Page 1

Installation Guide

Heating cables in concrete

Concrete >3 cm

Intelligent solutions

with lasting eect

Visit DEVI.com

Page 2

Table of contents

1 Introduction . . . . . . . . . . . . . . . . . . . . 2

1.1 Safety Instructions . . . . . . . . . . . . . . .2

1.2 Installation guidelines . . . . . . . . . . . . .4

2 Installation step by step . . . . . . . . . . . . . 5

2.1 Calculating C-C distance for heating cables

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Planning the installation . . . . . . . . . . .5

2.3 Preparing the installation area. . . . . . . .6

3 Installing elements . . . . . . . . . . . . . . . . 6

3.1 Installing heating elements. . . . . . . . . .8

3.2 Sensor Installation . . . . . . . . . . . . . . .8

4 Indoor applications . . . . . . . . . . . . . . . . 9

4.1 Floor heating in concrete oors (> 3 cm) .9

5 Optional settings . . . . . . . . . . . . . . . . 10

1 Introduction

In this installation manual, the word “element” refers

to both heating cables and heating mats.

If the words “heating cable” or “heating mat” are

used, the instruction in question applies only to this

type of element.

All dimensioning, product selection, installation

and commissioning of any given application are the

responsibility of an authorized installer.

Any application using heating elements or thermostats purchased by end user must be approved by an

authorized electrician prior to commissioning.

• Including type, size, installation and connection

of the heating element.

• Including type, size, connection and settings

of the thermostat controlling the heating

element.

• Children shall not play with the heating

element.

• This heating element can be used by children

aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they

have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved.

• Cleaning and user maintenance shall not be

made by children without supervision.

The intended use of the heating elements covered

by this installation manual is oor heating, only.

• According to IEC 60335 the mats may not be

installed in a metallic oor or storage heating

application.

• Mats shall be fully embedded in at least 5 mm

concrete, screed, tile adhesive or similar. incl. tiles

1.1 Safety Instructions

Page 3

Never cut or shorten the heating element

!

1

2

3

4

5

6

7

• Cutting the heating element will void the

warranty.

• Cold leads can be shortened to suit requirements.

Elements must always be installed according to

local building regulations and wiring rules as well

as the guidelines in this installation manual.

• Any other installation may hamper element

functionality or constitute a safety risk, and will

void the warranty.

Elements must always be connected by an

authorised electrician using a xed connection.

• De-energize all power circuits before installation and service.

• Each heating element screen must be earthed

in accordance with local electricity regulations

and connected to a residual current device

(RCD).

• RCD trip rating is max. 30 mA.

• Heating elements must be connected via a

switch providing all pole disconnection.

• The element must be equipped with a correctly

sized fuse or circuit breaker according to local

regulations.

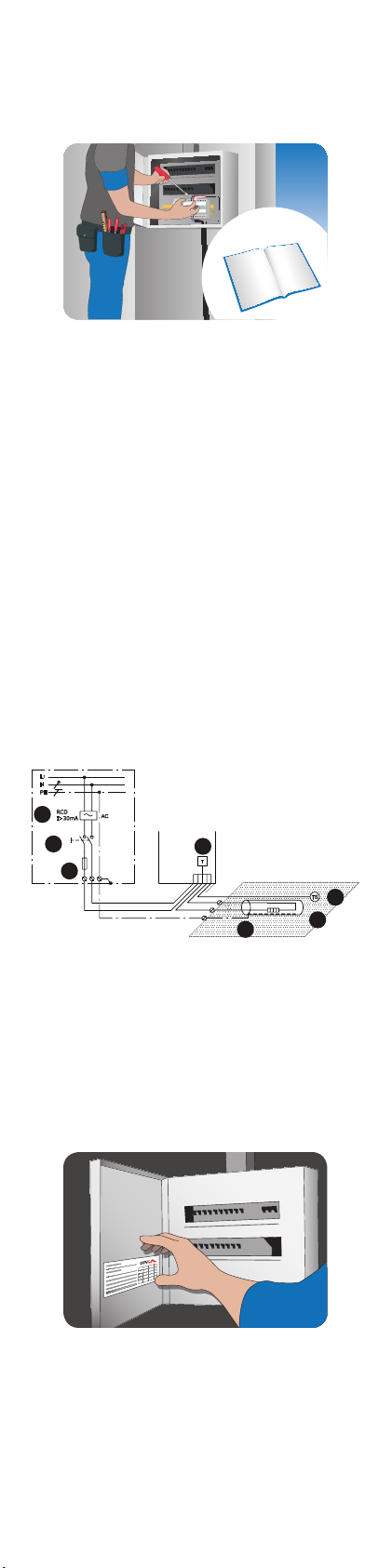

1. Heating cable

2. Thermostat

3. Sensor

4. Screen

5. RCD

6. All-pole switch

7. Fuse

The presence of a heating mat must

• be made evident by axing caution signs or

markings at the power connection ttings and/

or frequently along the circuit line where clearly

visible

• be stated in any electrical documentation

following the installation.

Connections

• Phase - Brown

• Neutral - Blue

• Earth - Screen

Page 4

Never exceed the maximum heat density (W/m)

for the actual application.

1.2 Installation guidelines

Prepare the installation site properly by removing

Regularly measure ohmic resistance and insula-

tion resistance before and during installation

Do not lay heating elements under walls and xed

sharp objects, dirt, etc.

obstacles. Min. 6 cm air is required

Keep elements clear of insulation material, other

heating sources and expansion joints

Elements may not touch or cross themselves or

other elements and must be evenly distributed

The elements and especially the connection must

be protected from stress and strain.

on areas.

The elements and sensors shall be installed minimum 30 mm away from conductive parts of the

building, e.g. water pipes.

Page 5

A oor sensor is mandatory and must be connect-

ed to a thermostat limiting the oor temperature

The element should be temperature controlled

and not operate at ambient temperature higher

to maximum 35°C.

than 10°C in outdoor applications.

2 Installation step by step

2.1 Calculating C-C distance

The C-C distance is the distance in centimetres from

the centre of one cable to the centre of the next.

C - C [cm] =

or

C - C[cm] =

• Max. C-C distance in Concrete oors (>3 cm) is

15 cm.

• Heating cable bending diameter must be at

least 6 times cable diameter.

• The actual cable length may vary +/- 2 %.

C-C [cm] 5 7,5 10 12,5 15

6 W/m 120 80 60 48 40

10 W/m 200 130 100 80 67

18 W/m - - 180 144 120

20 W/m - - 200 160 133

2.2 Planning the installation

Draw a sketch of the installation showing

• element layout

• cold leads and connections

• junction box/cable well (if applicable)

• sensor

• connection box

• thermostat

Area [m]

Cable length [m]

Cable output [W/m]

Heat density [W/m]

230V/400V

x 100 cm

x 100 cm

Page 6

Save the sketch

• Knowing the exact location of these components makes subsequent troubleshooting and

repair of faulty elements easier.

Please the following:

• Observe all guidelines - see section 1.2 .

• Observe correct C-C distance (heating cables

only) - see section 2.1.

• Observe required installation depth and

possible mechanical protection of cold leads

according to local regulations.

• When installing more than one element, never

wire elements in series but route all cold leads

in parallel to the connection box.

• Two or more elements may be installed in

the same room but a single element is not

to be installed across two or more rooms.

• All heating elements in the same room must

have the same heat density (W/m) unless

they are connected to separate oor sensors

and thermostats.

• For single conductor cables, both cold leads

must be connected to the connection box.

2.3 Preparing the installation area

• Remove all traces of old installations, if applicable.

• Ensure that the installation surface is even,

stable, smooth, dry and clean.

• If necessary, ll out gaps around pipes,

drains and walls.

• There must be no sharp edges, dirt or foreign

objects.

3 Installing elements

It is not recommended to install elements at temperatures below -5 °C.

At low temperatures, heating cables can become

rigid. After rolling out the element, briey connect

it to the mains supply to soften the cable before

fastening.

Measuring Resistance

Measure, verify and record element resistance during installation.

• After unpacking

• After fastening the elements

• After the installation in nalized

If ohmic resistance and insulation resistance are not

as labelled, the element must be replaced.

Page 7

• The ohmic resistance must be within -5 to +10

% of the value labelled.

• The insulation resistance should read >20 M

after one minute at min. 500V DC.

3.1 Installing heating elements

Observe all instructions and guidelines in section 1.1

and 1.2.

Heating elements

• Position the heating element so that it is at

least half the C-C distance from obstacles.

• Elements must always be in good contact with

the heat distributor (e.g. concrete), see section

4 for details.

Heating mats

• Always roll out heating mats with the heating

cables facing up.

• When the heating mat reaches the area boundary, cut the liner/net and turn the mat before

rolling it back.

Extending cold leads

• Avoid extending cold leads if possible. Wire

cold leads to e.g. junction boxes or cable wells.

• Be aware of power loss in the cable according

to local regulations.

3.2 Sensor Installation

• Mandatory under wooden oors and on wooden sub oors.

• The oor sensor should be mounted in an insulating conduit, sealed at the oor end, for easy

replacement of the sensor if required.

• The oor sensor must be considered a LIVE cable; therefore any extension made to the sensor

wiring should be treated in the same way as

normal mains voltage cabling.

• The sensor can be extended up to a total of 50

m using 1.5 mm installation cable.

• The minimum bending radius for the pipe is 50

mm (1).

• The sensor cable must be placed between two

loops of the heating cable (2).

• To avoid cracks in the concrete oor do not

switch on the heat until the oor has completely hardened.

Page 8

12

≥

• Shall be placed in an appropriate place, where

1

2

1

2

3

4

5

6

7

8

not exposed to sunlight or draft from door

openings.

• The conduit should be ush with the sub oor.

• Route the conduit to the connection box.

4 Indoor applications

Sub oor

Wood -

Concrete

Floor type

Wood, parquet, laminate Max. 150 W/m

Carpet, vinyl, linoleum, etc. Max. 150 W/m

Tiled oors in bathrooms,

conservatories cellars, etc.

Tiled oors in kitchens,

living rooms halls, etc.

May be up to 225 W/m in rim zones e.g. under large

windows.

• On concrete sub oors and under tiles, only.

• If connected to a separate oor sensor and

thermostat.

Max. 20 W/m and

225 W/m

100 - 200 W/m

100 - 150 W/m

Wooden oor coverings

Wood shrinks and swells naturally depending on the

relative humidity (RH) in the room.

• Avoid beech and maple in multilayered oor

coverings unless press dried.

• Install a vapour barrier for sub oors <95% RH

and a damp proof membrane >95%.

• Ensure 100% contact between the element and

the embedding material above (no air pockets).

• Install the heating system in the whole oor

area at 15°C surface temperature.

• Always install a oor sensor to limit the max.

oor temperature.

4.1 Floor heating in concrete oors (> 3 cm)

New tiles on existing tiles, concrete oors or

wooden oors

Page 9

1. Top ooring.

2. Noise absorption mat/rag felt, tile adhesive

depending on top ooring.

3. Vapour barrier.

4. Concrete.

5. Heating cable.

6. Concrete slab or reinforced mesh.

7. Insulation.

8. Capillary-breaking layer, concrete, etc.

Other combinations of oor covering and existing

oor construction are also possible.

The heating cables may not touch the insulation

• The heating cable must be separated by reinfored mesh or concrete slab.

Embedding in concrete or screed

• The bedding must not contain sharp stones.

• Must be suciently wet, homogeneous, free of

air voids.

• Pour at a moderate delivery speed to avoid

displacement of the element

• Avoid damaging the cable with any tools.

• The heating element must be fully embedded

and at least 5 mm

• Allow a drying time of approximately 30 days

for concrete and 7 days for moulding compounds.

Installation summary

Apply reinforced mes or concrete slab onto the

Roll out the cable and attach it to the sub oor or

mesh reinforcement by means of DEVIclip™ fasten-

insulation.

ing accessories or similar.

Pour at a moderate delivery speed to avoid dis-

placement of the element.

5 Optional settings

If the element is connected to a thermostat such as

a DEVIreg™, congure basic settings according to

the table below and as described in the thermostat

installation manual.

If applicable, adjust the temperature limit in accordance with the manufacturer’s recommendations in

order to prevent damage to e.g. the oor or the pipe.

Page 10

Thermostat Max. load

DEVIreg™ 13x 16A

DEVIreg™ 330 16A

DEVIreg™ 53x 15A

DEVIreg™ 610 10A

DEVIreg™ Touch 16A

DEVIlink™ CC 15A (FT)

Floor heating

in general

Room temp.

20-22° C.

VIIWD102

Loading...

Loading...