Data sheet

Rotary valves HFE 3

Description

Ordering

Danfoss HFE rotary valves are primarily designed

for regulation of flow temperature in heating

systems where a certain leakage can be accepted

and where a defined control characteristic is not

required.

Typ e

HFE 3

DN

(mm)

20 12

25 18 065Z0429

32 28 065Z0430

40 44 065Z0431

50 60 065Z0432

65 90 065Z0433

80 15 0 065Z0434

100 225 065Z0435

125 280 065Z0436

150 400 065Z0437

k

VS

(m3/h)

PN Code No.

065Z0428

6

HFE rotary valves can be used in combination

with electric actuators AMB 162 and AMB 182.

Features:

• Cast iron body with flange connection

• Lowest leakage in class

• Valve position indicator

• Ergonomic handle

• For mixing and diverting applications

• Flange PN 6 connection

Main data:

• DN 20–150

• kVS 12– 400 m3/h

• PN 6

• t

110 °C

max

• 3-way

• S characteristic

Spare parts and accessories

Typ e DN Code No.

Replacement handle 065Z0443

20-25 065Z0454

32-40 065Z0455

Stuffing box and sealing

Linkage kit for AMB (Gen. 2014) 082H0255

50-65 065Z0456

80 065Z0457

100-125 065Z0458

150 065Z0459

© Danfoss | 2019.10 VD.LH.A5.02 | 1

Data sheet Rotary valves HFE 3

Technical data

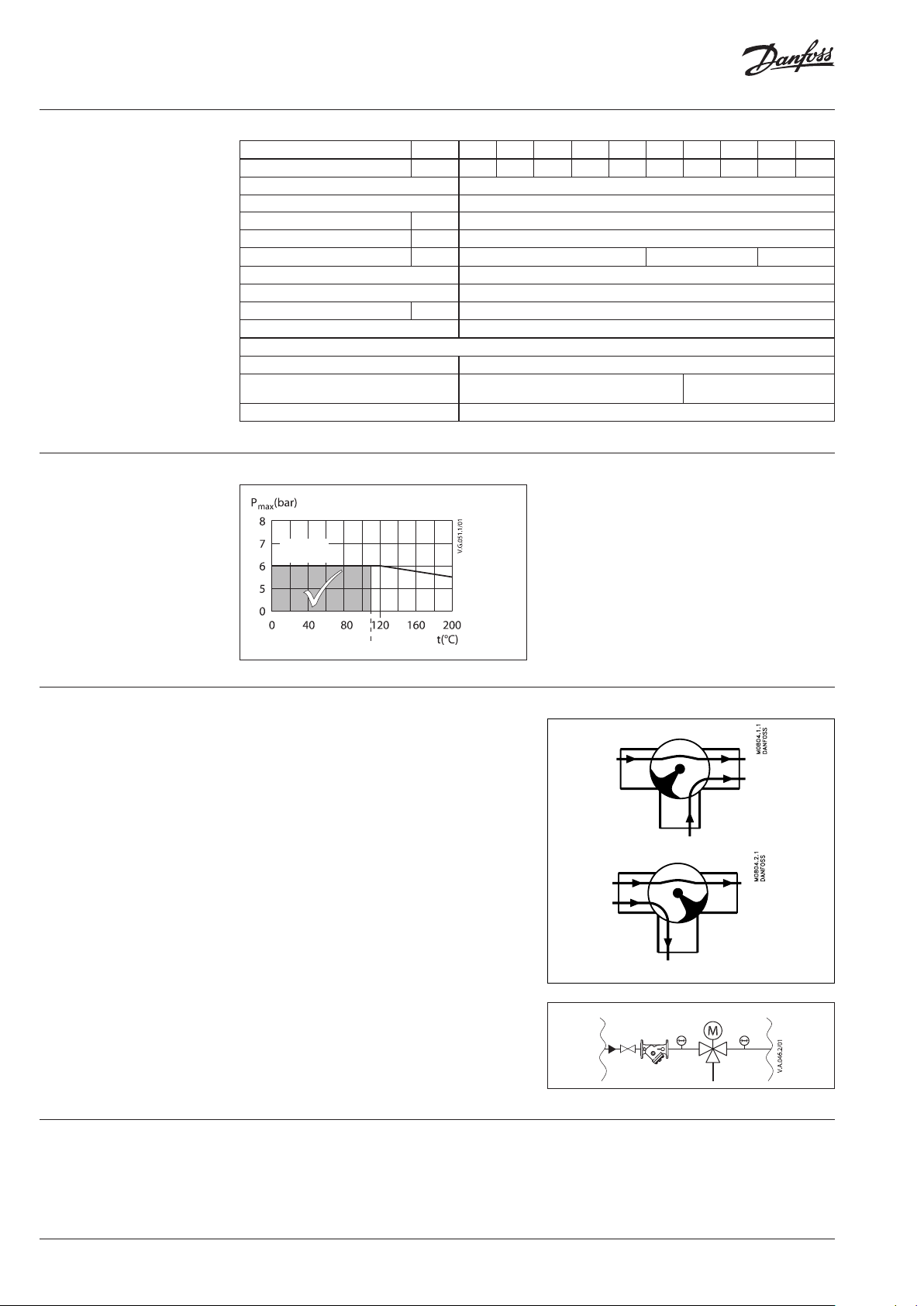

Pressure temperature

diagram

Nominal diameter DN 20 25 32 40 50 65 80 100 125 15 0

k

VS

Control characteristic S characteristic

Leakage Diverting: max. 0.75% of kVS / Mixing: max. 1.5% of k

Nominal pressure PN 6

Max. closing pressure bar 0.5

Torque at PN Nm 5 10 15

Medium Circulation water / glycolic mixture up to 50%

Medium pH Min. 7, max. 10

Medium temperature °C 2 … 110

Connections Flanges PN 6

Materials

Valve body and cover Grey cast iron EN-GJL-250 (GG25)

Slide shoe CuZn36Pb2As (BrassDZR, CW 602N)

Stuffing box sealing EPDM

m3/h 12 18 28 44 60 90 15 0 225 280 400

VS

Stainless steel,

EN 1.4301 (304)

PN 6

EN-GJL-250

(GG-25)

Installation

110

Valve mounting

Before valve mounting pipes have to be cleaned

and free from abrasion. Mechanical loads on

valve body caused by the pipes are not allowed.

It is recommended to install a strainer into

application to avoid damaging controlling

components.

Connection

HFE 3 can be used as a mixing valve, diverting

valve and in connection with heat exchangers

where a certain leakage can be accepted.

Note:

Install a strainer upstream of the valve

(e.g. Danfoss FVR/FVF)

Mixing

Diverting

AMB

FVR/FVF

Disposal

The valve must be dismantled and the elements

sorted into various material groups before

disposal.

2 | VD.LH.A5.02 © Danfoss | 2019.10

Data sheet Rotary valves HFE 3

Application principles

Sizing

HFE 3 mixing function

HFE 3 diverting function

HFE 3 diverting function

Reverse function can be achieved by changing

motor rotation direction (Valve label must also be

turned round). See further details in valve and motor

instructions.

Flow Rate

(liquid w ith specific a gravi ty of 1)

l/sec m3/h

FLOW Pressure drop kPa (100 kPa = 1bar = ~ 10 m H2O)

max

Δp

VD.LH.A5.02 | 3© Danfoss | 2019.10

Danfos

produc

Al

Danfoss A/S

Heating Segment

Data sheet Rotary valves HFE 3

Design

1. Valve body

2. Slide shoe

3. Valve cover

4. Stuffing box

5. Handle

Dimensions

106

n

1

H

H

L

1

B

K

1

L

фd

40

79

1

L

L

L

DN

20 137 92 14 0 131 140 70 45 65 11. 5 4 3.5

25 142 92 14 0 136 150 75 50 75 11. 5 4 4.0

32 158 98 152 14 6 160 80 60 90 15 4 6.6

40 163 98 15 7 146 175 88 65 100 15 4 7. 2

50 177 107 171 155 19 5 98 70 110 15 4 9.4

65 187 107 181 155 200 100 80 130 15 4 11. 5

80 215 120 208 167 235 118 95 15 0 18 4 17

100 233 128 228 177 265 133 105 170 18 4 22.5

125 259 13 9 253 187 300 15 0 120 200 18 8 29.5

150 277 145 271 192 350 175 133 225 18 8 40.2

H H

H

H

1

2

L L

3

mm

B K фd

1

Weight

n

(kg)

Actuator

AMB 162

AMB 182

90

75

92

H

3

H

2

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its pro ducts without notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are property of the r espective companies. Danfoss and all Danfoss logot ypes are trademarks of Danfoss A/S. All rights reserved.

• heating.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

© Danfoss | DHS-SDBT/SI | 2019.104 | VD.LH.A5.02

Loading...

Loading...