Page 1

MAKING MODERN LIVING POSSIBLE

Fitters Notes

Hints and tips for the installer

REFRIGERATION &

AIR CONDITIONING DIVISION

Manual

Page 2

This Fitters Notes, gives practical hints about Danfoss commercial

refrigeration controls (mechanical) and Danfoss compressors.

If you need further information about the Danfoss product range please

contact your dealer or local Danfoss agency. You can also find some very

useful information on our web site:

www.danfoss.com

We hope that this book will help you in your daily work.

Danfoss A/S

Page 3

Fitters notes

Chapter 1 . . . . . . . . . . . . . . . . . . Thermostatic expansion valves . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3

Chapter 2 . . . . . . . . . . . . . . . . . . Solenoid valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 13

Chapter 3 . . . . . . . . . . . . . . . . . . Pressure controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 19

Chapter 4 . . . . . . . . . . . . . . . . . . Thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 27

expansion valves Solenoid valves Pressure controls Thermostats

Thermostatic

Chapter 5 . . . . . . . . . . . . . . . . . . Pressure regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 35

Chapter 6 . . . . . . . . . . . . . . . . . . Water valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 45

Chapter 7 . . . . . . . . . . . . . . . . . . Filter driers & sight glasses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 51

Chapter 8 . . . . . . . . . . . . . . . . . . Danfoss compressors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 61

regulators Water valves

Pressure

Filter driers &

sight glasses

compressors Practical tips Trouble shooting

Danfoss

Chapter 9 . . . . . . . . . . . . . . . . . . Practical tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 125

Chapter 10 . . . . . . . . . . . . . . . . . Trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 145

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 1

Page 4

Page 5

Fitters notes Thermostatic expansion valves

Contents Page

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Superheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Subcooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

External pressure equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Universal charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MOP charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MOP ballast charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Thermostatic expansion valve selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Orifice assembly replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Danfoss product range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

expansion valves

Thermostatic

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 3

Page 6

Notes

4 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 7

Fitters notes Thermostatic expansion valves

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 5

Thermostatic

expansion valves

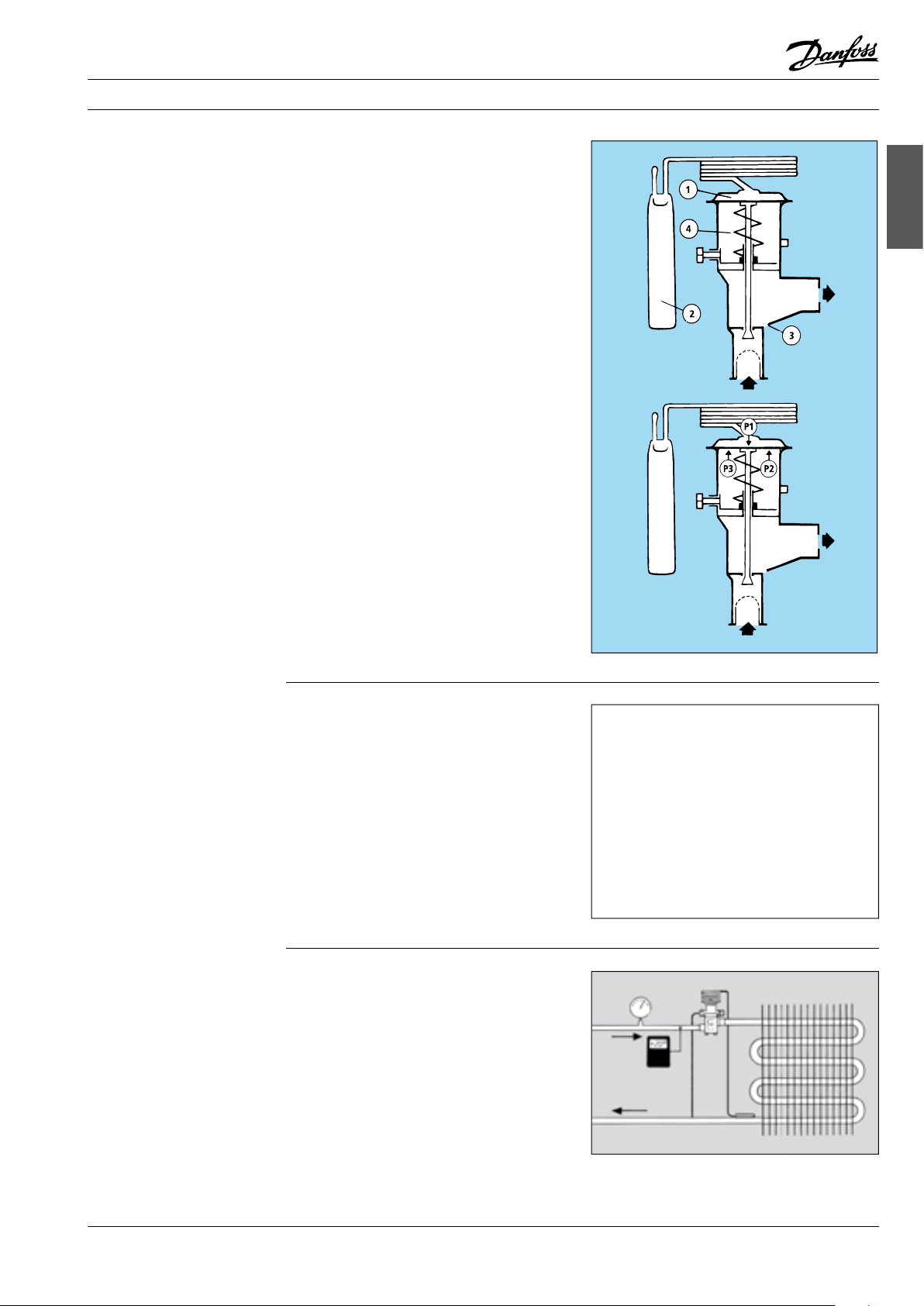

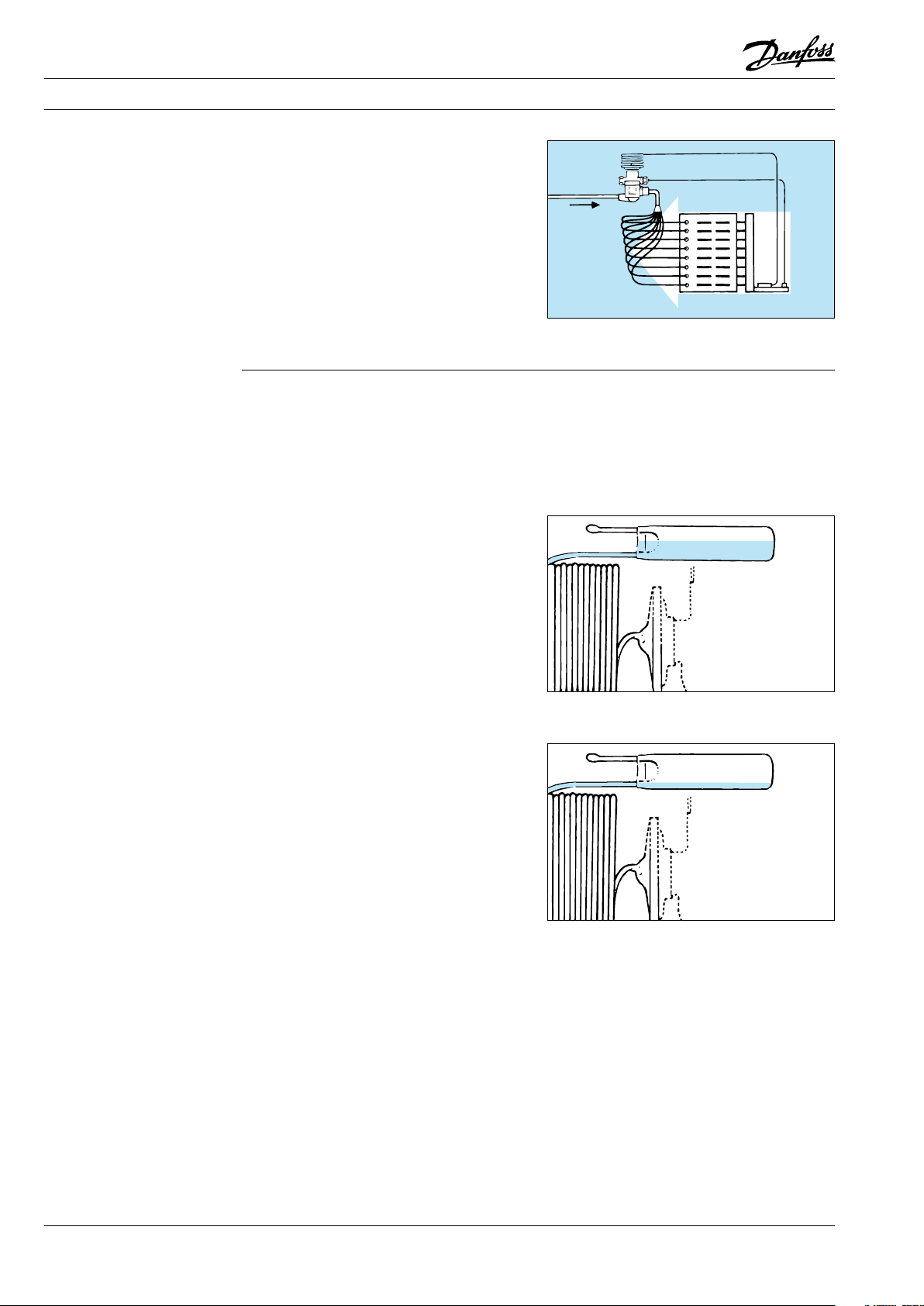

A thermostatic expansion valve is built up around

a thermostatic element (1) separated from the

valve body by a diaphragm.

A capillary tube connects the element to a bulb

(2) and a valve body with valve seat (3) and a

spring (4).

A thermostatic expansion valve works like this:

The function of a thermostatic expansion valve is

determined by three fundamental pressures:

P1: Bulb pressure which acts on the upper

surface of the diaphragm, in the valve

opening direction.

P2: Evaporating pressure which acts on the

underside of the diaphragm, in the valve

closing direction.

P3: Spring pressure which also acts on the

underside of the diaphragm, in the valve

closing direction.

When the expansion valve regulates, balance is

created between bulb pressure on one side of the

diaphragm and evaporating pressure plus spring

force on the other side.

The spring is used to set superheat.

Ad0-0001

Introduction

Superheat is measured at the point where the

bulb is located on the suction line and is the

diff erence between the temperature at the

bulb and the evaporating pressure/evaporating

temperature at the same point.

Superheat is measured in Kelvin (K) and is used as

a signal to regulate liquid injection through the

expansion valve.

Ad0-0012

Ad0-0015

Superheat

Subcooling Subcooling is defi ned as the diff erence between

condensing pressure/temperature and liquid

temperature at the expansion valve inlet.

Subcooling is measured in Kelvin (K).

Subcooling of the refrigerant is necessary to

avoid vapour bubbles in the refrigerant ahead of

the expansion valve.

Vapour bubbles in the refrigerant reduce capacity

in the expansion valve and thereby reduce liquid

supply to the evaporator.

Subcooling of 4-5K is adequate in most cases.

Page 8

Fitters notes Thermostatic expansion valves

External pressure equalization

Expansion valves with external pressure equalization must always be used if liquid distributors

are installed.

Typically, the use of distributors gives a pressure

drop of 1 bar across distributor and distribution

tubes.

Expansion valves with external pressure equalization should always be used in refrigeration

systems with heavy evaporators or plate

exchangers, where normally the pressure drop

will be greater than pressure corresponding to

2K.

Charges Thermostatic expansion valves can contain one

of three different types of charge:

1. Universal charge

2. MOP charge

3. MOP charge with ballast, standard for Danfoss

expansion valves with MOP.

Universal charge

Expansion valves with Universal charge are used

in most refrigeration systems where there is no

pressure limitation requirement and where the

bulb can be located warmer than the element

or at high evaporating temperature/evaporating

pressure.

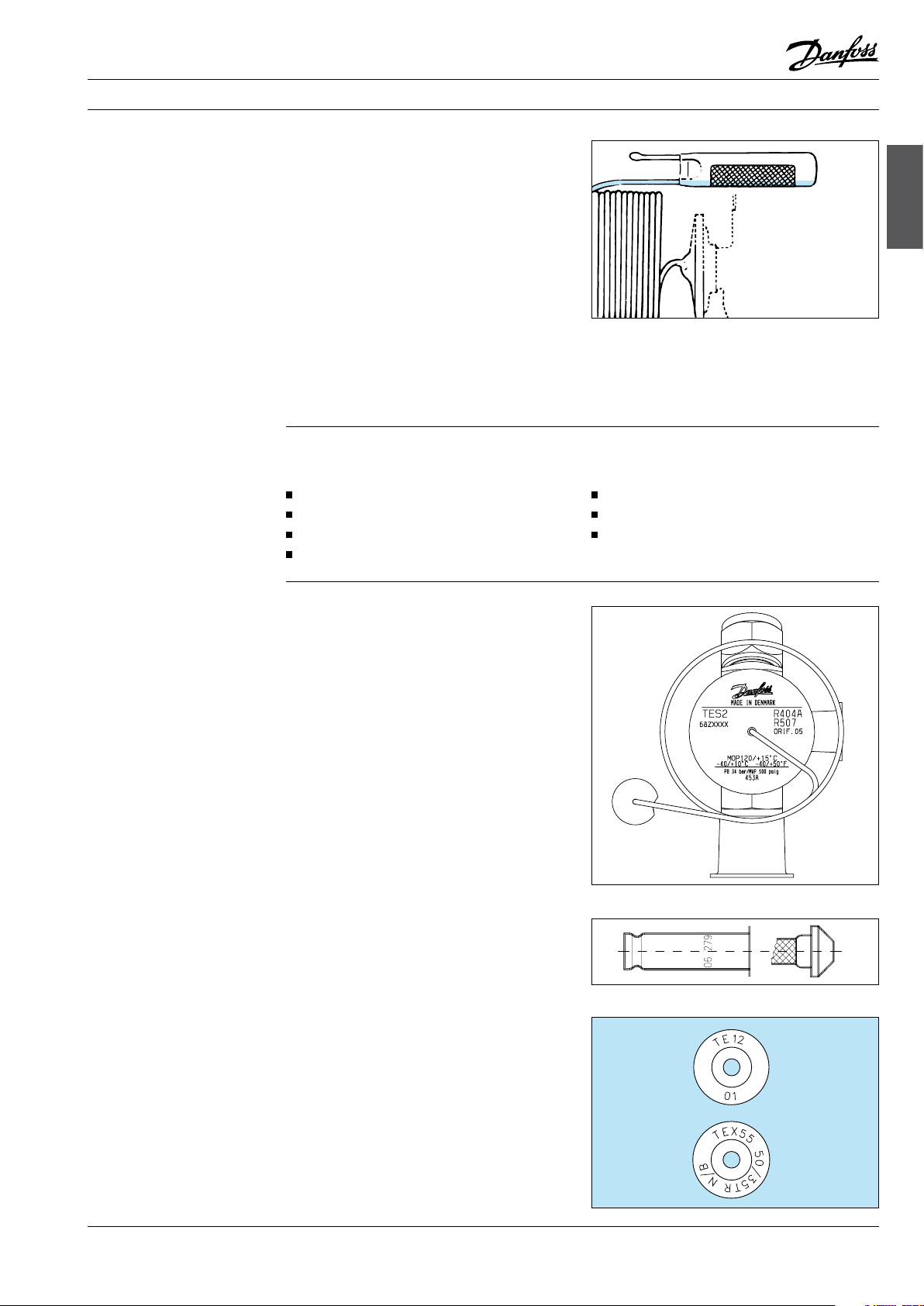

Ad0-0016

MOP charge

Universal charge means that there is liquid

charge in the bulb. The amount of charge is so

large that charge remains in the bulb irrespective

of whether the element is colder or warmer than

the bulb.

Expansion valves with MOP charge are typically

used on factory-made units where suction

pressure limitation on starting is required, e.g.

in the transport sector and in air conditioning

systems.

All expansion valves with MOP have a very small

charge in the bulb.

This means that the valve or the element must be

located warmer than the bulb. If it is not, charge

can migrate from the bulb to the element and

prevent the expansion valve from functioning.

MOP charge means limited liquid charge in the

bulb.

“MOP” stands for Maximum Operating Pressure

and is the highest suction pressure/ evaporating

pressure permissible in the evaporator/suction

line.

The charge will have evaporated when the

temperature reaches the MOP point. Gradually,

as the suction pressure rises, the expansion valve

begins to close at approx. 0.3/0.4 bar below the

MOP point. It becomes completely closed when

the suction pressure is the same as the MOP

point.

Ad0-0017

Ad0-0018

MOP is often called “Motor Overload Protection”.

6 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 9

Fitters notes Thermostatic expansion valves

MOP ballast charge

Thermostatic expansion valve selection

Expansion valves with MOP ballast charges are

used mainly in refrigeration systems with “highdynamic” evaporators, e.g. in air conditioning

systems and plate heat exchangers with high

heat transfer.

With MOP ballast charge, up to 2 - 4 K less

superheat can be obtained than with other types

of charge.

The bulb in a thermostatic expansion valve

contains a material of high porosity and large

surface area in relation to weight.

MOP charge with ballast has a damping effect on

expansion valve regulation.

The valve opens slowly as bulb temperature rises

and closes quickly as bulb temperature fails.

The thermostatic expansion valve can be selected when the following are known:

Refrigerant

Evaporator capacity

Evaporating pressure

Condensing pressure

Ad0-0021

Subcooling

Pressure drop across valve

Internal or external pressure equalization

expansion valves

Thermostatic

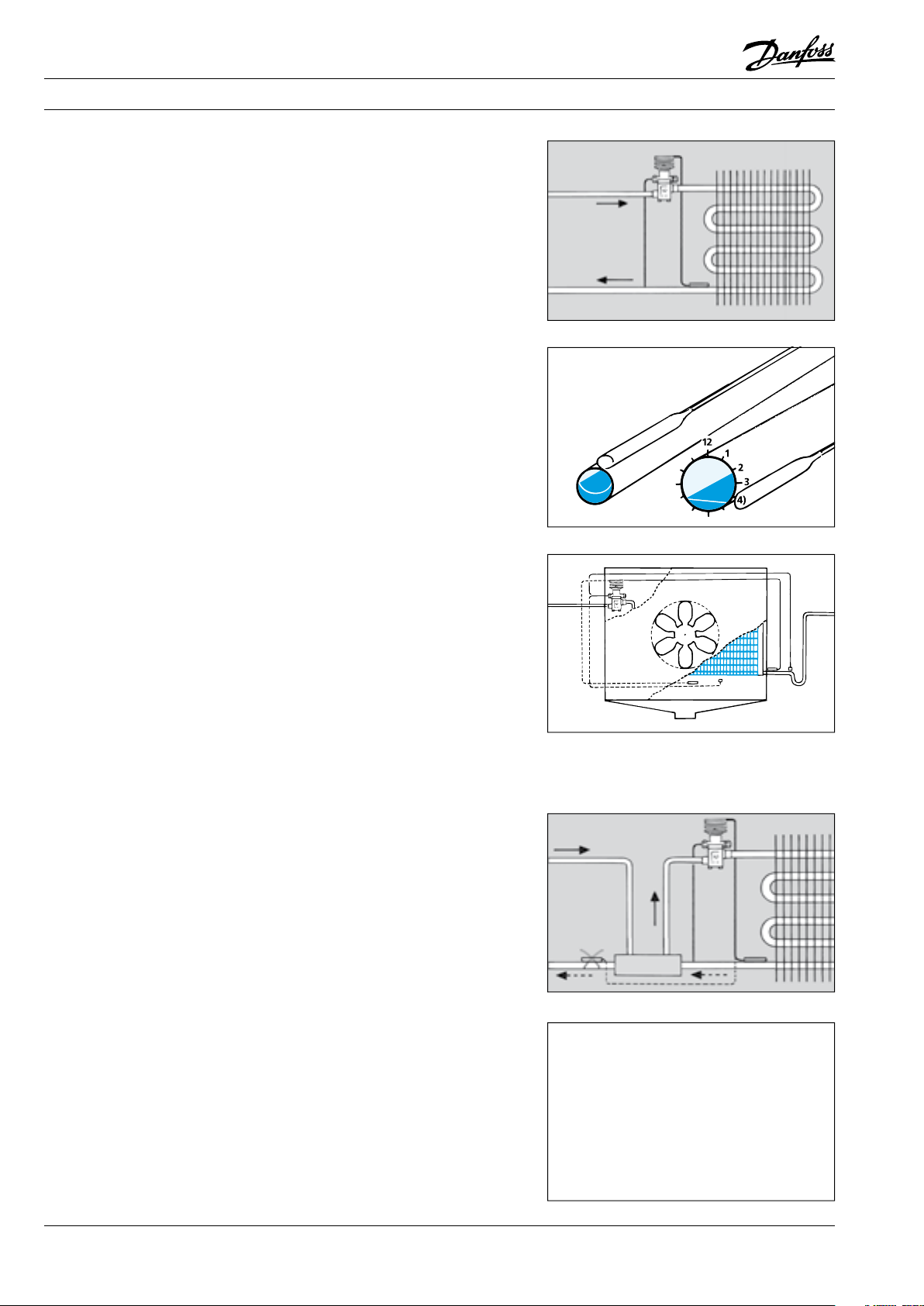

Identification The thermostatic element is fitted with a laser

engraving on top of the diaphragm.

The code refers to the refrigerant for which the

valve is designed:

L = R410A

N = R134a

S = R404A/ R507

X = R22

Z = R407C

This engraving gives valve type (with code

number), evaporating temperature range, MOP

point, refrigerant, and max. working pressure,

PS/MWP.

With TE 20 and TE 55 the rated capacity is

stamped on a band label fastened to the valve.

The orifice assembly for T2 and TE2 is marked

with the orifice size (e.g. 06) and week stamp +

last number in the year (e.g. 279).

The orifice assembly number is also given on the

lid of its plastic container.

On TE 5 and TE 12 the upper stamp (TE 12)

indicates for which valve type the orifice can be

used. The lower stamp (01) is the orifice size.

On TE 20 and TE 55 the lower stamp (50/35 TR

N/B) indicates the rated capacity in the two

evaporating temperature ranges N and B, and the

refrigerant. (50/35 TR = 175 kW in range N and

123 kW in range B).

The upper stamp (TEX 55) refers to the valve type

for which the assembly can be used.

Ad0-0019

Ad0-0023

Ad0-0020

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 7

Page 10

Fitters notes Thermostatic expansion valves

8 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

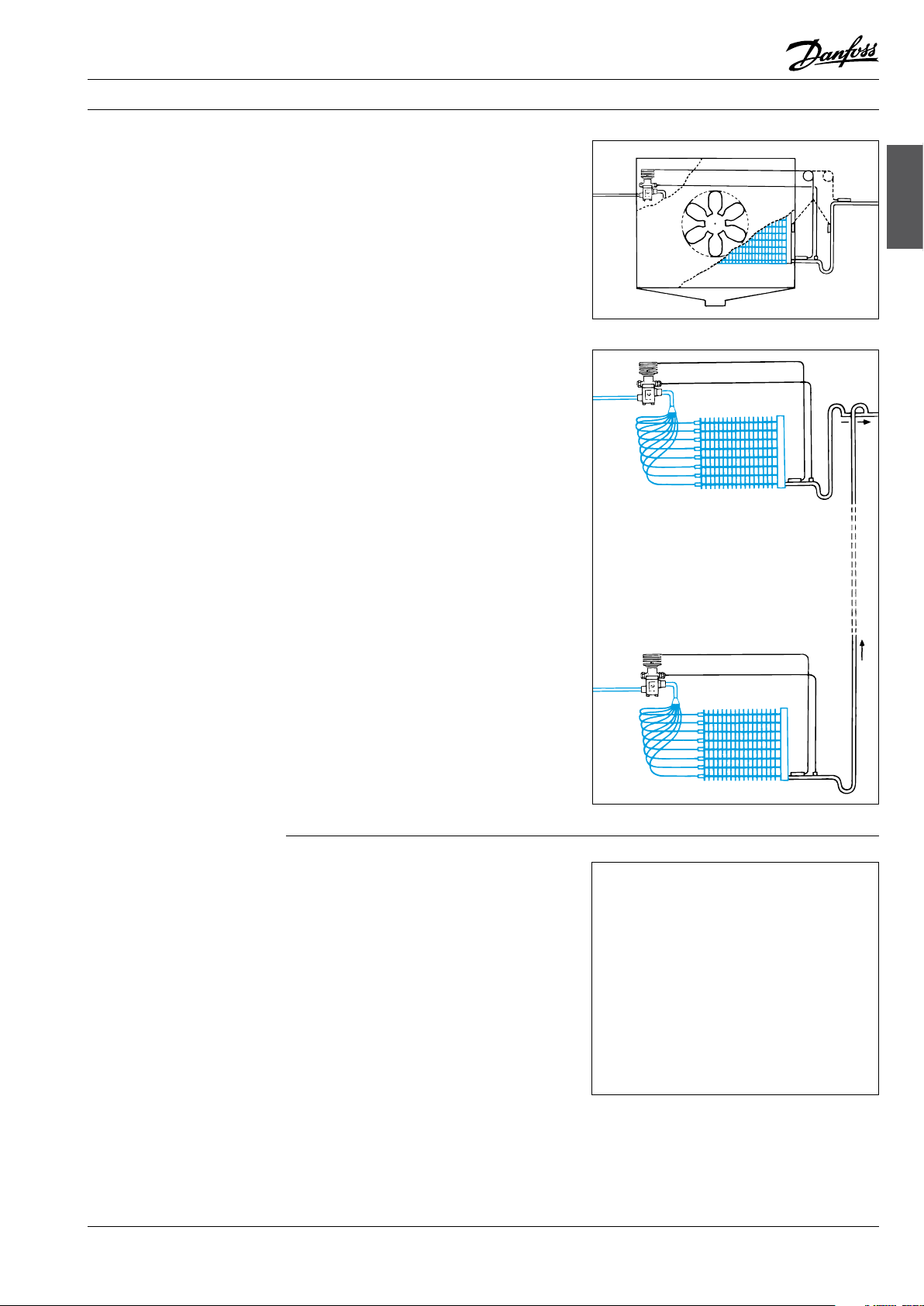

The bulb is best mounted on a horizontal suction

line tube and in a position corresponding to

between 1 o’clock and 4 o’clock.

Location depends on the outside diameter of the

tube.

Note:

The bulb must never be located at the bottom

of the suction line due to the possibility of oil

laying in the bottom of the pipe causing false

signals.

Ad0-0002

Ad0-0003

Installation The expansion valve must be installed in the

liquid line, ahead of the evaporator, with its

bulb fastened to the suction line as close to the

evaporator as possible.

If there is external pressure equalization, the

equalizing line must be connected to the suction

line immediately after the bulb.

The bulb must not be installed after a heat

exchanger because in this position it will give

false signals to the expansion valve.

The bulb must not be installed close to components of large mass as this also will give rise to

false signals to the expansion valve

Ad0-0004

Ad0-0005

Ad0-0006

The bulb must be able to sense the tem pe ra tu re

of the superheated suction vapour and must

therefore not be located in a position that will

expose it to extraneous heat/cold.

If the bulb is exposed to a warm air current,

insulation of the bulb is recommended.

The Danfoss bulb strap allows a tight and secure

fi tting of the bulb to the tube, thereby securing

that the bulb has ultimate thermal contact to

the suction tube. The TORX design of the screw

makes it easy for the fi tter to transfer the torque

from the tool to the screw without having to

press the tool into the screw slot. Furthermore,

with the TORX slot design, there is no risk of

damaging the screw slot.

Page 11

Fitters notes Thermostatic expansion valves

Installation (cont.)

As previously mentioned, the bulb must be

installed to the horizontal part of the suction line

immediately after the evaporator. It must not be

installed to a collection tube or a riser after an oil

pocket.

The expansion valve bulb must always be

installed ahead of any liquid lock.

Ad0-0007

expansion valves

Thermostatic

Ad0-0008

Setting The expansion valve is supplied with a factory

setting suitable for most applications.

If necessary, readjustment can be made using the

setting spindle on the valve.

Turning the spindle clockwise increases the

expansion valve superheat and turning it

counterclock-wise reduces it.

For T /TE 2, one turn of the spindle produces a

change of approx. 4K in the superheat at 0°C

evaporating temperature.

Ad0-0009

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 9

Page 12

Fitters notes Thermostatic expansion valves

Setting (cont.)

For TE 5 and following sizes, one turn of the

spindle produces a change of approx. 0.5K in

the superheat at 0°C evaporating temperature.

For TUA and TUB, one turn of the spindle

produces a change of approx. 3K in the superheat at 0°C evaporating temperature.

Hunting in the evaporator can be eliminated by

the following procedure:

Increase the superheat by turning the expansion

valve setting spindle well to the right (clockwise)

so that hunting stops. Then turn the setting

spindle in counter-clockwise steps so that

hunting again occurs.

From this position, turn the spindle about once

clockwise (but only 1/4 turn for T /TE 2 valves).

On this setting the refrigeration system will not

hunt and the evaporator is fully utilized.

A variation of 1 K in superheat is not regarded as

hunting.

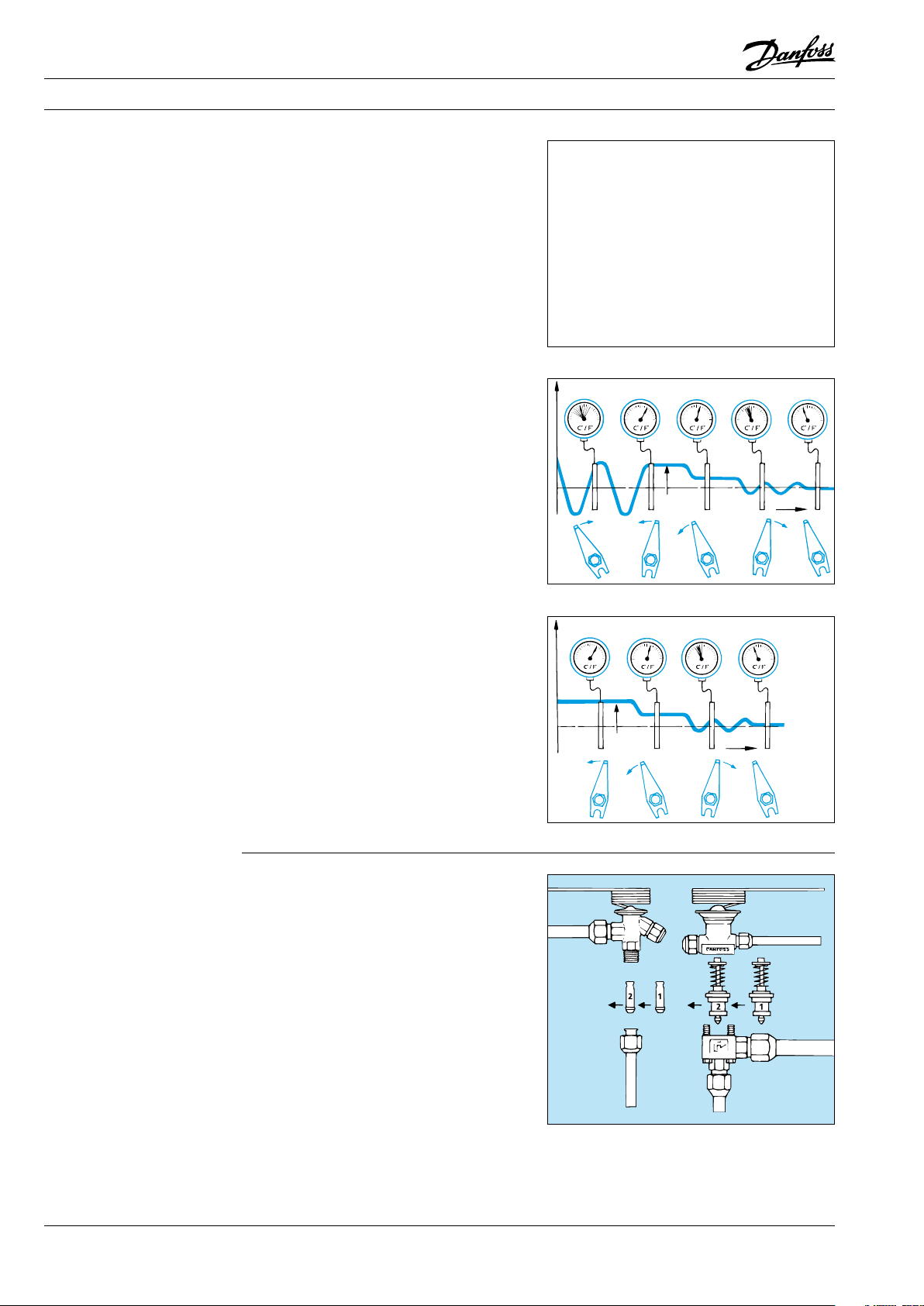

Ad0-0010

Ad0-0011

Orifice assembly

replacement

If the superheat in the evaporator is too high, the

reason might be an inadequate supply of liquid

refrigerant.

The superheat can be reduced by turning the

expansion valve setting spindle counterclockwise

in steps until hunting is observed.

From this setting, the spindle must be turned

about once clockwise (but only 1/4 turn for T/TE

2). This setting fully utilizes the evaporator.

A variation of 1 K in superheat is not regarded as

hunting.

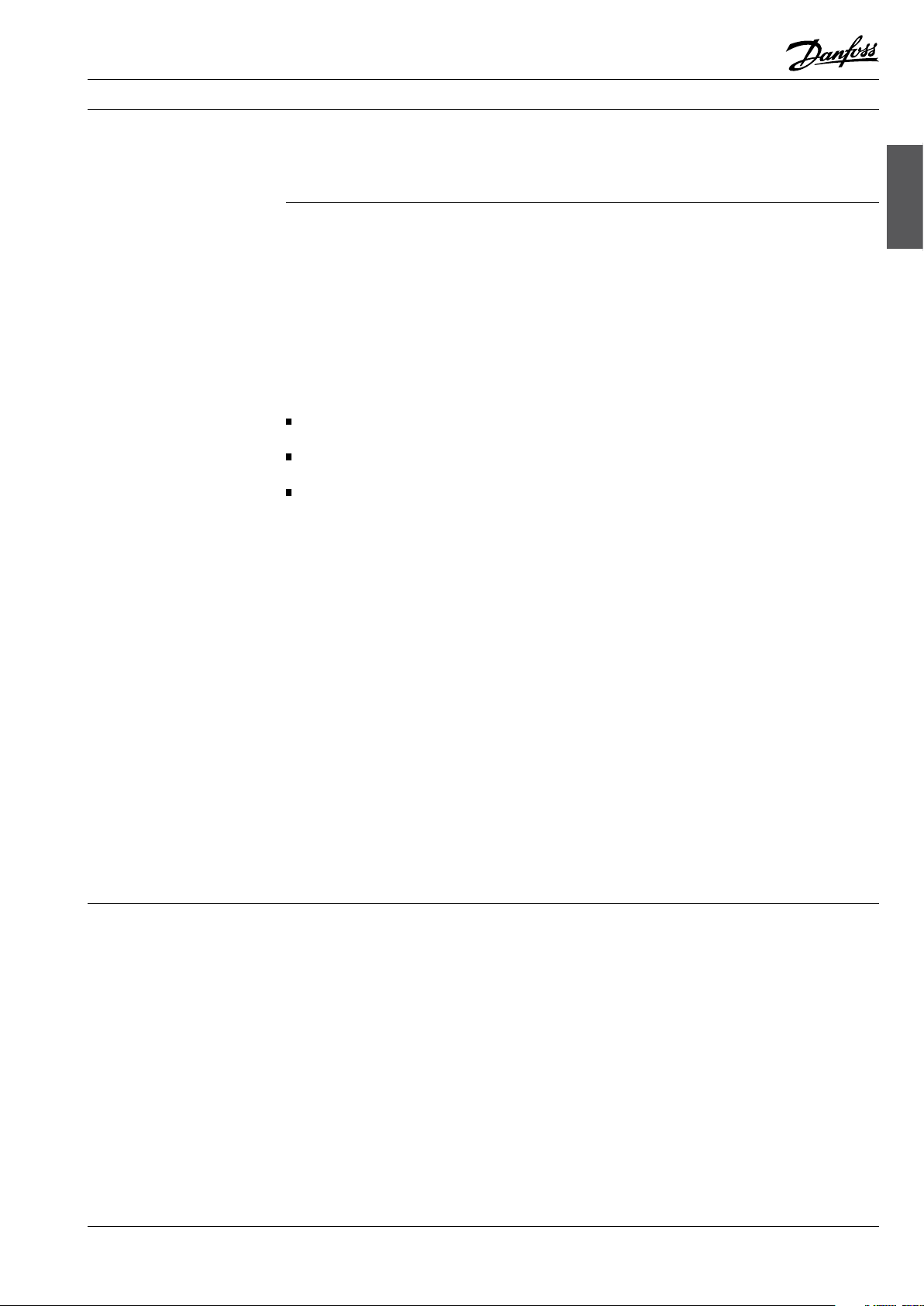

Ad0-0013

If the evaporator continues to hunt, regardless of

the superheat setting, the valve capacity might

be too high and the orifice assembly, or the valve,

needs replacing with a smaller one.

If the evaporator superheat is too high the valve

capacity is too low and the orifice assembly must

be replaced with a larger one.

TE, T2, TUA, TCAE valves are supplied with an

interchangeable orifice.

Ad0-0014

10 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 13

Fitters notes Thermostatic expansion valves

Danfoss product range

Thermostatic expansion

valves

Danfoss offers a comprehensive range of

thermostatic expansion valves with capacities

from 0.4 to 1083 kW (R134a).

T/TE 2 valves have a brass housing and flare/

flare or solder/flare connections.

Rated capacity: 0.4 - 10.5 kW (R134a).

TUA, TUB, TUC valves have a stainless steel

housing and stainless steel/copper bimetal

solder connections.

Rated capacity: 0.5 - 12 kW (R134a).

The valves can be supplied with or without

external pressure equalization.

TUA has an interchangeable orifice

assembly and adjustable superheat.

TUB has a fixed orifice and adjustable

superheat.

TUC has a fixed orifice and factory set

superheat.

TUB and TUC are primarily for OEM customers.

All TUB and TUC valves can be replaced by TUA

valves.

TCAE, TCBE, TCCE valves have a stainless steel

housing and stainless steel/copper bimetal

solder connections.

Rated capacity: 12 - 18 kW (R134a).

The valves are designed as the TU valves but with

a higher capacity.

TDE valves have a brass housing and copper

solder connections.

Rated capacity: 10.5 - 140 kW (R407C)

The valves are supplied with a fixed orifice and

adjustable superheat.

TE 5 - TE 55 valves have a brass housing.

The valves are supplied as a part programme

consisting of valve housing, orifice and thermostatic element.

The valve housing is available in a straightway

or angleway version with solder, flare and flange

connections.

Rated capacity: 12.9 - 220 kW (R134a).

The valves are supplied with external pressure

equalization.

PHT 85 - 300 valves are supplied as a part

programme consisting of valve housing, flanges,

orifice and thermostatic element.

Rated capacity: 55 - 1083 kW (R134a).

For further information consult the internet or

the catalogue material.

expansion valves

Thermostatic

The valves are supplied with external pressure

equalization.

TRE valves have a brass housing and stainless

steel/copper bimetal connections.

Rated capacity: 18 - 196 kW (R134a).

The valves are supplied with a fixed orifice and

adjustable superheat.

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 11

Page 14

Page 15

Fitters notes Solenoid valves

Contents Page

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

EVRA 32 & 40 precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

When pressure testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

The correct product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Solenoid valves

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 13

Page 16

Notes

14 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 17

Fitters notes Solenoid valves

Installation

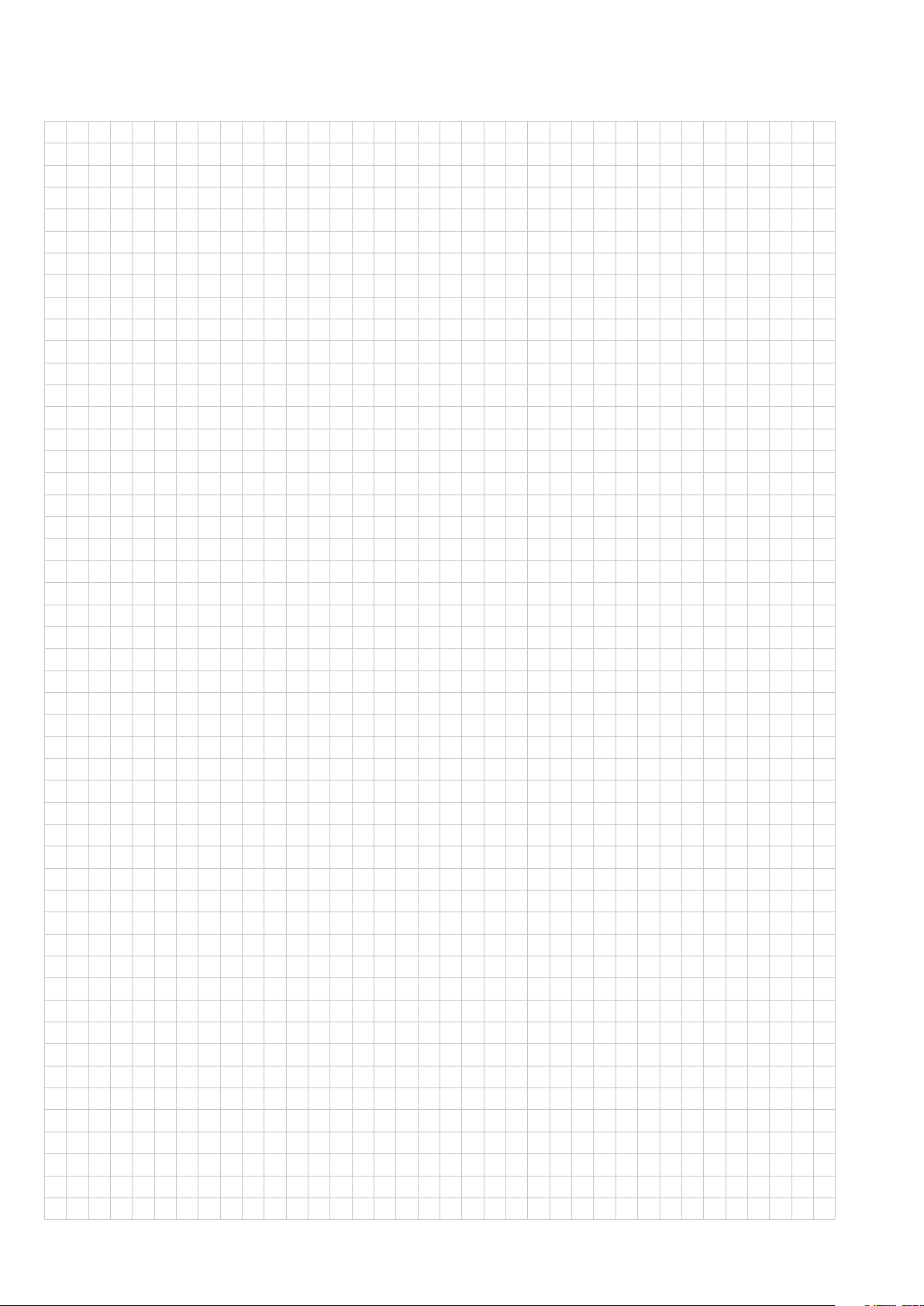

All EVR/EVRA, and EVH types solenoid valves

operate only when installed correctly in the

direction of flow, i.e. in the direction indicated by

the arrow.

Normally, solenoid valves installed ahead of a

thermostatic expansion valve must be close to

that valve.

This avoids liquid hammer when the solenoid

valve opens.

Ensure that pipes around the valve are properly

installed so that no fracture can occur.

Solenoid valves

Af0_0001

Af0_0003

EVRA 32 & 40 precautions

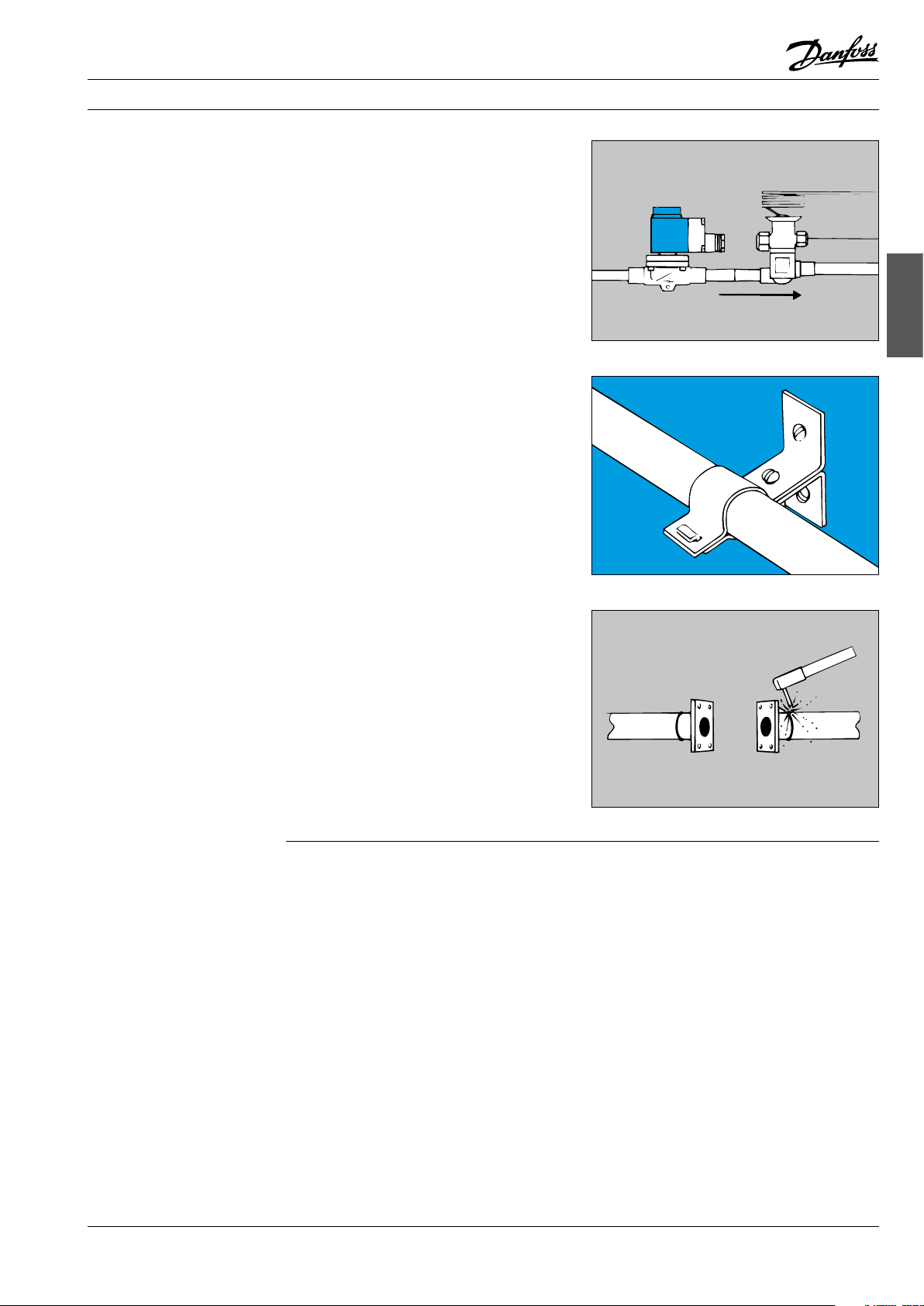

Brazing/welding EVR/EVRA and EVH solenoid

valves does not normally necessitate dismantling,

provided steps are taken to avoid heating the

valve.

Note! Always protect the armature tube against

weld spatter.

After tacking the valve to the pipe, remove the

valve body to protect O-rings and gaskets against

heat. In installations with welded steel pipe, a

FA type strainer or similar mounted ahead of the

solenoid valve is recommended. (On new plant,

flushing out before starting up is recommended).

Af0_0004

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 15

Page 18

Fitters notes Solenoid valves

16 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Af0_0005

All solenoid valves in the system must be open,

either by applying voltage to the coils or by

opening the valves manually (provided a manual

operation spindle is fi tted).

Remember to screw the spindle back before

starting up, otherwise the valve will be unable to

close.

When pressure testing

Always use counter force when fi nally

tightening the solenoid valve on pipes, i.e.

two spanners on the same side of the valve.

Af0_0006

Page 19

Fitters notes Solenoid valves

The coil

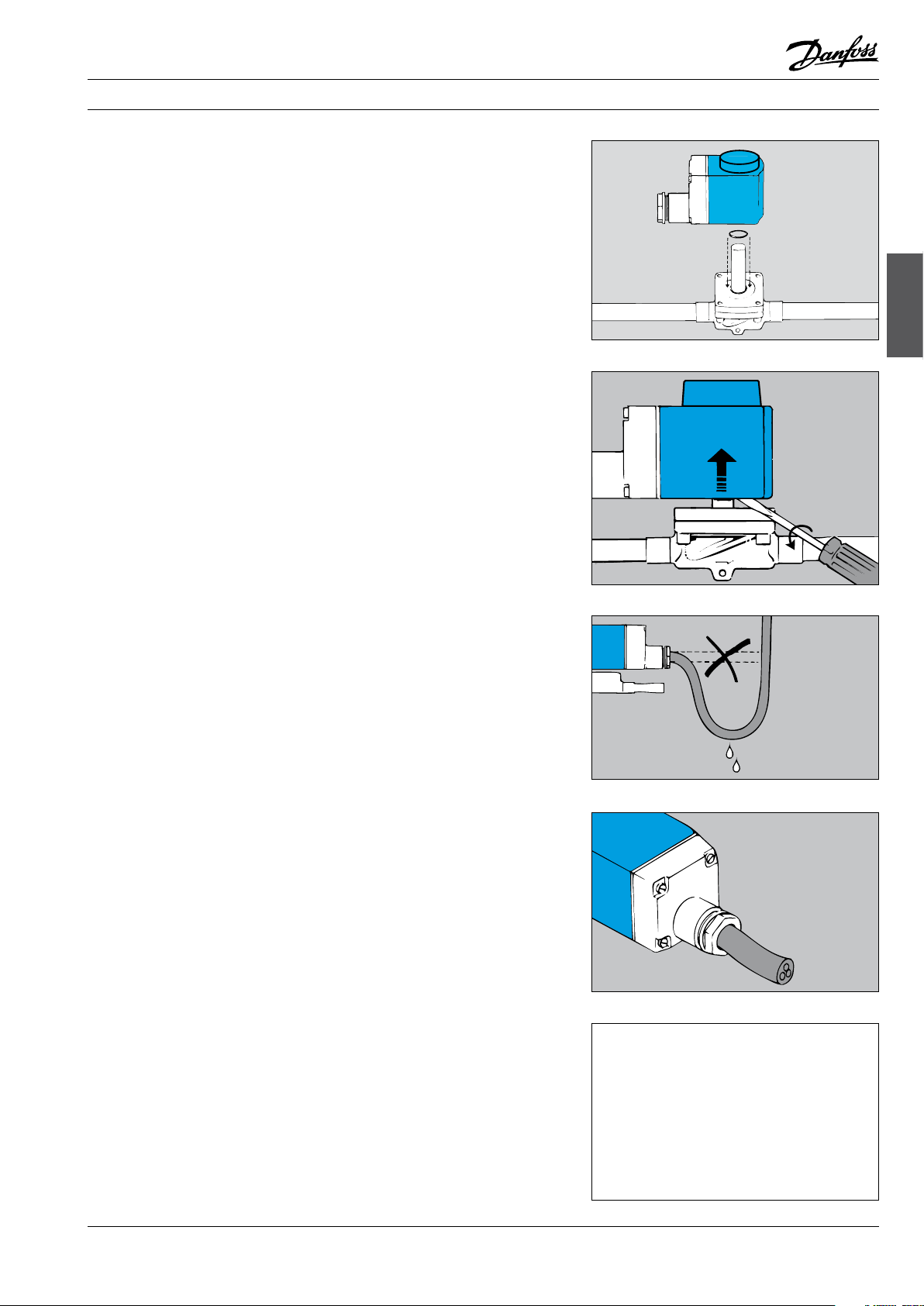

When fitting the coil, it has merely to be pressed

down over the armature tube until a click is

heard. This means that the coil has been correctly

fitted.

Note: Remember to fit an O-ring between valve

body and coil.

Be sure that the O-ring is smooth, not damaged

and that the surface is free from paint or any

other material.

Note: The O-ring must be changed at service.

The coil can be removed by inserting a

screwdriver between valve body and coil. The

screwdriver can then be used as a lever to loosen

the coil.

Solenoid valves

Af0_0018

Af0_0019

Be careful with cable entries. It must not be

possible for water to enter the terminal box. The

cable must be led out via a drip loop.

The entire cable circumference must be retained by the cable entry.

Therefore, always use round cable (which is the

only type of cable that can be sealed effectively).

Be aware of the colour of leads in the cable.

Yellow/green is always earth.

Leads of one colour are either phase or neutral.

Af0_0009

Af0_0010

Af0_0011

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 17

Page 20

Fitters notes Solenoid valves

The coil (cont.)

The correct product

(The “old” coil type)

When removing a coil it might be necessary to

use hand tools, e.g. two screwdrivers.

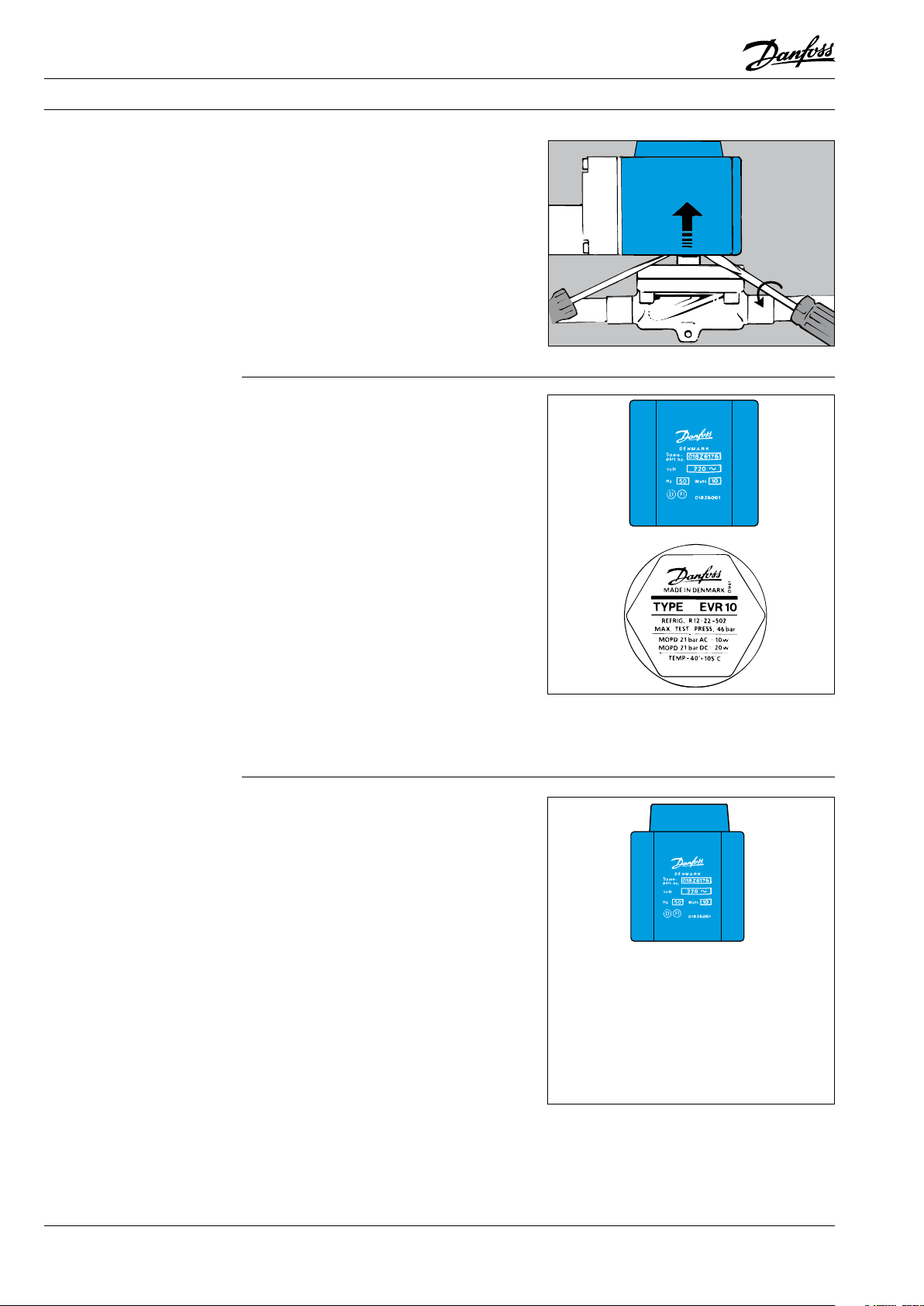

Make sure that coil data (voltage and frequency)

and supply voltage correspond. If they do not,

the coil might burn out. Always ensure that valve

and coil match each other.

When replacing a coil in an EVR 20 NC

(NC = normally closed) note:

- A valve body using an a.c. coil has a square

armature.

- A valve body using a d.c. coil has a round

armature.

Fitting the wrong coil results in a lower MOPD.

See data on the top nut. As far as possible, always

choose single-frequency coils. These give off

less heat than double-frequency coils.

Use NC (normally closed) solenoid valves for

systems in which the valve must remain closed

(de-energised) for most of the operating time.

Use NO (normally open) solenoid valves for

systems in which the valve must remain open

(de-energised) for most of the operating time.

Never replace an NO (normally open) solenoid

valve with an NC (normally closed) valve - or vice

versa.

Af0_0012

Af0_0013

Af0_0014

(The new “clip-on” coil type)

Two labels are supplied with each clip-on coil

(see illustration).

The adhesive label is for attaching to the side of

the coil, while the other, perforated label should

be placed over the armature tube before the coil

is clicked into position.

Af0_0015

Af0_0020

18 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 21

Fitter notes Pressure controls

Contents Page

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Placing of surplus capillary tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Low-pressure control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

High-pressure control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Example with four compressors in parallel (R404A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting LP for outdoor location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Indicative evaporating pressures (pe) for different types of systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Test of contact function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The correct pressure control for your system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pressure controls

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 19

Page 22

Notes

20 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 23

Fitter notes Pressure controls

Installation

Mount the KP pressure control on a bracket or on

a completely flat surface.

The pressure control can also be mounted on the

compressor itself.

In unfavourable conditions, an angle bracket

could amplify vibration in the mounting plane.

Therefore, always use a wall bracket where strong

vibration occurs.

If the risk of water droplets or water spray is

present, the accompanying top plate should be

used. The plate increases the grade of enclosure

to IP 44 and is suitable for all KP pressure controls.

To obtain IP 44, the holes in the backplate of the

control must be covered by mounting on either

an angle bracket (060-105666) or a wall plate

(060-105566).

The top plate is supplied with all units incorporating automatic reset. It can also be used on

units with manual reset, but in that case must

be purchased separately (code no.: for single unit,

060-109766; for dual unit, 060-109866).

If the unit is to be used in dirty conditions or

where it might be exposed to heavy spray -

from above or from the side - it should be fitted

with a protective cap. The cap can be used

together with either an angle bracket or a wall

bracket.

Al0_0001

Al0_0007

Pressure controls

Al0_0008

If the unit risk being exposed to heavy water

influence a better grade of enclosure can be

achieved when mounting the product in a special

IP 55 enclosure.

The IP 55 enclosure is available for both single

unit (060-033066) and dual unit (060-035066).

Ak0_0020

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 21

Page 24

Fitter notes Pressure controls

Installation (cont.)

Placing of surplus

capillary tube

The pressure connection of the control must

always be fitted to the pipe in such a way that

liquid cannot collect in the bellows. This risk is

present especially when:

the unit is located in a low ambient condition,

e.g. in an air current,

the connection is made on the underside of

the pipe.

Such liquid could damage the high-pressure

control.

Consequently, compressor pulsation would

not be damped and might give rise to contact

chatter.

Surplus capillary tube can fracture if vibration

occurs and might lead to complete loss of system

charge. It is therefore very important that the

following rules are observed:

When mounting direct on compressor:

Secure the capillary tube so that the compressor/control installation vibrates as a

whole. Surplus capillary tube must be coiled

and bound.

Note:

According to EN rules it is not allowed to use

capillary tube for connecting safety pressure

controles. In such case a 1/4 inch tube is

prescribed.

Al0_0009

Al0_0010

Setting

Low-pressure control

High-pressure control

Other types of mounting:

Coil surplus capillary tube into a loose loop.

Secure the length of capillary tube between

compressor and loop to the compressor.

Secure the length of capillary tube between

loop and pressure control to the base on

which the pressure control is mounted.

In case of very strong vibrations, Danfoss

steel capillary tubes with flare connection are

recommended:

Code no. 0.5 m = 060-016666

Code no. 1.0 m = 060-016766

Code no. 1.5 m = 060-016866

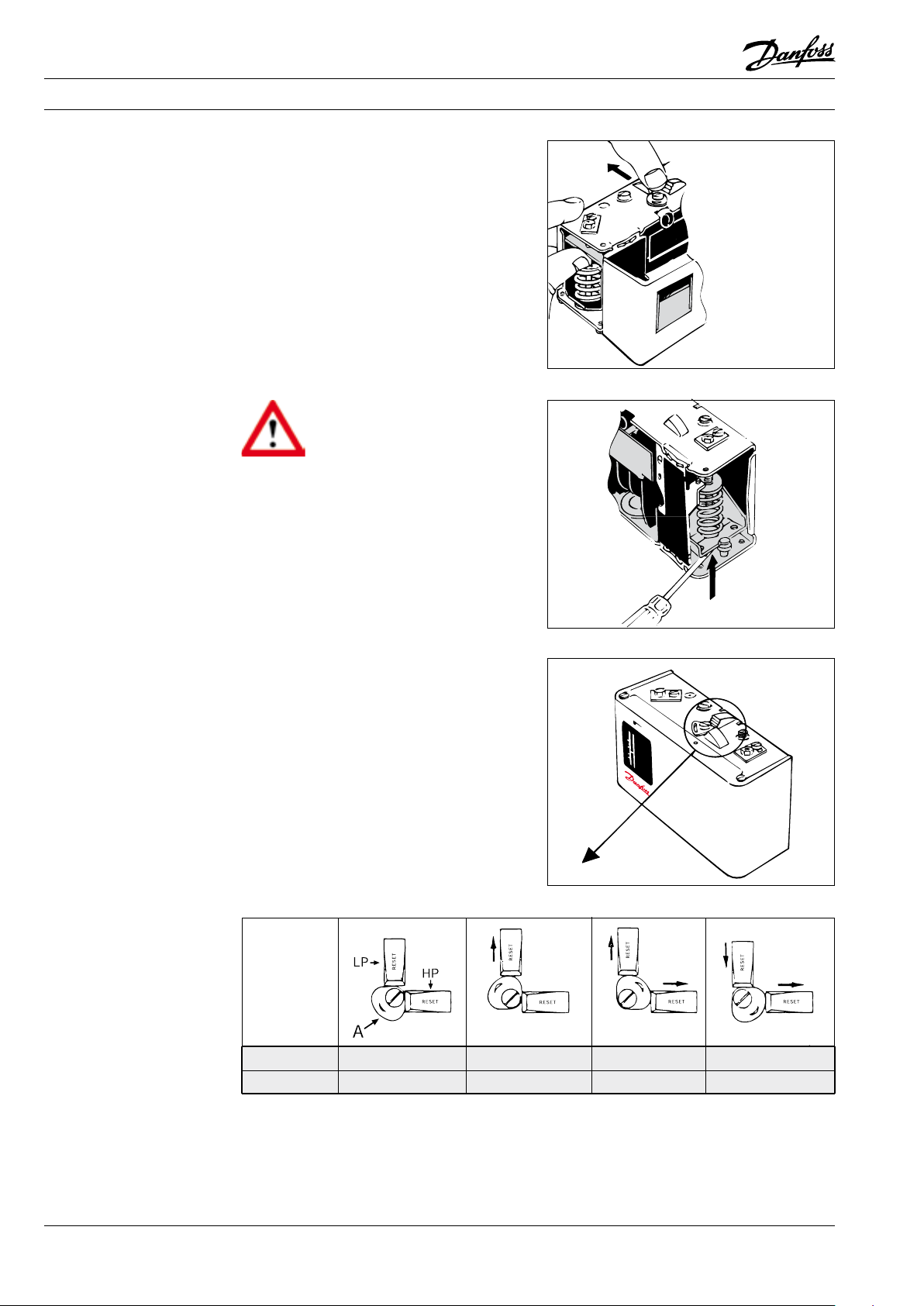

KP pressure controls can be preset using a compressed air cylinder. Ensure that the change-over

contacts are correctly connected for the required

function.

Set the start pressure (CUT IN) on the range scale

(A). Then set the differential on the differential

scale (B).

Stop pressure = CUT IN minus DIFF.

Set the stop pressure (CUTOUT) on the range

scale (A). The set the differential on the

differential scale (B).

Start pressure = CUT OUT minus DIFF.

Remember: The scales are indicative only.

Al0_0011

Al0_0012

22 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 25

Fitter notes Pressure controls

Example with four compressors

in parallel (R404A)

Setting LP for outdoor location

Indicative evaporating

pressures (pe) for different

types of systems

Medium: ice cream at –25°C,

t0 ≈ –37°C,

Compressor CUT OUT CUT IN

p0 ≈ –0.5 bar,

∆p suction line corresponding to 0.1 bar.

Each pressure control (e.g. KP 2) must be set

individually in accordance with the following

table.

The pressure control must be mounted in such

a way that liquid cannot collect in the bellows.

If the compressor, condenser and receiver are

situated outdoors, KP low pressure must be set to

a “CUT IN” setting lower than the lowest occurring

pressure (temperature around compressor)

during winter operation. In this case, after longer

standstill periods the pressure in the receiver

determines the suction pressure.

Example:

Lowest occurring temperature around the

compressor –20°C means, for R404A, a pressure

of 1 bar. CUT IN must be set at –24°C (corresponding to 1.6 bar).

Al0_0013

Room temp. (tr) System type Difference

+0.5°/+2°C Fan-cooled

meat cold room

+0.5°/+2°C Meat cold room with

natural air circulation

–1°/0°C Refrigeration meat

counter (open)

+2°/+6°C Milk cold room 14K 1.0 bar

0°/+2°C Fruit cold room

Vegetable chiller

–24°C Freezer 10K 1.6 bar

–30°C Ventilated deep

freeze room

–26°C Ice cream freezer 10K 1.4 bar

between te

and t

media

10K 1.0 - 1.1 bar

12K 0.8 - 0.9 bar

14K 0.6 bar

6K 1.3 - 1.5 bar

10K 1 bar

Evaporating

pressure (pe)

(air)

(R134a)

(R134a)

(R134a)

(R134a)

(R134a)

(R404A)

(R404A)

(R404A)

1 –0.05 bar 0.35 bar

2 0.1 bar 0.5 bar

3 0.2 bar 0.6 bar

4 0.35 bar 0.75 bar

RH

Setting of KP2/KP1

[%]

(cut in - cut out)

D = Operating press. cont.

S = Safety press. cont.

85 0.9 - 2.1 bar (D)

85 0.7 - 2.1 bar (D)

85 0.5 - 1.8 bar (D)

85 0.7 - 2.1 bar (D)

90 1.2 - 2.1 bar (D)

90 0.7 - 2.2 bar (S)

90 0.3 - 2.7 bar (S)

90 0.5 - 2.0 bar (S)

Pressure controls

Al0_0015

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 23

Page 26

Fitter notes Pressure controls

Test of contact function

When the electrical leads are connected and the

system is under normal operating pressure, the

contact function can be tested manually.

Depending on the bellows pressure and setting,

the test device must be pressed up or down.

Any reset mechanism becomes inoperative

during the test.

On single units:

Use the test device at top left.

On dual units:

Use the test device on the left for low-pressure

testing and the one at bottom right for highpressure testing.

Al0_0018

Warning!

The contact function on a KP

Pressure Control must never be

tested by activating the device at top

right. If this warning is ignored, the control may

go out of adjustment. In the worst case function

can be impaired.

Al0_0019

On the KP 15 dual pressure control with optional

automatic or manual reset on low-pressure

and high-pressure side, automatic reset must

be set when servicing is being carried out. The

pressure control can then automatically restart.

Remember, the original reset function must be

set after servicing.

The pressure control can be protected against

being set on automatic reset: Simply remove the

washer controlling the reset function!

If the unit is to be protected against tampering,

the washer can be sealed with red lacquer.

Al0_0020

Low pressure Manual reset *) Automatic reset Automatic reset Manual reset

High pressure Manual reset *) Manual reset Automatic reset Automatic reset

*) Factory setting

Al0_0021

24 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 27

Fitter notes Pressure controls

The correct pressure control for your system

KP with solder connections can be used instead

of flare connections on hermetic systems.

In ammonia plant where KP pressure controls are

used, they must be type KP-A.

A connector with M10 × 0.75 – 1/

no. 060- 014166).

- 18 NPT (code

4

Al0_0006

Pressure controls

For refrigerating systems containing a large

quantity of charge medium and where extra

safety is desired/demanded (Fail-safe): Use KP

7/17 with double bellows. The system will stop

if one of the bellows ruptures - without loss of

charge.

For systems operating with low pressure on the

evaporator side, and where the pressure control

must regulate (not just monitor): Use KP 2 with a

small differential.

An example where pressure control and thermostat are in series:

KP 61 regulates the temperature via compressor

stop/start.

KP 2 stops the compressor when suction pressure

becomes too low.

KP 61:

CUT IN = 5°C (2.6 bar)

CUT OUT = 1°C (2.2 bar)

KP 2 low pressure:

CUT IN = 2.3 bar

CUT OUT = 1.8 bar

Al0_0002

Al0_0003

Al0_0004

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 25

Page 28

Fitter notes Pressure controls

The correct pressure control

for your system (cont.)

For systems where KP is activated occasionally

(alarm) and for systems where KP is the signal

source for PLC, etc.: Use KP with gold contacts;

these give good contact at low voltages.

Al0_0005

26 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 29

Fitters notes Thermostats

Contents Page

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

KP thermostat with air sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostats with automatic reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostats with maximum reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostats with minimum reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Test of contact function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

KP 98 dual thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

The correct thermostat for your refrigeration system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Vapour charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Absorption charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Low voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Placing of surplus capillary tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Thermostats with vapour charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Thermostats

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 27

Page 30

Notes

28 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 31

Fitters notes Thermostats

Installation

If the risk of water droplets or water spray is

present, fit a top plate. The plate increases the

grade of enclosure to IP 44 and is suitable for all

KP thermostats. The top plate must be purchased

separately (Code no.: for single unit, 060-109766;

for dual unit, 060-109866).

To obtain IP 44, cover all holes in the backplate of

the thermostat.

If the unit is to be used in dirty conditions or

where it might be exposed to heavy spray it

should be fitted with a protective cap. The

cap can be used together with either an angle

bracket (060-105666) or a wall bracket (060-

105566).

Aj0_0001

Thermostats

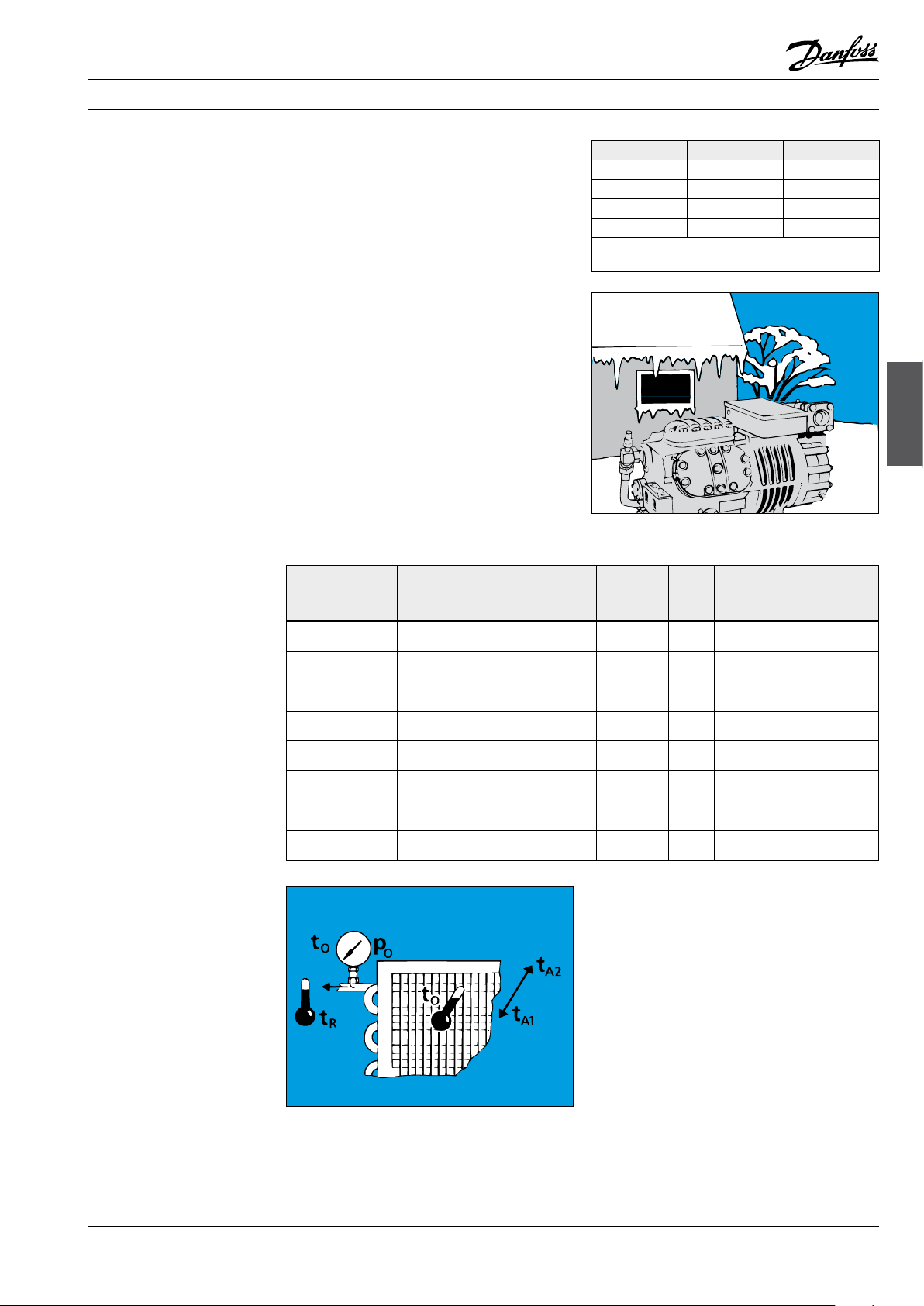

KP thermostat with air sensor

Aj0_0002

If the unit risk being exposed to heavy water

influence a better grade of enclosure can be

achieved when mounting the product in a special

IP 55 enclosure

The IP 55 enclosure is available for both single

unit (060-033066) and dual unit (060-035066).

Ak0_0020

Remember that the differential is affected by

air circulation around the sensor. Insufficient air

circulation can increase the differential by 2-3°C.

Place the room thermostat so that air is able to

flow freely around the sensor. At the same time,

ensure that the sensor is not exposed to draughts

from doors or radiation from the evaporator

surface.

Never place the thermostat directly on a cold

wall; this increases the differential. Instead,

mount the unit on an insulating plate.

Aj0_0003

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 29

Page 32

Fitters notes Thermostats

KP thermostat with air sensor

(cont.)

Setting

Thermostats with

automatic reset

When placing the sensor: Remember that air

must be able to circulate freely around the

sensor. With control from, for example, return

air temperature, the sensor must not touch the

evaporator.

KP thermostat with cylindrical sensor

There are three ways of securing the sensor:

1) The pipe.

2) Between evaporator fins.

3) In a pocket.

Always set the highest temperature on the range

scale. Then set the differential on the DIFF scale.

The temperature setting on the range scale

then corresponds to the temperature at which a

refrigeration compressor will be started on rising

temperature. The compressor will stop when the

temperature corresponds to the value set on the

DIFF scale.

For pre-setting of vapour charged thermostats,

the graph curves stated in the customer

instruction sheet should be used.

If the compressor will not stop when it is set for

low stop temperatures: Check to see whether

the differential has been set at too high a value.

Ah0_0006

When using a pocket: Always use heat-conductive compound (code no. 041E0110) to ensure

good contact between sensor and medium.

Aj0_0004

Aj0_0005

Thermostats with

maximum reset

Set the highest temperature = stop temperature

on range scale.

The differential setting is fixed. When the temperature on the thermostat sensor corresponds

to the differential setting, the system can be

restarted by pressing the "Reset" button.

Thermostats with

minimum reset

Set the lowest temperature = stop temperature

on range scale.

The differential setting is fixed.

When the temperature around the thermostat

sensor has risen to the differential setting, the

compressor can be restarted by pressing the

“Reset” button.

Aj0_0006

30 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 33

Fitters notes Thermostats

Setting example

Test of contact function

The temperature in a deep freeze room is to be

controlled by a thermostat that closes a solenoid

valve. The system is of the pump-down type and

is stopped via a low-pressure control.

Here, the pressure control must not be set to

cut out at a pressure lower than necessary.

At the same time, it must cut in at a pressure

corresponding to the cut-in temperature of the

thermostat.

Example:

Deep freeze room with R404A

Room temperature: –20°C

Thermostat cut out temperature: –20°C

Thermostat cut in temperature: –18°C

Pressure control cut out

pressure: 0.9 bar (–32°C)

Pressure control cut in

pressure: 2.2 bar (–18°C)

Thermostats

Aj0_0007

When the electrical leads are connected, the

contact function can be tested manually.

Depending on the sensor temperature and

the thermostat setting, the test device must

be pressed up or down. Any reset mechanism

becomes inoperative during the test.

Use the test device at top left.

KP 98 dual thermostat

Aj0_0009

Warning!

The contact function on a KP

single thermostat must never

be tested by activating the

device on the righthand side. If this warning

is ignored, the thermostat might go out of

adjustment. In the worst case, function can be

impaired.

Use the test device on the lefthand side to

test function on rising oil temperature and the

test device at bottom right to test function on

rising pressure gas temperature.

Aj0_0010

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 31

Page 34

Fitters notes Thermostats

The correct thermostat for

your refrigeration system

Vapour charge

Absorption charge

A thermostat must contain the correct charge, as

described below.

Low temperatures, coldest bellows, not enclosure-sensitive.

Thermostat with air coil: On gradual temperature

rise and fall (less than 0.2K/min), e.g. in large,

sluggish cold rooms containing many items, KP

62 with vapour charge is recommended.

High temperatures, enclosure-sensitive. Bellows

colder or warmer.

Thermostat with air coil: On fast changes in

temperature (more than 0.2K/ min), e.g. in

smaller cold rooms where the produce turnover

rate is high, KP 62 with absorption charge is

recommended.

Straight

capillary tube

60I8012

Remote air coil

60I8032

Vapour charge

Air coil

(integral with

thermostat)

60I8013

Double contact

remote bulb

60I8017

Cylindric

remote bulb

60I8008

Low voltage

For systems where KP is activated occasionally

(alarm) and for systems where KP is the signal

source for PLC, etc. (low voltage): Use KP with

gold contacts; these give good contact at low

voltages.

Absorption charge

Aj0_0012

Air coil

(integral with

thermostat)

60I8013

Remote air coil

(for duct mounting)

60I8018

32 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 35

Fitters notes Thermostats

Placing of surplus

capillary tube

Thermostats with

vapour charge

Dual thermostat KP 98:

Surplus capillary tube can fracture if vibration

occurs and might lead to loss of thermostat

charge. It is therefore very important that the

following rules be observed:

When mounting direct on compressor:

Secure the capillary tube so that the

compressor/thermostat installation vibrates as

a whole. Surplus capillary tube must be coiled

and bound.

Other types of mounting: Coil surplus capillary

tube into a loose loop. Secure the length of

capillary tube between compressor and loop

to the compressor.

Secure the length of capillary tube between

loop and thermostat to the base on which the

thermostat is mounted.

Never locate a KP thermostat with vapour charge

in a room where the temperature is or can be

lower than that in the cold room.

Aj0_0017

Thermostats

Never allow the capillary tube from a KP

thermostat to run alongside of a suction line in a

wall entry.

Aj0_0014

Aj0_0015

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 33

Page 36

Page 37

Fitters notes Pressure regulators

Contents Page

Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

KVP evaporating pressure regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

KVR condensing pressure regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

KVL crankcase pressure regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

KVC capacity regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

KVD receiver pressure regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Soldering/brazing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pressure testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

KVP evaporating pressure regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

KVL crankcase pressure regulators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

KVR + NRD condensing pressure regulators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

KVR + KVD condensing pressure regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Danfoss pressure regulators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

regulators

Pressure

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 35

Page 38

Notes

36 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 39

Fitters notes Pressure regulators

Application

KVP evaporating

pressure regulator

Type KV pressure regulators will control the low

and high pressure sides of the system under

varying load conditions:

KVP is used as an evaporating pressure

regulator.

KVR is used as a condensing pressure regulator.

KVL is used as a crankcase pressure regulator.

KVC is used as a capacity regulator.

NRD is used as a differential pressure regulator

and as a receiver pressure regulator.

KVD is used as a receiver pressure regulator.

CPCE is used as a capacity regulator.

The evaporating pressure regulator is installed in

the suction line after the evaporator to regulate

the evaporating pressure in refrigeration systems with one or more evaporators and one

compressor.

In such refrigeration systems (operating on

different evaporating pressures) KVP is installed

after the evaporator with the highest evaporating

pressure.

Each evaporator is activated by a solenoid valve

in the liquid line. The compressor is contolled by

a pressure switch in a pump down function.

The maximum pressure on the suction side

corresponds to the lowest room temperature.

Ak0_0031

Ak0_0025

regulators

Pressure

In refrigeration systems with parallel coupled

evaporators and common compressors, and

where the same evaporating pressure is required,

KVP must be installed in the common suction

line.

The KVP evaporating pressure regulator has a

pressure gauge connection for use when setting

the evaporating pressure. KVP maintains constant

pressure in the evaporator.

KVP opens on rising inlet pressure (evaporating

pressure).

Ak0_0019

Ak0_0023

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 37

Page 40

Fitters notes Pressure regulators

KVR condensing

pressure regulator

KVR is normally installed between the air-cooled

condenser and the receiver. KVR maintains

constant pressure in air-cooled condensers.

It opens on rising inlet pressure (condensing

pressure).

KVR together with a KVD or an NRD ensures a

sufficiently high liquid pressure in the receiver

during varying operating conditions.

The KVR condensing pressure regulator has a

pressure gauge connection for use when setting

the condensing pressure.

Ak0_0026

In situations where both the air-cooled condenser and the receiver are located outdoors in

very cold surroundings it can be difficult to start

the refrigeration system after a long standstill

period.

In such conditions, KVR is installed ahead of the

air-cooled condenser, with an NRD in a bypass

line around the condenser.

NRV prevent back flow during start up process.

Ak0_0027

KVR is also used in heat recovery. In this

application, KVR is installed between the heat

recovery vessel and condenser.

It is necessary to install an NRV between condenser and receiver in order to prevent backcondensation of the liquid in the condenser.

Ak0_0028

KVR can be used as a relief valve in refrigeration

systems with automatic defrosting. Here, KVR

is installed between the outlet tube from

evaporator and receiver.

Note!

KVR must never be used as a safety valve.

Ak0_0029

KVL crankcase

pressure regulator

KVL crankcase pressure regulator limits compressor operation and start-up if the suction

pressure becomes too high.

It is installed in the refrigeration system suction

line immediately ahead of the compressor.

KVL is often used in refrigeration systems with

hermetic or semihermetic compressors designed

for low-temperature ranges.

KVL opens on falling outlet pressure (suction

pressure).

Ak0_0024

38 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 41

Fitters notes Pressure regulators

KVC capacity regulator

KVC is used for capacity regulation in refrigeration systems where low-load situations occur

and where it is necessary to avoid low suction

pressure and “compressor cycling”.

Too low a suction pressure will also cause

vacuum in the refrigeration system and thus

create the risk of moisture ingress in refrigeration

systems with open compressor. KVC is normally

installed in a bypass line between compressor

discharge tube and suction tube. KVC opens on

falling outlet pressure (suction pressure).

Ak0_0030

A CPCE capacity regulator can be used as

an alternative to KVC if the requirement

is greater accuracy in the regulation, low

suction pressure or if higher pressure drop is

given between CPCE outlet and the suction

pressure.

KVD receiver

pressure regulator

KVC can also be installed in a bypass line from

the compressor discharge pipe, with valve outlet

led to a point between expansion valve and

evaporator.

This arrangement can be used on a liquid cooler

with several parallelcoupled compressors and

where no liquid distributor is used.

KVD is used to maintain sufficiently high

receiver pressure in refrigeration systems with

or without heat recovery.

KVD is used together with a KVR condensing

pressure regulator.

The KVD receiver pressure regulator has a

pressure gauge connection for use when

setting receiver pressure.

KVD opens on falling outlet pressure (receiver

pressure).

Ak0_0002

Ak0_0003

regulators

Pressure

Ak0_0004

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 39

Page 42

Fitters notes Pressure regulators

PS

Identification

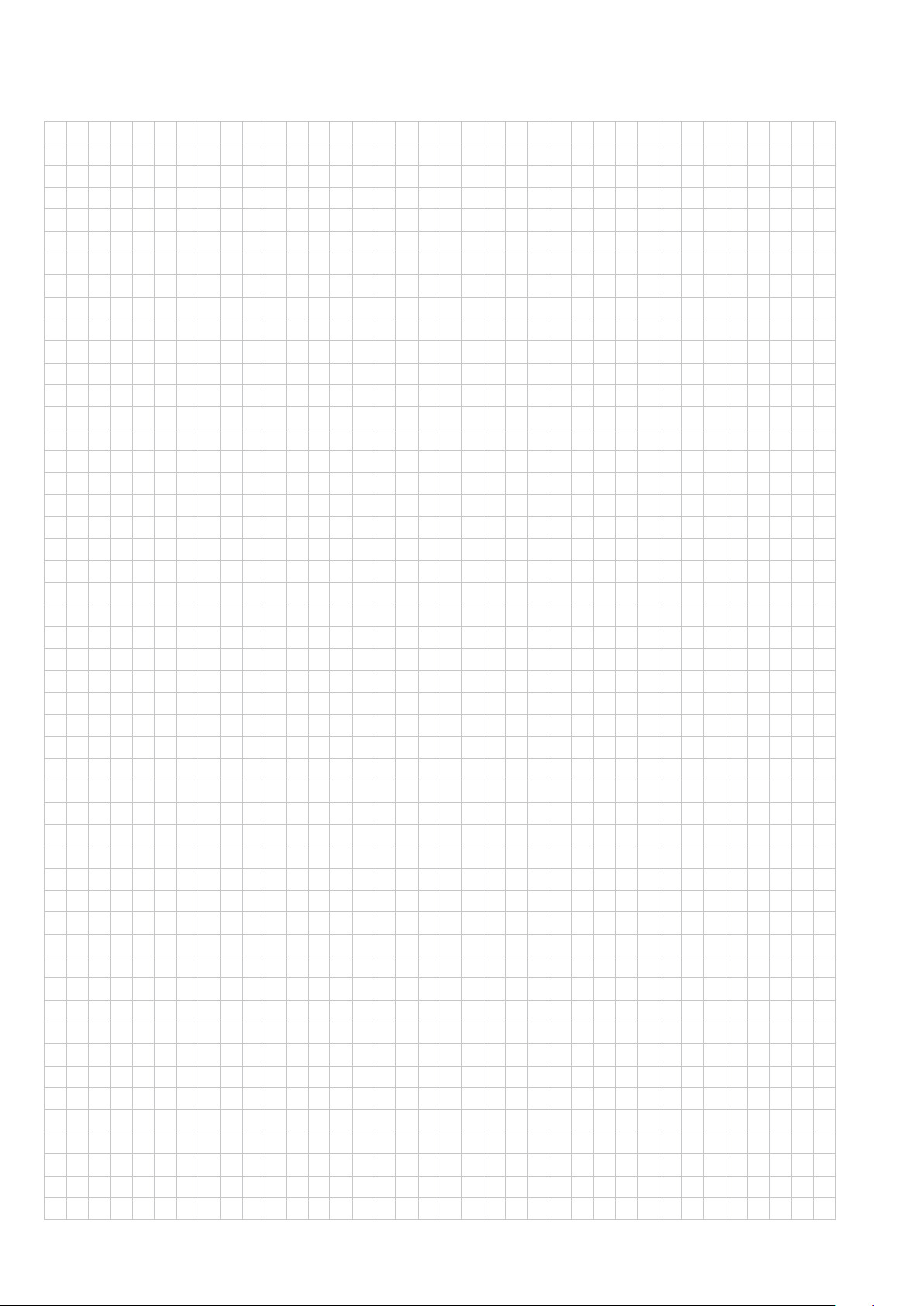

All KV pressure regulators carry a label giving the

valve function and type, e.g. CRANKCASE PRESS.

REGULATOR type KVL.

The label also gives the operating range of the

valve and its max. permissible working pressure

(PS/MWP).

A double-ended arrow (“+” and “-“) is printed

on the bottom of the label. Direction “+” (plus)

means higher pressure and “–“ (minus) means

lower pressure.

KV pressure regulators can be used with all

existing refrigerants except ammonia (NH3),

provided valve pressure ranges are respected.

The valve body is stamped with the valve size,

e.g. KVP 15, with an arrow to indicate valve flow

direction.

Ak0_0032

Ak0_0005

Installation

Soldering/brazing

Ensure that piping around KV valves is clean and

well-secured. This will protect valves against

vibration.

All KV pressure regulators must always be

installed so that flow is in the direction of the

arrow.

KV pressure regulators can otherwise be installed

in any position, but they must never be able to

create an oil or liquid lock.

Ak0_0006

During soldering, it is important to wrap a wet

cloth around the valve.

Always point the gas flame away from the valve

so that the valve is never subjected to direct heat.

When soldering, be careful not to leave soldering

material in the valve as this can impair function.

Before soldering a KV valve, be sure that any

pressure gauge insert has been removed. Always

use inert gas when soldering KV valves.

Ak0_0007

Warning!

Alloys in soldering materials and

flux give off smoke which can be

hazardous to health. Please read

gases. It is a good idea to use safety goggles.

Soldering while refrigerant is present in the

system is not recommended.

suppliers’ instructions and follow their safety

precautions. Keep the head away from the smoke

during soldering. Use good ventilation and/or an

extract at the flame and do not inhale smoke and

Aggressive gases might be created which can, for

example, break down the bellows in KV valves or

other parts in the refrigeration system.

40 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 43

Fitters notes Pressure regulators

Pressure testing

Evacuation

KV pressure regulators can be pressure-tested

after they have been installed, provided the

test pressure does not exceed the maximum

permissible pressure on the valves.

The maximum test pressure for KV valves is

shown in the table.

During evacuation of the refrigeration system, all

KV valves must be open.

Factory-set KV valves will have the following

positions when supplied:

KVP, closed

KVR, closed

KVL, open

KVC, open

KVD, open

It is therefore necessary to screw the setting

spindle of KVP and KVR right back counterclockwise during system evacuation.

In individual cases it can be necessary to

evacuate from both discharge side and lowpressure side in the refrigeration system.

Evacuation through the pressure gauge connections of KVP, KVR and KVD is not advisable because the orifice in these ports are very small.

Type Test pressure, bar

KVP 12 - 15 - 22 28

KVP 28 - 35 25

KVL 12 - 15 - 22 28

KVL 28 - 35 25

KVR 12 - 15 - 22 31

KVR 28 - 35 31

KVD 12 - 15 31

KVC 12 - 15 - 22 31

regulators

Pressure

Ak0_0009

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 41

Page 44

Fitters notes Pressure regulators

Setting

KVP evaporating

pressure regulators

When setting KV pressure regulators in refrigeration systems it can be a good idea to use

the factory setting as the starting-out point.

The factory setting for individual pressure

regulators can be found again by measuring

from the top of the valve to the top of the

setting screw.

The table shows the factory setting, the

distance “x” and the pressure change per

revolution of the setting screw for all KV types.

KVP evaporating pressure regulators are always

supplied with a factory setting of 2 bar. Turning

clockwise gives higher pressure and turning

counterclockwise gives lower pressure.

After the system has been in normal operation for

a time, fine adjustment is necessary. Always use a

pressure gauge when making fine adjustments.

If KVP is used for frost protection, fine adjustment

must be made when the system is operating

under minimum load.

Remember to always replace the protective cap

on the setting screw after final setting.

Type

KVP 12 - 15 - 22 2 bar 13 0.45

KVP 28 - 35 2 bar 19 0.30

KVL 12 - 15 - 22 2 bar 22 0.45

KVL 28 - 35 2 bar 32 0.30

KVR 12 - 15 -22 10 bar 13 2.5

KVR 28 - 35 10 bar 15 1.5

KVD 12 - 15 10 bar 21 2.5

KVC 12 - 15 - 22 2 bar 13 0.45

Ak0_0010

Factory

setting

X mm bar/rev.

KVL crankcase

pressure regulators

KVR + NRD condensing

pressure regulators

Ak0_0011

KVL crankcase pressure regulators are always

supplied with a factory setting of 2 bar.

Turning clockwise gives higher pressure and

turning counterclockwise gives lower pressure.

The factory setting is the point at which KVL

begins to open or where it just closes. Since the

compressor must be protected, the KVL setting is

the max. permissible suction pressure of the

compressor.

The setting must be made using the compressor

suction pressure gauge.

Ak0_0012

In refrigeration systems with KVR + NRD, the

setting of KVR must give a suitable receiver

pressure.

Pressure in the condenser of between 1.4 and 3.0

bar (pressure drop across NRD) higher than the

pressure in the receiver should be acceptable. If it

cannot be accepted, an arrangement with KVR +

KVD must be used.

This setting is best made during operating in a

winter period.

Ak0_0013

42 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 45

Fitters notes Pressure regulators

KVR + KVD condensing

pressure regulators

In refrigeration systems with KVR + KVD, the

condensing pressure must first be set with KVR

while KVD is closed (setting screw turned back

fully counterclockwise).

Then, KVD must be set to a receiver pressure, e.g.

about 1 bar lower than condensing pressure.

A pressure gauge must be used for this setting

which is best made during operation in a winter

period.

If the condensing pressure is set during summer

operation, one of two procedures can be used:

1) In a newly-installed refrigeration system with

a KVR/KVD setting of 10 bar as the starting

out point, the system can be set by counting

the number of turns on the setting screw.

2) In an existing refrigeration system, where

the KVR/KVD setting is not known, the

Ak0_0014

starting-out point must first be established.

The number of turns on the setting screw

can then be counted.

Danfoss pressure regulators

Product Used as Opens Pressure range

KVP Evaporating pressure regulator on a rise in pressure on the inlet side 0 - 5.5 bar

KVR Condensing pressure regulator on a rise in pressure on the inlet side 5 - 17.5 bar

regulators

Pressure

KVL Crankcase pressure regulator at a fall in pressure on the outlet side 0.2 - 6 bar

KVC Capacity regulator at a fall in pressure on the outlet side 0.2 - 6 bar

CPCE Capacity regulator at a fall in pressure on the outlet side 0 - 6 bar

NRD Differential pressure regulator Begins to open when the pressure drop in the

3 - 20 bar

valve is 1.4 bar, and is fully open when the

pressure drop is 3 bar.

KVD Receiver pressure regulator at a fall in pressure on the outlet side 3 - 20 bar

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 43

Page 46

Page 47

Fitters notes Water valves

Contents Page

Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Water valves

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 45

Page 48

Notes

46 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 49

Fitters notes Water valves

Application

Identification

WV pressure-operated water valves are used

in refrigeration systems with water-cooled

condensers to maintain constant condensing

pressure under varying loads.

The water valves can be used for common

refrigerants provided the operating range of the

valves is not exceeded. The WVS can be

used for R717 (ammonia)

Ag0_0001

Danfoss water valve type WVFM consists of a

valve body and bellows housing. The bellows

housing carries a label giving valve type,

operating range and max. permissible working

pressure.

The label also indicates the max. permissible

working pressure on the water side, given as PN

10 in accordance with IEC 534-4.

The direction in which the setting spindle must

be turned for greater or lesser water quantity is

given at the bottom of the valve.

Ag0_0002

Water valve type WVFX consists of a valve body

with setting unit on one side and a bellows

housing on the other.

The bellows housing carries a label giving valve

type, operating range and permissible working

pressure.

All pressures given apply to the condenser side.

Moulded in on one side of the valve body are PN

16 (nom. pressure) and, for example, DN 15 (nom.

diameter), together with kvs 1.9 (valve capacity in

m3/h at a pressure drop of 1 bar).

RA and DA are moulded in on the opposite side

of the valve body.

RA means “reverse acting” and DA means “direct

acting”.

When WVFX is used as a condensing pressure

valve the bellows housing must always be

mounted nearest the DA marking.

Water valves

Ag0_0003

Ag0_0004

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 47

Page 50

Fitters notes Water valves

Installation

WVFM and WVFX are installed in the water line,

normally ahead of the condenser, with flow in the

direction of the arrow.

It is a good idea to always install an FV filter

ahead of the water valve to exclude dirt from the

moving parts of the valve.

To prevent vibrations from being transmitted

to the bellows housing the housing must be

connected to the discharge line after the oil

separator, via a capillary tube.

The capillary tube must be connected to the top

side of the discharge line to prevent the backflow of oil and perhaps dirt.

WVFM and WVFX 32-40 water valves are normally installed with bellows housing upwards.

Ag0_0005

Ag0_0006

Setting

WVFX 10-25 water valves can be installed in any

position.

WVFM and WVFX water valves must be set

to obtain the required condensing pressure.

Turning the setting spindle clockwise gives lower

pressure, turning it counterclockwise gives higher

pressure.

The scale marks 1 - 5 can be used for coarse

setting. Scale mark 1 corresponds to about 2 bar,

and scale mark 5 corresponds to about 17 bar.

Note that the valve setting range is given for

when the valve begins to open.

The condensing pressure must increase by 3 bar

to fully open the valve.

Ag0_0007

Ag0_0008

48 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 51

Fitters notes Water valves

Maintenance

It is a good idea to include water valves in

preventive maintenance because dirt (sludge)

can collect around the moving parts of the valves.

The maintenance routine can include flushing the

water valves, partly to wash out impurities and

partly to be able to “sense” whether the reaction

of valves has become slower.

Ag0_0009

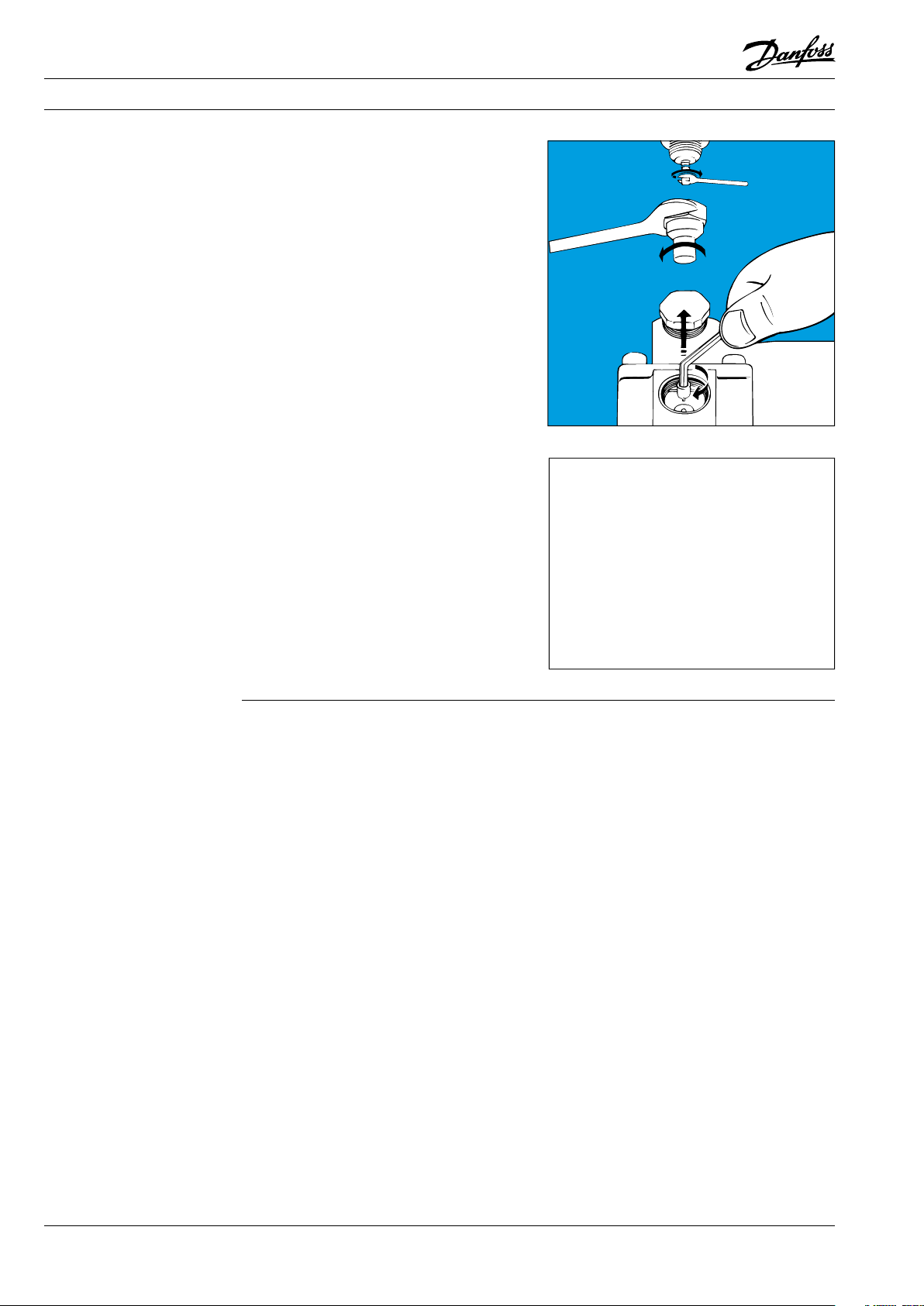

Flushing a WVFM water valve is easiest to

perform if two screwdrivers are inserted under

the setting screw.

The screw can then be levered up to give greater

water flow.

Ag0_0010

WVFX valves can be flushed similarly using two

screwdrivers inserted in the slots on each side of

the setting unit (spring housing) and under the

spring cup.

Levering the screwdrivers down towards the

piping gives greater water flow.

If operating irregularities appear in a water

valve, or if leakage occurs across the valve seat,

dismantle the valve and clean it.

Before dismantling a valve, the pressure must

always be relieved from the bellows housing, i.e.

it must be disconnected from the refrigeration

system condenser.

Before dismantling, screw the setting spring fully

clockwise towards the lowest pressure setting.

The O-ring and remaining seals must always be

replaced after dismantling.

Water valves

Ag0_0011

Ag0_0012

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 49

Page 52

Fitters notes Water valves

Spare parts

Spare parts for WVFM and WVFX water valves can

be obtained from Danfoss:

one bellows housing.

one service kit (containing spare parts,

gaskets and grease for the water side of the

valve).

A gasket set is also supplied as a spare part for

type WVFM.

The code numbers of spare parts and gasket sets

are given in the spare parts catalogue*.

Ag0_0013

*) Find spare part documentation on http://www.danfoss.com

50 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 53

Fitters notes Filter driers & sight glasses

Contents Page

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Filter drier selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Location in refrigeration system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Soldering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Replace the filter drier when . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Using gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mounting gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Filter drier replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Special filters from Danfoss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Combidriers type DCC and DMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Burn-out filter, type 48-DA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Special application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

DCL/DML filter driers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Dimensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

EPD (Equilibrium Point Dryness) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Drying capacity (water capacity). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59