Page 1

Installation Guide

Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

0.0 Table of Contents

1. General.......................................3

1.1 Introduction.............................................3

1.2 Application..............................................3

2. Specification ..................................4

2.1 General Description .....................................4

2.1.1 Type ....................................................4

2.1.2 Design ..................................................4

2.1.3 Characteristics...........................................4

2.1.4 Display ..................................................5

2.1.5 Electronics ..............................................5

2.1.6 Versions.................................................5

2.1.7 Optical Interface.........................................5

2.1.8 Radio Transmission ......................................5

2.2 Operating mode.........................................6

2.2.1 Cycle Time...............................................6

2.2.2 Single Sensor Version with Start Sensor...................6

2.2.3 Double Sensor Version...................................6

2.2.4 Comparison of the Measuring Principles..................7

2.2.5 Temperature Measurement and Calculation ..............7

2.2.6 Calculation of the Displayed Consumption Value .........8

2.2.7 Start of Counting ........................................9

2.3 Display and Additional Functions .......................10

2.3.1 The Menu Sequences of the Digital Display..............10

2.3.2 The Digital Displays.....................................12

2.3.3 Rolling Digital Display ..................................15

2.3.4 Energy-Saving Night Mode between 20.00 and 6.00 h ...16

2.3.5 Communication Indicator ..............................16

2.3.6 Real Time Clock and Calendar ...........................16

2.3.7 Readout................................................17

2.3.8 Check Code ............................................17

2.3.9 Change of Battery ......................................18

2.3.10 Protection against Outside Influences . . . . . . . . . . . . . . . . . . .18

2.4 Special Functions.......................................19

2.4.1 Suppression of Summer Counting.......................19

2.4.2 Programmable Start Temperature of

Summer and Winter period .............................19

2.4.3 Annual Reset of the Values..............................19

2.4.4 Unit Scale and Product Scale ............................19

2.5 Parameterisation .......................................21

2.6 Error ...................................................21

2.6.1 Description of the Function Control .....................21

2.6.2 List of Errors ............................................22

2.7 Radio Standby – Radio-HCA INDIV-X-10W ...............22

2.7.1 Sleeping Mode .........................................22

2.7.2 Installation Mode .......................................22

2.7.3 Operation Mode........................................23

3. Installation ..................................24

3.1 Introduction............................................24

3.2 DIN Standard Requirements for the Installation..........24

3.3 General Restrictions ....................................25

3.4 Operating Range .......................................25

3.5 Installation to the Radiator..............................26

3.6 Wall-Mounting .........................................27

3.7 Installation of Fastening-Parts Kits.......................28

3.7.1 Installation to Sectional Radiator ........................28

3.7.2 Wall-Mounting - Sectional Radiator .....................28

3.7.3 Installation to Folded Radiator ..........................29

3.7.4 Wall-Mounting – Folded Radiator .......................30

3.7.5 Installation to Panel-Type Radiator ......................31

3.7.6 Wall-Mounting - Panel-Type Radiator....................32

3.7.7 Installation to Panel-Type Radiator

with Front Convection Plate.............................33

3.7.8 Bathroom radiator – Towel rails .........................34

3.7.9 Sectional radiator wide .................................35

3.8 Overview mounting accessories.........................36

3.9 Mounting and Sealing ..................................37

4. Commissioning ..............................38

5. Readout .....................................39

5.1 Manual Readout ........................................39

5.2 Readout over the Optical Interface ......................39

5.2.1 Optical Probe...........................................39

5.2.2 Transmission Protocol ..................................39

5.2.3 Timing of the Optical Interface ..........................40

5.2.4 Frames of the Optical Readout ..........................41

5.2.5 Remote Radio Readout .................................43

5.2.6 Stationary Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Danfoss Heating VIIGC102

1

Page 2

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

0.0 Table of Contents

5.2.7 Timing of Radio Transmission ...........................44

5.2.8 Frame of the Radio Transmission ........................45

6. Rating factors ................................46

6.1 Taking Measurements ..................................46

6.1.1 Rating of Radiators of Over Length or

High Nominal Output...................................46

6.1.2 Rating of Radiator ......................................47

6.2 Table of Rating factors ..................................48

7. Technical Data ...............................50

7.1 Dimensional Drawing...................................51

8. Enclosure ....................................52

8.1 Enclosure 1.............................................52

8.2 Enclosure 2.............................................53

8.3 Temperature Limits acc. to EN 834.......................54

8.4 Calculation of Temperature – Interpolation Table ........55

8.5 Rating factors acc. to EN 834 ............................56

2

VIIGC102 Danfoss Heating

Page 3

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

1. General

1.1 Introduction

This installation guide is used for the users and the service

personnel of the Danfoss heat cost allocators. It describes the

handling of the heat cost allocator INDIV-X-10V and the radio heat

cost allocator INDIV-X-10W. Since the measuring functions are the

same for both heat cost allocators the descriptions in this guide

apply for both versions. In case of deviations, a special note is

made to this end.

Primarily, the installation of the heat cost allocator to the most

common radiator types is described. Apart from the information

on the installation of the heat cost allocator, basic information

(rating of heat cost allocators) is given and special features of our

devices (design, function, installation) are described in this guide

as well.

1.2 Application

The heat cost allocator is an accessory measuring device to record

the heat output of radiators in units.

Units are apartments, office-, and business-, commercial or

industrial premises where the heat is supplied by a conjoint

central heating system or via a conjoint district heating station.

The entity of the units forms a billing unit.

If one billing unit consists of units with typical differences (e.g.

technical differences such as different heating systems or different

consumptions of e.g. industrial premises and apartments), a

sub-division of the billing unit in unit groups may be necessary.

Each radiator is equipped with a heat cost allocator which

records and assesses the heat output of the radiator and displays

the consumption value. The consumption value is the basis for

allocating the heating costs to each unit which is necessary for the

annual billing of the heating costs.

Danfoss Heating VIIGC102

33

Page 4

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.1 General Description

2.1.1 Type

The electronic heat cost allocators Danfoss INDIV-X-10V / INDIVX-10W operate either according to the single sensor principle

with start sensor or the double sensor principle. The device has

been developed and approved in accordance with the European

Standard EN 834:2013.

2.1.2 Design

The heat cost allocator consists of a microprocessor, a lithium

battery, two temperature sensors, a heat conducting aluminium

back plate, a multi-functional display and a plastic housing.

The measuring circuit consists of the temperature sensors,

the analogue-digital conversion, the reference resistance

for standardising the measuring transformation and the

microprocessor for accessing the radiator heat output. During

each measuring the circuit tolerances are eliminated with a

reference resistance and the heat cost allocator carries out an

automatic self-test.

2.1.3 Characteristics

• Measuring by two temperature sensors, radiator and ambient

temperature sensor (NTC-resistor)

• Optional measuring principle: 1 sensor mode with start sensor

or two sensor mode

• Unit scale or product scale

• Recording of cumulated heat consumption on the annual set

day

• Recording of 36 monthly values or 18 monthly and half monthly

values

• Optical interface for the readout of the data and programming

• Readout via radio optional with a mobile radio modem or

directly by the billing office over the radio central installed

outside the unit

• User-friendly operation by push button

• 6-digit and high-contrast LCD display

• Check code for postcard mail-in method

• Remote sensor version with 1.5 m cable

• Standard aluminium back plate for nearly all existing bolts with

common dimensions and installation possibilities – thus easy

installation (no cutting and welding of bolts necessary)

• Snap-on blind to cover colour shadows for increased aesthetics

• Safe operation and fraud detection

• Factory seal protecting against unauthorized manipulation

• Possibility to use seal sticker as second seal for further

protecting against manipulation

• Lithium battery with a capacity of up to 10+1 years

• Meets EN 834:2013.

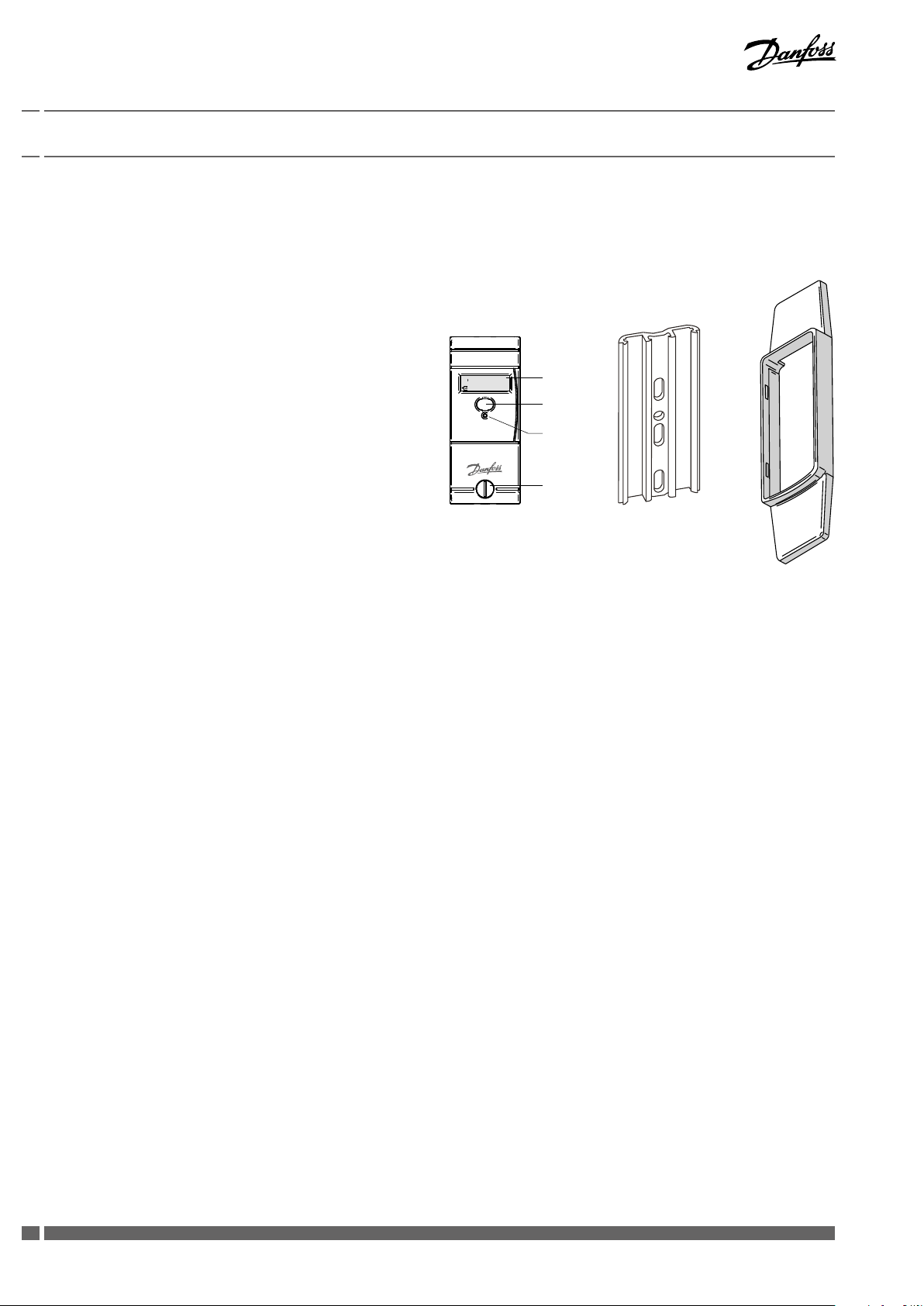

::

LCD-Display

Optical

Interface

Push Button

Seal

Standard aluminium

back plate for nearly

all existing bolts with

common dimensions

and mounting

possibilities – thus

easy installation.

Snap-on blind

to cover colour

shadows for

increased

aesthetics.

4

VIIGC102 Danfoss Heating

Page 5

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

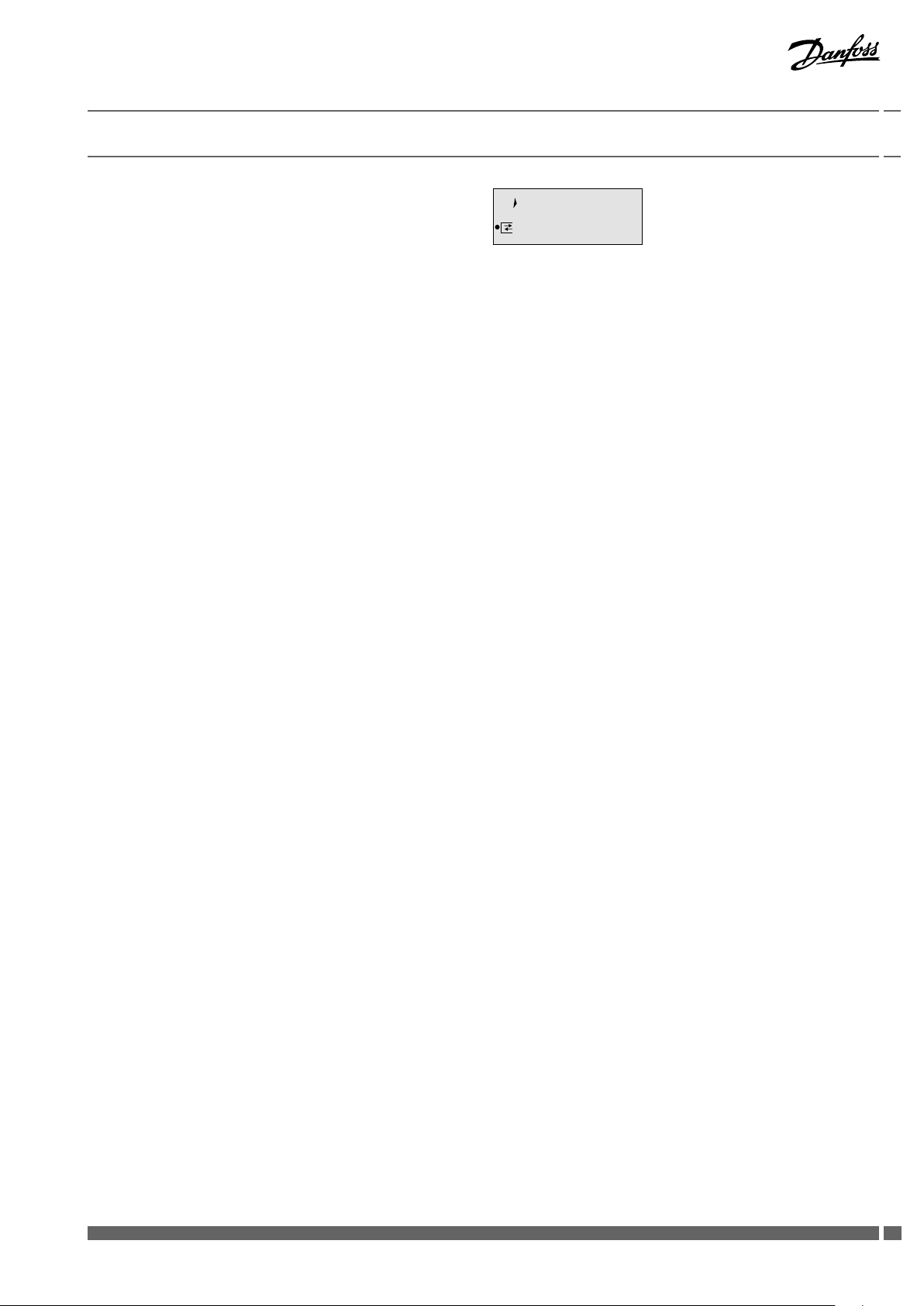

2.1.4 Display

The heat cost allocator has a LCD-display with 6 large main digits

on the right and 2 smaller digits on the left as well as two special

symbols and one communication indicator. The main digits are

separated by four decimal points. Below, please find the display

segments:

Normally, the heat cost allocators INDIV-X-10V / INDIV-X-10W are

supplied with switched-off LCD-display. On request, the heat cost

allocators can also be supplied with permanent LCD- display.

2.1.5 Electronics

The device has an electrical circuitry with an 8-Bit-CMOS-micro

controller of the latest generation H8-300L with extremely low

current consumption operating at a voltage as from 1.8 V.

The temperature measuring circuit with automatic self-calibration

measures the discharging time of a capacitor. The accuracy of the

measuring circuit is independent of the supply voltage.

2.1.6 Versions

• Heat cost allocator INDIV-X-10V with optical interface, standard

device

• Heat cost allocator INDIV-X-10VT with optical interface, remote

sensor device with 1.5 m cable

::

Display with all active segments

• Radio heat cost allocator INDIV-X-10W with optical interface,

standard device

• Radio heat cost allocator INDIV-X-10WT with optical interface,

remote sensor device with 1.5 m cable.

2.1.7 Optical Interface

With a standardised optical probe the consumption and

configuration values can be transferred directly to a computer.

With the radio heat cost allocator INDIV-X-10W all consumption

values can thus be readout over the optical interface and over

radio. The data are transmitted in M-bus-format acc. to EN1434.

Authorised personnel can alter the configuration of the device

over the optical interface with an optical probe.

2.1.8 Radio Transmission

The radio heat cost allocator INDIV-X-10W features a transceiver

circuit in the 433 MHz band with integrated antenna. With the

radio system, proven since more than 10 years; it is possible to

readout the consumption values via a mobile radio modem or via

a radio central installed directly in the office. The radio system is a

bidirectional system, i.e. the radio heat cost allocator is only called

from a mobile PDA or a radio central upon request to send its data.

It is a great advantage that this system allows the alteration of the

parameters over radio.

Danfoss Heating VIIGC102

55

Page 6

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.2 Operating mode

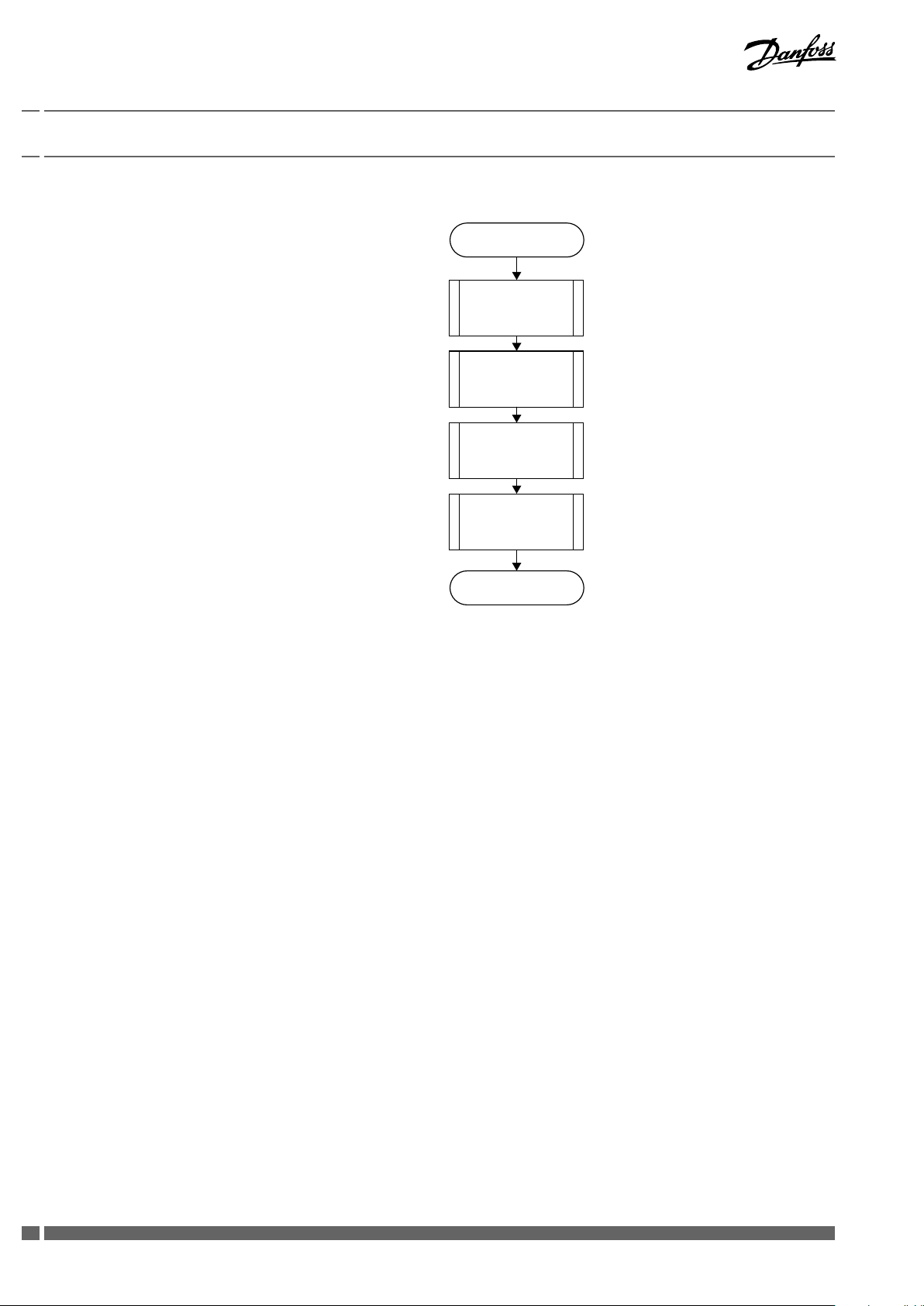

2.2.1 Cycle Time

The heat cost allocators INDIV-X-10V / INDIV-X-10W operate in

a cycle of 4 minutes. Most of the time, the device is in sleeping

mode. Every 4 minutes the device is set into operation and

operates according to the adjoining diagram.

The clock-pulse generator is a counter which is completely

independent from the rest of the programme. This counter is

designed in a way so that it is impossible to stall the cycle or to

skip one or more cycles.

Each cycle follows the adjoining diagram. The measuring and

calculating processes are explained in detail later.

The tasks carried out during one cycle are taking approx. 200 ms.

This means that the device is in sleeping mode more than 99.8 %

of the time. It can be set into operation between two cycles over

the optical probe or by pushing the button. In this case it carries

out the requested task and then returns to sleeping mode.

In case an optical probe is connected or the button is pushed

during the course of the cycle, the respective value is readout at

the end of the cycle.

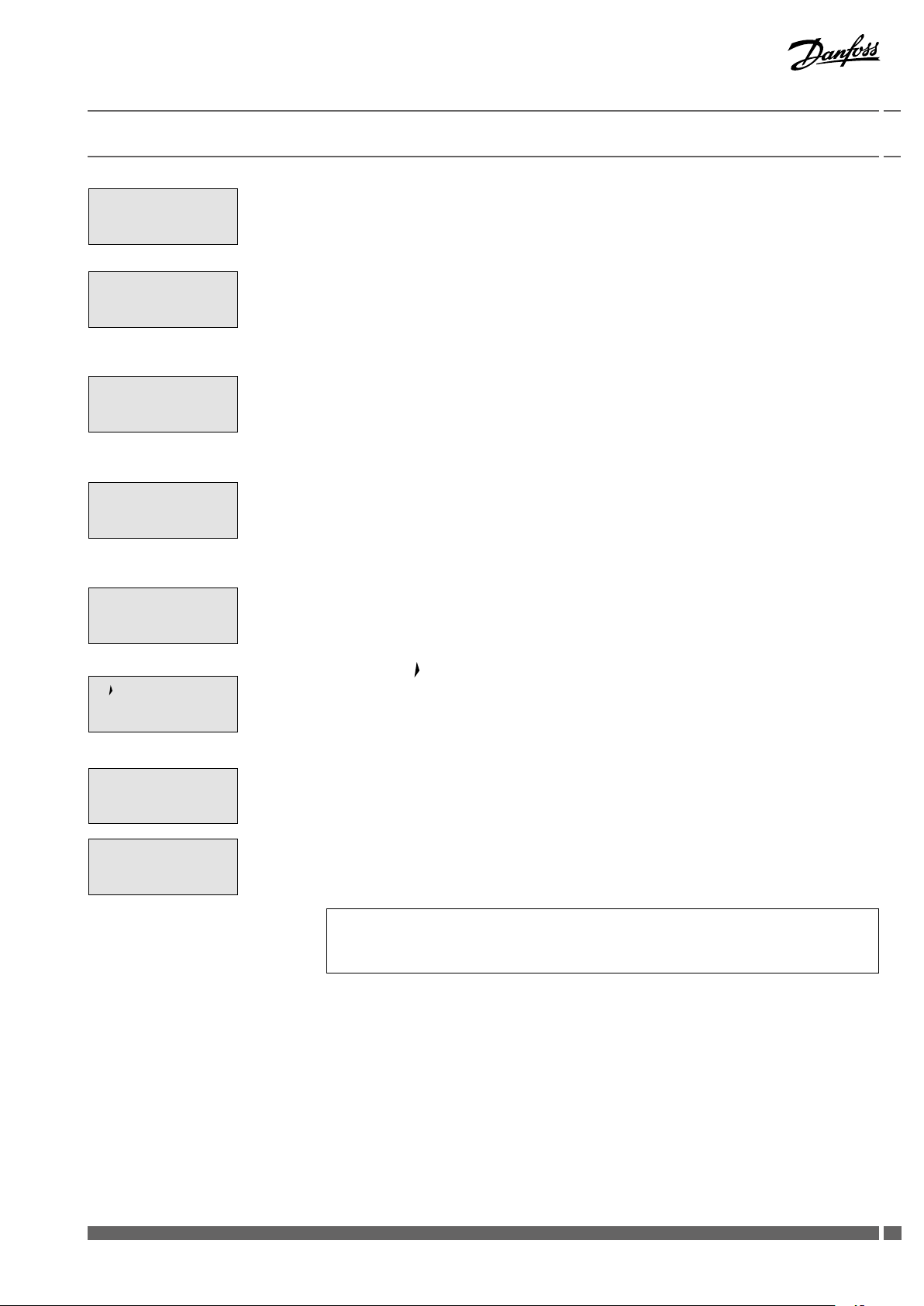

Start of cycle

Update time and

date

Measuring and

calculation of the

temperatur

Calculation of the

new consumtion

value

Update display

End of cycle

The button can be pushed for an indefinite period of time and the

optical probe can be left in its position since the normal function

of the device is not impaired by an influence from outside.

2.2.2 Single Sensor Version with Start Sensor

The start sensor of the single sensor version serves as an ambient

temperature sensor which mainly functions during the heating up

period.

The start temperature is the threshold temperature of the radiator

at which the device always starts to carry out energy ratings. For

these ratings, the measured radiator temperature and an assumed

ambient temperature of 20° C are used as calculation basis.

2.2.3 Double Sensor Version

For the double sensor version basically the same specifications

apply as for the single sensor ver-sion with start sensor. However,

for calculating the room temperature the real temperature,

meas-ured by the ambient temperature sensor (corrected via the

corresponding radiator-dependent „Kair-value“), is used as the

basis.

2.2.3.1 Heat Accumulation Mode

In order to avoid faulty measuring due to heat accumulation (e.g.

in case the radiator is hidden by panels), the device switches from

a defined ambient temperature (e.g. 28°C) to the one sensor mode

and calculates with an ambient temperature of 20° C.

6

VIIGC102 Danfoss Heating

Page 7

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

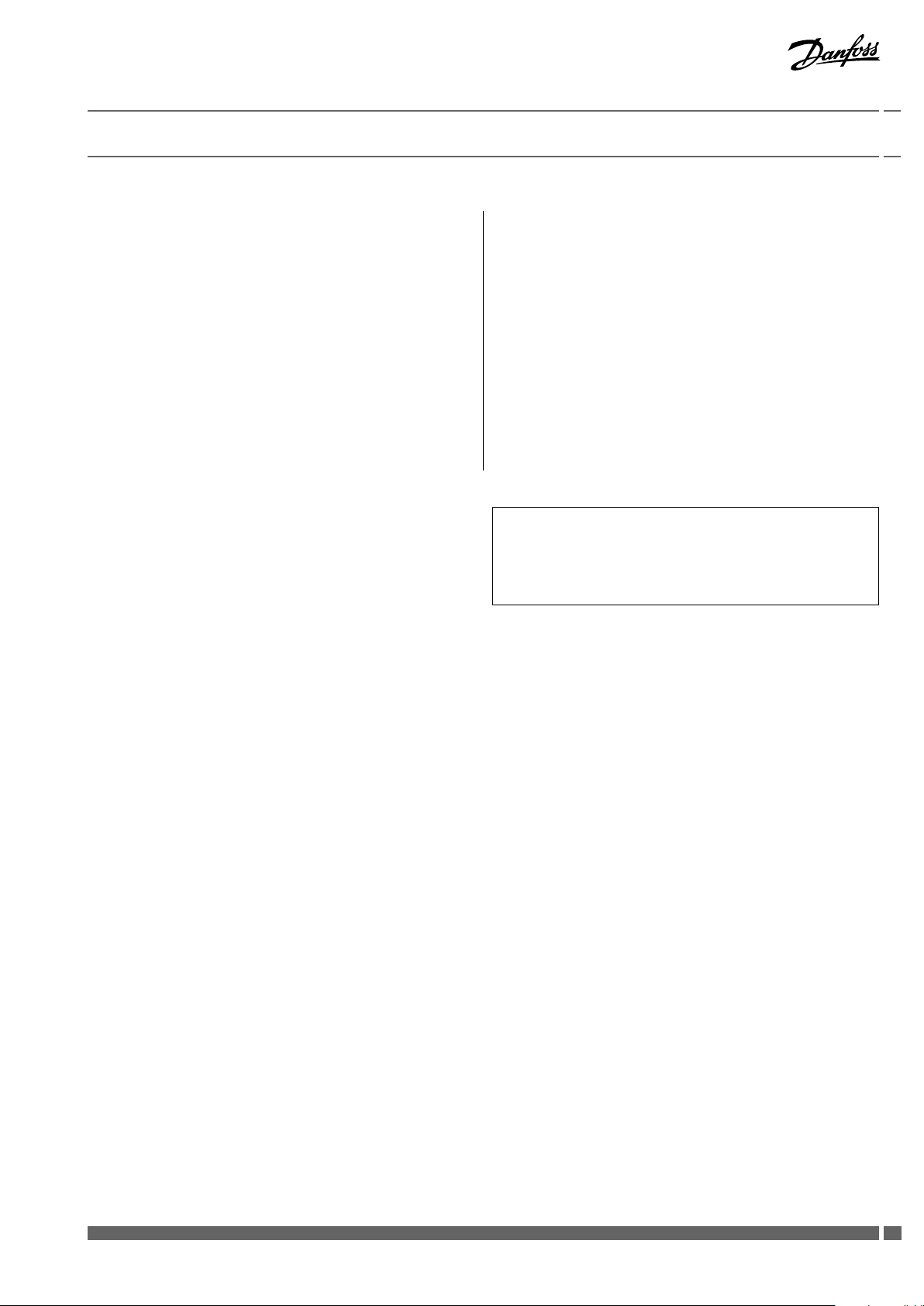

2.2.4 Comparison of the Measuring Principles

Single sensor device with start sensor measuring principle

For heating systems with tm

≥ 55 °C

min

The heat cost allocator calculates with a set reference temperature

of 20 °C

Application:

Single sensor devices with start sensor are used in areas where

normal ambient temperatures are given. For low temperature

heating systems the double sensor device is recommended.

For radiators which are covered or blocked by fixtures, normally

the single sensor devices are used because the double sensor

device is not in a position to capture the current ambient

temperature due to the heat accumulation.

The processes for determining the K-value for the single sensor

device with start sensor and the double sensor device are

identical. It is only the measuring principle that is different.

2.2.5 Temperature Measurement and Calculation

The temperature is measured with an NTC – resistor. For the

resistance measurement the dis-charging time of the capacitor is

measured. The measurement is carried out as follows:

2.2.5.1 Measuring of a Resistor, Principle

1. Charging of the capacitor

Double sensor measuring principle

For heating systems with tm

≥ 35 °C

min

The heat cost allocator calculates with a variable reference

temperature T

air temperature

Application:

Double sensor devices are used in areas where precise measuring

of the ambient temperature is necessary and/or in low

temperature heating systems.

Radiators which are covered or blocked by fixtures are detected

automatically by the double sensor system which then switches

over internally to the single sensor mode.

Within one billing unit, only one measuring principle

(either single sensor measuring principle with start sensor

or double sensor measuring principle) can be used. Mixed

fitments or the use of different types of devices in the same

billing unit is therefore also not allowed.

2. Discharging of the capacitor through the resistance which is to

be measured. At the same time a 16-bit-timer starts with the

discharge to measure the discharging time.

3. As soon as the voltage on the capacitor terminals reaches a

certain value, an interrupt is in-duced and the timer stops. At the

same time the discharging of the capacitor is stopped as well.

After the three mentioned stages, the timer provides a 16-bitvalue which corresponds to the dis-charging time of the capacitor

through the resistance which is to be measured. In case the

resistance is known (reference resistance), the constant ratio

between discharging time and resistance can be assessed.

Danfoss Heating VIIGC102

77

Page 8

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

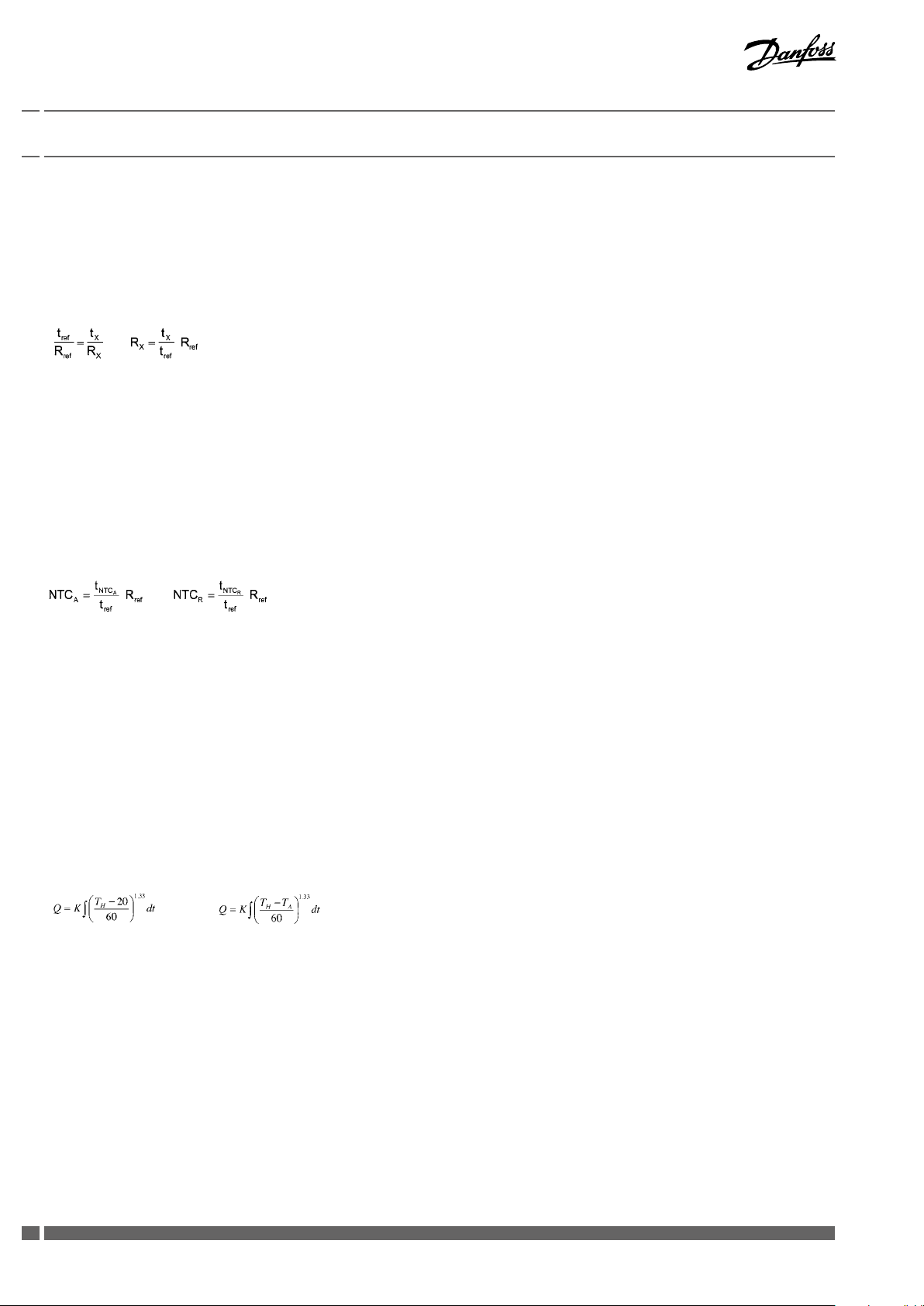

2.2.5.2 Calculation of the Value of an Unknown Resistance

(e.g. sensor resistance)

The capacitor C is loaded at constant current. The interrupt at the

end of the discharge is triggered by the same threshold voltage (a

fraction of the discharge voltage). If these two conditions are met,

the discharge time is directly proportional to the resistance. With

a reference resistance R

possible to calculate the unknown resistance value Rx with the

following equation:

From this equation the self-calibration of the converter can

be derived, which is given by measuring the discharging time

through the reference resistance.

2.2.5.3 Measuring of the Radiator and Ambient Temperature

The following measurements are carried out during one cycle:

1. Measuring of the reference resistance R

2. Measuring of the ambient temperature sensor NTC

3. Measuring of the radiator temperature sensor NTC

whose exact value is known, it is now

ref

ref

A

R

The measuring values are calculated with the following formula:

The reference resistance value is defined ex works with a tolerance

of 0.5% with 50 ppm. The reference resistance features an excellent

temperature and long-term stability.

The capacitor value and the threshold voltage have to remain

stable over the whole cycle. However, they can vary at the

medium- or long term without causing any failures because the

self-calibration of the converter is repeated in every cycle while

measuring the reference resistance.

2.2.6 Calculation of the Displayed Consumption Value

The value displayed on the heat cost allocator is calculated as

follows:

Single sensor device Double sensor device

Explanation: TH Temperature of the radiator surface in [°C]

TA Ambient temperature in [°C]

Q Displayed consumption value, without unit

K Correction factor

Unit scale: K = 1, set, transmitted via readout telegram 0.

Product scale: Acc. to entry K = KC * KQ

! see also in chapter 6.1.2 Rating of radiators !

8

VIIGC102 Danfoss Heating

Page 9

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.2.7 Start of Counting

The updating (increment) of the consumption value is carried out

under the following conditions:

During winter period (heating period):

(TR ≥ 25 °C)

OR

(TR ≥ 20 °C ) AND (TR - TA ≥ ΔT

MIN

)

During summer period (off heating period):

(TR ≥ 35 °C)

OR

(TR ≥ 20 °C ) AND (TR - TA ≥ ΔT

Explanation: T

TA Ambient temperature

ΔT

radiator and room

Radiator temperature

R

Minimum temperature difference between

MIN

MIN

)

3K for standard device (winter heating

period standard setting)

4K for remote sensor device (summer

heating period standard setting)

Danfoss Heating VIIGC102

99

Page 10

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

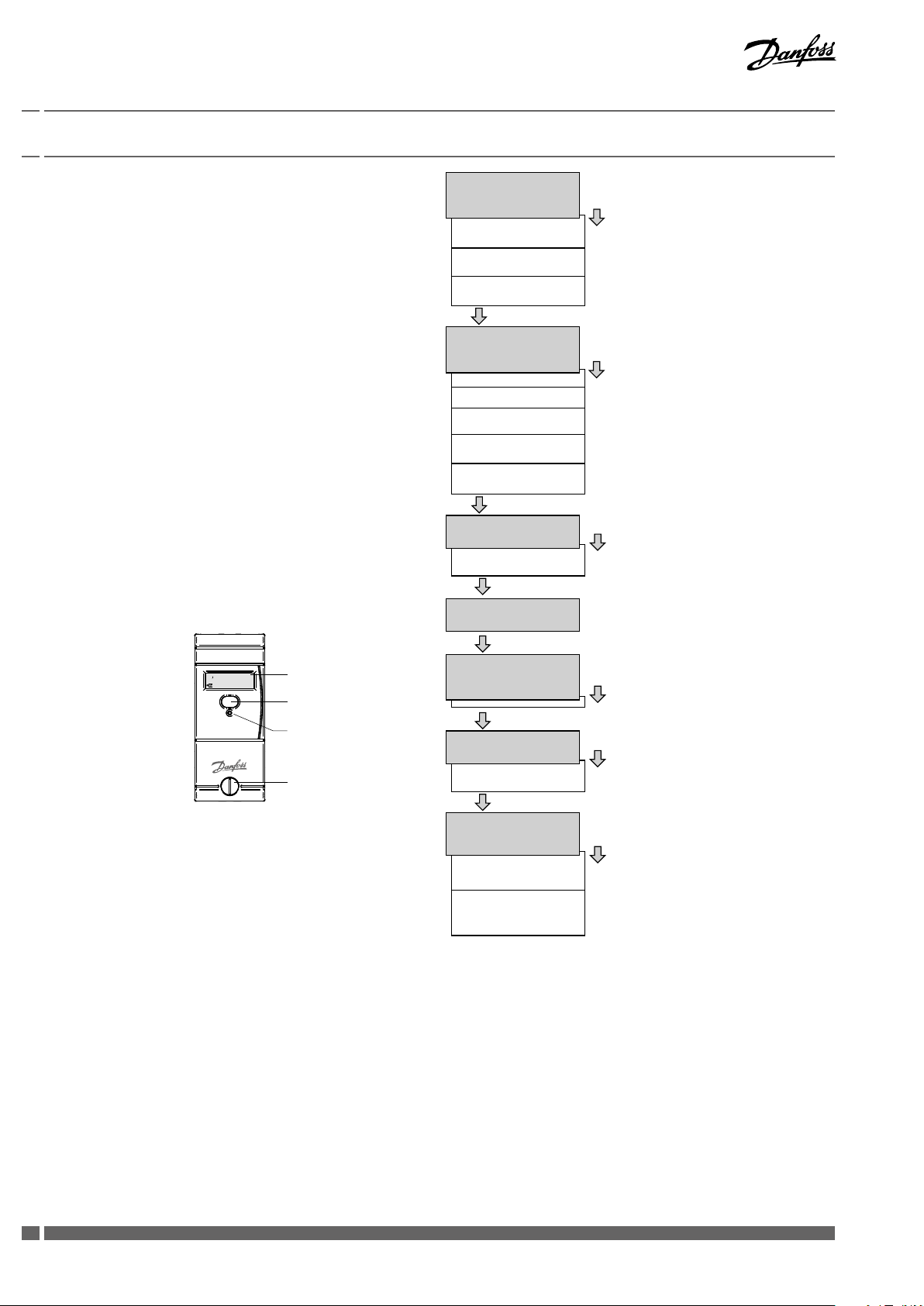

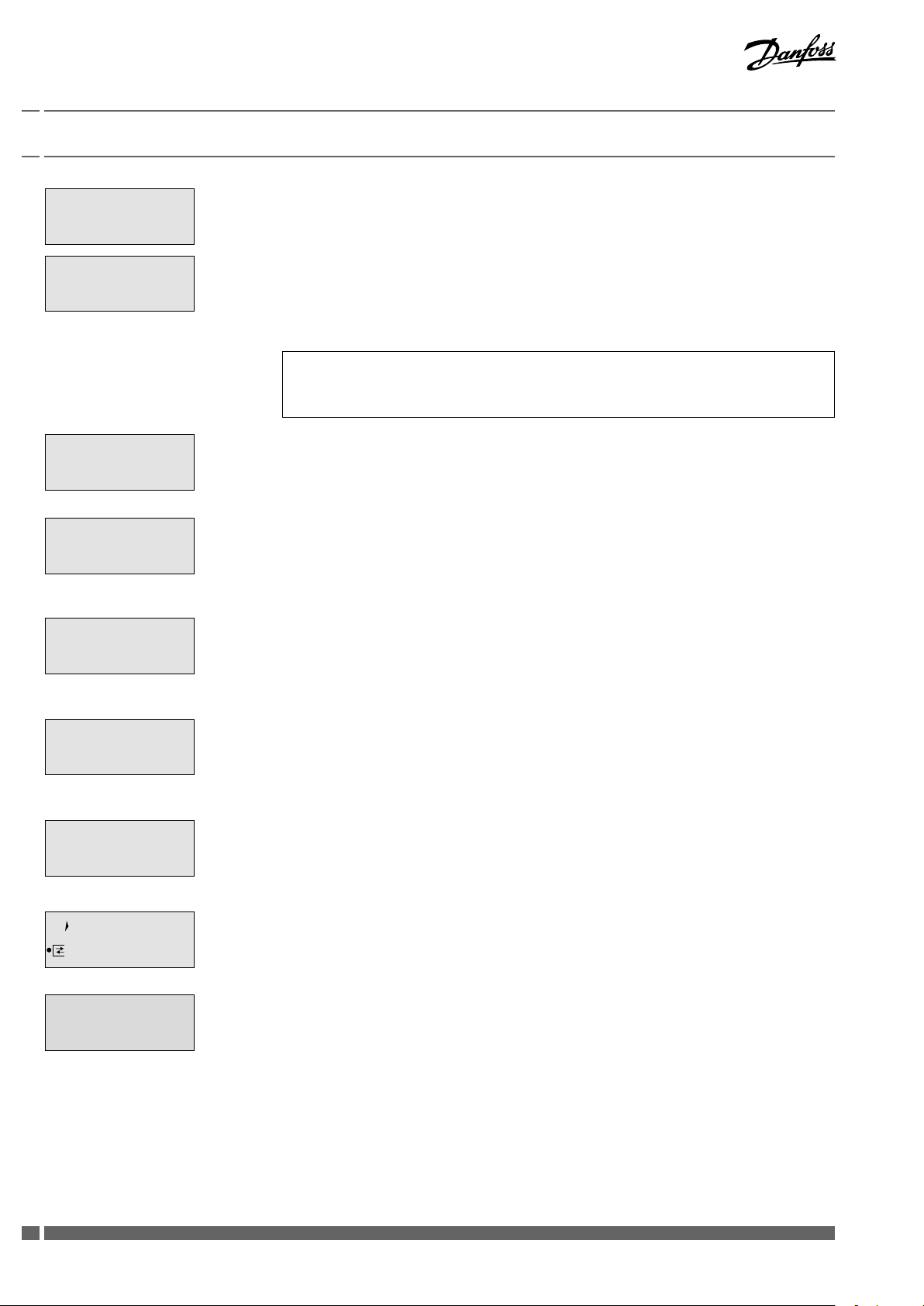

Long key press

Long key press

Long key press

Long key press

Long key press

Long key press

Display position 7

Display position 6

Display position 5

Display position 4

Display position 2

Display position 1

Display position 3

2. Specification

2.3 Display and Additional Functions

Comsumption value

2.3.1 The Menu Sequences of the Digital Display

The menu sequences

Ex factory all menu sequences are activated. With the software

INDIV-X-VISUAL-CONF the order of the menu sequences 1 - 7 can

be changed in any order. However the order within the individual

menu sequences 1 – 7 can-not be changed. It is also possible to

hide individual menu sequences so that they are not visible to the

end-user.

When reading out over the optical interface or via radio the

complete set of data is always readout and transferred.

Operation of the Push Button

When pushing the button briefly the digital display always goes to

the next menu sequence.

When pushing the button in one menu sequence for 2 seconds

the individual values within the selected menu sequence can

be accessed. When the last value within one menu sequence

has been displayed, the next menu sequence can be reached by

pushing the button again.

If the button is not pushed for 2 minutes, the digital display

returns to the cumulated consumption value.

::

LCD-Display

Optical

Interface

Push Button

Set day value

Check code

Value on December 31st

or before the reset to 0

Short key press

Current time

Current date

Set day date

Date of opening of the

device

Commissionen date

Cumulated duration of the

opening of the device

Short key press

Set day value

Check code

Short key press

Check code

Short key press

Monthly values

Short key press

Radiator temperature

Seal

10

VIIGC102 Danfoss Heating

Ambiant temperature

Short key press

Segment test

Identication number

Measuring principle +

software version

Page 11

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

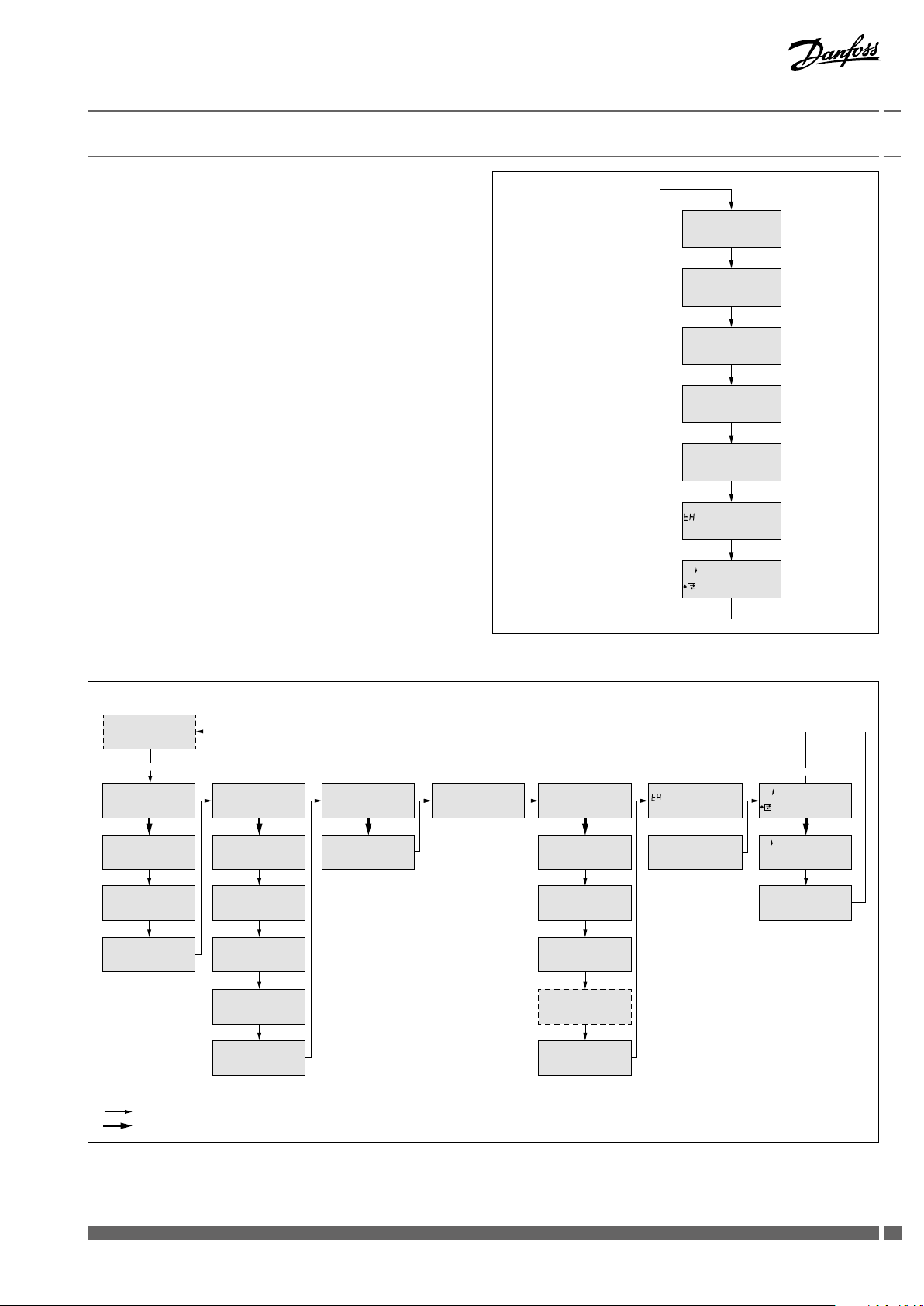

Display loops and display menu sequences – example

The display loops and display menu sequences are customized, for

example, the rolling display:

Current consumtion

unit scale

Date and Time

Set Day Value unit scale

Check code

Last monthly value

Radiator Temperature

Segment Test

::

.

::

7 S

7 S

7 S

7 S

7 S

7 S

1 S

And the display menu sequences:

Error messages

Current consumtion

unit scale

Short pression on push button (1s)

Long pression on push button (>2s)

Date and Time

::

..

..

..

..

Set Day Value unit scale Check code Monthly Value Radiator Temperature Segment Test

.

.

::

.

Danfoss Heating VIIGC102

1111

Page 12

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.3.2 The Digital Displays

During normal operation the display is deactivated and can

be activated by pushing the button. On request, the heat cost

allocator is also available with permanent display from 06:00 –

20:00 h or 24 hours a day. The consumption value is displayed.

By pushing the button and depending on the configuration of the

heat cost allocator more than 50 different values can be displayed.

If the button is not pushed, the display will be active for 2 minutes

only. Exception: permanent display mode.

Consumption Value Unit Scale

On the display of the heat cost allocator with unit scale an index u for unit is shown on the left

side. If the index u is not displayed, the heat cost allocator is equipped with the product scale.

Consumption Value Product Scale

When commissioning the device this value is 000000. When reaching the value 999999, the

counting restarts automatically at 000000.

Set Day Value

With the index ud the consumption value in unit scale recorded at midnight of the set day is

displayed.

Set day Value product scale

Check Code

Consumption Value of the

Previous Heating Period

Time

If a new device has not yet reached the programmed set day, 000000 is displayed.

With the index d the consumption value in product scale recorded at midnight of the set day is

displayed.

If a new device has not yet reached the programmed set day, 000000 is displayed.

With the index cc the check code for the plausibility check of the manual readout is displayed.

With the index uI the consumption value is displayed which was recorded on December 31st or

before the reset to zero.

000000 is displayed on a new device as long as a reset has not been carried out.

The current time (always winter time)

:

12

VIIGC102 Danfoss Heating

Page 13

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

Date

The current date of the heat cost allocator

..

Set Day

..

Date of Opening of the Device

..

Commissioning Date

It is possible to program an annual set day on which the cumulated consumption value as well

as the maximal radiator temperature are recorded.

With the index Sd the programmed annual set day is displayed.

Each heat cost allocator is equipped with a manipulation protection which detects an

unauthorised opening of the device after installation to the radiator. The date of the opening of

the device is recorded and displayed with the index od.

With the index cd the commissioning date is displayed, i.e. the date on which the device has

been activated by pushing the button or the date of commissioning programmed ex factory.

..

Cumulated Duration of the

Opening of the Device

Identification Number

Monthly Values

Values

The cumulated duration in minutes during which the device was opened is detected. This

display turns up only after commissioning in case the heat cost allocator was opened or

removed.

With the index

identical with the identification number. The first two digits of the identification number are

the two small digits on the left upper side of the digital display.

The cumulated consumption values are recorded automatically at midnight on the last day of

each month.

Number of monthly values: 18 or 36

The small digits on the upper left side show the number of previous monthly values. Digit 01

stands for the recent full month and digit 18 or 36 stands for the least recent month.

All monthly values are set to 000000 when the device is commissioned.

an 8 digit identification number is displayed. Ex factory the serial number is

Note INDIV-X-10W radio:

The radio heat cost allocator INDIV-X-10W only transmits the first 16 monthly values

via radio telegram.

Danfoss Heating VIIGC102

1313

Page 14

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

Half Monthly Values

Radiator Temperature

The cumulated consumption values are recorded automatically at midnight on the 16th of

each month.

The small digits on the upper left side indicate the number of half monthly values. Digit 41

stands for the recent half monthly value and digit 58 for the least recent half monthly value. All

half monthly values are set to 000000 when the device is commissioned.

If the heat cost allocator INDIV-X-10V is programmed with 36 monthly values the menu

sequences for the half monthly values are omitted.

Note INDIV-X-10W radio:

The heat cost allocator INDIV-X-10W does not transmit the half monthly values via

radio telegram.

With the index tH the current radiator temperature is displayed.

.

Ambient Temperature

With the index tA the current ambient temperature is displayed.

.

Maximum Radiator Temperature

of the Current Heating Period

With the index P0 the maximum radiator temperature since the last reset or of the current

heating period is displayed.

.

Maximum Radiator Temperature

of the Previous Heating Period

With the index P1 the maximum radiator temperature before the last reset or of the previous

heating period is displayed.

.

Measuring Principle and

Software Version

.

Segment Test

With the index F1 or F2 the measuring principle is displayed.

F1 = single sensor device with start sensor

F2 = double sensor device

On the right side the software version x.xx of the heat cost allocator is displayed.

Segment test of the display.

::

Error Message

If an error is detected, Err is displayed in the first display sequence with the corresponding error

message.

14

VIIGC102 Danfoss Heating

Page 15

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.3.3 Rolling Digital Display

The EHCA INDIV-X-10V and INDIV-X-10W also feature the

possibility of a rolling display between 06:00 – 20:00 h.

With the software INDIV-X-VISUAL-CONF it is possible to

individualise the rolling display. Up to 7 parameters can be chosen

optionally from the list below. These parameters can be combined

in any order and are then shown on the rolling display.

• Consumption value

• Time

• Date

• Set day

• Set day value

• Last monthly value

• Last half monthly value

• Radiator temperature

• Ambient temperature

• Maximum radiator temperature of the current heating period or

since the last reset

• Segment test

The duration of the display of the values can be chosen

individually as follows:

• Short duration: 1 s (set, cannot be changed)

• Long duration: 2 - 7 s (only one value can be chosen)

Example:

Order and duration of display

• Pos. 0: Error (parameter ex factory, cannot be changed [5 s]

(only displayed in case of an error message)

• Pos 1: Time [1 s]

• Pos 2: Segment test [1 s ]

• Pos 3: Consumption value [4 s]

• Pos 4: Set day [1 s]

• Pos 5: Set day value [4 s]

• Pos 6: Last monthly value [1 s]

• Pos 7: Blank (therefore no display. It is not necessary to

occupy all positions)

The rolling display can also be deactivated by the

INDIV-X-VISUAL-CONF, i.e. the device operates as in standard

menu mode except that only these values and the values of the

corresponding sub-menus that have been defined in the rolling

menu can be displayed by pushing the button. After 2 minutes

during which the button has not been pushed, the display goes

out.

Danfoss Heating VIIGC102

1515

Page 16

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.3.4 Energy-Saving Night Mode between 20.00 and 6.00 h

If the LCD-display is activated, the heat cost allocator switches

automatically to the energy-saving night mode between 20.00

and 06.00 h (winter time). During this period the LCD-display is

deac-tivated and switched off generally.

2.3.5 Communication Indicator

The communication indicator displays if the heat cost allocator is

currently making a calculation and/or if it communicates internally

or externally over the optical or wireless interface.

2.3.6 Real Time Clock and Calendar

The device has a 24 h real time clock and a calendar. However, the

change from summer to winter time is not taken into account. The

calendar is programmed until December 31 2099, including all

leap years. The real time clock as well as the date of the heat cost

allocator can be readout over the optical interface or via radio and

if necessary be updated.

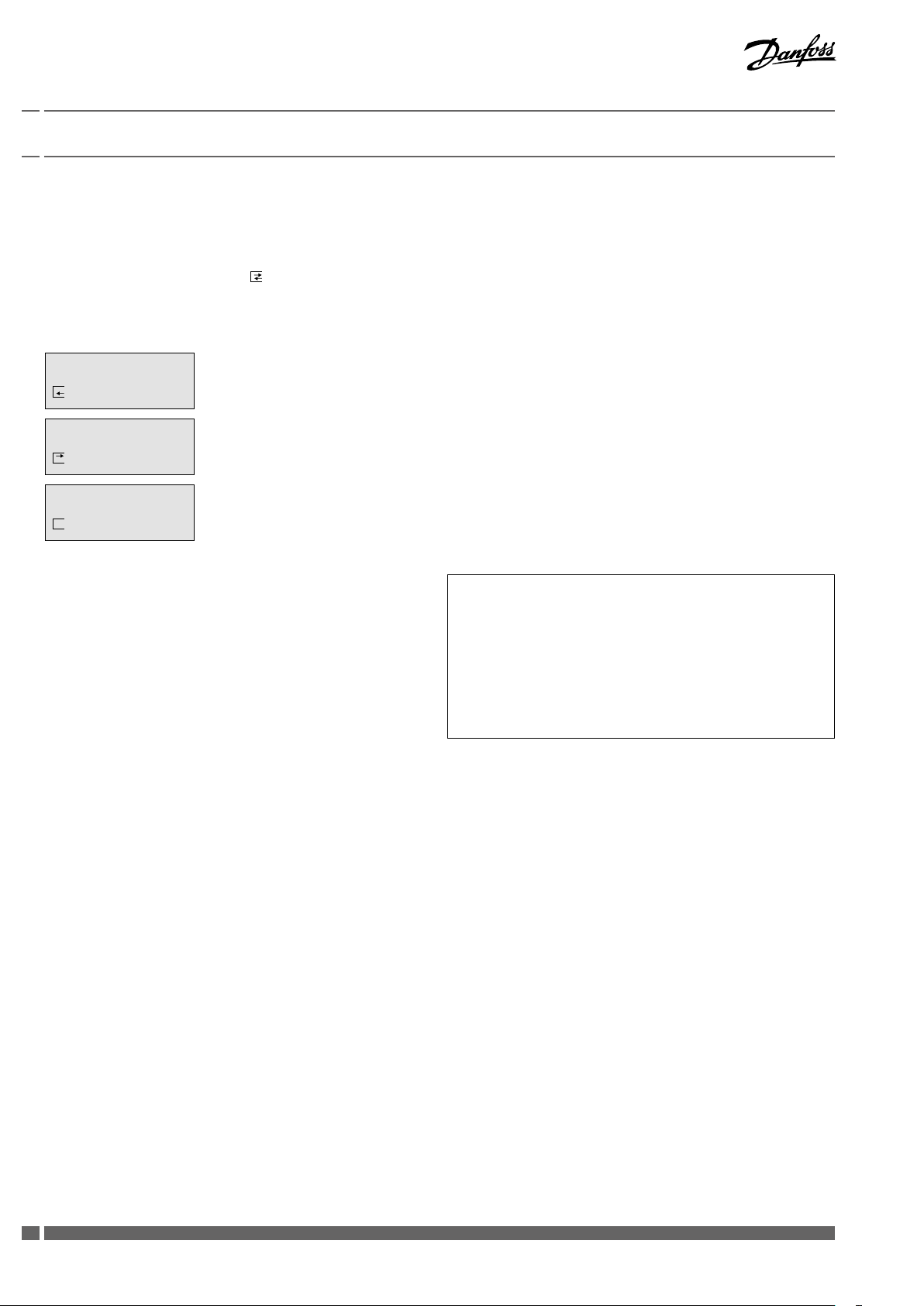

If the arrow of the communication indicator points inwardly internal communication takes

place over the optical or wireless interface.

If the arrow of the communication indicator points outwards external communication takes

place over the optical or wireless interface.

If the frame of the communication indicator appears the heat cost allocator is carrying out a

measuring or a calculation.

If the current date and time have to be updated over the

optical interface or via radio, it is necessary to check the

date of the computer first. Date and time of the device

aim at those of the computer. If the reading/programming

device (computer/PDA/ Smart Phone) has a wrong time, this

time will be programmed into the heat cost allocator and

suddenly no longer be reached at the usual time, because

the time of the heat cost allocator possibly is shifted by

several hours.

16

VIIGC102 Danfoss Heating

Page 17

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.3.7 Readout

The current and monthly values recorded by the heat cost

allocator INDIV-X-10V and INDIV-X-10W as well as several other

parameters can be readout over the optical interface or also over

radio with the heat cost allocator INDIV-X-10W (see description

chapter 5).

The following parameters are transmitted:

• Identification number (information in header)

• Error

• Software version

• Date and time

• Consumption value

• K

-value x KQ-value

c

• Current radiator temperature

• Current ambient temperature

• Date of the opening of the housing

• Cumulated duration of the opening of the housing in minutes

• Date of commissioning

• Set day

• Set day value

• Value of previous heating period

• Maximum radiator temperature of current heating period

• Maximum radiator temperature of previous heating period

• Monthly values

• Half monthly values

• Serial number

2.3.8 Check Code

A special additional feature of the electronic heat cost allocator

INDIV-X-10V is the check code function for the postcard mail-in

method.

With especially developed algorithms a 6 digit check code is

generated out of several device data. With this check code the

values stated on the postcards mailed-in by tenants can be cross

checked.

For this check

• the date

• the current consumption value

• the set day value and

• the check code

are required.

For the verification of the check code Danfoss places all necessary

tools (programmes, formulas) at the disposal of the authorised

personnel.

Danfoss Heating VIIGC102

1717

Page 18

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.3.9 Change of Battery

The battery of the heat cost allocator is soldered. The lithium

battery is not rechargeable. A change of battery is not planned.

Therefore the heat cost allocators have to be replaced after 10

years.

Disposal

It is mandatory to dispose of the heat cost allocator

environmentally friendly or to return it after use to the

manufacturer for appropriate disposal to ensure that the

components are recycled in accordance with the battery and

electronic scrap regulations. Should you do the disposal yourself

please get information from your local authority on the recycling

possibilities.

2.3.10 Protection against Outside Influences

2.3.10.1 Seal and seal sticker

The heat cost allocator is closed with a seal which cannot be

removed without damaging it. Thus it is impossible to open the

device unnoticed.

A seal sticker as second seal is used for further protecting against

manipulation. After mounting, the seal sticker is fixed between

housing of heat cost allocator and aluminium back plate. Heat cost

allocator cannot be removed from aluminium back plate without

damaging a sticker.

After installation, the electronic part of the device is no longer

accessible. The digital display, the push button and the optical

interface are covered by a sight glass. It is impossible to access the

inside of the device through these openings without damaging

the sight glass.

2.3.10.2 Electronic Detector in Case of an Opening of the Device

The electronic detector detects unauthorised opening, removing

and closing of the heat cost allocator. As soon as the housing of

the heat cost allocator is opened and/or removed, the electronic

detector triggers an error message. The duration of each opening

is counted, cumulated and only the last date of opening recorded.

18

VIIGC102 Danfoss Heating

Page 19

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.4 Special Functions

2.4.1 Suppression of Summer Counting

The period during which summer counting is suppressed can be

programmed by the software.

If the heat cost allocator is in the period of summer counting

suppression, consumption measuring is deactivated. If an

automatic readout is carried out during this period the

temperatures can be read anyway since the temperature

measuring is still active.

2.4.2 Programmable Start Temperature of Summer and

Winter period

The threshold values for the start temperature can be

programmed separately for the summer and winter period within

a temperature range of 25 - 40 °C in steps of 0.01°C. The respective

change-over days (e.g. summer period as from May 15th and

winter period as from October 15th) are also freely programmable.

By separating the start temperature for the summer and winter

period, it is possible to avoid a faulty energy rating due to sun

exposure. If the value is below the start temper-ature, an energy

calculation is carried out in accordance with the conditions

mentioned in chapter 2.2.7.

2.4.3 Annual Reset of the Values

The function of the annual reset of the cumulated consumption

value can be programmed by the software over the optical

interface. One of the following dates can be chosen for the reset:

• December 31st

• Set day

• Start summer period

• Start winter period

If the special function „suppression of summer counting“

is activated, the homologation acc. to EN 834 is void. This

special function is not included in the applicable standard.

Please note that only the cumulated consumption value is reset.

All other values are not reset.

2.4.4 Unit Scale and Product Scale

For the heat cost allocators INDIV-X-10V and INDIV-X-10W,

distinction is made between the unit scale and the product scale.

If heat cost allocators are used with the same scale on all radiators,

this scale is called unit scale. The display values are the same on

the different radiators if the heat cost allocators are exposed to the

same temperature for the same period of time.

The evaluation of the display values is carried out arithmetically

with the rating factors of the calculation software to receive the

final consumption values.

Danfoss Heating VIIGC102

1919

Page 20

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.4.4.1 Advantages of the Unit Scale

• Easy and quick installation of the heat cost allocator, no

programming necessary

• Possible errors by doing the scaling on site are avoided due to

allocation by experts.

With the product scale, the radiator rating data are programmed

in the heat cost allocator on site. The overall rating factor K

is calculated directly in the heat cost allocator and thus the

consump-tion value is displayed immediately.

2.4.4.2 Advantages of the Product Scale

• The actual consumption of each consuming point within one

billing unit can be compared easi-ly and quickly on site.

total

20

VIIGC102 Danfoss Heating

Page 21

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.5 Parameterisation

With the software INDIV-X-VISUAL-CONF the following

parameterisations can be carried out over the optical interface:

Parameterisation ex factory - Example

Date and time UTC+1 (winter time)

Set day 01.01.

Date of commissioning deactivated

Start of summer period May15

End of summer period October 15

Start temperature summer period 35°C (Radiator temperature)

Start temperature winter period 25°C (Radiator temperature)

Activation of heat accumulation mode summer period 35°C (Maximum ambient temperature)

Activation of heat accumulation mode winter period 28°C (Maximum ambient temperature)

Double sensor measuring principle activated

Single sensor measuring principle with start sensor deactivated

Reset to zero of consumption value deactivated

Suppression of summer counting deactivated

Unit scale activated §

Product scale deactivated

Rating factor KC 1.0 §

Rating factor KQ 1.0 §

36 monthly values activated

18 monthly and 18 half monthly values deactivated

Check code activated

Identification number identical with serial number

Digital display deactivated

Menu sequences all

Rolling display activated

Sleeping mode activated

Cold counting deactivated

§ Unit scale ➞ K

With the software INDIV-X-VISUAL-CONF it is also possible to reset all recorded consumption values as well as all error

messages. Furthermore, the device can also be reprogrammed from operation to sleeping mode.

= KQ = 1.0 displayed in the telegramme as KC * KQ = 1.0

C

2.6 Error

2.6.1 Description of the Function Control

After a hardware reset and before each measuring the

microcontroller carries out a self-test. In case an error is detected,

the corresponding error-bit in the RAM is set and the respective

error message is displayed on the digital display. After 4 minutes a

reset is carried out (before the next measuring) and the recorded

error-bit in the RAM is deleted automatically. If after the reset the

error is detected again, the corresponding error-bit in the RAM

is also set and the respective error message is displayed on the

digital display.

Danfoss Heating VIIGC102

2121

Page 22

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.6.2 List of Errors

Err.001 Manipulation (fraud) ! Disabled with remote sensor

version !

Err.002 Measuring error

Err.008 Only INDIV-X-10W: error EEPROM, error of radio

communication

Err.016 Error of digital display – the data to be processed cannot

be displayed

Err.032 Button pushed constantly

Err.064 Measured temperature not within temperature range

(0..105°C; 0..120°C remote sensor). Cable of remote

temperature sensor are in contact (short-circuited).

Err.066 Cable of remote temperature sensor are not in contact.

2.7 Radio Standby – Radio-HCA INDIV-X-10W

In order to achieve a user-friendly and power-saving radio standby,

the radio heat cost allocator features the following different

operating modes:

2.7.1 Sleeping Mode

Ex factory the radio heat cost allocator INDIV-X-10W is in sleeping

mode, but the internal clock and the date are running.

Current consumption is reduced to a minimum since no

measuring and no calculations are carried out and furthermore

communication options are not assisted.

Transition from sleeping to installation mode is achieved by

pushing the button once or by reaching the programmed

commissioning date.

2.7.2 Installation Mode

During the installation mode all functions of the radio heat cost

allocator are carried out and radio transmission is possible for max.

24 hours. This guarantees an optimal availability of the radio heat

cost allocator for test purposes during installation.

The radio heat cost allocator remains in installation mode until

midnight and then switches over automatically to operation

mode.

midnight

Sleeping mode Installation mode Operation mode

Transition from sleeping mode to installation mode is

achieved by pushing the button once or by reaching the

programmed commissioning date

22

VIIGC102 Danfoss Heating

Page 23

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

2. Specification

2.7.3 Operation Mode

2.7.3.1 Walk-By Radio Remote Readout

A walk-by remote readout of the data of the heat cost allocator

INDIV-X-10W is possible every day from 6.00 to 17.58 (winter time).

No readout possible between 18.00 and 20.00 (winter time)!

2.7.3.2 Readout over Radio Central (installed directly in

the building)

For the readout over a radio central installed in the building, the

following applies (see table below):

The device with the corresponding final numeral of the serial

number is ready for radio transmission during the time stated in

the table below.

Time Serial Number

20:00 – 20:58 XXXXXXX0

21:00 – 21:58 XXXXXXX1

22:00 – 22:58 XXXXXXX2

23:00 – 23:58 XXXXXXX3

00:00 – 00:58 XXXXXXX4

01:00 – 01:58 XXXXXXX5

02:00 – 02:58 XXXXXXX6

03:00 – 03:58 XXXXXXX7

04:00 – 04:58 XXXXXXX8

05:00 – 05:58 XXXXXXX9

After readout of the data from the radio heat cost allocator, the

radio availability is deactivated again.

Danfoss Heating VIIGC102

2323

Page 24

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.1 Introduction

To guarantee the proper functioning of the heat cost allocator

INDIV-X-10V and INDIV-X-10W, it is of great importance that it

is installed by an expert. On one hand, a constant heat transfer

between radiator and heat cost allocator has to be guaranteed.

On the other hand, the installation of the heat cost allocators to a

large variety of radiator types should be as easy as possible.

The installation can be carried out in two different ways. The

standard device is installed directly to the radiator. For the

wall-mounted version the remote sensor is installed to the radiator

and the heat cost allocator is wall-mounted. For the installation of

the heat cost allocators, special fastening-parts kits are available.

To avoid faulty installation, we also recommend reading the Kcdata in the data base prior to the installation.

The heat cost allocator is an electronic device which – like all

other similar devices – has to be handled with care. It is sensible to

electric discharge and contacting certain areas of the PCB. Electric

discharge can destroy the device or – even worse - damage it in a

way that it fails after an indefinite period of time.

For this reason it is essential to avoid contact with the PCB.

3.2 DIN Standard Requirements for the Installation

a. Heat cost allocators can be installed in heating systems where

the mean design heating medium temperature is between

the upper operating temperature limit tmax and the lower

operating temperature limit t

technical data, see enclosure)

b. The installation of the devices has to be durable and safe against

manipulation.

c. The devices have to be installed in a place where sufficient

correlation between the displayed value and the heat output of

the radiator is given over a maximum operating range.

d. Within one billing unit (in case of pre-distribution of the energy

consumption: within one users’ group) only heat cost allocators

of the same make and the same type with identical rating

systems may be used. Each device type has to be identifiable as

such.

e. Combinations of radiators and heat cost allocators with a

measured value of c > 0.3 in basic condition are not permitted.

In exceptional cases c-values of up to 0.4 are permitted within

one billing unit if the concerned heating surface does not

exceed 25 % of the overall heated surface or if the mean design

heating medium temperature is above 80°C. Heat cost allocators

may only be installed to radiators where the c-value is known at

the time of billing.

min

(t

and t

max

are stated in the

min

24

VIIGC102 Danfoss Heating

Page 25

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.3 General Restrictions

Electronic heat cost allocators cannot be used with steam heating,

floor heating, ceiling radiant heaters and flap-controlled radiators.

In case of combined valve- and flap-controlled radiators, the

installation of an electronic heat cost allocator is only permitted if

the flap control is dismounted or shut down in position „open“.

Convector heaters where the performance can be altered by an

electric blower as well as heat towel racks with an electric heating

cartridge may only be equipped with an electronic heat cost

allocator if the additional electric attachments are dismounted or

shut down.

3.4 Operating Range

The heat cost allocators can be used in heating systems with the

following mean heating medium temperatures:

For single sensor devices with start sensor

55°C…105° C for standard heat cost allocator

55°C…120°C for wall-mounted heat cost allocator (remote sensor)

For double sensor devices

35°C…105° C for standard heat cost allocators

55°C…120°C for wall-mounted heat cost allocators (remote

sensor)

A heat cost allocator can be used in heating systems where the

suitability of the system is in line with the operating conditions for

which the heat cost allocator has been approved.

The diagram in the enclosure 1 should be used to check if the

heating system is in line with the operating range.

Please refer to standard EN 834 (excerpt in enclosure 3) for the

definition of the terms.

Danfoss Heating VIIGC102

2525

Page 26

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

0,75 x BH

3. Installation

3.5 Installation to the Radiator

The heat cost allocator is always installed in the middle of the

overall length (0,5 x BL) of the radiator at a height of ¾ of the

overall height (0,75 x BH) measured from the bottom to the small

round whole in the middle.

If the height of the radiator is less than (<) 470 mm, the heat

cost allocator must be installed at 50% BH.

If the radiator has an even number of sections the heat cost

allocator is installed between the middle sections. If the radiator

has an uneven number of sections the device is installed next to

the valve-sided middle section.

When welding the heat cost allocator the upper threaded bolt has

to be welded from the bottom side in the middle of the overall

length (0,5 x BL) and at a height of (0,75 x BH) + 2 cm. The lower

bolt is positioned vertically 5 cm below the upper bolt and welded.

Before welding the lacquer has to be removed from the welding

points. Atten-tion has to be paid that the bolts are welded onto a

water-bearing area or a flute. Only use M3 bolts with a maximum

length of 8 mm or there’s a risk that the device will be damaged.

Mount the back plate through the 2 oval holes, adjusted to the top

edge of the 2 ovals holes.

0,5 x BL

0,5 x BL

0,75 x BH

If the radiator is of a length of more than 3 m, two heat cost

allocators have to be installed. This radiator is thus regarded as

two series connected individual radiators which however are

individually.

Example of 2 heat cost allocators

Mounting: 0.75 X BH + 2 cm to the upper bolt

5 cm

(0,75xBH)+2 cm

0,5 x BL

0,5 x BL

0,25 BL

0,25 BL

26

VIIGC102 Danfoss Heating

0,75 BL

Page 27

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.6 Wall-Mounting

The heat cost allocator has to be wall-mounted if the overall

height of the radiator is less than 250 mm or if, for aesthetical

reasons, the heat cost allocator cannot be mounted directly onto

the radiator.

In this case, the heat cost allocator is wall-mounted on the side

opposite to the valve and at a minimum distance from the radiator

of 10 cm.

at least

10 cm

at least

10 cm

• After marking and drilling the holes, the aluminium profile is

fastened with 2 metal screws and 2 spring washer.

• The parts necessary for the wall-mounting are included in the

corresponding fastening-parts kits for the installation of the

remote sensor.

• After installation of the device to the wall and the sensor to the

radiator, the sensor cable is laid in a cable duct.

• Mount the back plate through the 2 oval holes adjusted to the

top edge of the 2 oval holes.

088H2424

088H2345

088H2420

088H2423

Mounting Accessories Code No.

2 plastic dowels Ø5 mm 3.25 088H2424

1 aluminium back plate (supplied with EHCA) 088H2345

2 spring washers 088H2420

2 oval head wood screws 3 x 35 088H2423

Danfoss Heating VIIGC102

2727

Page 28

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7 Installation of Fastening-Parts Kits

3.7.1 Installation to Sectional Radiator

088H2408

088H2345

088H2420

• For radiators made from cast iron it is necessary to apply heat

transfer compound (Electrolu-be HTS) onto the contact

surfaces of the aluminium profile before installation. Mount the

back plate through the little hole in the middle.

088H2412

Mounting Accessories Code No.

1 tensioning bracket 088H2408

1 aluminium back plate (supplied with EHCA) 088H2345

1 cylinder head screw M4 x 40 088H2412

1 spring washer B 4 088H2420

3.7.2 Wall-Mounting - Sectional Radiator

• The remote sensor has to be fixed in the receiver

housing with adhesive to avoid loosening.

• The contact surfaces of the cover angles have to be

coated with adhesive before bringing them together.

• After mounting, it possible to fix a seal sticker on the receiver

housing.

0088H2408

Remote

sensor

088H2410

088H2420

088H2412

088H2406

Mounting Accessories Code No.

1 tensioning bracket 088H2408

1 aluminium profile „receiver housing“ 088H2410

1 spring washer B 4, DIN 128 088H2420

1 cylinder head screw M4 x 40 (with crosshead) 088H2412

2 cover angles, white 088H2406

2 plastic dowels Ø5 mm 3.25 (wall) 088H2424

2 oval head wood screws 3 x 35 (wall) 088H2423

28

VIIGC102 Danfoss Heating

Page 29

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7.3 Installation to Folded Radiator

088H2413

088H2421

088H2345

088H2420

088H2411

• Mount the aluminium back plate

through the small round hole

Mounting Accessories Code No.

1 hexagon nut B M4, DIN 934 088H2413

2 bracing angles 088H2421

2 spring washers B4, DIN 128 088H2420

1 oval head screw M4 x 30 088H2411

1 aluminium back plate (supplied with EHCA) 088H2345

• If necessary use 2 x 2 bracing angles to improve more stability

(photo) and, if needed, short the screw

Mounting Accessories Code No.

2 hexagon nut B M4, DIN 934 088H2413

2 x 2 bracing angles 088H2421

4 spring washers B4, DIN 128 088H2420

2 oval head screw M4 x 30 088H2411

1 aluminium back plate (supplied with EHCA) 088H2345

Danfoss Heating VIIGC102

2929

Page 30

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7.4 Wall-Mounting – Folded Radiator

088H2415

088H2414

088H2409

088H2405

088H2407

• The remote sensor has to be fixed in the

receiver housing with adhesive to avoid loosening.

• The contact surfaces of the cover angles have to be coated with

adhesive before bringing them together.

• After mounting, it possible to fix a seal sticker on the receiver

housing.

Mounting Accessories Code No.

1 tensioning nut 088H2415

1 tensioning bolt 088H2414

1 aluminium profile « receiver housing» 088H2409

1 safety plate 088H2405

2 cover angles, white 088H2407

2 plastic dowels Ø5 mm 3.25 (wall) 088H2424

2 oval head wood screws 3 x 35 (wall) 088H2423

30

VIIGC102 Danfoss Heating

Page 31

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7.5 Installation to Panel-Type Radiator

088H2422

088H2345

088H2418

088H2416

• Mount the back plate through

the 2 oval holes adjusted to the top edge of the 2 oval holes

Mounting Accessories Code No.

2 threaded bolts M3 x 8 (see page 27!) 088H2422

2 spring washers B3, DIN 137 088H2418

2 slotted nuts M3, DIN 546 088H2416

1 aluminium back plate (supplied with EHCA) 088H2345

Tool: Screw driver size 5 for M3

or

Mounting Accessories Code No.

2 threaded bolts M3 x 8 (see page 27!) 088H2422

2 Nuts M3 6-kant size 5.5 with flange

1 aluminium back plate (supplied with EHCA) 088H2345

Tool: Socket wrench hexagonal size 5.5

or

Mounting Accessories Code No.

2 threaded bolts M3 x 8 (see page 27!) 088H2422

2 Nuts M3 mit 6-kant size 5.5

1 aluminium back plate (supplied with EHCA) 088H2345

Tool: Socket wrench hexagonal size 5.5

Danfoss Heating VIIGC102

3131

Page 32

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

20 mm

¼ BH**

or

½ BH**

088H2422

088H2417

Remote

sensor

088H2404

Remain inside sensor

Detached part

3. Installation

3.7.6 Wall-Mounting - Panel-Type Radiator

088H2422

20 mm

Remote

sensor

¼ BH**

or

½ BH**

088H2417

088H2404

Remain inside sensor

Detached part

• The remote sensor has to be coated with heat transfer

compound (Electrolube HTS) on the contact surface.

• Turn on the pull-off nuts 088H2417 till it breaks. After put on the

HK-sensor cover to ensure the manipulation protection.

• Mount the back plate through the 2 oval holes adjusted to the

top edge of the 2 oval holes

Mounting Accessories Code No.

2 threaded bolts M3 x 8 088H2422

2 pull-off nuts M3 088H2417

1 HK-sensor cover 088H2404

2 plastic dowels Ø5 mm 3.25 (wall) 088H2424

2 oval head wood screws 3 x 35 (wall) 088H2423

088H2424

088H2345

088H2420

088H2423

32

VIIGC102 Danfoss Heating

Page 33

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7.7 Installation to Panel-Type Radiator with Front

Convection Plate

088H2425

088H2419

• The contact surfaces of the aluminium screws have to be coated

with heat transfer compound (Electrolube HTS).

• The aluminium screws have to be fastened with adhesive to

avoid loosening.

Mounting Accessories Code No.

3 sheet-metal screws 2.9 x 9.5 088H2419

1 aluminium back plate 088H2425

Danfoss Heating VIIGC102

3333

Page 34

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7.8 Bathroom radiator – Towel rails

Heat cost allocator mounted verticaly on distributor or

collector part

• Assembly with 2 threaded bolts welded on 75% BH +50mm on

the side or front of the flow distributor or return collector

Mounting Accessories Code No.

2 threaded bolts M3 x 8 (see page 27!) 088H2422

2 spring washers B3, DIN 137 088H2418

2 slotted nuts M3, DIN 546 088H2416

1 aluminium back plate (supplied with EHCA) 088H2345

Tool: Screw driver size 5 for M3

Heat cost allocator mounted horizontally on cross tubes

• Assembly to the nearest possible place to

the flow place or return place on the cross tubes

on 75% BH with 2 tensioning brackets

Mounting Accessories Code No.

2 tensioning bracket 088H2408

1 aluminium back plate (supplied with EHCA) 088H2345

2 cylinder head screw M4 x 40 088H2412

2 spring washer B 4 088H2420

34

VIIGC102 Danfoss Heating

Page 35

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.7.9 Sectional radiator wide

088H2428

088H2430

088H2427

088H2345

• Mount the back plate through the 2 oval

holes adjusted to the top edge of the

2 oval holes

Mounting Accessories Code No.

2 tensioning bracket 50mm 088H2428

1 aluminium back plate (supplied with EHCA) 088H2345

1 heat conductor aluminium plate 60mm 088H2427

2 cylinder head screw M4 x 40 088H2412

1 cylinder head screw M3 x 10 088H2429

1 Nut M3 088H2430

088H2412

088H2429

Danfoss Heating VIIGC102

3535

Page 36

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.8 Overview mounting accessories

Code No. Designation

088H2400 Replacement seal 1000 pieces

088H2345 Aluminium back plate

088H2401 Plastic blind cover

088H2402 Optical head USB

088H2403 Bracket for Opto-probe

088H2404 Cover for sensor

088H2405 Safety plate

088H2406 Cover angles, white , Sectional radiator

088H2407 Cover angles, white , Folded radiator

088H2408 Tensioning bracket

088H2409 Aluminium profile « receiver housing»

088H2410 Aluminium profile « receiver housing»

088H2411 Raised head screw M4 x 30

088H2412 Pan head screw 4 x 40

088H2413 Hexagon Nut B M4, DIN 934

088H2414 Pins

088H2415 Tensioning nut

088H2416 Slotted nuts M3, DIN 546

088H2417 Two-nuts M3

088H2418 Spring washers B3, DIN 137

088H2419 Tapping screw 2,9 x 9,5

088H2420 Spring washers

088H2421 Angle spreader

088H2422 Headless pinsM3 x 8

088H2423 Crosshead wood screws 3 x 35

088H2424 Plastic screw plug Ø5 mm 3.25

088H2425 Aluminium plate case support for front plate radiator

088H2427 Heat conductor aluminium plate 60mm

088H2428 Angle bracket 50mm

088H2429 Cylinder screw M3 x 10

088H2430 Nut M3

(Protection plate white radiator with sections)

(Protection plate white corrugated radiator)

(Angle bracket)

(Aluminium plate case support for corrugated radiator)

(Aluminium plate case support for sectional radiator)

36

VIIGC102 Danfoss Heating

Page 37

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

3. Installation

3.9 Mounting and Sealing

After installation of the respective fastening-parts kit to the

radiator, the heat cost allocator can be mounted and sealed as

described below.

1. The heat cost allocator is placed at the upper end of the

aluminium back plate. Move the heat cost allocator down so

that the hooks in the housing fit in the aluminium back plate.

1.

2. The heat cost allocator is swinged on the aluminium back plate

in the direction of the arrow.

3. Introduce the seal in the slot of the housing, then press until the

seal clicks into the aluminium back plate.

Now the heat cost allocator can only be opened by destroying the

seal.

2.

Danfoss Heating VIIGC102

3737

Page 38

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

4. Commissioning

Ex factory the heat cost allocators INDIV-X-10V and INDIV-X-10W

are in the so-called sleeping mode. In this mode no measuring

is carried out and thus no consumption values are calculated.

Furthermore the digital display, the communication options as

well as the device opening detection are deactivated.

The date and time are running in the background.

The measuring mode is set off by pushing the button or when

reaching the programmed commissioning date.

Heat cost allocator INDIV-X-10W: in addition to the measuring

mode, the installation mode is activated as well. During

installation mode the radio transmission is possible for max. 24

hours.

After the commissioning and before leaving a new site, we

recommend to perform a radio read out test and to create

an installation protocol, to ensure that all the radio communication between the heat cost allocators and the radio

central or radio modem was successful.

The measuring mode is set o

by pushing the button (> 2 s)

or when reaching the

programmed commisioning

date.

After midnight the radio heat cost allocator INDIV-X-10W changes

automatically from installation to operation mode.

38

VIIGC102 Danfoss Heating

Page 39

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

5.1 Manual Readout

The recorded consumption values can be displayed by pushing

the button. (see chapter 2.3)

Then the displayed values are copied to a data collection sheet or

entered into a portable data acquisition device.

5.2 Readout over the Optical Interface

All data recorded in the heat cost allocator INDIV-X-10V and

INDIV-X-10W can be transmitted directly to a computer over the

optical interface.

5.2.1 Optical Probe

The hardware of the optical bidirectional interface which is built in

the device is in line with standard EN 61107, 9.1992, part 3.2.

The optical probe is positioned on the front side of the device in

the round cavity below the display. The position of the connecting

cable is irrelevant. Thus access to the device is guaranteed even

under difficult conditions.

5.2.2 Transmission Protocol

The format of the transmitted data corresponds to the following

standards:

• IEC 870-5

• prEN 1434, 2006, (M-BUS, CEN / TC 176) :

2.2 Optical interface

4.2 Frame formats used

4.4 Coding of data records

4.6 Variable data structure

The following table and the diagram describe the format of a

transmitted data byte:

Transmission serial, asynchronous

Connection half duplex

Speed 2’400 / 9’600 Baud

Data 8 bit

Parity 1 bit, even

No. of stop bits 1 bit

Danfoss Heating VIIGC102

3939

Page 40

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

The readout of the data can be subdivided in several stages. The

following diagram describes the standard process from the point

of view of the computer:

5.2.3 Timing of the Optical Interface

40

VIIGC102 Danfoss Heating

Page 41

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

5.2.4 Frames of the Optical Readout

The frame of the optical readout corresponds to the M-bus

standard EN1434. Thus the optical interface can communicate

with a M-bus standard software with the commands “request

REQ_UD2“ and “normalize SNP_NKE“.

Frame 1:

Danfoss Heating VIIGC102

4141

Page 42

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

Frame 2:

42

VIIGC102 Danfoss Heating

Page 43

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

5.2.5 Remote Radio Readout

5.2.5.1 General Information on the Remote Radio Readout

Danfoss expressly points out that the data transmission via

mobile radio modem depends on the radio propagation

conditions existing at the installation point and that under

certain atmospheric or geographic conditions (especially within

secluded areas as well as in so-called radio shadows) mobile radio

connections cannot be established at any time and at any place.

It is solely incumbent on the user to check the radio propagation

conditions at the planned installation point.

5.2.5.2 Mobile Readout

The mobile radio readout of the radio heat cost allocator

INDIV-X-10W is done via the mobile radio modem which

is equipped with a transceiver including antenna for radio

transmission. The radio modem operates at the frequency of

433.82 MHz and is combined with a PDA.

Danfoss program for the readout and parameterisation features

the following main functions:

• Readout and display of an individual radio heat cost allocator

• Readout and display of a group of radio heat cost allocators

• Adding of devices in a router file

• Removing of devices in a router file

• Parameterization of an individual or a group of heat cost

allocator via radio

Danfoss Heating VIIGC102

4343

Page 44

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

5.2.6 Stationary Readout

With the stationary readout, the radio central receives the data

from the radio heat cost allocator or other Danfoss devices which

are equipped with radio. The data recorded in the radio central can

be readout over:

• Optical head

• USB

• RS-232

• M-Bus

• GSM / GPRS

5.2.7 Timing of Radio Transmission

44

VIIGC102 Danfoss Heating

Page 45

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

5. Readout

5.2.8 Frame of the Radio Transmission

Danfoss Heating VIIGC102

4545

Page 46

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

6. Rating factors

6.1 Taking Measurements

The value displayed by the heat cost allocator has to be converted

to the value of the actual heat output of each radiator. Thereby the

design and the performance of the radiator as well as the mode of

installation have to be taken into account.

Therefore each radiator has to be identified precisely by taking

measurements. The following data have to be established:

• Design and make of radiator

• Overall length

• Overall height

• Overall depth

• Number of sections

• Pitch

• In-line configuration

6.1.1 Rating of Radiators of Over Length or

High Nominal OutputOu

If the radiator has an overall length of approx. 3 m we strongly

recommend installing two heat cost allocators.

Under certain circumstances minimal flows might not be noticed

on these radiators. The same applies for radiators with an

extremely high nominal output of more than 10.0000 watt = 10kW.

At least two heat cost allocators should be installed to these

radiators. The standard performance of each radiator is divided by

the number of heat cost allocators installed.

Example: Standard performance KQ= 16.000 W = 16

Number of heat cost allocators installed to the

radiator = 2

KQ individual = 16 / 2 = 8

46

VIIGC102 Danfoss Heating

Page 47

Installation Guide Electronic Heat Cost Allocator INDIV-X-10V, INDIV-X-10W Radio

6. Rating factors

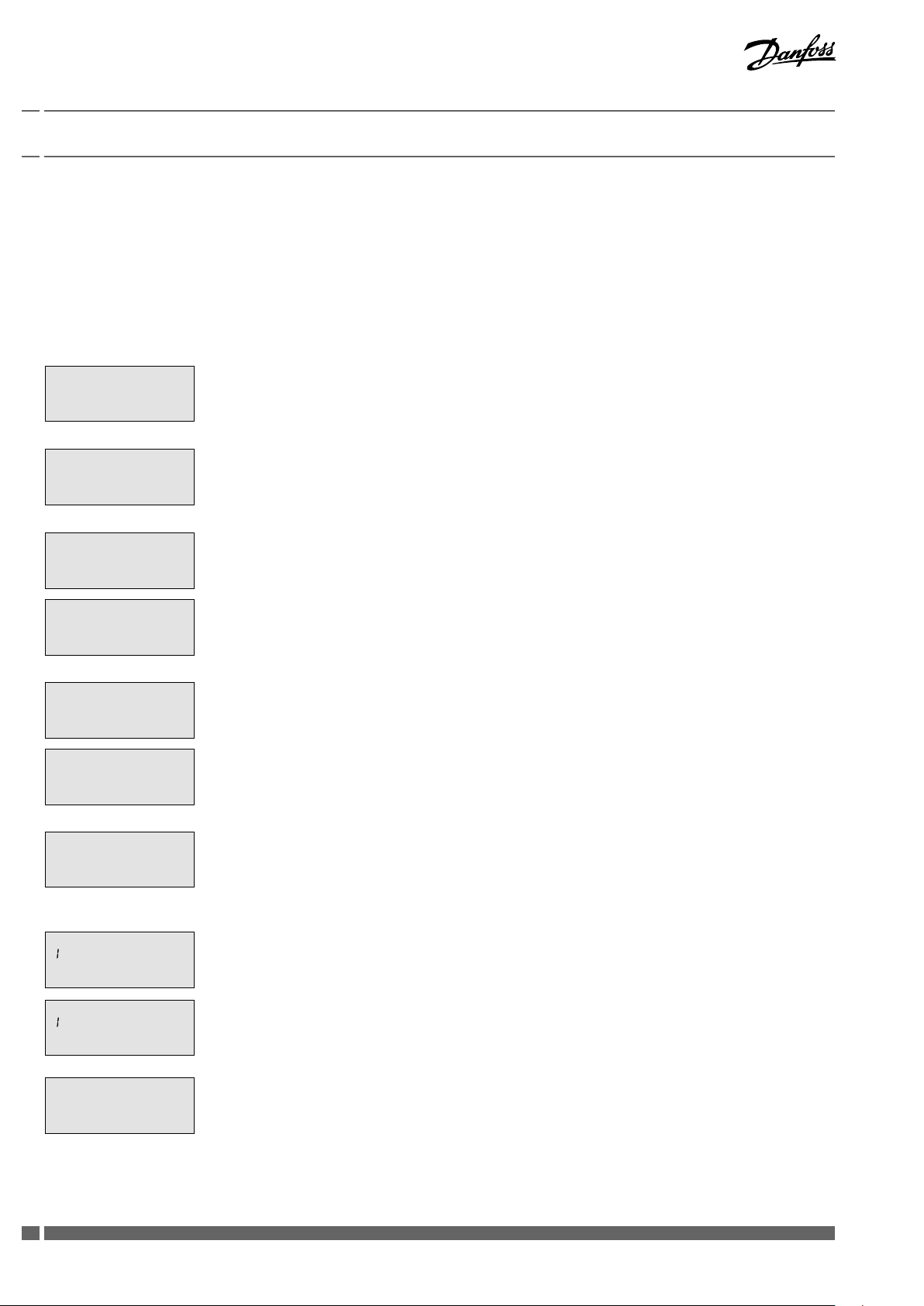

6.1.2 Rating of Radiator

For each radiator type the K-value is calculated according to the

following diagram:

The heat cost allocator determines the heat output of the radiator,

displays the consumption and records the consumption values on

the set day.

The heating medium temperature is captured by the temperature

sensor installed to the radiator. Thus the heat output of the

radiator is calculated in consideration of the radiator performance.

These calculations are started as soon as the temperature

difference between ambient temperature and heating medium

temperature is bigger than the parameterised value.

Radiator:

- type

- model

- dimensions

Nominal power in

KW, vendor factor

K

Q

Functional principle:

- panel

- wall mounting

(deported sensor)

See KC factors into

the table (into this

manual)

X XX

K

C

* if not, take the vendor factors

Internal consign

temperature

normally = 1.0*

K

T

=

K

total

Out of this functional principle the necessity arises to rate the

display of the heat cost allocator. For the calculation of the heat

output of the radiator it is not sufficient to measure the heating

medium temperature. Radiators with different performances