Page 1

Data sheet

DCAB

H

G

EF

Oil Nozzles Types HFD/HD and SFD/SD

Application Oil nozzles types HFD/HD and SFD/SD are

designed for domestic and commercial high

pressure oil burners operating with light or

heavy fuel.

The steel nozzles are available with hollow or

solid spray pattern in 3 different spray angles

with capacities from 0.3 to 2.50 USgal/h.

The types HFD and SFD have two sintered bronze

filters while the types HD and SD only have one

filter of sintered bronze or monel mesh.

Features:

• Light and heavy oil

• EN nozzles from 1.50 to 6.55 kg/h

• 100% test of capacity and performance

Identification

The nozzles are marked with the following

information (example):

Stampe d on the flats

0.60 Reference capacity (USgal/h)

60° SFD Spray angle and pattern (S = solid, H = Hollow, F = Double filter)

2.24 EN specified capacity (kg/h)

EN 60 I Spray angle & Angle index (according to EN 293/EN 299)

EN specif ication point 1000 kPa (10 bar), 3.4 cSt., 840 kg/m

Batch no. for internal use

Reference specification point 700 kPa (7 bar), 2.7 cSt., 820 kg/m

3

3

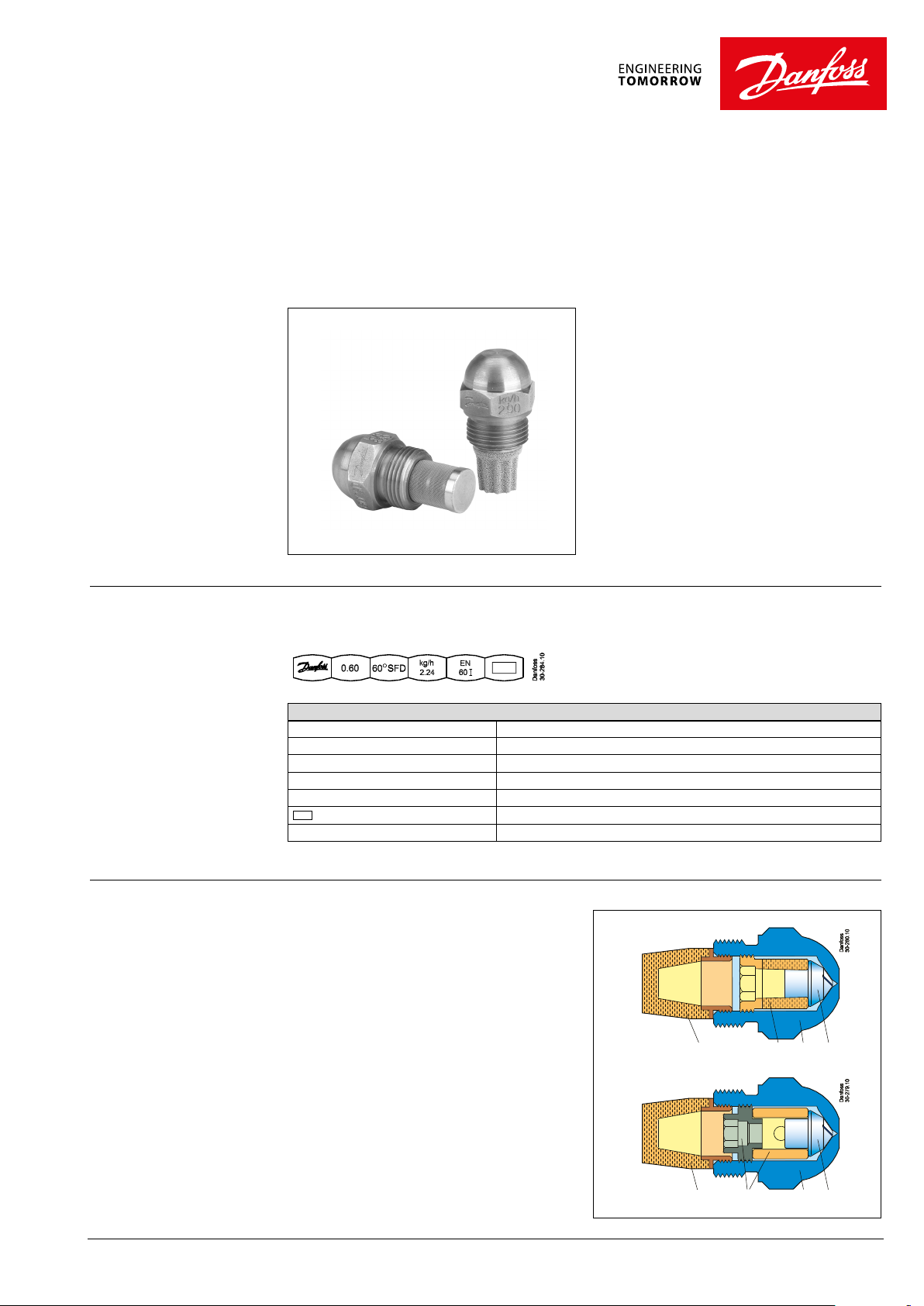

Design

Types HFD and SFD with double sinter filter

A: Nozzle housing

B: Nozzle cone

C: Inner filter (secondary)

D: External filter (primary)

Types HD and SD with single filter

(example with external filter)

E: Nozzle housing

F: Nozzle cone

G: Locknut

H: Filter

© Danfoss |03/2018 VDCEW322 | 1

Page 2

Data sheet Oil Nozzles Types HFD/HD and SFD/SD

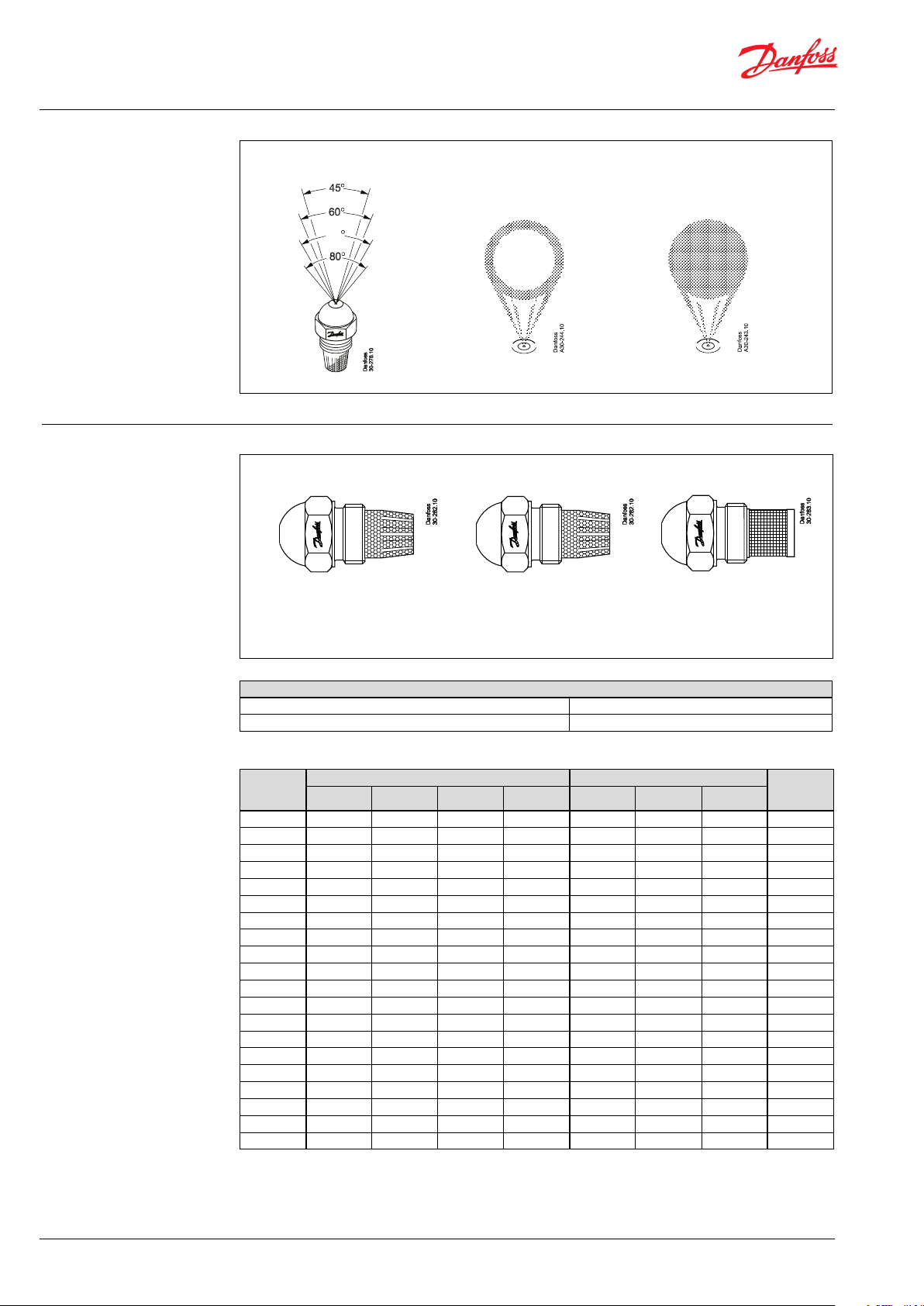

Spray angles/patterns

Technical Data

Spray angles Schematic spray patterns

70

Hollow

Filters

SFD, SDHFD, HD

Solid

Capacity 0.30 – 1.00 USgal/h

30-40 μm sintered bronze

Capacity 1.10 - 1.50 USgal/h

30-40 μm sintered bronze

Capacity 1.65 – 2.50 USgal/h

105 μm Monel mesh

(primary and secondary)

Tightening torques

Recommended tightening torque 25 to 30 Nm (2.5 to 3.0 kpm)

Max. tightening torque 35 Nm (3.5 kpm)

Program

Reference

capacity

(Usgal/h)

0.30 - - - - 030F4002 030F6002 030F8002 1.12

0.35 - - - - 030F4 003 030F6003 030F8003 1. 31

0.40 030H4004 030H6004 030H7004 030H8004 030F4004 030F6004 030F800 4 1.50*

0.45 030H4006 030H60 06 - 030H8006 030F4 006 030F6006 030F8006 1.68*

0.50 030H4008 030H6008 030H7008 030H8008 030F4008 030F6008 030F8008 1.87 *

0.55 030H4010 030H 6010 - 030H8010 030F4010 030F6 010 030F8 010 2.06*

0.60 030H4012 030H6 012 - 030H8012 03 0F4 012 0 30F6 012 030 F8012 2.24*

0.65 030H4 014 030 H6014 - 030H8014 030F4014 03 0F6014 03 0F8014 2 .43*

0.75 030H4016 030H 6016 - 030H8016 03 0F4016 030F 6016 030 F8016 2 .81*

0.85 030H4018 030H 6018 - 030H8018 0 30F4018 030 F6018 030 F8018 3.18 *

1.00 030H4020 030H 6020 - 030H8020 030F4020 030F6020 030 F8020 3 .74*

1.10 030H4022 030H6022 - 030H8022 030F4 022 030F6022 030F8022 4.12 *

1.25 030H4024 030H 6024 - 030H8024 030F4024 030F6024 030 F8024 4.68*

1.35 030H4026 030H6026 - 030H8026 030F4026 030F6026 030F8026 5.05*

1.50 030H4028 030H6028 - 030H8028 030F4028 030F6028 030F8028 5.61*

1.65 030H4029 030H6029 - 030H8029 030 F4029 030F6029 030F8029 6.17*

1.75 030H4030 030H6030 - 030H8030 030F4030 030F6030 030F8030 6. 55*

2.00 030H4032 030H6 032 - 030H8032 030F4032 030F6032 030F8032 7.4 8

2.25 030H4034 030H6034 - 030H8034 030F4034 030F6034 030F8034 8.42

2.50 030H4036 030H6036 - 030H8036 030F4036 030F6036 030F8036 9.35

*EN nozzles

45° 60° 70° 80° 45° 60° 80°

Hollow HFD/HD Solid SFD/SD Specified

capacity

(kg/ h)

2 | VDCEW322 © Danfoss | 03/2018

Page 3

Data sheet Oil Nozzles Types HFD/HD and SFD/SD

Dimensions

* EN - norm

Nozzle holder

VDCEW322 | 3© Danfoss | 03/2018

Page 4

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Oil Nozzles Types HFD/HD and SFD/SD

Danfoss

Toronto, ON/Baltimore, MD

Toll Free: 888-DANFOSS (326-3677) Option #3 for Heating

heating.danfoss.us

heating.cs.na@danfoss.com

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 03/20184 | VDCEW322

Loading...

Loading...