Page 1

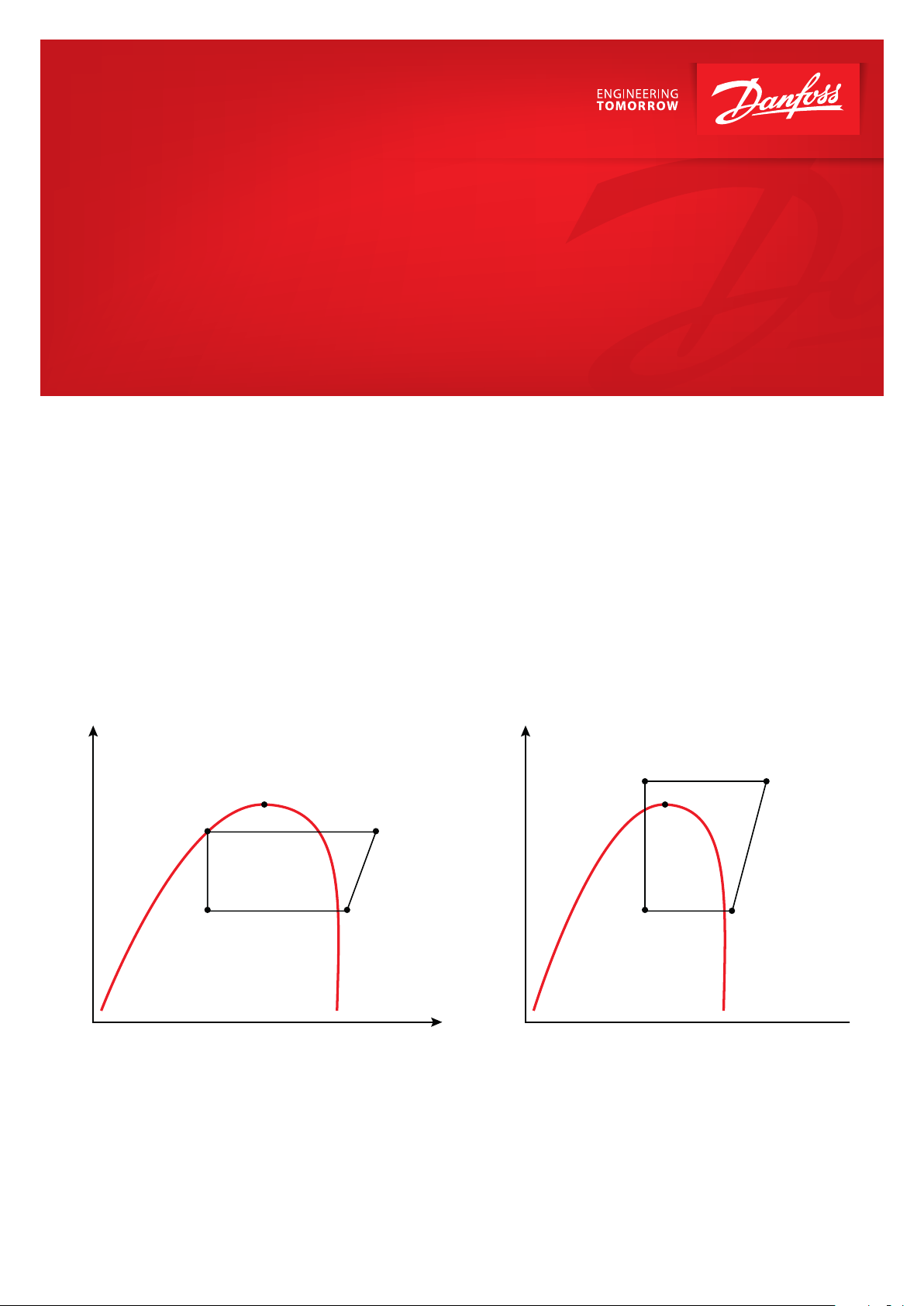

Pressure (Logarithmic scale)

Application guide

Heat Reclaim in Transcritical

CO2 Systems

General description

When using CO2 as refrigerant the critical point is reached

already at 31 °C (74 bar). At temperatures and pressures

above this point there is no relationship between pressure

and temperature (not tied together as seen in the sub critical

refrigeration process) why temperature and pressure can be

controlled individually. In this condition there are no phase

changes and no liquid is present but the mixture is best

described as a gas. Compressor discharge temperatures

between 80 and 120 °C are typical reached and furthermore in

the transcritical refrigeration condition it’s possible to reclaim

most of the energy normally rejected by a gas cooler.

To be able to reclaim heat, one or two heat exchangers are

mounted before the gas cooler. To ensure robust refrigeration

process a superior control strategy is crucial to control

pressure as well as temperature when reclaiming heat to

avoid condensation of liquid in the heat exchangers and to

avoid risk of liquid hammering. Also it’s important that the

minimum temperature out of the gas cooler is at least 3 K

higher than the receiver pressure (converted to temperature)

to avoid condensation of gas in the receiver if cold liquid

should be entering and thereby causing too low receiver

pressure.

These unique features are utilised when reclaiming heat that

is normally rejected or wasted by an air cooled gas cooler.

3

Expansion

4

CP

Condensation

Evaporation

2

Compression

1

Pressure (Logarithmic scale)

Specic enthalpy

Difference between a subcritical and transcritical refrigeration process

3

CP

Expansion

4

Evaporation

Specic enthalpy

Gas cooling

2

Compression

1

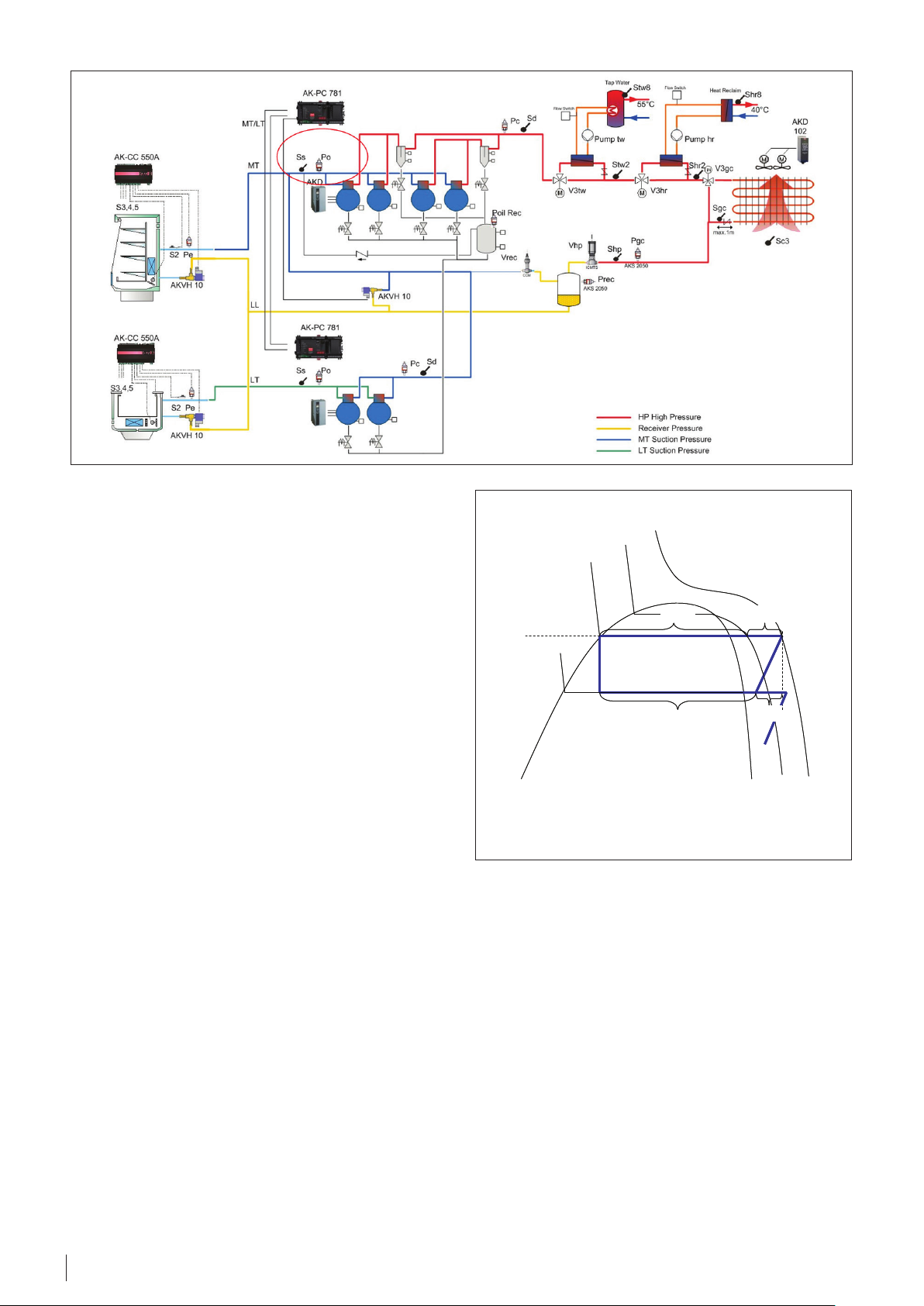

Page 2

Efficient heat reclaim with CO

25° C

55° C

5° C

-10° C

Qo

Wgc Whr

40 Bar

Wc

25° C

55° C

5° C

-10° C

Qo

Wgc Whr

40 Bar

Wc

2

In theory all the heat rejected from a refrigeration process can

be reclaimed. In a supermarket application this is typical all

the heat removed from refrigerated display cases and cold

rooms in addition to the electricity used by the compressors.

Lets say the refrigeration capacity is 3 KW with a COP of 3

then the heat rejected would be 3 KW +1 KW compressor

load equal 4 KW which as a rule of thumb could be reclaimed.

Unfortunately the load of the refrigeration system is typical

low in cold periods where there is a high load on the heating

system, never the less it makes sense to reclaim heat especially

for hot tap water where the consumption is normally constant

throughout the year.

By using CO2 as refrigerant it’s attractive to invest in heat

reclaim because of the high discharge temperatures (often

100 – 120 °C) and the high enthalpy compared to traditionally

used HFC refrigerants meaning that a bigger part of the

rejected heat (energy) can be reclaimed or more heat can be

reclaimed at a higher efficiency compared to other traditional

HFC refrigerants.

Qo: Refrigeration load

Wc: Compressor work

Whr: Heat that can be reclaimed (55° down to 25°C)

Wgc: Heat rejected by the gas cooler (25 down to 5°C)

Transcritical booster system running at winter condition (subcritical condition).

When using CO2 for MT refrigeration it’s possible to work with

condensing temperatures down to 5 °C. As dimensioning

criteria the minimum temperature out of the gas cooler is

often set as low as 5 to 8 °C and minimum pressure in the gas

cooler is typical set around 40 to 45 bar to ensure a receiver

pressure to be kept at 35 to 40 bar to maintain sufficient

pressure differential across the expansion valves in the display

cases.

Heat reclaim without compromising COP

In practical the discharge temperature on the high

temperature pack in a CO2 trans-critical booster system, is

typically above 55 °C even at winter conditions. With above

mentioned design criteria it’s possible to reclaim heat for hot

tap water without increasing pressure making it possible to

reclaim heat at highest possible refrigeration COP. The higher

the ambient temperature is, the more heat can be reclaimed

without compromising the refrigeration COP.

2

Increasing pressure in the gas cooler

If more heat is needed eg. for floor heating it’s possible to

increase the pressure in the gas cooler which will increase the

compressor work but as the COP is typical between 2 and 7

depending on running conditions, heat reclaim is often an

attractive heat source compared to other heat sources even

at winter time.

What can be seen is that by only adding a limited extra

compressor work “Wchr” its suddenly possible to reclaim

around 80 % of heat Whr2” (100 down to 25 °C), and only

around 20 % is typically not possible to reclaim as the

temperature of the gas is below 25 °C.

Page 3

25° C

55° C

5° C

-10° C

Qo

Wgc Whr

Wc

40 Bar

Wgc2 Whr2

Wchr

80 Bar

100° C

25° C

55° C

5° C

-10° C

Qo

Wgc Whr

Wc

40 Bar

Wgc2 Whr2

Wchr

80 Bar

100° C

25

°

C

55

°

C

5

°

C

-

10

°

C

Qo3

Wgc Whr

Wc

40 Bar

Whr3

Wchr

80 Bar

100

°

C

25

°

C

55

°

C

5

°

C

-

10

°

C

Qo3

Wgc Whr

Wc

40 Bar

Whr3

Wchr

80 Bar

100

°

C

Qo: Refrigeration load

Wc: Compressor work

Whr: Heat that can be reclaimed (55° down to 25°C)

Wgc: Heat rejected by the gas cooler (25 down to 5°C)

The high pressure has been increased to 80 bar (transcritical condition).

By passing the gas cooler – 100 % heat reclaim

To be able to reclaim the last part of the heat rejected through

the gas cooler, the gas cooler has to be bypassed. Since it’s

typically not possible to reclaim at a lower temperature

than 25 °C (to maintain 20° inside a supermarket) the gas

temperature should then be lifted from 5 – 25 °C (at low

ambient temperatures only) resulting in lower Qo. To maintain

same Qo more compressor capacity would be needed again

resulting in a lower COP but with the possibility to reclaim

100% of the generated heat from 100°C down to 25 °C.

Arguments for heat reclaim with CO

2

Even in wintertime where the system is running in subcritical

condition, sufficient heat is normally available to reclaim for

hot tap water without increasing pressure in the gas cooler.

If more heat is needed the pressure in the gas cooler can be

increased. When passing into the transcritical condition there

is suddenly a lot more heat available for heat reclaim with only

a limited amount of extra compressor work.

Occasionally 100 % heat reclaim from the refrigeration system

would be sufficient heat source to fulfil the heating and hot

tap water demand in a supermarket, making it possible to

save investment and running cost for other heat sources, all

depending on load conditions and cost of alternative heat

sources. Reclaiming the last part is not very efficient why the

cost has to be judged against alternative heat sources.

When bypassing the gas cooler, the gas temperature is lifted

from 5 °C (at low ambient temperatures only) to 25 °C to be

able to reclaim 100 % of the heat “Whr3” generated by the

refrigeration system. To compensate for the reduced Qo

“Q03” a higher refrigerant mass flow is required resulting in

more compressor capacity or longer compressor run time is

needed.

Same process but the gas cooler has been bypassed.

Heat reclaim with AK-PC 781

The integrated heat reclaim function in AK-PC 781 is able to

control the heating temperature in up to two independent

circuits, one typically used for hot tap water and a second

circuit typically used for room heating at a lower temperature

level. It’s possible to select hot tap water only, heat reclaim for

heating purpose only, or both together (selection between

“None”, “Tap water”, “Heat reclaim”, “Tap and heat”, in the service

tool).

If heat reclaim is setup but no heat reclaim is requested, then

the controller will bypass the heat exchangers by means

of the valves “V3tw” / “V3hr” and the pumps “Pump tw” /

“Pump hr” will be stopped. If no heat reclaim is requested

the refrigeration process is controlled at lowest possible gas

temperature “Sgc” depending on ambient temperature “Sc3”

and optimum high pressure “Pgc” to ensure optimum COP of

the refrigeration process.

3

Page 4

Safety functions

A number of safety functions have been integrated to ensure

proper refrigeration of food and trouble free operation. These

features request that all shown sensors have to be mounted

to be able to activate heat reclaim.

Boiling water protection:

At 95 °C measured at any sensors in the water circuits, heat

reclaim will be disabled in the specific circuit.

Too low discharge “Sd” temperature:

If “Sd” is measured lower then the return temperature in the

water circuit “Stw3”/”Shr3” Heat reclaim will be disabled / can

not be activated for the specific circuit.

Broken temperature sensors:

If any of the temperature sensors in a specific heat reclaim

circuit is broken or not available, Heat reclaim will be

disabled / can not be activated for the specific circuit.

Too low gas temperature:

If the gas temperature out of the heat exchangers

“Stw2” / “Shr2” is too low the Heat reclaim will be disabled for

the specific circuit.

It’s possible to choose between three different control

strategies/control sensors:

• Based on delta T between “Stw4” and “Stw3” . The pump

can only be variable speed controlled where a reference

for the “delta T” (Stw4-Stw3) has to be set. Kp and Tn can

be set for the PI control loop as well as min. and max.

speed for the pump.

• Based on reference and thermostat band for Stw8. The

pump can now be operated in two different ways:

− On/off based on reference and thermostat band.

− Variable speed (0-10 V) based on reference for Stw8. KP

and Tn can be set for the PI control loop as well as min

and max speed for the pump.

• Based on reference for the combination of Stw8 and Stw8a.

The pump can only be on/off controlled following the

cut in measured with Stw8 and cut out measured with

Stw8a.

No water flow:

If flow switch is available (optional in setup) the flow switch

has to be active for a defined delay time when pumps are

running (eg. 30 sec.) before the heat reclaim can be activated.

If flow signal is lost while pumps are running the heat reclaim

will be deactivated after the defined delay time.

Heat reclaim for hot tap water

The overall control sensor for hot tap water heat reclaim

is “Stw8” and a reference can be set for the hot tap water

temperature eg. 55 °C. A thermostat band eg. 5 °C is placed

around the reference, starting the heat reclaim at eg. 52,5 °C

and stopping the heat reclaim at 57,5 °C.

To avoid too frequently stat/stop of hot water heat reclaim it’s

possible to mount a second temperature sensor at a lower

level in the hot water boiler using two sensors “Stw8” and

“Stw8a” for the thermostat function. If temperature measured

at the upper sensor “Stw8” is equal or lower than ex. 52,5 °C

the heat reclaim function is started but will first be stopped

when the water temperature at the lower sensor “Stw8a” has

reached ex. 57,5 °C.

It’s not possible to force the gas pressure to a defined

minimum limit while reclaiming through the hot tap water

circuit. If increase of the pressure is requested for tap water

the Heat reclaim circuit for heating purpose could be used

also for tap water.

4

Page 5

Heat reclaim for heating purpose

For supermarket applications there is typically more heat to

reclaim as needed for hot tap water, why it makes sense to

invest in heat reclaim for heating purpose ex floor heating or

pre heaters in ventilation systems.

The heat reclaim for heating purpose can be set in three

different modes:

No HP-Offset

When this mode is selected the functionality is very similar to

hot tap water heat reclaim where the pressure is kept as low

as possible according to ambient temperature.

HP-Offset

At low ambient temperatures it could be necessary to increase

the pressure in the gas cooler to enable more energy for

heat reclaim. A minimum pressure (Pgc HR min) can now be

defined when reclaiming with the option of external override

from up to 5 external heat consumers. The heat consumer

with the highest demand (measured with 0-10 V analogue

inputs) will drive the pressure increase to the set Pgc HR offset.

Eg. 49 + 30 = 79 bar at 10 volt

Max heat reclaim

In applications where 100% heat reclaim is requested it’s

possible to bypass the gas cooler by the valve “V3gc” which

has to be enabled in advanced settings within configuration

of HP control.

Based on the highest override signal (0 – 10 V) from up to

5 external heat consumers the function takes place in a

sequence of 4 steps:

1. Start of heat reclaim where the pressure will be increased

to the minimum defined limit.

2. The gas cooler pressure will be lifted to the maximum

offset.

3. The reference for the gas cooler fans (reference is

calculated by the controller) is increased to reduce fan

capacity.

4. Gas cooler is bypassed.

5

Page 6

It’s possible to choose between three different control

strategies / sensors giving different possibilities for control of

the pump “Pump hr”:

• Based on delta T between “Shr4” and “Shr3” The pump can

only be variable speed controlled where a reference for

the “Delta T” (Shr4 – Shr3) has to be set. KP and Tn can be

set for the PI controller as well as min. and max. speed for

the pump.

• Based on reference and thermostat band for Shr8. The

pump can now be operated in two different ways:

− On/Off based on reference and thermostat band

− Variable speed control (0 – 10 V) based on reference for

Shr8. KP and Tn can be set for the PI controller as well as

min. and max. speed for the pump.

• Based on constant water temperature Shr4 The pump can

only be variable speed controlled where the “Reference”

is target for Shr4. The “Thermostat band” is still used to

start or stop the heat reclaim. KP and Tn can be set for the

PI controller as well as min. and max. speed for the pump.

Summing up

The AK-PC 781 pack controller offer a number of integrated

features especially developed for transcritical CO2 booster

systems:

• COP optimised gas pressure control

• Receiver and gas by pass control

• Variable speed control of lead compressor and gas cooler

fans

• Oil management functions

• Advanced heat reclaim for tap water and heating

purpose.

By integrating all control functions it has been possible to

control a transcritical pack with the highest possible COP at all

load conditions. Next to safety the quality of refrigerated food

has highest priority why a number of build in override and

safety functions secure optimum control of the refrigeration

system. Requested amount of heat reclaimed is automatically

controlled as long as the refrigeration load is satisfied, and

integrated control functions will automatically disable a heat

reclaim circuit in case too much heat is retrieved usually

causing loss of refrigeration capacity.

Control sensor

If Shr8 or Delta T (Shr4 – Shr3) is used as control signal the

overall heat reclaim control sensor for heating purpose is

“Shr8” and a reference can be set for the requested water

temperature eg. 40 °C. A thermostat band eg. 5 °C is placed

around the reference, starting the heat reclaim at eg. 37,5 °C

and stopping the heat reclaim at 42,5 °C.

If Shr4 is selected as control signal (controlling of constant

water temperature to heat consumers) the overall control

sensor for the heat reclaim is Shr4 and the Shr8 is used for

monitoring purpose only.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCE.PA.R1.F1.22 © Danfoss | DCS (scg) | 2015.07

Loading...

Loading...