Page 1

User Manual

PLUS+1® Compliant

HMK_Basic_Ctrl Function Block

www.danfoss.com

Page 2

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

Revision history Table of revisions

Date Changed Rev

April 2019 First edition 0101

2 | © Danfoss | April 2019 AQ298774658115en-000101

Page 3

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

Contents

HMK_Basic_Ctrl

Overview..............................................................................................................................................................................................4

Inputs....................................................................................................................................................................................................4

Parameters..........................................................................................................................................................................................5

Outputs................................................................................................................................................................................................ 5

Diagnostic Signals............................................................................................................................................................................5

Status and Fault Logic.....................................................................................................................................................................6

Status Logic...................................................................................................................................................................................6

Fault Logic..................................................................................................................................................................................... 6

Instalation............................................................................................................................................................................................6

About the Namespace Feature.............................................................................................................................................. 6

How to Enter a Namespace Value.........................................................................................................................................7

HMK_Basic_Ctrl Service Screen...................................................................................................................................................8

©

Danfoss | April 2019 AQ298774658115en-000101 | 3

Page 4

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

HMK_Basic_Ctrl

Overview

This function block configures the function for use with the HMK and is used to send out basic

commands to control the LEDs on the device.

Inputs

Entering the HMK_Basic_Ctrl function block gives an overview about the block’s signals.

To avoid compiler errors, use only the data types specified in this table.

Function Block Inputs

Input Type Range Unit Description

Chkpt BOOL T/F --

CAN.Port PORT -- -- Determines which physical CAN port of the hardware to receive data from.

Loop_Tm U16 0 to 65535 ms Processing time of one program loop.

Enable BOOL T/F --

Buttons BUS -- -- Contains control signals for the LEDs on the HMK.

Button(1-8).

Backlight_Color

Button(1-8).

Indicator_Color

Button(1-8).

LED_State

LED_Group U8 0 to 3 --

U8 0 to 3 --

U8 0 to 3 --

U8 0 to 3 --

Enables advanced checkpoints with namespace for each Diag signal.

T: Include checkpoints when compiled

F: Do not include checkpoints when compiled

This variable can be found in the CAN sub-bus if using the Main Template.

Enables the block to send out CAN messages.

T: Function is enabled

F: Function is disabled

Index for Backlight color.

0: Backlight Color Index 0

1: Backlight Color Index 1

2: Backlight Color Index 2

3: No change

Index for Indicator color.

0: Indicator Color Index 0

1: Indicator Color Index 1

2: Indicator Color Index 2

3: No change

State of LED.

0: Backlight Active

1: Indicator Active

2: Blink - Medium

3: No change

LED group selection.

0: LEDs 1 to 8

1: LEDs 9 to 16

2: LEDs 17 to 24

3: LEDs 25 to 32

4 | © Danfoss | April 2019 AQ298774658115en-000101

Page 5

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

HMK_Basic_Ctrl

Parameters

Learn how the function block uses parameters to customize the function.

To avoid compiler errors, use only the data types specified in this table.

Function Block Parameters

Parameter Type Range Unit Description

Src_Addr U8 0 to 253 -- Source Address of the local device.

Dest_Addr U8 0 to 253 -- Destination Address of the HMK.

TxRate U16 100 to 65535 ms How often the message will be sent out.

Outputs

Learn how the outputs of the function block work.

Function Block Outputs

Parameter Type Range Unit Description

OR BOOL T/F -- CAN Tx OverRun Flag.

Pend BOOL T/F -- CAN Tx Pending Flag.

Diag BUS -- -- This bus provides diagnostic values for troubleshooting. In addition, all

Status U16 0, 0x8008 --

Fault U16 0, 0x8002 --

inputs, parameters, and output signals are contained inside of the bus.

This signal indicates if a parameter fault is declared. It’s a bitwise code, so

multiple items can be reported at a time. The following status codes are

provided:

0x0000: No fault

0x8008: At least one parameter is out of range

This signal indicates if an input fault is declared. It’s a bitwise code, so

multiple items can be reported at a time. The following fault codes are

provided:

0x0000: No fault

0x8002: An input value is too high

Diagnostic Signals

Entering the Checkpoints page on the second level of the function block provides access to the block’s

diagnostic signals. It contains checkpoints on input, parameter, output, and internal signals. Only the

internal signals are explained below. Input, parameter, and output signals are described in the above

chapters.

Function Block Diagnostic Signals

Name Type Range Unit Description

CAN_ID U32 -- -- The resulting 29-bit J1939 ID.

CAN_Data ARRAY[8

CAN_Send BOOL T/F --

©

Danfoss | April 2019 AQ298774658115en-000101 | 5

]U8

-- -- Data that is to be sent over CAN.

Pulses true when a message is being sent.

T: Pulse triggered

F: Idle

Page 6

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

HMK_Basic_Ctrl

Status and Fault Logic

This topic describes how status and fault logic is indicated for the function block.

Status Logic

The status code indicates whether the parameters used in the function are within their valid range.

Status Logic

Condition Hex

Invalid Setup 0x8008 1000 Dest_Addr > 253, Src_Addr > 253, TxRate

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

Fault Logic

Condition Hex

An input is too

high

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

*

Binary Cause Response Correction

0x8002 0010

<100

Fault Logic

The fault code indicates whether the inputs of the function are within their valid range.

Buttons.Button(1-8).Backlight_Color > 3

Buttons.Button(1-8).Indicator_Color > 3

Buttons.Button(1-8).LED_State > 3

Buttons.LED_Group > 3

Status Code, Transmission is

disabled

Fault Code, Transmission is

disabled

Correct Dest_Addr, or

Src_Addr or TxRate value.

Correct out of range input

value.

Instalation

Chkpt enables the checkpoints for each Diag Bus Signal. It is pre-connected to a constant True. It only

makes sense to set it to False if you don’t want to use the checkpoints or if you need to free up some

memory. Be aware that Fault and Status signal will also disappear from the service screen by this action.

About the Namespace Feature

If you use this function block more than once in an application, you must change each function block’s

Namespace value to avoid compiler errors.

This function block contains one or more components that allocate memory using memory names

(“aliases”). Identical function blocks have identical memory names. Identical memory names cause

compiler errors.

The Namespace value adds a unique prefix to each component name to avoid errors. Keep each

Namespace value short to save controller memory.

6 | © Danfoss | April 2019 AQ298774658115en-000101

Page 7

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

HMK_Basic_Ctrl

How to Enter a Namespace Value

1. In the PLUS+1 GUIDE menu bar, click the Query/Change button.

2. Click the function block’s page name to display the Edit Page window.

3. In the Edit Page window, enter a meaningful Namespace value.

Namespace values are case-sensitive.

4. Press the Enter key.

5. Repeat these steps to enter unique Namespace values for other identical function blocks.

©

Danfoss | April 2019 AQ298774658115en-000101 | 7

Page 8

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

HMK_Basic_Ctrl

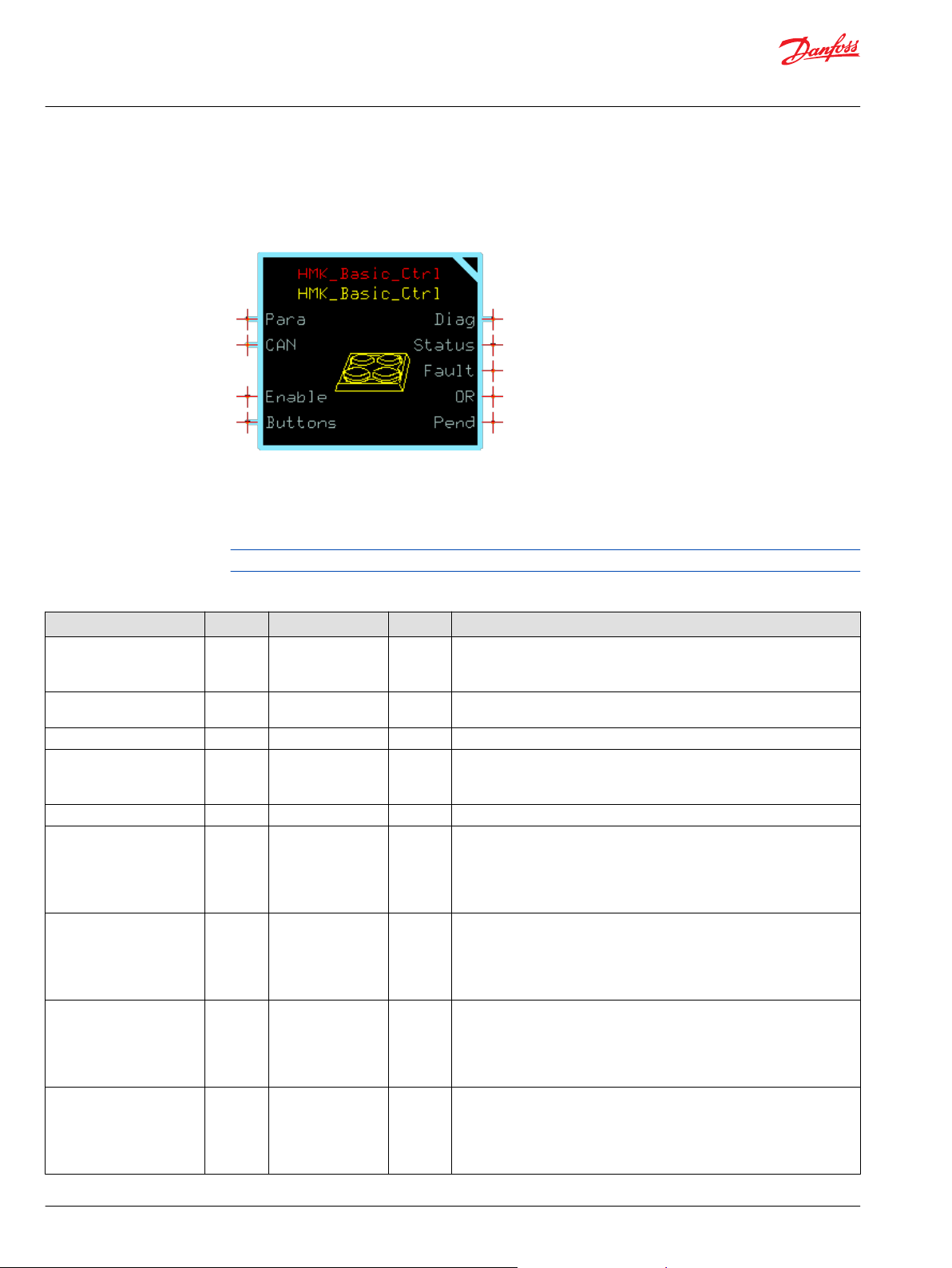

HMK_Basic_Ctrl Service Screen

This screen shows a panel for the HMK_Basic_Ctrl Function Block. This panel can be reused in other

diagnostic applications.

HMK_Basic_Ctrl Reusable Panel Screen

Item Unit Description

Input – Enable --

Source Address -- Source Address of the local device.

Dest Address -- Destination Address of the HMK.

TxRate ms How often the message will be sent out.

Outputs – Status --

Outputs - Fault --

Enables the block to send out CAN messages.

T: Function is enabled

F: Function is disabled

This signal indicates if a parameter fault is declared. It’s a bitwise code, so multiple items can be

reported at a time. The following status codes are provided:

0x0000: No fault

0x8008: At least one parameter is out of range

This signal indicates if an input fault is declared. It’s a bitwise code, so multiple items can be

reported at a time. The following fault codes are provided:

0x0000: No fault

0x8002: An input value is too high

8 | © Danfoss | April 2019 AQ298774658115en-000101

Page 9

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

©

Danfoss | April 2019 AQ298774658115en-000101 | 9

Page 10

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

10 | © Danfoss | April 2019 AQ298774658115en-000101

Page 11

User Manual

Plus+1® Compliant HMK_Basic_Ctrl Function Block

©

Danfoss | April 2019 AQ298774658115en-000101 | 11

Page 12

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | April 2019 AQ298774658115en-000101

Loading...

Loading...