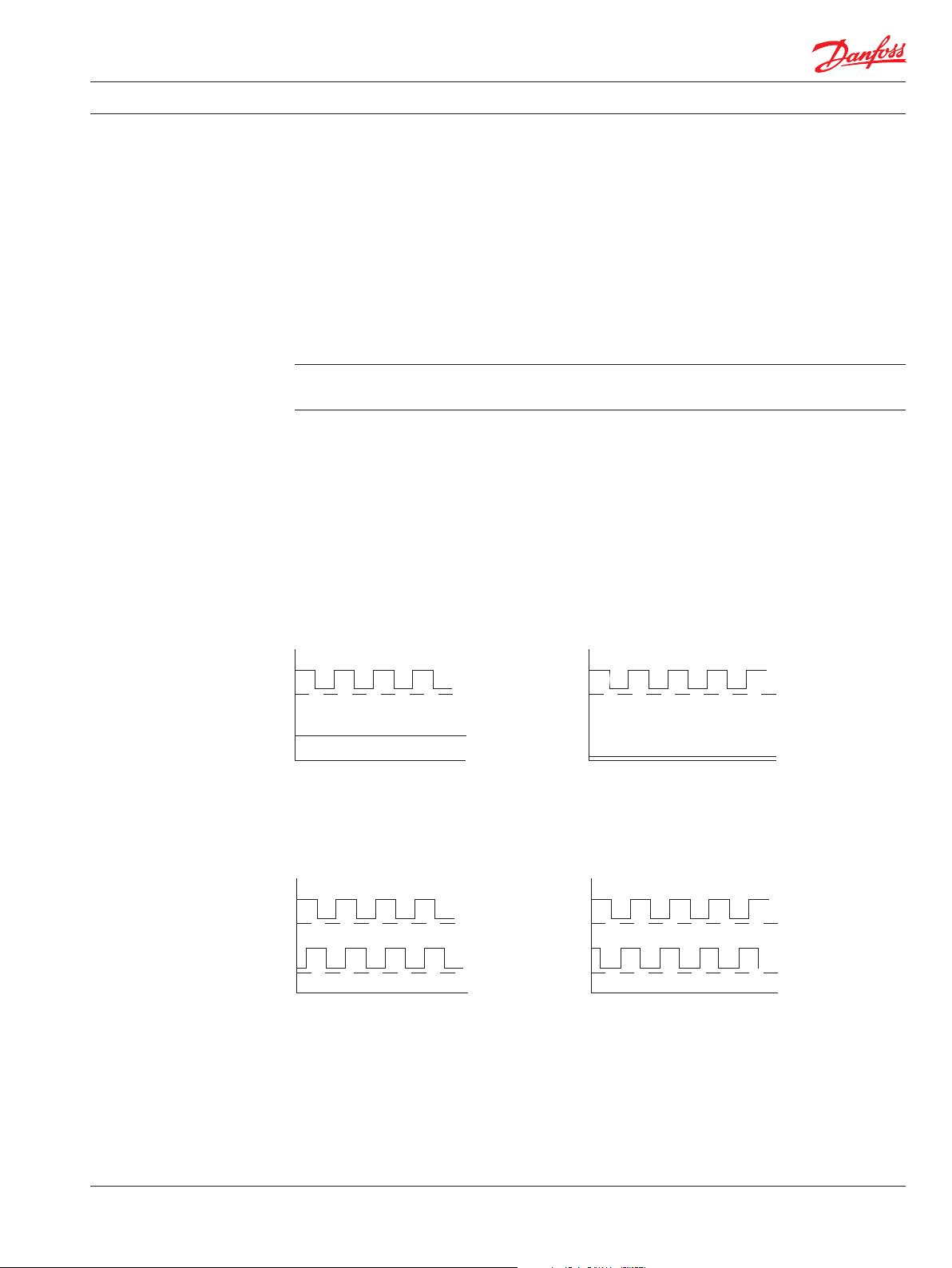

Theory of Operation

An external source powers the KPP pulse pickup (PPU). It needs a magnetic eld to pass by its Hall

switch(s) to provide a speed signal. The speed ring on the cylinder block has alternately magnetized

north and south segments. For the non-directional PPU (KPPX12X), when a north segment is above

the Hall switch, the switch output voltage is high, and when a south segment is above the switch,

output is low. The digital (on-o-on-o) pulse train feeds to a controller, that interprets its rate of

change as a speed.

The direction-sensing PPU (KPPA13X) uses two Hall sensors mounted side-by-side in the same case.

With proper orientation, the pulse train output from one sensor leads the other sensor by 90°. A logic

circuit decodes the two signals to give a direction indication at the speed output (high or low

depending on direction). For quadrature directional signal, the logic is bypassed and the direction

signal is phase shifted by a nominal of 90° from the signal A. Refer to Directional Pulse Train, on this

page below.

Do not attempt to apply a quadrature output PPU without rst consulting with a

Sauer-Danfoss eld applications engineer for specic application requirements.

The KPPC,D,E models are an improved version of the KPPA12X PPU. It is not necessary to align the ats

on its housing with the speed ring for proper speed readings.

Refer to Typical Speed Control, page 13, as an example of a simple closed-loop speed control

application for the PPU. Connections for a three and four-wire application, refer to Connection

Diagram, page 17.

The KPPXN8Nnn divides the standard signal output by two.

Directional Pulse Train

HI

Speed signal B

LOW

HI

Direction D

Clockwise rotation Counter-clockwise rotation

LOW

Quad Directional Pulse Train

HI

Speed signal B

LOW

HI

Direction D

LOW

Clockwise rotation Counter-clockwise rotation

HI

Speed signal B

LOW

HI

Direction D

LOW

HI

LOW

HI

Direction D

LOW

2189

11029257 • Rev BB • July 2013 5

Technical Information KPP PPU

Improvements Continuous improvements to reduce environmental eects of moisture and corrosive liquids

found in some mobile environments include:

D Revision (June 1996)

y Use of a potting compound around the lead wires exiting the housing was eliminated.

– The sealing now works like an O-ring:

y The internal cavity of the housing was lled with a silicone oil.

y The wires now pass through a molded rubber piece compressed between two plates.

E Revision (September 1996)

y Silicone oil was replaced with a rm compound.

y External housing was changed to a zinc chromate nish.

F Revision (June 1999)

y The internal wire to the circuit board joint was modied.

y A new seal received and the circuit board assembly was improved.

G Revision (February 2002)

y The housing is now machined from a solid block of aluminum-silicone-bronze.

11029257 • Rev BB • July 20136

Technical Information KPP PPU

Speed ring

3520

Orientation notch

3521

3522

Dimensions

Common Lead Wire Conguration (at end)

Air gap approximately

1/2 to 1 turns of thread

1.52 [0.060] maximum

9/16-18 UNF-2A THD (all models)

Red

White

Black

O-ring

P/N 9004201-3700

Locking nut

P/N K13988

57.15 [2.25]

Torque lock nut

13 ± 1.3 N•m

[10 ± 1 lbf•ft]

Green

Conguration Used Only for Series 51 and 51-1 Cartridge Motors (conical end)

22.9 [.90]

1.52 [0.060] maximum

Air gap approximately

2-3 turns of thread

9/16-18 UNF -2A THD

Speed ring

Non-adjustable Wire Conguration (conical end)

8.99 [0.35]

02.7 [0.11]

45.5 [1.79]

1.52 [0.060] maximum

Speed ring

Dimensions in mm [inches].

11029257 • Rev BB • July 2013 7

Technical Information KPP PPU

Ordering Information

Considerations

When specifying the pulse pickup there are important considerations listed below. For KPP

selection see Ordering Nomenclature, page 9 and Part Number Quick Reference, pages 11 to 12.

Supply Voltage

You cannot power most KPP models directly from a battery because of the voltage transients

(voltage spikes above 15 Vdc) that may cause permanent damage. Battery voltage transients are a

common occurrence with 12 or 24 Vdc systems.

Most mobile systems have an alternator that helps ensure a given voltage level but does not

prevent against voltage transients. Therefore you must use a separate voltage regulator as the

voltage source for the majority of KPP models.

Those applications using a microcontroller can utilize their 5 Vdc regulated power supply to

power the KPP models that are rated 4.5 to 8.5 Vdc. It is acceptable when powering the 4.5 to 8.5

Vdc models to use a regulated 15 Vdc maximum.

Directional versus Non-directional KPPs

When sensing speed only and supplying the KPP directly from the battery, always specify a KPP

model that is rated 7 to 32 Vdc. If you require directional sensing, ensure the supply voltage is

regulated.

Housings

There are two basic housings at end and conical end. Refer to Dimensions, page 7.

4-wire KPP

The 4-wire KPP can be used when only speed sensing is required. For these applications connect

to pins A, B, C. Fill the unused cavity (D) with a cavity plug (refer to Common Lead Wire

Conguration (at end), page 7). Use the cavity plug oered in the 4 pin mating electrical

connector kit, which is used with the 4 pin Delphi/Packard Weather-Pack connector (SauerDanfoss part umber K03379).

11029257 • Rev BB • July 20138

Technical Information KPP PPU

Ordering Nomenclature

KPP X X X X XX

Hall eect PPU

Revision

Mechanical conguration (housing)

1 Flat end

2 Conical end

3 Conical end, xed position

4 Flat end, xed position

Electrical conguration

2 Regulated supply 4.5 to 8.5 Vdc, 3 connection,

non-directional, wire fault detection

3 Regulated supply 4.5 to 8.5 Vdc, 4 connection, directional,

wire fault detection, low current

4 Regulated supply 4.5 to 8.5 Vdc, 4 connection, directional,

wire fault on speed signal, open collector on direction signal

5 Regulated supply 4.5 to 8.5 Vdc, 4 connection, directional wire

fault detection, high current, ltered speed output

6 Battery supply 7 to 32 Vdc, 3 connection, non-directional,

limited wire fault detection

7 Regulated supply 4.5 to 8.5 Vdc, 4 connection, directional,

wire fault detection, low current, quad output**

8 Regulated supply 4.5 to 8.5 Vdc, 4 connection, directional,

wire fault detection, low current, output signal divided by 2

9 Regulated supply 4.5 to 8.5 Vdc, 4 connection, directional,

wire fault detection, high current, quad output**

A Battery supply 7 to 32 Vdc, 4 connection, directional, limited

wire fault detection, high current, quad output**

B Regulated supply 4.5 to 8.5 Vdc, 3 connection, non-

directional, wire fault detection, high current, ltered speed

output

Electrical connector

1 Amp Mate-n-Lok

41 Delphi/Packard Weather-Pack (3 pin)

2

Delphi/Packard Weather-Pack (4 pin), used when direction signal is required

5 Delphi/Packard Metri-Pack

6 Integral Turck Eurofast (no leadwires)

71 Deutsch DT04 (3 pin)

2

Deutsch DT04 (4 pin), used when direction signal is required

8 Delphi/Packard Metri-Pack 150 series plug

9 Delphi/Packard Metri-Pack 150 series jack

All leadwire length is described in inches unless denoted with m (meters)

Specialties

A Special connector pinouts

B Special connector pins

**Do not attempt to apply a quadrature output PPU without rst consulting with a Sauer-

Danfoss eld applications engineer for specic application requirements.

11029257 • Rev BB • July 2013 9

Technical Information KPP PPU

Ordering Nomenclature

Codes and Denitions

Mechanical Conguration (Housing)

Code Description

1 Flat end: Typical use, Sauer-Danfoss Series 90 pump and motor, M46 pump and motor, Series 42

pump (M46 pump pending)

2 Conical end: Typical use, Sauer-Danfoss Series 51 and 51-1 MV cartridge type motor

Electrical Conguration

Code Description

2 Non-directional: Common, supply voltage 4.5 to 8.5 Vdc, 3 wire connection, speed sensing only

with wire fault detection

3 Directional: Common, supply voltage 4.5 to 8.5 Vdc, 4-wire connection, direction and speed

sensing with wire fault detection capability on both its speed and direction signals. Can also be

used if only speed sensing is required (3 wire connection)

4 Directional: Special, supply voltage 4.5 to 8.5 Vdc, 4-wire connection, directional sensing signal

compatible with the standard DC2 digital input lines. Higher current sinking capability and no wire

fault detection for the direction signal only which can sink up to 20 mA and source nothing (open

collector).

5 Directional: Special, supply voltage 4.5 to 8.5 Vdc, 4-wire connection, direction and speed sensing

with wire fault detection capability on both its speed and direction signals. Capable of driving

higher currents from its outputs. Special provision to lter the speed output signal for reducing

electromagnetic emissions

6 Non-Directional: Common, supply voltage 7 to 32 Vdc, 3 wire connection, speed sensing only

with limited wire fault detection

7 Directional: Special, supply voltage 4.5 to 8.5 Vdc, 4 wire connection, direction and speed sensing

with wire fault detection capability, low current, features quadrature (decoded) directional

output**

8 Directional: Common, supply voltage 4.5 to 8.5 Vdc, 4 wire connection, direction and speed

divided by 2 sensing with wire fault detection capability on both its speed and direction signals

9 Directional: Special, supply voltage 4.5 to 8.5 Vdc, 4 wire connection, high current, direction and

speed sensing with wire fault detection capability, high current, features quadrature (decoded)

directional output**

A Directional: Special, supply voltage 7 to 32 Vdc, 4 wire connection, direction and speed sensing

with wire fault detection capability, high current, features quadrature (decoded) directional

output**

B Non-directional: Special, supply voltage 4.5 to 8.5 Vdc, 3 wire connection, speed sensing with

wire fault detection capability, high current, ltered speed output

**Do not attempt to apply a quadrature output PPU without rst consulting with a Sauer-Danfoss

eld applications engineer for specic application requirements.

Electrical Connector

Code Mating connector kit description Sauer-Danfoss part number

4 Delphi/Packard Weather Pack 3 pin shroud K08620

Delphi/Packard Weather Pack 4 pin tower, used when

directional signal is required

5 Delphi/Packard Metri-Pack 3 pin K10309

6 Turck Eurofast 4 pin K14956 (straight); K14957 (right angle)

7 Deutsch, 3 pin K22335

Deutsch, 4 pin, used when directional signal is required K 23511

8 Delphi/Packard Metri-Pack 4 pin plug K22254

9 Delphi/Packard Metri-Pack 4 pin jack K32219

K03379

11029257 • Rev BB • July 201310

Technical Information KPP PPU

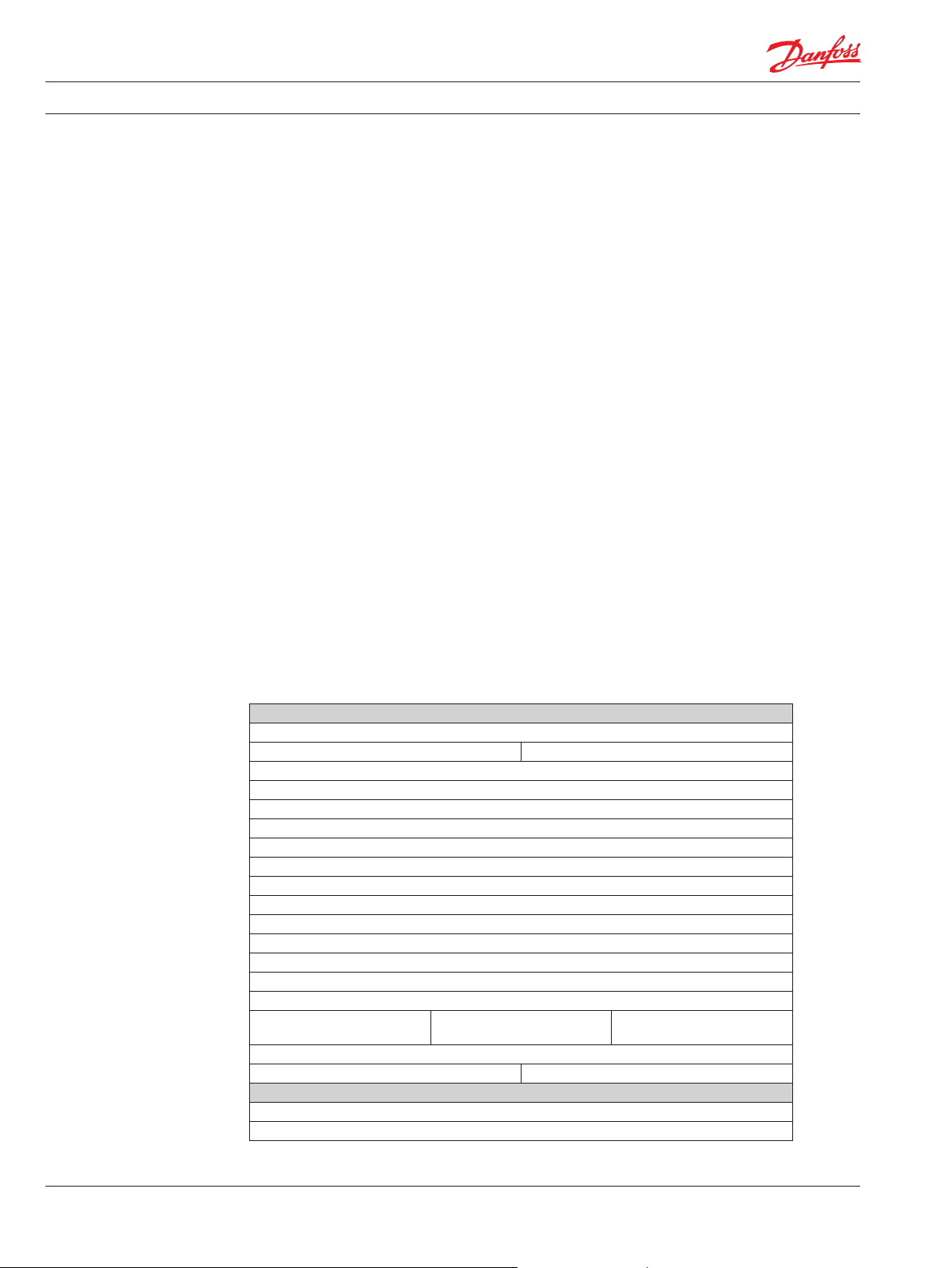

PPU Quick Reference

Table continues on

pag e 12.

Reference Ordering

Nomenclature and

Nomenclature Codes

and Denitions,

pages 9 and 10.

Material number

Supply voltage (Vdc) Application Electrical

4.5 to 8.5 7 to 32 Common Special

KP PG124 08 X X 4

KP PG125 08 X X 5

KP PG126 X X 6

KP PG12703A X X 7

KP PG12704A X X 7

KP PG12730A X X 7

KPPG1273MA X X 7

KP PG134 03 X X 4

KP PG134 08 X X 4

KP PG13436 X X 4

KP PG136 X X 6

KP PG1370 3 X X 7

KP PG1370 4 X X 7

KPPG13808 X X 8

KPPG14 408 X X 4

KPPG14 6 X X 6

KP PG1540 8 X X 4

KP PG156 X X 6

11046858 K PPG15 824 X X 8

KPPG16008 X X 4

KPPG16 408 X X 4

KPPG1650 8 X X 5

KPPG16511 X X 5

KPPG16 6 X X 6

KPPG16703A X X 7

KPPG16704A X X 7

KPPG16708 X X 7

KPPG16708B X X 7

KPPG16719 X 7

KPPG18 408 X 4

KPPG18708 X X 7

KPPG197XXB X X 7

KPPG22408 X X 4

KPPG23408 X X 4

KPPG236 X X 6

KPPG23703 X X 7

KPPG23808 X X 8

KPPG256 X X 6

KPPG25808 X X 8

KPPG26008 X X 4

KPPG26408 X X 4

KPPG26508 X X 5

KPPG266 X X 6

KPPG26708 X X 7

KPPG26708B X X 7

KPPG26724A X X 7

KPPG33703* X X 7

KPPG356* X X 6

* Conical end, xed position.

connector

1

1

1

1

1

2

2

2

2

2

2

2

2

1

1

1

1

1

1

2

2

1

1

2

2

2

1

1

1

1

2

11029257 • Rev BB • July 2013 11

Technical Information KPP PPU

PPU Quick Reference

(continued)

Reference Ordering

Nomenclature and

Nomenclature Codes

and Denitions,

pages 9 and 10.

Material number Supply voltage (Vdc) Application Electrical

4.5 to 8.5 7 to 32 Common Special

KPPG35708* X X 7

connector

2

KPPG35808* X X 8

KPPG36708* X X 7

KPPG36708B* X X 7

KPPG36708B* X X 7

1

1

2

KPPG456** X X 6

11068105 KPPG4A408** X X 4

KPPG4B724B** X X 7

* Conical end, xed position.

** Flat end, xed position.

2

1

11029257 • Rev BB • July 201312

Technical Information KPP PPU

Electrical displacement control (EDC)

1668A

Speed Rings

Speed rings vary according to the diameter of cylinder block to which they are attached. You may

order them directly from the pump manufacturer or a Sauer-Danfoss Global Service Partner may

retrot them to existing pumps and motors (mounting requires some specialized tooling). Order

them using numbers in the following table. Pump and motor listed is typical. Several may use the

same speed ring.

Speed Ring Part Numbers

Speed ring part number Pump/motor Total pole pairs per revolution

KK14701 51V0 60 45

KK14702 51V080 49

KK14703 51V110 54

KK14704 51V160 61

KK14705 51V250 71

KK14706 M25 & 90P030 43

KK14707 90P042 48

KK14708 90P055 52

KK14709 90P075 58

KK14710 90P100 63

KK14711 90 P130 69

KK14712 LV2 5 &42 P028 41

KK14713 40P046 51

KK14714 SMF21089 65

KK14715 60/470 78

KK14716 60/104 8 101

KK14717 6 0/175 0 121

KK14718 60/780 93

KK14719 60/606 86

KK14720 90 P180 77

KK14721 90P250 85

KK14722 42P 041 47

KK14723 MF035 & 044D 46

Typical Speed Control

Speed ring

Pulse pickup

Microcontroller

11029257 • Rev BB • July 2013 13

Technical Information KPP PPU

Product Installation

Procedures for Flat End and

Conical End Models

Refer to Installation Diagrams, page 16, regarding these procedures.

Procedure A

Non-directional KPP at end models. Models included: KPPG12XXX, KPPG16XXX. Installation steps:

1. Turn in (CW) by hand until bottom end gently touches the speed ring.

2. Back out (CCW) 1/2 to 3/4 turn.

3. Using a 1/2 inch wrench to hold the KPP, torque the lock nut to 13 N•m [10 lbf•ft] with an 11/16 inch

hex wrench.

Procedure B:

Directional KPP at end models. Models included: KPPG13XXX, KPPG14XXX, KPPG15XXX, KPPG18XXX.

Installation steps:

1. Turn in (CW) by hand until bottom end gently touches the speed ring.

2. Back out (CCW) 1/4 turn. Continue backing out until the ats are 22° (most open-end wrenches

have a 22° oset) either side of pump or motor shaft center line (20° to 30° is acceptable). Do not

back out the KPP more than 3/4 of a turn from touching.

3. Using the 1/2 inch wrench to hold the KPP, torque the lock nut to 13 N•m [10 lbf•ft] with an 11/16

inch hex wrench.

4. Special KPP FLAT END models include: KPPG17XXX, KPPG19XXX, KPPG1AXXX. Installation range is

application specic:

5. Turn in (CW) by hand until bottom end gently touches the speed ring.

6. Back out (CCW) 1/4 turn. Continue backing out until the ats are 22° (most open-end wrenches

have a 22° oset) either side of pump or motor shaft center line (acceptable range is determined

per application). Do not back out the KPP more than 3/4 of a turn from touching.

7. Using the 1/2 inch wrench to hold the KPP, torque the lock nut to 13 N•m [10 lbf•ft] with an 11/16

inch hex wrench.

11029257 • Rev BB • July 201314

Technical Information KPP PPU

Procedures for Flat End and

Conical End Models

(continued)

Procedure C

Non-directional and Directional KPP conical end models. Models included: KPPG2XXXX.

Installation steps:

1. Turn in (CW) by hand until bottom end gently touches the speed ring.

2. Back out (CCW) 2 turns. Continue backing out until the KPP orientation notch is 180±15° to

motor shaft center line, (reference Directional Conical End Models, Series 51 and 51-1 Cartridge

Motors Only, page 17).

3. Using the 1/2 inch wrench to hold the KPP, torque the lock nut to 13 N•m [10 lbf•ft] with an

11/16 inch hex wrench.

Special KPP CONE END models include: KPPG29XXX. Installation range is application specic:

1. Turn in (CW) by hand until bottom end gently touches the speed ring.

2. Back out (CCW) 1 turn. Continue backing out until the KPP Orientation Notch is 180° to motor

shaft center line, acceptable range is determined per application, (reference Directional Conical

End Models, Series 51 and 51-1 Cartridge Motors Only, page 17).

3. Using the 1/2 inch wrench to hold the KPP, torque the lock nut to 13 N·m [10 lbf·ft] with an 11/16

inch hex wrench.

Procedure D

When Directional KPP at end models are used for sensing speed only, the same installation steps

in Procedure A are acceptable. Models included: KPPG13XXX, KPPG14XXX, KPPG15XXX,

KPPG18XXX.

Procedure E

Fixed position. Non-directional and Directional KPP conical end models KPP3XXXX and at end

models KPP4XXXX. Installation steps:

1. Insert PPU housing; align the hole in mounting ange with mounting hole in block housing.

2. Torque M6x12 capscrew 8 ± 1 N•m [5.9 ± 0.7 lbf•ft].

11029257 • Rev BB • July 2013 15

Technical Information KPP PPU

2055A

2052A

Installation Diagrams

Pulse Pickup Installation

22° 22°

22° 22°

Sensor with

Turck Eurofast connector

Magnetic speed ring

Speed sensor

12,7 [0.50]

Flats

12,7 [0.50]

Flats

Gap

11/16 hex wrench

Torque: 13 N•m [10 lbf•ft]

after adjustment

Hold sensor in position

while tightening locknut

Shaft cernterline

Shaft cernterline

Sensor with

Packard connector

Directional Conical End Models, Series 51 and 51-1 Cartridge Motors Only

Orientation notch

Speed sensor

180° ± 15°

11029257 • Rev BB • July 201316

Technical Information KPP PPU

Speed ring

Installation Diagrams

Connection Diagram

(continued)

S

N

S

N

S

N

S

N

Pulse Pickup

S

N

S

N

S

N

S

N

S

N

S

N

Red

White

Black

Green

Supply voltage

Supply 0.5 V

Supply ground

Direction

Applies only to direction and quadrature models

System Wiring Guidelines 1. Protect all wires from mechanical abuse. Run wire in exible metal or plastic conduits.

2. Separate high current wires such as solenoids, lights, alternators, or fuel pumps from control

wires.

3. Run wires along the inside of, or close to metal machine frame surfaces where possible. This

simulates a shield, which minimizes the eects of EMI/RFI radiation.

4. Do not run wires near sharp metal corners. Consider running the wire through a grommet

when rounding a corner.

5. Do not run wires near hot machine member or engine exhaust pipes

6. Provide strain relief for all wires.

7. Avoid running wires near moving or vibrating components.

8. Avoid long, unsupported wire spans.

9. Use harness anchors that allow wires to oat rather than rigid anchors.

Speed

1669C

11029257 • Rev BB • July 2013 17

Technical Information KPP PPU

3 pin Deutsch Plug DT Series connector

3523

Speed

3 or 4 pin Delphi Connector

3524A

4 pin Deutsch® Plug DT Series Connector

Po

3525

3526

4 pin Turck Eurofast connector

Direc

Connector Pin Assignments

Troubleshooting Steps

B

C

Ground

1

wer +

2

Speed

A

Power +

3

Ground

4

Direction

A

B

C

D

Keyway ref

B

C

Speed

tion

Power +

Speed

Ground

Direction

12.7 [0.50]

Flats

A

Power +

D

Ground

The following steps require a 1/2 inch open end wrench with standard 22° oset and a Volt Ohm

Meter (VOM):

1. Installation

First ensure that KPP is installed correctly. There are distinct directional and installation

procedures, (reference Procedures for Flat End and Conical End Models, page 14 to 15).

2. Speed Signal

Check for speed output using a VOM. Place VOM across the ground and speed pins or

terminals, (reference Dimensions, page 7) and set VOM to the DC Volt scale and low range. To

check for an output, turn pump or motor very slowly by hand or check output just as the prime

mover is coming to a stop. Note a voltage pulse at meter. It will likely be dicult to read exactly,

simply note a pulse (approximately. 60 pulses per rev.). If there is no indication of a pulse,

replace KPP.

3. Directional Signal

Check for a direction signal change using a VOM. Use the same VOM setup as in the above

speed signal check. Turn the motor slowly and note a polarity change (±) on the VOM display as

you change the motor direction.

11029257 • Rev BB • July 201318

Technical Information KPP PPU

Notes

11029257 • Rev BB • July 2013 19

Products we o er:

Bent Axis Motors

Closed Circuit Axial Piston

Pumps and Motors

Displays

Electrohydraulic Power

Steering

Electrohydraulics

Hydraulic Power Steering

Integrated Systems

Joysticks and Control

Handles

Microcontrollers and

Software

Open Circuit Axial Piston

Pumps

Orbital Motors

PLU S+1® GUIDE

Proportional Valves

Sensors

Steering

Transit Mixer Drives

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile o -highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of o -highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever o -highway vehicles are at work, so is Danfoss.

We o er expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-

Local address:

inverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Danfoss

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11029257 • Rev BB • July 2013 www.danfoss.com © Danfoss A/S, 2013

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Loading...

Loading...