Page 1

Danfoss heating cable mats

specifications!

Danfoss heating

cable mat: EFTM

Type: 2-conductor

Voltage: 230 Volt

Output: 100 or 150 W/m

2

Covers: W = 500 mm

L = See table

T = approx. 4 mm

Wire insulation: FEP

Casing: PVDF 90ºC

Max. temperature: 90ºC

Bending radius: Min. 30 mm

08090213-01.01 09-2003

INSTRUCTION GB

Danfoss heating cable mats type 100/150

Danfoss heating cable mats for thin floors

NB!

Read page 2 before installing the product

if you intend to connect 2 mats to the

same thermostat

The insulation value of floors in which

Danfoss heating cable mats DTIF has been

installed must not exceed approx. 0.125 m

2

K/W.

Typical insulation values

• Thin floor with tiles, vinyl 0.035 m2K/W

• Thick floor with vinyl

or similar 0.040 m2K/W

• Floor with parquet,

cork or carpet 0.125 m2K/W

• Heavy-duty fibreboard

and wall-to-wall carpet 0.175 m2K/W

•Wooden floor on battens 0.375 m2K/W

Connection

Phase - Black

Neutral - Blue

Earth - Shield

CE

Danfoss heating cable mat

type 100/150

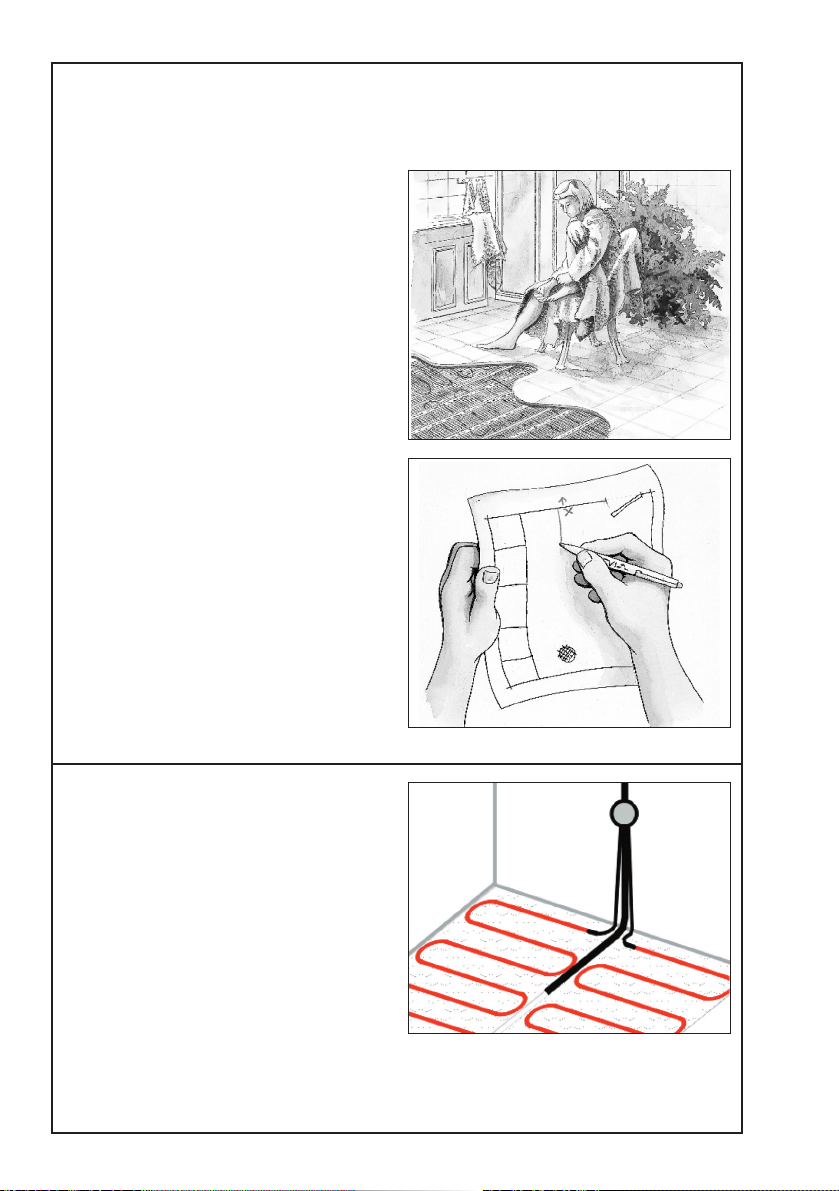

Danfoss heating cable mats are primarily

used when renovating existing floors where

a low floor construction height is required.

Danfoss heating cable mat is only 4 mm

thick, plus the thickness of the floor surface.

Danfoss heating cable mats 100 provides an

output of 100 W/m2per mat. If your requirements exceed the m2output of 100 W/m

2

e.g. in the case of badly insulated stone

floors or old concrete floors in basements,

you may wish to use Danfoss heating cable

mats 150 which have an output of 150 W/m2.

The required output should be determined

by an authorised electrician.

Areas of use!

Danfoss heating cable mats 100 W/m2can

be installed in wooden floors, plaster or concrete floors. Danfoss heating cable mats 150

W/m2must only be installed on a concrete

surface or similar.

NB!

Must be installed in accordance with local

building regulations.

Must be connected by an authorised

electrician.

Page 2

2

General Installation Guidelines

The following guidelines must be observed

when installing Danfoss heating cable mats.

Preparation

1. All traces of old floor covering must be

removed so that the concrete surface or

the floorboards are visible.

2. Clean the surface and remove any loose

particles.

3. The floor must be securely anchored to

prevent it from shifting. Floor plaster is

recommended for wooden floors to

prevent the formation of cracks in joints

and clinkers. The floor must be smooth in

order to prevent any damage to the heating mat.

4. The floor must be primed.

5. Any gaps in the floor around outflow

pipes, floor drains and doorsills, or near

the outer edges where the floor screed

may penetrate, must be filled.

6. You are advised to draw up an

installation plan before laying out the

mats.

Use page 9 in this manual to draw up a

plan.

Remember to indicate the sensor tube,

connection tails and the connection to

the cold cable.

NB!

Please consult the manufacturer for information on suitable temperatures if using

Danfoss heating cable mats 100 under

wooden floors the concrete layer must not

be less than 5 mm on top of the cable.

Please note when using 2 mats!

The sensor must be positioned between the

two mats as illustrated – this is important as

it must be able to detect the temperature of

both mats.

Page 3

3

Installing the Danfoss heating cable mats

The heating mat should not be installed at

room temperatures below 5°C.

The heating mat must be installed in accordance with the installation instructions.

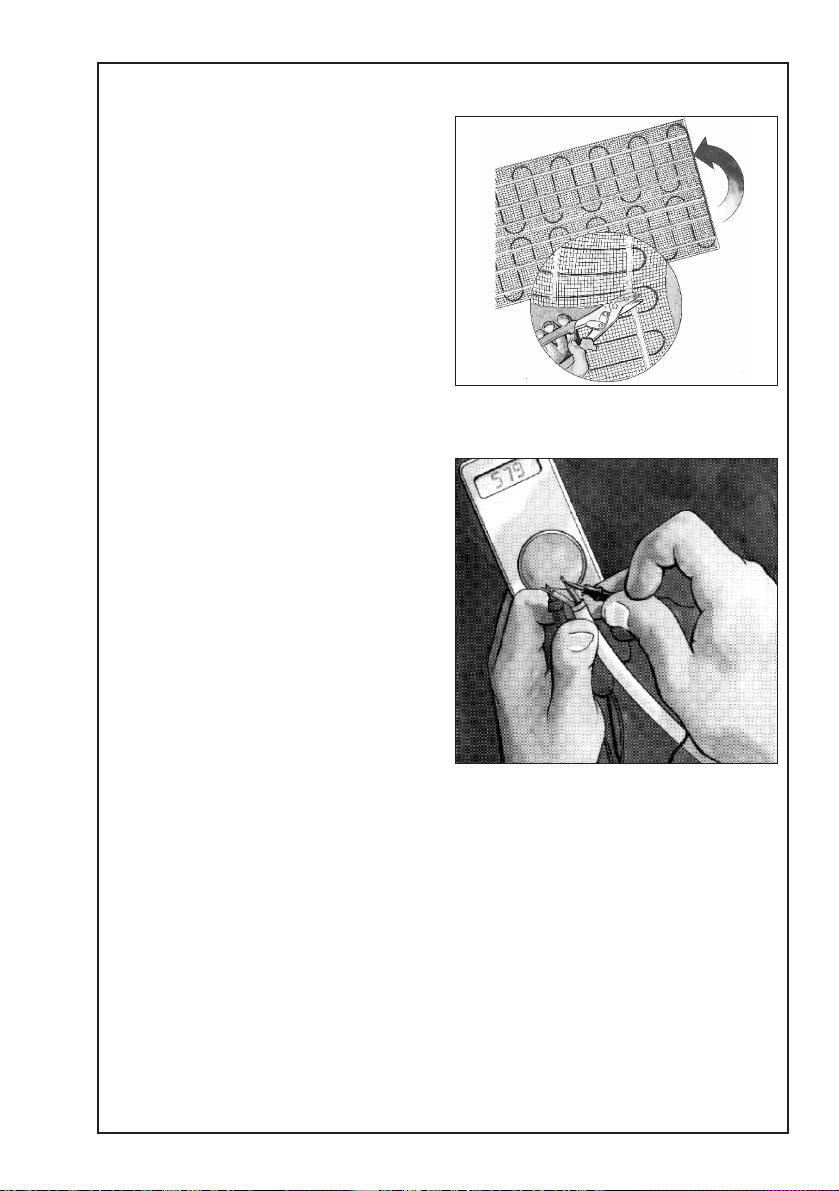

Roll out the mat on the primed floor with the

adhesive side on the bottom and the heating

cable on the top.

Distribute the heating mat evenly across the

floor surface, avoiding areas where the mat

may be squeezed or damaged by screws,

e.g. from the toilet. The heating mat should

lie flush against the surface and be securely

fastened to avoid any movement of the mat

when the floor screed is laid.

If the heating cable mat is rolled out towards

the opposite wall, the mat will need to be

cut before being rolled back.

To do so, cut the mat material carefully without damaging the heating wire. Next, flip the

mat over and roll it back parallel to the first

length of mat, etc.

DO NOT CUT THE CABLE ONLY THE

MESH.

NB!

The heating mat must not be shortened or

exposed to mechanical stress.

The heating mat must not be fitted below

objects that can produce heat, e.g. tumble

driers.

Please observe care when installing the mat

and laying the screed in order to prevent

damage to the heating mat.

When turning the heating mat just cut the

mesh. Do not cut the cable.

Test the heating mat in accordance with the

table on page 8 (resistance) before the

screed is poured.

Page 4

4

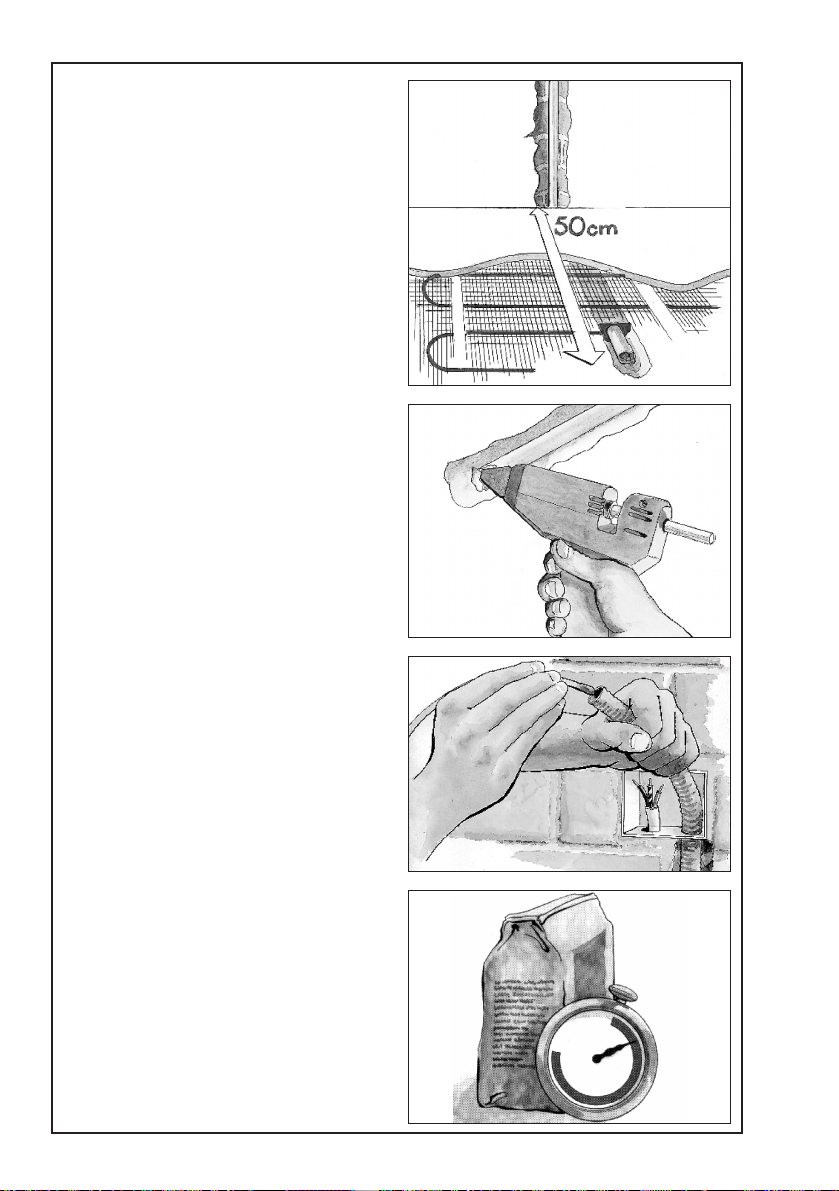

The flex tubing for the thermostat’s sensor

should be positioned so that the sensor is

located between the heating conductors on

a clear patch of floor. A thermostat should

always control the heated area.

NB!

Do not fit under cupboards, bathtubs, or

similar.

NB!

Please see text and illustration page 2 if

installing two mats on the same surface.

The flex tubing may be countersunk into the

floor to reduce the floor construction height.

Seal the flex tubing at the end so that the

screed cannot penetrate the tube.

The sensor cable and the cold cable for the

heating mat should be connected to the

thermostat box or directly to the thermostat

located elsewhere in a convenient position,

e.g. near your electric meter.

Test the ohm value of the heating mat before

applying the screed.

When covering the mat with screed, please

follow the manufacturer’s recommendations

as regards the drying time of the screed.

Humidity seals and floor coverings such as

vinyl and wooden floors require all moisture

in the screed, depending on the thickness,

to have been eliminated fully in accordance

with the drying times recommended by the

manufacturer.

The under floor heating must not be used

until the screed has dried out fully, usually

around 28 days.

Page 5

5

The mat should be tested as specified

earlier before the floor covering is laid.

The installation should be equipped with a

circuit breaker.

The heating cable mat is designed for under

floor heating purposes only.

The heating mat must be embedded.

Page 6

Controlling the heating mat

Danfoss thermostat type 520

Danfoss heating cable mats 100/150 may be

controlled by means of Danfoss thermostat

type 520 which is flush mounted. The thermostat keeps the floor at a constant temperature by means of the floor sensor, which

should be placed between two loops or mat

sections.

Danfoss thermostat type 550

Danfoss heating cable mats 100/150 may be

controlled by means of Danfoss thermostat

type 550, an intelligent thermostat with digital display and built-in timer for lowering the

temperature at night.

Please contact your supplier for further

information.

IMPORTANT

Please consult the manufacturer for information on suitable temperatures if using

Danfoss heating cable mats 100/150 under

wooden floors, laminate floors or vinyl.

6

Danfoss 550

8

85 mm

Danfoss 521

Page 7

The authorised who connected the product

should complete the guarantee certificate.

The label from the heating mat should be

placed in the designated space on the guarantee certificate.

The guarantee certificate should remain in

the possession of the customer.

The guarantee is subject to the guarantee

conditions listed on page 10.

The underfloor heating system is now ready

to use.

Increase the floor temperature gradually and

adjust it until it reaches what you feel is a

comfortable level depending on the type of

room and your personal preferences.

7

Page 8

8

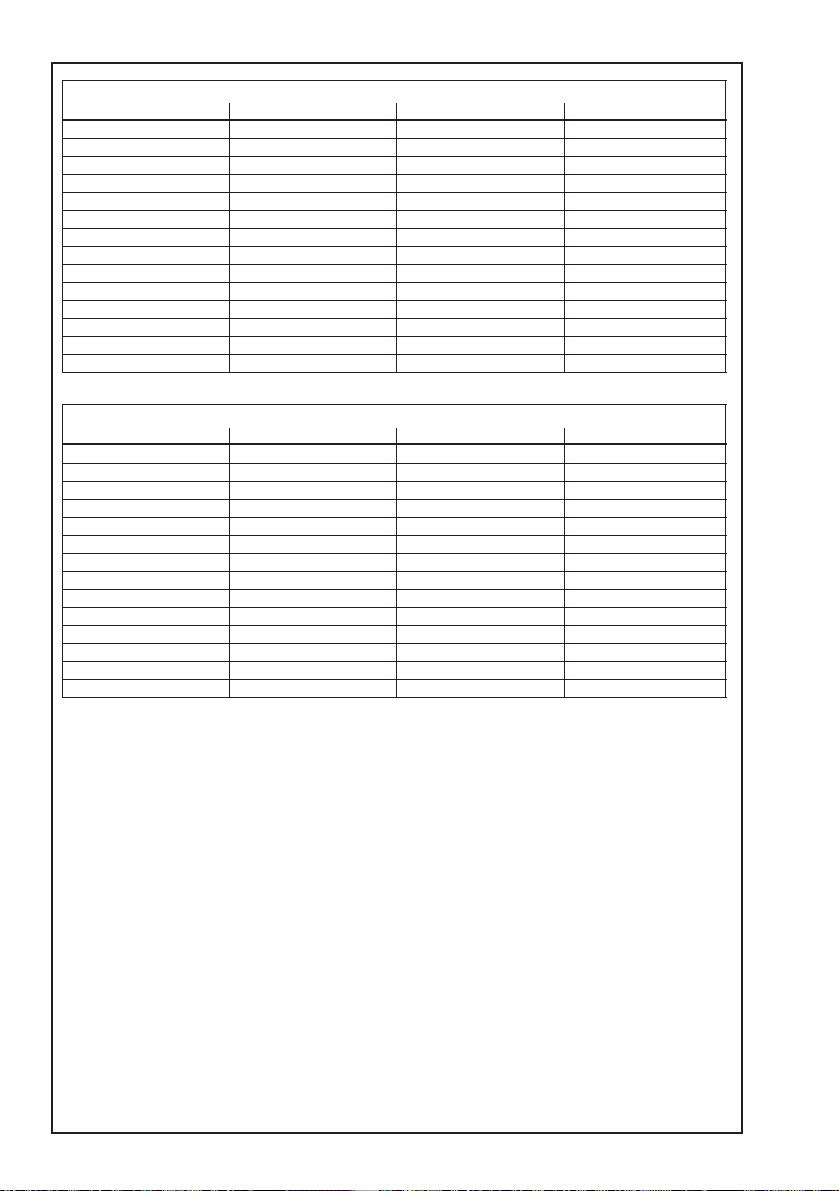

Danfoss heating cable mats 100, 100 w/m2, 230 V

Length Area to be heated Output Total ohm

2 m 1 m

2

100 W 529

3 m 1.5 m

2

150 W 352

4 m 2 m

2

200 W 264

5 m 2.5 m

2

250 W 211

6 m 3 m

2

300 W 176

7 m 3.5 m

2

350 W 151

8 m 4 m

2

400 W 132

10 m 5 m

2

500 W 105

12 m 6 m

2

600 W 88.1

14 m 7 m

2

700 W 75.5

16 m 8 m

2

800 W 66.1

18 m 9 m

2

900 W 58.7

20 m 10 m

2

1000 W 52.4

24 m 12 m

2

1200 W 44.1

Danfoss heating cable mats 150, 150 w/m2, 230 V

Length Area to be heated Output Total ohm

2 m 1 m

2

150 W 352

3 m 1.5 m

2

225 W 235

4 m 2 m

2

300 W 176

5 m 2.5 m

2

375 W 141

6 m 3 m

2

450 W 117

7 m 3.5 m

2

525 W 100

8 m 4 m

2

600 W 88.1

10 m 5 m

2

750 W 70.5

12 m 6 m

2

900 W 58.7

14 m 7 m

2

1050 W 50.3

16 m 8 m

2

1200 W 44.0

18 m 9 m

2

1350 W 39.1

20 m 10 m

2

1500 W 35.2

24 m 12 m

2

1800 W 29.3

Page 9

9

Use this page to

sketch the

installation

Page 10

10

The Danfoss Warranty:

You have purchased a Danfoss heating

system which we are sure will serve to

improve the comfort and economy of your

home.

Danfoss heating system provides a

complete heating solution with Danfoss

heating cables or Danfoss heating mats,

Danfoss thermostats and devifast™ fixing

strips.

Should you, against all expectations,

experience a problem with your Danfoss

heating system, you will find that Danfoss,

whose products are manufactured in

Denmark and sold throughout the European

Union, is subject to the standard regulations

pertaining to product liability as specified in

EU directive 85/374/CEE as well as all

applicable legislation in the individual

countries on the following conditions:

Danfoss offers a 10-year guarantee on all

Danfoss heating cable mats type 100/150,

and a 2-year guarantee against material

defects and production defects in

connection with any other Danfoss products.

The guarantee shall be valid only if the

GUARANTEE CERTIFICATE is completed

correctly and in accordance with the

instructions, and provided the fault is

inspected by or submitted to Danfoss or an

authorised Danfoss dealer.

Please note that the GUARANTEE

CERTIFICATE must be completed in your

local language, and that the ISO code for

your country, should be printed in the top

right-hand corner on the front of the

Instruction.

Danfoss shall undertake any repair free of

charge or supply the customer with a new

unit. Repairs shall be carried out at no

further cost to the customer. In the case of

faulty Danfoss thermostats, Danfoss

reserves the right to repair the unit free of

charge and without any unreasonable delays

for the customer.

The Danfoss Guarantee shall not cover

installations that have been carried out by

non-authorised electricians, faults which

arise as a result of misuse by other

suppliers, damage caused by third parties,

incorrect installations or consequential

damage. All work will be invoiced in full if

Danfoss is required to inspect or repair

faults that have arisen as a result of any of

the above. The Danfoss Guarantee shall not

extend to equipment which has not been

paid in full.

Danfoss will, at all times, provide a rapid,

effective and honest response to all queries

and reasonable demands from our

customers.

The above guarantee covers product liability

only, while purchases are subject to local

legislation.

Page 11

Name: Telephone:

Address: Zip code:

Please Observe!

In order to obtain The Danfoss Warranty, the following

must be carefully filled in. See other conditions

on the overleaf

Danfoss heating cable mats layed by: Laying date:

Connected by: Inst. date:

Mat length: Watt: Art. number:

Installed on: Floor covering:

■■

■■ Concrete on floor

■■

■■ Vinyl

■■

■■ Wooden on floor

■■

■■ Wood

■■

■■

11

Warranty Certificate

The Danfoss Warranty is granted to:

Suppliers Stamp Place label here

Page 12

12

Produced by Danfoss G1 advertising agency 03.09 Bi.DS

08090213-01.01 09-2003

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

DK-6430 Nordborg

Denmark

Tel.: +45 74 88 22 22

Telefax: +45 74 49 09 49

E-mail: danfoss@danfoss.com

Loading...

Loading...