Page 1

Data Sheet

Float valve

Type HFI

Robust and reliable solution for high pressure control

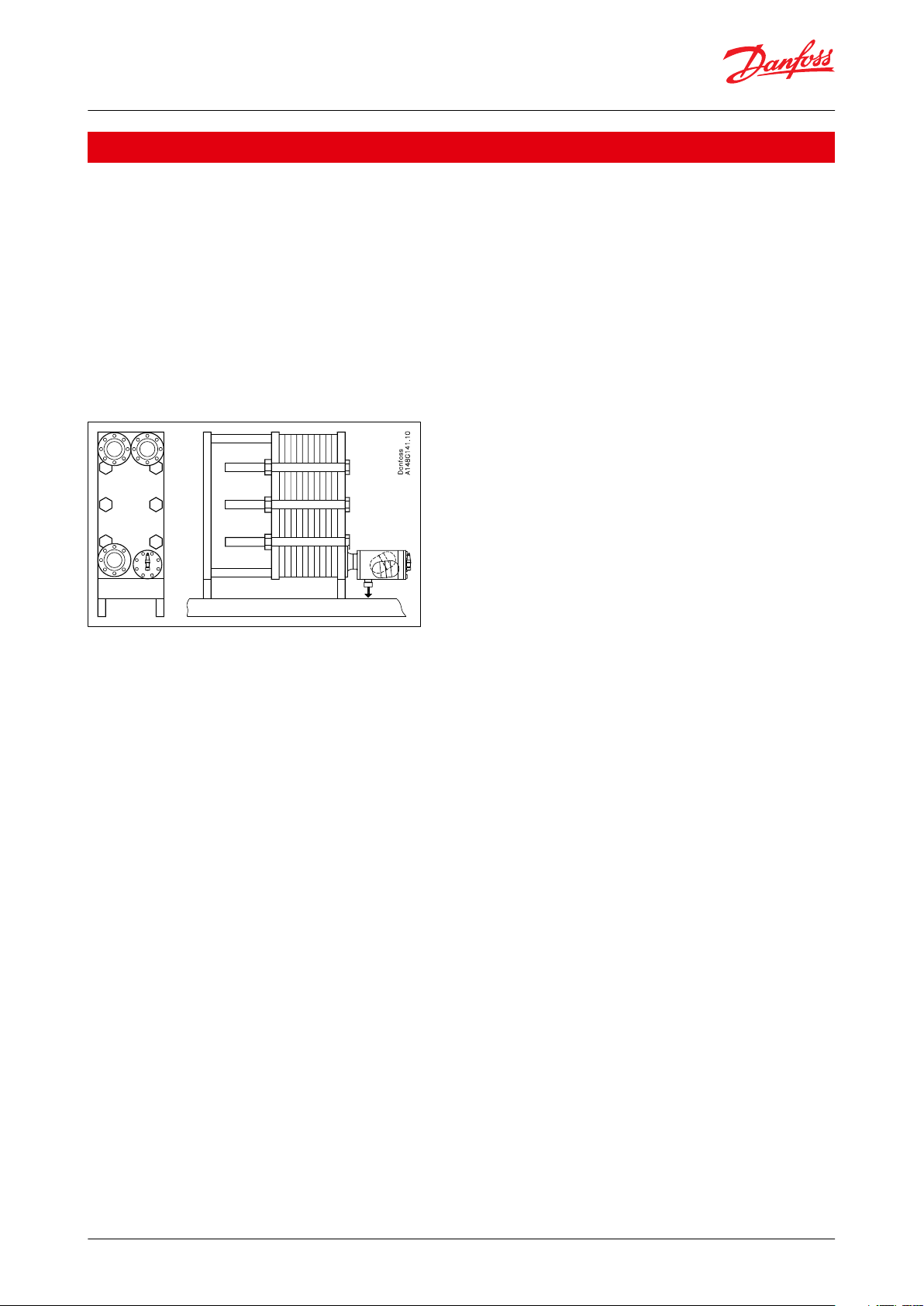

HFI is a high pressure oat valve with internal

liquid measuring device. The oat valve is

designed for direct ange mounting or welding

on to plate heat exchanger type condensers, as

illustrated in Figure 1: Plate heat exchanger

HFI is direct acting, therefore no dierential

pressure is required to activate the valve.

HFI is robust and reliable due to its simple

design. The oat valve is equipped with a purge

valve for purging non condensable gases e.g.

air from the top of the valve housing. This

feature is also useful if the valve has to be

serviced.

The HFI is available with two external

connections on the housing for drainage and

pressure equalizations.

AI220786430153en-001101

Page 2

Float valve, type HFI

Features

• Designed for direct ange mounting on to plate heat exchanger type condensers

• Can be mounted directly on vessels

• Temperature range: -50 °C /+80 °C (-58 °F/+176 °F)

• Equipped with purge valve for purging non condensable gasses

• Available with external connections for drainage and pressure equalizations

• Maximum operating pressure is 25 bar (363 psig)

• Suitable for R717 (ammonia), HCFC and HFC with a density of 500 through 700 kg/m3 (31.21 - 43.70 lb/ft3). For

densities outside this range please contact your local Danfoss sales company.

• Housing i.e. shell and ange are made of special steel approved for low temperature application

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company.

Figure 1: Plate heat exchanger

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 2

Page 3

Float valve, type HFI

Media

Refrigerants

Refrigerants

Suitable for R717 (ammonia), HCFC and HFC with a density of 500 through 700 kg/m3 (31.21 - 43.70 lb/ft3). For

densities outside this range please contact your local Danfoss sales company.

Flammable hydrocarbons are not recommended. For further information please contact your local Danfoss Sales

Company.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 3

Page 4

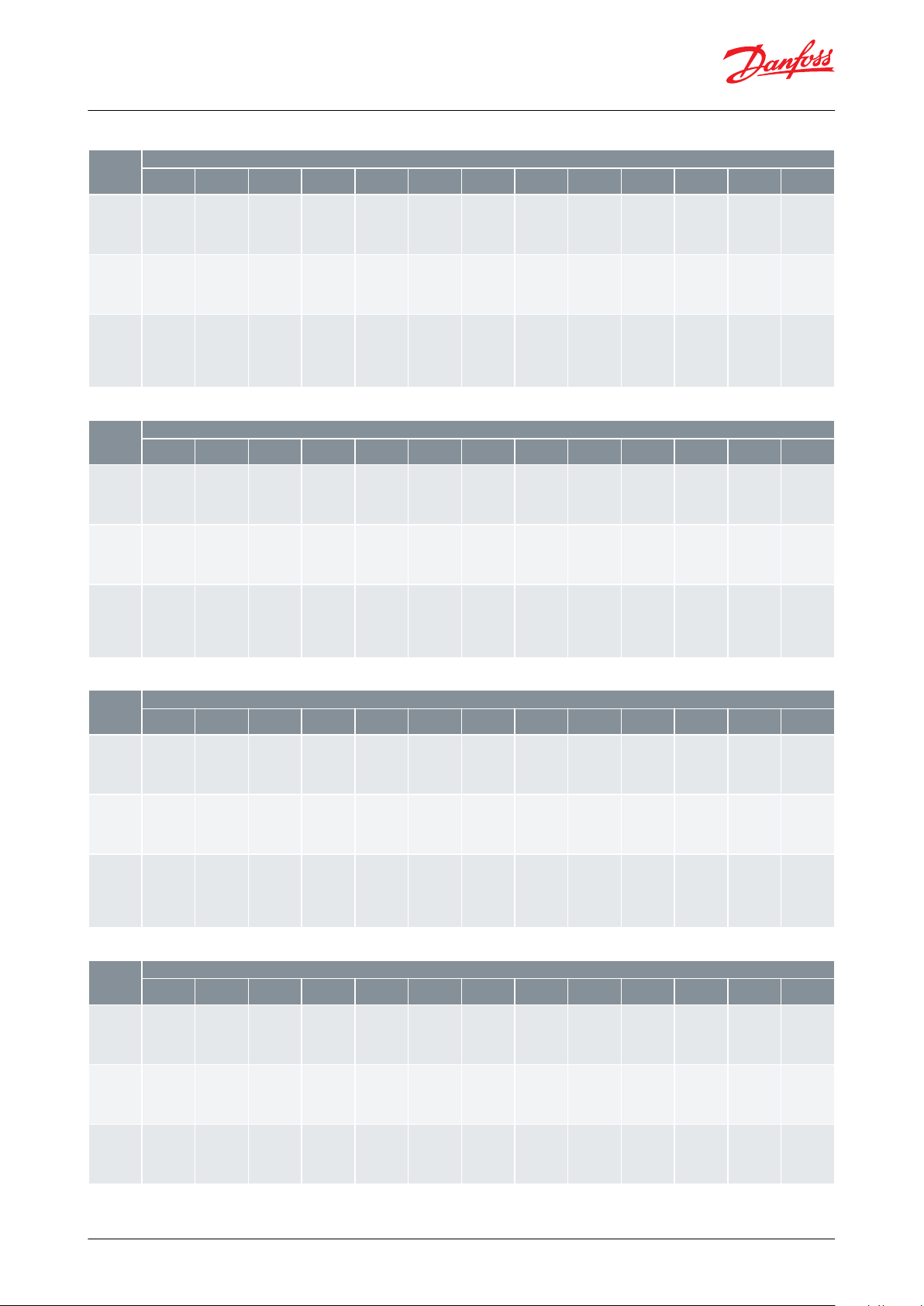

Description

Values

Temperature range

-50 °C / +80 °C (–58 °F /+176 °F)

The oat valve is designed for: Maximum operating pressure

Housing PED 28 bar (407 psig)

Ball (oat) 25 bar (363 psig)

Float valve, type HFI

Product specication

Design

Housing

Housing i.e. shell and ange is made of special steel approved for low temperature operation.

Installation

Refer to installation instruction for HFI.

Figure 2: Identication:

Pressure and temperature data

Table 1: Pressure and temperature

If test pressure exceeds 25 bar (363 psi g) the ball should be removed during test.

Valves for higher pressure are available on request.

The principle of high pressure control

Introduction

In installations with one application high pressure control is an eective and cost saving way of expanding liquid

from the condenser to the low pressure side.

High pressure refrigerant entering the condenser will start to condense, consequently condensate will accumulate

at the bottom of the condenser and in the oat valve.

When capacity demands increase, the liquid level in the oat valve will rise, which will cause the valve to open and

the refrigerant to expand into the separator at the low pressure side.

When the valve is closed, there will still be a small by-pass over the seat, so any remaining liquid will equalize slowly

to the low pressure side, for instance during an o cycle. Therefore the system will equalize automatically and the

compressor can start up without excessive back pressure. The size of the bypass is predetermined and dened by

geometry of the elements.

It follows from the above, that almost all the refrigerant will be accumulated on the low pressure side under normal

conditions. Therefore under normal conditions no high pressure receiver is necessary when using the HFI for high

pressure control.

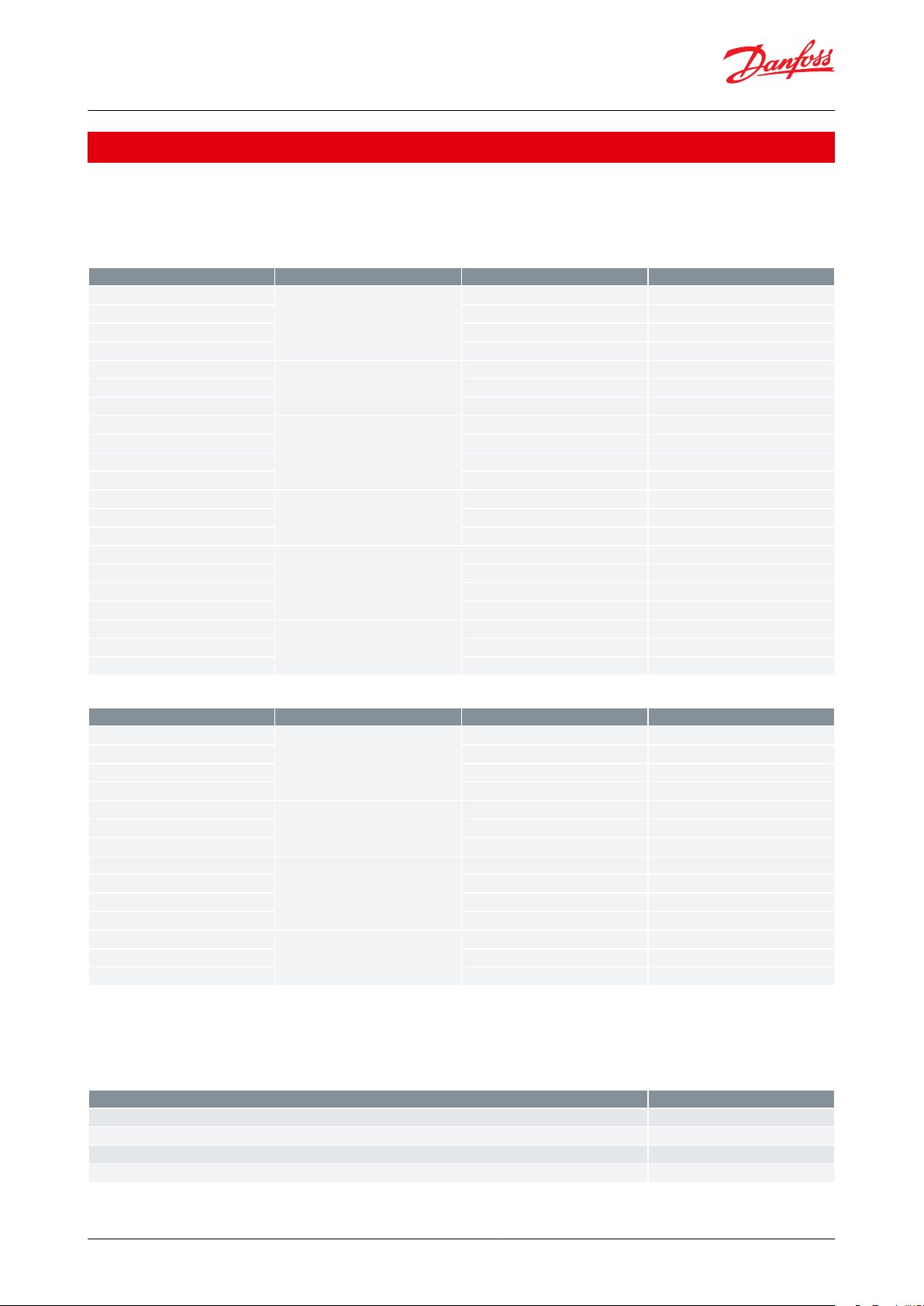

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 4

Page 5

ΔpρK

Valve type

Nominal capacity

[kW]

(R 717, –10/+35°C)

Valve constant [K]

HFI 040 FD

400

16.79

HFI 050 FD

800

33.58

HFI 060 FD

1200

50.36

HFI 070 FD

2400

100

dierential pressure [bar]

density of liquid [kg/m3]

valve constant (from the above table)

Condens‐

ing temp.

(°C)

Evaporating temperature (°C)

–40

–35

–30

–25

–20

–15

–10–505101520

50

45

40

35

475

460

440

420

480

460

440

420

480

460

440

420

475

460

440

415

475

455

435

415

475

455

430

405

470

445

425

400

460

440

415

390

455

430

405

375

445

420

390

360

430

405

375

340

415

385

350

315

395

360

325

280

30

25

20

15

400

380

360

340

400

380

355

335

400

375

355

330

395

370

350

325

390

365

340

315

385

360

330

300

375

345

315

285

360

330

300

265

345

315

280

240

325

290

250

200

300

260

210

150

270

220

155

230

160

10

5

0

–5

–10

315

290

270

245

220

310

285

260

235

210

305

280

255

225

200

295

270

240

210

180

285

255

225

190

155

270

240

205

165

115

250

215

175

120

225

185

125

195

135

140

Float valve, type HFI

Insert for the high pressure oat valve

Figure 3: Detail A Fully closed Figure 4: Detail B Fully open

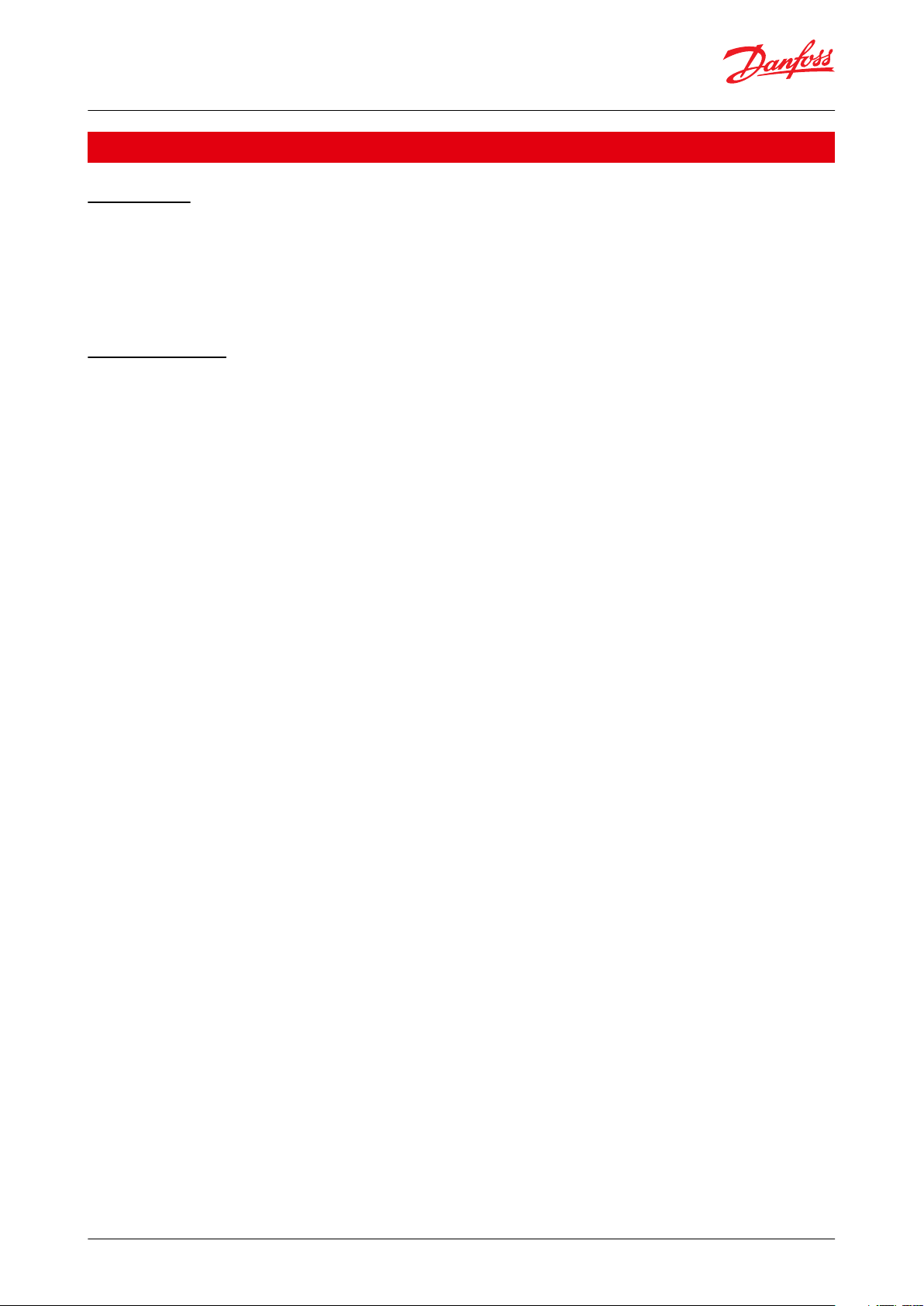

Computation and selection

In R 717 plants (ammonia)

On the following pages you will nd tables with capacities of the oat valve at various operating conditions.

Select a valve using the specic operating conditions. The chosen valve must have a capacity higher than the

required capacity during nominal operation, as well as during plant start up.

In plants using other refrigerants than ammonia

The capacity of the oat valve can be calculated by using the values and the equation to the right. However, the

density of the refrigerant must be in the range: 500 to 700 kg/m3.

For densities outside this range please contact your local Danfoss Sales Company.

Table 2: Valve capacity values

Mass ow

G = K Δp × ρ

[kg / h]

Computation and selection capacity tables - SI units

Table 3: HFI 040 - R 717, evaporating capacity [kW]

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 5

Page 6

Condens‐

ing temp.

(°C)

Evaporating temperature (°C)

–40

–35

–30

–25

–20

–15

–10–505101520

50

45

40

35

955

920

880

845

955

920

880

845

955

920

880

840

955

915

875

835

950

910

870

825

945

905

860

815

935

895

850

800

925

880

830

780

910

860

810

755

890

835

780

720

865

805

745

680

830

770

700

625

790

725

645

560

30

25

20

15

805

765

720

675

800

760

715

670

800

755

705

660

790

745

695

645

780

730

680

630

765

715

660

605

750

695

635

570

725

665

600

530

695

630

555

480

655

580

500

405

605

520

420

295

540

440

310

455

320

10

5

0

–5

–10

630

585

540

490

440

625

575

525

475

420

610

560

505

455

395

595

540

485

425

360

570

515

450

385

305

545

480

405

325

230

505

430

345

240

455

365

255

385

270

285

Condens‐

ing temp.

(°C)

Evaporating temperature (°C)

–40

–35

–30

–25

–20

–15

–10–505101520

50

45

40

35

1430

1380

1325

1265

1435

1380

1325

1265

1435

1380

1320

1260

1430

1375

1315

1250

1425

1370

1305

1240

1420

1360

1290

1220

1405

1340

1270

1200

1385

1320

1245

1170

1365

1290

1215

1130

1335

1255

1170

1080

1295

1210

1120

1020

1245

1155

1055

940

1190

1085

970

840

30

25

20

15

1205

1145

1080

1015

1205

1140

1070

1005

1195

1130

1060

990

1185

1115

1045

970

1170

1100

1020

940

1150

1075

990

905

1120

1040

950

860

1085

995

900

795

1040

940

835

715

980

870

750

605

905

780

635

445

810

660

465

685

485

10

5

0

–5

–10

945

875

805

735

660

935

860

785

710

635

915

840

760

680

595

890

810

725

635

540

860

770

675

575

460

815

720

610

490

340

755

645

520

360

680

550

380

580

405

425

Condens‐

ing temp.

(°C)

Evaporating temperature (°C)

–40

–35

–30

–25

–20

–15

–10–505101520

50

45

40

35

2445

2680

2545

2400

2775

2640

2490

2335

2725

2580

2425

2260

2665

2510

2340

2160

2590

2420

2235

2035

2495

2310

2105

1880

2375

2170

1940

1680

30

25

20

15

2090

1940

2340

2195

2040

1885

2300

2145

1980

1810

2245

2080

1900

1715

2170

1995

1800

1595

2080

1885

1670

1435

1960

1745

1500

1210

1815

1565

1265

890

1625

1320

930

1370

965

10

5

0

–5

–10

1470

1325

1725

1575

1425

1265

1835

1680

1520

1360

1190

1785

1620

1450

1270

1080

1715

1540

1350

1150

920

1630

1435

1220

980

685

1515

1295

1040

725

1365

1100

765

1160

810

850

Condens‐

ing temp.

(°F)

Evaporating temperature (°F)

–40

–30

–20

–10010203040506070

80

120

110

100

90

134

129

123

117

135

129

123

117

135

129

122

116

134

128

122

115

134

127

120

113

132

126

118

111

131

123

116

107

128

121

112

103

125

117

108

98

121

112

102

91

116

106

94

81

109

98

84

69

101

87

71

50

80

70

60

50

110

103

97

90

110

103

96

88

109

102

94

86

107

100

92

83

105

97

89

80

102

94

84

74

99

89

79

67

94

83

71

57

87

75

60

42

78

63

44

66

47

49

40

30

20

10

82

75

67

59

81

73

65

56

78

70

61

51

75

65

55

44

70

59

47

33

63

51

35

54

38

40

Float valve, type HFI

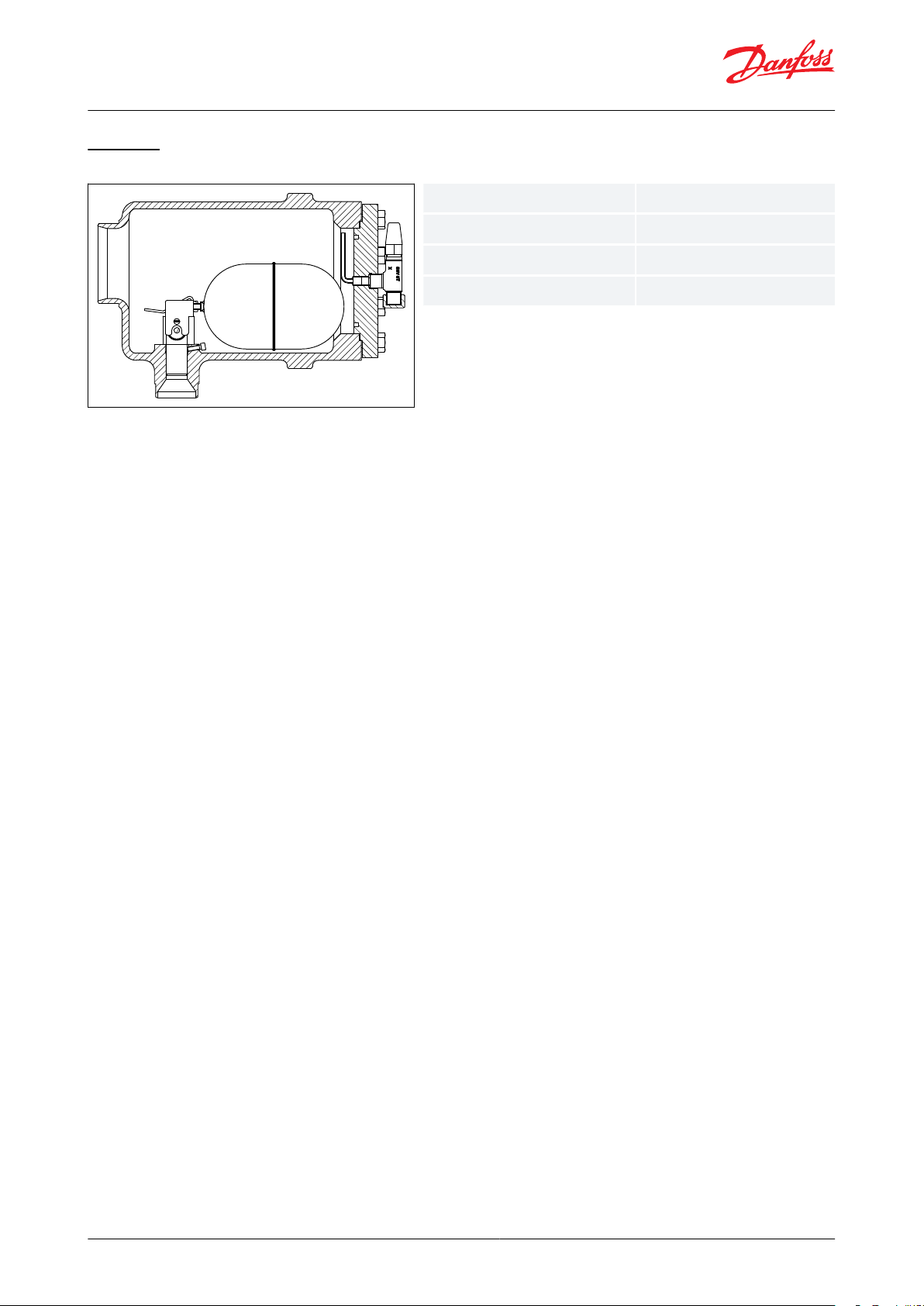

Table 4: HFI 050 - R 717, evaporating capacity [kW]

Table 5: HFI 060 - R 717, evaporating capacity [kW]

Table 6: HFI 070 - R717, evaporating capacity [kW]

Table 7: HFI 040 - R 717, evaporating capacity [TR]

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 6

Page 7

Condens‐

ing temp.

(°F)

Evaporating temperature (°F)

–40

–30

–20

–10010203040506070

80

120

110

100

90

268

258

246

234

269

258

246

233

269

257

245

232

269

256

243

229

267

254

241

226

265

251

237

221

261

247

232

215

256

241

224

207

250

233

215

196

242

224

204

181

231

211

189

163

218

195

169

138

201

175

143

101

80

70

60

50

221

207

193

179

220

206

191

176

218

203

188

172

215

200

184

167

211

194

177

159

205

187

169

149

197

178

157

134

187

166

142

114

174

149

121

84

156

127

89

132

93

97

40

30

20

10

165

150

135

119

161

145

129

112

156

139

121

102

149

130

110

88

140

118

95

65

127

102

70

108

75

80

Condens‐

ing temp.

(°F)

Evaporating temperature (°F)

–40

–30

–20

–10010203040506070

80

120

110

100

90

403

386

369

350

404

387

368

350

404

386

367

348

403

384

365

344

401

381

361

339

397

377

355

332

392

370

347

322

385

362

337

310

375

350

323

293

363

335

305

272

347

317

283

244

327

293

253

207

302

262

214

151

80

70

60

50

331

310

290

269

329

309

287

265

327

305

282

259

322

299

275

250

316

292

266

239

307

281

253

223

296

267

236

202

281

249

213

172

261

224

181

126

234

190

133

199

140

146

40

30

20

10

247

225

202

178

242

218

194

168

234

209

182

153

224

196

165

132

209

178

142

98

190

152

106

162

113

120

Condens‐

ing temp.

(°F)

Evaporating temperature (°F)

–40

–30

–20

–10010203040506070

80

120

110

100

90

678

710

664

784

741

695

645

769

723

673

620

750

700

646

587

725

671

611

544

694

633

566

489

654

586

507

413

603

524

428

302

80

70

60

50

517

599

551

500

632

583

532

477

615

562

506

446

592

534

472

403

561

497

426

343

521

447

362

253

469

380

267

397

279

292

40

30

20

10

404

357

483

436

387

336

469

418

364

307

448

391

331

263

419

355

284

195

380

305

211

325

226

240

Float valve, type HFI

Table 8: HFI 050 - R 717, evaporating capacity [TR]

Table 9: HFI 060 - R 717, evaporating capacity [TR]

Table 10: HFI 070 - R717, evaporating capacity [TR]

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 7

Page 8

Compressor

Vapor

Water chiller (evaporator)

Liquid

High pressure

Float Valve - HFI

High pressure

condenser

1

2

3

4

5

6

7

8

No

Part

Material

DIN/EN

ASTM

1

Housing

Steel

G20Mn5+QT

EN10213-3

2

Float Ball

Steel3Tube

Steel4Gasket

Aluminium

5

Gasket

Non asbestos

6

End cover with cylinder

Steel

PE275 NL1

EN 10028-3

7

Purge valve, SNV-ST

(1)

8

Set screw

Stainless steel

A2-70

Float valve, type HFI

High pressure control in refrigeration system with condenser/evaporator

Figure 5: A water chiller with plate heat exchanger as both condenser and evaporator. HFI is anged directly on to the

condenser.

Material specication

Figure 6: Housing parts

Table 11: Material specication

(1)

(1)

SNV-ST G½-G½ (148B3745).

SNV-ST G½-G½ (148B3745).

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 8

Page 9

OD

T

HFI size mm

HFI size in.

Outlet

For use with valve

type

ODmmTmmOD

in.Tin.

100460.3

2.9

2.37

0.11

HFI 040

HFI 050

HFI 060

HFI 070

150660.3

2.9

2.37

0.11

HFI 050

HFI 060

HFI 070

OD

T

HFI size mm

HFI size in.

Outlet

For use with valve

type

ODmmTmmOD

in.Tin.

100460.3

3.9

2.37

0.15

HFI 040

HFI 050

HFI 060

HFI 070

150660.3

3.9

2.37

0.15

HFI 050

HFI 060

HFI 070

OD

T

Float valve, type HFI

Connections

Available connections

Flange:

Inlet: Flange DN 100 or DN 150 (DIN-2635/DIN 2512-F)

Outlet: Welding connection DN 50 (EN 10220)

Butt-weld, DIN:

Inlet: DN 100 or DN 150 (EN 10220)

Outlet: Welding connection DN 50 (EN 10220)

Butt-weld, ANSI:

Inlet: DN 100 (4 in.) or DN 150 (6 in.) (ANSI B 36.10)

Outlet: Welding connection DN 50 (2 in.) (ANSI 36.10)

Figure 7: DIN - Outlet

Table 12: Butt-weld DIN (EN 10220)

Figure 8: ANSI - Outlet

Table 13: Butt-weld ANSI (B 36.10 Schedule 40)

Figure 9: DIN - Inlet

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 9

Page 10

HFI size mm

HFI size in.

Inlet

For use with valve

type

ODmmTmmOD

in.Tin.

1004114.3

3.6

4.50

0.14

HFI 040

HFI 050

HFI 060

HFI 070

1506168.3

4.5

6.63

0.18

HFI 050

HFI 060

HFI 070

OD

T

HFI size mm

HFI size in.

Inlet

For use with valve

type

ODmmTmmOD

in.Tin.

1004114.3

6.3

4.50

0.25

HFI 040

HFI 050

HFI 060

HFI 070

1506168.3

7.1

6.63

0.28

HFI 050

HFI 060

HFI 070

øDbøk

ød42ød

43

F

ød2

Z

Size 100 (4 in.)

mm

in.

235

9.3240.94

190

7.48

129

5.08

149

5.87

4.5

0.18220.97

8 pcs.

Size 150 (6 in.)

mm

in.

300

11.8281.10

250

9.84

183

7.20

203

7.99

4.5

0.18261.02

8 pcs.

Float valve, type HFI

Table 14: Butt-weld DIN (EN 10220)

Figure 10: ANSI - Inlet

Table 15: Butt-weld ANSI (B 36.10 Schedule 40)

Figure 11: Inlet ange

Table 16: 40 bar / DIN 2635 / DIN 2512-F*

*Inlet ange and DIN outlet

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 10

Page 11

B

A1

A3

A2

C

D

Fmin

Valve size

A1A2A3BC

ΦD

F

min

Weight

HFI 100

mm

in.

192

7.56

113

4.45250.98

280.5

11.05

440

17.32

227

8.94

200

7.87

43 kg

94.8 lb

HFI 150

mm

in.

167

6.57

113

4.45

280.5

11.05

440

17.32

227

8.94

200

7.87

43 kg

94.8 lb

B

A1

A3

A2

D

C

Fmin

Valve size

A1A2A3BC

ΦD

F

min

Weight

HFI 100

mm

in.

192

7.56

180

7.09250.98

280.5

11.05

506

19.92

227

8.94

200

7.87

49 kg

108 lb

HFI 150

mm

in.

167

6.57

189

7.44

280.5

11.05

506

19.92

227

8.94

200

7.87

49 kg

108 lb

Float valve, type HFI

Dimensions and weights

Figure 12: High pressure oat valve without ange

Table 17: High pressure oat valve without ange

NOTE:

Specied weights are approximate values only.

Figure 13: High pressure oat valve with ange

Table 18: High pressure oat valve with ange

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 11

Page 12

B

A1

A3

A2

C

D

Fmin

E

A4

EXC1

EXC2

External Connections

EXC1

EXC2

⅜ - 18 NPT

½ - 14 NPT

B

A1

A3

A2

D

C

Fmin

E

A4

EXC1

EXC2

External Connections

EXC1

EXC2

⅜ - 18 NPT

½ - 14 NPT

Valve size

A1A2A3A4BCΦD

E

F

min

Weight

HFI 100

mm

in.

192

7.56

113

4.45250.98

176

6.93

280.5

11.05

440

17.32

227

8.94

247

9.72

200

7.87

43 kg

94.8 lb

HFI 150

mm

in.

167

6.57

113

4.45

176

6.93

280.5

11.05

440

17.32

227

8.94

247

9.72

200

7.87

43 kg

94.8 lb

Valve size

A1A2A3A4BCΦD

E

F

min

Weight

HFI 100

mm

in.

192

7.56

180

7.09250.98

176

6.93

280.5

11.05

506

19.92

227

8.94

251

9.88

200

7.87

49 kg

108 lb

HFI 150

mm

in.

167

6.57

180

7.09

176

6.93

280.5

11.05

506

19.92

227

8.94

247

9.72

200

7.87

49 kg

108 lb

Float valve, type HFI

Dimensions and weights (HFI with external connections)

Figure 14: High pressure oat valve without ange

Table 19: High pressure oat valve without ange

NOTE:

Specied weights are approximate values only.

Figure 15: High pressure oat valve with ange

Table 20: High pressure oat valve with ange

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 12

Page 13

Internal volume (gross):

Internal volume with oat ball:

Liquid volume at max. level:

Liquid volume at min. level:

11.4 × 10–3 m3 (3.01 US

gal

)

9.6 × 10–3 m3 (2.54 US

gal

)

6.3 × 10–3 m3 (1.66 US

gal

)

3.6 × 10–3 m3 (0.95 US

gal

)

Float valve, type HFI

Volumes

Figure 16: Min. and Max. volumes

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 13

Page 14

Type

Inlet connection size

Nozzle size

Code numbers

HFI 040 FD 100

100 (4 in.) DIN Flange

40

148G3102

HFI 050 FD 100

50

148G3103

HFI 060 FD 100

60

148G3104

HFI 070 FD 100

70

148G3422

HFI 050 FD 150

150 (6 in.) DIN Flange

50

148G3105

HFI 060 FD 150

60

148G3106

HFI 070 FD 150

70

148G3423

HFI 040 D 100

100 (4 in.) DIN BW

40

148G3092

HFI 050 D 100

50

148G3093

HFI 060 D 100

60

148G3094

HFI 070 D 100

70

148G3418

HFI 050 D 150

150 (6 in.) DIN BW

50

148G3095

HFI 060 D 150

60

148G3096

HFI 070 D 150

70

148G3419

HFI 040 A 100

100 (4 in.) ANSI BW

40

148G3097

HFI 050 A 100

50

148G3098

HFI 060 A 100

60

148G3099

HFI 070 A 100

70

148G3420

HFI 050 A 150

150 (6 in.) ANSI BW

50

148G3100

HFI 060 A 150

60

148G3101

HFI 070 A 150

70

148G3421

Type

Inlet connection size

Nozzle size

Code numbers

HFI 040 FD 100 w. 2 ext. con

100 (4 in.) DIN Flange

40

148G3196

HFI 050 FD 100 w. 2 ext. con

50

148G3727

HFI 060 FD 100 w. 2 ext. con

60

148G3670

HFI 070 FD 100 w. 2 ext. con

70

148G3671

HFI 050 FD 150 w. 2 ext. con

150 (6 in.) DIN Flange

50

148G3762

HFI 060 FD 150 w. 2 ext. con

60

148G3763

HFI 070 FD 150 w. 2 ext. con

70

148G3764

HFI 040 D 100 w. 2 ext. con

100 (4 in.) DIN BW

40

148G3765

HFI 050 D 100 w. 2 ext. con

50

148G3704

HFI 060 D 100 w. 2 ext. con

60

148G3766

HFI 070 D 100 w. 2 ext. con

70

148G3720

HFI 050 D 150 w. 2 ext. con

150 (6 in.) DIN BW

50

148G3767

HFI 060 D 150 w. 2 ext. con

60

148G3768

HFI 070 D 150 w. 2 ext. con

70

148G3769

Type

Code numbers

Insert for HFI 070 (complete insert with

oat ball - without oat housing)

148G3584

Insert for HFI 060 ( complete insert with

oat ball - without oat housing)

148G3663

Insert for HFI 050 ( complete insert with

oat ball - without oat housing)

148G3662

Insert for HFI 040 ( complete insert with

oat ball - without oat housing)

148G3661

Float valve, type HFI

Ordering

The table below is used to identify the valve required.

Example: HFI 040 D 100 = 148G3092

Table 21: Type of inlet connection size and nozzle size

Table 22: HFI with 2 external connections

FD = inlet ange DIN

D = Butt welding DIN

A = Butt welding ANSI

Table 23: Connection types

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 14

Page 15

Danfoss

148B8106

Type

Connection type

Quantity

Code no.

Welding nipple incl. aluminium gasket

G½-ND6

2 pcs.

148B4184

Al gaskets included

¼” FPT – ½” G

1 pc.

148B3860

Al gaskets included

⅜” G - ½” G

1 pc.

148B3861

Float valve, type HFI

Accessories

Figure 17: Connection types

Table 24: Connection types

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 15

Page 16

The HFI-valves are approved in accordance with the European standard specied in the Pressure Equipment Directive and are CE marked.

HFI valves

Nominal bore

DN 100 and 150 mm (4 in. and 6 in.)

Classied for

Fluid group I

Catagory

III

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

03709-F0 BV

Marine - Safety Certicate

-BVRU Д-DK.РА01.B.72054_20

EAC Declaration

PED

EAC

RU C-DK.БЛ08.B.01093_20

Pressure - Safety Certicate

PED

EAC

033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

0045 202 1204 Z 00355 19 D 001(00)

Pressure - Safety Certicate

-

TÜV

033F0473.AD

Manufacturers Declaration

ATEX

Danfoss

19.10327.266

Marine - Safety Certicate

-

RMRS

Float valve, type HFI

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 25: Pressure Equipment Directive (PED)

For further details / restrictions - see Installation Instruction

Table 26: Valves specications

Table 27: Certicates and declarations

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 16

Page 17

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.09 AI220786430153en-001101 | 17

Loading...

Loading...