Application Guide

High pressure lift ejector and

liquid ejector systems

Application Guide | High pressure lift ejector and liquid ejector systems

Contents 1. High Pressure lift ejector system - a general description ............................................................................3

1.1 System design with a High Pressure lift ejector (HP) ...................................................................................4

2. The Liquid Ejector (LE) system – a general description ................................................................................9

2.1 Superheat control including new Adaptive Liquid Control (ALC) ..........................................................9

2.2 CO Adaptive Liquid Management (CALM™) ...............................................................................................10

2.3 Suction accumulator design .............................................................................................................................. 11

2.4 Example of system load with Liquid ejector ................................................................................................ 12

3. System design with a High Pressure lift ejector (HP) and a Liquid Ejector (LE) ............................. 13

3.1 Example of system load with Combi (HP + LE) ejector ............................................................................ 14

4. Configuration of the AK-PC 782A .........................................................................................................................15

4.1 HP control ............................................................................................................................................................... 15

4.2 Receiver control......................................................................................................................................................17

4.3 CALM™ set-up in Pack Controller AK-PC 782A ............................................................................................18

4.4 I/O Configuration ................................................................................................................................................... 19

4.5 CALM™ set-up in System Manager AK-SM 8xx ...........................................................................................19

5. What is an ejector, and how does it work? ....................................................................................................... 22

6. Coolselector®2 Selecting components ..............................................................................................................25

6.1 HP ejector selection .............................................................................................................................................. 25

6.2 LE ejector selection ............................................................................................................................................... 26

6.3 Combi ejector selection (HP+LE) ..................................................................................................................... 27

7. Multi Ejector Solution™ ............................................................................................................................................. 28

2 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

0.6

Entrainment rao

-6°C/29,6 bar(a) -4°C/31,3 bar(a)

s

80G445

Application Guide | High pressure lift ejector and liquid ejector systems

1. High Pressure lift ejector

system - a general

description

A parallel compression system is one of the

concepts that can be used in warmer climates

to enhance the efficiency of a transcritical CO

system. The system is using the same layout

as the booster system with an extra suction

group connected to the receiver. For parallel

compressors and their suction line we will use

the designations IT (intermediate) compressors

and IT suction group.

In cold periods, the system works as a booster

system, but in warmer periods the amount of

flash gas after high pressure expansion grows

and parallel compressors should take over while

the gas bypass valve should close. Depending on

the variable capacity IT compressor selection and

its minimum mass flow capacity, typical ambient

conditions for changeover should be between

The High-Pressure lift ejector (HP ejector) is an

add-on to enhance the parallel compression

system.

An ejector is a device that utilizes the expansion

work from the high-pressure expansion. This

expansion work is transformed into compression

work that compresses some of the MT evaporator

flow into higher pressure (receiver). Since the

expansion work is given by the conditions

(temperature and pressure out of the gas

cooler together with the receiver pressure),

the compression work is also given (assuming

constant efficiency). That means that the system

offers some flexibility.

We can adjust the pressure in the receiver in a

way such that the ejector produces a high lift

(pressure difference between receiver and MT

evaporator), but since the expansion work is

given, the flow cannot be high at the same time.

If the receiver pressure is then lowered and the

ejector thereby enabled only to produce a low

lift, the mass flow will be higher. However, it will

reach some limits, based on developed chocked

flow in the suction flow. When chocked limits are

reached, the suction flow can be higher, despite

the low requested pressure lift.

The suction mass flow is controlled by the

entrainment ratio (ratio between suction mass

flow and motive mass flow). The entrainment

ratio is a characteristic of the ejector and depends

15 °C and 20 °C. At this condition the gas mass

flow in the receiver that needs to be bypassed

increases to 25 – 30% of gas cooler mass flow and

should be taken by the gas bypass valve (GBV) or

preferably the IT suction group.

In very warm periods, close to ambient

conditions 40 °C, the mass flow ratio between

MT suction and IT suction will be MT 55% / IT

45%. Because of the higher suction pressure of

the parallel compressors, the system efficiency

will rise allowing to reduce installed MT/IT

compressors total swept volume comparing

to the standard booster system. Depending

on yearly climate conditions, the parallel

compression system will provide an annual

energy reduction compared to standard booster

system at a level between 5 – 9%.

on the ejector geometry and operational

conditions (pressure temperatures and densities

in the inlets and outlet of the ejector).

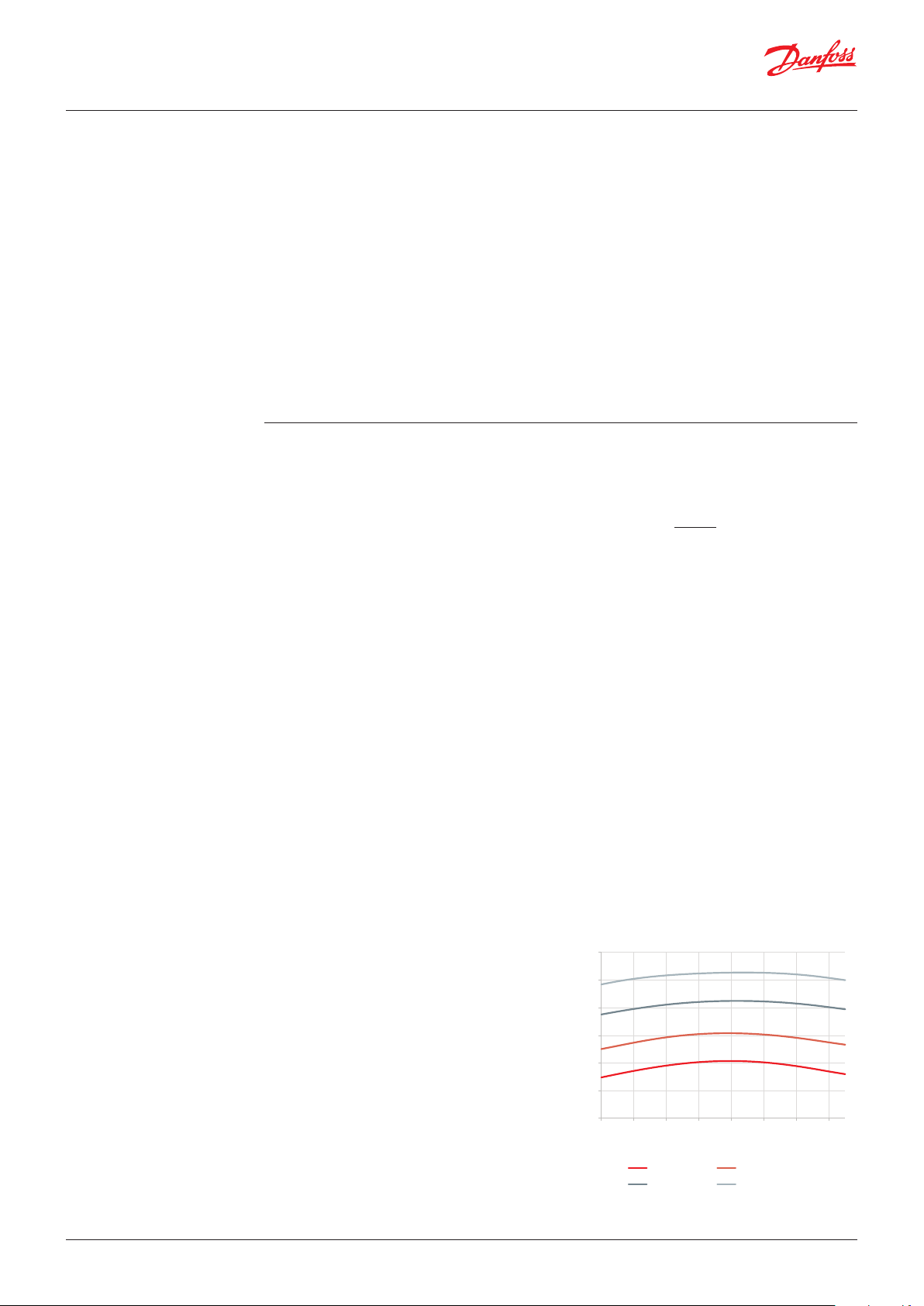

er (entrainment ratio):

m

suction

er =

m

motive

The optimal entrainment ratio is between

20 – 25% and the pressure lift between 5

– 14 bar. The pressure lift will be highest at

high ambient temperatures where we need

most of the ejector’s benefit. There is also a

dependency on suction flow super heat, as

laboratory experiments show that the highest

entrainment ratio is between 4 K and 12 K and

our recommendation is to take the flow from

the MT evaporators instead of common suction

line from MT evaporators and LT compressors

as the superheat can be higher depending on

LT/MT ratio. The high superheated gas in the

suction line will also result in reduced system

performance (COP).

Reduced COP can also occur if the LT mass flow

is relatively high in comparison to residual MT

evaporators’ flow, resulting in significantly high

MT compressors’ suction superheat and high

discharge temperatures at extreme ambient

conditions. To avoid this, an LT discharge

desuperheater can be applied or liquid injected

into the MT compressors’ suction line to maintain

acceptable superheat at those conditions.

Danfos

0.5

To the right is an example with different MT

evaporating temperatures (pressures) and ejector

suction superheat between 0 K and 15 K but

keeping constant:

• Temperature out of the gas cooler = 35 °C

• Pressure in the gas cooler = 90 bar(a)

• Pressure in the receiver = 38 bar(a)

0.4

0.3

0.2

0.1

0

0246810 12 14

Sucon Superheat

-10°C/26,5 bar(a) -8°C/28 bar(a)

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 3

Application Guide | High pressure lift ejector and liquid ejector systems

The high-pressure flow (ejector motive flow)

from the gas cooler enters the ejector which in

this system works like a high-pressure control

valve. The opening of the different ejectors is

controlled in order to maintain the high pressure

with the purpose of achieving optimum system

COP. The pressure/temperature curve and the gas

cooler outlet, contributing to optimum COP of

the system, is predefined and integrated in the

Danfoss pack controllers. In the ejector, energy

from the high-pressure side is used to entrain

gas from the suction side of the MT evaporators

and lifts it to the receiver. In the receiver, the gas

and liquid are separated and if the amount of

gas is higher than the minimum capacity of the

IT suction group, the controller should use IT

compressors instead of a gas bypass valve.

The benefit of the HP ejector is that it unloads

the MT compressors and enhances the IT

compressors by feeding gas that should be

compressed by the MT compressors. If we

consider the same design criteria for a variable

capacity IT compressor and its minimum mass

flow, the typical ambient conditions for engaging

the IT compressors will be lower than in a parallel

system without HP ejectors.

In well-designed IT suction group it will be

possible to start compressors at ambient

conditions from 15 – 20 °C, while comparing

to system with HP ejectors, and allowing the

receiver pressure fluctuation by using the IT

optimize function (one of the receiver control

options in AK-PC 782A pack controller), the

typical ambient conditions that can enable IT

compressors will be 5 – 7K lower. This control

strategy will contribute with more hours utilizing

the IT suction group during the year.

When using HP ejectors and the IT Optimize

function in regions with ambient conditions up

to 40 °C, the mass flow ratio between MT suction

and IT suction will be MT 35% / IT 65%. This will

give a significant reduction in annual energy

consumption compared to a standard booster

system, between 9 – 15%, depending on yearly

climate conditions and the ratio between LT and

MT load.

The energy consumption reduction is considered

without implemented Heat Recovery. When Heat

Recovery is applied in CO2 transcritical systems,

the pack controller will increase the pressure

in the gas cooler to above the critical point (74

bar(a)) in order to enable more heat rejection.

By doing this, the HP ejector will again have

a high potential to lift mass flow from the MT

evaporators to the receiver, like in warm ambient

conditions.

As for parallel compression, the oil management

of the parallel compressor enhanced with a highpressure ejector needs special attention because

the mass flow ratio for the parallel compressor

is high. However, it is possible to build a system

with safe oil return if the oil carry-over is

managed.

1.1 System design with a

High Pressure lift

ejector (HP)

Systems with High Pressure lift ejectors (HP

ejectors) are in many ways identical to parallel

compression systems, but the ejector enhances

the operation of the parallel compressors. The

ejector takes mass flow from MT compressors

and delivers it through the receiver to the IT

compressors. Consequently, the MT compressors

can be reduced in size and since the parallel

compressors are running at a higher suction

pressure the total swept volume will be reduced.

Oil return to the MT compressors are just as

on the standard system with gas bypass. The

oil/refrigerant mixture will even be richer on

oil. As there is no oil returning to the parallel

compressors through the suction line, extra

attention needs to be paid to this part of the oil

management system.

4 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

Design of MT/IT suction groups

To extract the maximum performance of a

system with ejectors it is important to be careful

when sizing the MT and IT suction group. For

the ejector and the overall system to yield a high

performance the receiver pressure should follow

the variable reference that as realized by the “IToptimize” reference mode for the IT compressor.

This however make it less trivial to size the

compressor groups (IT and MT) as it is important

to look at part load performance and not only

at the high design temperature and maximum

system load. Temperatures out of the gas cooler

between 15 – 20 °C and a part load operation

with a load of approximately 40 – 60% of the full

load condition (depending of the application)

should be considered. As the load on the IT

compressors are highly depended on the ejector

and the receiver pressure, they should be able to

cover a larger load span than a system without

ejectors, this makes it difficult to construct

an efficient system with only one parallel IT

compressor.

Parallel IT compressor capacity control

For MT and LT compressors suction groups, it

is important to have possibility to match the

actual compressor suction mass flow with the

system load. If there is no match, it will result

in suction pressure oscillations when cutting

in capacity steps (for increasing capacity) or

cutting out steps (for decreasing capacity). For

that reason, one or two Variable Speed Drives

(VSD) are used on leading compressors. When

considering the design of IT suction compressors,

having an as linear capacity control as possible

is even more important, because oscillations

in the receiver pressure control will affect both

the MT/LT evaporating pressure and the gas

cooler pressure, resulting in an unstable system

with compressors and fans running capacity

oscillations.

If cost is the driver, the performance at the

very warmest conditions can be sacrificed by

designing the compressors at part load condition

and then accept that the energy performance

at maximum load and maximum temperature

is not ideal. This is the same consideration as

with parallel compression systems. In case of

maximum load and maximum temperature,

the receiver pressure is allowed to increase and

therefore the entrainment ratio is decreasing,

leaving more gas to the MT compressors. In this

way the system can be cost optimized with only a

small penalty on energy.

The same design analogy can be applied to HP

ejectors by installing a High Pressure expansion

valve in parallel to it in order to cover the gas

cooler mass flow that cannot be taken by the HP

ejectors at very high temperature conditions. It

is possible to install more HP ejectors connected

in parallel, and in AK-PC 782A it is possible to

configure up to four ejector blocks in this way.

Higher receiver pressure oscillations can lead

to the IT compressors frequently reaching their

pump down limit. The pump down limit pressure

level will switch off IT compressors and start GBV

operation resulting in even more unstable system

operation. It is important to avoid long periods

with the MT and IT running large part of the

installed capacity in part load. At part load the

compressor is really inefficient. We have seen that

installing an ejector which removes load from

the MT and adds to the IT cause longer periods of

both MT and IT running part load causing overall

worse efficiency compared to not running with

the ejector. This is also an important argument

for splitting the capacity on more compressors.

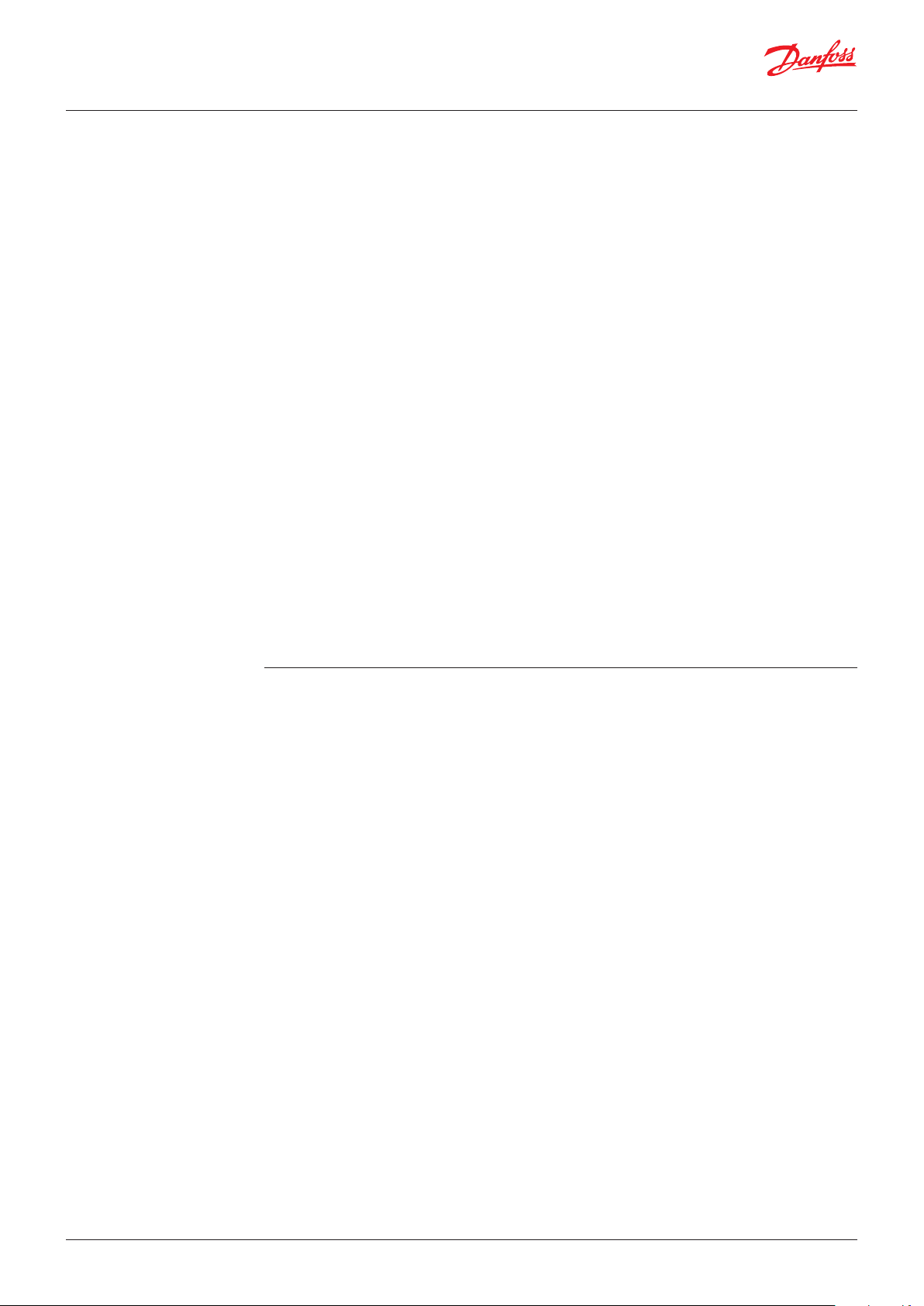

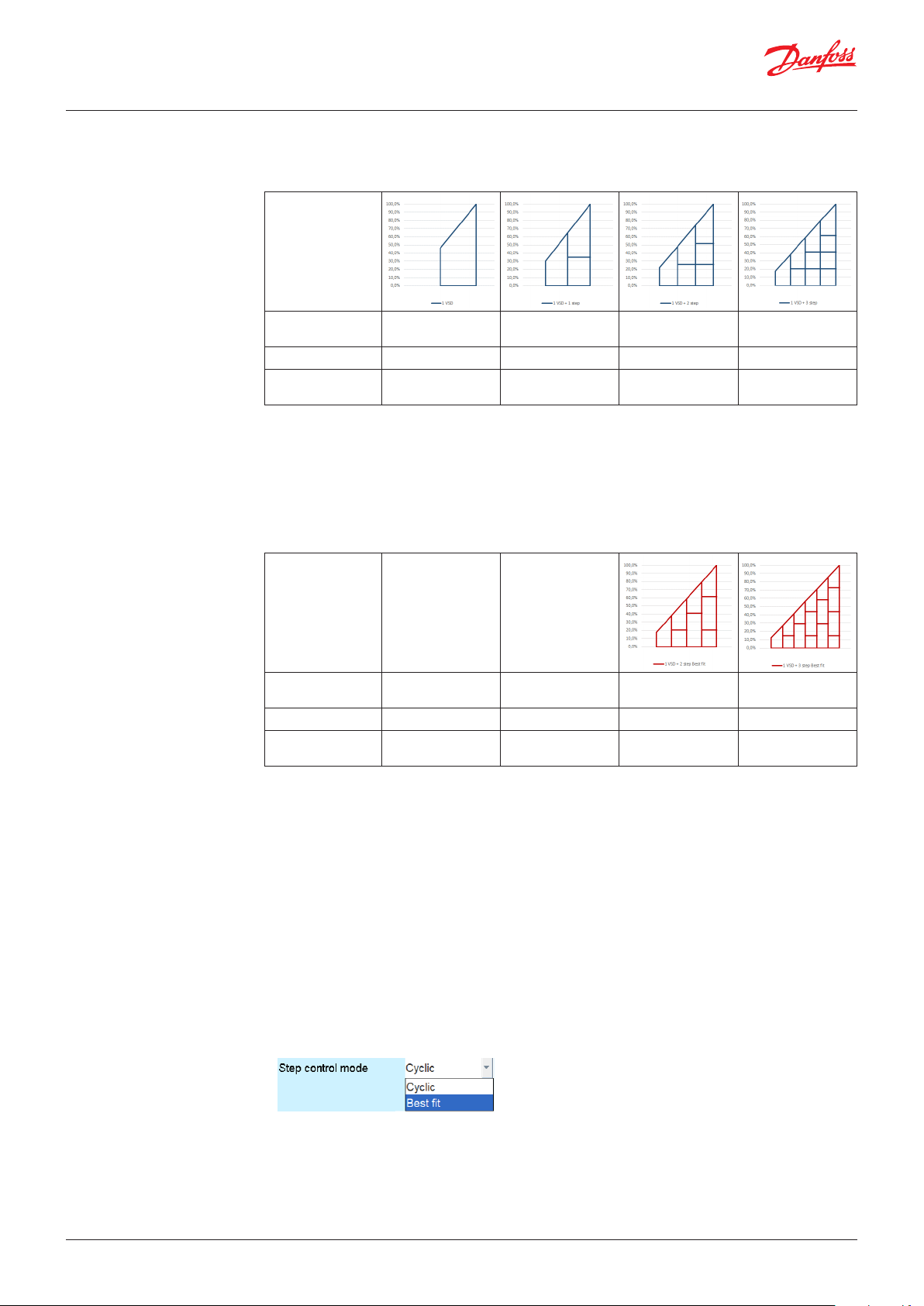

Compressor suction group capacity control:

Example 1:

All compressors are same nominal size.

The first compressor has VSD control from 30 – 65 Hz. The rest are single step compressors.

Compressor index

Starting capacity

Gap between

compressor steps

1)

Compressor index represents capacity of each compressor as a relative number.

2)

Capacities represented as % of total suction line mass flow capacity.

1)

2)

2)

130 130 + 100 = 230

46% 26% 18% 14%

- 13% 9% 7%

130 + 100 + 100

= 330

130 + 100 +

100 + 100 = 430

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 5

Application Guide | High pressure lift ejector and liquid ejector systems

Example 2:

The first compressor has VSD control from 30 – 65 Hz. The rest are single step compressors, but 30%

smaller capacity compared to VSD nominal capacity at 50 Hz.

Compressor index

Starting capacity

Gap between

compressor steps

1)

Compressor index represents capacity of each compressor as a relative number.

2)

Capacities represented as % of total suction line mass flow capacity.

1)

2)

2)

130 130 + 70 = 200 130 + 70 + 70 = 270

46% 30% 22% 17%

- 0% 0% 0%

130 + 70 +

70 + 70 = 340

Example 3:

The first compressor has VSD control from 30 – 65 Hz. First single step compressor is 30% smaller

capacity compared to VSD nominal capacity at 50 Hz. Second and third double size of first single

step compressor. This configuration is applicable in systems with 1 VSD and 2 or more single step

compressors with Step control mode “Best fit”.

Compressor index

Starting capacity

Gap between

compressor steps

1)

Compressor index represents capacity of each compressor as a relative number.

2)

Capacities represented as % of total suction line mass flow capacity.

1)

2)

2)

- -

- - 17% 12%

- - 0% 0%

130 + 70 + 140

= 340

130 + 70 +

140 + 140 = 480

Conclusions:

• Example 1: More single step compressors will allow us to start the VSD compressor much earlier in

relation to total suction group capacity. Second, with more compressors there will be smaller gaps

between capacity control.

• Example 2: Using 30% smaller capacity single step compressors in comparison to nominal VSD

compressor, will result in linear capacity control (VSD control from 30 – 65 Hz). Drawback of such

configuration is less total capacity comparing to Example 1. because all single step compressors are

smaller.

• In Danfoss pack controllers it is possible to select a “Best-fit” option which makes it possible to select

different sizes of single step compressors (Example 3.). To achieve linear control and higher capacity,

it is important that the first single step compressor has 30% less capacity than a VSD nominal capacity

at 50 Hz. Other bigger size compressors should not be larger than double size of the first single step

compressor. Having this kind of regulation, it is possible to achieve a higher total capacity comparing

to systems in Example 1 and 2.

• Examples 2 and 3 presents optimal sizing compressors to achieve linear control and maximum

overall capacity. In reality, it is good to have certain capacities overlapping in the area between two

steps it does not immediately trigger stating a new compressor and lower the speed on the VSD.

• When evaluating IT suction group design, to avoid system oscillations, it is extremely important to

have linear capacity control. By doing this we can utilize IT compressors and HP ejectors in optimum

way through the year and provide energy savings.

6 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

Single parallel compressor system design

The ideal solution is to have - as a minimum - two

IT parallel compressors and two MT compressors

with linear capacity control, but very often this

is not possible in smaller systems due to cost

reasons. Therefore, it is often seen that there

is only one parallel compressor. If this parallel

compressor is selected for maximum load, it

would give the optimum performance at high

ambient temperatures, but it will give very

poor performance in the medium ambient

temperature, where there are many operating

hours. The turning point, when the IT compressor

should start and the gas bypass valve should be

closed, is the condition where the minimum gas

mass flow IT compressor capacity (at minimum

speed) should match the gas mass flow in the

receiver. The challenge of selecting the right

compressor is even bigger considering that

lower ambient conditions (lower pressure in the

Maximum utilization of parallel compressor

system with HP ejectors design

In general, when selecting the compressors, the

following scenarios need to be considered:

• In a well-designed system with IT compressors

and HP ejectors the change-over between

the gas bypass valve and the IT compressors’

operation happen at ambient temperatures

between 12 – 15 °C. So below that turning

point, the minimum mass flow that the IT

compressors can handle needs to be added to

the MT compressor mass flow capacity. This is

not a huge issue as the gas quality is low and

the MT compressors will have more capacity

because the pressure in the gas cooler will be

low too.

• Receiver pressure: The system can be tuned

by optimizing the receiver pressure. This

functionality is embedded in the Danfoss AKPC 782A controller and is activated by selecting

Reference mode for the IT compressors

with the function “IT optimize”. At higher

temperatures out of the gas cooler (Sgc), the

receiver pressure is lifted gradually, depending

gas cooler), will result with higher compressor

capacity comparing to high extreme ambient

conditions.

As a result of the above considerations and

compromises, single parallel compressor systems

should be sized for the part load condition and

medium temperature conditions to achieve more

operation hours. With such configuration at full

load condition and high ambient temperature,

an IT compressor will run at full speed and the

suction pressure (receiver pressure) for the IT

compressor is allowed to rise to a determined

limit, causing the gas bypass valve to open

and release the surplus gas mass flow that

the IT compressor cannot handle to the MT

compressors. This will of course increase the load

on the MT compressors and should be taken into

account when designing the MT suction group.

on the MT suction and the gas cooler pressure.

If the receiver pressure is too low, savings will

be lower because the pressure is too close

to the MT suction pressure. A higher receiver

pressure also yields a smaller compressor due

to the higher suction pressure. Keep in mind

that a higher suction pressure also gives a

higher oil carry-over, so the compressor and

oil management need to be able to handle it.

There is a limitation on the receiver pressure

given by the manufacturer receiver design.

• Gas cooler mass flow: Due to mass flow

balances in systems with a HP ejector there

will be a higher mass flow through the gas

cooler than in parallel compressor systems

only. Depending how you control the pressure

in the receiver, the mass flow increase will

be different. If you run with the “IT optimize”

function at high ambient temperatures

increase will be up to 3%. If you run with

constant pressure in the receiver, the increase

at high ambient temperatures can be 6%

higher.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 7

160.0

Pressure bar(a)

Enthalpy kJ/kg

80G449

s

80G450

160.0

Pressure bar(a)

Application Guide | High pressure lift ejector and liquid ejector systems

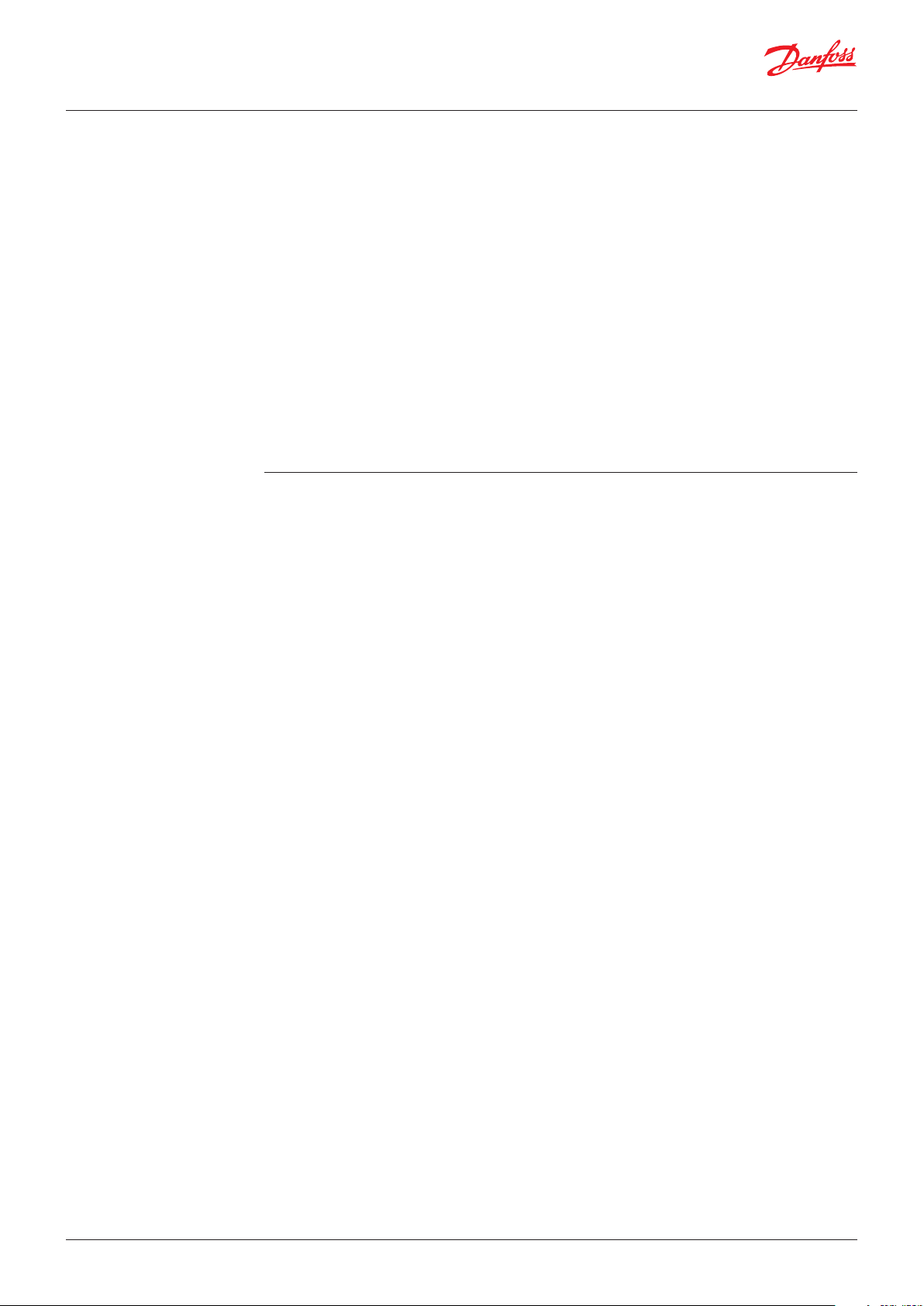

1.2 Example of system load

with a High Pressure lift

ejector

At above conditions (Po-MT/Prec/Pgc), the HP ejector is unable to make a necessary lift of 8.5 bar

and the amount of gas after the HP expansion is relatively small, so the system works as a standard

booster. To enable the ejector to provide a lift at specified Po-MT/Pgc conditions it will be necessary

to decrease the Prec pressure to 32 bar(a). This can be achieved using the receiver control mode “IT

optimize” and allowing lower minimum pressure reference in the receiver. There is also a feature for

keeping a minimum pressure difference between the receiver and the MT suction.

x = 17%

80.0

40.0

20.0

10.0

150.0 200.0 250.0 300.0350.0 400.0450.0 500.0550.0

Danfoss

x = 55%

80.0

40.0

20.0

10.0

150.0 200.0 250.0300.0 350.0400.0 450.0500.0 550.0

Enthalpy kJ/kg

In warm ambient conditions, the HP ejector has the ability to create a higher pressure lift. To optimize

system efficiency, we can gradually increase the receiver pressure and by doing this control the ejector

suction mass flow, keeping the entrainment ratio between 0.2 and 0.25. At above conditions, the

ejector suction mass flow is 24% of the motive mass flow (er = 0.24). Any gas after the HP expansion

and the ejector suction gas must be taken by the IT compressors.

Danfos

8 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

2. The Liquid Ejector (LE)

system – a general

description

2.1 Superheat control

including new Adaptive

Liquid Control (ALC)

The Liquid Ejector is designed for both standard

booster and parallel compression systems.

The working principle in the Liquid Ejector is

similar to the gas ejectors. The Liquid Ejector

is optimized to lift liquid from the suction

accumulator and returning it to the receiver. In

a Liquid Ejector system, the evaporators operate

with a very low superheat and a fraction of liquid

is returned to the suction accumulator, located

downstream of the evaporators. With the support

of an appropriate and intelligent case controller

the evaporator functions more efficiently at

a higher suction pressure. This enables the

suction pressure to be raised, thereby reducing

the energy consumption on the compressors.

Typically, the pressure in MT evaporators will

be increased, utilizing network Master Control

function Po optimization by 3.5 – 5 bar.

As the Liquid Ejector is powered by the work

which would have been otherwise lost, there is

no additional energy used to accomplish this.

with an Adaptive Liquid Control (ALC) algorithm,

Superheat across an evaporator, represented with a single tube:

• Zero superheat can be measured in all of the

evaporator where fluid exists (until Dry-Out

point).

• The ALC point (Adaptive Liquid Control point)

can be found at the Dry-Out point on the

borderline between the Annular Flow area

and the Mist Flow area. With ALC the highest

evaporator efficiency is realized but with

droplets of refrigerant leaving the evaporator,

which is not a safe situation compressor wise,

so a suction accumulator must be applied.

The key to achieving the performance benefits

enabled by the Liquid Ejector is the use of the

Adaptive Liquid Control (ALC) algorithm available

in the newest generation of Danfoss case

controllers. This algorithm makes full use of the

entire surface of the evaporator, maximizing its

efficiency and operating with the lowest possible

superheat (close to 0 K).

The amount of liquid is difficult to estimate,

but a good estimate form experience is approx.

10% from the MT evaporators that are in liquid

mode (by using the Danfoss evaporator/case

controllers with the ALC functionality), also only

those evaporators which are maximum loaded

are in liquid mode, resulting in a reduced amount

of returned liquid. In general, the experience

shows that approx. 30% of the evaporators are

running in liquid mode at a given time, so the

amount of liquid returned is then approximately

10% x 30% = 3% of the total MT evaporators’

mass flow returning to the suction accumulator.

• The MSS point (Minimum Stable Superheat)

can be found on the borderline between the

Mist Flow area and the Single Phase Flow. With

MSS control the highest evaporator efficiency

is achieved while all liquid is evaporated and

only superheated gas is leaving the evaporator,

which is a safe situation compressor wise.

• Dry SH control. Stable superheat can be

measured when the superheat is higher than

the MSS point.

This assumption is valid for systems with many

evaporators of similar size like in a supermarket

application (more than 10). For systems like

cold storage plants with only a few evaporators

where some of them can represent a high ratio

in total MT evaporator capacity, the amount of

liquid returned as a percentage of the total MT

evaporator mass flow can be significantly higher.

Fig. 1: Returned liquid estimation of returned liquid as a

function of evaporators quantity.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 9

Application Guide | High pressure lift ejector and liquid ejector systems

2.2 CO Adaptive Liquid

Management (CALM™)

The Danfoss solution for managing liquid in transcritical CO refrigeration applications is based

on enhanced versions of case controllers (AK-CC 550A, AK-CC55, AK-CC 750A), pack controller

AK-PC 782A, system managers of the range AK-SM 8xxA and Liquid Ejector. This solution is called

CO Adaptive Liquid Management (CALM) and represents a major step forward in refrigerant

management. CALM ensures integration between the case controls, pack controls and system

managers, enabling a safe operation in Liquid Ejector systems in all conditions.

To operate CALM™ it is necessary to set up the

system in the following way:

Pack Controller:

It is important to enable the Po optimization

feature on the MT suction line driven by a System

Manager AK-SM 8xxA. This Master Control

network feature constantly analyzes the most

loaded MT evaporator controllers and adjusts the

MT evaporation pressure in the pack controller

AK-PC 782A within specified limits.

Case (evaporator) Controllers with ALC

superheat control feature:

Modulated thermostat control should be

enabled. By using this feature, the amount of

liquid from the MT evaporators is limited as only

the most loaded will operate with ALC superheat

or at the minimum SH.

CALM™ solution:

1. If Liquid Ejectors are unable to take all the

liquid collected in the suction accumulator,

the liquid level will rise. When the liquid level

switch (ideally positioned 1/3 from the bottom

of the total height) indicates too high a level, a

digital signal triggers AK-PC 782A input.

2. Information about high level is transmitted via

a communication line to the System Manager

AK-SM 8xxA.

3. By using a communication line to the MT

evaporator controllers, superheat control will

switch from ALC to MSS (dry SH control) and

stop releasing liquid to the MT return line.

4. When the liquid level in the suction

accumulator drops to an acceptable level, the

system will send a signal to the evaporator

controllers to start the ALC superheat control

algorithm.

10 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

2.3 Suction accumulator

design

The suction accumulator is an important element in the system and very critical. It needs to be sized

so that it can handle the liquid returned in case the ejector stops working, and you must design the

system with oil return to the MT compressors.

Oil return can be done in following ways:

The simplest way is to have a U-tube in the suction accumulator with a hole at the lowest point where

an oil rich mixture will be returned to the compressor. The other option is to do the same but move

the hole into a solenoid valve or motor valve so the return can be controlled. For both principles it is

important that the suction port for the ejectors is higher than the oil return port. If this is not the case,

the ejector will take all the oil and there will be nothing to return to the compressors. It is important in

the design of the system to ensure that liquid trapped in the oil has evaporated before it reaches the

compressors.

Sizing the suction accumulator

There are several ways to estimate the size here is one proposal. To do the sizing, some

assumptions must be made:

• Worst case is that 3% of the flow returning

is the part where the system is emptied and

the last third is safety to ensure the liquid can

be separated. These distribution levels can of

course be made differently.

to the suction accumulator is liquid. If there

are less than 10 evaporators, this number

needs to be higher - see Figure 1. “Returned

liquid estimation as a function of evaporators

quantity”

• The time for dry out if we go from ALC

superheat mode to MSS superheat mode is set

to 10 min. Experiences from the field indicate

that it takes approx. 5 min for the system to dry

out, but it will depend on the installation.

• The suction accumulator is divided into 3 equal

size sections where the lower third is the part

Liquid separator with 3 equal levels

we use for normal operation, the second third

Example:

Based on the above information, liquid that is

returning can be calculated based on an MT

evaporator’s cooling capacity.

An MT cooling capacity of 100 kW will result in an

evaporator flow around 1540 kg/hr (depending

on the MT evaporating pressure and the pressure

in the receiver):

With the assumptions made above, the maximum

holding time is set to 10 min. That means that

the accumulator’s yellow zone should be able to

hold 47/6 = 7,8 kg and with some safety ~ 9 liters.

The total size of the suction accumulator should

be 100 kW with an MT system of approximately

3 x 9 = 27 liters. The suction accumulator CALM

operation level switch must be placed between

the green and the yellow zone (at 1/3 level) and

will send MT evaporators back to MSS superheat

mode (dry SH control). The safety level switch

that protects the MT compressors from liquid

slugging must be placed between the yellow and

the red zone.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 11

oss

80G451

160.0

.0

Pressure bar(a)

80G452

160.0

Pressure bar(a)

Application Guide | High pressure lift ejector and liquid ejector systems

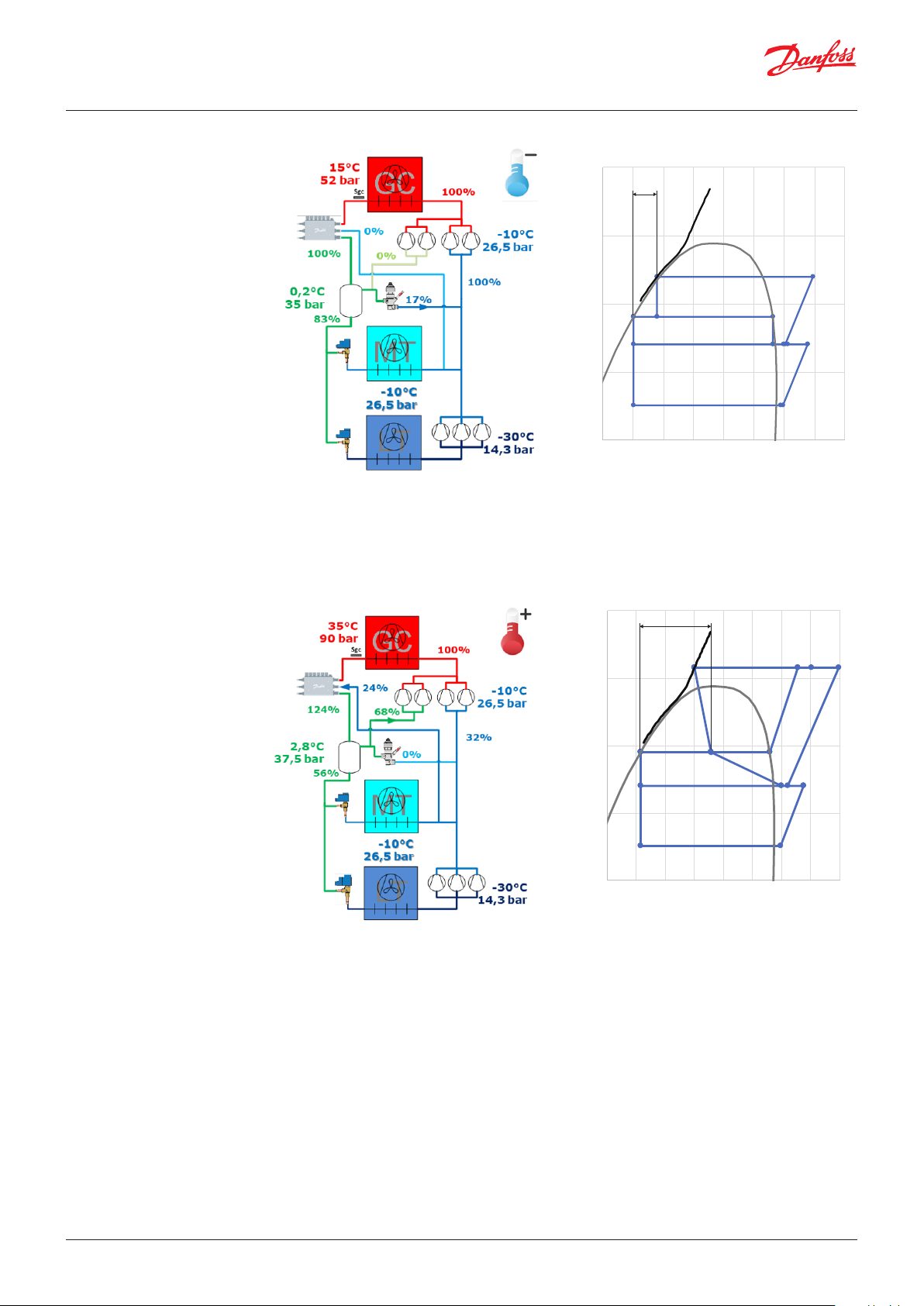

2.4 Example of system load

with Liquid ejector

The MT evaporation pressure is 4 bar higher than in a standard system due to the ALC superheat

control. The pressure difference between the receiver and Po-MT is 4.5 bar, enabling the Liquid Ejector

to lift also in colder ambient conditions. We can control the pressure difference Prec – Po_MT all year

round allowing LE operation.

80.0

40.0

20.0

10.0

150.0 200.0 250. 0 300.0350.0 400. 0 450.0 500. 0550

Enthalpy kJ/kg

Danf

80.0

40.0

20.0

10.0

150.0 200.0 250.0 300. 0 350. 0400.0 450. 0500.0 550. 0

Enthalpy kJ/kg

In warm ambient conditions all is the same as in cold ambient conditions. We could have a higher

pressure difference Prec – Po_MT, but not more than 7 – 8 bar as the LE is not able to create a higher

pressure lift.

Danfoss

12 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

3. System design with a

High Pressure lift ejector

(HP) and a Liquid Ejector

(LE)

This solution is meant for medium to large sized

commercial refrigeration systems with parallel

compression. The system will benefit from both

technologies - HP and LE - and it is the most

optimized solution with Danfoss ejectors. By

utilizing the ALC superheat control, there will

be zero or very low superheat from the MT

evaporators’ return line. The common suction line

to gas and liquid ejectors should be connected

in the same way as in an LE system, I.e. in the

suction accumulator’s lower part, but not at the

very bottom because that should be used for oil

return process.

In cold ambient conditions, a LE has the

possibility to lift liquid, allowing MT evaporators

to work at higher evaporation temperatures. By

also having HP ejectors operating and taking

liquid and gas from the suction accumulator, it is

possible to have a higher pressure in the receiver

in warm ambient conditions, enabling better

operating conditions for parallel compressors

HPV+Combi

The below outline shows a solution for medium

to large sized commercial refrigeration systems

with parallel compression. Combi ejector with

HP/LE combination all in one block.

under such conditions. A higher pressure in the

receiver will support the IT suction group in

becoming even more efficient.

The LT compressors’ discharge flow will be mixed

with residual flow from the MT evaporators,

resulting in a lower MT compressor superheat

than in standard booster systems.

To simplify the installation for medium sized

systems, Danfoss offers Combi ejectors - a

combination of HP and LE ejectors in one

component. There should be one suction line to

the Combi ejector block connected to the lower

part of the suction accumulator.

The ejectors (gas and liquid) control the gas

cooler pressure. Depending on the ejector

envelopes and the pressure conditions in the

system, the pack controller AK-PC 782A decides

which ejector cartridge that will open first: liquid

or gas ejector.

HPV+HP+LE

The below outline shows a solution for large

sized commercial refrigeration systems with

parallel compression. Separate HP and LE ejector

blocks.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 13

oss

80G451

160.0

.0

Pressure bar(a)

Enthalpy kJ/kg

s

80G453

160.0

Pressure bar(a)

Enthalpy kJ/kg

Application Guide | High pressure lift ejector and liquid ejector systems

3.1 Example of system load

with Combi (HP + LE)

ejector

In cold ambient conditions the system benefits from CALM, resulting in a higher MT evaporation pressure.

80.0

40.0

20.0

10.0

150.0 200.0 250. 0 300.0350.0 400. 0 450.0 500. 0550

Danf

Danfos

80.0

40.0

20.0

10.0

150.0200.0 250.0300.0 350.0400.0 450.0500.0 550.0

When ambient temperatures become higher, the HP ejector has the capability to take gas + liquid. This

can create a higher pressure lift, which enables an increase in the receiver pressure for further optimization

of the IT suction group.

14 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

4. Configuration of the

AK-PC 782A

4.1 HP control

No matter if it is an HP-, LE-, or HP+LE ejector solution, setting the AK-PC 782A for supporting the

various ejector solutions is fully integrated in the controller. This will only impact the settings that

need to be made for the "HP control" and the selection of reference mode in the IT compressor

settings.

Under the HP control, the selection of the various supported ejector blocks is made. The ejector can

be selected either as pure HP-ejector block in combination with LE-ejector block or as combi blocks

– see figure below. Note that if more HP-ejector blocks are selected (“Number of block” larger than 1)

they will be operated in parallel and hence only one set of DOs is assigned. Hence, ejector 1 from the

parallel blocks should all be connected to the designated ejector DO point under the IO configuration.

Selecting multiple LE ejector blocks will result in individual DO points for each ejector cartridge.

Here it is also selected whether the CALM solution (MC Liq. Ctrl.) should be activated or not (see

explanations above).

The HP valve and the multi ejectors are all considered as actuators for controlling the gas cooler

pressure. This means that the HP controller needs to prioritize the actuation between the HP valve, HP

ejector and LE ejector.

The prioritization is roughly speaking done in two steps:

1. First, it is decided whether the HP valve or the multi ejector (HP+LE) is going to be used for

actuation – the multi ejector always has first priority, meaning that if more actuation is needed

and there is spare capacity available on the multi ejector (HP+LE), it will be actuated. Only when

no more ejector capacity is available, will the HP valve be activated. The figure below illustrates the

behavior during rising and falling gas cooler pressure:

The gas cooler pressure is controlled with

ejectors with a high-pressure valve or both (as

installed).

Ejectors only:

The ejector opening degree (required capacity)

increases when the pressure is too high and

closes when the pressure is too low.

High-pressure valve only:

The high-pressure valve opening degree

increases when the pressure is too high and

closes when the pressure is too low.

Ejectors and High-pressure valve:

The ejectors operate first, and the high-pressure

valve only comes into action when the ejectors

are fully utilized. The ejectors remain fully open

until the high-pressure valve has closed.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 15

1

15

20

25

3

35

4000

45

50

Increasing cap preferred LE

LE 200 LE 400 HP 1 HP 2 HP 3 HP 4 HP 5 HP 6

oss

80G454

1

15

2

25

3

35

4

45

5

Increasing cap preferred HP

HP 1 HP 2 HP 3 HP 4 HP 5 HP 6 LE 20 0 LE 400

Danfoss

80G455

Application Guide | High pressure lift ejector and liquid ejector systems

2. The second step of prioritization is between

the HP ejector and the LE ejector. This

prioritization is done based on the ejector

maps. The figure to the right shows the areas

in which the preferred ejector type is the

HP ejector or the LE ejector respectively,

depending on the pressure lift (Plift=Prec-P0MT) and the pressure drop (Pdrop=Pgc-Prec).

Note: the max pressure lift for the LE ejector

has been increased to 10 bar in PC782A v.2.71

from 8 bar in previous versions.

For details in switching patterns, please see the graph below.

The ejectors steps are combined to form a capacity as close as possible to the requested capacity

by the control. In case the same capacity can be obtained by combinations of liquid and gas ejector

respectively the controller will:

- For increasing capacity demand open for the prioritized ejector type

- For decreasing demand close for the lowest prioritized ejector type

See also the figures below for HP 3875 and LE 600:

00

00

00

000

00

00

00

000

500

0

135791113151719212325272931333537

Danf

000

00

000

00

000

00

000

00

000

500

0

1357911131517192123252729313335

All the standard settings around the gas cooler i.e. fan control, high-pressure curve etc. still applies

when running with ejectors, however there are a couple of dedicated settings that only apply for the

ejector:

1. When controlling the pressure using

the ejector block, the ejector capacity is

modulated in steps like indicated in the

figures above. Practically, this means that the

HP controller is likely to be switching between

two steps to maintain a certain pressure

reference. To avoid too frequent switching,

a neutral zone (Pgc neutral zone) on top of

the high-pressure reference is implemented.

This allows the pressure to drift (default 3

bar) above the pressure reference without

stepping up in ejector capacity, hence

reducing the number of switches of ejector

capacity.

2. When the ejectors are actively controlling the

gas cooler pressure, the PI-controller tuning

factors (Kp or Tn) are set separately.

3. To enable the CALM™ solution it is necessary

to start the Master Control feature “MC Liq.

c t rl .”

4. If the condition of being inside the ejector

envelopes to enable CALM™ wants to be

avoided, you can select feature “MC Liq.

discard map” to “No”.

16 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

5. “MC liq.ctrl. via DO” is using Digital Output on

AK-PC 782A to send a signal to the evaporator

controllers’ bypassing network unit AK-SM.

Note that if a DO is used, be careful to make

the connections such that if the cable is

removed the ALC will be stopped. By default,

the ALC is enabled when the DO is closed.

6. It is possible to disable ejectors by dedicated

DI (Digital Input).

4.2 Receiver control

For plant types without IT compressors but with

e.g. an LE ejector, it is important to configure

a receiver setpoint, which secures that the

operating point of the ejector stays inside the

ejector map (see figure in previous section). For

the LE ejector the pressure lift should not be

higher than around 9 – 10 bar (for AK-PC 782A

version 2.71 and up) to avoid losing LE ejector

efficiency. This means that if e.g. the ToMT = -10

°C ~ 25.5 bar, the receiver setpoint “Prec setpoint”

should not be set higher than around 25.5+7 =

32.5 bar to ensure that there is always lift from

the LE ejectors.

For systems with IT compressors it is possible to

select between various reference modes for the

IT compressor. It is generally recommended to

use the “IT-Optimize”. This will strive to adjust the

setpoint for the IT compressor to optimize the

system efficiency – however it does not ensure

that the maximum pressure lift for the ejectors

are obeyed. To ensure the maximum pressure lift

stays inside the ejector envelope, the maximum

IT reference (P-IT max. reference) should be

limited.

To give an example: assuming that a system is

running with HP ejectors, the maximum pressure

lift is around 15 bar. Further assume that the

reference for the To-MT is -8 °C (~27 bar), then the

maximum receiver pressure reference (P-IT max.

reference) should be limited to 27+15 = 42 bar.

Same considerations should be done when

working with Liquid Ejectors only but minimum

and maximum references need to be aligned.

Note: When running in the IT-Optimize mode

the reference to the receiver can be as high as

the bottom of the receiver P-band, if not limited

by P-IT max. reference. This means that if the

neutral zone of the IT-compressor overlaps with

the P-band, then the receiver valve is forced open

before the second IT compressor is started. This

can result in the second to last IT-compressors

not activating when needed the most. (This

is an issue for systems with two or more ITcompressors).

To avoid this, the following settings are

recommended:

P-IT min reference = Prec setpoint (used for Vrec –

Gas Bypass Valve)

P-IT max reference < Prec max – Prec max Pband

– NZ/2+1 = 55 -3 - 3/2+1 = 51.5 bar

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 17

Application Guide | High pressure lift ejector and liquid ejector systems

4.3 CALM™ set-up in Pack

Controller AK-PC 782A

For systems with HP and/or LE ejectors it is

possible to utilize the CALM™ solution (see

explanation of the CALM™ function in a previous

section). Under the HP Control, the CALM™ can

be selected by enabling the “MC. Liq.ctrl.” The

“MC. Liq. Ctrl” is a safety control feature that

monitors the operation of the ejectors and of the

liquid level in the suction accumulator to ensure

safe operation without liquid getting back to the

compressors. There are several criteria for when

ALC is allowed:

• If no ejectors are configured, then ALC is not

allowed.

• In the suction accumulator (a receiver in the

suction line of the MT compressors) there

MUST be a level switch. When the liquid hits

this level switch or there is an error on the

switch, then ALC is NOT allowed for the next

30 minutes The countdown timer is set to 30

minutes every time it hits this condition. This

time should be enough to empty the suction

accumulator.

• If the ejectors are not able to lift (meaning

that no ejectors are operated inside the map

of according to ejector type) or no ejector are

open, then ALC is not allowed for the next two

minutes. This is to prevent ALC at uncertain

ejector pumping capacity. The countdown

timer returns to two minutes every time it is

outside the map or the last ejector is closed.

• Both timers must be 0 before ALC is allowed.

• If at least one ejector is active and operated

inside the ejector map, then it is expected to

be able to pump/lift liquid and therefore ALC is

allowed if the former criteria is fulfilled.

Following “MC liq.ctrl status” can be observed:

• Timer

• No lift

• Permitted

• High level

To check whether the ejectors are operated

inside their maps, following the pressure drop

(Pdrop) and pressure lift (Plift) is used.

Pdrop = Pgc reference - Prec reference*

Plift = Prec reference* - PoMT

Where Prec reference* = Max (Prec reference, Prec

filtered 60 sec). This means that if the measured

Prec is above its reference for approximately 60

sec then this will be used in the calculations of

Pdrop and Plift.

18 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

4.4 I/O Configuration

When the AK-PC controller has been configured

for control of an HP/LE ejector system, several

Digital outputs and Digital inputs need to be

configured.

This includes outputs used for controlling the

Multi Ejector (I/O configuration Digital outputs)

and if using the CALM™ solution input for Suction

accumulator level switch (I/O configuration

Digital Inputs).

The outputs used for controlling the smallest HP

ejectors and LE ejectors must be of the SolidState Relay type (SSR).

In this example the four smallest ejectors are

configured to be controlled by the four SSR

outputs available on the AK-PC 782A controller

(IO points 1-12 to 1-15).

If multiple HP ejector blocks are selected

(“Number of block” larger than 1), they will be

operated in parallel and only one set of DOs is

assigned. Therefore, Ejector 1 from the parallel

blocks should all be connected to the same

designated ejector DO point under the IO

configuration. If selecting more LE ejector or

combi blocks each liquid ejector cartridge needs

individual DO in IO configuration.

4.5 CALM™ set-up in System

Manager AK-SM 8xx

In the pack controller the decision whether to allow ALC is made, which means that the decision

should be communicated to the case controllers via the System Manager. For this feature there are

two options: either hardwired via a pack controller DO (selecting “MC.Liq.ctrl. via DO” explained at the

end of chapter 4.1 HP control) or via the fieldbus.

After configuring MT and LT suction groups, proceed to menu Control Refrigeration Suction.

Select MT Suction Group and then enable following Master Control functions:

• Suction Optimization

• Adaptive Liquid Management (this feature is only available for AK-CC55 evaporator controllers)

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 19

Application Guide | High pressure lift ejector and liquid ejector systems

For other evaporator controllers with ALC superheat control (AK-CC 550A, AK-CC 750A but also

AK-CC55), it is possible to set up the CALM™ feature manually via Custom Schedule.

1. Import the right controlling parameter from AK-PC 782A to the AK-SM - “MC liq.ctrl allowed” - so it

can be used in the Custom Scheduler

AK-SM 782A sw 2.08, 2.12, 2.21 AK-SM 782A sw 2.65 and higher

2. Configure Custom Schedule under menu Control Refrigeration Schedules in following way

3. Select device parameter in the evaporator controller:

4. Select the controllers that should receive “ALC MC Liq.ctrl” command:

20 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

5. Evaporator controllers’ status for AK-CC 550A and AK-CC55, depending on SH control mode:

6. Setup “Thermostat mode” on the MT evaporators to “Modulating”

7. In AK-SM 8xx you can observe the ejector operation under Detail menu HP control and drill down

the menu Ejector control. When using the Service tool, the second tab under “HP control” shows the

same measurements / statuses.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 21

32F870.10

Application Guide | High pressure lift ejector and liquid ejector systems

5. What is an ejector, and

how does it work?

An ejector is a device that utilizes the energy

from the high-pressure work. The ejector

converts the high-pressure potential energy in

the motive flow (primary) into kinetic energy,

drawing a flow from the suction port (secondary

flow).

The process, shown on the right, is driven by the

high CO pressure gas leaving the gas cooler.

The gas enters the ejector at the high-pressure

port (PH) and flows through the throat, causing

the flow to accelerate. At the exit of the ejector

nozzle, the gas is at supersonic speed, creating

a low pressure (PS). As low pressure (PS) is lower

than the pressure (PL) at the suction (secondary)

nozzle, CO is flowing from the suction port into

the ejector. The two flows are mixed in the mixing

chamber and the pressure is gradually increased.

The flow finally enters the diffuser at the end of

the ejector. Because of the conic diffuser shape,

the flow gradually slows down, and the pressure

Danfoss Multi Ejector design

All ejectors in the Danfoss portfolio have a highpressure inlet for CO gas coming from the gas

cooler, a suction inlet from MT suction and an

outlet for returning the gas and liquid to the

receiver.

The coils activating the individual ejectors are

available from 110 – 230 V, 50 and 60 Hertz.

The Multi Ejectors High Pressure and Combi are

delivered with three pressure transmitters, used

for pressure control in the pack controller.

Each block has a variable number of ejectors of

different sizes mounted vertically.

Multi Ejectors HP are available with 4 to 6 high

pressure ejectors. Liquid Ejectors is available

is increased. This means that the kinetic energy

of the flow (velocity) is converted to potential

energy (pressure). After leaving the diffuser,

CO is at a higher pressure (PD) than the suction

pressure (PL).

with 1 to 2 liquid ejectors. But Multi Ejectors

Combi are available with 4 to 5 high pressure

ejectors and 1 to 2 liquid ejectors. The capacity

demand is matched by using different numbers

and combinations of ejectors. The characteristics

of the ejectors remain the same no matter how

many ejectors are in use. On each individual

ejector a built-in non-return valve prevents

backflow, removing the need for external check

valves in suction lines.

Each individual ejector and the strainer are easily

serviced by simply removing the four mounting

screws, using a flat screwdriver to lift the ejector

or strainer, and pulling it out of the block. The

strainer can easily be taken apart for cleaning or

replacement.

Coils adv. (230 V DIN and 120 V UL all 50 – 60 Hz)

HP Pressure

transmitter

MT Pressure

transmitter

Receiver pressure

transmitter

All pressure transmitters MBS 8250 with round Packard, radiometric output and 7/16-20 UNF (same type as CCMT valves)

HP inlet from

Suction inlet from

MT evaporator

Danfoss

Strainer

gas cooker

Outlet to

receiver

22 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

s

80G456

10

15

20

25

Increasing cap preferred LE

LE 200#1 LE 200#2 HP 1 HP 2 HP 3 HP 4

s

80G457

10

15

20

25

Increasing cap preferred HP

HP 1 HP 2 HP 3 HP 4 LE 200#1 LE 200#2

Application Guide | High pressure lift ejector and liquid ejector systems

Multi Ejector Capacity Control

Multi Ejector capacity control is achieved through

a binary coupling of various capacities of a

number of ejectors. The Multi Ejector Combi, for

example, comes in three versions. The version

with four high-pressure ejectors and two liquid

ejectors has high-pressure ejectors providing

125 kg/h, 250 kg/h, 500 kg/h, 1000 kg/h and two

liquid ejectors each providing 200 kg/h of motive

mass flow.

There are also two versions with five highpressure ejectors and one liquid ejector. Both

versions provide the same high-pressure capacity

which consists of ejectors giving 125 kg/h, 250

kg/h, 500 kg/h, 2 x 1000 kg/h of motive mass

flow, but depending on the version there are two

sizes of liquid ejectors providing 200 kg/h or 400

kg/h of motive mass flow.

This allows to modulate high pressure capacity

in 18 steps between 0 and 2875 kg/h in 125 kg/g

steps and liquid capacity in two steps between

0 and 400 kg/h in 200 kg/h steps. But if more

capacity is required, a second Multi Ejector can

be added which will be controlled parallel to the

first one.

Liquid ejectors are activated when there’s some

liquid in MT suction accumulator. They might

operate alone when high-pressure ejectors are

not activated or in parallel to the high-pressure

ejectors. One line is used to supply liquid and gas

from suction accumulator to low-pressure inlet

of Multi Ejector. The liquid ejectors take in the

liquid, whereas the gas is taken by high-pressure

ejectors.

00

00

00

00

500

0

12345678910 11 12 13 14 15 16 17 18 19 20

Capacity regulation with four HP ejectors and two LE

ejectors where LE are preferred.

Multi Ejector High Pressure

Danfos

00

00

00

00

500

0

123456789101112131415161718

Capacity regulation with four HP ejectors and two LE

where HP ejectors are preferred.

Danfos

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 23

Multi Ejector Liquid Ejector

Multi Ejector Combi

Application Guide | High pressure lift ejector and liquid ejector systems

The liquid ejectors and/or largest ejectors are placed closest to the connectors.

How does the Multi Ejector solution work?

The flow enters the Multi Ejector through the strainer in front of the high-pressure inlet. The AK-PC

controller decides which ejector is activated to meet the requested capacity. Through the open nozzle,

the high-pressure flow is transformed into high velocity flow. The high velocity creates a very low

pressure, making the suction of the MT possible. The flow from the MT suction inlet enters the ejector

through the check valve, mixing with the high velocity flow. The mixed flow is slowed down in the

diffuser part of the ejector, transforming the velocity to pressure. From here the mixed flow is lead to

the receiver and thereby recovering a part of the expansion work.

24 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

10

HP 3875 OD% at constant load

II+H P Prec Opt II+HP Prec 35bar II+H P Prec 36 II+HP Pr ec 37

80G458

Application Guide | High pressure lift ejector and liquid ejector systems

6. Coolselector®2

Selecting components

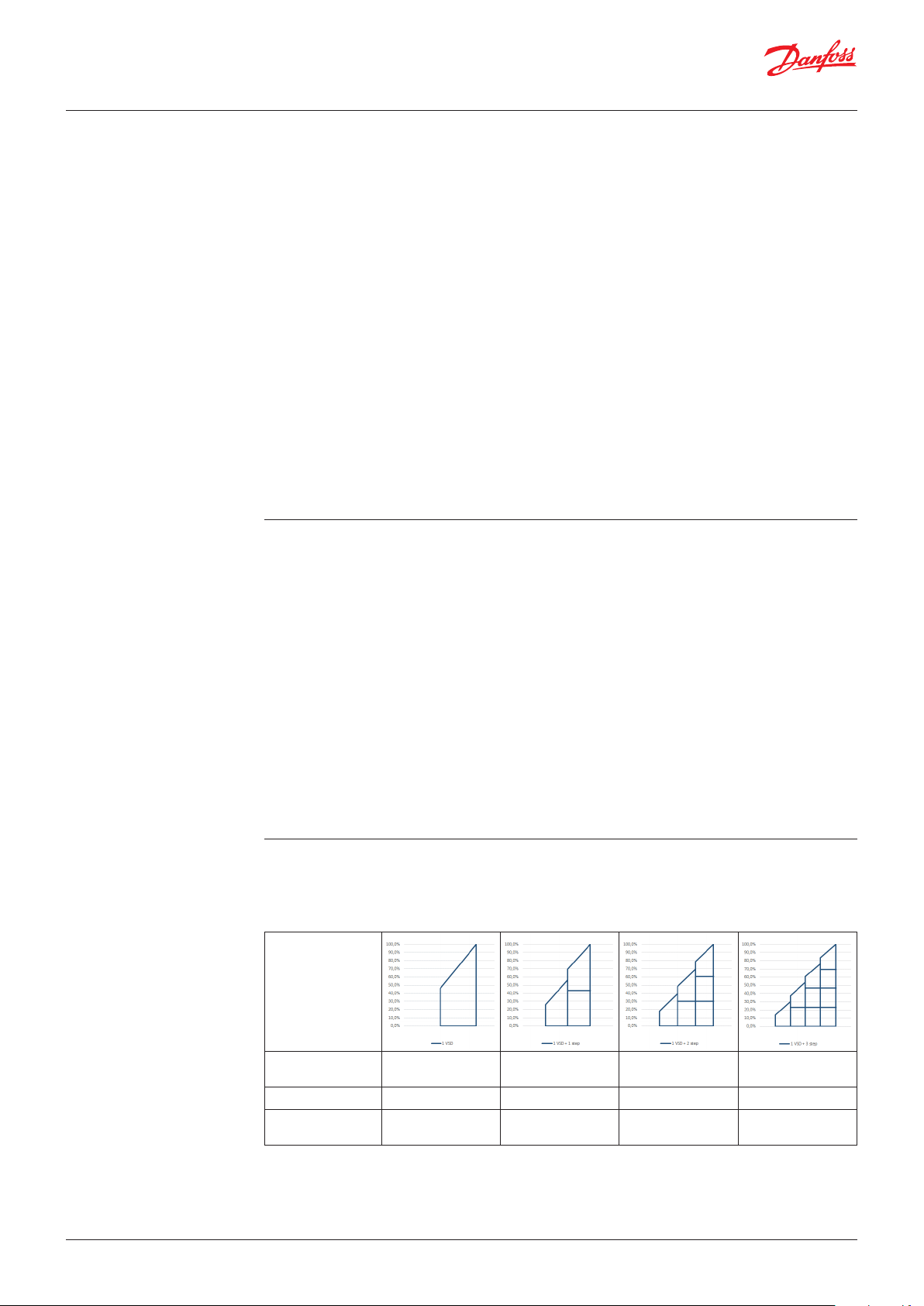

6.1 HP ejector selection On the diagram to the right there is an example of

how the HP ejector Opening Degree (OD%) changes

by keeping constant cooling evaporators’ load at

different Gas cooler Outlet temperatures (Sgc).

Notice two peeks around 26 – 27 °C and 35 – 36 °C.

There is also a dependency in how it is controlled

pressure in the receiver. By keeping the pressure

in the receiver constantly at 35 bar(a), the peak

load for the HP ejector is at 36 °C. If the pressure is

controlled with the “IT Optimize” feature, the load

peeks are at 27 °C and 35 °C.

By using a Gas cooler Outlet temperature at 35 °C

and an Optimal gas cooler pressure around 90 bar(a)

is a good starting point for selecting HP ejectors.

0.0%

95.0%

90.0%

85.0%

80.0%

75.0%

70.0%

65.0%

60.0%

22 24 26 28 30 32 34 36 38 40

Outlet temperature Sgc (°C)

Danfoss

1. 2. 3.

m_motive : Gas Cooler / motive mass flow

m_suction : Ejector suction mass flow

m_comp_MT : MT compressors’ mass flow

m_comp_IT : IT compressors’ mass flow

er : entrainment ratio

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 25

msuction 843

er = =

mmotive

3419

Operating envelope:

= 0.25

Application Guide | High pressure lift ejector and liquid ejector systems

6.2 LE ejector selection

In section 2.1 “System design with Liquid ejector

(LE)”, there is an explanation about the amount

of returned liquid from the MT evaporators

depending on the application. In a typical

supermarket application with more than 10

evaporators we can assume that the amount of

liquid returned is 3% of the total MT evaporators’

mass flow. The default value in Coolselector®2 is

3%. If the application is different, it is necessary to

For LE the most critical condition is cold ambient

and related to this minimum pressure in the gas

cooler. The most critical condition is minimum

gas cooler outlet temperature and related

optimum pressure in the gas cooler. If the gas

cooler pressure is kept at e.g. 50 bar and the

temperature out of the gas cooler is lowered,

then the LE will have even better performance

than on optimal COP curve.

change this value in following preferences.

1. 2.

3.

The required suction mass flow calculated as percentage of the MT evaporator mass flow:

m_motive : motive mass flow though Liquid ejector

m_suction : Ejector liquid suction mass flow

m_suction_required : calculation based on assumption of 3% of m_evap_MT mass flow

er : entrainment ratio

msuction 168

er = =

mmotive

631

= 0.27

Operating envelope:

26 | AB351943880096en-000101 © Danfoss | DCS (vt) | 2020.10

Application Guide | High pressure lift ejector and liquid ejector systems

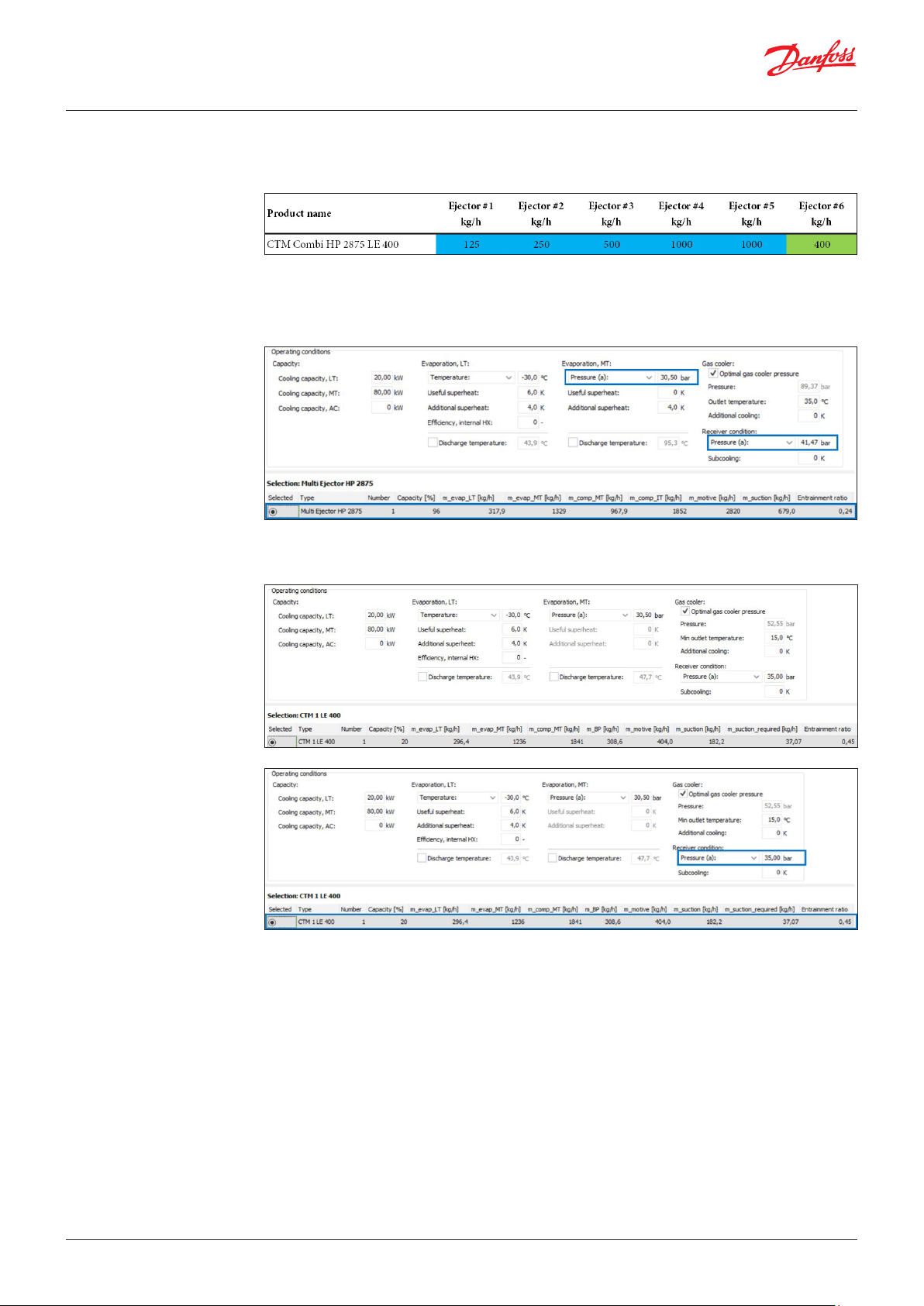

6.3 Combi ejector selection

(HP+LE)

As in Coolselector®2 there is no direct selection for Combi ejector. The selection will be done

separately using an HP and LE module. The below example shows a selection for Combi HP2875 LE400

consisting of 5 x HP ejectors and one LE 400.

The MT evaporating pressure will be higher because of ALC and CALM leading to 0 K Useful superheat.

The receiver pressure level is optimized for the best system efficiency. The HP ejector should fulfill

the necessary motive flow for the given capacity load and gas cooler conditions at high ambient

conditions.

Liquid ejectors should be capable to lift liquid in cold ambient conditions, but with lower receiver

pressure.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 27

7. Multi Ejector Solution™

Danfoss offers a wide range of market leading Multi Ejectors. Including 3 MBS 8250

sensors and additional coils and LED plugs are needed.

CTM Multi Ejector - High Pressure (optimizing parallel compression systems):

• Energy consumption reductions up to 9% annually in warm climates compared to

parallel compression, and by up to 17% compared to booster systems.

• Available ejector types: HP 1874 (4 ejectors), HP 2875 (5 ejectors), HP 3875 (6 ejectors).

• It is recommended for stores with a refrigeration load in the range of 35 – 140 kW.

CTM Multi Ejector - Liquid Ejector (optimal evaporator utilization and efficient

compressor protection):

• Energy consumption can be lowered by 2 – 12% annually in any climate compared to

regular booster systems.

• Available ejector types: LE 200 (1 ejector), LE 400 (1 ejector), LE 400 (2 ejectors),

LE 600 (2 ejectors), LE 800 (3 ejectors).

• It is recommended for stores with a refrigeration load in the range of 25 – 480 kW.

CTM Multi Ejector - Combi HP/LE (optimizing parallel compression systems and

evaporator utilization and efficient compressor protection):

• Enables 15 – 35 % savings on compressor swept volume, compared to booster

systems.

• Available ejector types: Combi HP 1875 LE 400 (6 ejectors),

Combi HP 2875 LE 200 (6 ejectors), Combi HP 2875 LE 400 (6 ejectors).

• It is recommended for stores with a refrigeration load in the range of 35 – 120 kW.

CTM Multi Ejector - Low Pressure (optimizing booster system energy consumption):

• Energy consumption can be lowered by up to 15% compared to a booster system.

• Available ejector types: LP 935 (4 ejectors), LP 1435 (5 ejectors), LP 1935 (6 ejectors).

• It is recommended for stores with a refrigeration load in the range of 18 – 72 kW.

Pack controller - AK-PC 782A

Danfoss offers a wide range of market leading Pack Controllers.

Being the flagship and best in class controller for transcritical CO pack controls,

the AK-PC 782A offers the highest possible efficiency with the Multi Ejector.

Coolselector®2 - Transcritical High Pressure Application

Helps you optimize energy consumption and increase efficiency in any system. Run

unbiased calculations based on a set of operating conditions — such as cooling

capacity, refrigerant, evaporation, and condensation temperature — and then select

the best components for your design.

Check out the new Transcritical High Pressure Application area.

© Danfoss | DCS (vt) | 2020.10 AB351943880096en-000101 | 28

ADAP-KOOL®

Loading...

Loading...